Dynamic compression property of distill-water ice and impurity-water ice at high strain rates

-

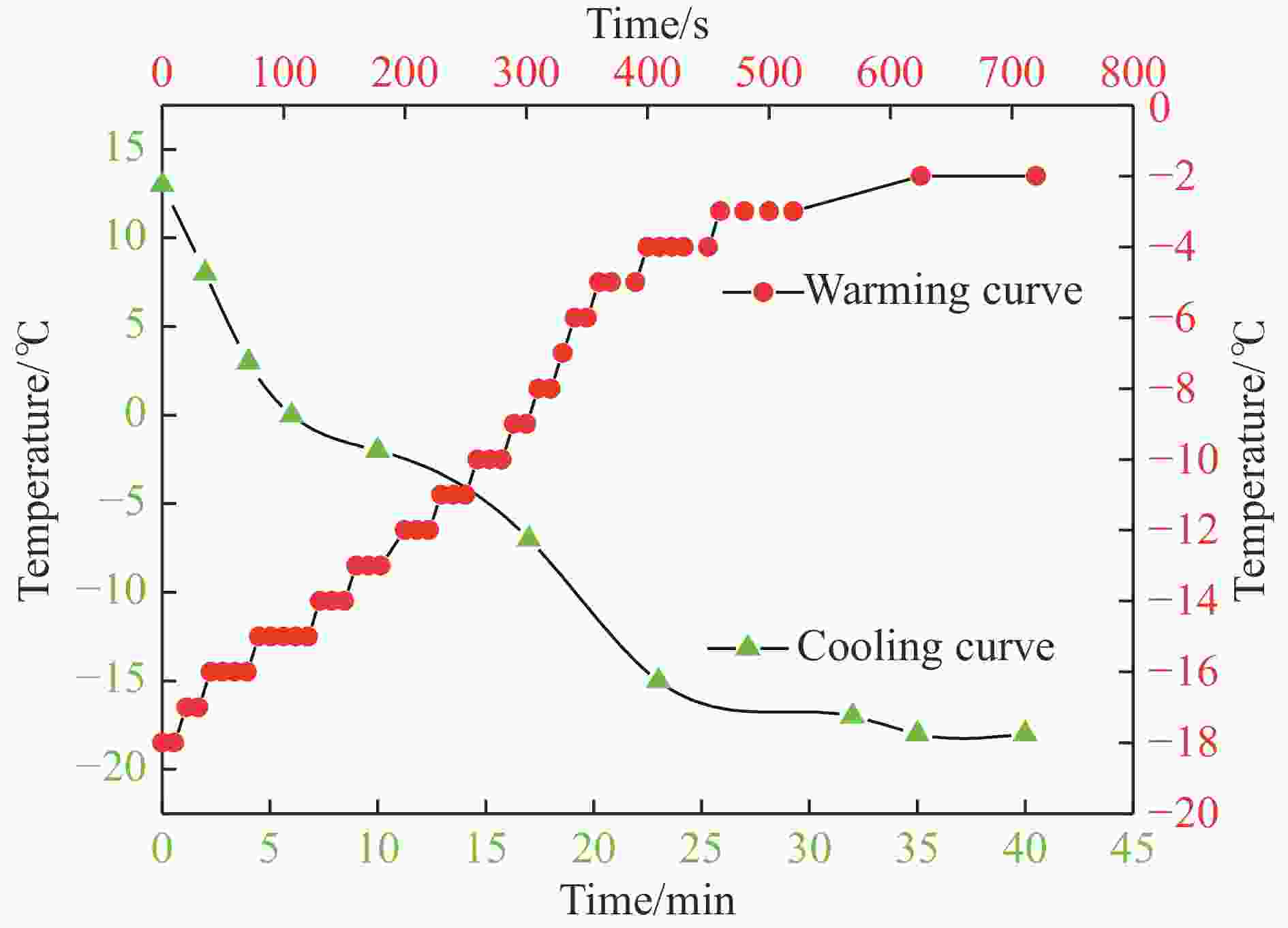

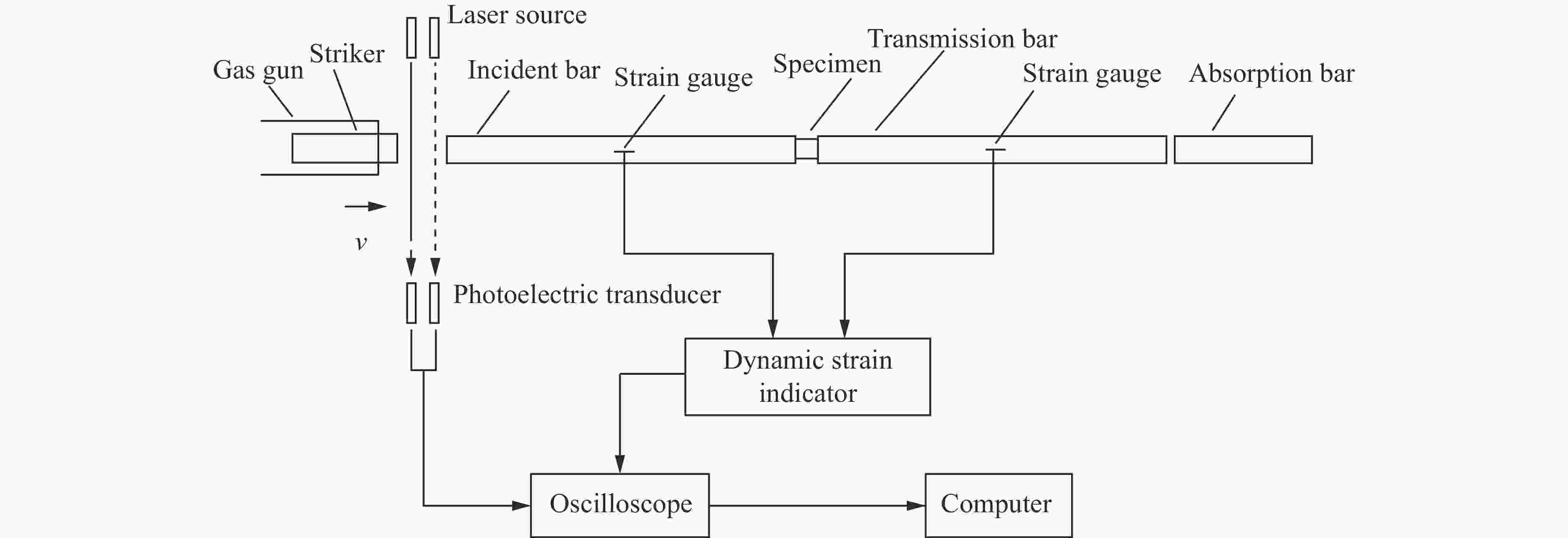

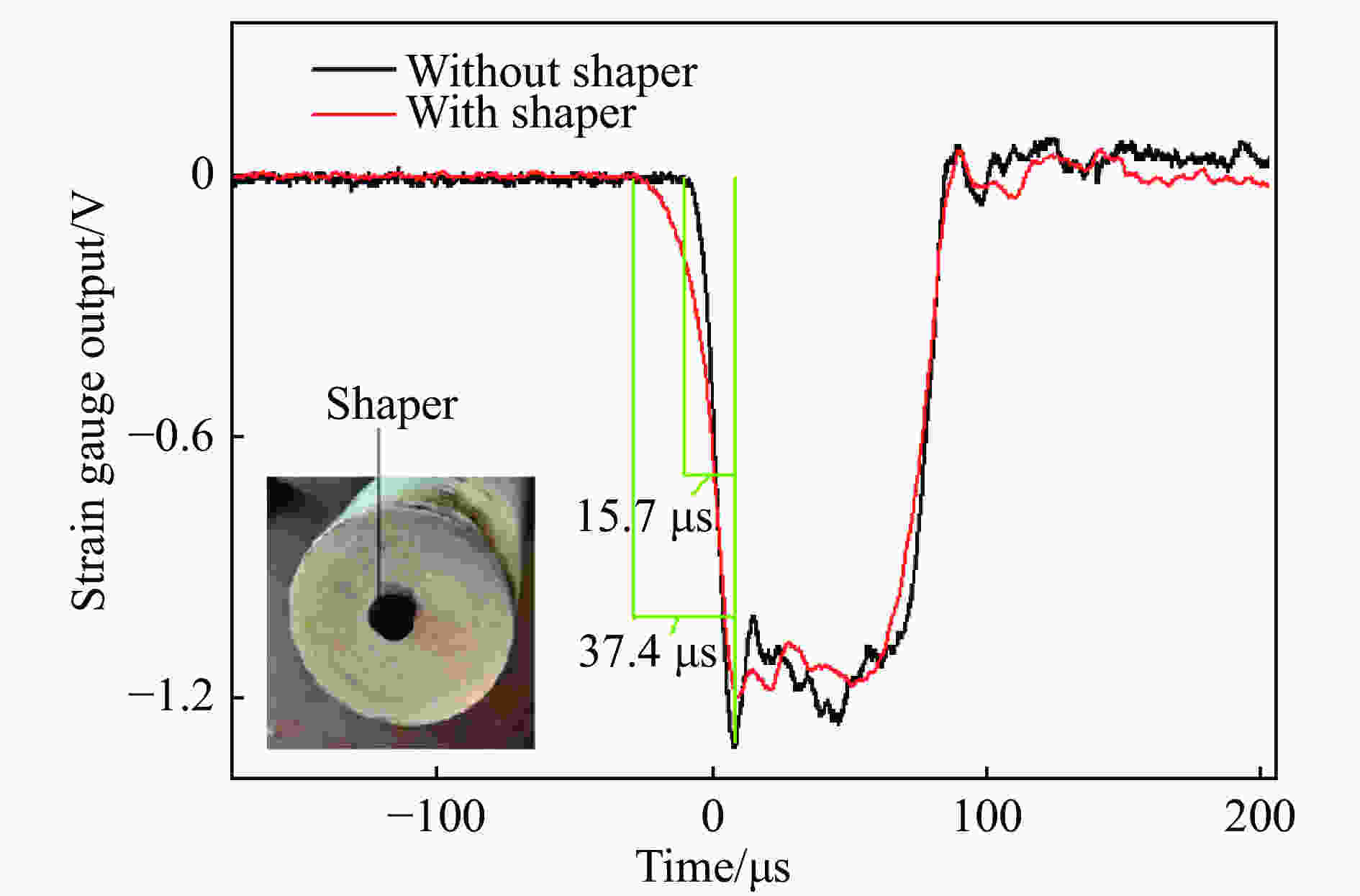

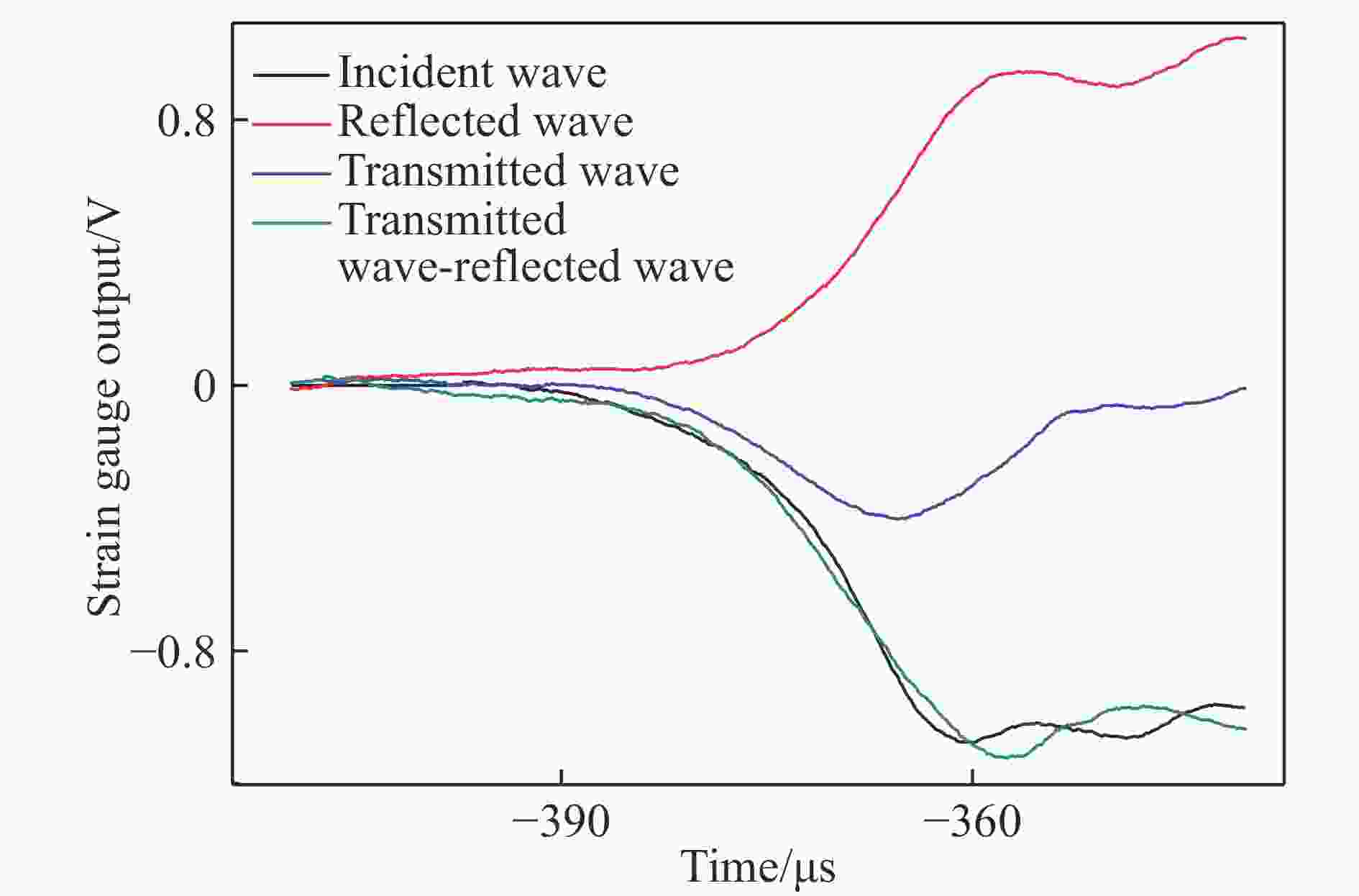

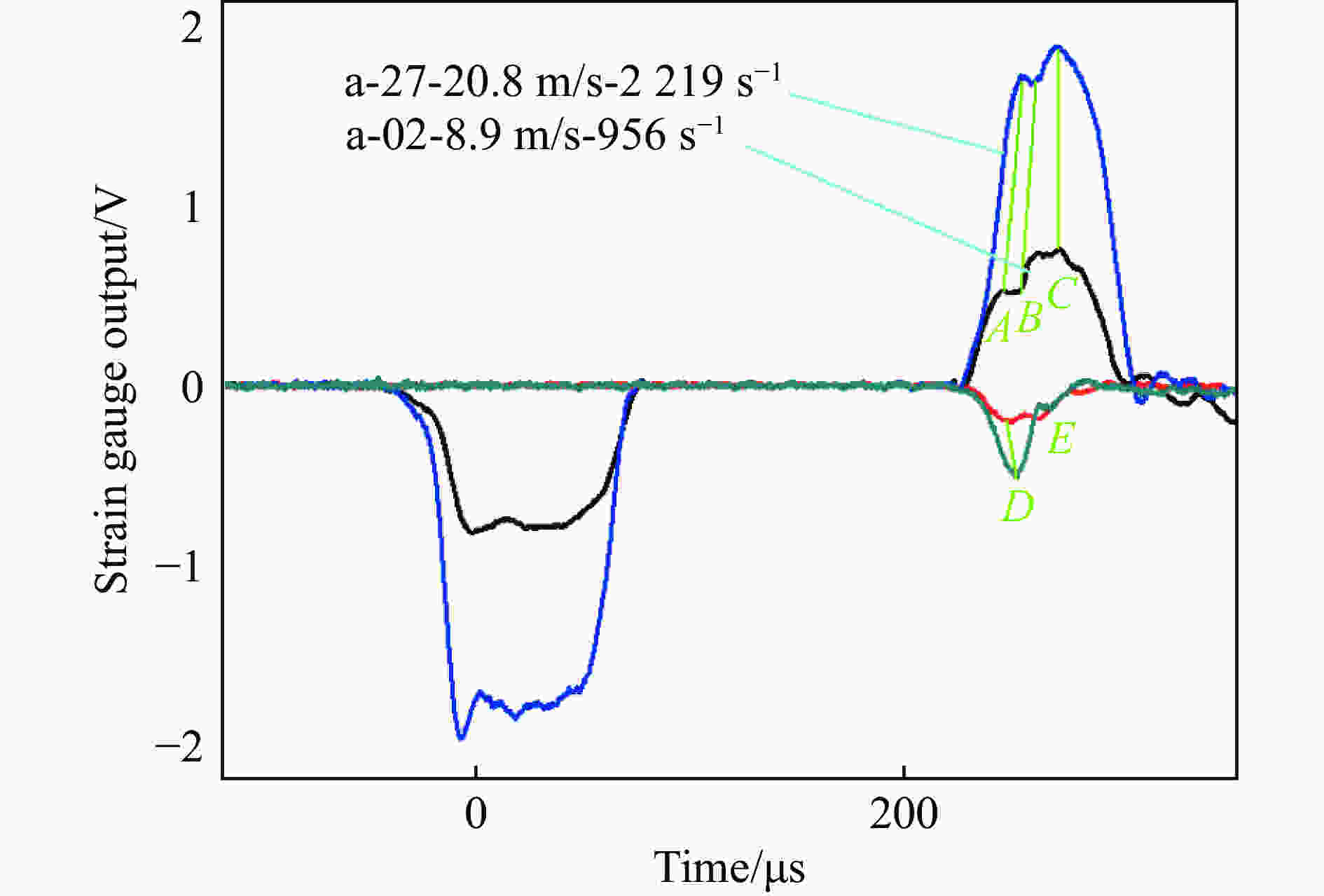

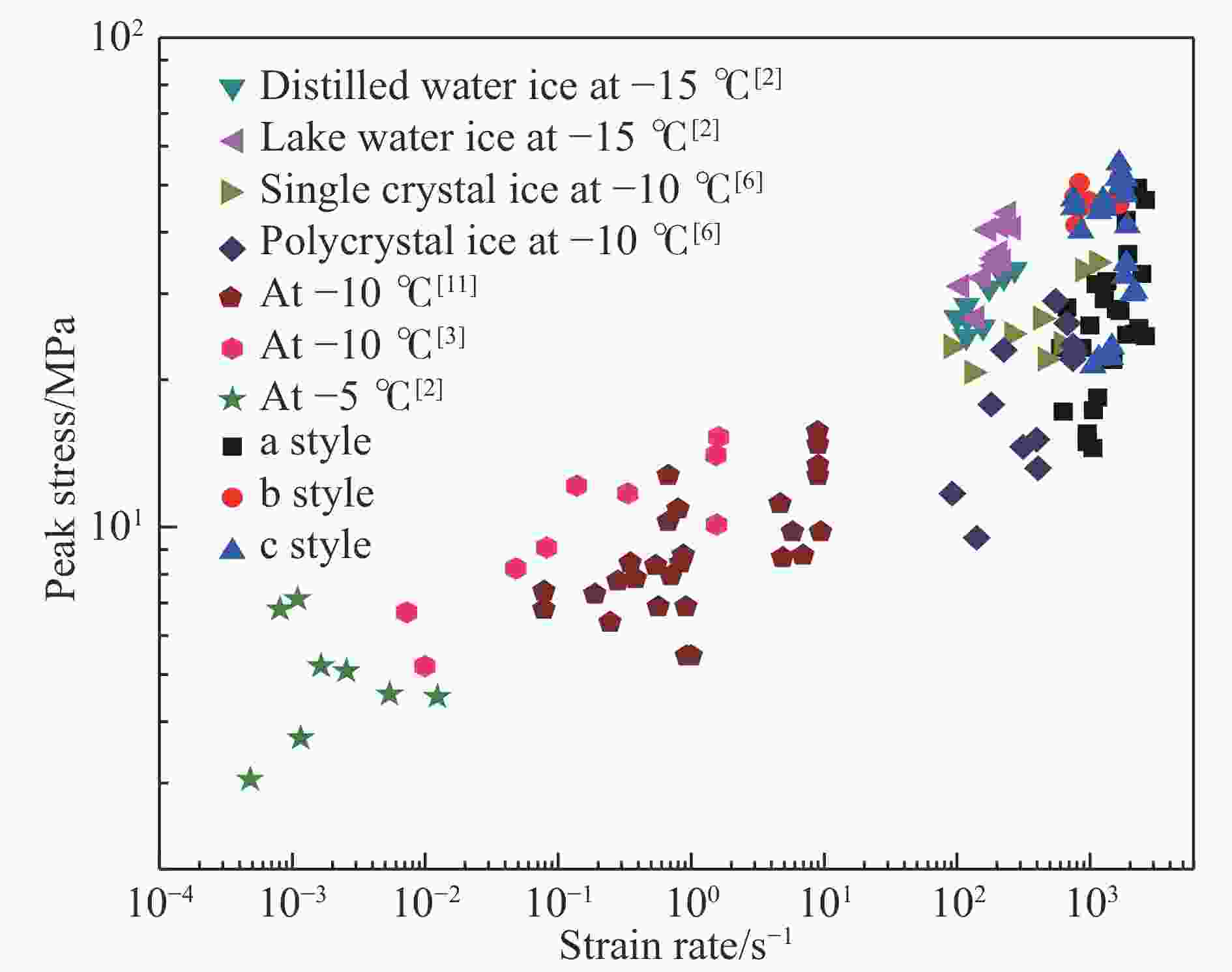

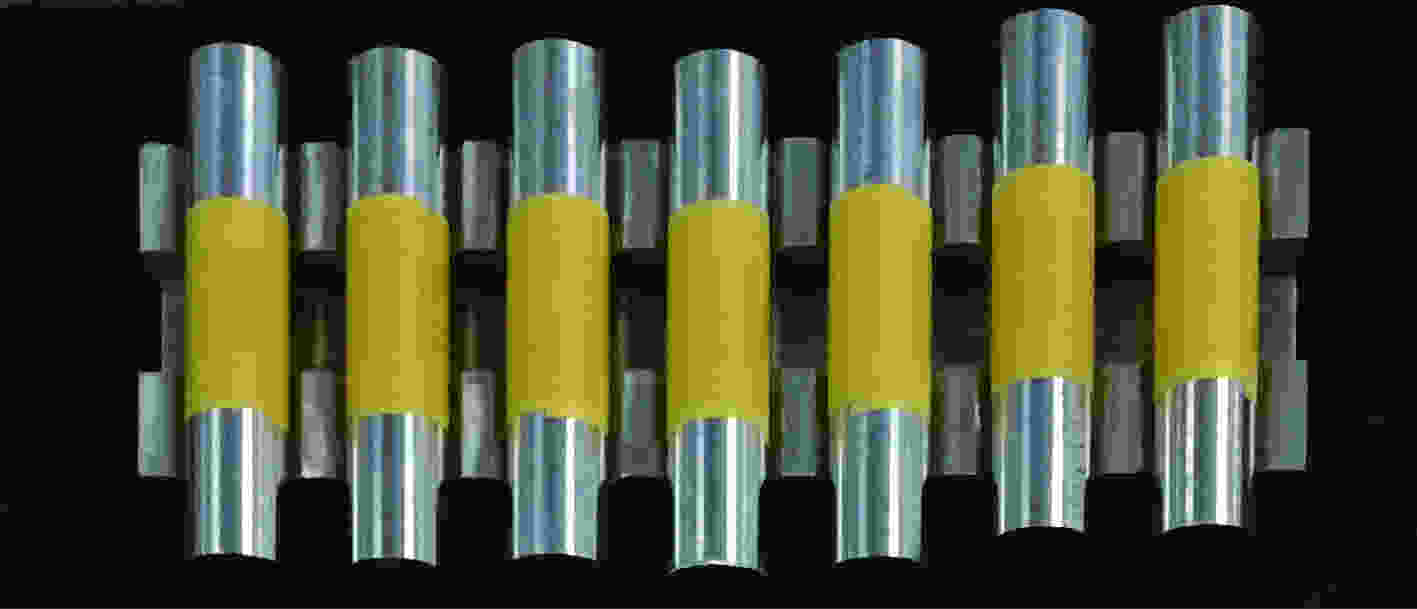

摘要: 通过采用大热惯性试件快速加载技术和波形整形技术,对3种冰材料在−18 ℃下的动态压缩性能进行测试,实验中试件达到了应力均衡和近似恒应变率加载等条件。通过实验波形对比分析,解释了反射波和透射波中的“双峰现象”。在700~2 700 s−1的应变率范围内,纯冰试件的压缩强度为14.5~49.3 MPa,相比于准静态结果表现出明显的动态增强效应。含有杂质的冰试件总体峰值应力相比于纯水冰试件有较大提升,而峰值应力对应的平均应变在减小,这表明添加了杂质的冰试件动态模量增大,冰材料变得更硬,其抵抗变形的能力更强。b型试件所表现出的强度(41.3~51.6 MPa)较a、c型试件均有提高并且分散性较小,说明该试件中杂质与冰晶体之间的结合力较强,抑制了微裂纹的萌生、扩展、成核等过程。Abstract: The dynamic strength of three kinds of ice specimens at −18 ℃ were tested by the split Hopkinson pressure bar (SHPB) method. The pulse-shaping technology was used to achieve constant strain rate loading and stress equalization. The double-peak phenomena of reflection wave and transmission wave were explained by comparing with stress waveforms. The compression stress of distill-water ice in the strain rate range from 700 to 2 700 s−1 is 14.5−49.3 MPa, and it is much higher than the static data. Generally, the dynamic compression stress of the impurity-water ice is higher than that of the distill-water ice, this indicate that the ice specimens become harder after adding impurities, and the capability to resist deformation is enhanced. Compared with a-type and c-type specimens, the crack stress of b-type specimens becomes higher and its dispersiveness is lower. This indicates that the adhesive forces between impurities and ice crystals become stronger, and the expending and nucleate process of cracks is restrained.

-

Key words:

- SHPB /

- ice specimen /

- dynamic compression property /

- pulse-shaping technology

-

表 2 冰试件峰值应力的统计结果

Table 2. The statistice results of peak stress for ice specimens

试件类型 峰值应力平均值/MPa 标准差/MPa 最小值/MPa 最大值/MPa a 26.8 9.1 14.5 49.3 b 46.8 3.2 41.3 51.6 c 39.5 11.1 21.3 55.4 表 1 部分冰试件的实验结果

Table 1. Part of experimental results

试件编号 加载速度/(m·s−1) 峰值应力/MPa 峰值应力处应变/% 应变率/s−1 a-03 8.8 14.5 1.27 1 053 a-06 8.8 18.4 1.58 1 143 a-11 12.0 22.0 1.55 1 396 a-12 12.0 21.9 1.09 1 502 a-21 17.9 27.6 1.14 1 687 a-22 18.4 25.5 1.47 2 331 b-02 12.5 50.4 0.88 837 b-05 12.1 47.3 1.18 772 b-06 21.6 51.6 1.18 1 688 b-08 21.6 47.1 1.13 1 592 c-05 9.3 21.3 1.06 1 058 c-12 12.0 46.7 1.08 1 251 c-15 17.4 55.4 1.15 1 655 c-17 17.1 51.5 1.34 1 627 c-18 21.2 51.4 1.25 1 845 -

[1] 汪洋, 李玉龙, 刘传雄. 利用SHPB测定高应变率下冰的动态力学行为 [J]. 爆炸与冲击, 2011, 31(2): 215–219. DOI: 10.11883/1001-1455(2011)02-0215-05.WANG Yang, LI Yulong, LIU Chuanxiong. Dynamic mechanical behaviors of ice at high strain rates [J]. Explosion and Shock Waves, 2011, 31(2): 215–219. DOI: 10.11883/1001-1455(2011)02-0215-05. [2] WU X, VIKAS P. Dynamic strength of distill water and lake water ice high strain rate [J]. International Journal of Impact Engineering, 2015, 76: 155–165. DOI: 10.1016/j.ijimpeng.2014.09.013. [3] SCHULSON E M. The structure and mechanical behavior of ice [J]. Journal of the Minerals Metals and Materials Society, 1999, 51(2): 21–27. DOI: 10.1007/s11837-999-0206-4. [4] MAJID K, MASOUD F. Compressive strength of atmospheric ice [J]. Cold Regions Science and Technology, 2007, 49: 195–205. DOI: 10.1016/j.coldregions.2007.05.003. [5] SCHULSON E M. Brittle failure of ice [J]. Engineering Fracture Mechanics, 2001, 68(18): 39−87. DOI: 10.1016/S0013-7944(01)00037-6. [6] SHAZLY M, PRAKASH V, LERCH B A. High strain-rate behavior of ice under uniaxial compression [J]. International Journal of Solids and Structures, 2009, 46(6): 1499–1515. DOI: 10.1016/j.ijsolstr.2008.11.020. [7] 王礼立, 王永刚. 应力波在用SHPB研究材料动态本构特性中的重要作用 [J]. 爆炸与冲击, 2005, 25(1): 17–25. DOI: 10.11883/1001-1455(2005)01-0017-09.WANG Lili, WANG Yonggang. The important role of stress waves in the study on dynamic constitutive behavior of materials by SHPB [J]. Explosion and Shock Waves, 2005, 25(1): 17–25. DOI: 10.11883/1001-1455(2005)01-0017-09. [8] PETROVIC J J. Mechanical properties of ice and snow [J]. Materials Science, 2003, 38(1): 1–6. DOI: 10.1023/A:1021134128038. [9] 陈刚, 张青平, 黄西成. 基于软材料的SHPB波形整形技术 [J]. 中国科学: 技术科学, 2016, 46: 393–399. DOI: 1360/N092015-00368.CHEN Gang, ZHANG Qingping, HUANG Xicheng. Pulse shaping with soft material for SHPB [J]. Sciatica Sinica: Technological, 2016, 46: 393–399. DOI: 1360/N092015-00368. [10] LV T H, CHEN X W, CHEN G. Analysis on the wave form features of the split Hopkinson pressure bar tests of plain concrete specimen [J]. International Journal of Impact Engineering, 2017, 103: 107–123. DOI: 10.1016/j.ijimpeng.2017.01.004. [11] JONES S. High strain-rate compression test on ice [J]. Journal of Physical Chemistry: B, 1997, 101(6): 99–101. [12] 冯晓伟, 冯高鹏, 方辉. 不同应变率下冰破坏特性的试验研究 [J]. 应用力学学报, 2016, 33(2): 223–229. DOI: 10.11776/cjam.33.02.B035.FENG Xiaowei, FENG Gaopeng, FANG Hui. Experimental investigation on compressive failure behavior of fresh-water ice at different compressive rates [J]. Chinese Journal of Applied Mechanics, 2016, 33(2): 223–229. DOI: 10.11776/cjam.33.02.B035. -

下载:

下载: