Mechanical behavior of long-term neutron-irradiated Al-Mg-Si alloy under compression

-

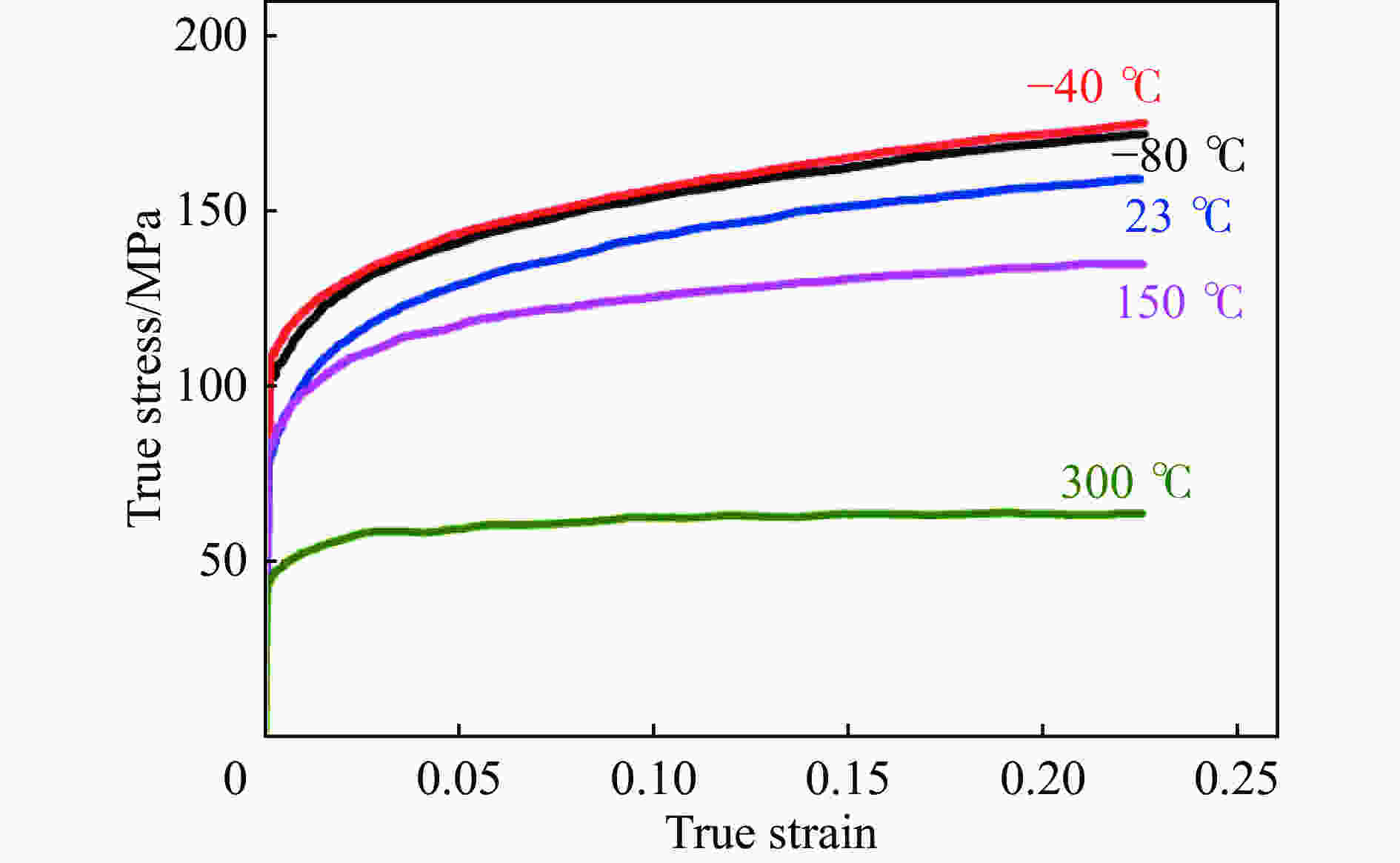

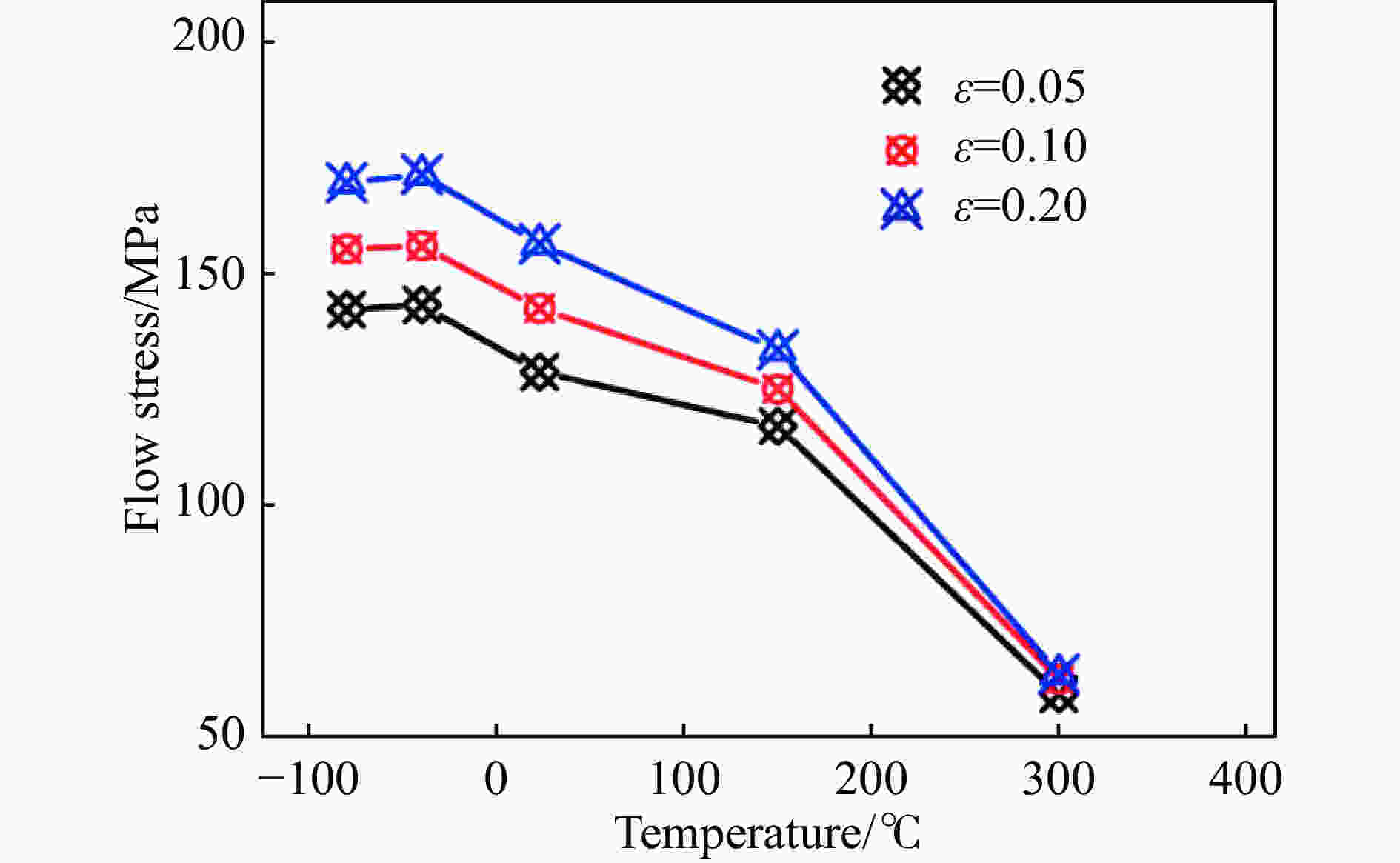

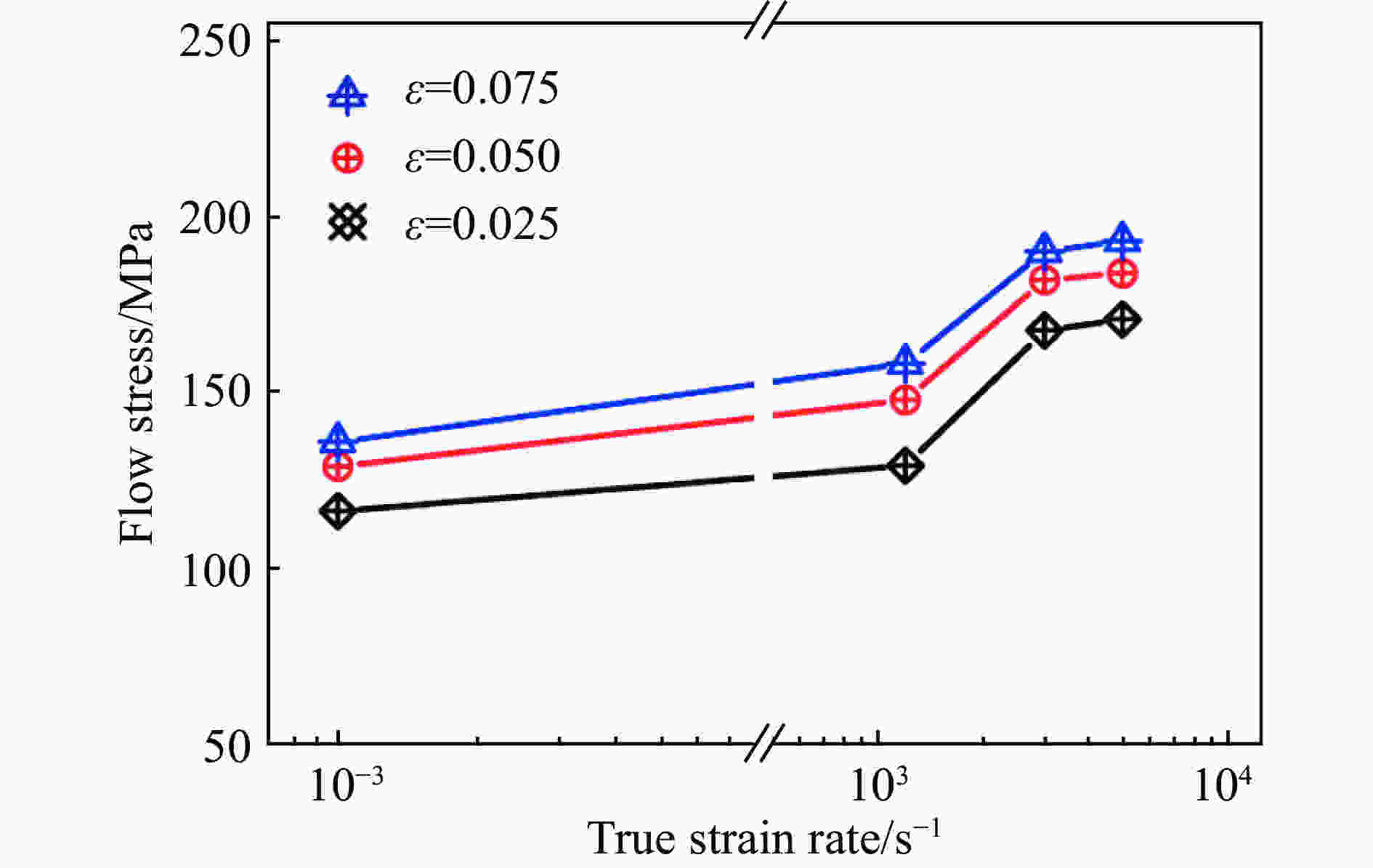

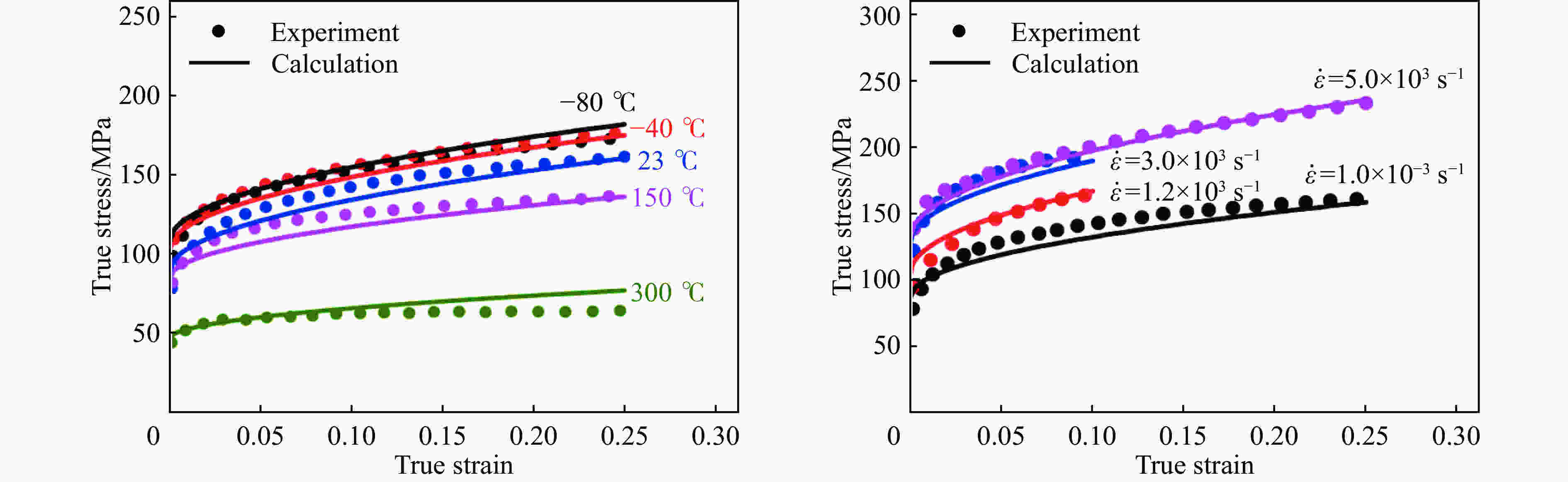

摘要: 利用材料试验机及分离式霍普金森压杆装置,开展长期中子辐照后的Al-Mg-Si合金(反应堆内实际服役近30年的LT21铝合金)在不同温度和应变率下压缩力学行为的实验研究,获得了实验温度、应变率对其屈服强度及流动应力的影响规律。结果表明:材料在一定的温度区间(−40~300 ℃)和应变率区间(0.001~3 000 s−1)内,分别呈现出较为明显的温度效应与正应变率效应;其中在较低的温度(−80~−40 ℃)和较高的应变率(3 000~5 000 s−1)区间力学性能受温度和应变率变化的影响较小;当温度升至300 ℃时,材料的塑性变形行为已趋于理想塑性流动。根据前述实验结果,计及材料内部的微观辐照缺陷对力学性能的影响,建立了考虑辐照损伤的Zerilli-Armstrong本构模型,模型的计算结果与前述实验结果吻合较好。结合文献中高纯铝的微观辐照缺陷的演化数据,对不同快中子辐照剂量LT21铝合金的屈服强度,以及另两个来自反应堆内不同受辐照区域试样在不同应变率和温度下的屈服强度进行了计算。上述研究表明,本文建立的考虑辐照损伤的Z-A本构方程不仅能较好地反映长期中子辐照后的Al-Mg-Si合金宏观应力和应变、应变率、温度等参数的关系,也能针对位错运动及辐照硬化机制进行较好地描述,并且能够为反应堆内相应结构元件的设计、运行和安全评估提供一定的参考。

-

关键词:

- 冲击动力学 /

- 辐照损伤 /

- Z-A本构模型 /

- SHPB /

- 中子辐照Al-Mg-Si合金

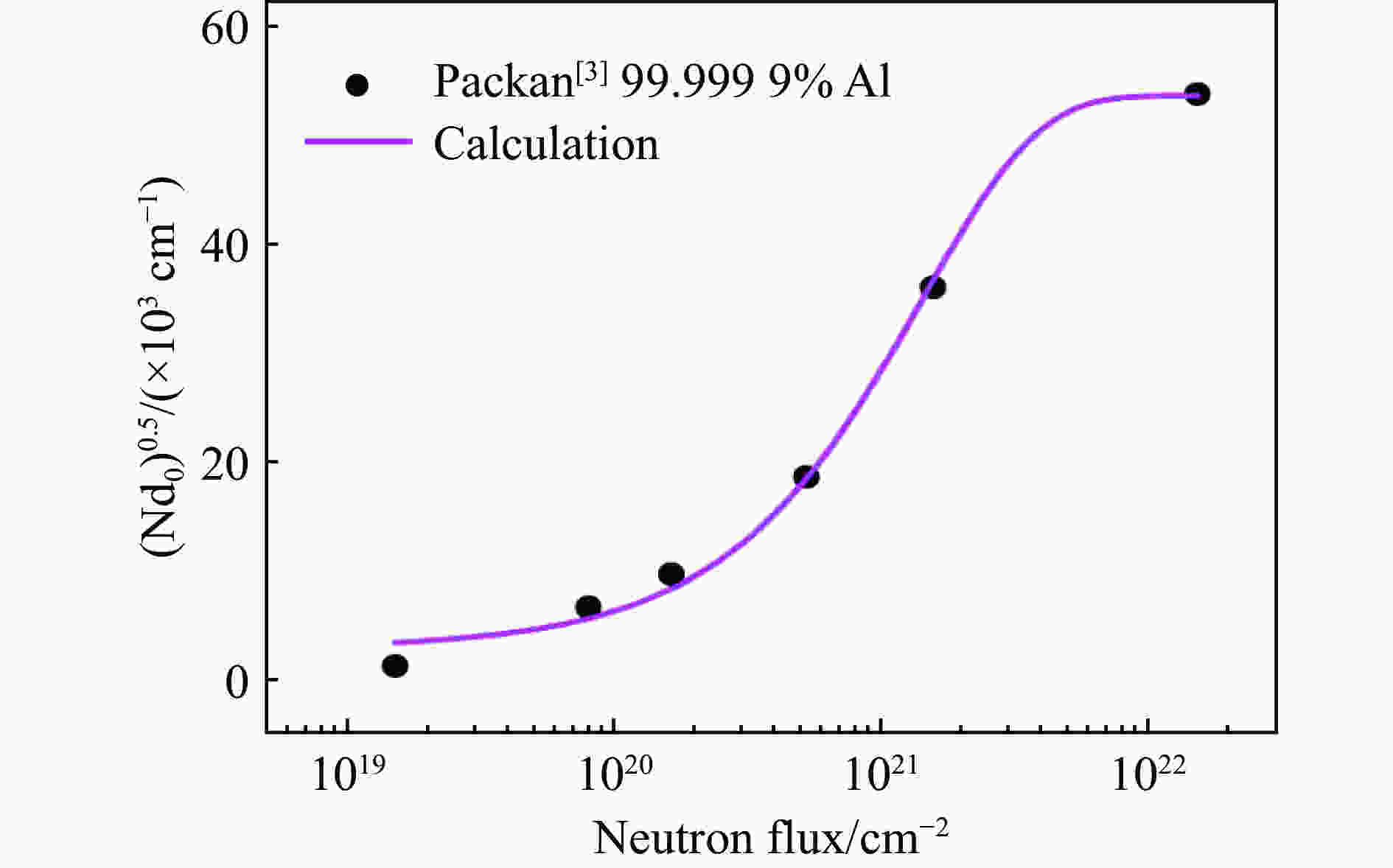

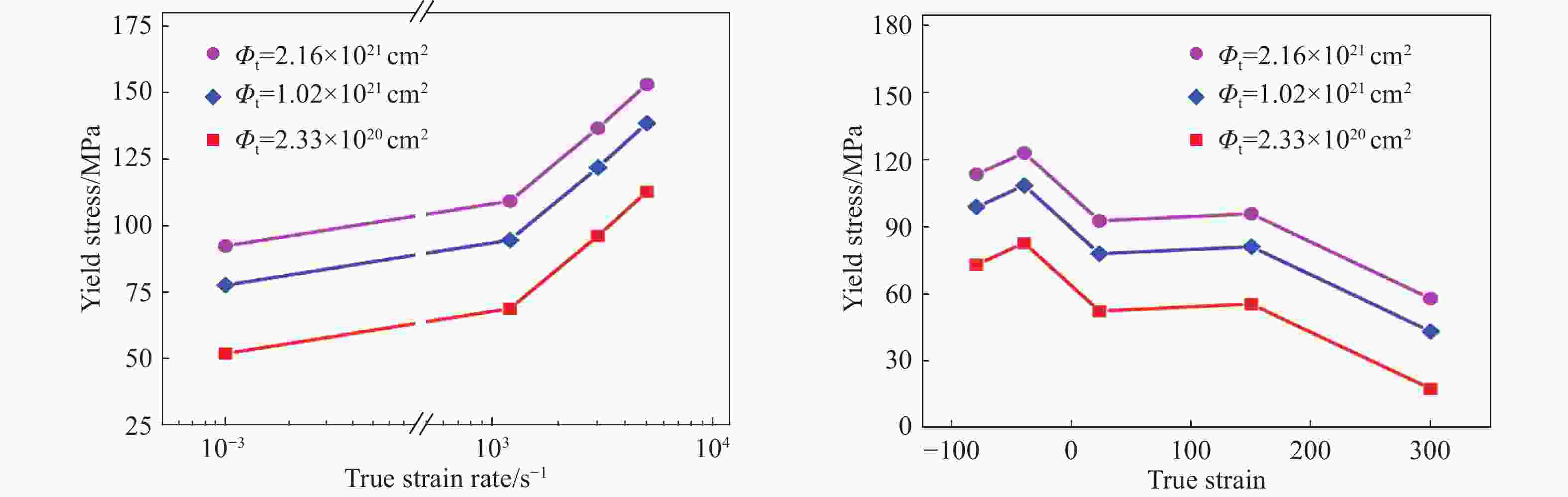

Abstract: The mechanical behavior of Al-Mg-Si alloy after long-term neutron irradiation (i.e. LT21 aluminum alloy served in the reactor for nearly 30 years) under compression loading with different temperature and strain rates is experimentally studied using material test system and split Hopkinson pressure bar. The effects of temperature and strain rate on its yield strength and flow stress are obtained. The results show that the material exhibits obvious temperature effect within a temperature rang from −40 ℃ to 300 ℃ and positive strain rate effect in a strain rate rang from 0.001 to 3 000 s−1, respectively. At a lower temperature range (from −80 to −40 ℃) and higher strain rates (from 3 000 to 5 000 s−1), the mechanical properties are insensitive to changes in temperature and strain rate. When the temperature reaches 300 ℃, the plastic deformation behavior of the material tends to ideal plastic flow. Based on the above experimental results, a modified Zerilli-Armstrong constitutive model considering irradiation damage is established by taking into account the effect of microscale irradiation defects on the mechanical properties of materials. The Zerilli-Armstrong model predictions are in good agreement with the experimental results. Furthermore, the yield strength of LT21 aluminum alloy with different fast neutron irradiation doses and the yield strength of another two samples obtained from different irradiated regions within the reactor at different strain rates and temperature are calculated by reference to the evolution of microscale irradiation defects of high purity aluminum. The above research shows that the Zerilli-Armstrong constitutive equation considering radiation damage established in this paper can not only establish the relationship between macroscale stress and strain, strain rate and temperature of the Al-Mg-Si alloy after long-term neutron irradiation, but also describe the dislocation motion and the mechanism of irradiation hardening. It can provide reference for the design, operation and safety evaluation of the corresponding structural elements in the nuclear reactor. -

表 1 被辐照LT21铝合金主要化学元素成分的质量分数

Table 1. Mass fraction of mian chemical elements in irradiated LT21 aluminum alloy

主要元素 Mg Si Fe Mn Al 质量分数 0.69% 0.68% 0.013% — — 表 2 考虑辐照损伤的Z-A本构模型参数

Table 2. Parameters for the modified Zerilli-Armstrong model

σ0/MPa B/MPa β1 β0 A/MPa α1 α0 40.00 148.58 0.000 127 0.002 86 237.838 0.000 101 0.001 52 -

[1] 郁金南. 材料辐照效应[M]. 北京: 化学工业出版社, 2007: 2−3. [2] 郁金南, 顾叔钊. 铝及铝合金拉伸机械性能的辐照效应 [J]. 原子能科学技术, 1962(10): 743–757, 761. [3] PACKAN N H. Voids in neutron irradiated aluminum [R]. Office of Scientific and Technical Information (OSTI), 1971. DOI: 10.2172/4080358 [4] FARRELL K. A spectral effect on phase evolution in neutron-irradiated aluminum [C] // Microstructure of Irradiated Materials, The Materials Research Society Symposium Proceedings, 1995, 373: 165−170. [5] 刘建章. 核结构材料[M]. 北京: 化学工业出版社, 2007: 483−486. [6] 赵培峰, 任广升, 沈智, 等. 6061铝合金热压缩变形条件对流变应力的影响及其本构方程的研究 [J]. 塑性工程学报, 2007, 14(6): 130–133. DOI: 10.3969/j.issn.1007-2012.2007.06.029.ZHAO Peifeng, REN Guangsheng, SHEN Zhi, et al. Influence of hot compressive deformation conditions of 6061 aluminum alloy on flow stress and research on its constitutive equation [J]. Journal of Plasticity Engineering, 2007, 14(6): 130–133. DOI: 10.3969/j.issn.1007-2012.2007.06.029. [7] 赵锡龙, 乔及森, 陈剑虹. 6061铝合金热变形行为的研究 [J]. 热加工工艺, 2009, 38(2): 10–12. DOI: 10.3969/j.issn.1001-3814.2009.02.003.ZHAO Xilong, QIAO Jisen, CHEN Jianhong. Hot compression behavior of 6061 aluminum alloy [J]. Hot Working Technology, 2009, 38(2): 10–12. DOI: 10.3969/j.issn.1001-3814.2009.02.003. [8] 李凤娇, 翟月雯, 边翊, 等. 6061铝合金高温流变行为 [J]. 塑性工程学报, 2015, 22(2): 95–99. DOI: 10.3969/j.issn.1007-2012.2015.02.017.LI Fengjiao, ZHAI Yuewen, BIAN Yi, et al. Study of plastic deformation behavior on 6061 aluminum alloy [J]. Journal of Plasticity Engineering, 2015, 22(2): 95–99. DOI: 10.3969/j.issn.1007-2012.2015.02.017. [9] 刘再德, 王冠, 冯银成, 等. 6061铝合金高应变速率本构参数研究 [J]. 矿冶工程, 2011, 31(6): 120–123. DOI: 10.3969/j.issn.0253-6099.2011.06.032.LIU Zaide, WANG Guan, FENG Yincheng, et al. High-strain-rate constitutive parameters of 6061 aluminum alloys [J]. Mining and Metallurgical Engineering, 2011, 31(6): 120–123. DOI: 10.3969/j.issn.0253-6099.2011.06.032. [10] 刘军, 杨黎明, 谢书港, 等. 6061铝合金的动态拉伸性能及其本构模型 [J]. 机械工程材料, 2017, 41(3): 49–53. DOI: 10.11973/jxgccl201703010.LIU Jun, YANG Liming, XIE Shugang, et al. Dynamic tensile properties and constitutive model of 6061 aluminum alloy [J]. Materials for Mechanical Engineering, 2017, 41(3): 49–53. DOI: 10.11973/jxgccl201703010. [11] 冯琦杰, 刘耀光, 杨万奎, 等. 300#研究堆寿期内上联箱铝材中子注量分析 [J]. 强激光与粒子束, 2015, 27(7): 301–305.FENG Qijie, LIU Yaoguang, YANG Wankui, et al. Calculating the accumulative neutron fluence rate of Al alloy on upper link chest of Swimming Pool Research Reactor-300 [J]. High Power Laser and Particle Beams, 2015, 27(7): 301–305. [12] BOCHIROL L, BRAUNS P, CLAUDET G. Effects of neutronic irradiations at 27 K on the tensile properties of aluminum at 27 K [J]. Progress in Refrigeration Science and Technology, 1973, 1: 643–650. [13] GUO W G. Dynamic strain aging during the plastic flow of metals [J]. Key Engineering Materials, 2007, 340/341: 823–828. DOI: 10.4028/www.scientific.net/KEM.340-341.823. [14] 郭伟国, 田宏伟. 几种典型铝合金应变率敏感性及其塑性流动本构模型 [J]. 中国有色金属学报, 2009, 19(1): 56–61. DOI: 10.3321/j.issn:1004-0609.2009.01.010.GUO Weiguo, TIAN Hongwei. Strain rate sensitivity and constitutive models of several typical aluminum alloys [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 56–61. DOI: 10.3321/j.issn:1004-0609.2009.01.010. [15] ZERILLI F J, ARMSTRONG R W. Dislocation-mechanics-based constitutive relations for material dynamics calculations [J]. Journal of Applied Physics, 1987, 61(5): 1816–1825. DOI: 10.1063/1.338024. [16] ZERILLI F J, ARMSTRONG R W. Description of tantalum deformation behavior by dislocation mechanics based constitutive relations [J]. Journal of Applied Physics, 1990, 68(4): 1580–1591. DOI: 10.1063/1.346636. [17] ZERILLI F J, ARMSTRONG R W. Constitutive equation for HCP metals and high strength alloy steels [C] // High Strain Rate Effects on Polymer, Metal and Ceramic Matrix Composites and other Advanced Materials. San Francisco, CA: ASME, 1995: 121−126. [18] 刘旭红, 黄西成, 陈裕泽, 等. 强动载荷下金属材料塑性变形本构模型评述 [J]. 力学进展, 2007, 37(3): 361–374. DOI: 10.3321/j.issn:1000-0992.2007.03.004.LIU Xuhong, HUANG Xicheng, CHEN Yuze, et al. A review on constitutive models for plastic deformation of metal materials under dynamic loading [J]. Advances in Mechanics, 2007, 37(3): 361–374. DOI: 10.3321/j.issn:1000-0992.2007.03.004. [19] 肖厦子, 宋定坤, 楚海建, 等. 金属材料力学性能的辐照硬化效应 [J]. 力学进展, 2015, 45(1): 141–178. DOI: 10.6052/1000-0992-14-071.XIAO Xiazi, SONG Dingkun, CHU Haijian, et al. Irradiation hardening for metallic materials [J]. Advances in Mechanics, 2015, 45(1): 141–178. DOI: 10.6052/1000-0992-14-071. [20] OROWAN E. A type of plastic deformation new in metals [J]. Nature, 1942, 149(3788): 643–644. DOI: 10.1038/149643a0. -

下载:

下载: