| [1] |

KALTHOFF J F, WINKLER S, BEINERT J. The influence of dynamic effects in impact testing [J]. International Journal of Fracture, 1977, 13(4): 528–531.

|

| [2] |

RUBINSTEIN A A. Macrocrack-microdefect interaction [J]. Journal of Applied Mechanics, 1986, 53(3): 505–510. DOI: 10.1115/1.3171803.

|

| [3] |

姚学锋, 熊春阳, 方竞. 含偏置裂纹三点弯曲梁的动态断裂行为研究 [J]. 力学学报, 1996, 28(6): 661–669. DOI: 10.3321/j.issn:0459-1879.1996.06.003.YAO X F, XIONG C Y, FANG J. Study of dynamic fracture behaviour on three-point-bend beam with off-center edge-crack [J]. Acta Mechanica Sinica, 1996, 28(6): 661–669. DOI: 10.3321/j.issn:0459-1879.1996.06.003.

|

| [4] |

岳中文, 宋耀, 陈彪, 等. 冲击载荷下层状岩体动态断裂行为的模拟试验研究 [J]. 振动与冲击, 2017, 36(12): 223–229.YUE Z W, SONG Y, CHEN B, et al. A study on the behaviors of dynamic fracture in layered rocks under impact loading [J]. Journal of Vibration and Shock, 2017, 36(12): 223–229.

|

| [5] |

李清, 郭洋, 马万权, 等. 半圆盘构件冲击断裂特性的动态焦散线实验研究 [J]. 振动与冲击, 2016, 35(9): 52–58.LI Q, GUO Y, MA W Q, et al. Dynamic caustics tests for semi-circular specimen under impact loading [J]. Journal of Vibration and Shock, 2016, 35(9): 52–58.

|

| [6] |

杨仁树, 丁晨曦, 杨立云, 等. 含缺陷结构的冲击断裂试验研究 [J]. 振动与冲击, 2016, 35(15): 103–108.YANG R S, DING C X, YANG L Y, et al. Tests for structures with flaws under impact loading [J]. Journal of Vibration and Shock, 2016, 35(15): 103–108.

|

| [7] |

杨立云, 张勇进, 孙金超, 等. 偏置裂纹对含双裂纹PMMA试件动态断裂影响效应研究 [J]. 矿业科学学报, 2017(4): 28–33.YANG L Y, ZHANG Y J, SUN J C, et al. The effect of offset distance on dynamic fracture behavior of PMMA with double cracks [J]. Journal of Mining Science and Technology, 2017(4): 28–33.

|

| [8] |

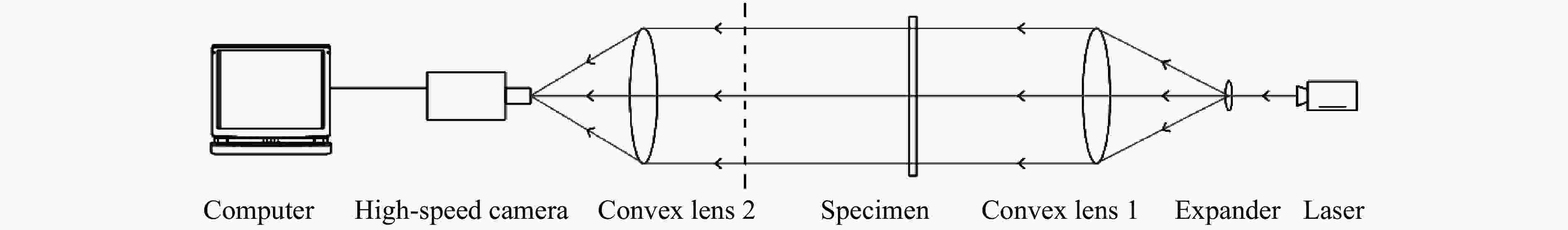

杨立云, 杨仁树, 许鹏. 新型数字激光动态焦散线实验系统及其应用 [J]. 中国矿业大学学报, 2013, 42(2): 188–194.YANG L Y, YANG R S, XU P. Caustic method combined with laser & digital high-speed camera and its application [J]. Journal of China University of Mining and Technology, 2013, 42(2): 188–194.

|

| [9] |

KALTHOFF J F, WINKLER S, BEINERT J. Dynamic stress intensity factors for arresting cracks in DCB specimens [J]. International Journal of Fracture, 1976, 12(2): 317–319. DOI: 10.1007/BF00036990.

|

| [10] |

杨仁树, 王雁冰, 岳中文, 等. 定向断裂双孔爆破裂纹扩展的动态行为 [J]. 爆炸与冲击, 2013, 33(6): 631–637. DOI: 10.11883/1001-1455(2013)06-0631-07.YANG R S, WANG Y B, YUE Z W, et al. Dynamic behaviors of crack propagation in directional fracture blasting with two holes [J]. Explosion and Shock Waves, 2013, 33(6): 631–637. DOI: 10.11883/1001-1455(2013)06-0631-07.

|

| [11] |

宋俊生, 王雁冰, 高祥涛, 等. 定向断裂控制爆破机理及应用 [J]. 矿业科学学报, 2016, 1(1): 16–28.SONG J S, WANG Y B, GAOL X T, et al. The mechanism of directional fracture controlled blasting and its application [J]. Journal of Mining Science and Technology, 2016, 1(1): 16–28.

|

| [12] |

LAGARDE A. Static and dynamic photoelasticity and caustics recent developments [M]// Static and Dynamic Photoelasticity and Caustics. Vienna: Springer, 1987.

|

| [13] |

肖同社, 杨仁树, 庄金钊, 等. 节理岩体爆生裂纹扩展动态焦散线模型实验研究 [J]. 爆炸与冲击, 2007, 27(2): 159–164. DOI: 10.11883/1001-1455(2007)02-0159-06.XIAO T S, YANG R S, ZHUANG J Z, et al. Dynamic caustics model experiment of blasting crack developing on sandwich rock [J]. Explosion and Shock Waves, 2007, 27(2): 159–164. DOI: 10.11883/1001-1455(2007)02-0159-06.

|

| [14] |

ROSSMANITH H, DAEHNKE A, NASMILLNER R, et al. Fracture mechanics applications to drilling and blasting [J]. Fatigue and Fracture of Engineering Materials and Structures, 1997, 20(11): 1617–1636. DOI: 10.1111/j.1460-2695.1997.tb01515.x.

|

| [15] |

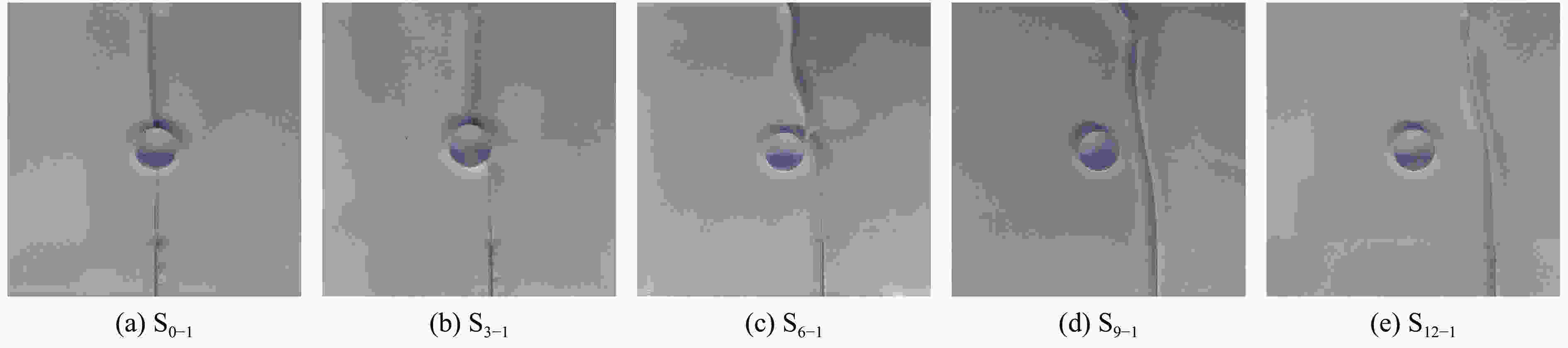

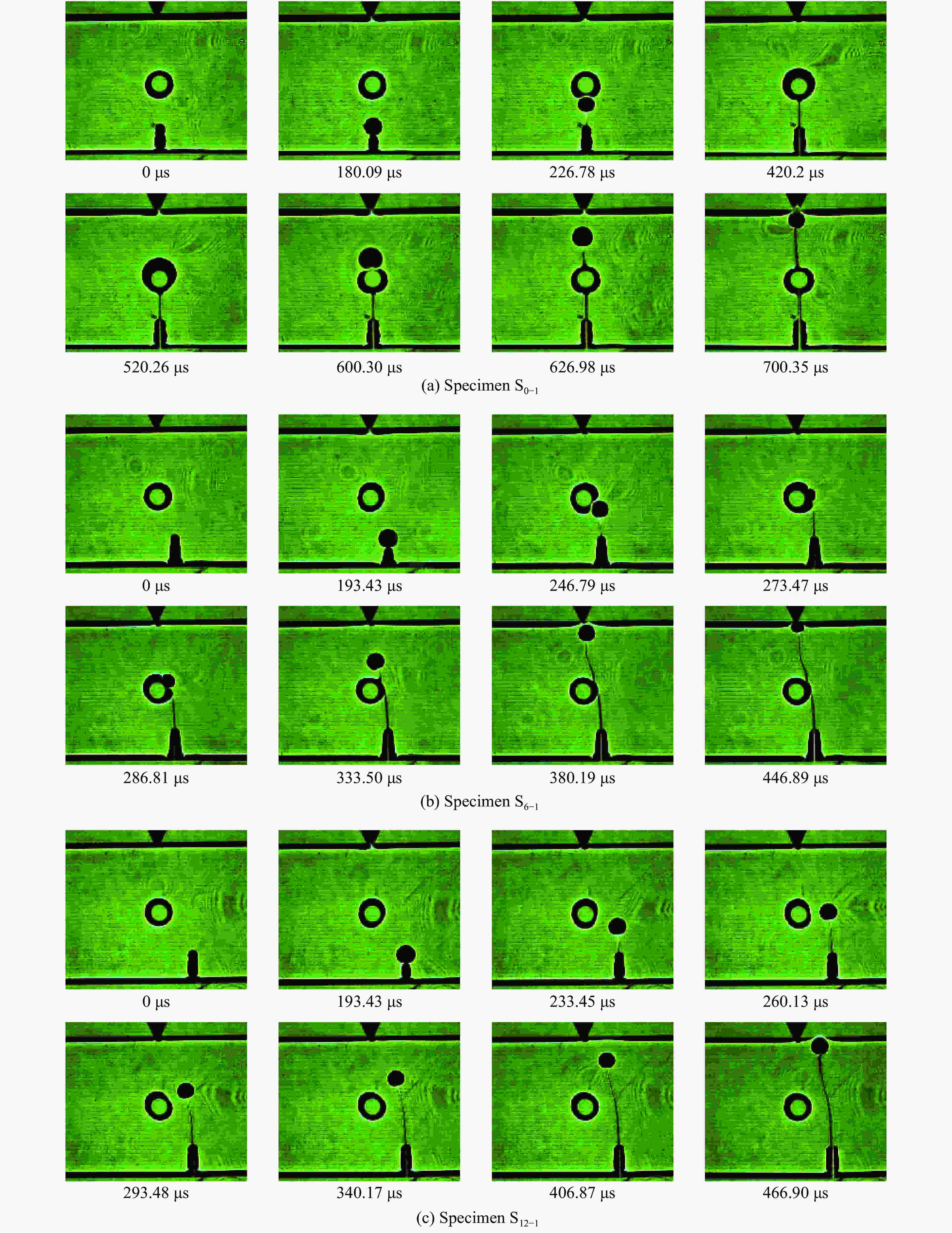

杨仁树, 陈程, 赵勇, 等. 空孔-裂纹偏置方式对PMMA冲击断裂动态行为的影响 [J]. 振动与冲击, 2018, 37(20): 127–133.YANG R S, CHEN C, ZHAO Y, et al. Influence of the void-crack offset method on the dynamic behavior of PMMA during impact fracture [J]. Journal of Vibration and Shock, 2018, 37(20): 127–133.

|

| [16] |

MANDELBROT, BENOIT B. The fractal geometry of nature [J]. American Journal of Physics, 1983, 51(3): 286. DOI: 10.1119/1.13295.

|

| [17] |

谢和平. 分形: 岩石力学导论[M]. 北京: 科学出版社, 1996.

|

| [18] |

谢和平. 分形应用中的数学基础与方法[M]. 北京: 科学出版社, 1997.

|

| [19] |

JU Y, XI C, ZHANG Y, et al. Laboratory in situ CT observation of the evolution of 3D fracture networks in coal subjected to confining pressures and axial compressive loads: a novel approach [J]. Rock Mechanics and Rock Engineering, 2018, 51(11): 3361–3375. DOI: 10.1007/s00603-018-1459-4.

|

| [20] |

杨军, 王树仁. 岩石爆破分形损伤模型研究 [J]. 爆炸与冲击, 1996, 16(1): 5–10.YANG J, WANG S R. Study on fractal damage model of rock fragmentation by blasting [J]. Explosion and Shock Waves, 1996, 16(1): 5–10.

|

| [21] |

彭瑞东, 谢和平, 鞠杨. 二维数字图像分形维数的计算方法 [J]. 中国矿业大学学报, 2004(1): 22–27.PENG R D, XIE H P, JU Y. Computation method of fractal dimension for 2-D digital image [J]. Journal of China University of Mining and Technology, 2004(1): 22–27.

|

| [22] |

周宏伟, 谢和平. 岩石节理张开度的分形描述 [J]. 水文地质工程地质, 1999(1): 3–6.ZHOU H W, XIE H P. The fractal description on the opening of a rock fracture [J]. Hydrogeology and Engineering Geology, 1999(1): 3–6.

|

下载:

下载: