Dynamic responses of a concrete pipeline with bell-and-spigot joints buried in a silty clay layer to blasting seismic waves

-

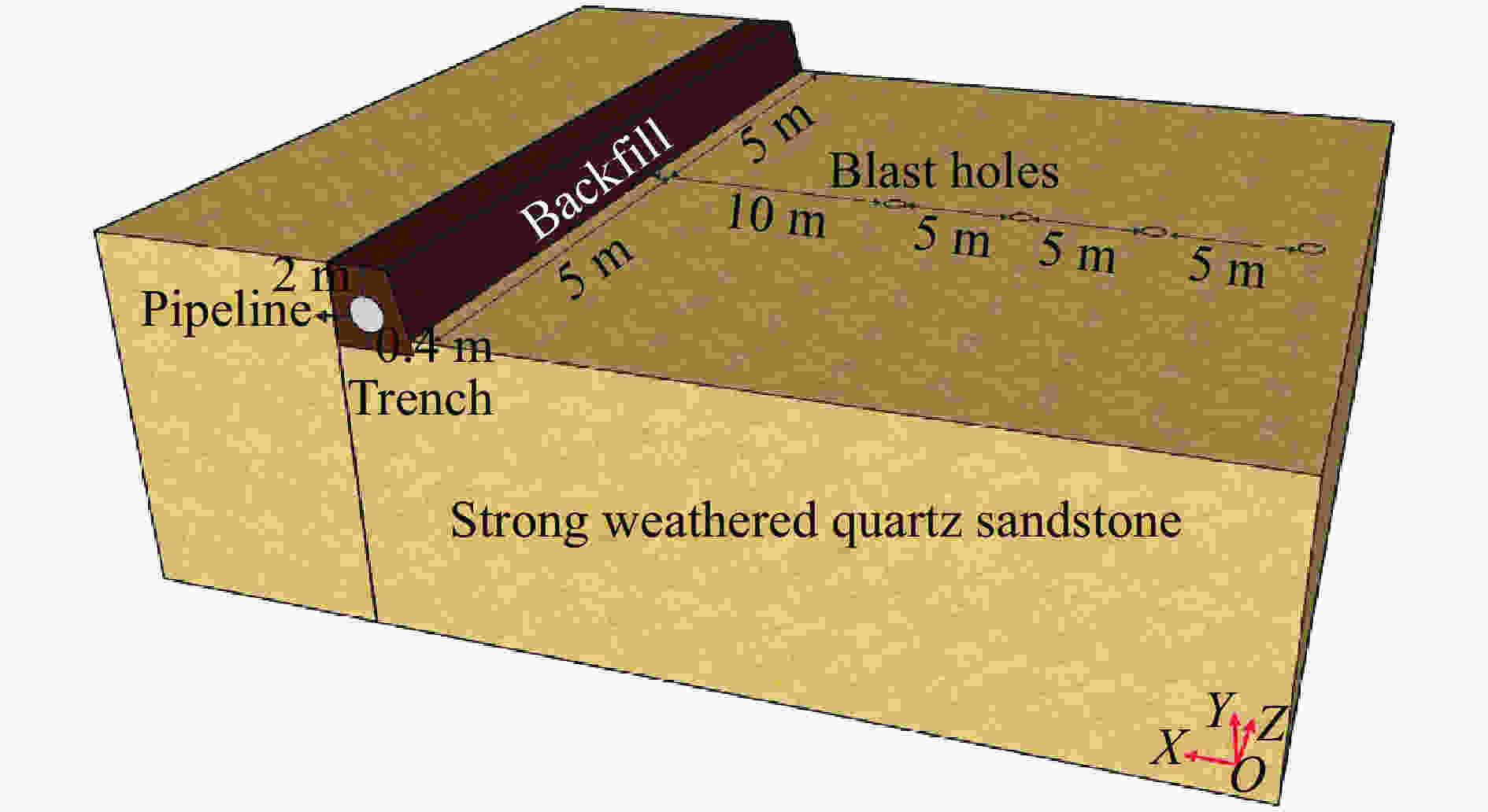

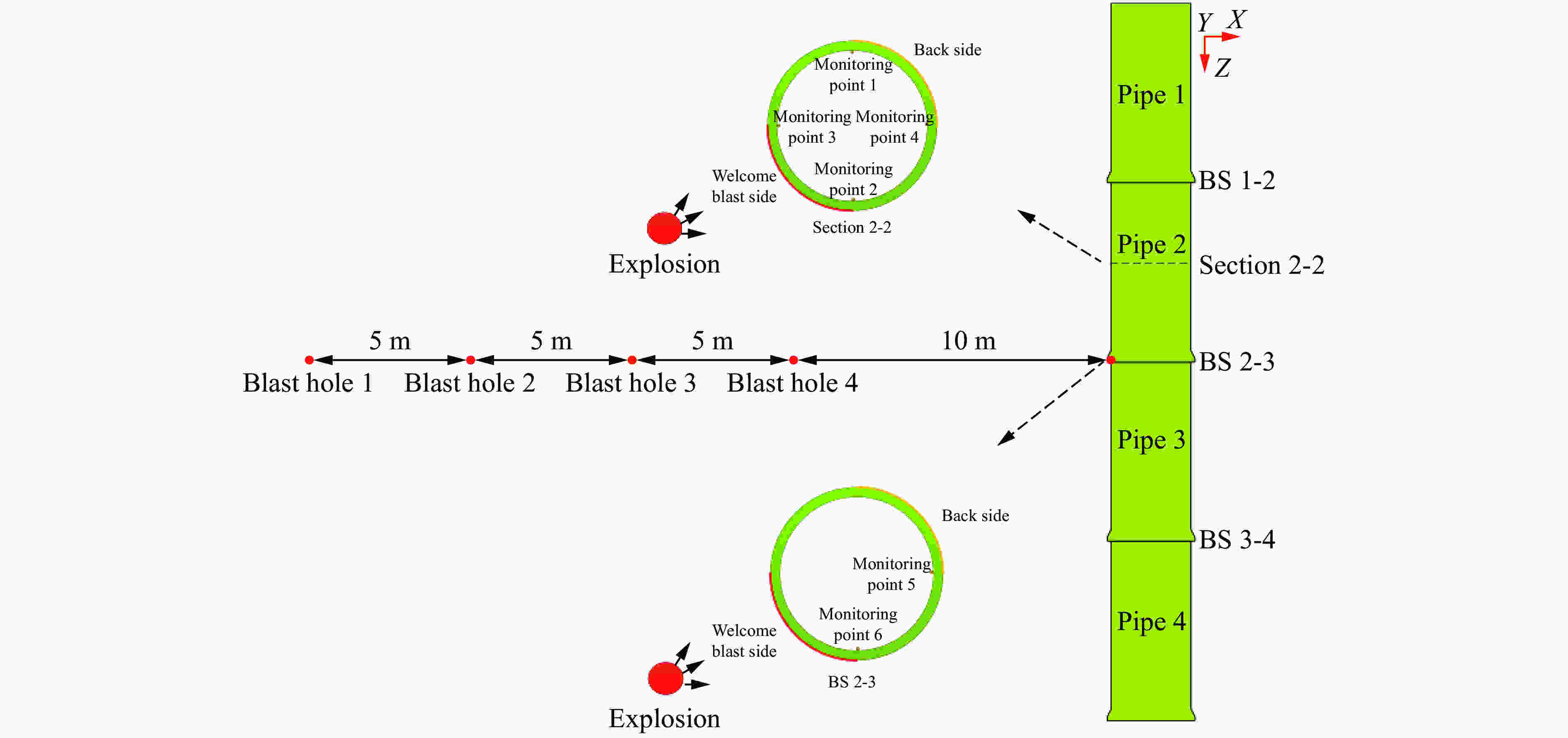

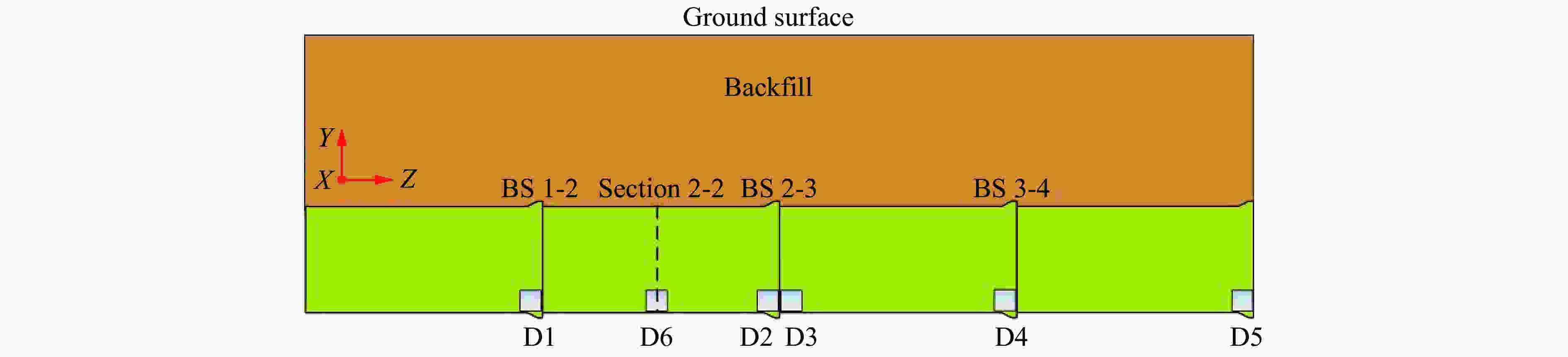

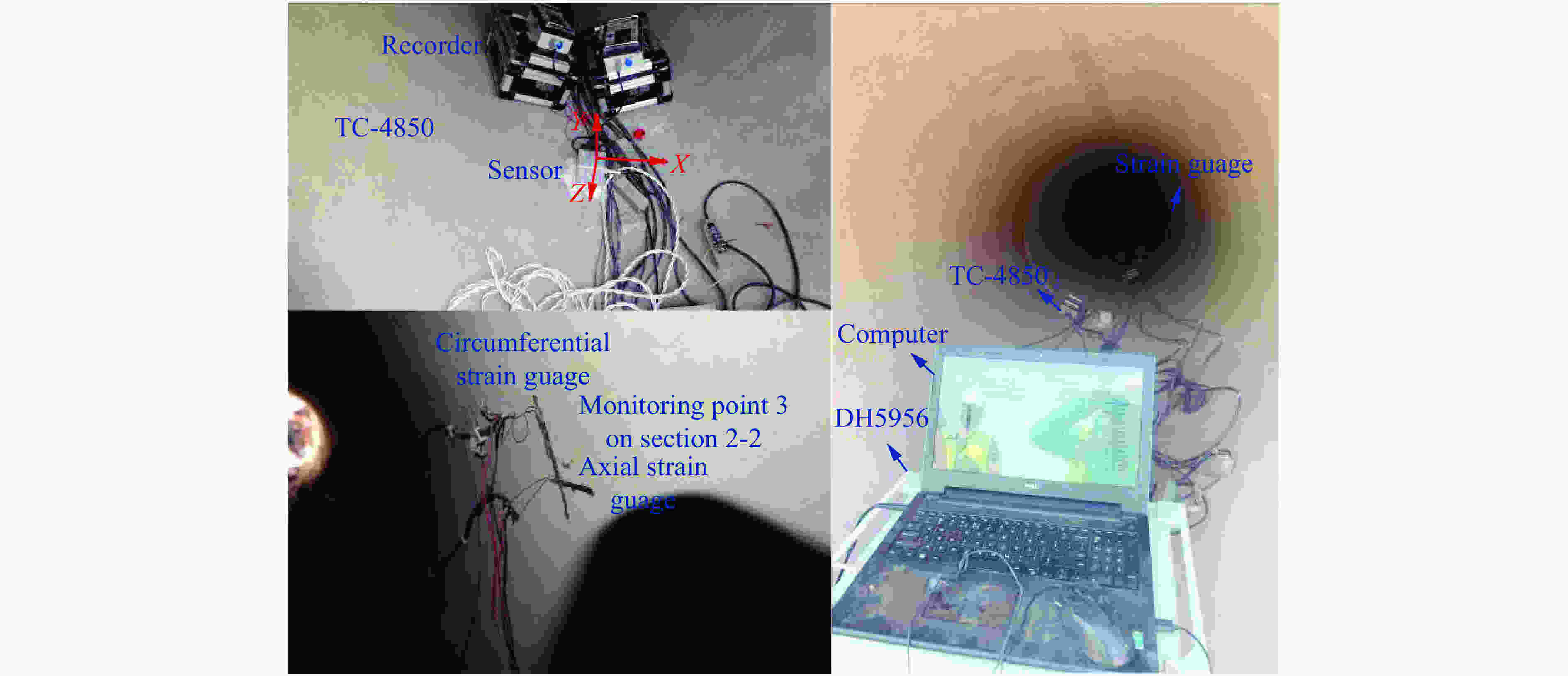

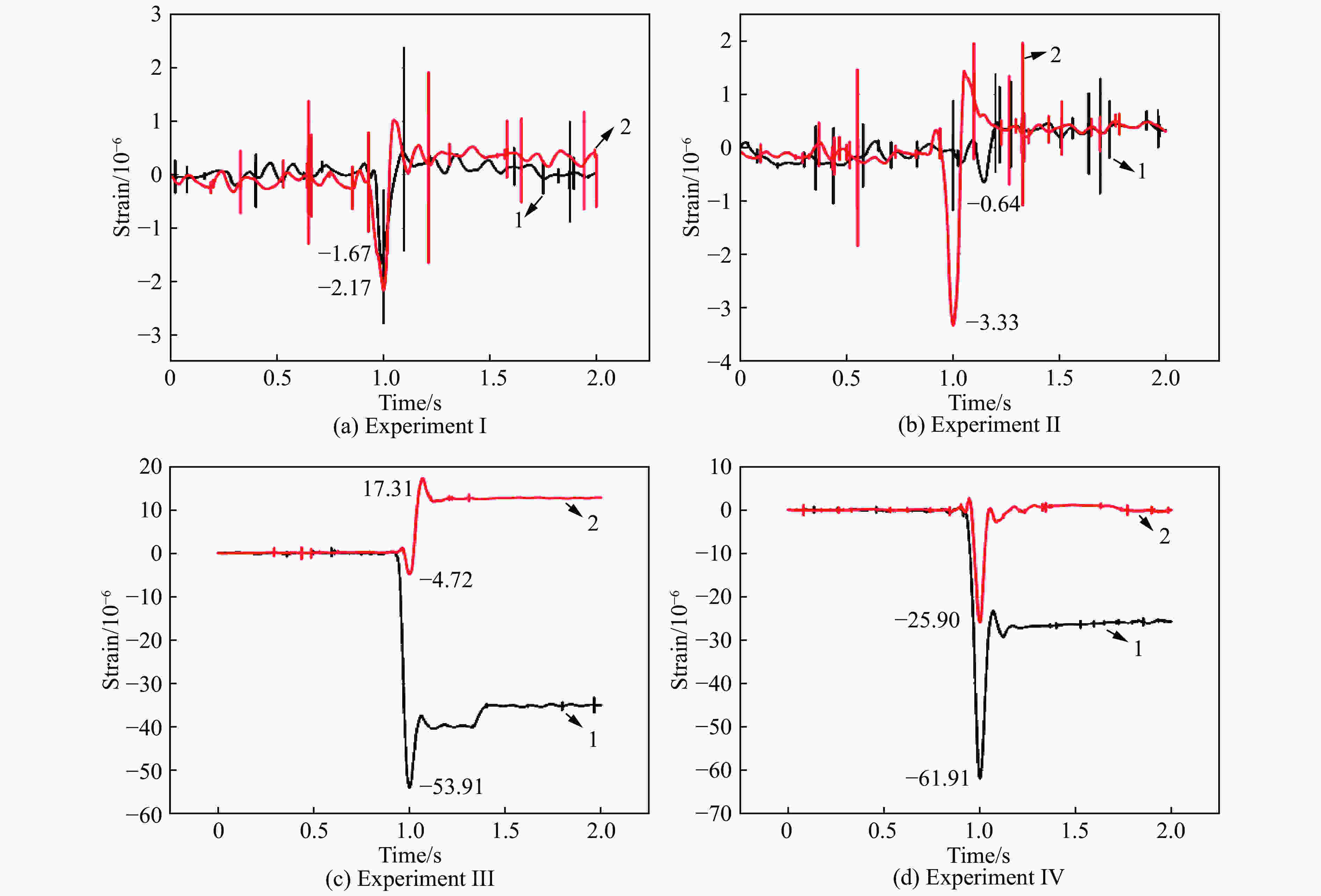

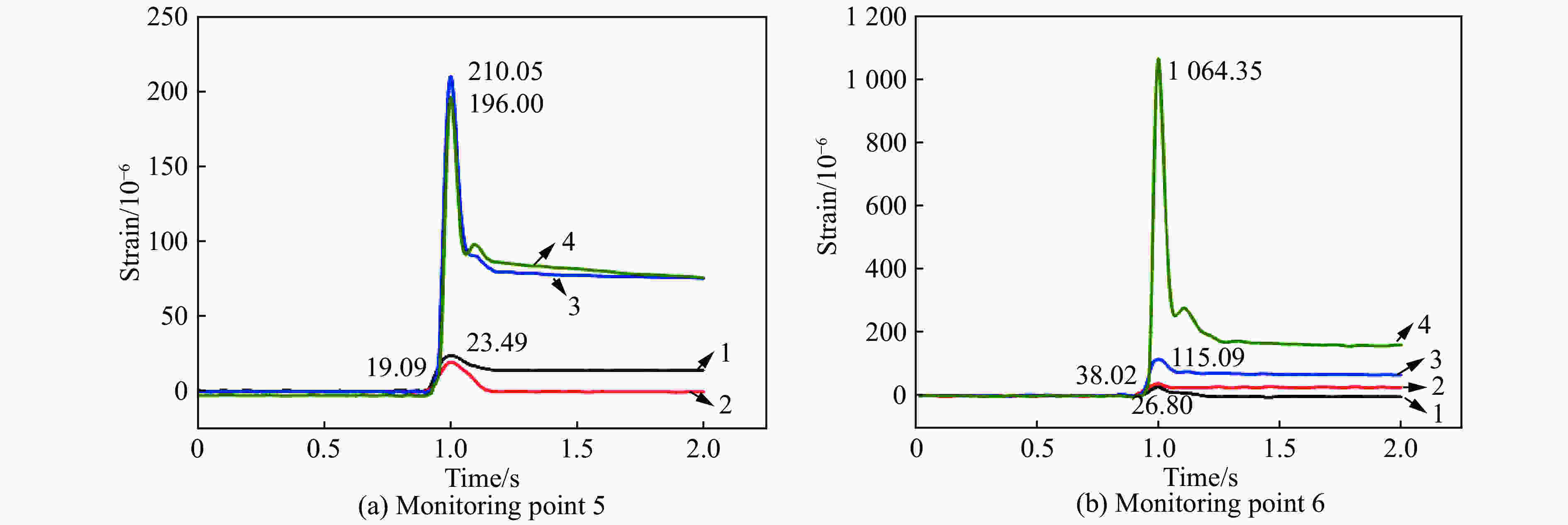

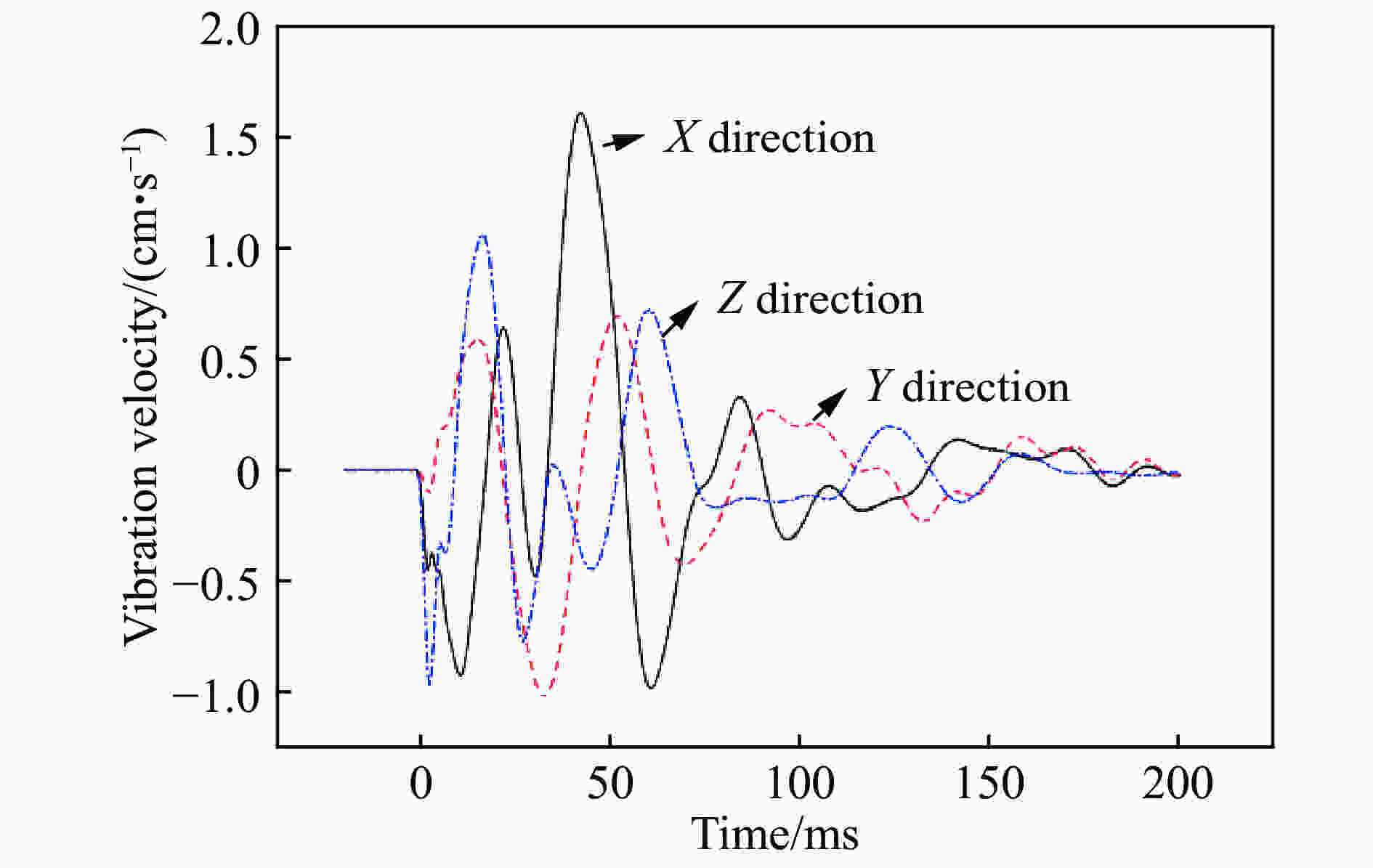

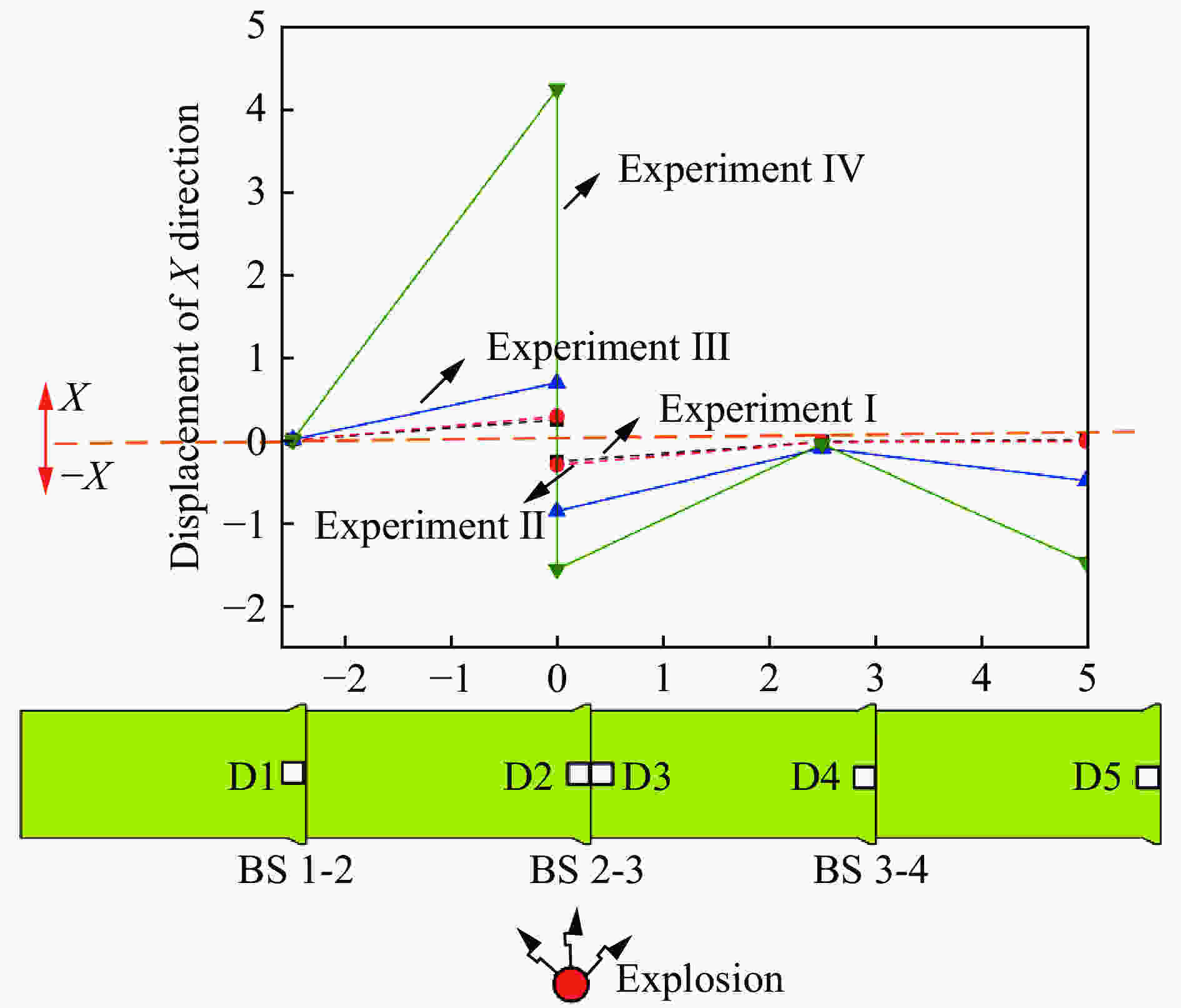

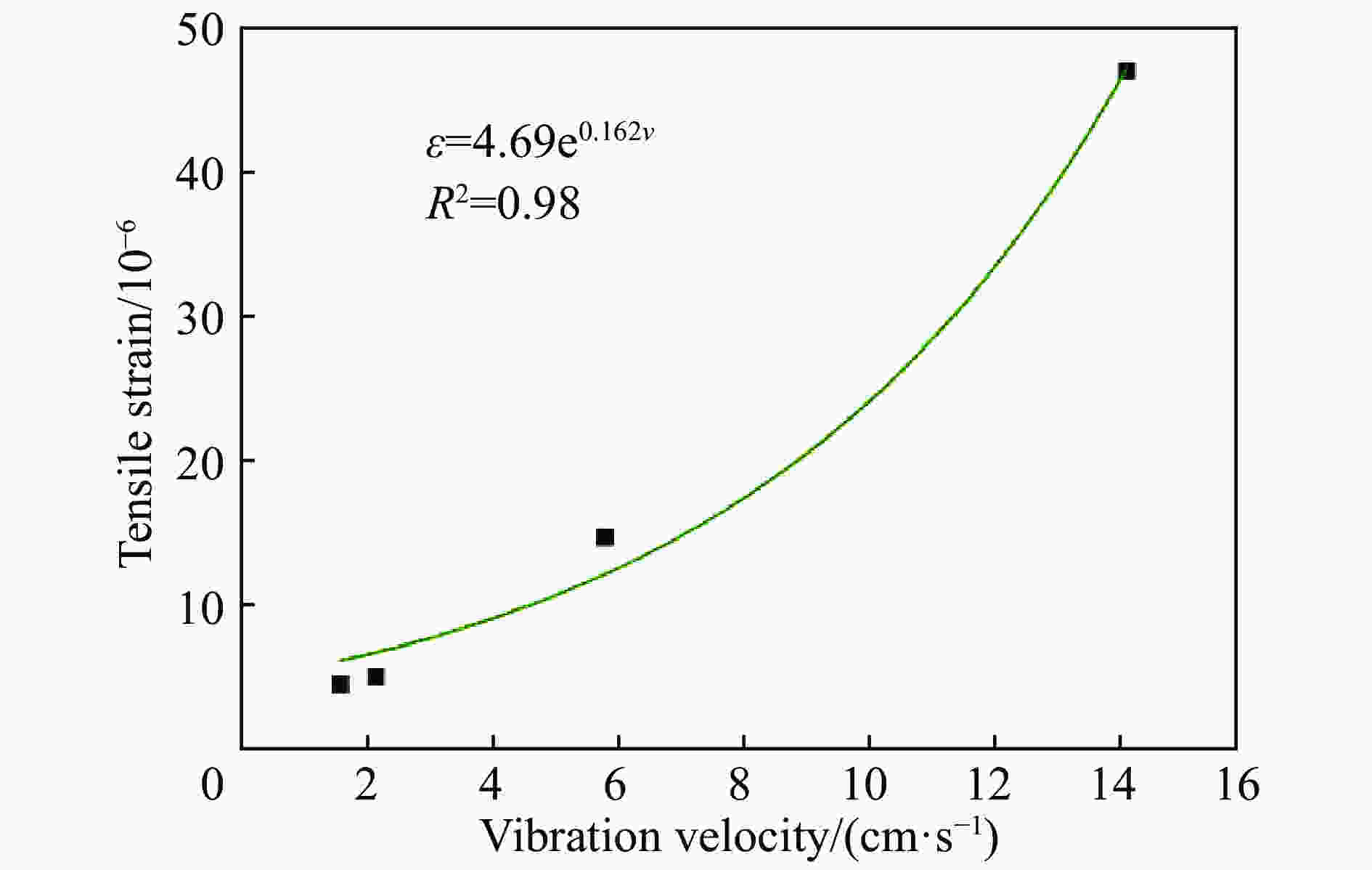

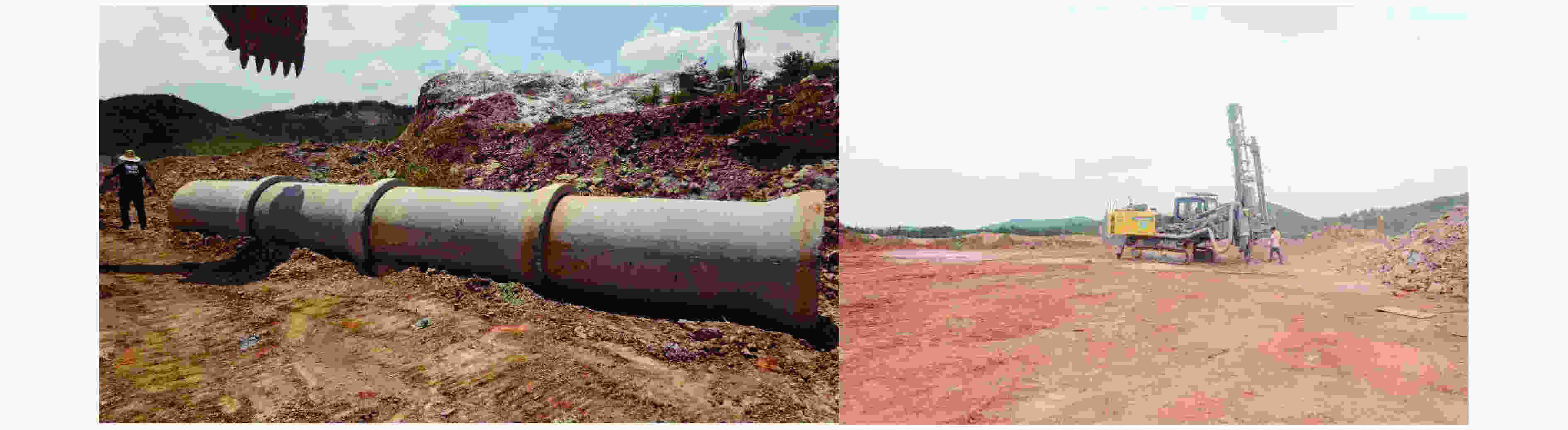

摘要: 为合理评价临近爆破施工振动作用对预埋在粉质黏土层承插式混凝土管道的影响,通过现场预埋多管节全尺寸管道的爆破试验,结合DH5956动态应变及TC-4850爆破振动等测试系统,研究了爆破振动作用下承插式混凝土管道动力响应特征,分析了管道管身及承插口动应变及振动速度空间分布规律;基于承插口允许转角规范及管身动态拉应变破坏准则,提出了承插式混凝土管道爆破振动速度安全判据。研究结果表明:爆破振动作用下管道管身及承插口之间存在不协调响应特征;爆破振动作用下管道承插口为管道最薄弱位置,爆破振动对承插式混凝土管道的影响应重点考虑承插口的失效;承插式混凝土管道爆破振动速度控制阈值为5 cm/s,结果可对类似地层中承插式埋地混凝土管道的保护起指导作用。Abstract: In order to evaluate the effect of blasting vibration on an adjacent concrete pipeline with bell-and-spigot joints buried in a silty clay layer, four blasting field experiments were conducted by applying the DH5956 dynamic strain testing system and TC-4850 blasting vibration device mounted on the buried pipelines, and the dynamic response characteristics of the concrete pipelines under blasting vibration were studied. The spatial distributions of the dynamic strain and vibration velocity of the pipe bodies and the bell-and-spigot joints were analyzed. Based on the maximum allowable deflection degree of the bell-and-spigot joints in the specification and the criterion of the dynamic tensile stress failure of the concrete, the safety criterion of the blasting vibration velocity for the bell-and-spigot concrete pipelines was proposed. The results show that there is an uncoordinated response between the pipe bodies and bell-and-spigot joints under the action of blasting vibration; the bell-and-spigot joints are the most venerable positions of the pipelines, and the failure of the the bell-and-spigot joints should be noticed when considering the effect of blasting vibration; the blasting vibration velocity control threshold of the the bell-and-spigot concrete pipelines is 5 cm/s, this research can provide a guidance for the pipeline protection in similar construction projects.

-

表 1 现场爆破试验参数

Table 1. Parameters for field blasting experiments

试验 炮孔深度H/m 炸药质量Q/kg 爆心距R/m Ⅰ 4 8 25 Ⅱ 4 8 20 Ⅲ 4 8 15 Ⅳ 4 8 10 表 2 4次爆破振动速度数据

Table 2. Vibration velocity data in four experiments

试验 爆破振动监测点 爆破振动速度/(cm·s−1) 试验 爆破振动监测点 爆破振动速度/(cm·s−1) X方向 Y方向 Z方向 X方向 Y方向 Z方向 Ⅰ D1 1.15 0.85 0.73 Ⅲ D1 3.56 2.62 1.35 D2 1.59 0.98 0.68 D2 5.85 2.36 1.89 D3 1.61 1.06 1.02 D3 5.82 3.60 2.42 D4 1.26 1.06 1.08 D4 4.23 2.83 1.94 D5 0.81 0.56 0.72 D5 3.23 2.56 2.84 D6 1.43 0.92 0.78 D6 5.02 2.57 1.72 Ⅱ D1 1.58 0.93 1.07 Ⅳ D1 9.12 6.44 2.28 D2 2.16 1.32 1.12 D2 14.25 8.56 4.02 D3 2.29 0.94 0.56 D3 14.46 7.53 3.19 D4 1.65 1.21 0.61 D4 9.81 5.66 2.21 D5 0.77 0.56 0.76 D5 9.02 3.12 2.56 D6 1.89 1.13 1.02 D6 12.56 7.95 3.64 表 3 4次试验承插口2-3偏转角度

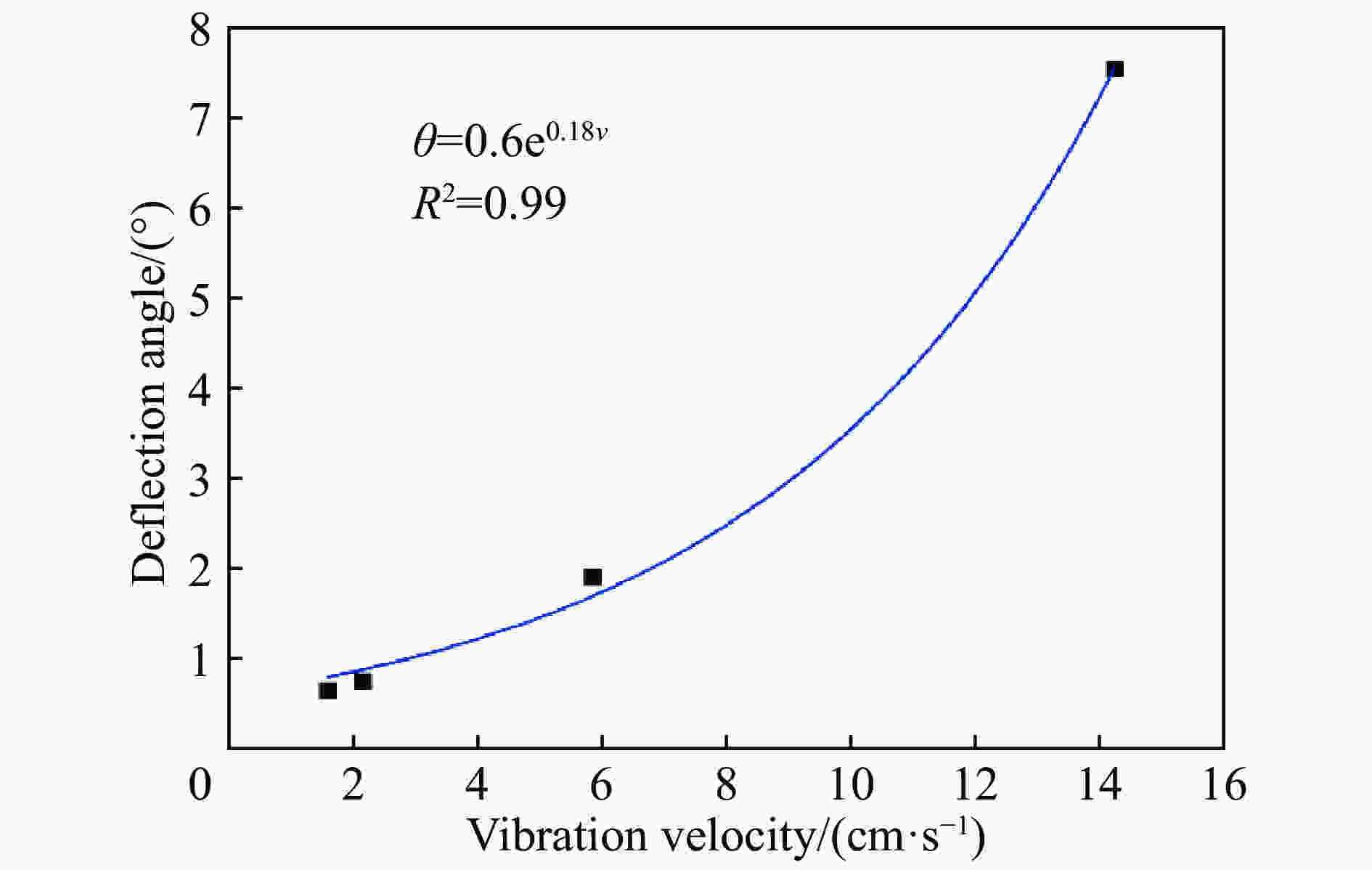

Table 3. Deflection angles of bell-and-spigot joint 2-3 in four experiments

试验 θL/rad θR/rad 总偏转角/rad 总偏转角/(°) Ⅰ 0.005 7 0.005 5 0.011 2 0.64 Ⅱ 0.006 6 0.006 3 0.012 9 0.74 Ⅲ 0.015 8 0.017 3 0.033 1 1.90 Ⅳ 0.097 1 0.034 6 0.131 7 7.55 -

[1] 中华人民共和国国家质量监督检验检疫总局. 爆破安全规程: GB6722−2014 [S]. 北京: 中国标准出版社, 2015. [2] 马维. 地下管道结构爆振效应和冲击破坏行为实验 [J]. 解放军理工大学学报(自然科学版), 2008, 9(1): 39–46. DOI: 10.7666/j.issn.1009-3443.20080109.MA W. Experimental investigation on effects of blast vibration and behaviors of impacting failure of underground pipeline structures [J]. Journal of PLA University of Science and Technology (Natural Science Edition), 2008, 9(1): 39–46. DOI: 10.7666/j.issn.1009-3443.20080109. [3] 刘建民, 陈文涛. 爆炸荷载下埋地管道动力响应分析研究 [J]. 工程爆破, 2008, 14(2): 20–24. DOI: 10.3969/j.issn.1006-7051.2008.02.005.LIU J M, CHEN W T. Dynamic response study of buried pipeline subjected to blast loads [J]. Engineering Blasting, 2008, 14(2): 20–24. DOI: 10.3969/j.issn.1006-7051.2008.02.005. [4] ZHANG J, ZHANG L, LIANG Z. Buckling failure of a buried pipeline subjected to ground explosions [J]. Process Safety and Environmental Protection, 2018, 114: 36–47. DOI: 10.1016/j.psep.2017.11.017. [5] 何忠明, 蔡军, 王利军, 等. 地铁隧道爆破开挖引起地表位移沉降的数值模拟 [J]. 中南大学学报(自然科学版), 2015, 46(9): 3496–3502. DOI: 10.11817/j.issn.1672-7207.2015.09.045.HE Z M, CAI J, WANG L J, et al. Numerical simulation of ground subsidence due to tunnel blasting excavation [J]. Journal of Central South University (Science and Technology), 2015, 46(9): 3496–3502. DOI: 10.11817/j.issn.1672-7207.2015.09.045. [6] 郑爽英, 杨立中. 隧道爆破地震下输气管道动力响应数值试验 [J]. 西南交通大学学报, 2017, 52(2): 264–271. DOI: 10.3969/j.issn.0258-2724.2017.02.008.ZHENG S Y, YANG L Z. Numerical experiments of dynamic response of buried gas pipeline under the action of seismic waves induced by tunnel blasting [J]. Journal of Southwest Jiaotong University, 2017, 52(2): 264–271. DOI: 10.3969/j.issn.0258-2724.2017.02.008. [7] MOKHTARI M, ALAVI NIA A. A parametric study on the mechanical performance of buried X65 steel pipelines under subsurface detonation [J]. Archives of Civil and Mechanical Engineering, 2015, 15(3): 668–679. DOI: 10.1016/j.acme.2014.12.013. [8] SONG K J, LONG Y, JI C, et al. Experimental and numerical studies on the deformation and tearing of X70 pipelines subjected to localized blast loading [J]. Thin-Walled Structures, 2016, 107: 156–168. DOI: 10.1016/j.tws.2016.03.010. [9] JIANG N, GAO T, ZHOU C B, et al. Effect of excavation blasting vibration on adjacent buried gas pipeline in a metro tunnel [J]. Tunneling and Underground Space Technology, 2018, 81: 590–601. DOI: 10.1016/j.tust.2018.08.022. [10] 王海涛, 金慧, 贾金青, 等. 地铁隧道钻爆法施工对邻近埋地管道影响的模型试验研究 [J]. 岩石力学与工程学报, 2018, 37(S1): 3332–3339. DOI: 10.13722/j.cnki.jrme.2016.1409.WANG H T, JIN H, JIA J Q, et al. Model test study on the influence of subway tunnel drilling and blasting method on adjacent buried pipeline [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(S1): 3332–3339. DOI: 10.13722/j.cnki.jrme.2016.1409. [11] 张黎明, 赵明生, 池恩安, 等. 爆破振动对地下管道影响试验及风险预测 [J]. 振动与冲击, 2017, 36(16): 241–247. DOI: 10.13465/j.cnki.jvs.2017.16.038.ZHANG L M, ZHAO M S, CHI E A, et al. Experiments for effect of blasting vibration on underground pipeline and risk prediction [J]. Journal of Vibration and Shock, 2017, 36(16): 241–247. DOI: 10.13465/j.cnki.jvs.2017.16.038. [12] 混凝土和钢筋混凝土排水管: GB/T11836−2009 [S]. [13] 给水排水管道工程施工及验收规范: GB50268−2008 [S]. [14] LUO Q X, BUNGEY J H. Using compression wave ultrasonic transducers to measure the velocity of surface waves and hence determine dynamic modulus of elasticity for concrete [J]. Construction and Building Materials, 1996, 10(4): 237–242. DOI: 10.1016/0950-0618(96)00003-7. [15] WU H, ZHANG Q, HUANG F, et al. Experimental and numerical investigation on the dynamic tensile strength of concrete [J]. International Journal of Impact Engineering, 2005, 32(1-4): 605–617. DOI: 10.1016/j.ijimpeng.2005.05.008. [16] 王铁成. 混凝土结构设计原理[M]. 北京: 中国建筑工业出版社, 2012: 15−22. -

下载:

下载: