Experimental study on influence of granite grain size on rockburst

-

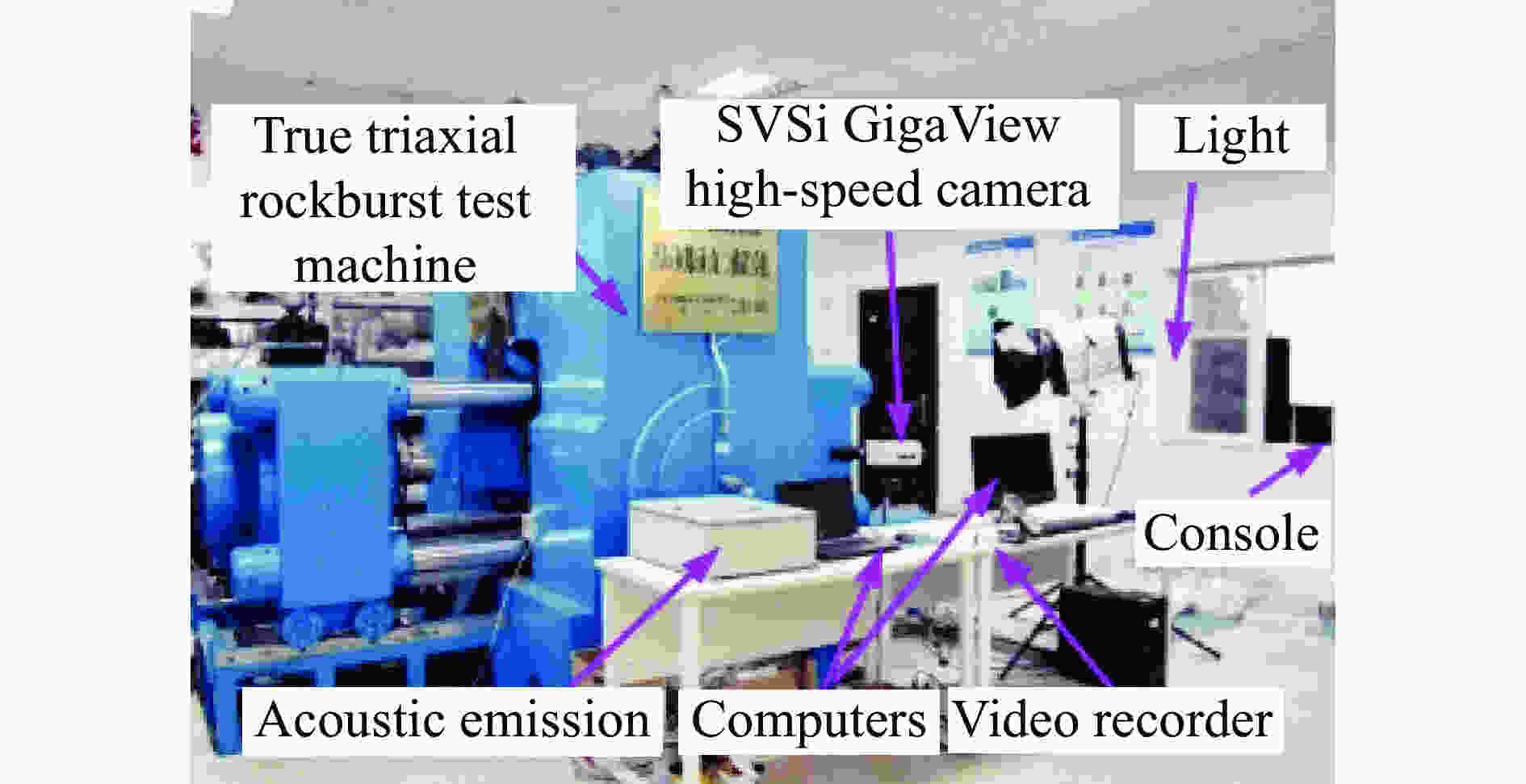

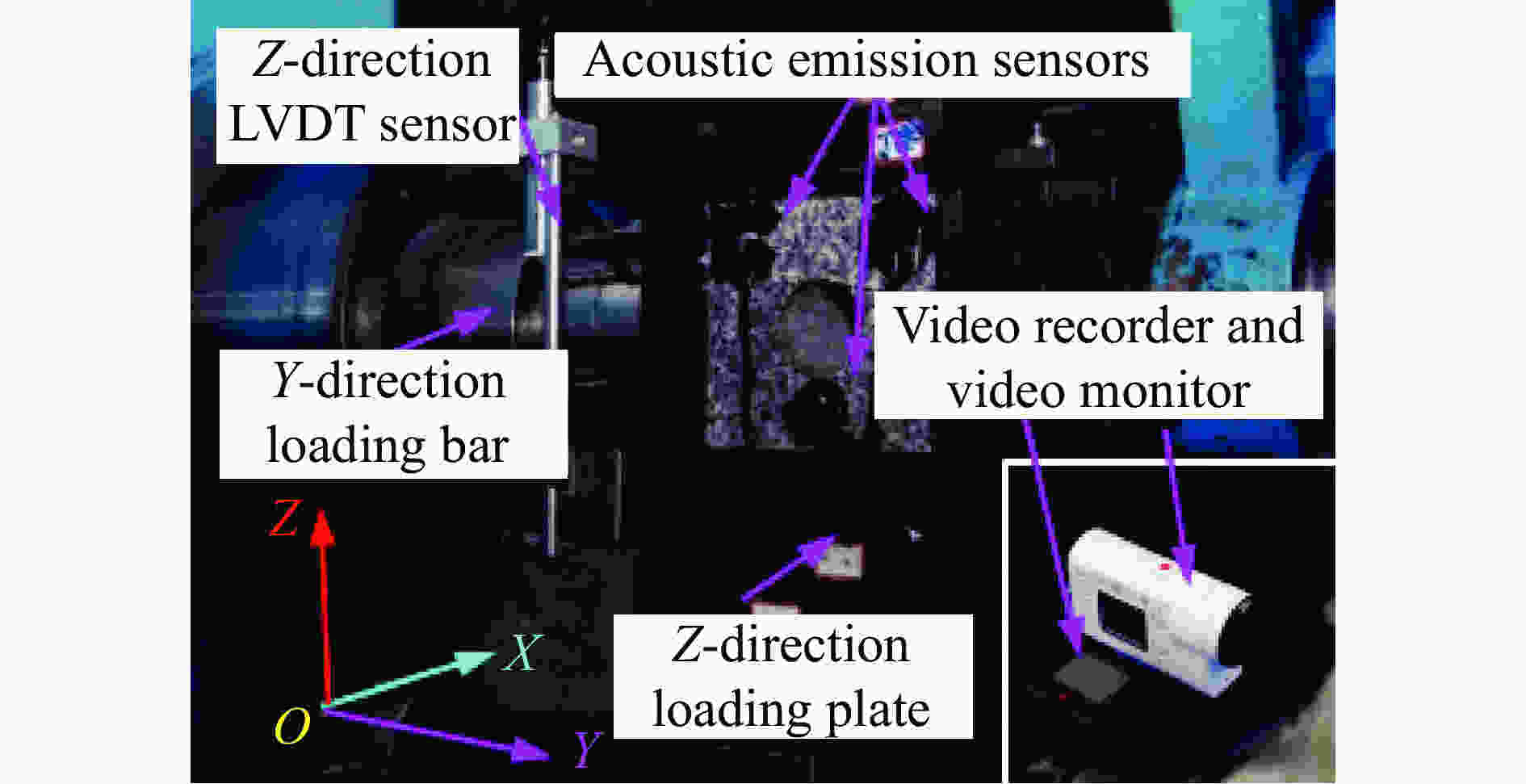

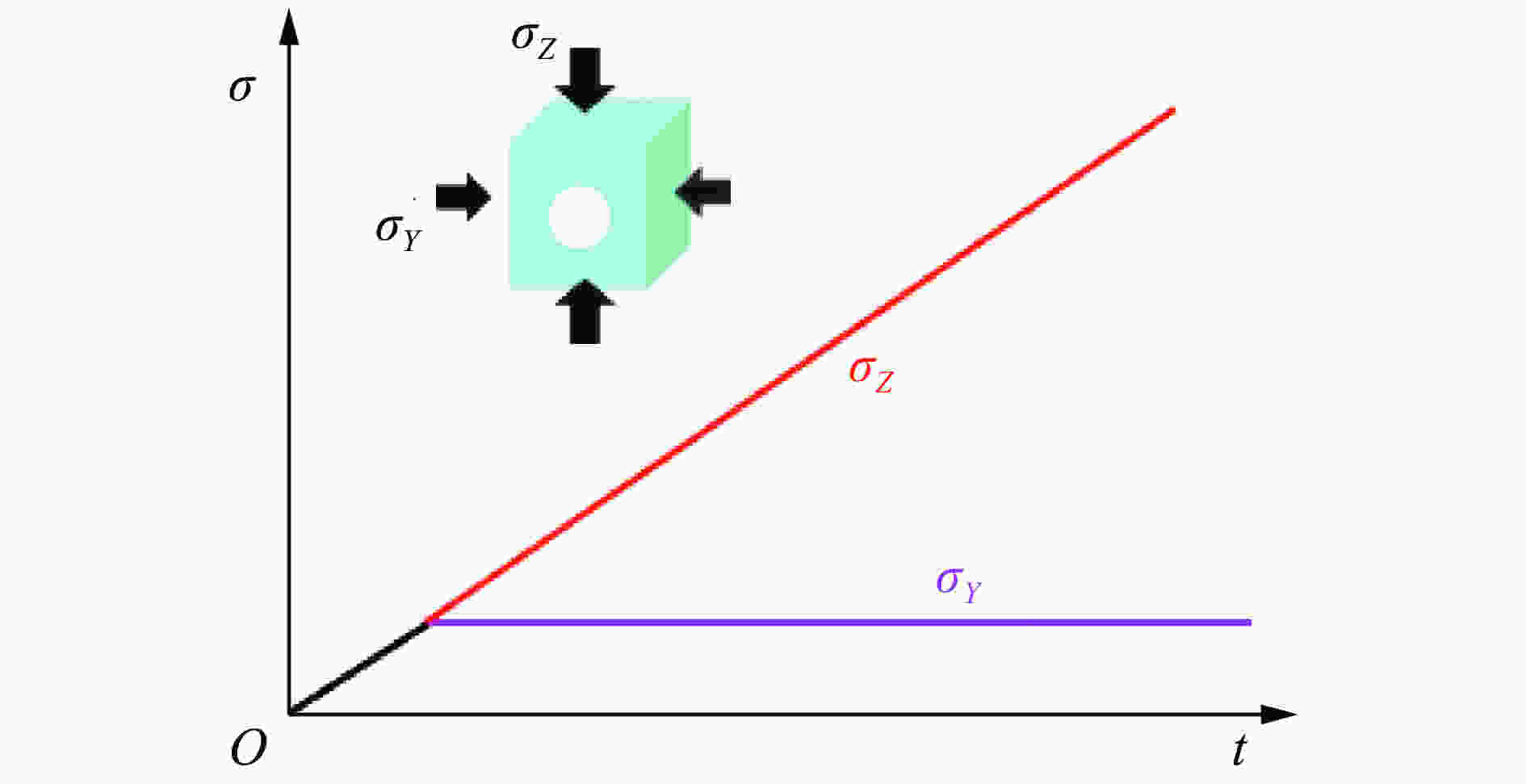

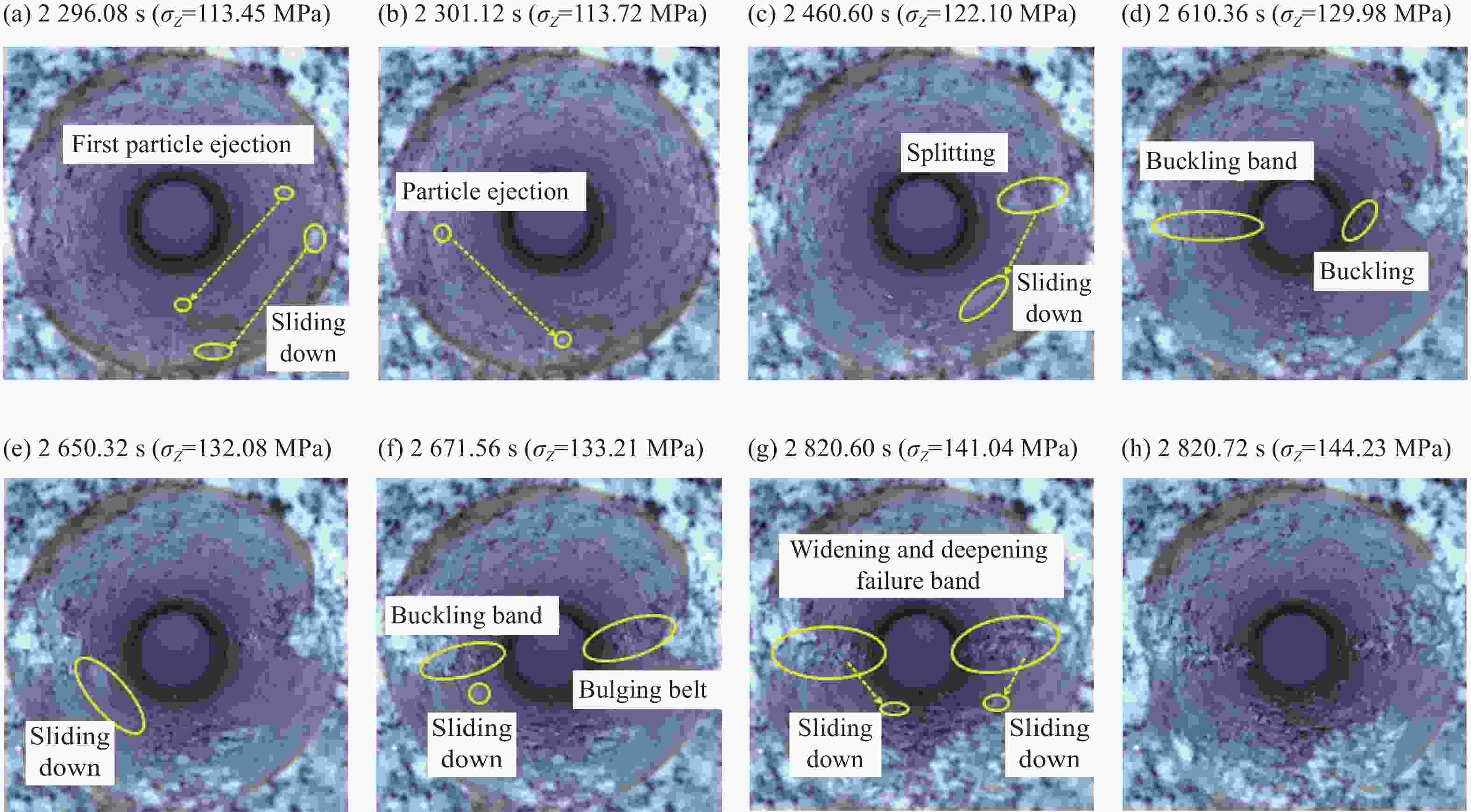

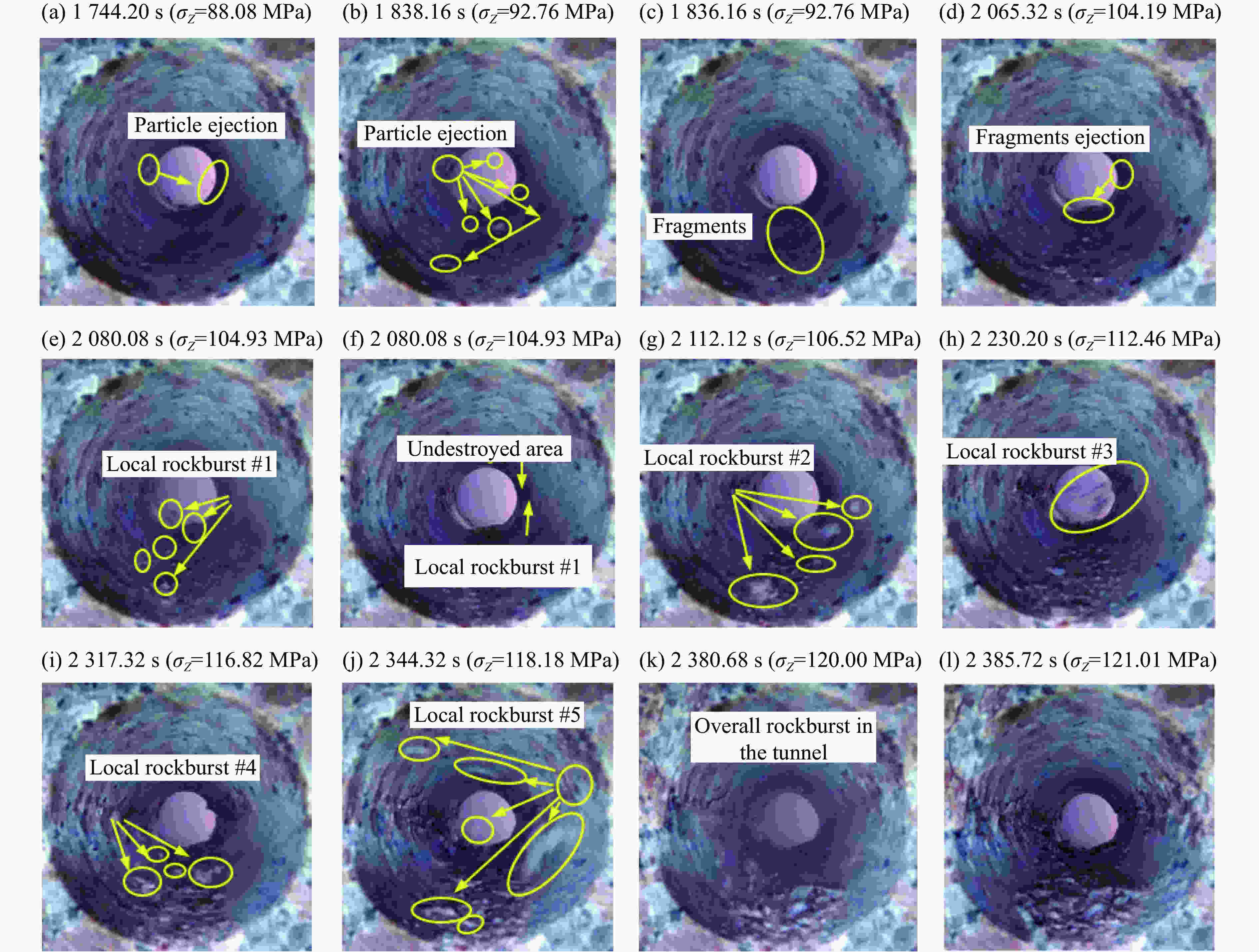

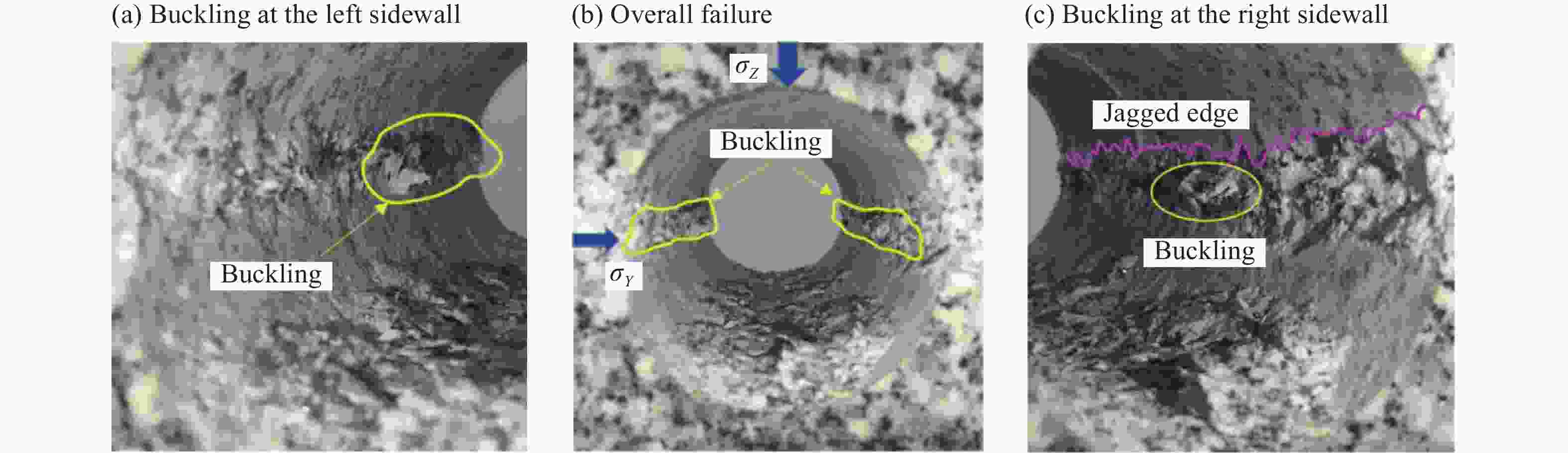

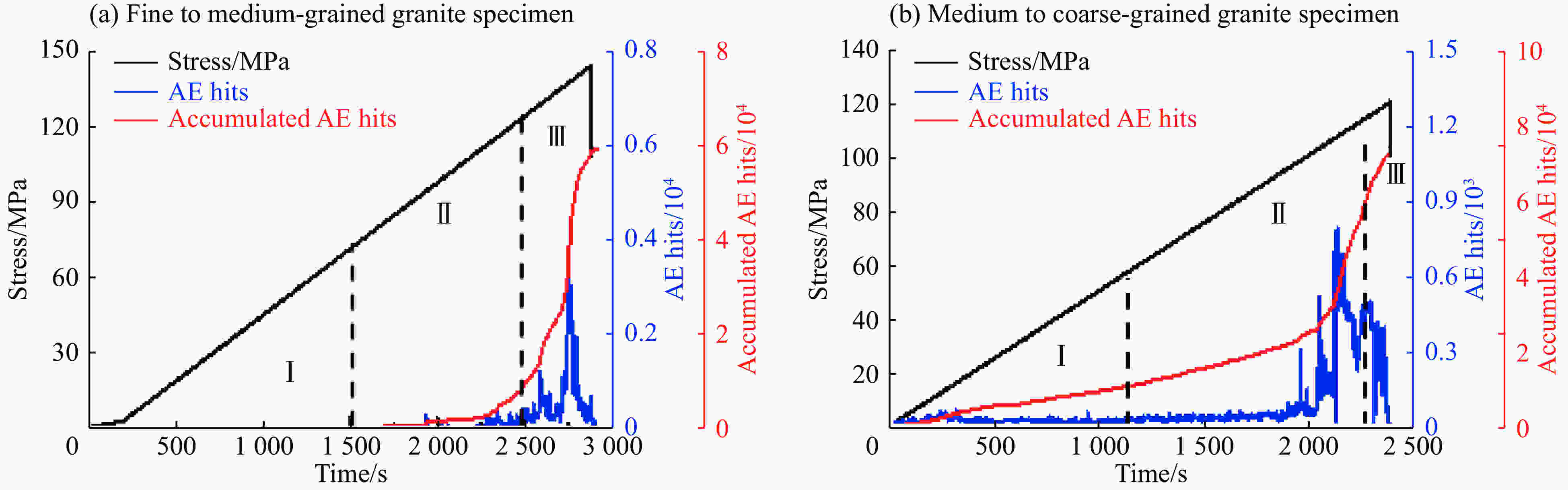

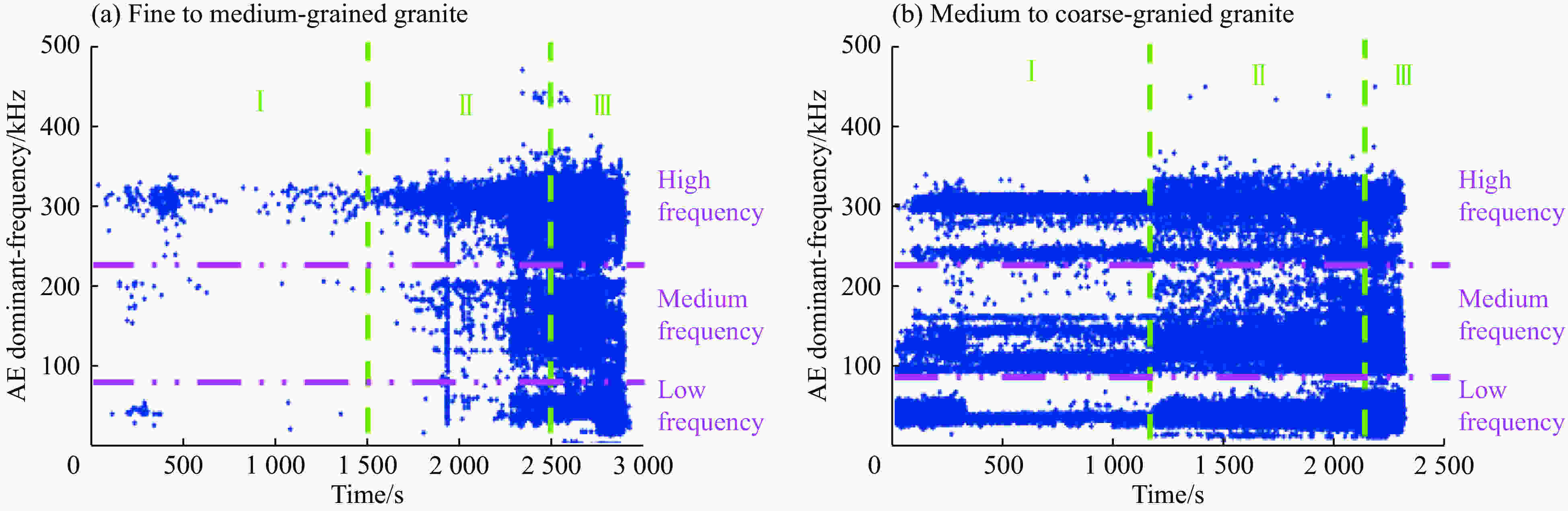

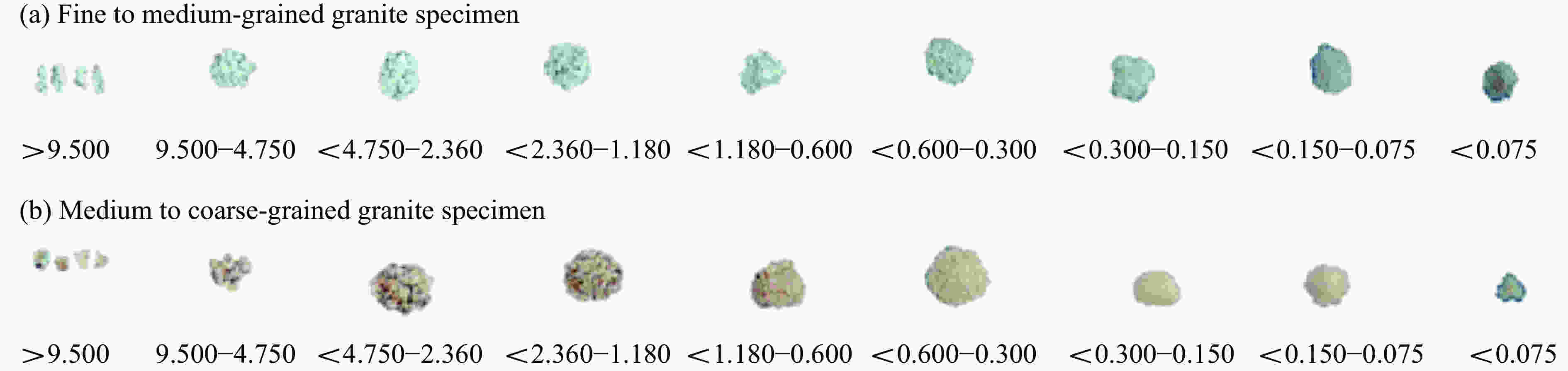

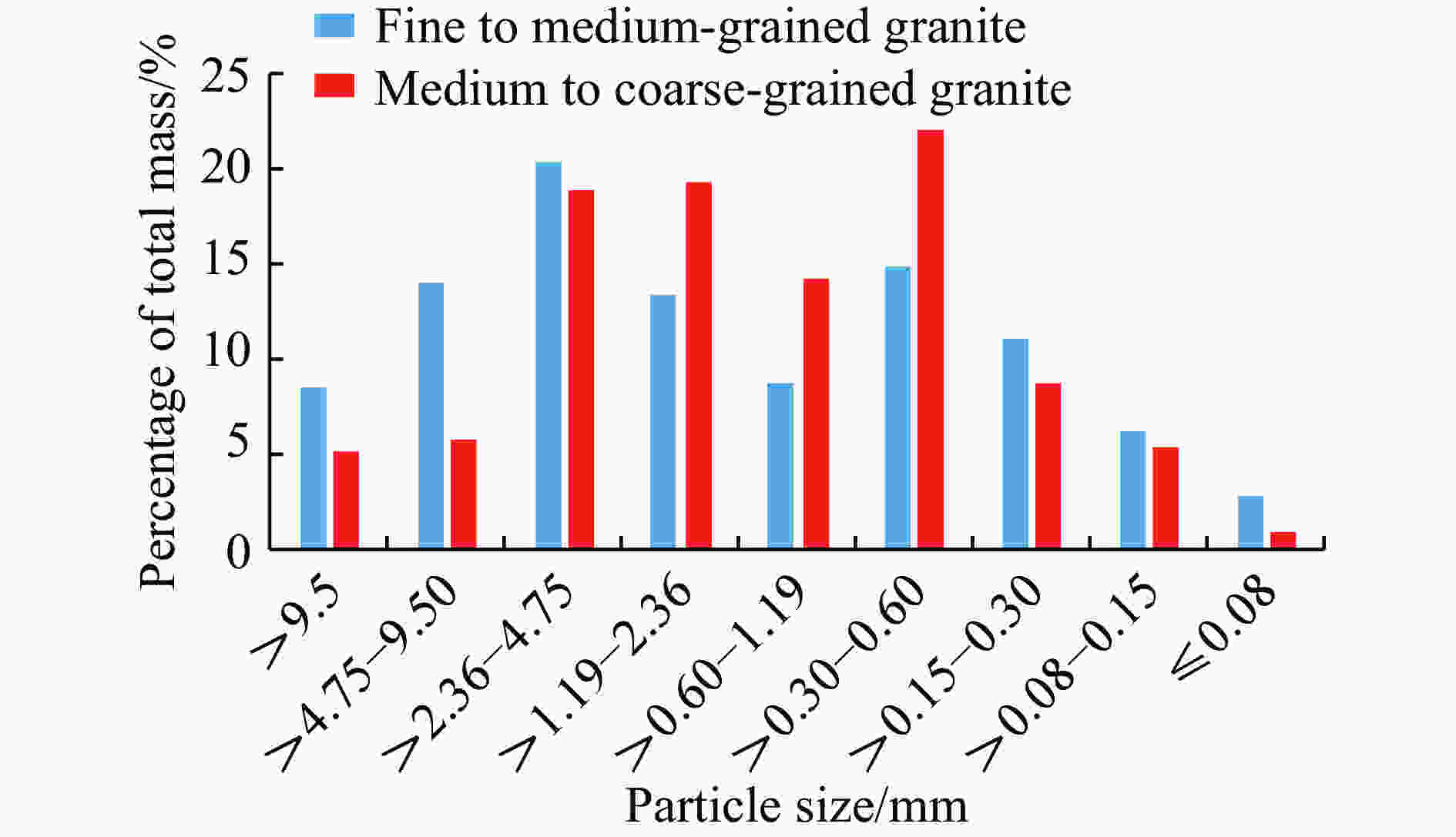

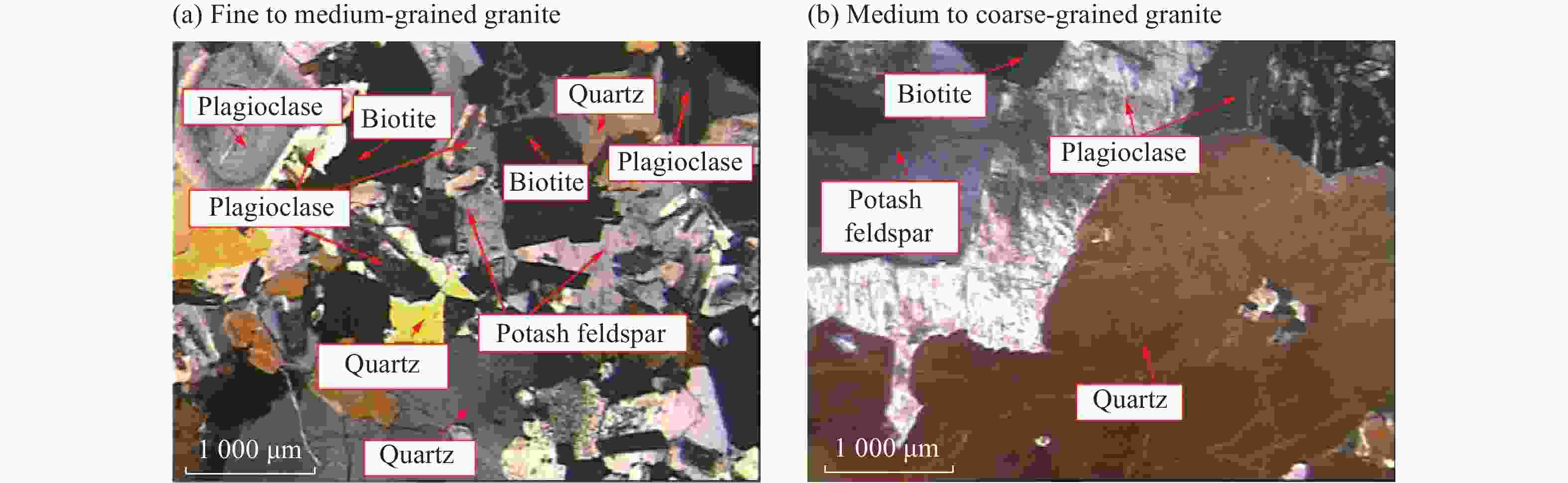

摘要: 为探究晶粒尺寸对硬脆性岩石岩爆的影响,利用真三轴岩爆试验系统,对细中、中粗两种不同晶粒尺寸的含预制圆孔花岗岩开展了岩爆模拟试验。试验结果表明:在相同的加载过程中,细中晶粒花岗岩出现板裂静态脆性破坏,而中粗晶粒花岗岩出现岩爆动力破坏;细中晶粒花岗岩早期声发射活动较弱,大破裂、低主频事件在时空分布上较集中,特征应力较大,而中粗晶粒花岗岩早期声发射活动较活跃,大破裂、低主频事件在时空分布上较离散,特征应力较小,碎屑破碎程度更高。晶粒尺寸对花岗岩的岩爆倾向性具有重要影响,晶粒尺寸较大的硬脆性岩石的岩爆倾向性更强。深部地下岩体工程的岩爆倾向性评价中,除强度和脆性外,晶粒尺寸也是需要考虑的重要因素。Abstract: In order to explore the influence of granite grain size on rockburst, cubic granite specimens with an opening and different grain sizes (fine to medium and medium to coarse) were used to conduct the rockburst tests using the true triaxial rockburst testing system. The experimental results show that the failure process of the fine to medium-grained granite is mainly composed of brittle failure. However, rockburst failure (dynamic failure) dominates the failure for the medium to coarse-grained granite. The acoustic emission (AE) activity in the early loading stage is weak for the fine to medium-grained granite, and the low-frequency large-rupture events are concentrated in time and space, and the characteristic stress is higher. However, the AE activity in the early loading stage is stronger for the medium to coarse-grained granite, and the low-frequency, large-rupture events are more discrete in time and space, and the characteristic stress is lower, and the fragments are broken more. The grain size has an important influence on the rockburst proneness of granites. The hard-brittle rock with coarser grain size has a stronger rockburst proneness. In addition to strength and brittleness, grain size is an important factor to be considered in rockburst proneness evaluation of deep underground rock mass engineering.

-

Key words:

- rockburst /

- spalling /

- granite /

- grain size

-

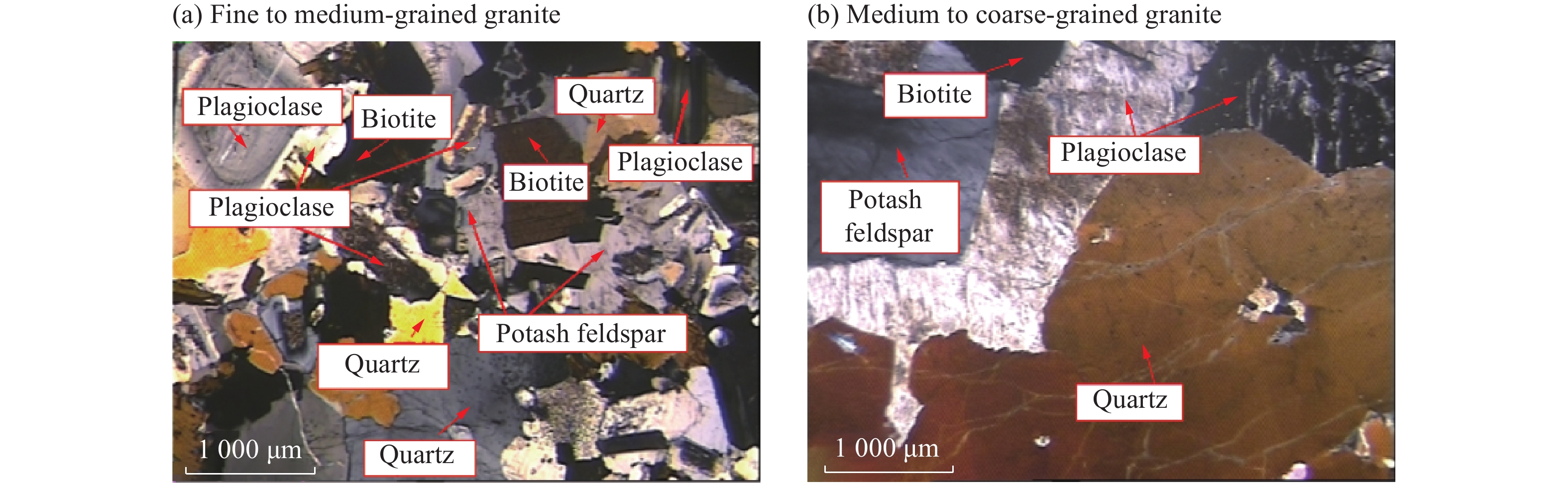

表 1 花岗岩基本物理、力学参数与矿物成分

Table 1. Basic physical and mechanical parameters and mineral composition

属地 晶粒 密度/

(kg·m−3)单轴强度/

MPa弹性模量/

GPa纵波速度/

(km·s−1)矿物成分 晶粒直径/

mm非均匀性 广东肇庆 细中 2 687 135 32.2 4.5 39%斜长石

28%石英

18%钾长石

7%黑云母

3%角闪石

5%其他0.6~5.0 低 广西梧州 中粗 2 680 110 30.6 5.3 54%钾长石

30%石英

10%斜长石

4%黑云母

2%其他2~22 高 表 2 加载过程中细中晶粒花岗岩的特征应力

Table 2. Characteristic stresses in the fine to medium-grained granite specimen during loading

特征应力 时间/s σZ/MPa σθ/MPa σθ/σθmax 起裂应力σci 1 547.64 74.00 212.00 0.55 明显颗粒弹射 2 301.12 113.72 331.16 0.86 损伤应力σcd 2 563.56 127.50 372.50 0.96 明显板裂化 2 650.32 132.08 386.24 1.00 表 3 加载过程中中粗晶粒花岗岩特征应力

Table 3. Characteristic stresses of the medium to coarse-grained granite specimen during loading

特征应力 时间/s 竖向应力σZ/MPa σθ/MPa σθ/σθmax 起裂应力σci 1 145.52 58.00 164.00 0.46 明显弹射 1 838.16 72.76 208.28 0.59 损伤应力σcd 2 241.36 113.00 329.00 0.93 明显岩爆 2 385.72 121.01 353.03 1.00 -

[1] 何满潮, 赵菲, 杜帅, 等. 不同卸载速率下岩爆破坏特征试验分析 [J]. 岩土力学, 2014, 35(10): 2737–2747; 2793. DOI: 10.16285/j.rsm.2014.10.001.HE Manchao, ZHAO Fei, DU Shuai, et al. Rockburst characteristics based on experimental tests under different unloading rates [J]. Rock and Soil Mechanics, 2014, 35(10): 2737–2747; 2793. DOI: 10.16285/j.rsm.2014.10.001. [2] ZHAO X G, WANG J, CAI M, et al. Influence of unloading rate on the strainburst characteristics of Beishan granite under true-triaxial unloading conditions [J]. Rock Mechanics and Rock Engineering, 2014, 47(2): 467–483. DOI: 10.1007/s00603-013-0443-2. [3] 苏国韶, 胡李华, 冯夏庭, 等. 低频周期扰动荷载与静载联合作用下岩爆过程的真三轴试验研究 [J]. 岩石力学与工程学报, 2016, 35(7): 1309–1322. DOI: 10.13722/j.cnki.jrme.2015.1249.SU Guoshao, HU Lihua, FENG Xiating, et al. True triaxial experimental study of rockburst process under low frequency cyclic disturbance load combined with static load [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(7): 1309–1322. DOI: 10.13722/j.cnki.jrme.2015.1249. [4] 朱万成, 左宇军, 尚世明, 等. 动态扰动触发深部巷道发生失稳破裂的数值模拟 [J]. 岩石力学与工程学报, 2007, 26(5): 915–921. DOI: 10.3321/j.issn:1000-6915.2007.05.007.ZHU Wancheng, ZUO Yujun, SHANG Shiming, et al. Numerical simulation of instable failure of deep rock tunnel triggered by dynamic disturbance [J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(5): 915–921. DOI: 10.3321/j.issn:1000-6915.2007.05.007. [5] 宫凤强, 李夕兵, 刘希灵. 三维动静组合加载下岩石力学特性试验初探 [J]. 岩石力学与工程学报, 2011, 30(6): 1179–1190.GONG Fengqiang, LI Xibing, LIU Xiling. Preliminary experimental study of characteristics of rock subjected to 3D coupled static and dynamic loads [J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(6): 1179–1190. [6] 苏国韶, 陈智勇, 蒋剑青, 等. 不同加载速率下岩爆碎块耗能特征试验研究 [J]. 岩土工程学报, 2016, 38(8): 1481–1489. DOI: 10.11779/CJGE201608016.SU Guoshao, CHEN Zhiyong, JIANG Jianqing, et al. Experimental study on energy dissipating characteristics of rockburst fragments under different loading rates [J]. Chinese Journal of Geotechnical Engineering, 2016, 38(8): 1481–1489. DOI: 10.11779/CJGE201608016. [7] SU Guoshao, JIANG Jianqing, ZHAI Shaobin, et al. Influence of tunnel axis stress on strainburst: an experimental study [J]. Rock Mechanics and Rock Engineering, 2017, 50(6): 1551–1567. DOI: 10.1007/s00603-017-1181-7. [8] SU Guoshao, ZHAI Shaobin, JIANG Jianqing, et al. Influence of radial stress gradient on strainbursts: an experimental study [J]. Rock Mechanics and Rock Engineering, 2017, 50(10): 2659–2676. DOI: 10.1007/s00603-017-1266-3. [9] 张艳博, 徐东强. 岩爆在不同岩石中的模拟实验 [J]. 河北理工学院学报, 2002, 24(4): 8–11. DOI: 10.3969/j.issn.1674-0262.2002.04.002.ZHANG Yanbo, XU Dongqiang. The analysis of the experiment of rock burst on different rocks [J]. Journal of Hebei Institute of Technology, 2002, 24(4): 8–11. DOI: 10.3969/j.issn.1674-0262.2002.04.002. [10] 赵康, 赵红宇, 贾群燕. 岩爆岩石断裂的微观结构形貌分析及岩爆机理 [J]. 爆炸与冲击, 2015, 35(6): 913–918. DOI: 10.11883/1001-1455(2015)06-0913-06.ZHAO Kang, ZHAO Hongyu, JIA Qunyan. An analysis of rockburst fracture micromorphology and study of its mechanism [J]. Explosion and Shock Waves, 2015, 35(6): 913–918. DOI: 10.11883/1001-1455(2015)06-0913-06. [11] 楼沩涛. 干燥和水饱和花岗岩的动态断裂特性 [J]. 爆炸与冲击, 1994, 14(3): 249–254.LOU Weitao. Dynamic fracture behaviour of dry and waterlogged granites [J]. Explosion and Shock Waves, 1994, 14(3): 249–254. [12] 冯夏庭, 陈炳瑞, 张传庆. 岩爆孕育过程的机制、预警与动态调控[M]. 北京: 科学出版社, 2013: 159–167. [13] 赵红亮, 周又和. 深埋地下洞室断裂型岩爆机理的数值模拟 [J]. 爆炸与冲击, 2015, 35(3): 343–349. DOI: 10.11883/1001-1455-(2015)03-0343-07.ZHAO Hongliang, ZHOU Youhe. Numerical simulation on mechanism of fractured rock burst in deep underground tunnels [J]. Explosion and Shock Waves, 2015, 35(3): 343–349. DOI: 10.11883/1001-1455-(2015)03-0343-07. [14] 周辉, 孟凡震, 张传庆, 等. 深埋硬岩隧洞岩爆的结构面作用机制分析 [J]. 岩石力学与工程学报, 2015, 34(4): 720–727. DOI: 10.13722/j.cnki.jrme.2015.04.008.ZHOU Hui, MENG Fanzhen, ZHANG Chuanqing, et al. Effect of structural plane on rockburst in deep hard rock tunnels [J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(4): 720–727. DOI: 10.13722/j.cnki.jrme.2015.04.008. [15] LAN H X, MARTIN C D, HU B. Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading [J]. Journal of Geophysical Research Atmospheres, 2010, 115(B1): B01202. DOI: 10.1029/2009jb006496. [16] WAWERSIK W R, FAIRHURST C. A study of brittle rock fracture in laboratory compression experiments [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1970, 7(5): 561–575. DOI: 10.1016/0148-9062(70)90007-0. [17] TANG C A, Kaiser P K. Numerical simulation of cumulative damage and seismic energy release during brittle rock failure: Part I: fundamentals [J]. International Journal of Rock Mechanics and Mining Sciences, 1998, 35(2): 113–121. DOI: 10.1016/S0148-9062(97)00009-0. [18] 张翀, 舒赣平. 颗粒形状对颗粒流模拟双轴压缩试验的影响研究 [J]. 岩土工程学报, 2009, 31(8): 1281–1286. DOI: 10.3321/j.issn:1000-4548.2009.08.020.ZHANG Chong, SHU Ganping. Effect of particle shape on biaxial tests simulated by particle flow code [J]. Chinese Journal of Geotechnical Engineering, 2009, 31(8): 1281–1286. DOI: 10.3321/j.issn:1000-4548.2009.08.020. [19] 黄润秋, 王贤能. 岩石结构特征对岩爆的影响研究 [J]. 地质灾害与环境保护, 1997, 7(2): 15–20.HUANG Runqiu, WANG Xianneng. Influence of the structure character of rock on rockburst intensity [J]. Journal of Geological Hazards and Environment Preservation, 1997, 7(2): 15–20. [20] 高秉璋, 洪大卫, 方宗斌. 花岗岩类区1∶5万区域地质填图方法指南[M]. 武汉: 中国地质大学出版社, 1991: 16–17. [21] 陈炳瑞, 冯夏庭, 明华军, 等. 深埋隧洞岩爆孕育规律与机制: 时滞型岩爆 [J]. 岩石力学与工程学报, 2012, 31(3): 561–569. DOI: 10.3969/j.issn.1000-6915.2012.03.014.CHEN Bingrui, FENG Xiating, MING Huajun, et al. Evolution law and mechanism of rockburst in deep tunnel: time delayed rockburst [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(3): 561–569. DOI: 10.3969/j.issn.1000-6915.2012.03.014. [22] HU Xiaochuan, SU Guoshao, CHEN Guanyan, et al. Experiment on rockburst process of borehole and its acoustic emission characteristics [J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 783–802. DOI: 10.1007/s00603-018-1613-z. [23] CAI M, KAISER P K, MORIOKA H, et al. FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations [J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(4): 550–564. DOI: 10.1016/j.ijrmms.2006.09.013. [24] CHANG S H, LEE C I. Estimation of cracking and damage mechanisms in rock under triaxial compression by moment tensor analysis of acoustic emission [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(7): 1069–1086. DOI: 10.1016/j.ijrmms.2004.04.006. [25] 许金余, 刘石. 大理岩冲击加载试验碎块的分形特征分析 [J]. 岩土力学, 2012, 33(11): 3225–3229. DOI: 10.16285/j.rsm.2012.11.005.XU Jinyu, LIU Shi. Research on fractal characteristics of marble fragments subjected to impact loading [J]. Rock and Soil Mechanics, 2012, 33(11): 3225–3229. DOI: 10.16285/j.rsm.2012.11.005. [26] PENG J, WONG L N Y, TEH C I. Influence of grain size heterogeneity on strength and microcracking behavior of crystalline rocks [J]. Journal of Geophysical Research: Solid Earth, 2017, 122(2): 1054–1073. DOI: 10.1002/2016JB013469. [27] DIEDERICHS M S, KAISER P K, EBERHARDT E. Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation [J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(5): 785–812. DOI: 10.1016/j.ijrmms.2004.02.003. -

下载:

下载: