Damage characteristics of polyurea coated ceramic/steel composite armor structures subjected to combined loadings of blast and high-velocity fragments

-

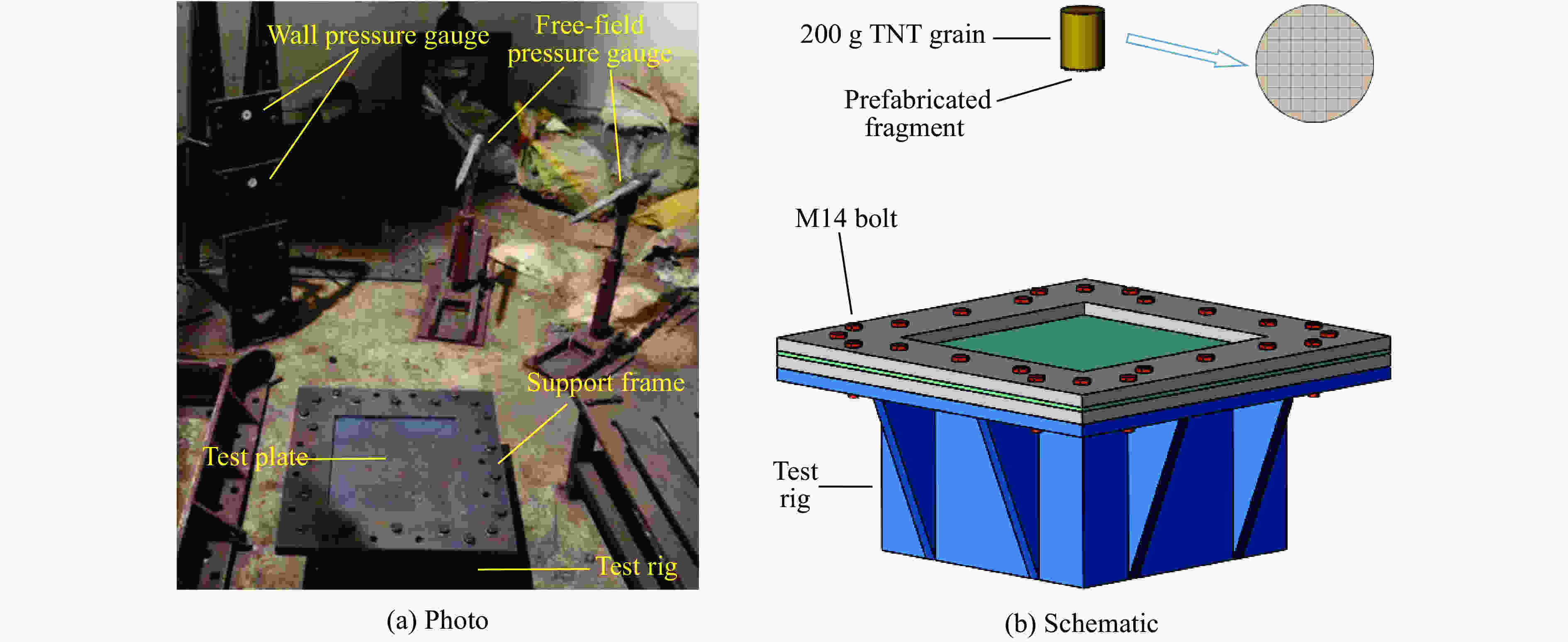

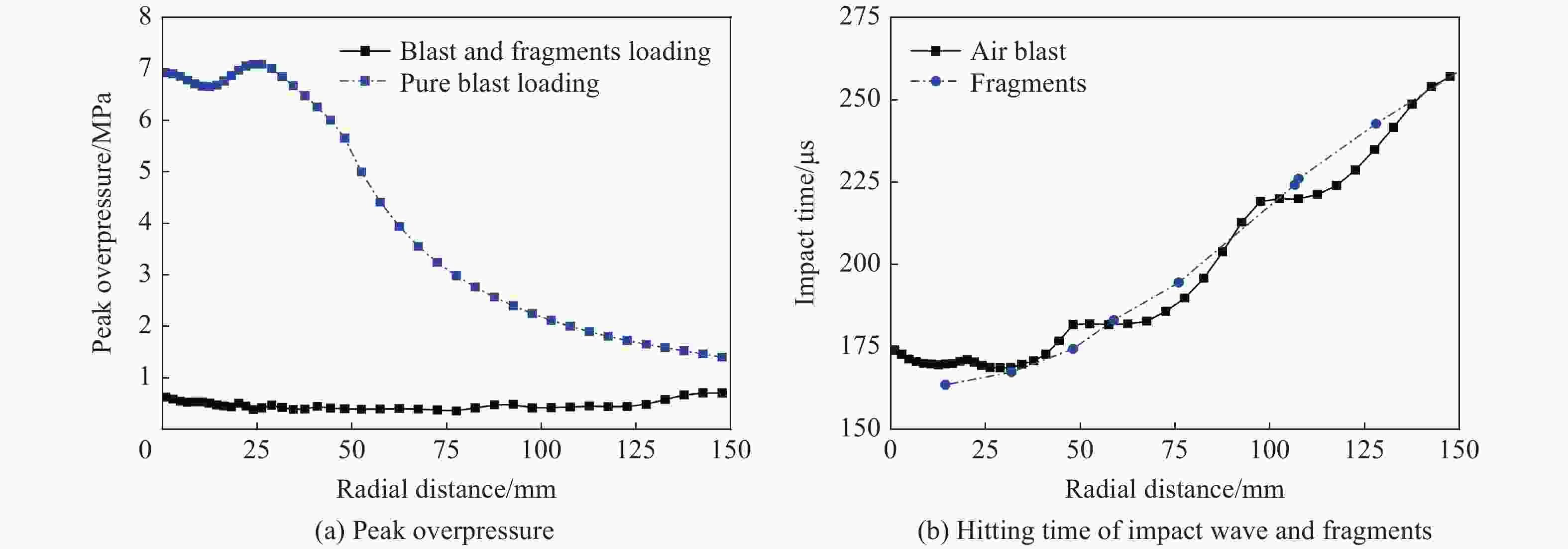

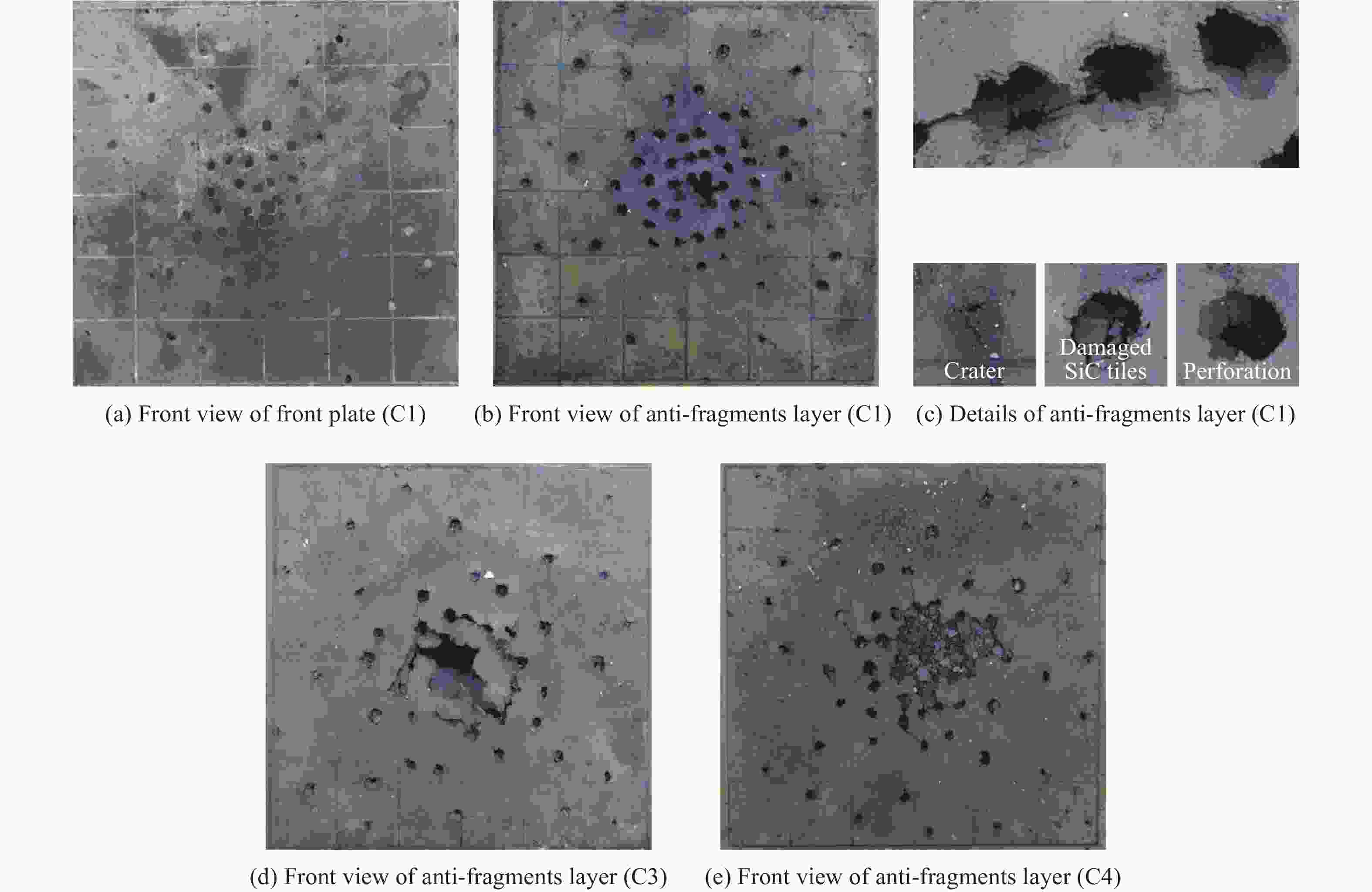

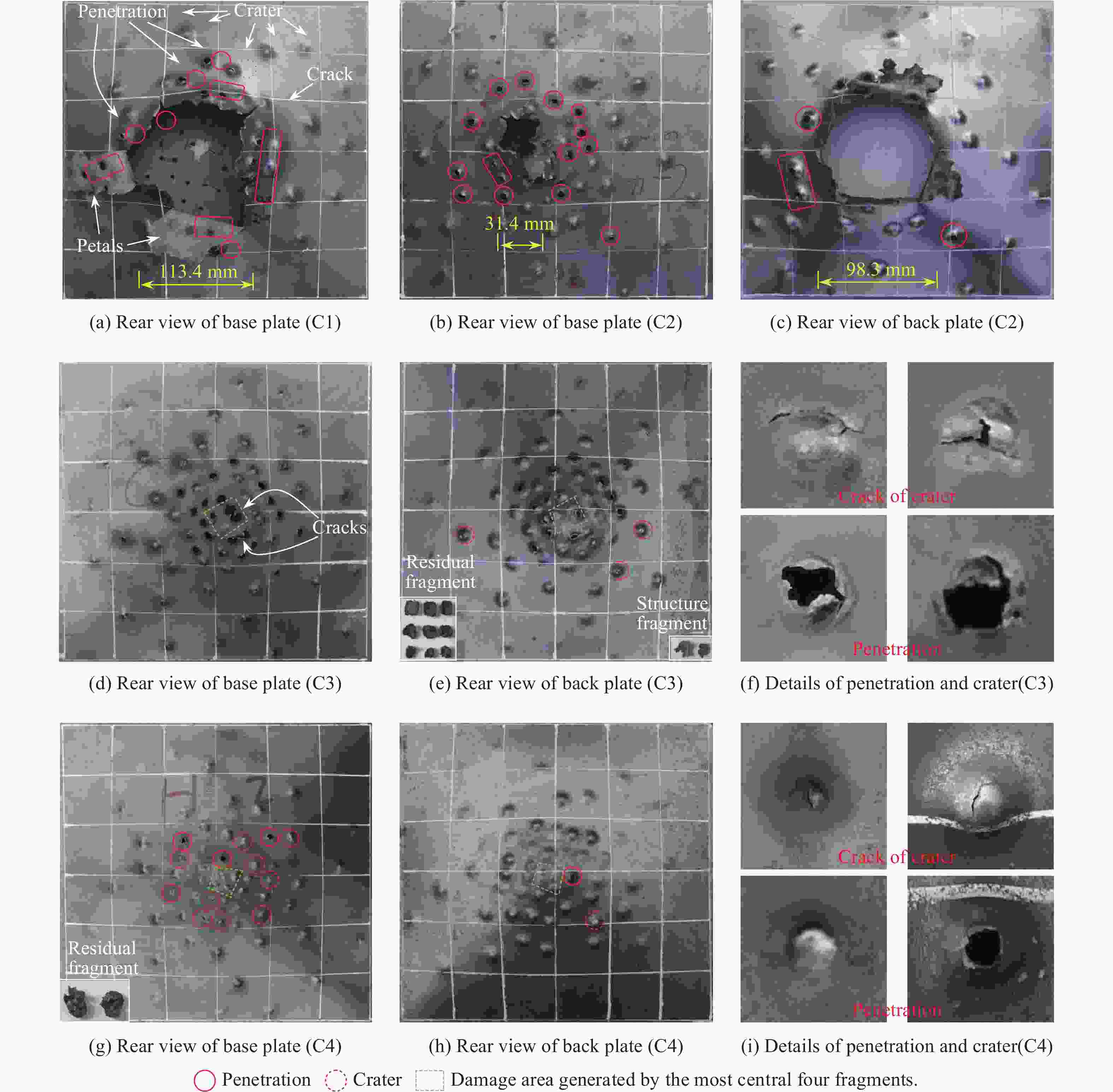

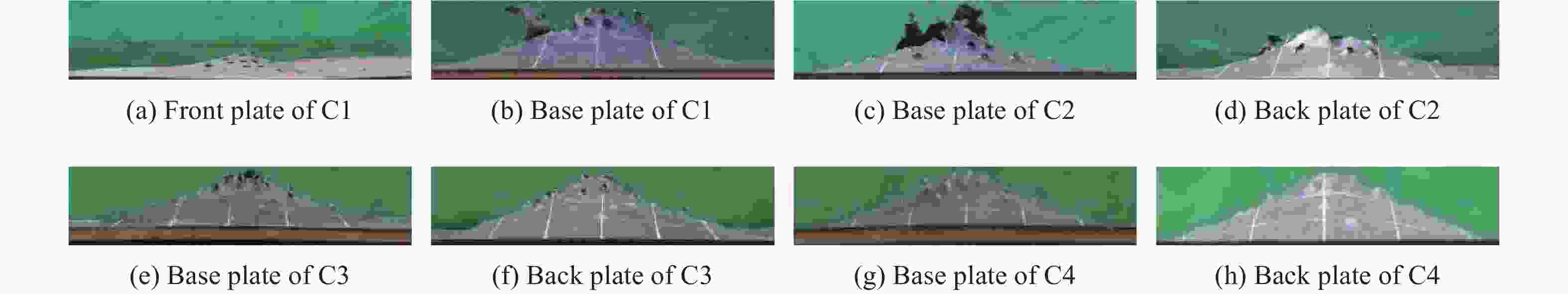

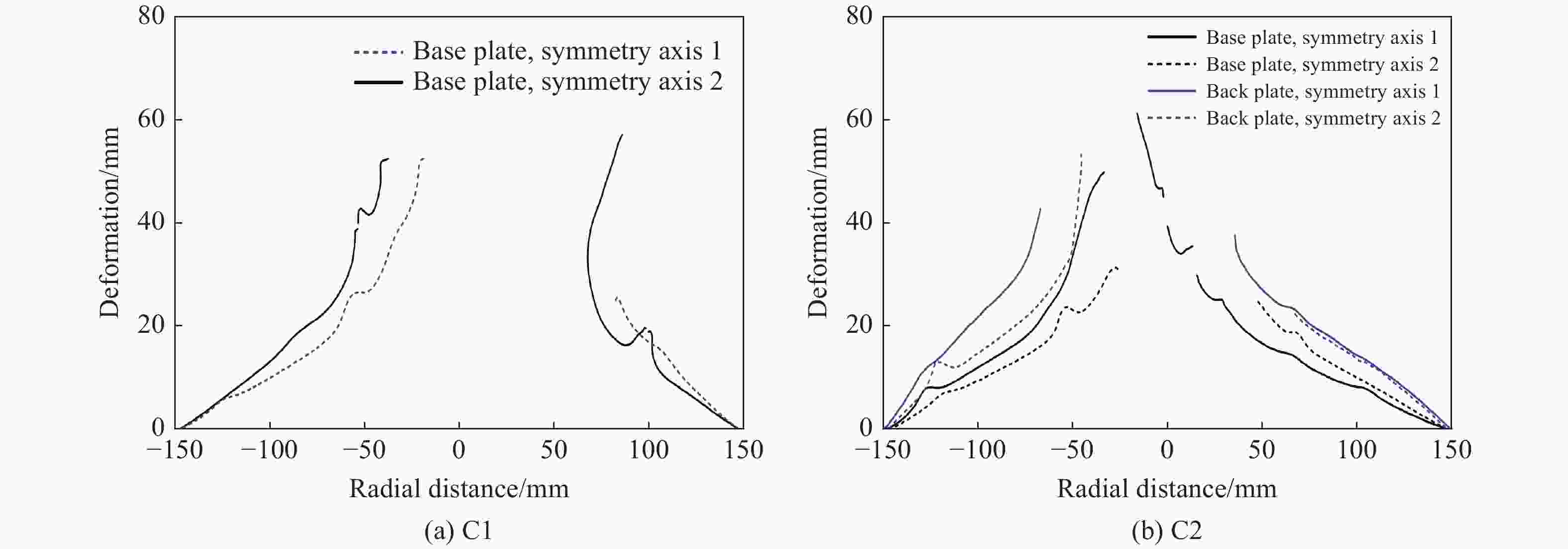

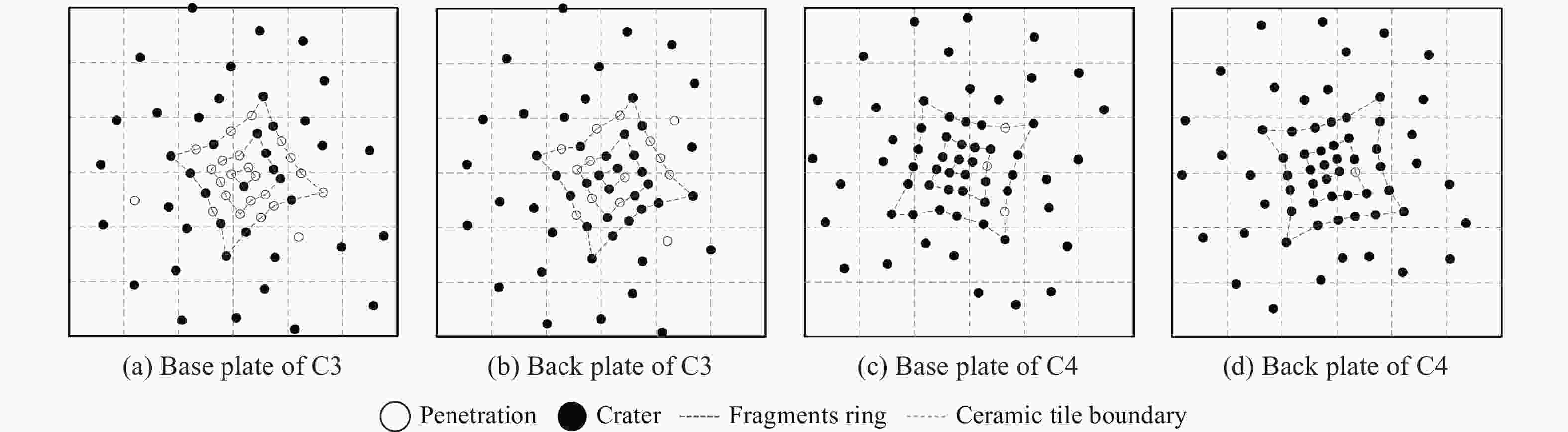

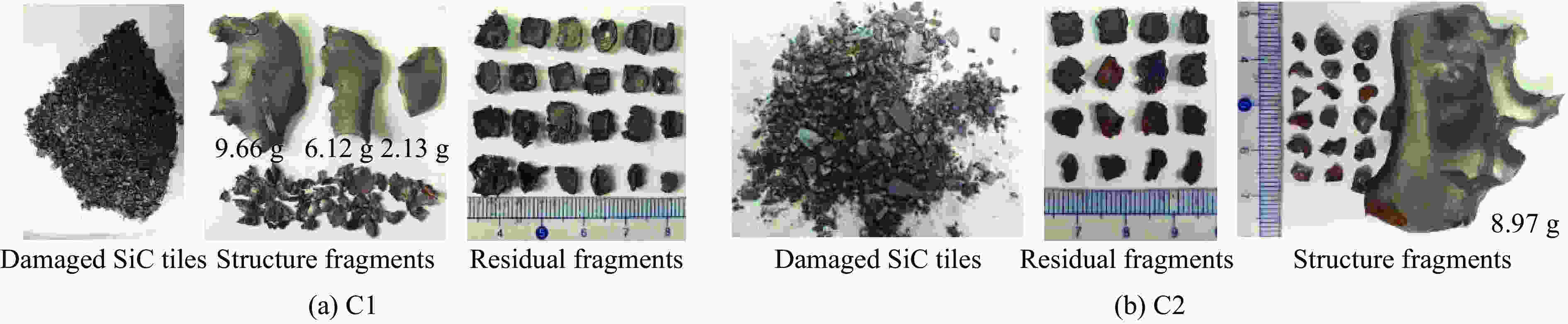

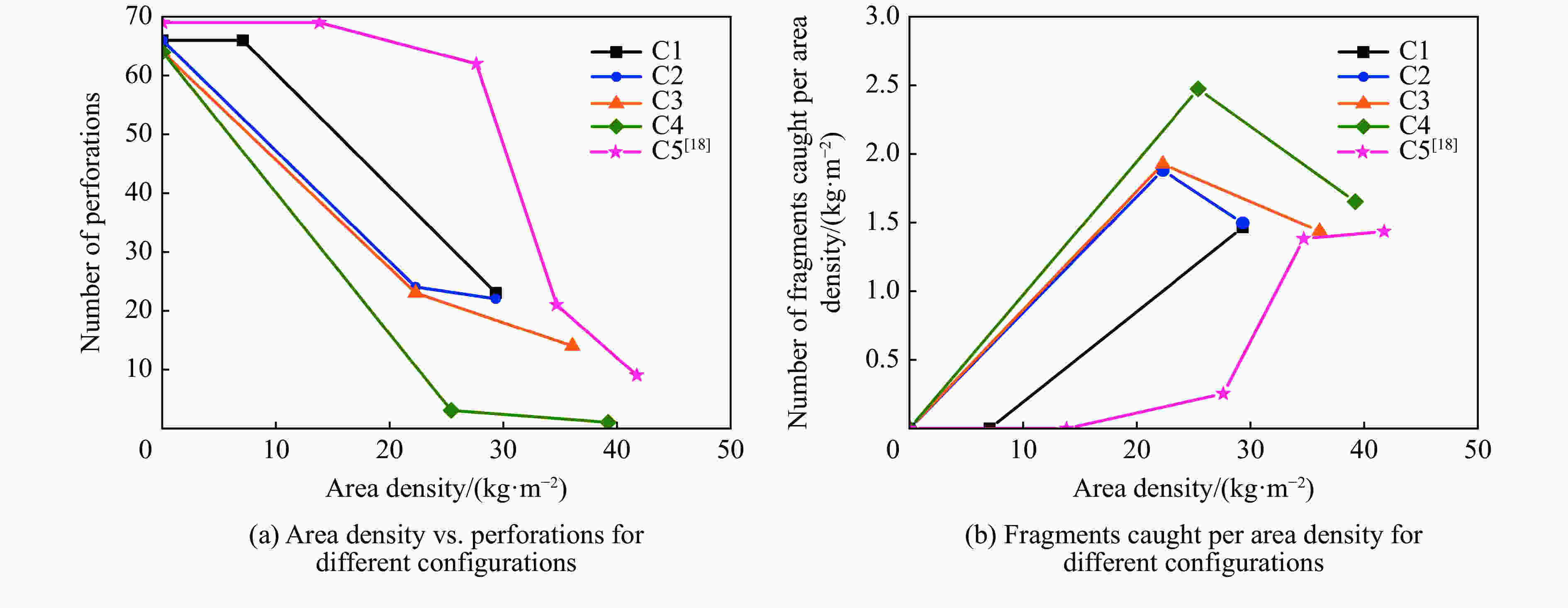

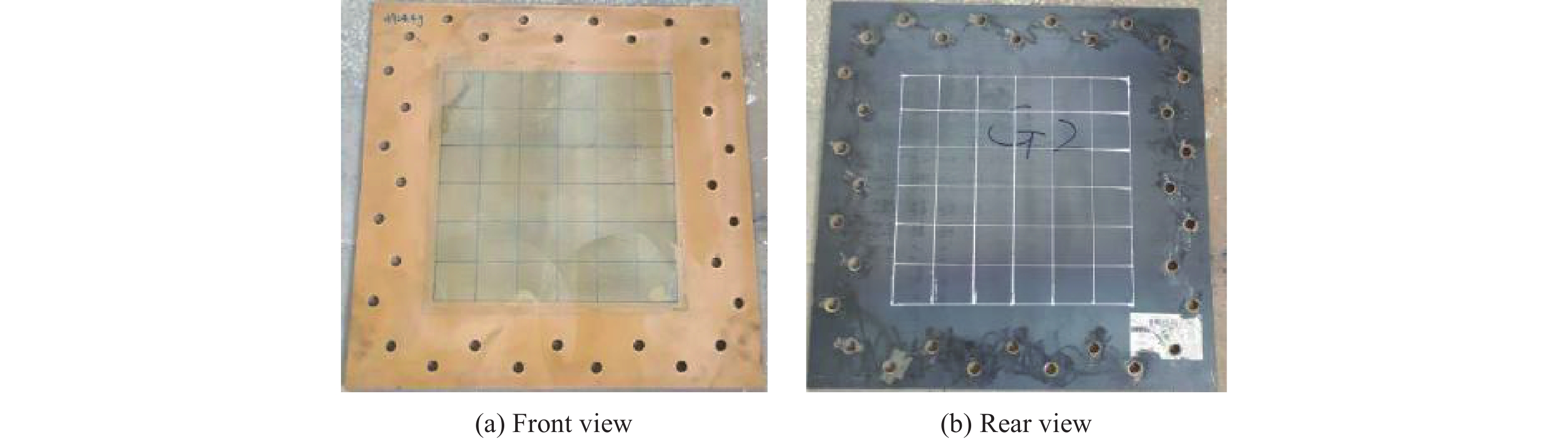

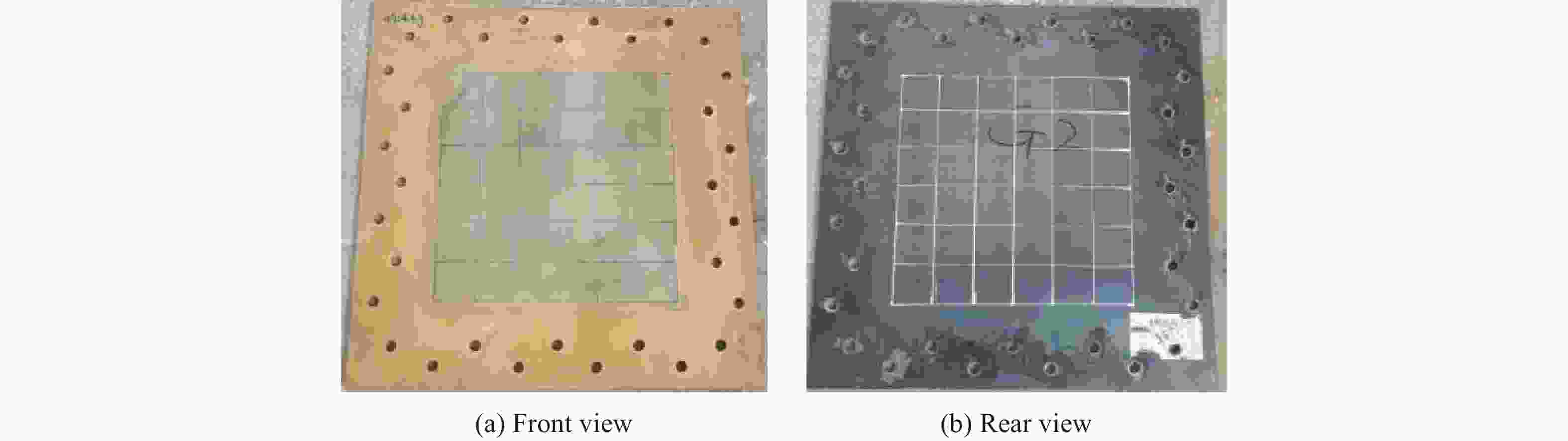

摘要: 基于均质钢板、聚脲涂层材料、SiC陶瓷材料设计了4种聚脲涂覆复合装甲结构,采用装药驱动预制破片试验方法开展了近炸下复合装甲结构毁伤特性实验研究,提出了各组分的毁伤破坏模式,对比分析了4种防护装甲结构的防护性能,探讨了复合装甲结构的防护机理。结果表明:作用于目标结构的破片动能远大于冲击波能,聚脲涂覆复合装甲结构的防护效能明显优于多层均质钢装甲,增加陶瓷厚度较增加背板、前面板厚度对提高整体防护效能更有效,破片撞击将引起陶瓷块大面积损伤,严重影响了其对后续着靶破片的防护性能。Abstract: Four types of polyurea coated composite armor structures were designed based on steel plates, SiC ceramic tiles and polyurea coatings. The near-field explosion damage characteristics of the composite armor structures were experimentally studied using the method of charge driven prefabricated fragments. The failure modes of the components of the armor structures were proposed, the protection performances of the armor structures were comparatively analyzed and the protection mechanisms were investigated. The experimental results indicate that the impact energy acted on the structures by the prefabricated fragments is far greater than that of the blast wave. The protection performances of the polyurea coated composite armor structures are much better than those of the multi-layer steel structures. Increasing the thickness of ceramic tiles can enhance the protection performance more efficiently than increasing the thickness of the front plate or back plate. Under the impact of fragment cluster, ceramic tiles are damaged on a large scale, and the anti-penetration capability against subsequent hitting fragments will be severely weakened.

-

Key words:

- combined damage /

- SiC ceramic /

- polyurea coating /

- composite armor

-

表 1 模型结构组成

Table 1. Structures of experimental models

编号 结构组成 面密度ρA /(kg·m−2) C1 1S+1PU+2SiC+1PU+2S:1 mm前面板+1 mm止裂层+2 mm 陶瓷层+1 mm缓冲层+2 mm基板 29.34 C2 1PU+2SiC+1PU+2S+1S:1 mm止裂层+2 mm 陶瓷层+1 mm缓冲层+2 mm基板+1 mm背板 29.34 C3 1PU+2SiC+1PU+2S+2S:1 mm止裂层+2 mm 陶瓷层+1 mm缓冲层+2 mm基板+2 mm背板 36.09 C4 1PU+3SiC+1PU+2S+2S:1 mm止裂层+3 mm 陶瓷层+1 mm缓冲层+2 mm基板+2 mm背板 39.24 注:名义厚度为1、2 mm的均质钢板,实测厚度分别为0.90、1.76 mm;聚脲止裂层、聚脲缓冲层的名义涂覆厚度均为1 mm;SiC陶瓷层名义厚度为2 mm或3 mm(与实测值相当)。 表 2 各模型各组分穿孔及弹坑统计结果

Table 2. A comparison of perforation and crates on each steel plate of different models

模型 前面板 抗弹层基板 背板 1S+1PU+2SiC+1PU+2S 66个穿孔 ≥23个穿孔,≤43个弹坑 1PU+2SiC+1PU+2S+1S 24个穿孔,42个弹坑 22个穿孔,44个弹坑 1PU+2SiC+1PU+2S+2S 23个穿孔,41个弹坑

(破片环1~3分别有3、8、10个穿孔)14个穿孔,50个弹坑

(破片环1~3分别有1、4、7个穿孔)1PU+3SiC+1PU+2S+2S 3个穿孔,61个弹坑

(破片环1~3分别有0、1、2个穿孔)1个穿孔,63个弹坑

(破片环1~3分别有0、1、0个穿孔) -

[1] 孙业斌. 爆炸作用与装药设计[M]. 北京: 国防工业出版社, 1987. [2] 李伟, 朱锡, 梅志远, 等. 战斗部舱内爆炸对舱室结构毁伤的实验研究 [J]. 舰船科学技术, 2009, 31(3): 34–37. DOI: 10.3404/j.issn.1672-7649.2009.03.005.LI W, ZHU X, MEI Z Y, et al. Experimental studies on damage effect of missile warhead on cabin’s structure under internal explosion [J]. Ship Science and Technology, 2009, 31(3): 34–37. DOI: 10.3404/j.issn.1672-7649.2009.03.005. [3] 陈长海, 侯海量, 朱锡, 等. 破片式战斗部空中爆炸下冲击波与破片的耦合作用 [J]. 高压物理学报, 2018, 32(1): 015104. DOI: 10.11858/gywlxb.20170849.CHEN C H, HOU H L, ZHU X, et al. Coupling action spans for air-blast waves and fragments by fragmentation warheads exploding in air [J]. Chinese Journal of High Pressure Physics, 2018, 32(1): 015104. DOI: 10.11858/gywlxb.20170849. [4] QIAN L, QU M. Study on terminal effects of dense fragment cluster impact on armor plate. Part II: numerical simulations [J]. International Journal of Impact Engineering, 2005, 31(6): 769–780. DOI: 10.1016/j.ijimpeng.2004.03.015. [5] 吴震, 金湖庭, 杜志鹏, 等. 破片与冲击波对舰船板架的耦合毁伤效应试验研究 [J]. 船舶力学, 2019, 23(2): 211–217. DOI: 10.3969/j.issn.1007-7294.2019.02.010.WU Z, JIN H T, DU Z P, et al. Experimental studies of ship stiffened plates under the synergistic effects of fragments and shock wave [J]. Journal of Ship Mechanics, 2019, 23(2): 211–217. DOI: 10.3969/j.issn.1007-7294.2019.02.010. [6] KONG X S, WU W G, LI J, et al. Experimental and numerical investigation on a multi-layer protective structure under the synergistic effect of blast and fragment loadings [J]. International Journal of Impact Engineering, 2014, 65: 146–162. DOI: 10.1016/j.ijimpeng.2013.11.009. [7] 李茂, 朱锡, 侯海量, 等. 冲击波和高速破片对固支方板的联合作用数值模拟 [J]. 中国舰船研究, 2015, 10(6): 60–67. DOI: 10.3969/j.issn.1673-3185.2015.06.009.LI M, ZHU X, HOU H L, et al. Numerical simulation of steel plates subjected to the impact of both impact waves and fragments [J]. Chinese Journal of Ship Research, 2015, 10(6): 60–67. DOI: 10.3969/j.issn.1673-3185.2015.06.009. [8] ZHANG C Z, CHENG Y S, ZHANG P, et al. Numerical investigation of the response of I-core sandwich panels subjected to combined blast and fragment loading [J]. Engineering Structures, 2017, 151: 459–471. DOI: 10.1016/j.engstruct.2017.08.039. [9] 董永香, 冯顺山, 李学林. 爆炸波在硬-软-硬三明治介质中传播特性的数值分析 [J]. 弹道力学, 2007, 19(1): 59–63. DOI: 10.3969/j.issn.1004-499X.2007.01.017.DONG Y X, FENG S S, LI X L. Numerical analysis of propagation characteristics of explosive wave in the hard-soft-hard sandwich media [J]. Journal of Ballistics, 2007, 19(1): 59–63. DOI: 10.3969/j.issn.1004-499X.2007.01.017. [10] 张成亮, 朱锡, 侯海量, 等. 爆炸冲击波与高速破片对夹层结构的联合毁伤效应试验研究 [J]. 振动与冲击, 2014, 33(15): 184–188. DOI: 10.13465/j.cnki.jvs.2014.15.032.ZHANG C L, ZHU X, HOU H L, et al. Tests for combined damage effect of blast waves and high-velocity fragments on composite sandwich plates [J]. Journal of Vibration and Shock, 2014, 33(15): 184–188. DOI: 10.13465/j.cnki.jvs.2014.15.032. [11] LI D, HOU H L, CHEN C H, et al. Experimental study on the combined damage of multi-layered composite structures subjected to close-range explosion of simulated warheads [J]. International Journal of Impact Engineering, 2018, 114: 133–146. DOI: 10.1016/j.ijimpeng.2017.12.007. [12] 侯海量, 张成亮, 李茂, 等. 冲击波和高速破片联合作用下夹芯复合舱壁结构的毁伤特性 [J]. 爆炸与冲击, 2015, 35(1): 116–123. DOI: 10.11883/1001-1455(2015)01-0116-08.HOU H L, ZHANG C L, LI M, et al. Damage characteristics of sandwich bulkhead under the impact of shock and high-velocity fragments [J]. Explosion and Shock Waves, 2015, 35(1): 116–123. DOI: 10.11883/1001-1455(2015)01-0116-08. [13] 郑盼, 朱锡, 李永清. SiO2气凝胶毡-陶瓷棉-高强聚乙烯多层复合抗弹结构隔热性能试验 [J]. 中国舰船研究, 2016, 11(5): 78–83, 99. DOI: 10.3969/j.issn.1673-3185.2016.05.012.ZHENG P, ZHU X, LI Y Q. Experiment on the thermal insulation performance of multi-layer composite ballistic structures by silicate aero-gel/ceramic/high-strength polyethylene [J]. Chinese Journal of Ship Research, 2016, 11(5): 78–83, 99. DOI: 10.3969/j.issn.1673-3185.2016.05.012. [14] 韩辉, 李军, 焦丽娟, 等. 陶瓷-金属复合材料在防弹领域的应用研究 [J]. 材料导报, 2007, 21(2): 34–37. DOI: 10.3321/j.issn:1005-023X.2007.02.009.HAN H, LI J, JIAO L J, et al. Study on the application of ceramic-metal composite materials in bulletproof field [J]. Materials Review, 2007, 21(2): 34–37. DOI: 10.3321/j.issn:1005-023X.2007.02.009. [15] CHATTOPADHYAY D K, RAJU K V S N. Structural engineering of polyurethane coatings for high performance applications [J]. Progress in Polymer Science, 2007, 32(3): 352–418. DOI: 10.1016/j.progpolymsci.2006.05.003. [16] 李茂, 侯海量, 朱锡, 等. 模拟破片杀伤战斗部空爆冲击波与高速破片群联合作用的等效试验方法 [J]. 振动与冲击, 2020, 39(1): 184–190. DOI: 10.13465/j.cnki.jvs.2020.01.025.LI M, HOU H L, ZHU X, et al. Equivalent test method to simulate combined damage action of air blast shock wave and high speed fragment group of fragment killing warhead [J]. Journal of Vibration and Shock, 2020, 39(1): 184–190. DOI: 10.13465/j.cnki.jvs.2020.01.025. [17] 高照, 李永清, 侯海量, 等. 聚脲涂层复合结构抗侵彻机理实验研究 [J]. 高压物理学报, 2019, 33(2): 025102. DOI: 10.11858/gywlxb.20180619.GAO Z, LI Y Q, HOU H L, et al. Penetration mechanism of polyurea coating composite structure [J]. Chinese Journal of High Pressure Physics, 2019, 33(2): 025102. DOI: 10.11858/gywlxb.20180619. [18] 郑红伟. 空爆冲击波与高速破片的相互作用机制及载荷特性研究 [D]. 武汉: 海军工程大学, 2018. -

下载:

下载: