Impact response of scaled models of an energy-absorbing container

-

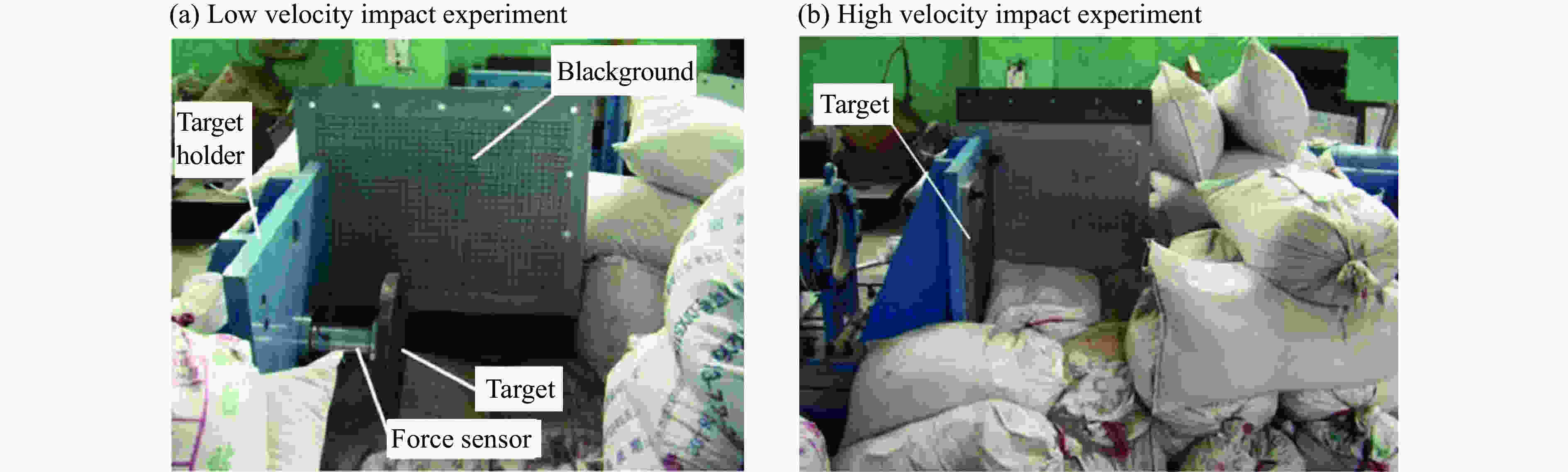

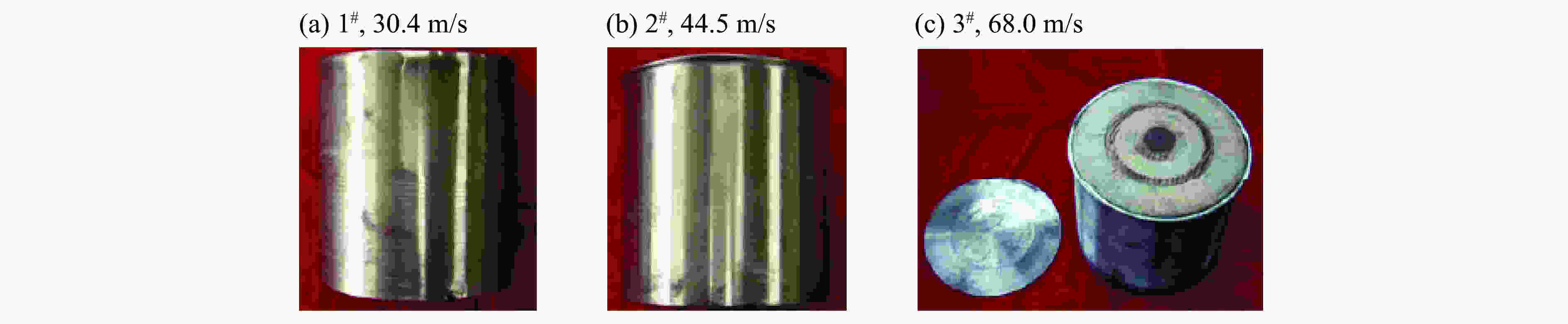

摘要: 利用空气炮冲击实验对吸能包装结构的跌落过程进行模拟,进行了缩比模型的正撞和30°斜撞实验,针对模型实验进行了数值分析,获得了吸能包装结构模型在撞击过程中的应力分布和塑性变形,并将计算情况与实验结果进行了分析。结果表明:在撞击中吸能包装结构主要通过缓冲木材的塑性变形及外钢壳屈曲产生的塑性铰吸收能量,塑性变形主要集中于撞击端,而远离撞击端未见塑性变形;计算中木材本构参数采用顺纹方向压缩应力应变曲线具有一定的有效性。Abstract: The drop process of an energy-absorbing container was simulated by air gun impact test, and the forward and 30° oblique impact experiments of the scale model were carried out. The numerical analysis for the model experiments was conducted to obtain the stress distribution and plastic deformation of the energy-absorbing container model in the impact process. And then the calculation and experimental results were compared. The results show that the energy-absorbing container absorbs energy mainly by the plastic deformation of cushion wood and the plastic hinges produced by the buckling of outer steel shell during impact, and its plastic deformation mainly concentrates at the impact end, while no plastic deformation is found far away from the impact end. In simulations, the compressive stress-strain curve of the wood in texture direction can be used to simulate the drop impact process of energy-absorbing container.

-

Key words:

- energy-absorbing container /

- impact /

- model experiment /

- oblique impact

-

表 1 弹丸撞击速度

Table 1. Impact velocity of projectile

撞击方向 弹号 质量/g 气压/MPa 弹速/(m∙s−1) 正撞 1# 3 405 0.20 30.4 2# 3 415 0.30 44.5 3# 3 450 0.55 68.0* 30°斜撞 4# 3 370 0.20 30.3 5# 3 410 0.30 44.1 6# 3 420 0.55 63.4 注:*测速系统未采到数据,此为根据高速摄影估算。 表 2 弹靶材料力学性能参数

Table 2. Material properties of projectiles and targets

材料名称 ρ/(kg∙m−3) E/GPa ν σs/MPa EP/MPa 失效应变 45钢 7 810 212 0.3 Johnson-Cook模型 云杉 413 11.33 0.1 采用实验测试顺纹方向压缩曲线 Q235 7 800 210 0.3 235 2 100 0.8 20钢 7 850 211 0.286 245 2 110 0.4 -

[1] JOSEPH C, MALONEY Jr. The History and Significance of Military Packaging: TECHNICAL REPORT 1-96 [R]. Fort Belvoir: Defense Systems Management College Press, 1996. [2] 肖冰, 黄晓霞, 彭天秀. 国外弹药包装的现状与发展趋势研究 [J]. 包装工程, 2005, 26(5): 220–227. DOI: 10.3969/j.issn.1001-3563.2005.05.088. [3] 周定如, 蔡建, 赵耀辉, 等. 美国军用包装技术发展的经验和启示 [J]. 包装工程, 2010, 31(7): 80–83.ZHOU Dingru, CAI Jian, ZHAO Yaohui, et al. Enlightenment from the experience in development of U.S. military packaging technique [J]. Packaging Engineering, 2010, 31(7): 80–83. [4] 苏远. 缓冲包装理论基础与应用[M]. 北京: 化学工业出版社, 2006: 1–15. [5] 王保乾. 有效载荷抗事故包装箱的环境与环境试验 [J]. 环境技术, 1995(4): 7–12.WANG Baoqian. Environments and environmental test of accident-resistant containers for payload [J]. Environmental Technology, 1995(4): 7–12. [6] 李明海, 翟贵立, 宋耀祖, 等. 抗事故包装箱热防护结构的设计及其性能分析 [J]. 包装工程, 2000, 21(2): 5–8. DOI: 10.3969/j.issn.1001-3563.2000.02.002.LI Minghai, ZHAI Guili, SONG Yaozu, et al. Design and performance analyses of thermal protection structure of accident-resistant packaging container [J]. Packaging Engineering, 2000, 21(2): 5–8. DOI: 10.3969/j.issn.1001-3563.2000.02.002. [7] 李明海, 任建勋, 罗群生, 等. 钢-木组合结构在火灾中的热响应数值模拟 [J]. 清华大学学报, 2001, 41(2): 68–71. DOI: 10.3321/j.issn:1000-0054.2001.02.018.LI Minghai, REN Jianxun, LUO Qunsheng, et al. Numerical simulation of the thermal response of steel- wood composite structure on fire [J]. Journal of Tsinghua University, 2001, 41(2): 68–71. DOI: 10.3321/j.issn:1000-0054.2001.02.018. [8] 胡宇鹏, 罗群生, 李友荣, 等. 不同压力下具有内热源的包装箱内传热特性 [J]. 包装工程, 2016, 37(11): 1–5.HU Yupeng, LUO Qunsheng, LI Yourong, et al. Heat transfer characteristics of a product with an inner heat source in a packaging container under different pressures [J]. Packaging Engineering, 2016, 37(11): 1–5. [9] 张鹏, 王文博, 王宏伟. ANSYS软件在导弹包装箱设计中的应用研究 [J]. 航空科学技术, 2015, 26(4): 53–57. DOI: 10.3969/j.issn.1007-5453.2015.04.011.ZHANG Peng, WANG Wenbo, WANG Hongwei. The application of ansys software on missile packing design [J]. Aeronautical Science and Technology, 2015, 26(4): 53–57. DOI: 10.3969/j.issn.1007-5453.2015.04.011. [10] 李娜, 刘剑钊, 张思才, 等. 抗事故包装箱碰撞过程靶体等效方法研究 [J]. 包装工程, 2016, 37(11): 25–38.LI Na, LIU Jianzhao, ZHANG Sicai, et al. Equivalent method for the targets in impact process of accident-resistant packaging container [J]. Packaging Engineering, 2016, 37(11): 25–38. [11] MICHAEL H, GENE H L, LAVERNE E R, et al. Analysis, scale modeling, and full-scale tests of low-level nuclear-waste-drum response to accident environments: SAND80-2517 [R]. Albuquerque, New Moxica: Sandia National Laboratories, 1983: 43–63. [12] 鲍平鑫, 宁伟宇, 张卫春. 基于CATIA与ADAMS军用爆炸品包装箱铁路运输冲击仿真实验研究 [J]. 军事交通学院学报, 2012(3): 20–25. DOI: 10.3969/j.issn.1674-2192.2012.03.005.BAO Pingxin, NING Weiyu, ZHANG Weichun. Research on impact simulation experment of military explosives packing through railway transportation based on CATIA and ADAMS [J]. Journal of Military Transportation University, 2012(3): 20–25. DOI: 10.3969/j.issn.1674-2192.2012.03.005. [13] 葛任伟, 欧阳勇, 张怀宇, 等. 抗事故包装箱缓冲结构厚度计算方法研究 [J]. 机械设计与制造, 2011(12): 38–40. DOI: 10.3969/j.issn.1001-3997.2011.12.015.GE Renwei, OUYANG Yong, ZHANG Huaiyu, et al. Research of computing methods for thickness of buffering structure of accident resistant packing cases [J]. Machinery Design and Manufacture, 2011(12): 38–40. DOI: 10.3969/j.issn.1001-3997.2011.12.015. [14] 屠兴. 模型实验的基本理论与方法[M]. 西安: 西北工业大学出版社, 1989: 1–10. [15] 谈庆明. 量纲分析[M]. 合肥: 中国科学技术大学出版社, 2005: 1–19. [16] 罗文泉, 叶霜. 模型实验的相似方法 [J]. 工业加热, 1999, 1(1): 17–19. DOI: 10.3969/j.issn.1002-1639.1999.01.005.LUO Wenquan, YE Shuang. Similarity method of model experiment [J]. Industrial Heating, 1999, 1(1): 17–19. DOI: 10.3969/j.issn.1002-1639.1999.01.005. [17] 周政, 葛任伟, 卢永刚, 等. 抗事故包装箱抗冲击性能的相似准则 [J]. 包装工程, 2018, 39(7): 31–38.ZHOU Zheng, GE Renwei, LU Yonggang, et al. Similarity criteria for impact resistance of accident resistant containers [J]. Packaging Engineering, 2018, 39(7): 31–38. [18] 钟卫洲, 宋顺成, 黄西成, 等. 三种加载方向下云杉静动态力学性能研究 [J]. 力学学报, 2011, 43(6): 1141–1150. DOI: 10.6052/0459-1879-2011-6-lxxb2010-450.ZHONG Weizhou, SONG Shuncheng, HUANG Xicheng, et al. Research on static and dynamic mechanical properties of spruce wood by three loading directions [J]. Chinese Journal of Theoretical and Applied Mechanics, 2011, 43(6): 1141–1150. DOI: 10.6052/0459-1879-2011-6-lxxb2010-450. -

下载:

下载: