Effects of TiH2 content on dynamic mechanical properties and impact sensitivity of Al/PTFE

-

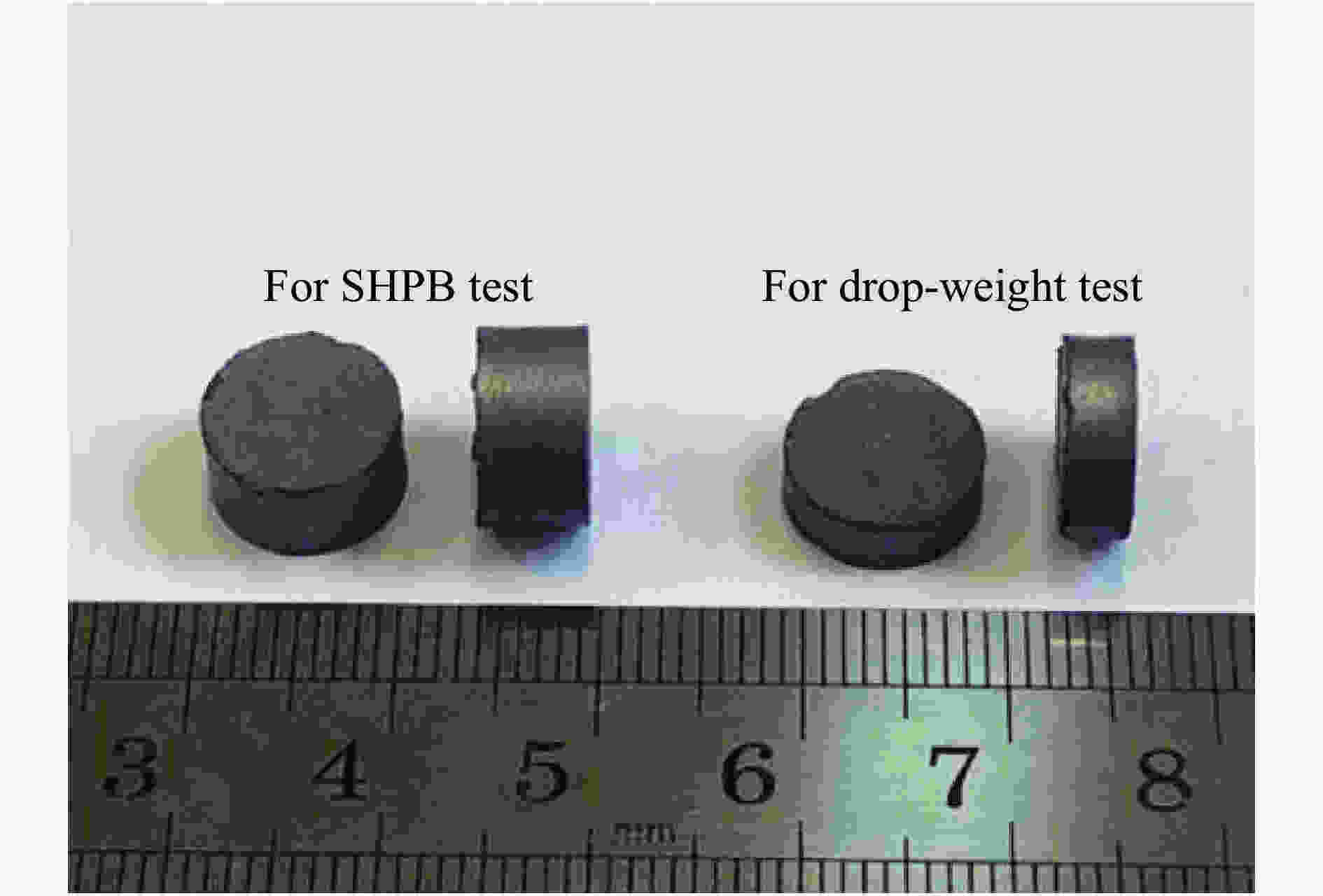

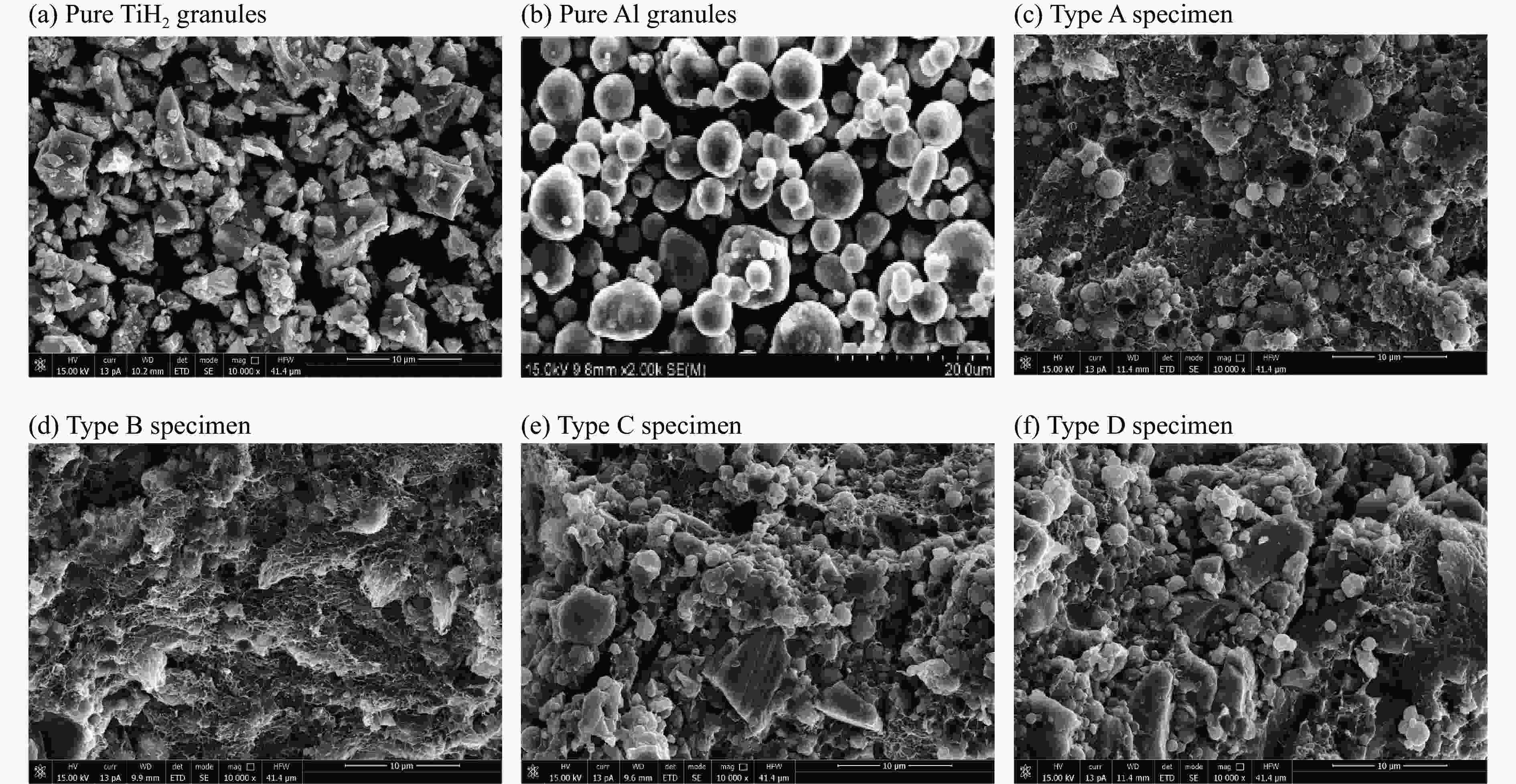

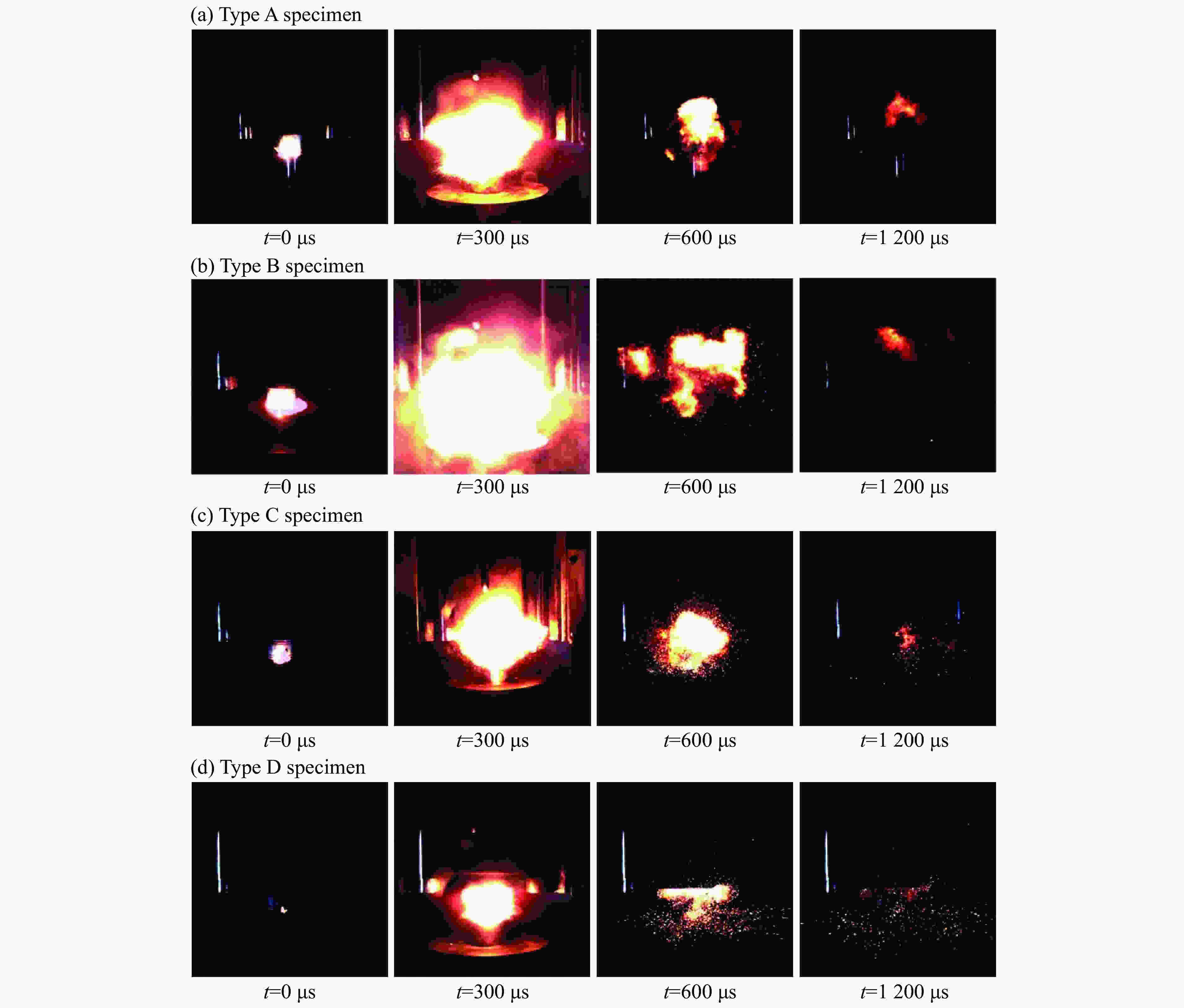

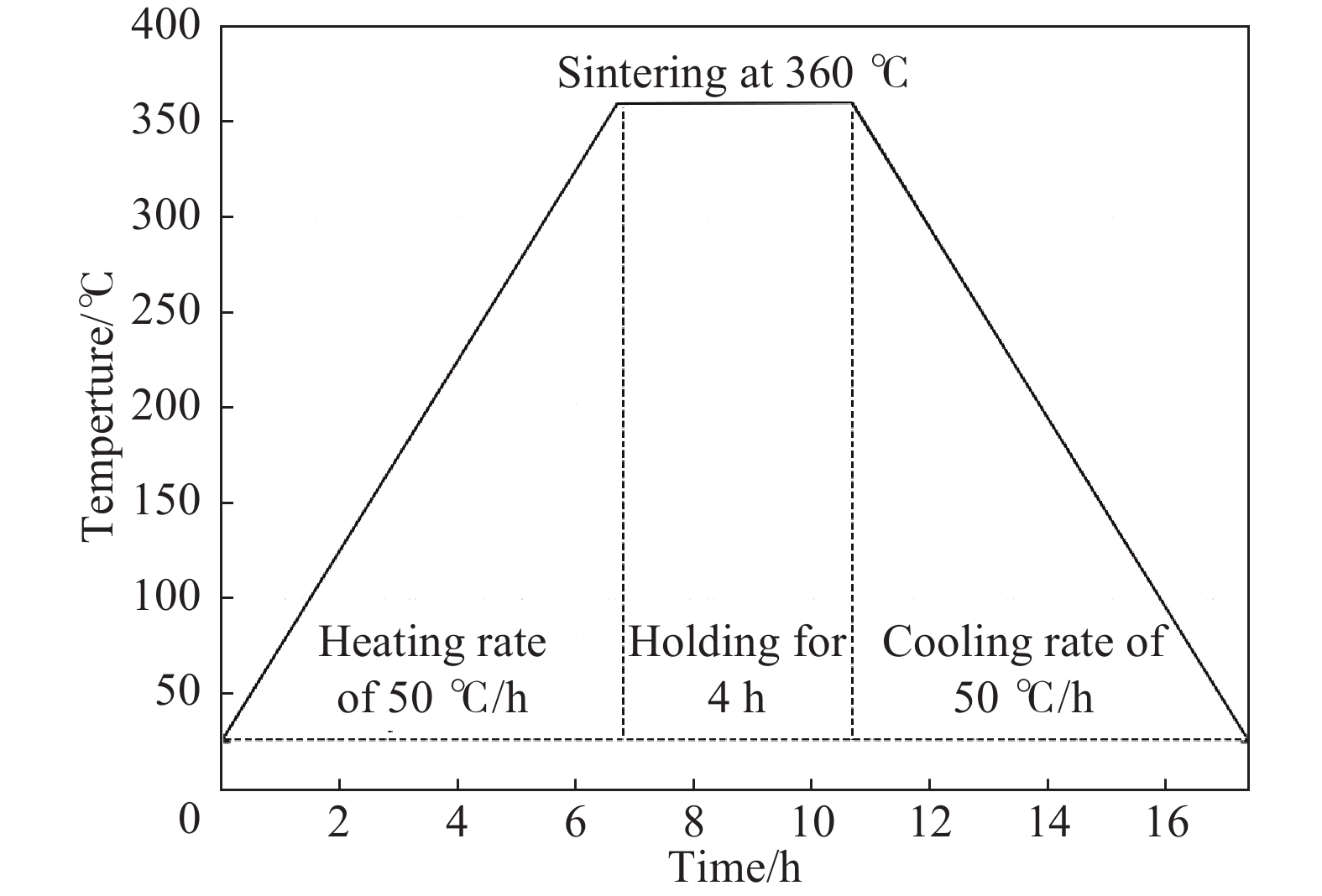

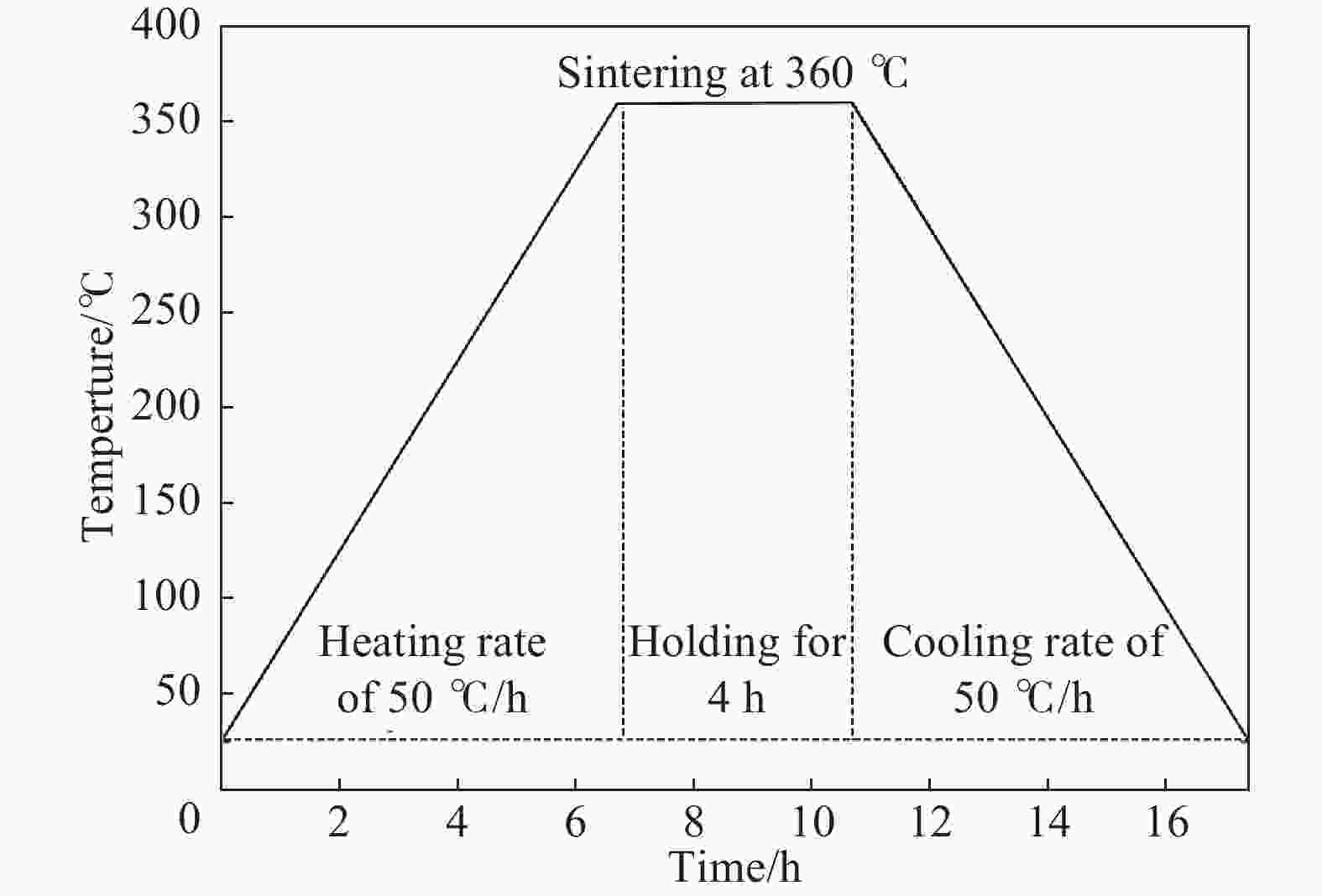

摘要: 采用混合压制烧结法制备了4种不同TiH2含量的铝/氢化钛/聚四氟乙烯(Al/TiH2/PTFE)试件,并基于分离式霍普金森杆和落锤冲击实验,对反应材料的动态压缩力学性能、撞击感度及反应特性进行了研究。实验结果表明,4种材料均存在应变硬化和应变率硬化效应,随加载应变率的提高,材料屈服强度和硬化模量增大。相同加载应变率下,材料屈服强度随TiH2含量的增加而增高,材料压缩强度则先增高后降低,TiH2质量分数为5%时材料压缩强度达到最大值166.4 MPa,比Al/PTFE强度提高6.8%。在一定含量范围内(小于5%),加入TiH2有助于提高Al/PTFE材料撞击感度和能量释放水平,而TiH2质量分数大于10%时,材料撞击感度和反应剧烈程度则逐渐降低。与Al/PTFE相比,含TiH2试件反应火光周围有明显的火星喷溅现象,且此现象TiH2含量越高越显著。Abstract: Four kinds of aluminum/ titanium hydride/ polytetrafluoroethylene (Al/TiH2/PTFE) samples with different TiH2 contents were prepared by the mixed/compression/sintering method. The dynamic compression mechanical properties, impact sensitivity and reaction characteristics of the reaction materials were studied based on the split Hopkinson pressure bar (SHPB) and drop-weight impact tests. The results indicate that the four materials all show strain hardening and strain rate hardening effects, and the yield strength and hardening modulus increase with the increasing of the strain rate. Under the same loading strain rate, the yield strength of the material increases with the increasing of TiH2 content, and the compressive strength of the material increases first and then decreases. When the mass fraction of TiH2 is 5%, the compressive strength of the material reaches the maximum value of 166.4 MPa, which is 6.8% higher than that of the Al/PTFE. Within a certain range of mass fraction (less than 5%), adding TiH2 helps to improve the impact sensitivity and energy release level of the Al/PTFE material, while the impact sensitivity and the reaction degree gradually decrease when the mass fraction of TiH2 exceeds 10%. Compared with the Al/PTFE, there are sparks spraying from the reaction region of the TiH2-contained specimens, and this phenomenon is more significant with the increasing of TiH2 content.

-

表 1 Al/TiH2/PTFE复合材料各组分配比及理论密度

Table 1. Component mass fractions and theoretical material densities of Al/TiH2/PTFE granular composites

材料类型 质量分数/% 材料理论密度/(g·cm−3) Al TiH2 PTFE A 26.5 0 73.5 2.31 B 25.2 5 69.8 2.36 C 23.8 10 66.2 2.41 D 21.2 20 58.8 2.52 表 2 3 200 s−1应变率下不同类型Al/TiH2/PTFE材料力学性能参数

Table 2. Mechanical property parameters for different types of Al/TiH2/PTFE at the strain rate of 3 200 s−1

材料类型 屈服强度/MPa 压缩强度/MPa 失效应变 A 48.3 155.8 0.62 B 52.4 166.4 0.70 C 57.1 154.5 0.65 D 61.3 150.9 0.57 表 3 不同类型Al/TiH2/PTFE材料特性落高

Table 3. Characteristic drop height for different types of Al/TiH2/PTFE

材料类型 H50/cm 材料类型 H50/cm A 67 C 75 B 58 D 83 -

[1] WANG Huaixi, LI Yuchun, FENG Bin, et al. Compressive properties of PTFE/Al/Ni composite under uniaxial loading [J]. Journal of Materials Engineering and Performance, 2017, 26(5): 2331–2336. DOI: 10.1007/s11665-017-2666-y. [2] XU Fengyue, LIU Shubo, ZHENG Yuanfeng, et al. Quasi-static compression properties and failure of PTFE/Al/W reactive materials [J]. Advanced Engineering Materials, 2017, 19(1): 1600350. DOI: 10.1002/adem.201600350. [3] FENG Bin, FANG Xiang, LI Yuchun, et al. An initiation phenomenon of Al-PTFE under quasi-static compression [J]. Chemical Physics Letters, 2015, 637: 38–41. DOI: 10.1016/j.cplett.2015.07.056. [4] 徐松林. PTFE/A1含能反应材料力学性能研究[D]. 长沙: 国防科学技术大学, 2010. [5] 葛超, 乌布力艾散·麦麦提图尔荪, 田超, 等. 基于气炮实验的PTFE/Al 复合材料冲击反应阈值 [J]. 爆炸与冲击, 2018, 38(1): 1–8. DOI: 10.11883/bzycj-2017-0030.GE Chao, MAIMAITITUERSUN Wubuliaisan, TIAN Chao, et al. Impact-induced initiation thresholds of polytetrafluoroethylene/Al composite by gas gun [J]. Explosion and Shock Waves, 2018, 38(1): 1–8. DOI: 10.11883/bzycj-2017-0030. [6] ZHANG X F, ZHANG J, QIAO L, et al. Experimental study of the compression properties of Al/W/PTFE granular composites under elevated strain rates [J]. Material Science and Engineering: A, 2013, 581(10): 48–55. DOI: 10.1016/j.msea.2013.05.063. [7] WANG Liu, LIU Jinxu, LI Shukui, et al. Investigation on reaction energy, mechanical behavior and impact insensitivity of W/PTFE/Al composites with different W percentage [J]. Materials and Design, 2016, 92(5): 397–404. DOI: 10.1016/j.matdes.2015.12.045. [8] 徐松林, 阳世清, 张炜, 等. PTFE/Al含能复合物的本构关系 [J]. 爆炸与冲击, 2010, 30(4): 439–444. DOI: 10.11883/1001-1455(2010)04-0439-06.XU Songlin, YANG Shiqing, ZHANG Wei, et al. A constitutive relation for a pressed PTFE/Al energetic composite material [J]. Explosion and Shock Waves, 2010, 30(4): 439–444. DOI: 10.11883/1001-1455(2010)04-0439-06. [9] 任会兰, 李蔚, 刘晓俊, 等. 钨颗粒增强铝/聚四氟乙烯材料的冲击反应特性 [J]. 兵工学报, 2016, 37(5): 872–878. DOI: 10.3969/j.issn.1000-1093.2016.05.014.REN Huilan, LI Wei, LIU Xiaojun, et al. Reaction behaviors of Al/PTFE materials enhanced by W particles [J]. Acta Armamentarii, 2016, 37(5): 872–878. DOI: 10.3969/j.issn.1000-1093.2016.05.014. [10] 周杰, 何勇, 何源, 等. Al/PTFE/W反应材料的准静态压缩性能与冲击释能特性 [J]. 含能材料, 2017, 25(11): 903–912. DOI: 10.11943/j.issn.1006-9941.2017.11.004.ZHOU Jie, HE Yong, HE Yuan, et al. Quasi-static compression and impact energy release characteristics of reactive materials [J]. Chinese Journal of Energetic Materials, 2017, 25(11): 903–912. DOI: 10.11943/j.issn.1006-9941.2017.11.004. [11] 乌布力艾散·麦麦提图尔荪, 葛超, 董永香, 等. SHPB 加载下 PTFE/Al冲击反应的临界条件 [J]. 爆炸与冲击, 2018, 38(5): 957–965. DOI: 10.11883/bzycj-2017-0075.MAIMAITITUERSUN Wubuliaisan, GE Chao, DONG Yongxiang, et al. Research on the impact-induced initiation criteria of PTFE/Al by split Hopkinson pressure bar [J]. Explosion and Shock Waves, 2018, 38(5): 957–965. DOI: 10.11883/bzycj-2017-0075. [12] FENG B, LI Y C, WU S Z, et al. A crack-induced initiation mechanism of Al-PTFE under quasi-static compression and the investigation of influencing factors [J]. Materials and Design, 2016, 108: 411–417. DOI: 10.1016/j.matdes.2016.06.125. [13] ZHANG Xinbo, LIU Jinxu, WANG Liu, et al. Effects of Al and W particle size on combustion characteristics and dynamic response of W-PTFE-Al composites [J]. Rare Metal Materials and Engineering, 2018, 47(6): 1723–1728. DOI: 10.1016/S1875-5372(18)30156-5. [14] GE C, DONG Y X, MAIMAITITUERSUN W. Microscale simulation on mechanical properties of Al/PTFE composite based on real microstructures [J]. Materials, 2016, 9(7): 590–605. DOI: 10.3390/ma9070590. [15] HUNT E M, MALCOLM S, PANTOYA M L, et al. Impact ignition of nano and micron composite energetic materials [J]. International Journal of Impact Engineering, 2009, 36(6): 842–846. DOI: 10.1016/j.ijimpeng.2008.11.011. [16] 李辰芳. 用氢化钛提高固体推进剂燃速的研究 [J]. 飞航导弹, 1997, 9(6): 34–37. DOI: 10.16338/j.issn.1009-1319.1997.06.009. [17] 薛冰, 马宏昊, 陈伟, 等. RDX基钛氢复合炸药空中爆炸性能 [J]. 含能材料, 2015, 23(11): 1046–1050. DOI: 10.11943/j.issn.1006-9941.2015.11.002.XUE Bing, MA Honghao, CHEN Wei, et al. Air explosion property of RDX-based titanium hydride composite explosive [J]. Chinese Journal of Energetic Materials, 2015, 23(11): 1046–1050. DOI: 10.11943/j.issn.1006-9941.2015.11.002. [18] COLLINS L W. The stability and compatibility of TiHx/KClO4 pyrotechnics [J]. Journal Hazardous Materials, 1982, 5(4): 325–333. DOI: 10.1016/0304-3894(82)85021-8. [19] COLLINS L W. Thermal ignition of titanium based pyrotechnics [J]. Combustion and Flame, 1981, 41(3): 325–330. DOI: 10.1016/0010-2180(81)90066-3. [20] 于钟深, 方向, 高振儒, 等. TiH2含量对Al/PTFE准静态压缩力学性能和反应特性的影响 [J]. 含能材料, 2018, 26(8): 720–724. DOI: 10.11943/CJEM2017387.YU Zhongshen, FANG Xiang, GAO Zhenru, et al. Effect of TiH2 content on mechanical properties and reaction characteristics of Al/PTFE under quasi-static compression [J]. Chinese Journal of Energetic Materials, 2018, 26(8): 720–724. DOI: 10.11943/CJEM2017387. [21] 王爱玉, 阮庆云, 陈海云, 等. 炸药实验方法: GJB772A-97 [S]. 北京: 国防科学技术工业委员会, 1997. [22] YU Zhongshen, FIANG Xiang, GAO Zhenru, et al. Mechanical and reaction properties of Al/TiH2/PTFE under quasi-static compression [J]. Advanced Engineering Materials, 2018, 20: 1800019. DOI: 10.1002/adem.201800019. [23] AMES R. Energy release characteristics of impact-initiated energetic materials [C] // MRS Proceedings, 2005, 896(3): 321−333. DOI: 10.1557/PROC-0896-H03-08. -

下载:

下载: