A temperature compensation method for explosion static pressure in finite space

-

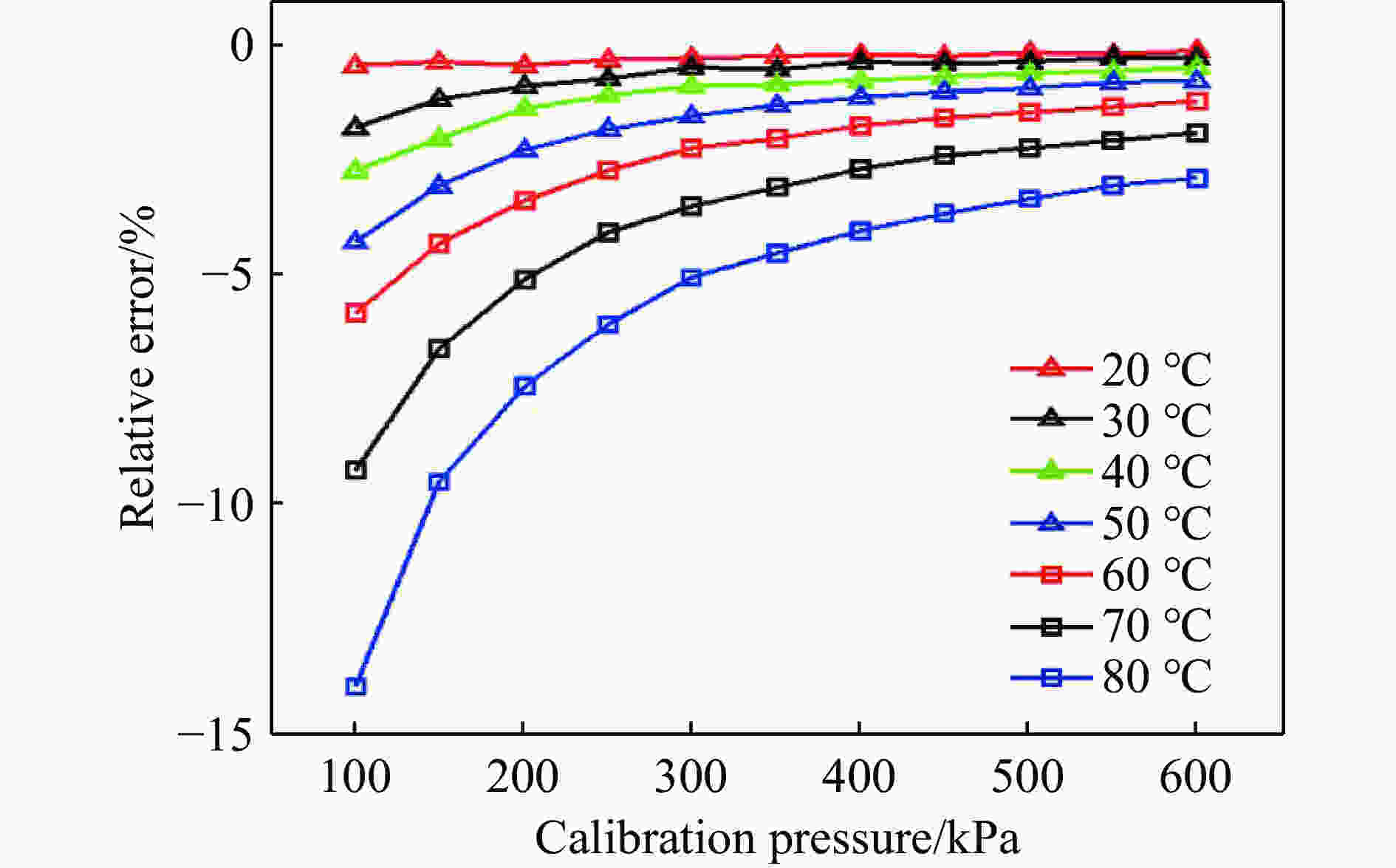

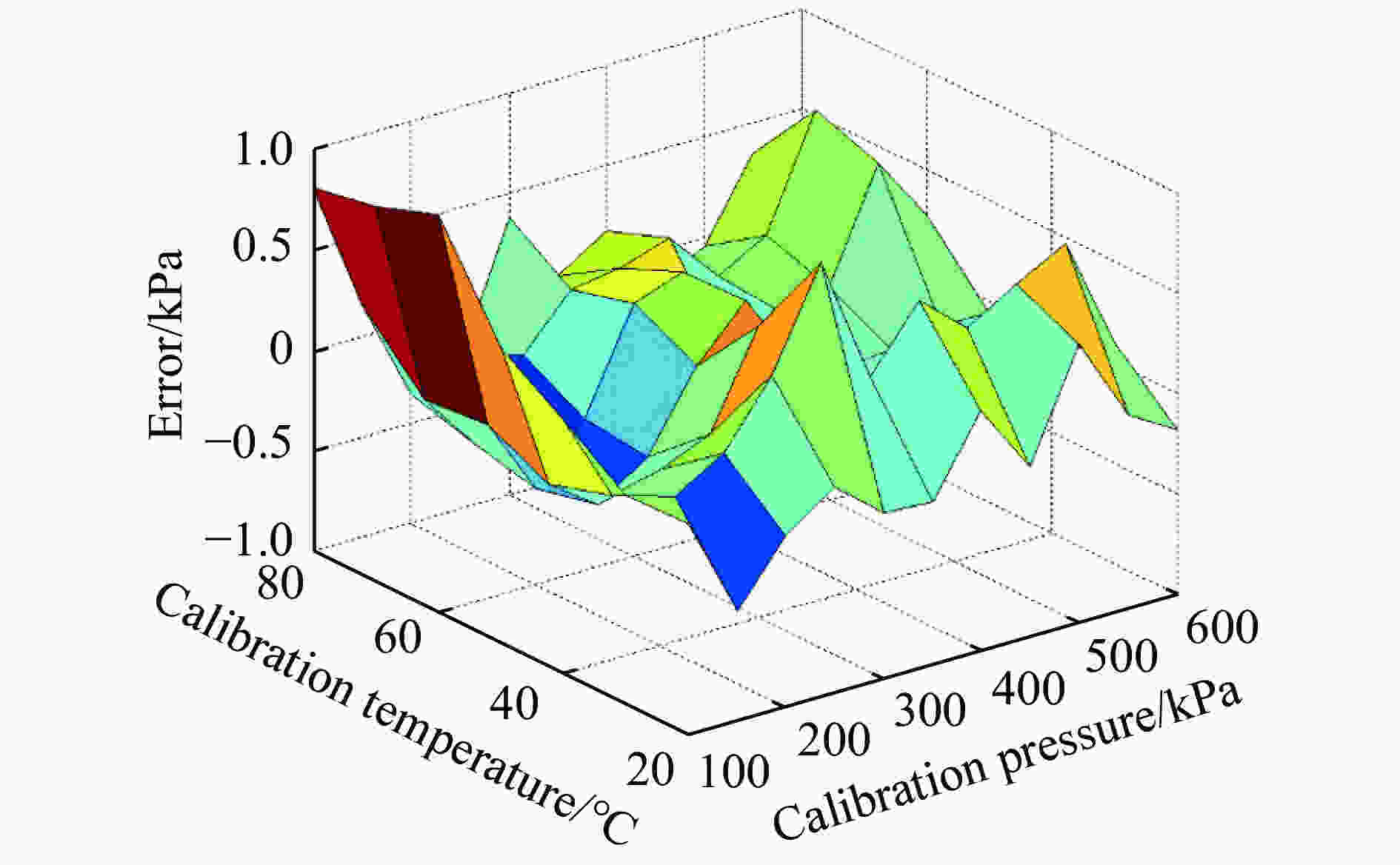

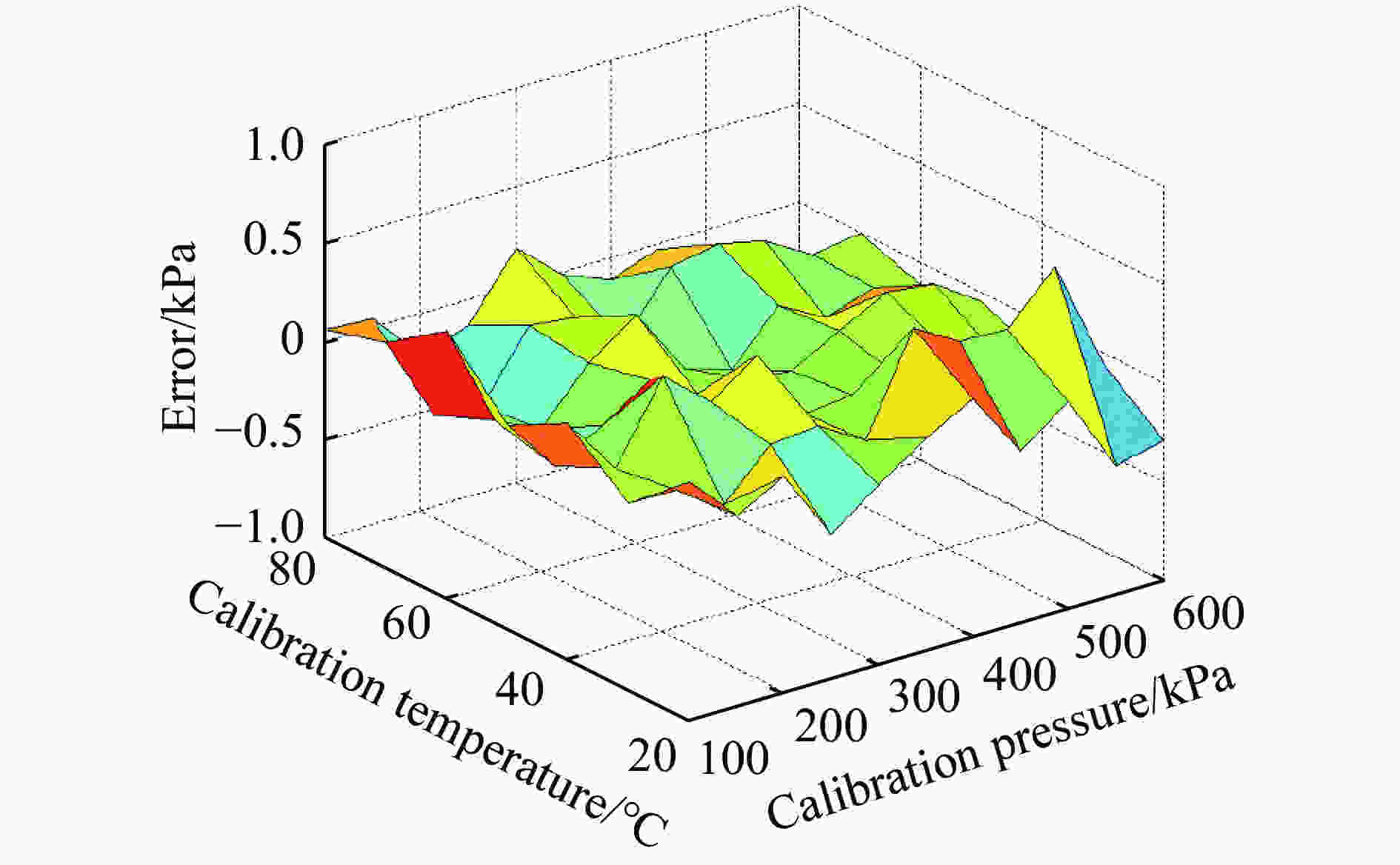

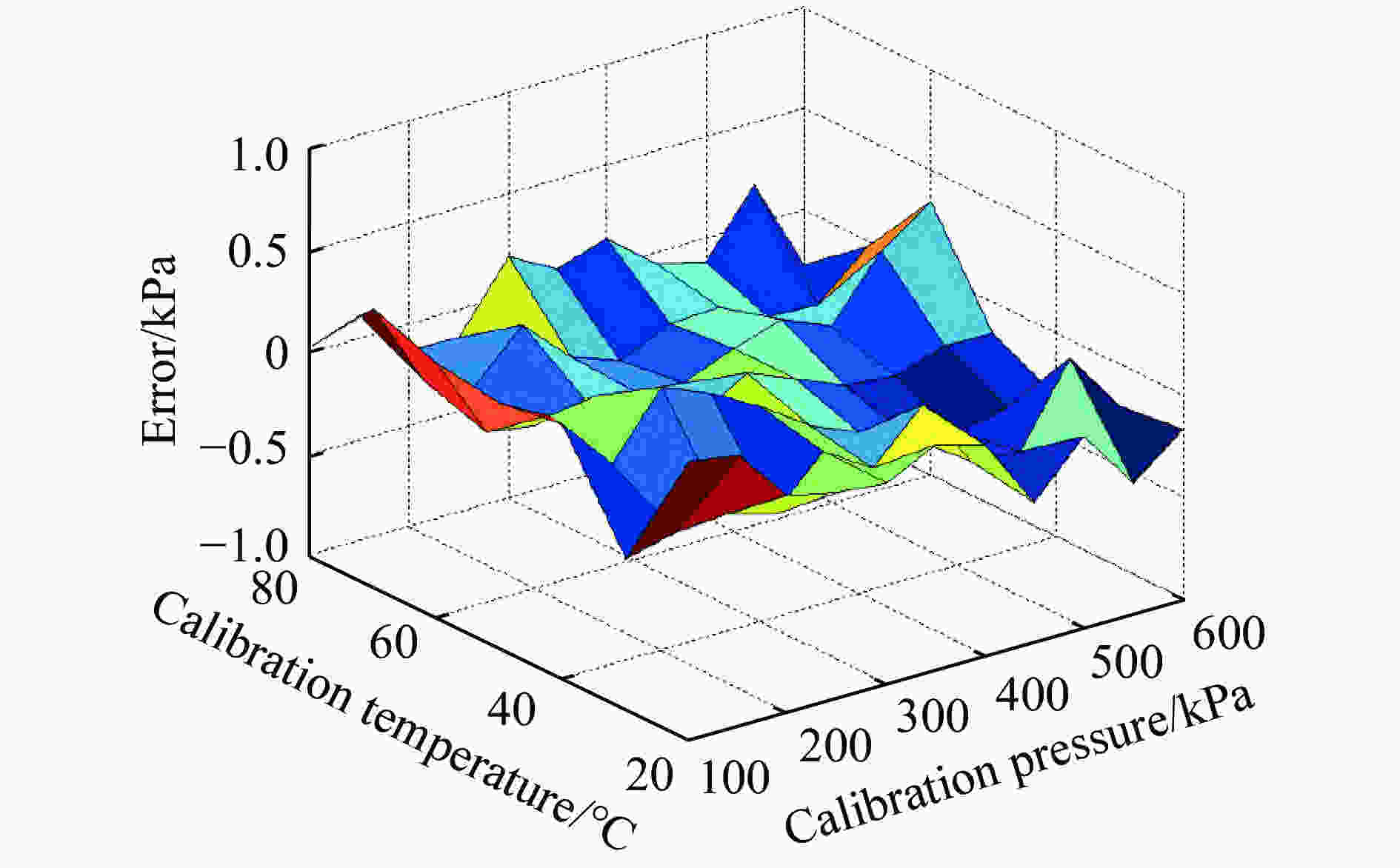

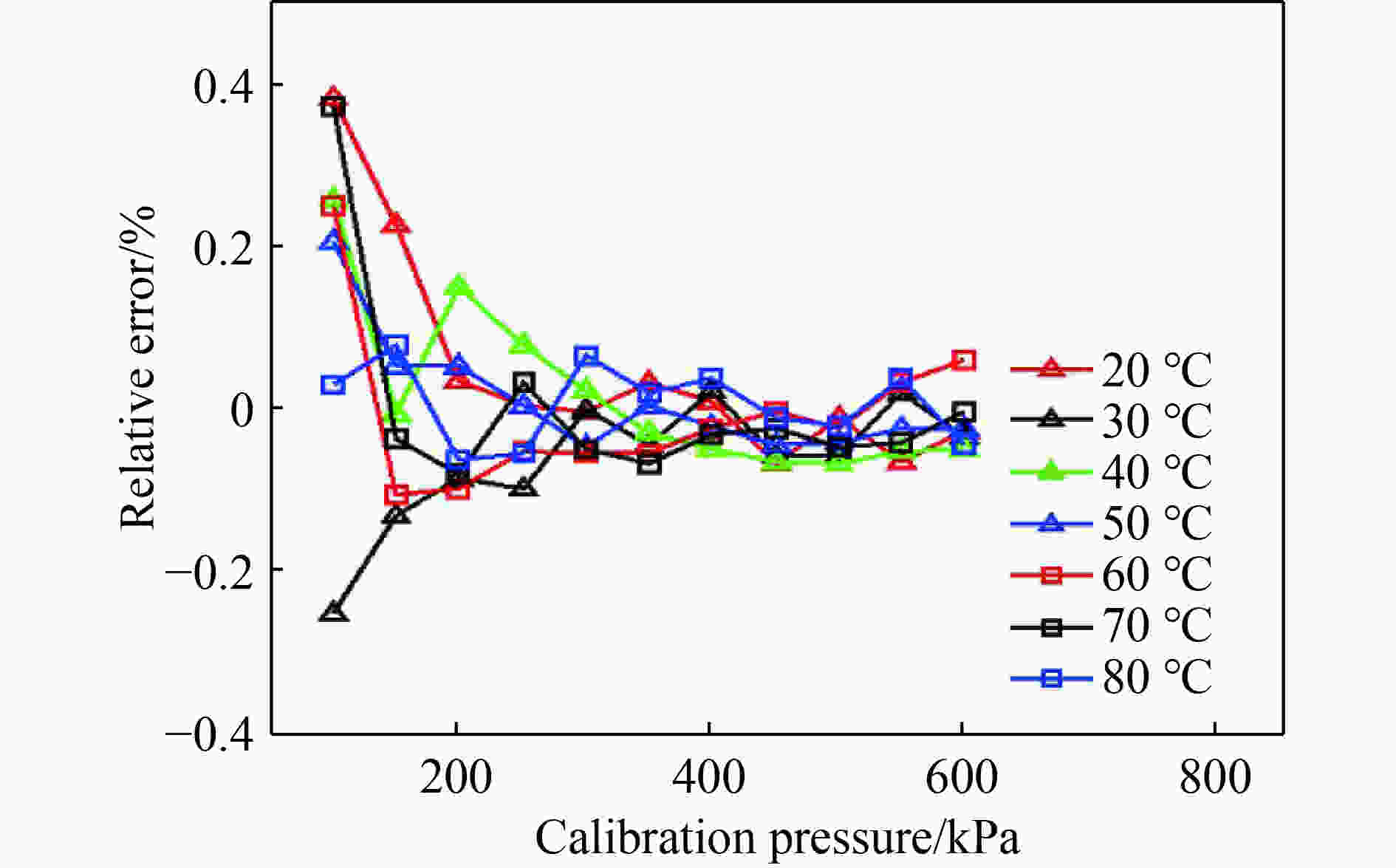

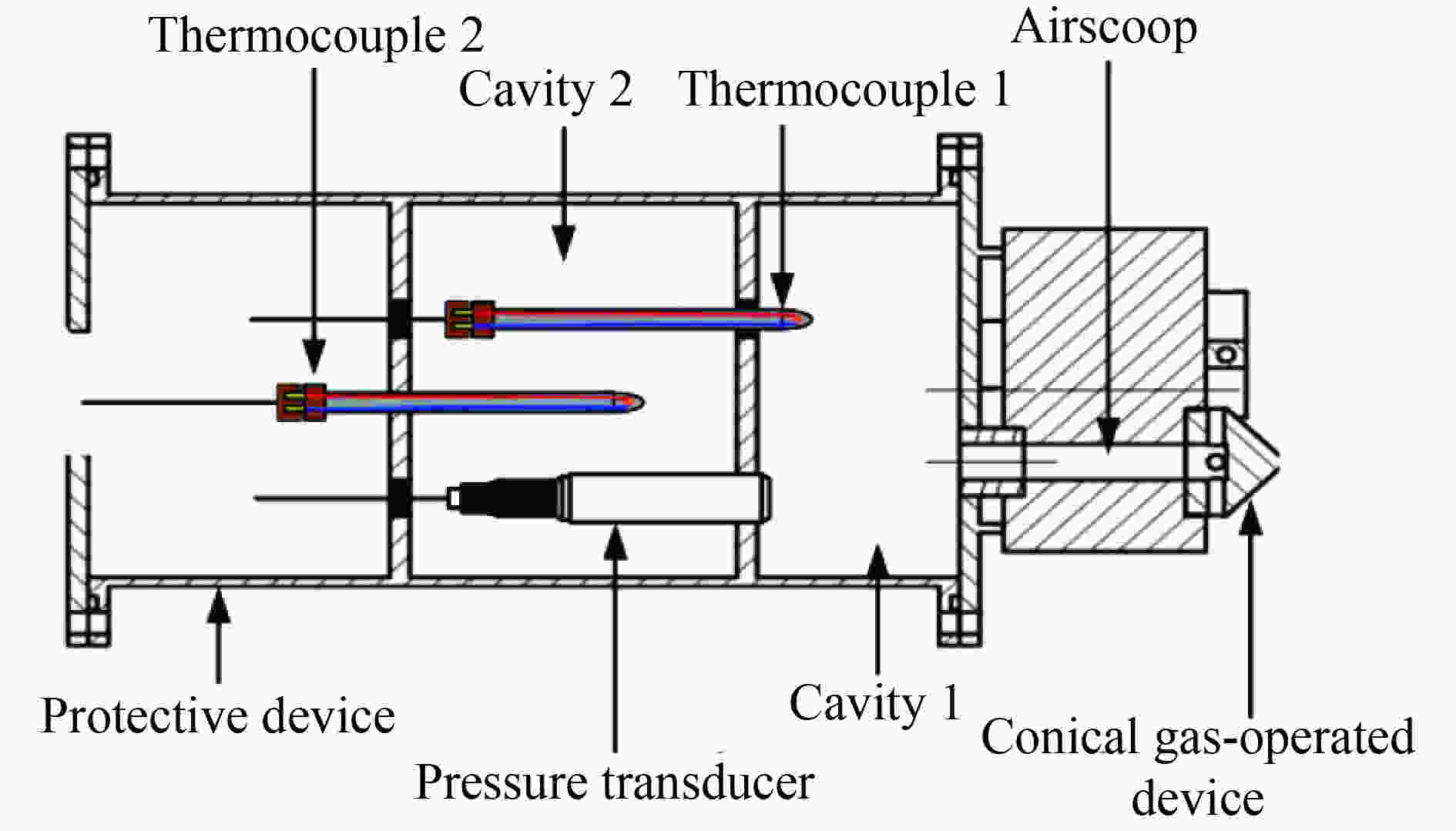

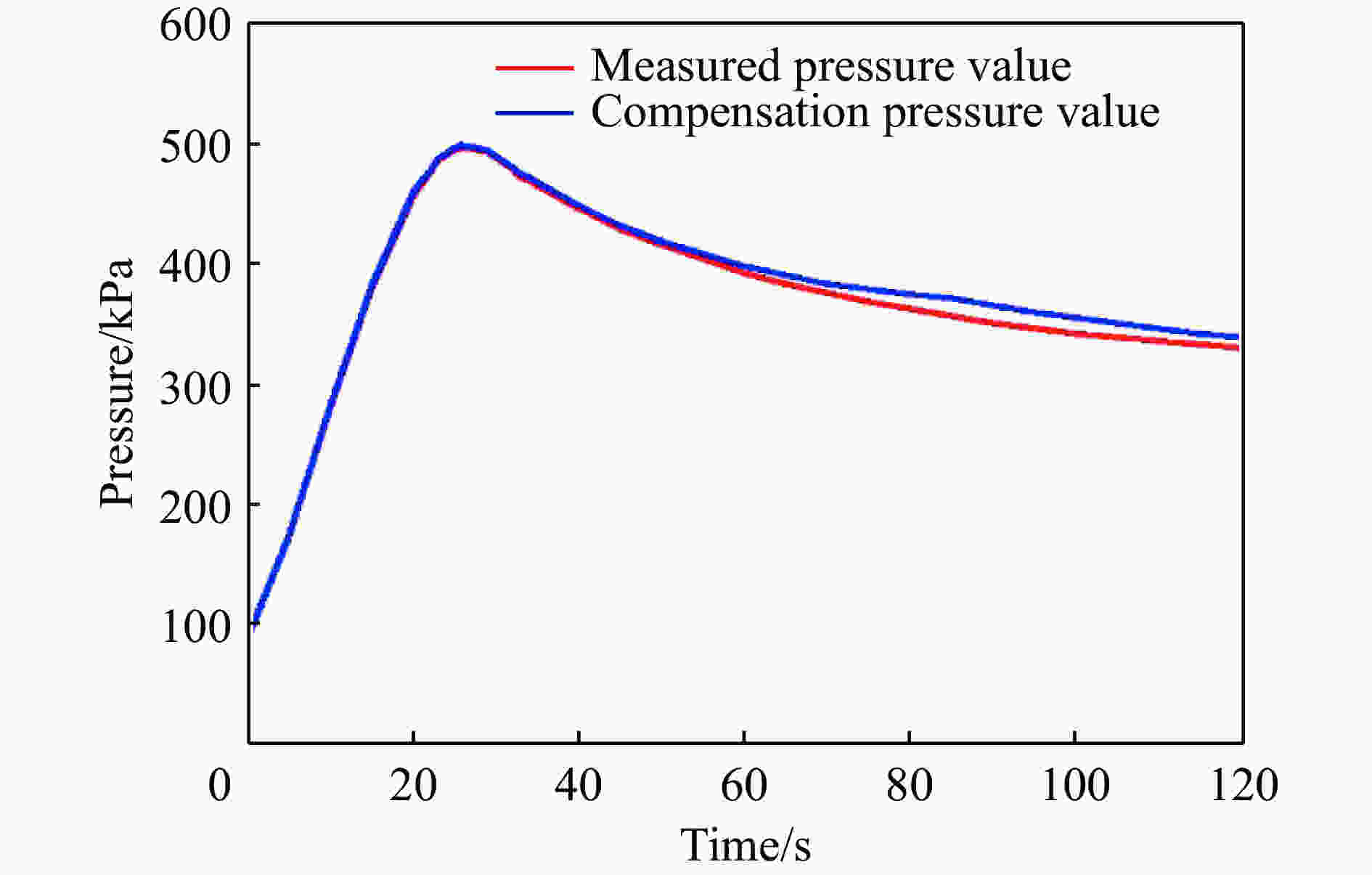

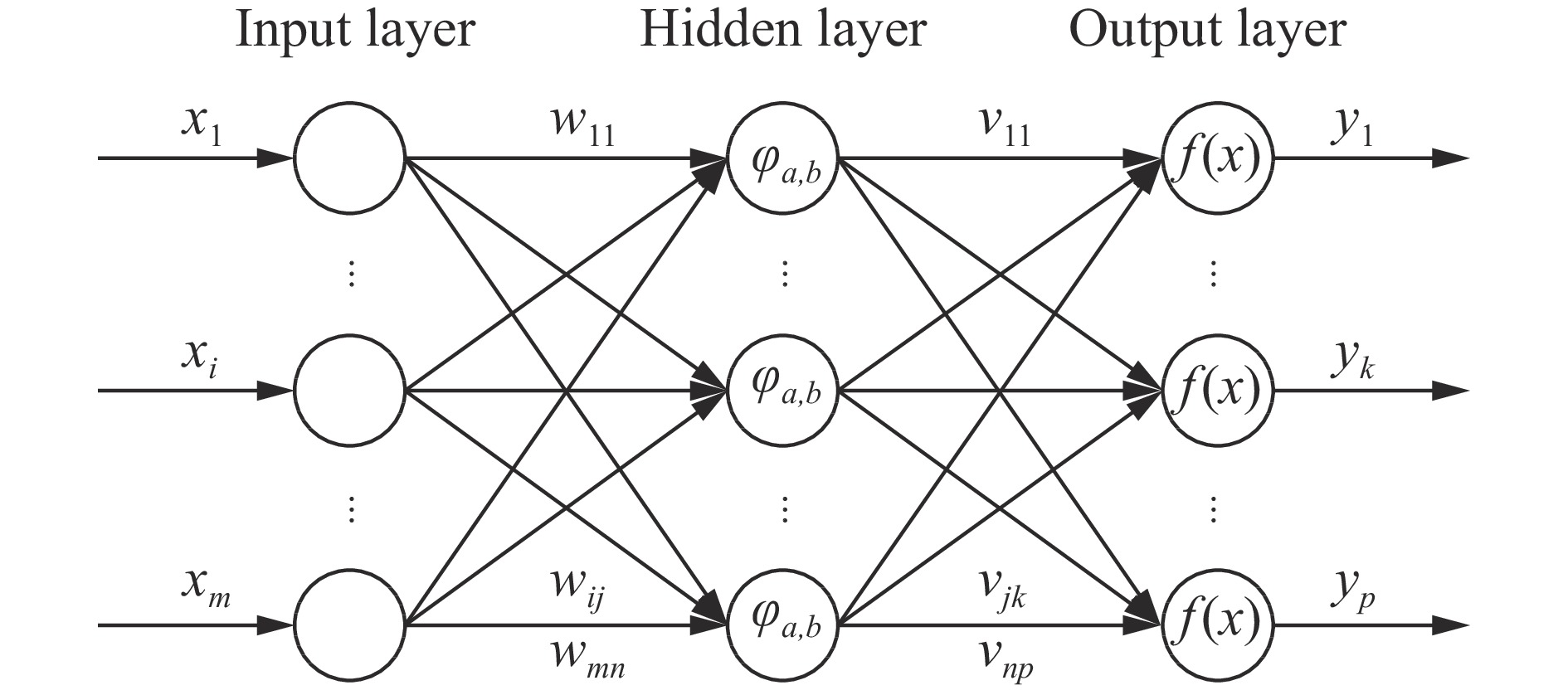

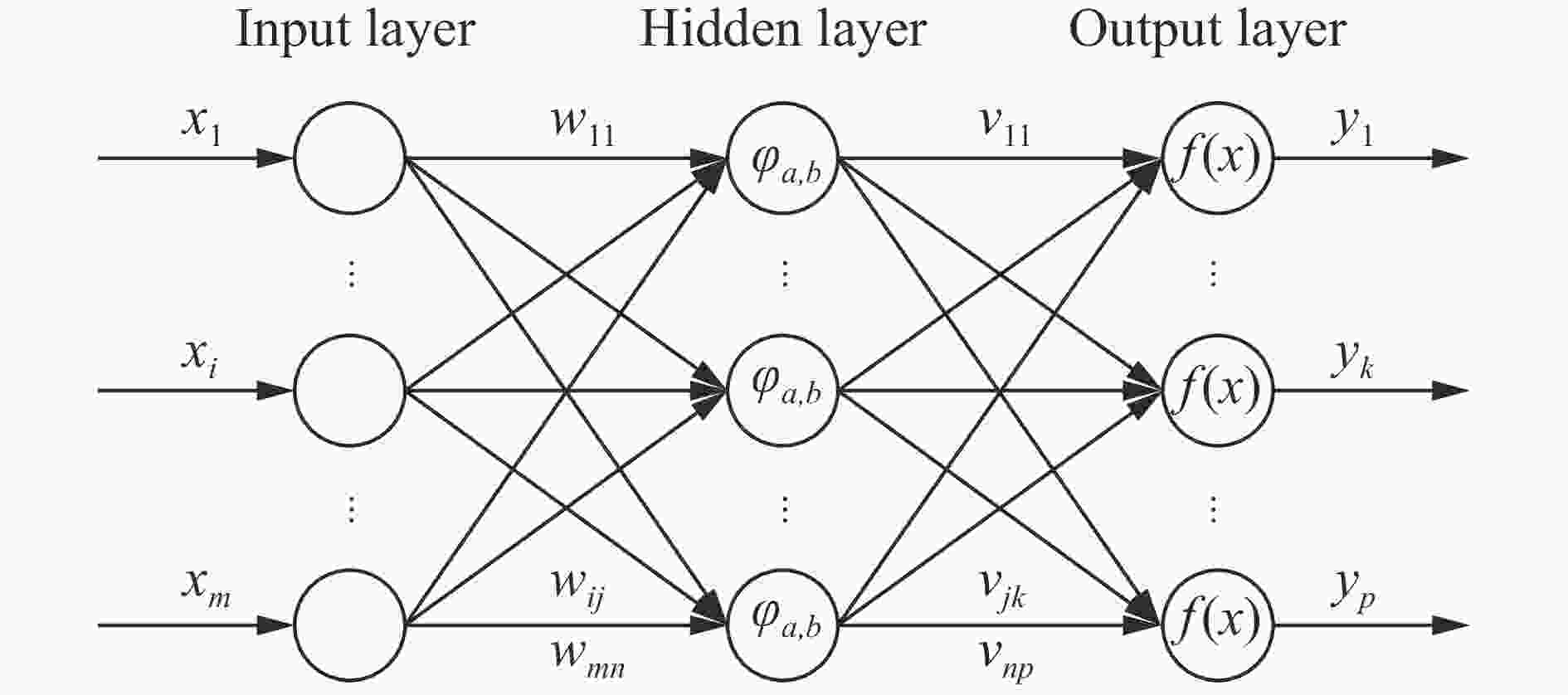

摘要: 为改善压阻式压力传感器的温度漂移特性,构建了基于遗传算法和小波神经网络的压力传感器温度补偿模型。针对小波神经网络收敛速度慢且易陷入局部最优解的问题,采用遗传算法对小波神经网络的连接权值、伸缩参数和平移参数进行优化。基于压力传感器的标定数据,分别采用BP神经网络、小波神经网络和遗传小波神经网络对其进行温度补偿研究,结果表明:遗传小波神经网络兼容了小波分析的时频局部特性和神经网络的自学习能力,表现出良好的收敛速度和补偿精度,经补偿后传感器的输出值更接近于标定值,其最大误差由−17.44 kPa变至0.38 kPa,最大相对误差由−14.0%变至0.38%。将该模型应用于有限空间爆炸静态压力的温度补偿中,取得了较好的实际应用效果。Abstract: To improve the temperature drift characteristics of piezoresistive pressure sensors, a temperature compensation model for the pressure sensors was constructed based on genetic algorithm and wavelet neural networks. By considering the problems of slow convergence and high probability of the local optimal solutions of the wavelet neural networks, the genetic algorithm was applied to optimize the connection weights, expansion parameters and translation parameters of the wavelet neural networks. Based on the calibration data of the pressure sensors, the BP neural network, wavelet neural network and genetic wavelet neural network were used to study the temperature compensation, respectively. The results show that the genetic wavelet neural network was compatible with the time-frequency local characteristics of the wavelet analysis and the self-learning ability of the neural networks, showing high convergence speed and compensation accuracy. After the compensation, the output values of the sensors were closer to the calibration ones. The maximum error was changed from −17.44 kPa to 0.38 kPa, and the maximum relative error was changed from −14.0% to 0.38%. The constructed model is applied in the temperature compensation of explosion static pressure in finite space, and the practical effect is good.

-

表 1 传感器标定数据

Table 1. The sensor calibration data

标定压力/kPa 不同标定温度下的输出值/kPa 20 ℃ 30 ℃ 40 ℃ 50 ℃ 60 ℃ 70 ℃ 80 ℃ 100 99.56 98.19 97.25 95.69 94.13 90.69 86.00 150 149.44 148.19 146.94 145.38 143.50 140.06 135.69 200 199.13 198.19 197.25 195.38 193.19 189.75 185.06 250 249.13 248.19 247.25 245.38 243.19 239.75 234.75 300 299.13 298.50 297.25 295.38 293.19 289.44 284.75 350 349.13 348.19 346.94 345.38 342.88 339.13 334.13 400 399.13 398.50 396.94 395.38 392.88 389.13 383.81 450 448.81 448.19 446.94 445.38 442.88 439.13 433.50 500 499.13 498.19 496.94 495.38 492.56 488.81 483.18 550 548.81 548.50 546.94 545.38 542.56 538.50 533.18 600 599.13 598.19 596.94 595.38 592.56 588.50 582.56 表 2 各标定温度下传感器输出误差比较

Table 2. Comparison of output errors of the sensor at each calibration temperature

标定温度/℃ 最大误差/kPa 标准差/kPa 标定温度/℃ 最大误差/kPa 标准差/kPa 20 −1.19 0.22 60 −7.44 0.47 30 −1.81 0.14 70 −11.50 0.67 40 −3.06 0.16 80 −17.44 1.10 50 −4.62 0.09 表 3 3种模型补偿精度和收敛速度比较

Table 3. Comparison of compensation accuracy and convergence rate of three models

补偿模型 误差分布区间/kPa 误差标准差/kPa 迭代次数 收敛时间/s BP神经网络 [−0.806 4,0.981 1] 0.351 2 94 3.627 1 小波神经网络 [−0.697 0,0.507 3] 0.192 2 65 2.542 3 遗传小波神经网络 [−0.360 3,0.380 9] 0.186 5 37 1.635 9 表 4 补偿后传感器的输出值

Table 4. The output value of the sensor after compensation

标定压力/kPa 不同标定温度下的输出值/kPa 20 ℃ 30 ℃ 40 ℃ 50 ℃ 60 ℃ 70 ℃ 80 ℃ 100 100.38 99.75 100.26 100.20 100.25 100.37 100.03 150 150.34 149.80 149.99 150.08 149.84 149.94 150.11 200 200.07 199.82 200.30 200.10 199.80 199.84 199.87 250 250.01 249.75 250.19 250.00 249.86 250.08 249.86 300 299.99 299.99 300.06 299.85 299.83 299.85 300.19 350 350.11 349.84 349.90 350.01 349.80 349.76 350.06 400 400.04 400.09 399.79 399.91 399.90 399.87 400.14 450 449.69 449.73 449.70 449.80 449.97 449.88 449.95 500 499.94 499.71 499.65 499.78 499.87 499.76 499.88 550 549.64 550.10 549.71 549.86 550.17 549.76 550.20 600 599.83 599.79 599.69 599.85 600.35 599.97 599.73 表 5 补偿后各标定温度下传感器输出误差比较

Table 5. Comparison of output errors of the sensor at each calibration temperature after compensation

标定温度/℃ 最大误差/kPa 标准差/kPa 标定温度/℃ 最大误差/kPa 标准差/kPa 20 0.38 0.23 60 0.35 0.20 30 −0.29 0.14 70 0.37 0.18 40 −0.35 0.24 80 −0.27 0.15 50 −0.22 0.14 表 6 起爆后各时段温度压力值

Table 6. Temperature and pressure values at various times after explosion

相对时间/s 介质温度/℃ 环境温度/℃ 实测压力/kPa 补偿后压力/kPa 误差/kPa 0 21.2 21.2 89.4 90.3 0.9 20 54.9 26.1 458.8 460.5 1.7 25 63.2 29.4 494.6 496.8 2.2 40 112.8 38.5 446.0 448.9 2.9 60 126.1 53.8 393.2 398.5 5.3 80 125.9 73.4 362.8 375.1 12.3 100 120.5 74.6 342.8 355.6 12.8 120 116.2 69.7 330.4 338.9 8.5 -

[1] 李芝绒, 翟红波, 闫潇敏, 等. 一种温压内爆炸准静态压力测量方法研究 [J]. 传感器技术学报, 2016, 29(2): 208–212. DOI: 10.3969/j.issn.1004-1699.2016.02.010.LI Z R, ZHAI H B, YAN X M, et al. Test method research for the quasi-static pressure on inside-explosive [J]. Chinese Journal of Sensors and Actuators, 2016, 29(2): 208–212. DOI: 10.3969/j.issn.1004-1699.2016.02.010. [2] 刘文祥, 张德志, 钟方平, 等. 球形爆炸容器内炸药爆炸形成的准静态气体压力 [J]. 爆炸与冲击, 2018, 38(5): 1045–1050. DOI: 10.11883/bzycj-2017-0056.LIU W X, ZHANG D Z, ZHONG F P, et al. Quasi-static gas pressure generated by explosive charge blasting in a spherical explosion containment vessel [J]. Explosion and Shock Waves, 2018, 38(5): 1045–1050. DOI: 10.11883/bzycj-2017-0056. [3] 张玉磊, 苏健军, 李芝绒, 等. TNT内爆炸准静态压力特性 [J]. 爆炸与冲击, 2018, 38(6): 1429–1434. DOI: 10.11883/bzycj-2017-0170.ZHANG Y L, SU J J, LI Z R, et al. Quasi-static pressure characteristic of TNT’s internal explosion [J]. Explosion and Shock Waves, 2018, 38(6): 1429–1434. DOI: 10.11883/bzycj-2017-0170. [4] 王冰冰, 李淮江. 基于三次样条插值的硅压阻式压力传感器的温度补偿 [J]. 传感技术学报, 2015, 28(7): 1003–1007. DOI: 10.3969/j.issn.1004-1699.2015.07.011.WANG B B, LI H J. Temperature compensation of piezo-resistive pressure sensor based on the interpolation of third order splines [J]. Chinese Journal of Sensors and Actuators, 2015, 28(7): 1003–1007. DOI: 10.3969/j.issn.1004-1699.2015.07.011. [5] 杨遂军, 康国炼, 叶树亮. 基于最小二乘支持向量机的硅压阻式传感器温度补偿 [J]. 传感技术学报, 2016, 29(4): 500–505. DOI: 10.3969/j.issn.1004-1699.2016.04.007.YANG S J, KANG G L, YE S L. Temperature compensation of silicon piezo-resistive sensor based on least square-support vector machine [J]. Chinese Journal of Sensors and Actuators, 2016, 29(4): 500–505. DOI: 10.3969/j.issn.1004-1699.2016.04.007. [6] 李冀, 胡国清, 周永宏, 等. 一种压阻式压力传感器的温度补偿方法 [J]. 仪表技术与传感器, 2018(6): 1–5. DOI: 10.3969/j.issn.1002-1841.2018.06.001.LI J, HU G Q, ZHOU Y H, et al. Temperature compensation method for piezo-resistive pressure sensor [J]. Instrument Technique and Sensor, 2018(6): 1–5. DOI: 10.3969/j.issn.1002-1841.2018.06.001. [7] 龙军, 关威, 汪旭东, 等. 基于岭回归的压力传感器高精度测量模型研究 [J]. 传感技术学报, 2017, 30(3): 391–396. DOI: 10.3969/j.issn.1004-1699.2017.03.010.LONG J, GUAN W, WANG X D, et al. Study on high accuracy measurement model of pressure sensor based on ridge regression [J]. Chinese Journal of Sensors and Actuators, 2017, 30(3): 391–396. DOI: 10.3969/j.issn.1004-1699.2017.03.010. [8] 孙艳梅, 苗凤娟, 陶佰睿. 基于PSO的BP神经网络在压力传感器温度补偿中的应用 [J]. 传感技术学报, 2014, 27(3): 342–346. DOI: 10.3969/j.issn.1004-1699.2014.03.013.SUN Y M, MIAO F J, TAO B R. The application of BP neural network based on PSO algorithm to pressure sensor temperature compensation [J]. Chinese Journal of Sensors and Actuators, 2014, 27(3): 342–346. DOI: 10.3969/j.issn.1004-1699.2014.03.013. [9] DING J C, ZHANG J, HUANG W Q, et al. Laser gyro temperature compensation using modified RBFNN [J]. Sensors, 2014, 14(10): 18711–18727. DOI: 10.3390/s141018711. [10] 梁伟峰, 汪晓东, 梁萍儿. 基于最小二乘支持向量机的压力传感器温度补偿 [J]. 仪器仪表学报, 2007, 28(12): 2235–2238. DOI: 10.3321/j.issn:0254-3087.2007.12.024.LIANG W F, WANG X D, LIANG P E. Pressure sensor temperature compensation based on least squares support vector-machine [J]. Chinese Journal of Scientific Instrument, 2007, 28(12): 2235–2238. DOI: 10.3321/j.issn:0254-3087.2007.12.024. [11] 杨松, 李开林, 胡国清, 等. 基于FOA优化SOM-RBF的压力传感器温度补偿研究 [J]. 仪表技术与传感器, 2018(2): 19–23. DOI: 10.3969/j.issn.1002-1841.2018.02.006.YANG S, LI K L, HU G Q, et al. Temperature compensation research of pressure sensor based on FOA improved SOM-RBF [J]. Instrument Technique and Sensor, 2018(2): 19–23. DOI: 10.3969/j.issn.1002-1841.2018.02.006. [12] 孙艳梅, 刘树东, 苗凤娟, 等. 基于遗传算法的小波神经网络温度补偿模型 [J]. 传感技术学报, 2012, 25(1): 77–81. DOI: 10.3969/j.issn.1004-1699.2012.01.016.SUN Y M, LIU S D, MIAO F J, et al. Temperature compensation model based on the wavelet neural network with genetic algorithm [J]. Chinese Journal of Sensors and Actuators, 2012, 25(1): 77–81. DOI: 10.3969/j.issn.1004-1699.2012.01.016. [13] 孙亚飞, 顾芳, 黄亚磊, 等. 基于GA-WNN温度补偿的红外CO2气体传感器系统研究 [J]. 传感技术学报, 2018, 31(10): 1613–1620. DOI: 10.3969/j.issn.1004-1699.2018.010.026.SUN Y F, GU F, HUANG Y L, et al. Research on infrared CO2 gas sensor system with temperature compensation based on GA-WNN [J]. Chinese Journal of Sensors and Actuators, 2018, 31(10): 1613–1620. DOI: 10.3969/j.issn.1004-1699.2018.010.026. [14] KUMAR S S, PANT B D. Erratum to: Design principles and considerations for the ‘ideal’ silicon piezoresistive pressure sensor: a focused review [J]. Microsystem Technologies, 2014, 20(7): 2303–2303. DOI: 10.1007/s00542-014-2289-2. [15] 宋志章, 孙艳梅, 李会, 等. 基于模糊神经网络的压力传感器零点漂移补偿法 [J]. 仪表技术与传感器, 2014(3): 11–13. DOI: 10.3969/j.issn.1002-1841.2014.03.004.SONG Z Z, SUN Y M, LI H, et al. Zero drift compensation method of pressure sensor based on fuzzy neural network [J]. Instrument Technique and Sensor, 2014(3): 11–13. DOI: 10.3969/j.issn.1002-1841.2014.03.004. [16] LI P, LIU M, ZHANG X, et al. Novel wavelet neural network algorithm for continuous and noninvasive dynamic estimation of blood pressure from photoplethysmography [J]. Science China (Information Sciences), 2016, 59(4): 1–10. DOI: CNKI:SUN:JFXG.0.2016-04-009. [17] ZHANG J H, WU Y S, LIU Q Q, et al. Research on high-precision, low cost piezoresistive MEMS array pressure transmitters based on genetic wavelet neural networks for meteorological measurement [J]. Micromachines, 2015, 6(5): 554–573. DOI: 10.3390/mi6050554. [18] 侯霞. 小波神经网络若干关键问题研究[D]. 南京: 南京航空航天大学, 2006: 8-9. [19] 刘宇鹏. 基于预测控制的盘件气体冲击射流换热过程的优化研究[D]. 哈尔滨: 哈尔滨工业大学, 2018: 24-25. [20] 包子阳. 智能优化算法及其MATLAB实例[M]. 北京: 电子工业出版社, 2018: 13−17. [21] 钱华明, 王雯升. 遗传小波神经网络及在电机故障诊断中的应用 [J]. 电子测量与仪器学报, 2009, 23(3): 81–86. DOI: CNKI: SUN:DZIY.0.2009-03-019.QIAN H M, WANG W S. Improved wavelet neural network based on genetic algorithm and its application in fault diagnosis of motor [J]. Journal of Electronic Measurement and Instrument, 2009, 23(3): 81–86. DOI: CNKI: SUN:DZIY.0.2009-03-019. -

下载:

下载: