The spurted nitrogen preventing the gas explosion in pipe

-

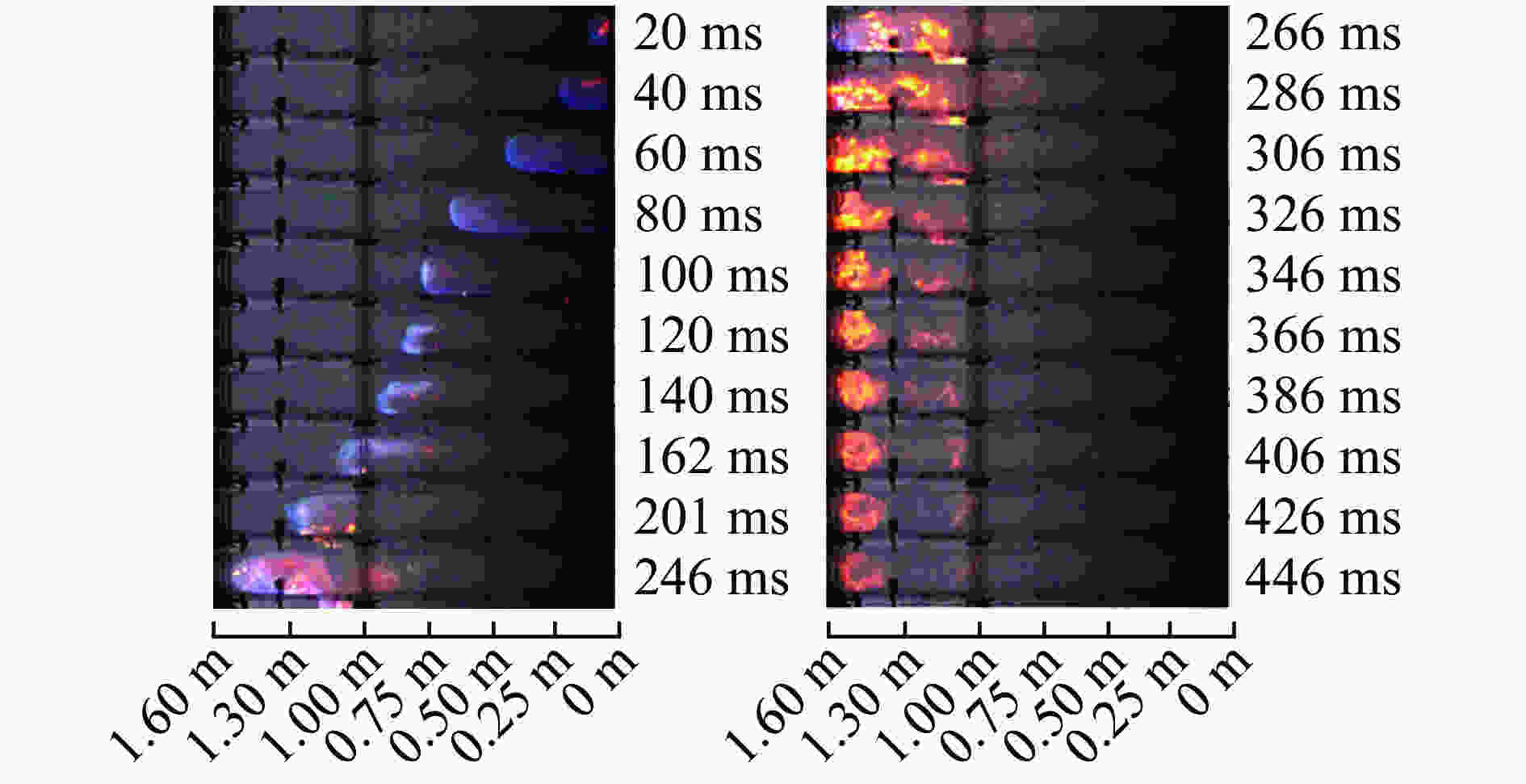

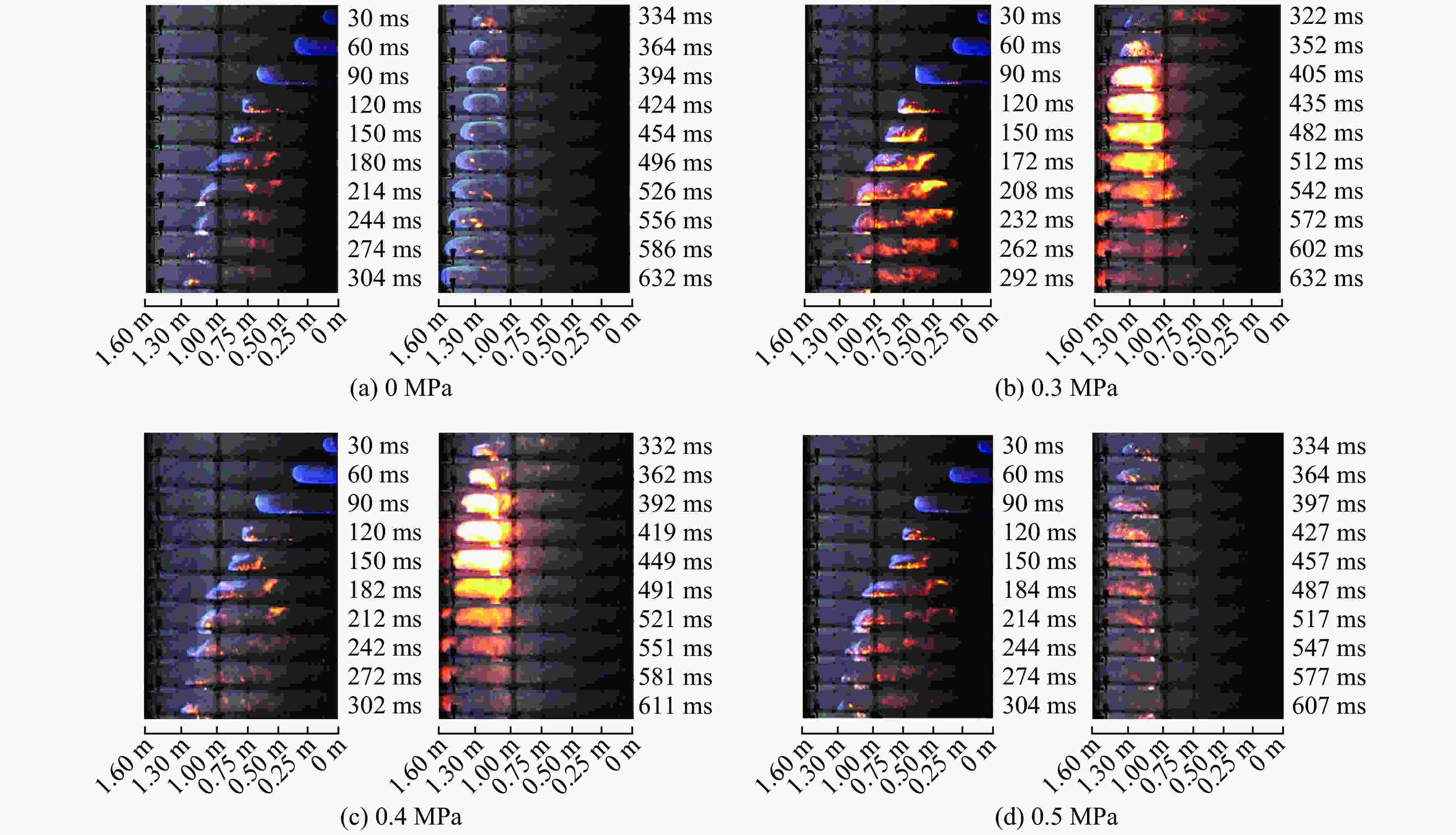

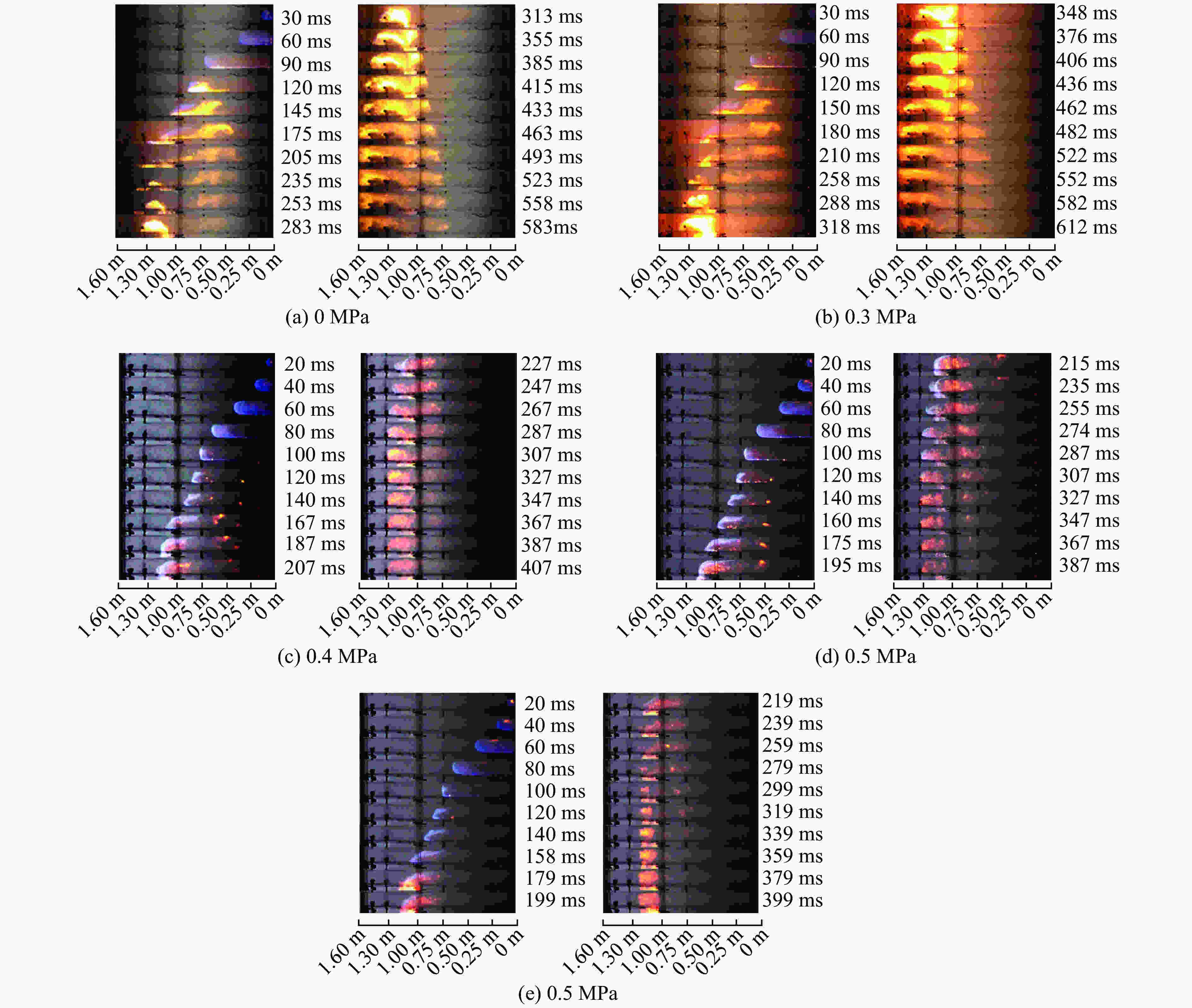

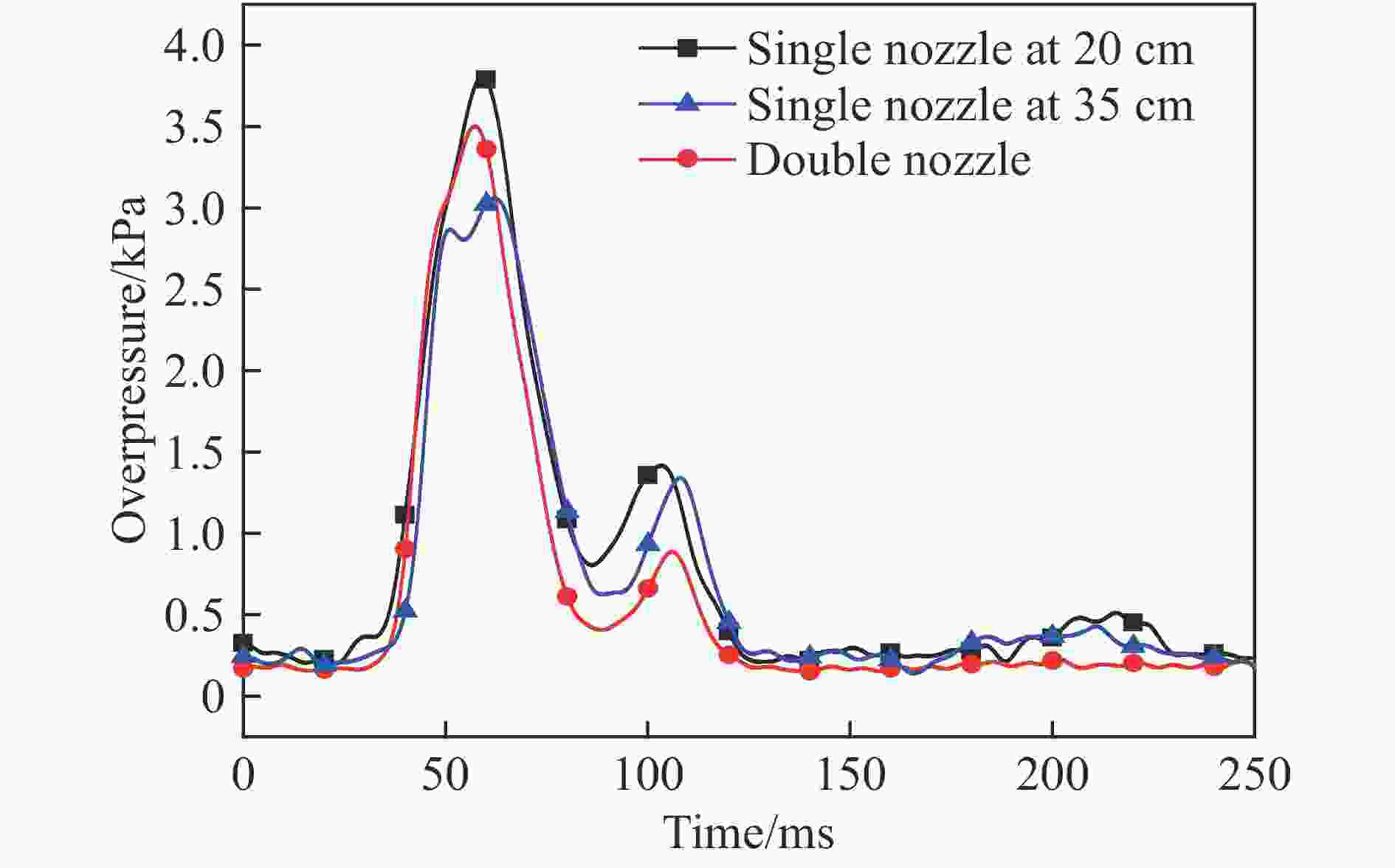

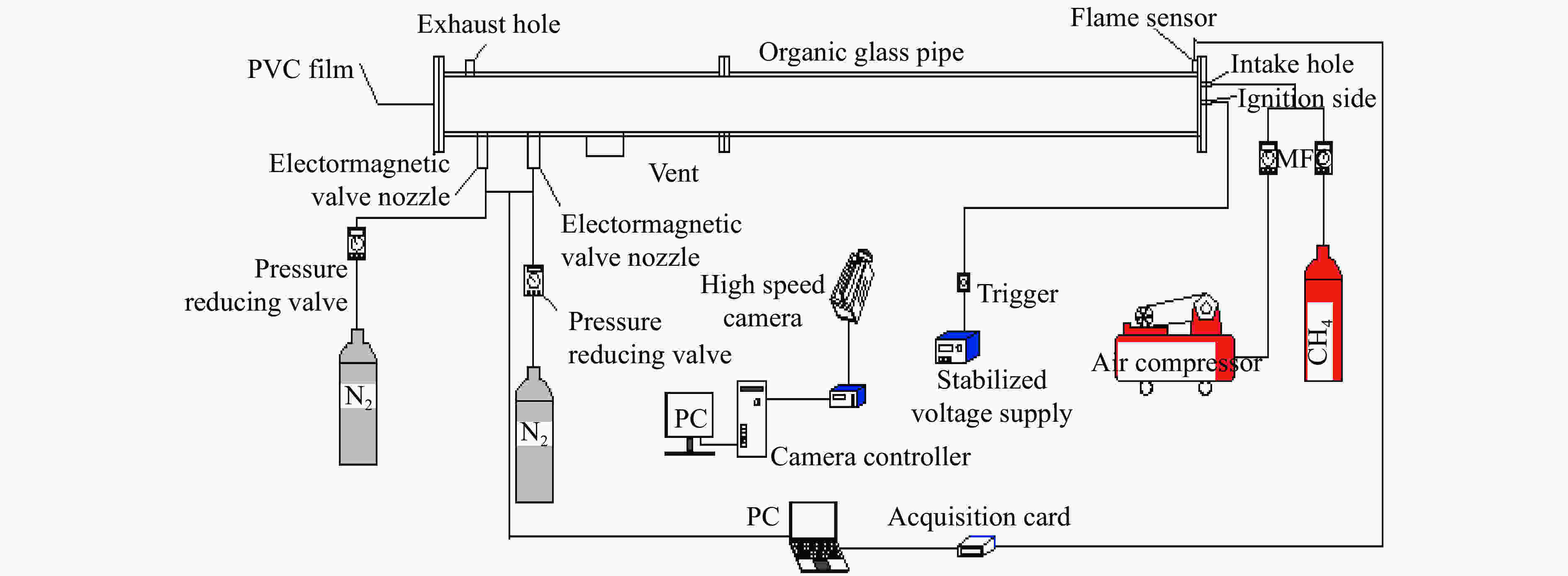

摘要: 为探究喷出氮气对瓦斯爆炸火焰传播的抑制能力,设置三种氮气喷头布置方式来进行阻爆实验,采用的氮气喷出压力有0.1、0.2、0.3、0.4和0.5 MPa,爆炸开始后喷射氮气,爆炸结束后氮气立刻关闭。结果表明,单喷头距泄压口20 cm时,各压力下喷出的氮气都未能阻爆,但火焰在整个管道内的平均传播速度随氮气压力增大而减小;单喷头距泄压口35 cm时,喷气压力0.5 MPa下成功阻爆,其他喷气压力下未能阻爆;双喷头喷气时,喷气压力0.3、0.4、0.5 MPa情况下都能够阻爆,且喷气压力越大,火焰被阻止的位置越靠前。阻爆的实现,需要氮气在阻爆位置将管道截面上的预混气稀释到可燃极限以下,因而氮气量是影响稀释的重要参数。单喷头时,喷头距离泄压口远更易于实现阻爆。采用双喷头时,氮气区扩大,阻爆所需氮气压力、氮气总量比单喷头时都大为降低。Abstract: After the gas explosion, preventing the propagation of explosion flame can better eliminate the disaster. In this paper, three kinds of nitrogen nozzle arrangement are set to carry out experiments for explosion prevention. The nitrogen pressures used in experiments include 0.1, 0.2, 0.3, 0.4 and 0.5 MPa, Nitrogen is spurted into the pipe after the occurrence of the explosion and immediately shut down after quenching the explosion. The results show that the spurted nitrogen under each pressure can not prevent the explosion with single nitrogen nozzle, which is 20 cm away from the vent. But the average propagation speed of the flame in the whole pipe decreases with the increase of nitrogen pressure. With single nitrogen nozzle, which is 35 cm away from the vent, the spurted nitrogen at pressure 0.5 MPa succeed in explosion prevention, while the explosion can not be prevented at other pressure. When double nozzle is used to spurt nitrogen, the explosion is prevented in the case of pressure 0.3, 0.4 and 0.5 MPa. And the greater the nitrogen pressure, the more forward the flame is blocked. The explosion prevention requires nitrogen to dilute the premixed gas below the combustible limit. Nitrogen volume is the important parameter affecting dilution. With single nitrogen nozzle, the situation of nozzle far from the vent is easier to prevent the explosion than that of nozzle near from the vent. When double nozzles are used, the nitrogen region will enlarge. With double nozzle, lower nitrogen pressure and less nitrogen quantity are required for preventing the explosion as comparing with single nozzle.

-

Key words:

- methane /

- preventing explosion /

- nitrogen /

- nozzle arrangement /

- flame

-

表 1 单喷头距泄压口20 cm的爆炸传播特征表

Table 1. Spread characteristics of the flame while single nozzle 20 cm away from the vent

序号 p/MPa t1/ms t2/ms t3/ms V/L 火焰阻隔状况 1 0 − 184 356 0 未阻爆 2 0.1 65 162 179 0.203 未阻爆 3 0.2 68 163 186 0.350 未阻爆 4 0.3 63 169 192 0.547 未阻爆 5 0.4 66 166 200 0.712 未阻爆 6 0.5 68 162 201 0.854 未阻爆 注:p为喷气压力,t1为喷气时刻,t2为火焰到达泄压口的时刻,t3为火焰到达喷头的时刻,V为火焰到达喷头前氮气的喷出量。 表 2 单喷头距泄压口35 cm的爆炸传播特征表

Table 2. Spread characteristics of the flame while single nozzle 35 cm away from the vent

序号 p/MPa t1/ms t2/ms t3/ms V/L 火焰阻隔状况 1 0 − 184 496 0 未阻爆 2 0.1 62 170 382 0.570 未阻爆 3 0.2 65 171 394 0.977 未阻爆 4 0.3 72 172 405 1.412 未阻爆 5 0.4 61 182 419 1.901 未阻爆 6 0.5 73 184 397 2.080 阻爆于喷头处 表 3 双喷头下的爆炸传播特征表

Table 3. The characteristics of explosion spread when double nozzle used

序号 p/MPa t1/ms t2/ms t3R/ms t3L/ms VR/L VL/L 火焰阻隔状况 1 0 − 184 356 496 0 0 未阻爆 2 0.1 59 145 253 355 0.691 1.054 未阻爆 3 0.2 62 150 258 376 1.164 1.865 未阻爆 4 0.3 70 167 267 − 1.671 − 阻爆于右喷头 5 0.4 67 175 274 − 2.198 − 阻爆于右喷头 6 0.5 65 158 (239)− − (2.234)− − 阻爆于泄压口与喷头间 注:(1)t3R和t3L分别为火焰到达右喷头和做喷头的时刻;VR和VL分别为火焰到达右喷头和左喷头时,双喷头的总喷气量;(2)表中“−”代表火焰没有到达,无数据;(3)“(239)−”表示火焰到达左侧最远位置对应的该项数值是239。 -

[1] 徐景德, 周心权, 吴兵. 矿井瓦斯爆炸传播的尺寸效应研究 [J]. 中国安全科学学报, 2001, 11(6): 1–2. DOI: 10.16265/j.cnki.issn1003.XU J D, ZHOU X Q, WU B. Study on the size effect in the propagation of gas explosion in mine pit [J]. China Safety Science Journal, 2001, 11(6): 1–2. DOI: 10.16265/j.cnki.issn1003. [2] 周心权, 陈国新. 矿井重大瓦斯爆炸事故致因的概率分析及启示 [J]. 煤炭学报, 2008, 33(1): 43–46. DOI: 10.13225/j.cnki.jccs.2008.01.019.ZHOU X Q, CHEN G X. The probability analysis of occurrence causes of extraordinarily serious gas explosion accidences and its revelation [J]. Journal of China Coal Soceity, 2008, 33(1): 43–46. DOI: 10.13225/j.cnki.jccs.2008.01.019. [3] CAO X, REN J, BI M S, et al. Experimental research on methane/air explosion inhibition usingultrafine water mist containing additive [J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 352–360. DOI: 10.1016/j.jip.2016.06.012. [4] YU M G, WAN S J, XU Y L, et al. Suppressing methane explosion overpressure using a charged water mist containing a NaCl additive [J]. Journal of Natural Gas Science and Engineering, 2016, 29: 21–29. DOI: 10.1016/j.jngse.2015.12.040. [5] 裴蓓, 余明高, 陈立伟, 等. CO2-双流体细水雾抑制管道甲烷爆炸实验 [J]. 化工学报, 2016, 67(7): 3101–3108. DOI: 10.11949/j.issn.0438-1157.20151388.PEI B, YU M G, CHEN L W, et al. Suppression effect of CO2-twin fluid water water mist on methane/air explosion in vented duct [J]. Journal of Chemical Industry and Engineering, 2016, 67(7): 3101–3108. DOI: 10.11949/j.issn.0438-1157.20151388. [6] 王信群, 王婷, 徐海顺, 等. BC粉体抑爆剂改性及抑制甲烷/空气混合物爆炸 [J]. 化工学报, 2015, 66(12): 5171–5178. DOI: 10.11949/j.issn.0438-1157.20141869.WANG X Q, WANG T, XU H S, et al. Modification of commercial BC dry chemical power suppressant and experiments on suppression of methane-air explosion [J]. Journal of Chemical Industry and Engineering, 2015, 66(12): 5171–5178. DOI: 10.11949/j.issn.0438-1157.20141869. [7] 路长, 刘洋, 于子凯, 等. 四氟乙烷对甲烷/空气爆炸特性的影响 [J]. 化工进展, 2017, 36(10): 3596–3603. DOI: 10.16085/j.ssn.1000-6613.2017-0315.LU C, LIU Y, YU Z K, et al. Experimental study on the effects of R134a on the characteristics of methane/air explosion [J]. Chemical Industry and Engeering progress, 2017, 36(10): 3596–3603. DOI: 10.16085/j.ssn.1000-6613.2017-0315. [8] 杨勇. 含添加剂的N2-双流体细水雾抑制甲烷/空气爆炸衰减特性研究[D]. 焦作: 河南理工大学, 2017. [9] 常琳. 煤矿井下区域自动喷粉灭火抑爆系统研究 [J]. 煤矿安全, 2018, 49(7): 13–15. DOI: 10.13347/j.cnki.mkaq.2018.07.004.CHANG L. Study on regional automatic power spraying fire extingguishing and explosion suppression system in underground coal mine [J]. Safety in Coal Mines, 2018, 49(7): 13–15. DOI: 10.13347/j.cnki.mkaq.2018.07.004. [10] 程方明, 邓军, 罗振敏, 等. 硅藻土粉体抑制瓦斯爆炸的实验研究 [J]. 采矿与安全工程学报, 2010, 27(4): 604–607. DOI: 10.3969/j.issn.1673-3363.2010.04.031.CHENG F M, DENG J, LUO Z M, et al. Experimental study on inhibiting gas explosion using diatomite powder [J]. Journal of Mining and Safety Engineering, 2010, 27(4): 604–607. DOI: 10.3969/j.issn.1673-3363.2010.04.031. [11] 王婷, 王信群, 吕岳, 等. 超细活性及惰性粉体对甲烷/空气预混物层流火焰传播的影响 [J]. 煤炭学报, 2016, 41(7): 1720–1727. DOI: 10.13225/j.cnki.jccs.2015.1759.WANG T, WANG X Q, LV Y, et al. Interaction of ultrafine chemical active and inert powder with premixed laminar flame of methane-air mixtures [J]. Journal of China Coal Soceity, 2016, 41(7): 1720–1727. DOI: 10.13225/j.cnki.jccs.2015.1759. [12] 薛少谦. 七氟丙烷抑制甲烷空气预混气体爆炸的实验研究 [J]. 矿业安全与环保, 2017, 44(1): 5–8. DOI: 10.3969/j.issn.1008-4495.2017.01.002.XU S Q. Experimental research on premixed methane-air explosion suppression with heptafluoropropane [J]. Mining safety and environmental protection, 2017, 44(1): 5–8. DOI: 10.3969/j.issn.1008-4495.2017.01.002. [13] LIANG Y T, ZENG W, HU E J. Experimental study of the effect of nitrogen addition on gas explosion [J]. Journal of Loss Prevention in the Process Industries, 2013, 26: 1–9. DOI: 10.16085/j.issn.1000-6613.2017-0315. [14] 李成兵. N2/CO2/H2O抑制甲烷爆炸化学动力学机理分析 [J]. 中国安全科学学报, 2010, 20(8): 88–92. DOI: 10.16265/j.cnki.isn1003-3033.2010.08.011.LI C B. Chemical kinetics mechanism analusis of N2/CO2/H2O suppressing methane explosion [J]. China Safety Science Journa, 2010, 20(8): 88–92. DOI: 10.16265/j.cnki.isn1003-3033.2010.08.011. [15] 张宇明, 邹高万, 郜冶, 等. ABC干粉对爆炸火焰传播抑制实验 [J]. 哈尔滨工程大学学报, 2012, 33(4): 449–453. DOI: 10.3969/j.issn.1006-7043.201105039.ZHANG Y M, ZOU G W, GAO Y, et al. Experimental research on deflagration flame propagation suppression by ABC powder [J]. Journal of Harbin Engineering University, 2012, 33(4): 449–453. DOI: 10.3969/j.issn.1006-7043.201105039. [16] WANG L Q, MA H H, SHEN Z W. The quenching of propane deflagrations by crimped ribbon flame arrestors [J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 567–574. DOI: 10.1016/j.jlp.2016.07.025. [17] ZHANG J F, SUN Z Q, ZHENG Y M, et al. Coupling effect of foam ceramics on the flame and shock wave of gas explosion [J]. Safety Science, 2012, 50: 797–800. DOI: 10.1016/j.ssci.2011.08.031. [18] 孙建华, 赵益, 魏春荣, 等. 金属丝网和泡沫陶瓷组合体抑制瓦斯爆炸的实验研究 [J]. 煤炭学报, 2012, 37(7): 1156–1160. DOI: 10.13225/j.cnki.jccs.2012.07.018.SUN J H, ZHAO Y, WEI C R, et al. Experimental study of combination of metal wire mesh and foam ceramic for suppressing the gas explosion [J]. Journal of China Coal Soceity, 2012, 37(7): 1156–1160. DOI: 10.13225/j.cnki.jccs.2012.07.018. [19] 张巨峰, 武元, 杨运尧, 等. 管道内多层金属丝网对预混可燃气体爆炸火焰传播的影响 [J]. 山西大同大学学报(自然科学版), 2012, 28(1): 66–70. DOI: 10.3969/j.issn.1672-9102.2012.02.004.ZHANG J F, WU Y, YANG Y Y, et al. Effect of multi-layer wire mesh upon pre-mixed combustible gas explosion in the tube [J]. Journal of Datong Vocational College (Natural Science Edition), 2012, 28(1): 66–70. DOI: 10.3969/j.issn.1672-9102.2012.02.004. [20] 马凯, 马志鹏, 张巨峰, 等. 泡沫陶瓷结构内瓦斯爆炸反应的断链 [J]. 矿业工程研究, 2013, 28(2): 33–36. DOI: 10.3969/j.issn.1674-5876.2013.02.008.MA K, MA Z P, ZHANG J F, et al. Chain scission of gas explosion reaction in foam ceramics [J]. Mineral Engineering Research, 2013, 28(2): 33–36. DOI: 10.3969/j.issn.1674-5876.2013.02.008. [21] 王俊峰, 邬剑明, 白云龙. 南非HS抑爆系统性能的试验研究 [J]. 中国安全科学学报, 2010, 20(6): 63–68. DOI: 10.16265/j.cnki.Issn1003-3033.2010.06.008.WANG J F, WU J M, BAI Y L. Experimental research on the effects of south africas HS suppression system [J]. China Safety Science Journa, 2010, 20(6): 63–68. DOI: 10.16265/j.cnki.Issn1003-3033.2010.06.008. [22] 荣佳, 胡双启, 于传利, 等. 煤矿井下自动抑爆装置的研制 [J]. 煤炭工程, 2014, 46(9): 135–137. DOI: 10.11799/ce2014090044.RONG J, HU S Q, YU C L, et al. Development of automatic explosion suppression device for underground coal mine [J]. Coal Engineering, 2014, 46(9): 135–137. DOI: 10.11799/ce2014090044. [23] LU C, WANG H B, PAN R K, et al. Preventing the propagation of gas explosion in ducts using spurted nitrogen [J]. Process Safety and Environmental Protection, 2019, 123: 11–23. DOI: 10.1016/j.pspe.2018.12.028. [24] WANG J F, WU J M, YU S, et al. The experiment research of the powder jetting performance for the south africa HS active explosion suppression system [J]. First International Symposium on Mine Safety Science and Engineering, 2011, 26: 388–396. DOI: 10.1016/j.proeng.2011.11.2183. [25] 路长, 王小康, 刘洋, 等. 采用火焰传感器的高速抑爆响应系统测试研究 [J]. 火灾科学, 2018, 27(3): 174–180. DOI: 10.3969/j.isscn.1004-5309.2018.03.07.LU C, WANG X K, LIU Y, et al. Test of the response system of high speed suppression with flame sensor [J]. Fire Safety Science, 2018, 27(3): 174–180. DOI: 10.3969/j.isscn.1004-5309.2018.03.07. -

下载:

下载: