Dynamic tensile behavior and spall fracture of GP1 stainless steel processed by selective laser melting

-

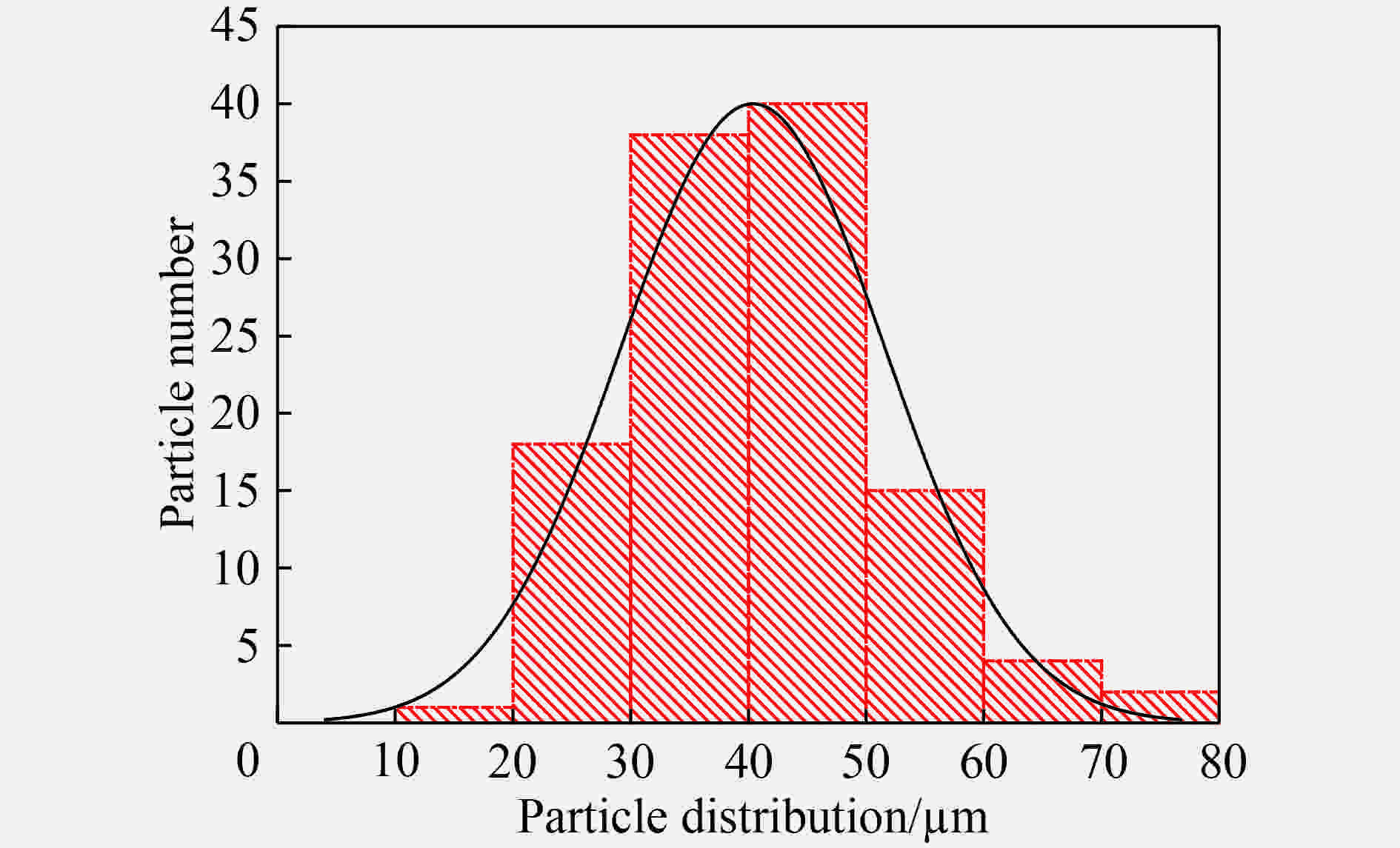

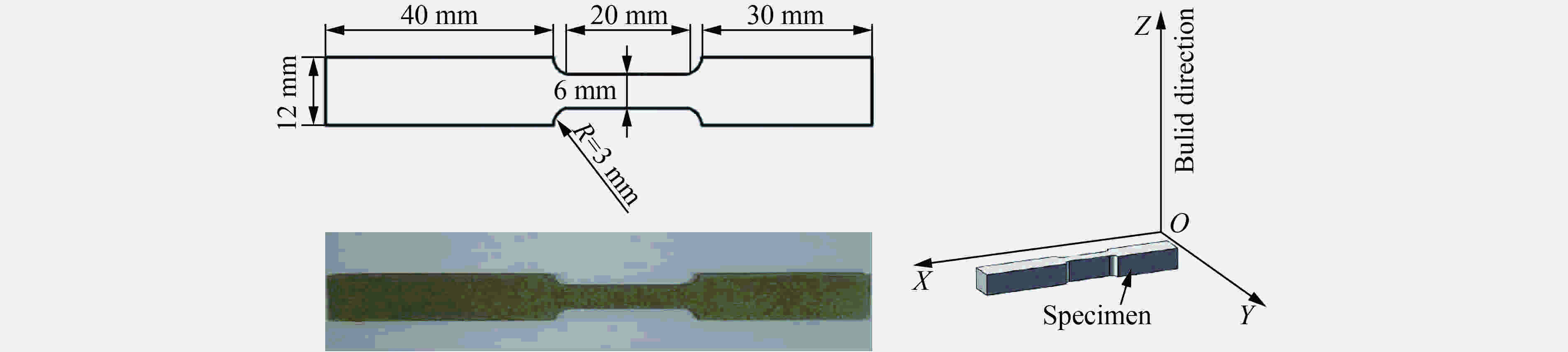

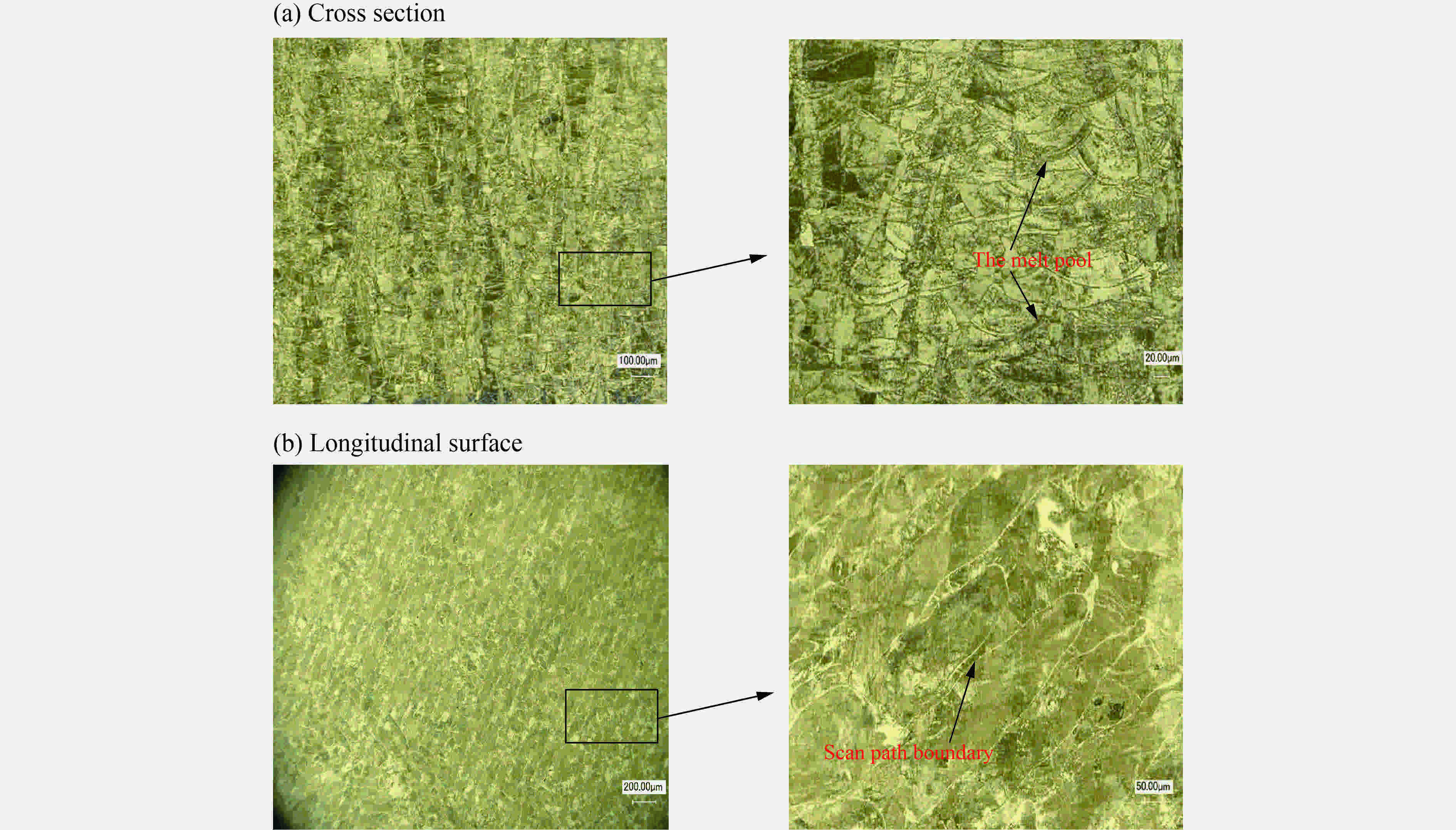

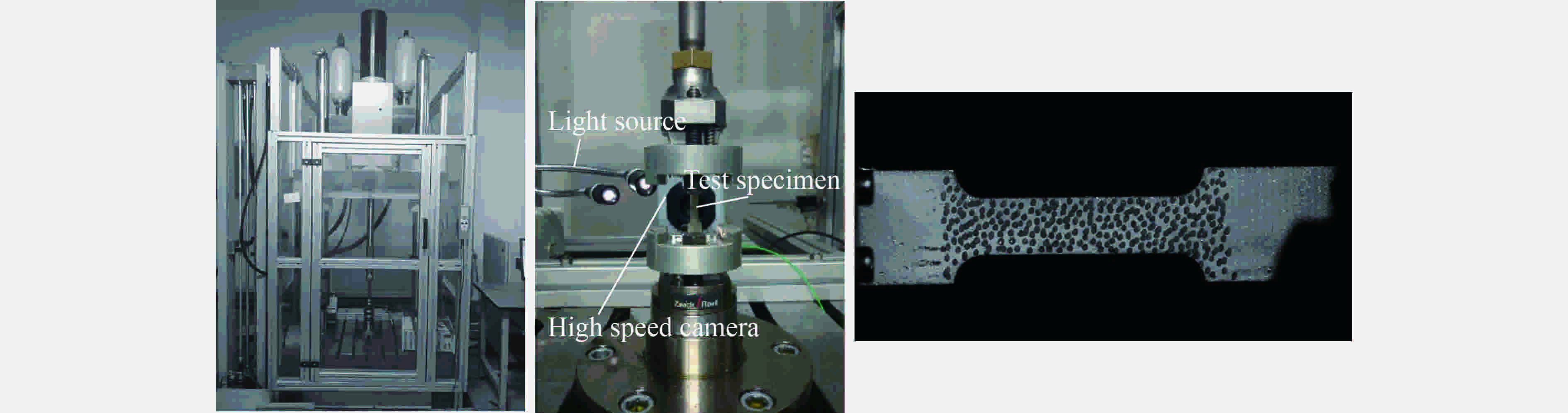

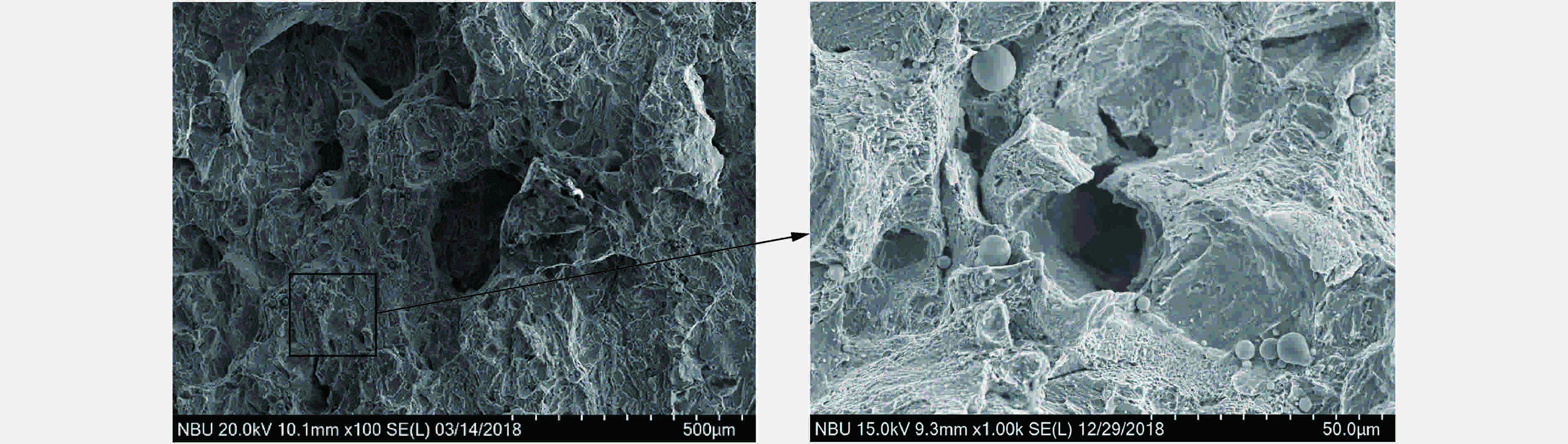

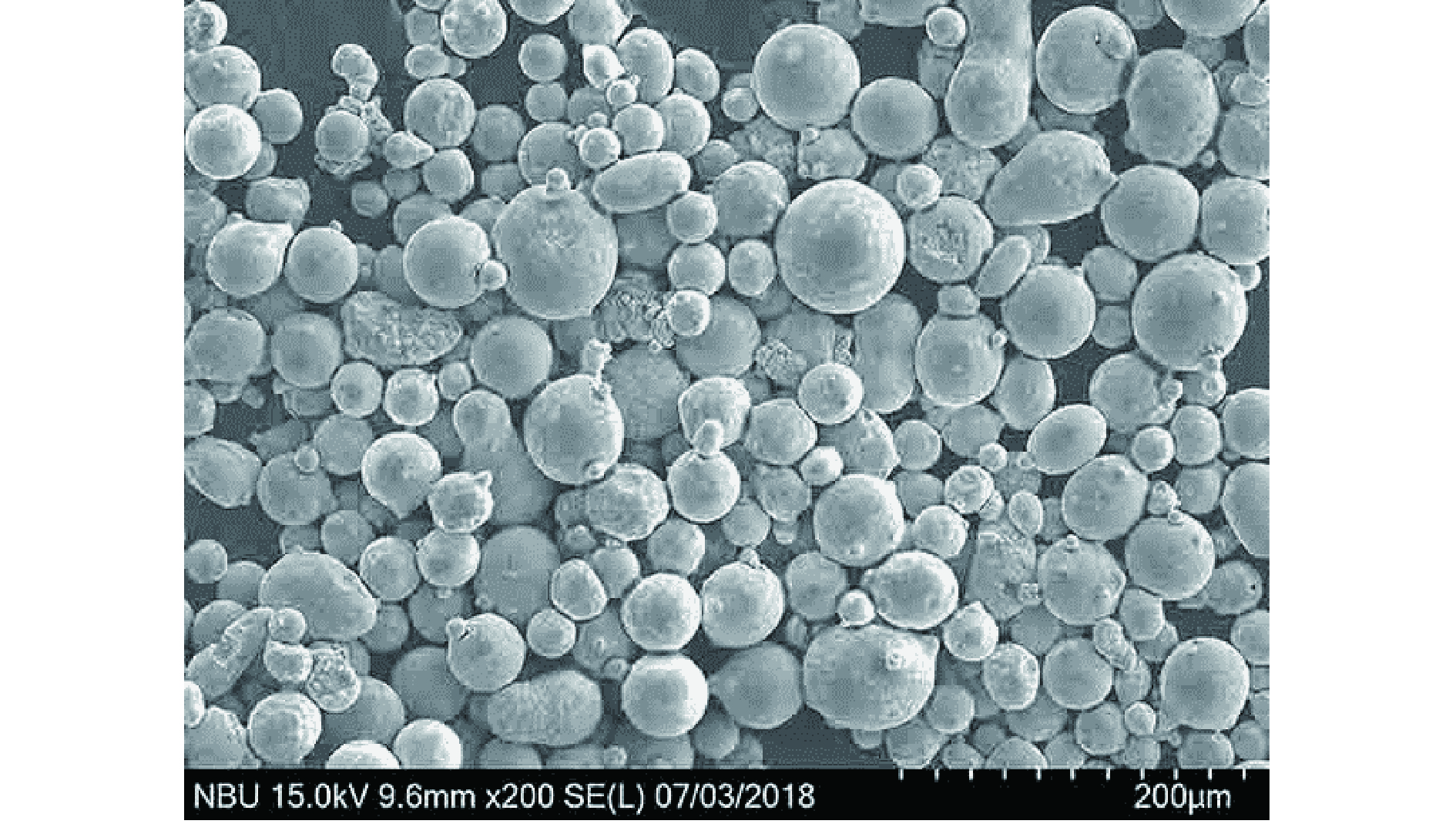

摘要: 采用选择性激光熔化增材制造技术,制备了GP1不锈钢单轴拉伸板条试样和层裂圆片试样,并对材料微观结构进行了表征。借助Zwick-HTM5020 高速拉伸试验机,并结合数字图像相关性全场应变测量技术,开展了增材制造GP1不锈钢材料的轴向拉伸力学性能实验研究,得到了不同应变率下材料的拉伸应力-应变曲线,结果显示:(1) GP1不锈钢流动应力具有比较显著的应变强化效应;(2)通过回收试样的电子背散射衍射表征,发现GP1不锈钢在拉伸变形过程中会发生奥氏体与马氏体之间的相变;(3) GP1不锈钢的屈服应力随着应变率呈幂指数增大,断裂应变在中低应变率下保持不变,但在高应变率下则显著减小。采用一级轻气炮实验装置和激光干涉粒子速度测量技术,开展了增材制造GP1不锈钢的层裂实验,发现GP1不锈钢的层裂强度随着飞片撞击速度增大而减小。单轴拉伸试样断口和层裂试样断口的显微分析结果表明:随着应变率增大,单轴拉伸断裂模式和断裂机理都发生了转变;层裂损伤易成核于激光熔池边界线的交汇处,断口韧窝形貌明显区别于单向拉伸断口。

-

关键词:

- 增材制造GP1不锈钢 /

- 单轴拉伸 /

- 应变率 /

- 层裂

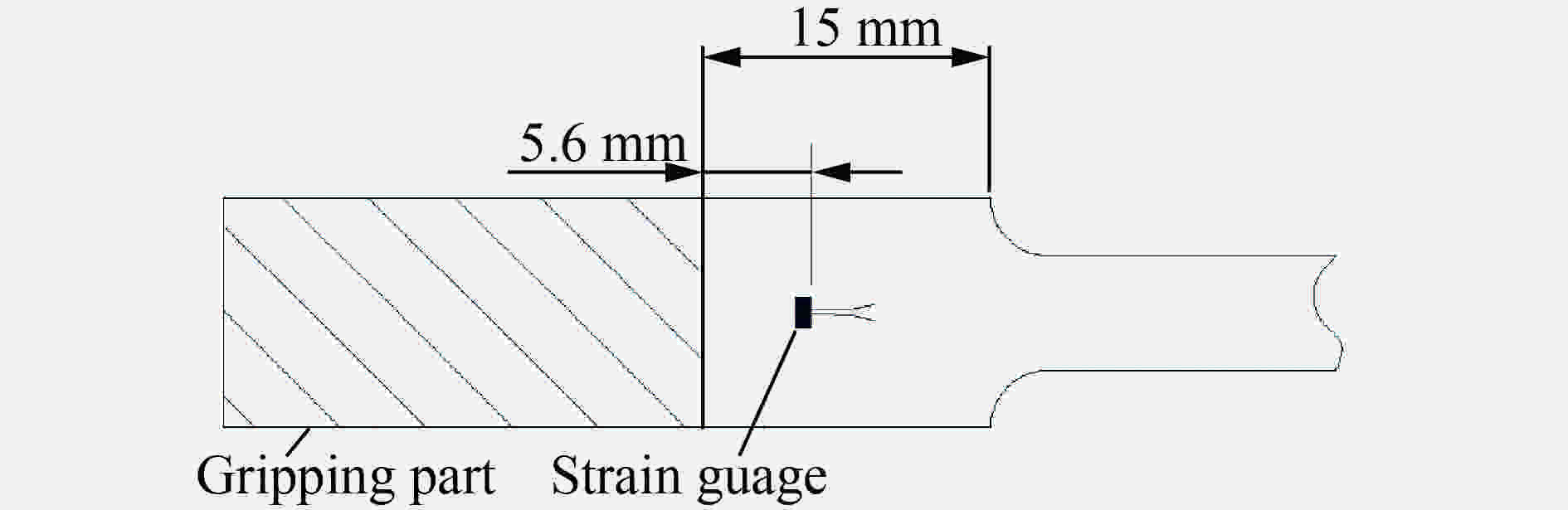

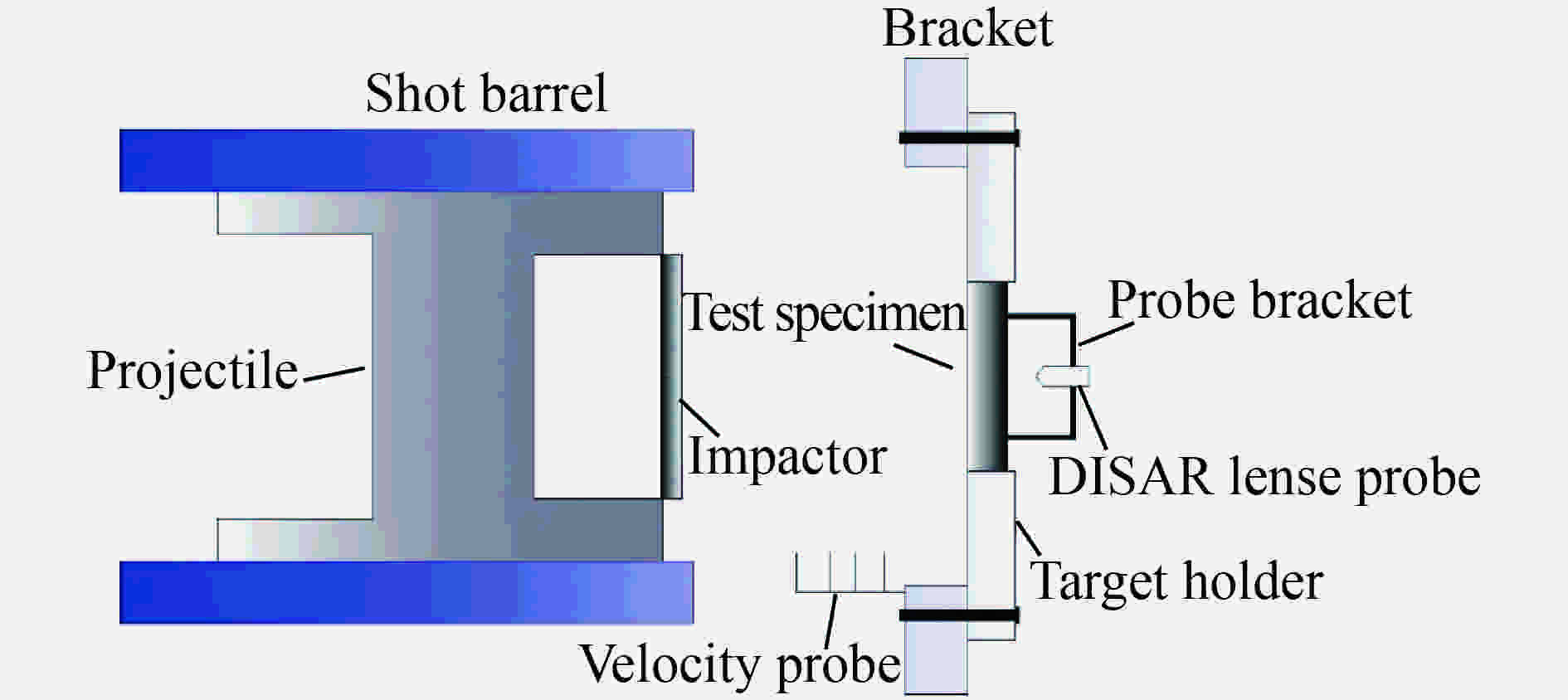

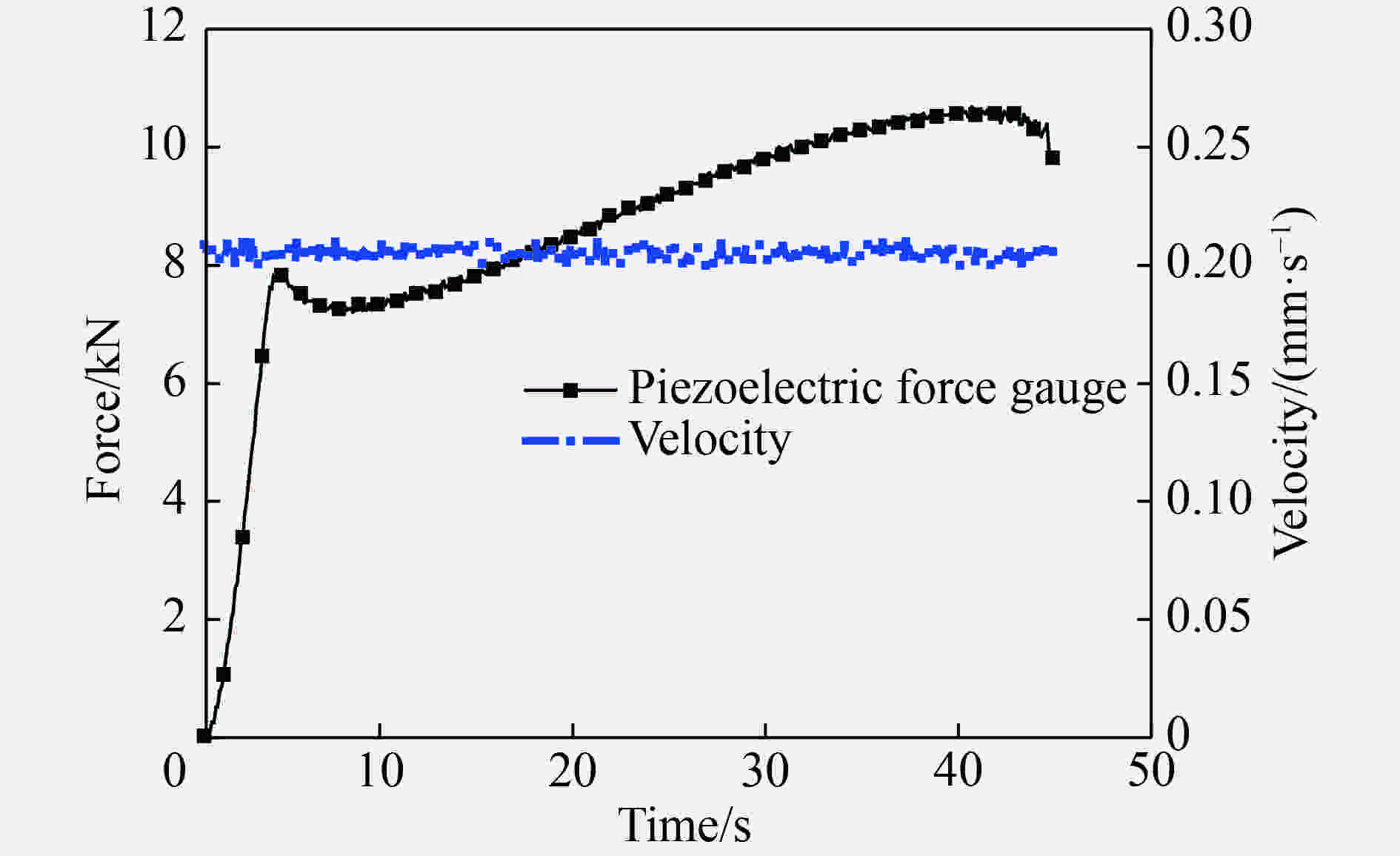

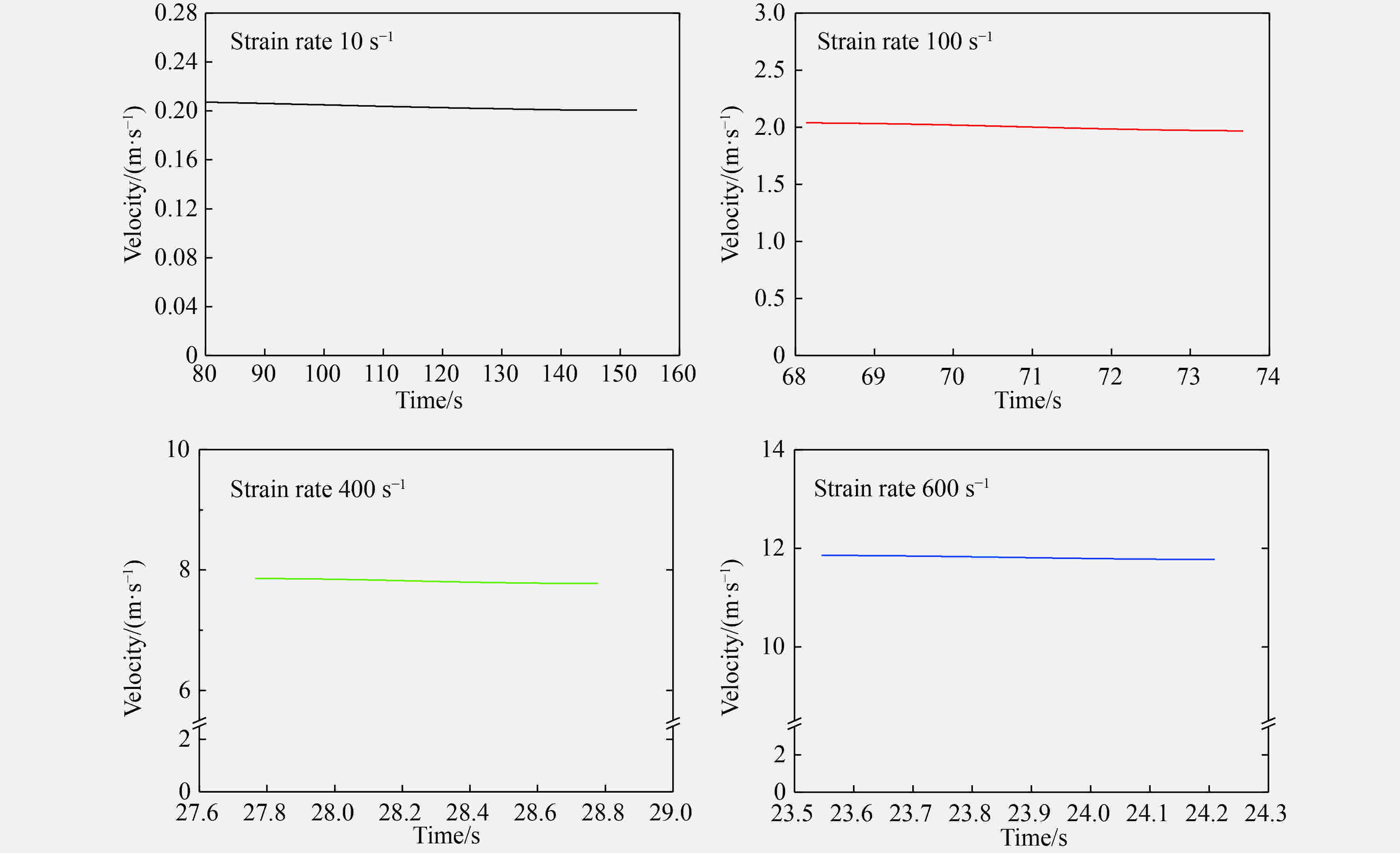

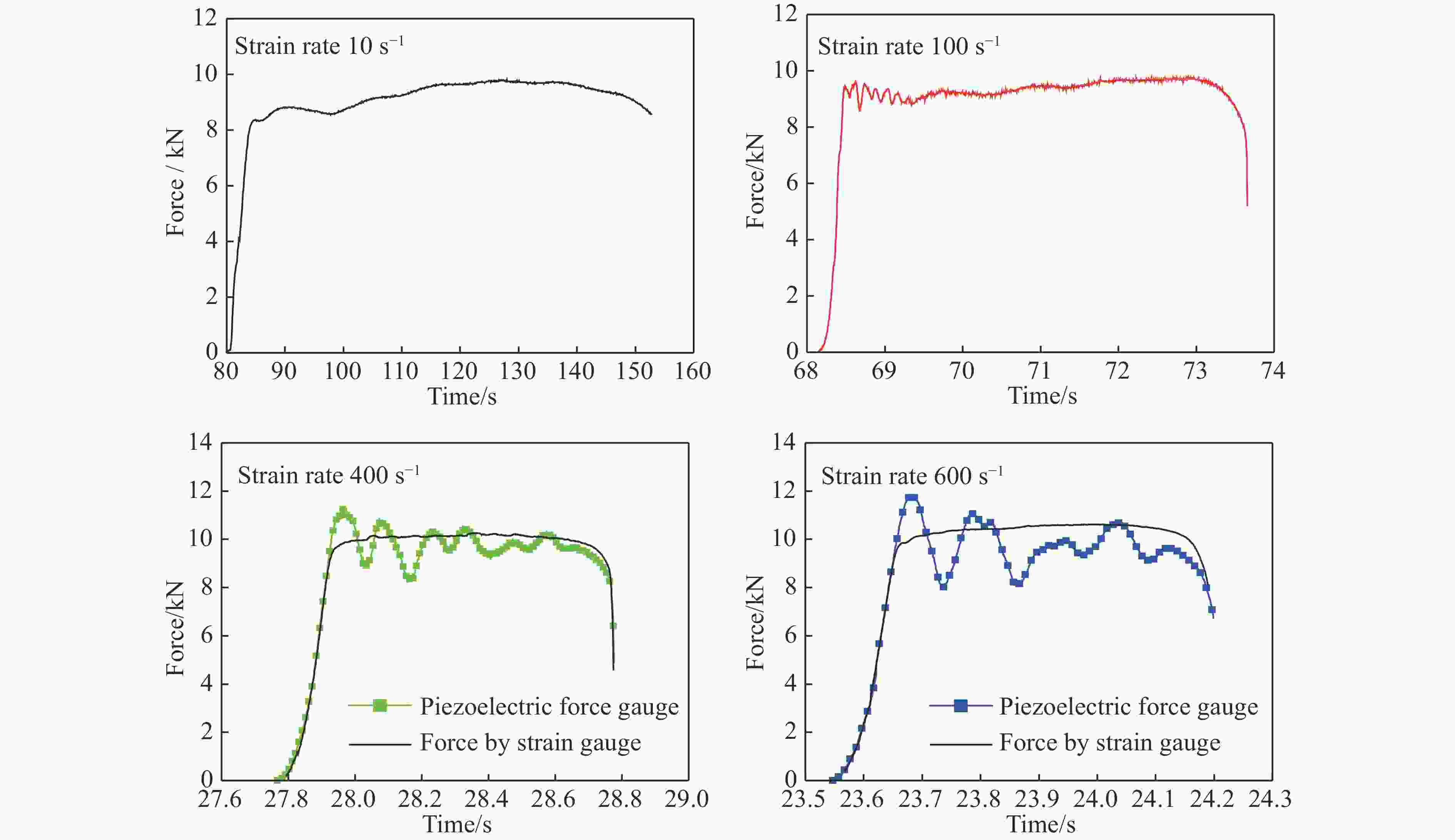

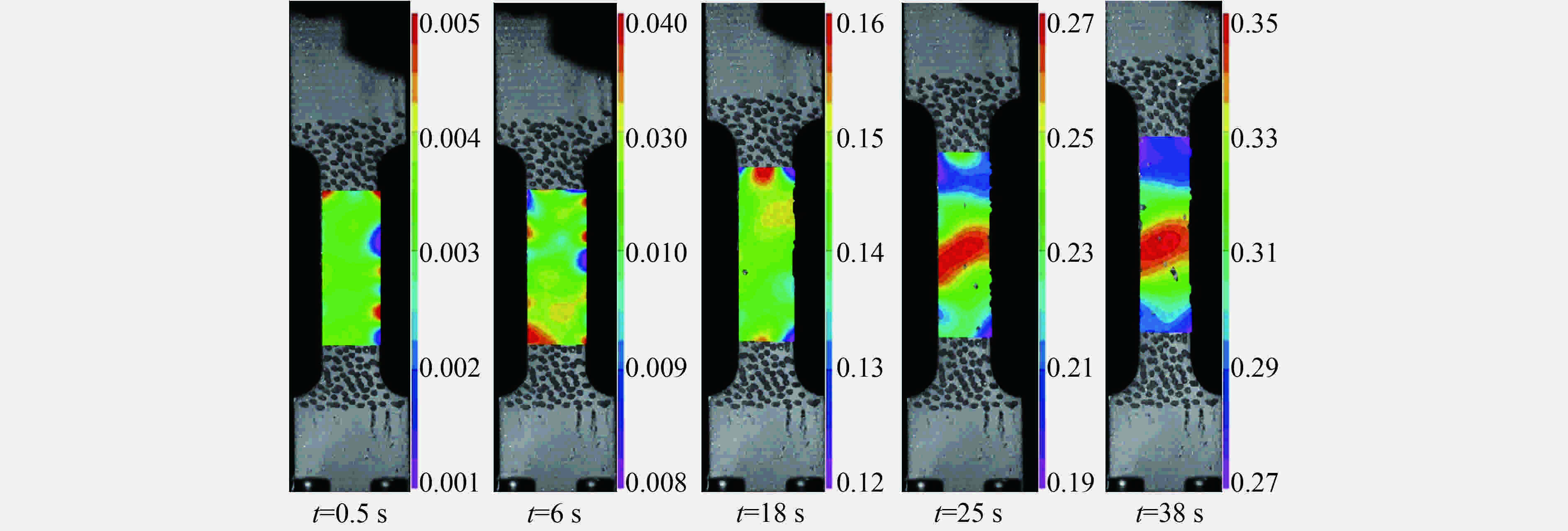

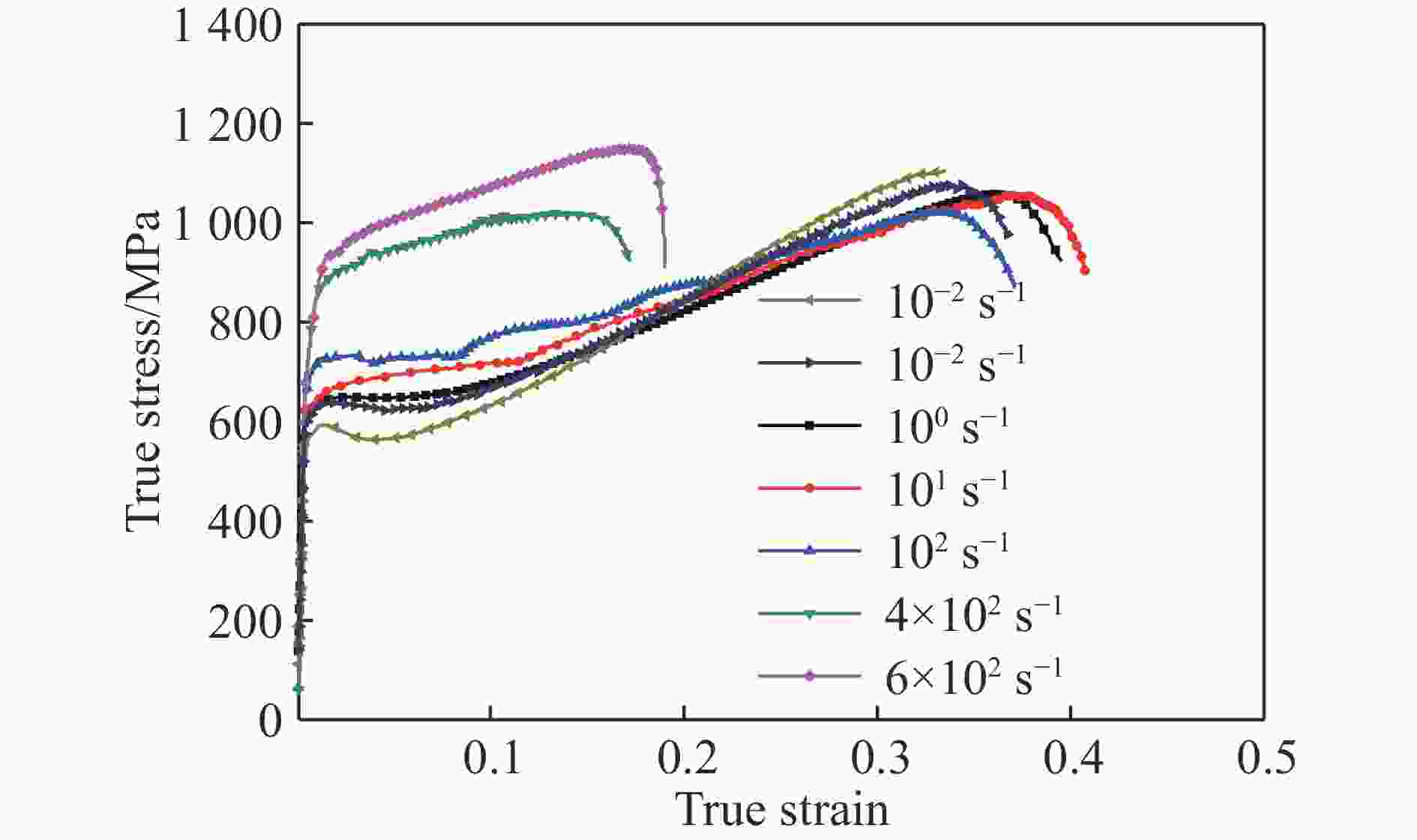

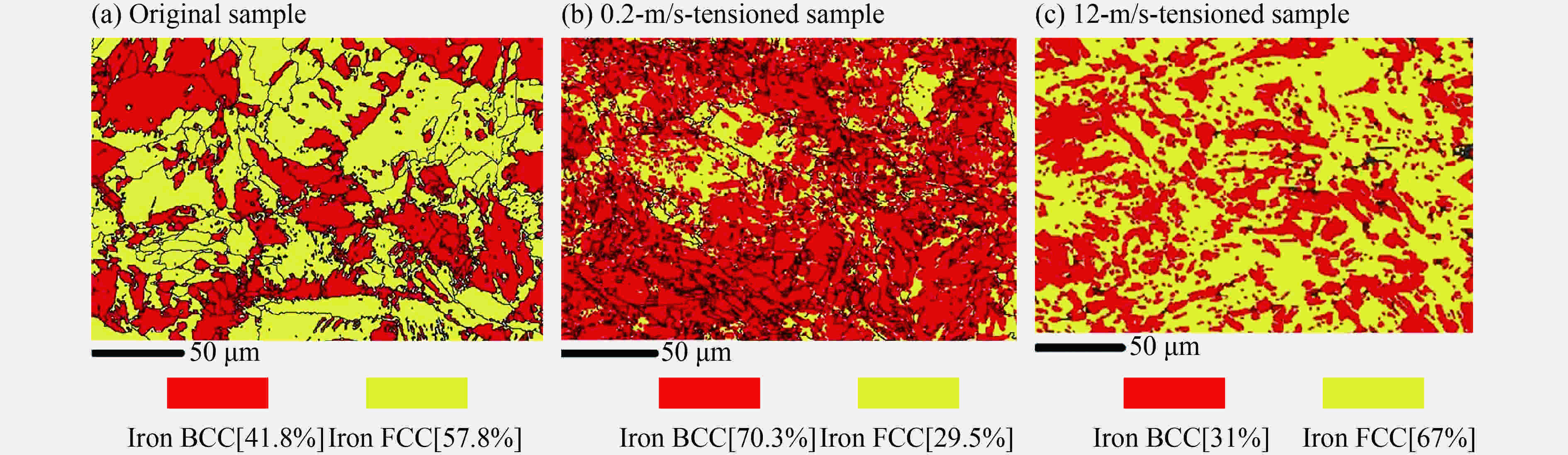

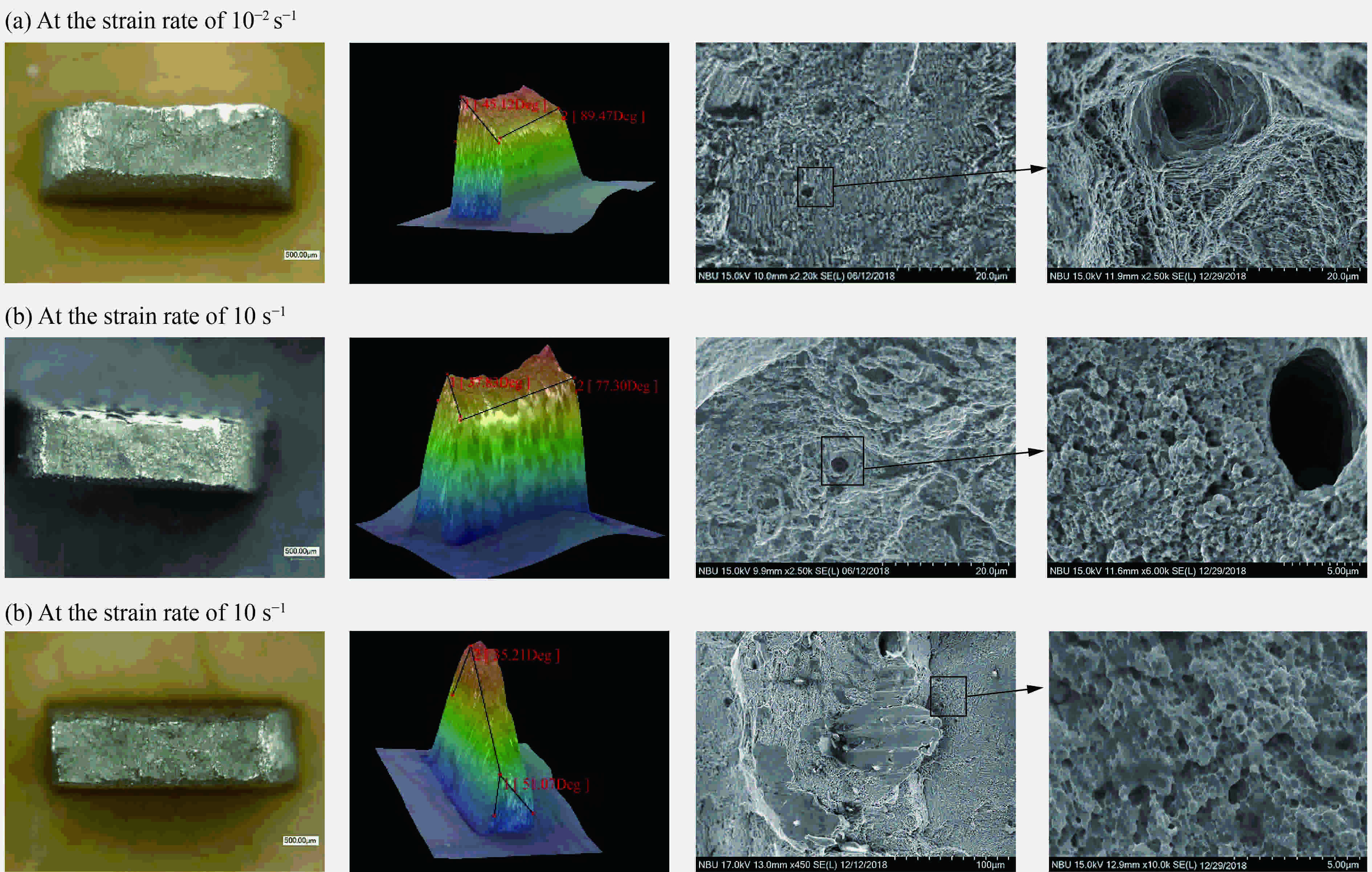

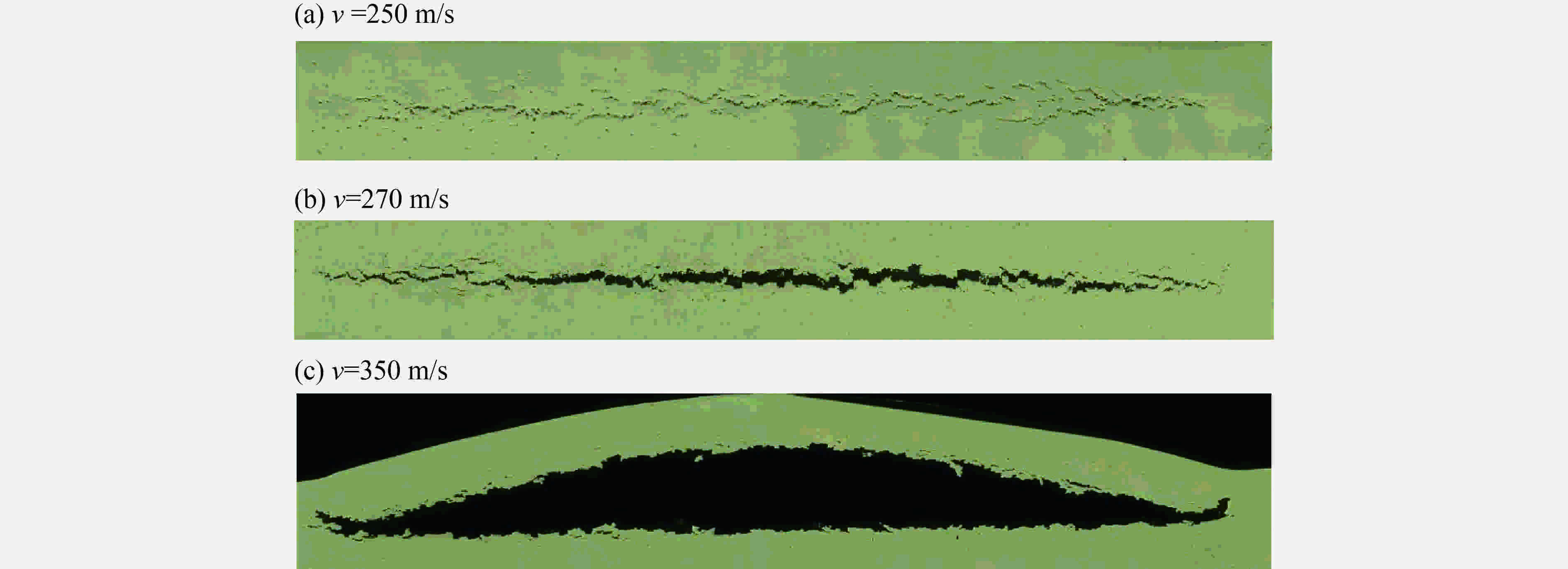

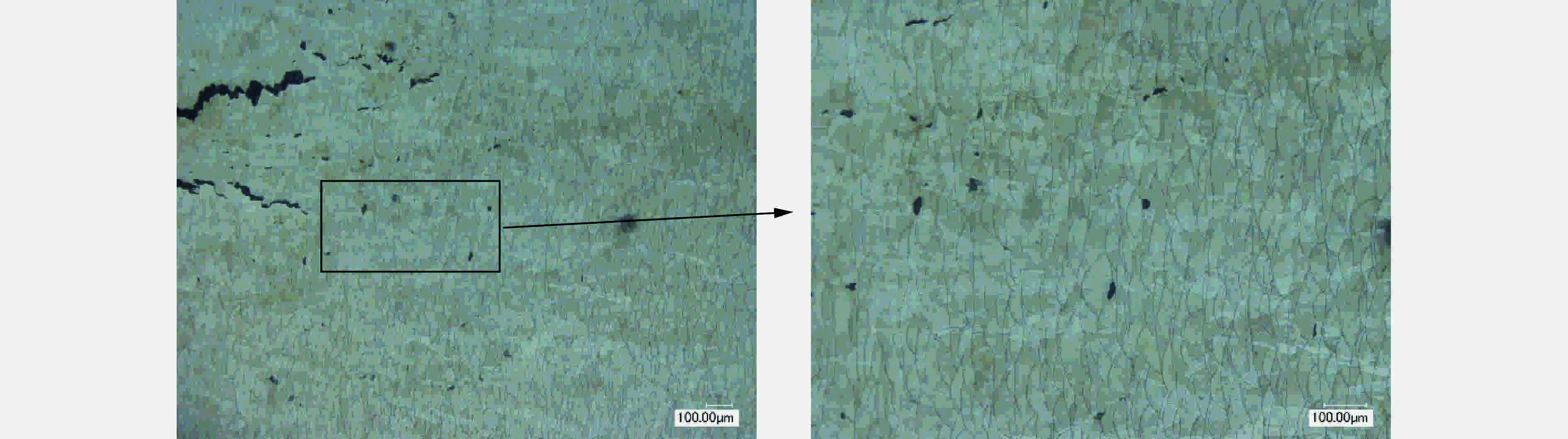

Abstract: Samples for uniaxial tension and spallation experiments of GP1 stainless steel were produced by selective laser melting (SLM). The microstructure of SLM GP1 was characterized by using the optical metallography and electron-backscatter diffraction (EBSD). The tensile mechanical behavior of SLM GP1 as a function of strain rate was studied by using a Zwick-HTM5020 high-speed tensile testing machine and the digital image correlation (DIC) full-field strain measurement method. Significant austenite-to-martensite phase transformation was observed during tensile loading with accompanied plastic strain hardening. Yield stress increases exponentially with strain rate, but at high strain rates (40 and 600 s−1), the yield stress rapidly increases, while the fracture strain decreases significantly. The spallation response of SLM GP1 was investigated by using plate impact experiments. Based on the free-surface particle velocity profiles measured by a displacement interferometer system for any reflector (DISAR), the spall strength of SLM GP1 was found to decrease with increasing flyer impact velocity. Fractography revealed the variation of the fracture mode and fracture mechanism of SLM GP1 as a function of strain rate. Damage nucleates easily at the intersection of the laser melting pool boundary line and grows along the laser pool boundary line. Fracture dimple morphology of the spalled samples is obviously different from that of the samples under the uniaxial tensile loading.-

Key words:

- SLM GP1 stainless steel /

- uniaxial tension /

- strain rate /

- spallation

-

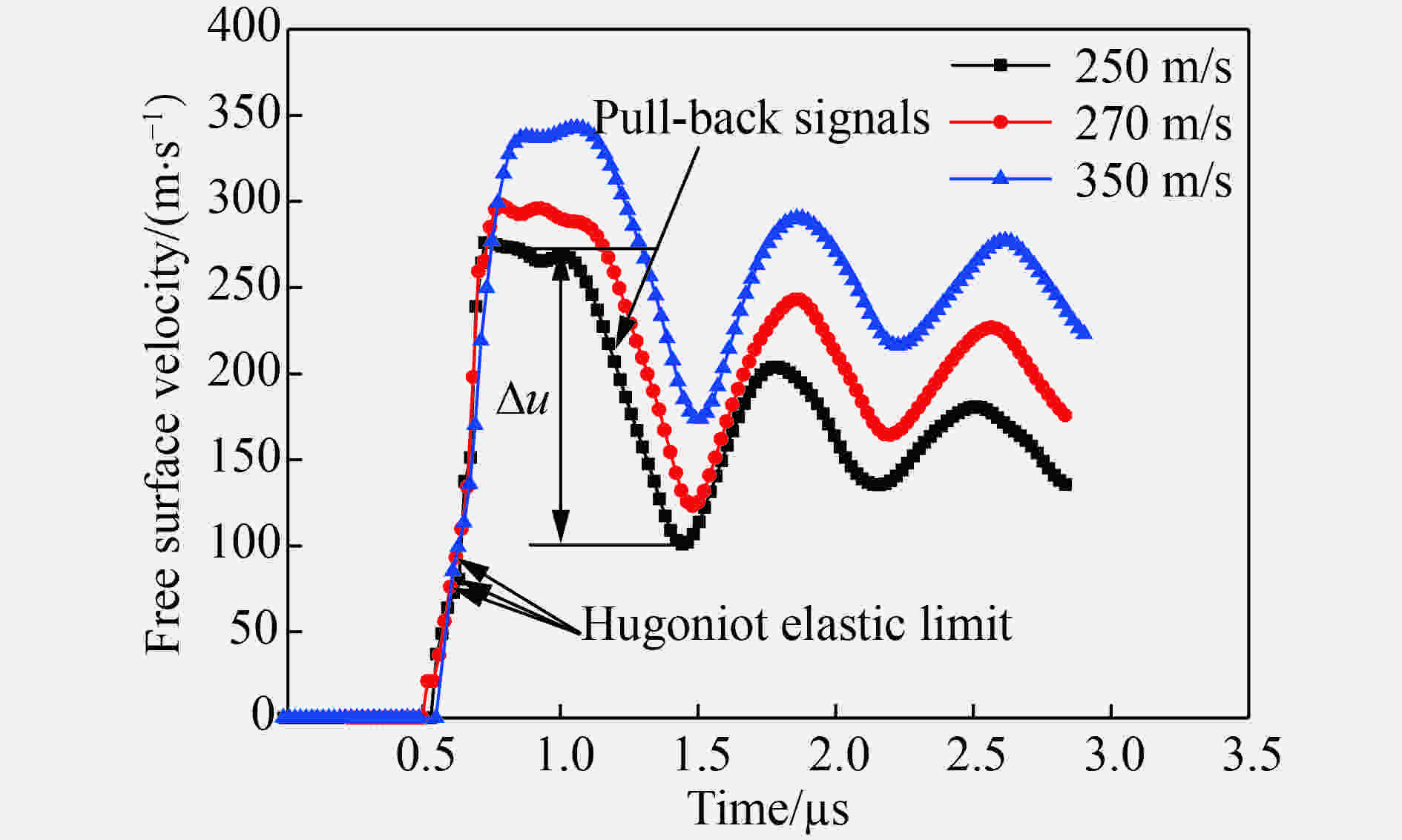

表 1 一维应变平板撞击实验结果

Table 1. Results of one-dimensional strain plane impact test

实验编号 初始速度/(m·s−1) Δu/(m·s−1) σHEL/GPa σy/GPa σs/GPa 1 250 176.23 1.78 1.01 3.91 2 270 174.97 1.79 1.02 3.88 3 350 169.99 1.85 1.05 3.76 -

[1] SAMES W J, LIST F A, PANALA S, et al. The metallurgy and processing science of metal additive manufacturing [J]. International Materials Reviews, 2016, 61(5): 1–46. DOI: 10.1080/09506608.2015.1116649. [2] ZHAI Y, LADOS D A, LAGOY J L. Additive manufacturing: making imagination the major limitation [J]. Journal of metals, 2014, 66(5): 808–816. DOI: 10.1007/s11837-014-0886-2. [3] YADOLLAHI A, SHAMSAEI N. Additive manufacturing of fatigue resistant materials: challenges and opportunities [J]. International Journal of Fatigue, 2017, 98(1): 14–31. DOI: 10.1016/j.ijfatigue.2017.01.001. [4] 王沛, 黄正华, 戚文军, 等. 基于SLM技术的3D打印工艺参数对316不锈钢组织缺陷的影响 [J]. 机械制造文摘: 焊接分册, 2016, 1(2): 2–7.WANG Pei, HUANG Zhenghua, QI Wenjun, et al. Effects of 3D printing process parameters based on SLM technology on structural defects of 316 stainless steel [J]. Mechanical Manufacturing Abstracts: Welding Brochures, 2016, 1(2): 2–7. [5] 吕豪, 杨志斌, 王鑫, 等. 激光增材制造GH4099合金热处理后的显微组织及拉伸性能 [J]. 中国激光, 2018, 45(10): 3–9. DOI: 10.3788/cjl.201845.1002003.LÜ Hao, YANG Zhibin, WANG Xin, et al. Microstructure and tensile properties of GH4099 alloy fabricated by laser additive manufacturing after heat treatment [J]. Chinese Journal of Lasers, 2018, 45(10): 3–9. DOI: 10.3788/cjl.201845.1002003. [6] 尹燕, 刘鹏宇. 路超., et al 选区激光熔化成形316L不锈钢微观组织及拉伸性能分析 [J]. 焊接学报, 2018, 39(8): 77–81. DOI: 10.12073/j.hjxb.2018390205.YIN Yan, LIU Pengyu, LU Chao, et al. Microstructure and tensile properties of selective laser melting forming 316L stainless steel [J]. Transactions of the China Welding Institution, 2018, 39(8): 77–81. DOI: 10.12073/j.hjxb.2018390205. [7] 王志会, 王华明, 刘栋. 激光增材制造AF1410超高强度钢组织与力学性能研究 [J]. 中国激光, 2016, 43(4): 59–65. DOI: 10.3788/CJL201643.0403001.WANG Zhihui, WANG Huaming, LIU Dong. Microstructure and mechanical properties of AF1410 ultra-high strength steel using laser additive manufacture technique [J]. Chinese Journal of Lasers, 2016, 43(4): 59–65. DOI: 10.3788/CJL201643.0403001. [8] YADOLLAHI A, SHAMSAEI N, THOMPSONS M, et al. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel [J]. International Journal of Fatigue, 2017, 94(11): 218–235. DOI: 10.1016/j.ijfatigue.2016.03.014. [9] SURYAWANSHI J. Mechanical behavior of selective laser melted 316L stainless steels [J]. Materials Science and Engineering: A, 2017, 696(7): 113–121. DOI: 10.1016/j.msea.2017.04.058. [10] WANG Y M, VOISIN T, MCKEOWN J T, et al. Additively manufactured hierarchical stainless steels with high strength and ductility [J]. Nature Materials, 2017, 17(1): 63–71. DOI: 10.1038/nmat5021. [11] YU S, HEBERT R J, MARK A. Effect of heat treatments on microstructural evolution of additively manufactured and wrought 17-4PH stainless steel [J]. Materials and Design, 2018, 156(10): 429–440. DOI: 10.1016/j.matdes.2018.07.015. [12] GRAY G T, LIVESCU V, RIGG P A, et al. Structure/property (constitutive and spallation response) of additive manufactured 316L stainless steel [J]. Acta Materialia, 2017, 138(10): 140–149. DOI: 10.1016/j.actamat.2017.07.045. [13] SONG B, NISHIDA E, SANBORN B, et al. Compressive and tensile stress-strain responses of additively manufactured (AM) 304L stainless steel at high strain rates [J]. Journal of Dynamic Behavior of Materials, 2017, 3(3): 412–425. DOI: 10.1007/s40870-017-0122-6. [14] BRANDON M W, BRAHMANNADA P, ANDELLE K, et al. High strain rate compressive deformation behavior of an additively manufactured stainless steel [J]. Additive Manufacturing, 2018, 9(24): 432–439. DOI: 1010.1016/j.addma.2018.09.16. [15] 丁利, 李怀学, 王玉岱, 等. 热处理对激光选区熔化成形316不锈钢组织与拉伸性能的影响 [J]. 中国激光, 2015, 42(4): 187–193. DOI: 10.3788/CJL201542.0406003.DING Li, LI Huaixue, WANG Yudai, et al. Heat treatment on microstructure and tensile strength of 316 stainless steel by selective laser melting [J]. Chinese Journal of Lasers, 2015, 42(4): 187–193. DOI: 10.3788/CJL201542.0406003. [16] WOOD P, SCHLEY C A, WILLIAMS M A, et al. A method to calibrate a specimen with strain gauges to measure force over the full-force range in high rate testing [C] // SCHLEY C A. DYMAT 2009: 9th International Conference on the Mechanical and Physical Behaviour of Materials under Dynamic Loading. Belgium: Experimental Techniques?, 2009: 265−273. DOI: 10.1051/dymat/2009036. [17] 申海艇, 蒋招绣, 王贝壳, 等. 基于超高速相机的数字图像相关性全场应变分析在SHTB实验中的应用 [J]. 爆炸与冲击, 2017, 37(1): 15–20. DOI: 10.11883/1001-1455(2017)01-0015-06.SHEN Haiting, JIANG Zhaoxiu, WANG Beike, et al. Full field strain measurement in split Hopkinson tension bar experiments by using ultra-high-speed camera with digital image correlation [J]. Explosion and Shock Waves, 2017, 37(1): 15–20. DOI: 10.11883/1001-1455(2017)01-0015-06. [18] PIERRON F, SUTTON M A, TIWARI V. Ultra high speed DIC and virtual fields method analysis of a three point bending impact test on an aluminum bar [J]. Experimental Mechanics, 2011, 51(4): 537–563. DOI: 10.1007/s11340-010-9402-y. [19] 王楠, 李恩普, 汤忠斌, 等. 二维数字图像相关方法的拉伸实验误差分析 [J]. 光学仪器, 2012, 34(3): 5–12. DOI: 10.3969/j.issn.1005-5630.2012.03.002.WANG Nan, LI Enpu, TANG Zhongbin, et al. An investigation of the experimental error of 2-D DIC method applied to tensile strain measurement [J]. Optical Instruments, 2012, 34(3): 5–12. DOI: 10.3969/j.issn.1005-5630.2012.03.002. [20] CHEVRIER P, KLEPACZKO J R. Spall fracture: mechanical and micro-structural aspects [J]. Engineering Fracture Mechanics, 1999, 63(3): 273–294. DOI: 10.1016/S0013-7944(99)00022-3. [21] 张万甲, 曾元金. 不锈钢(00Cr18Ni9)动态累积损伤研究 [J]. 爆炸与冲击, 1999, 19(4): 309–314. doi: 10.3321/j.issn:1001-1455.1999.04.004ZHANG Wanjia, ZENG Yuanjin. Study on the dynamic accumulation-damage for the stainless steel (00Cr18Ni9) [J]. Explosion and Shock Waves, 1999, 19(4): 309–314. doi: 10.3321/j.issn:1001-1455.1999.04.004 [22] WENG J, TAN H, WANG X, et al. Optical-fiber interferometer for velocity measurements with picosecond resolution [J]. Applied Physics Letters, 2006, 89(11): 111101-0. DOI: 10.1063/1.2335948. [23] CLAUSEN B, BROWN D W, CARPENTER J S, et al. Deformation behavior of additively manufactured GP1 stainless steel [J]. Materials Science and Engineering: A, 2017, 696(4): 331–340. DOI: 10.1016/j.msea.2017.04.081. [24] 刘超, 王磊, 刘杨. 应变速率对Q&P钢拉伸变形行为的影响 [J]. 特钢技术, 2012, 18(3): 18–22. DOI: 10.3969/j.issn.1674-0971.2012.03.007.LIU Chao, WANG Lei, LIU Yang. Effect of strain rates on tensile deformation behavior of quenching and partitioning steel [J]. Special Steel Technology, 2012, 18(3): 18–22. DOI: 10.3969/j.issn.1674-0971.2012.03.007. [25] COWPER G R, SYMONDS P S. Strain hardening and strain rate effects in the impact loading of cantilever beams [R] // Applied Mathematics Report. Brown University, 1958. [26] 蒋招绣, 辛铭之, 王永刚. 高强铝合金的动态拉伸断裂行为实验研究 [J]. 固体力学学报, 2014, 35(6): 552–558. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2014.06.007.JIANG Zhaoxiu, XIN Mingzhi, WANG Yonggang. Experimental study on dynamic tensile fracture of aluminum alloy [J]. Chinese Journal of Solid Mechanics, 2014, 35(6): 552–558. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2014.06.007. [27] 彭辉, 李平, 裴晓阳, 等. 平面冲击下铜的拉伸应变率相关特性研究 [J]. 物理学报, 2014, 63(19): 281–287. DOI: 10.7498/aps.63.196202.PENG Hui, LI Ping, PEI Xiaoyang, et al. Rate-dependent characteristics of copper under plate impact [J]. Acta Physica Sinica, 2014, 63(19): 281–287. DOI: 10.7498/aps.63.196202. [28] ANTOUN T, SEAMAN L, CURRAN D R, et al. Spall fracture [M]. New York, USA: Springer, 2003: 90−92. DOI: 10.1007/b97226. -

下载:

下载: