Energy-release characteristics of typical reactive materials under explosive loading

-

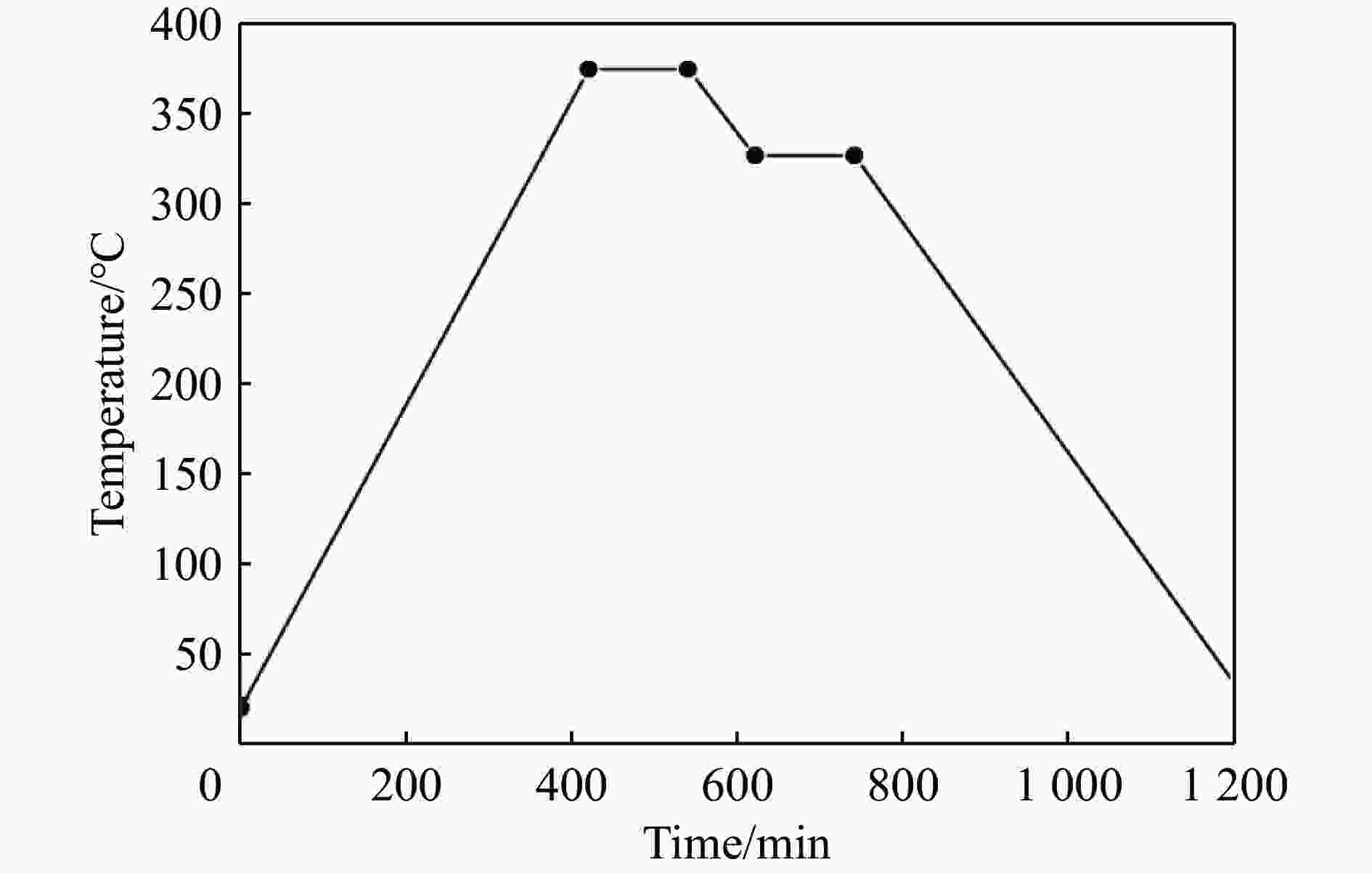

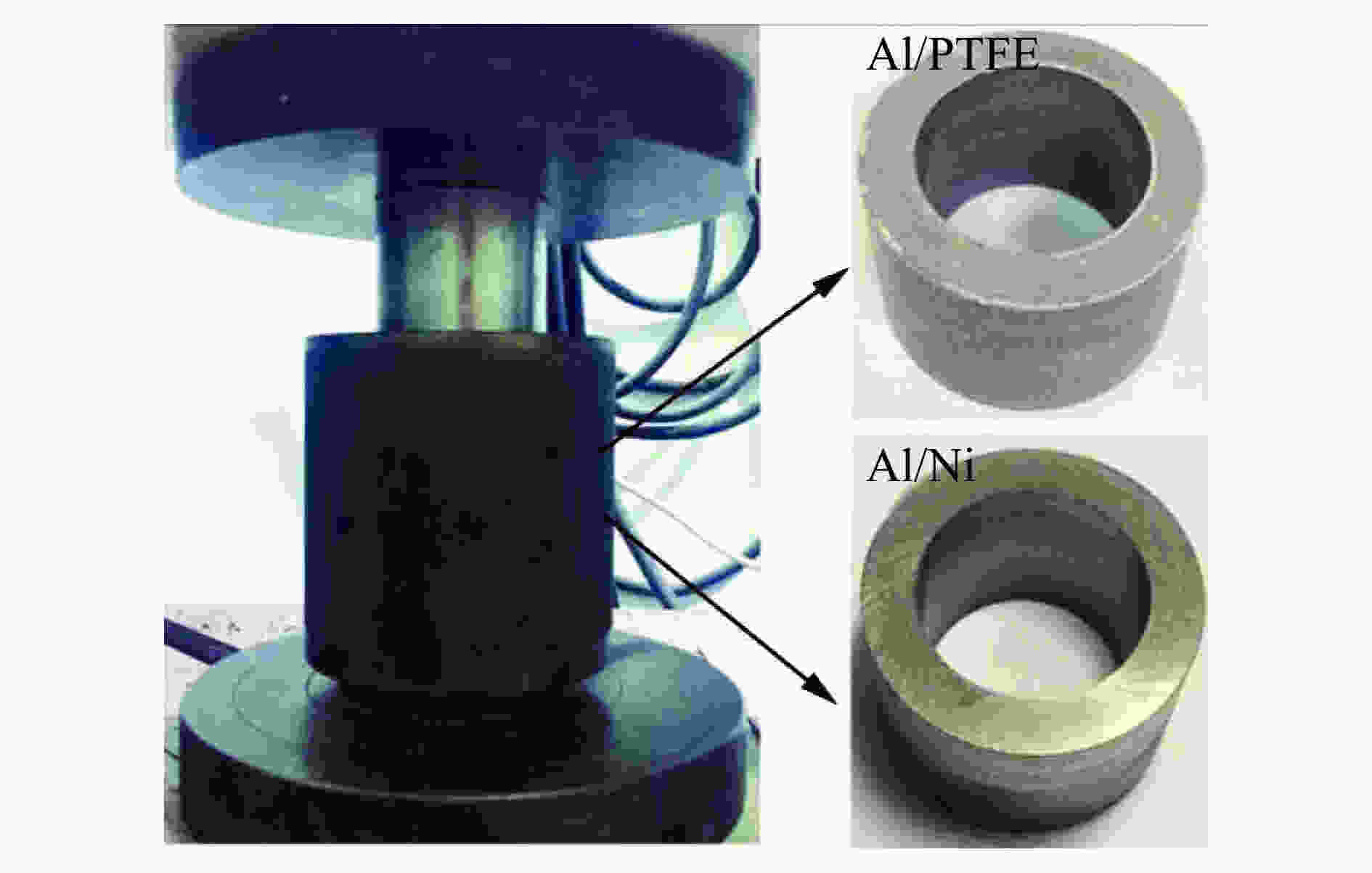

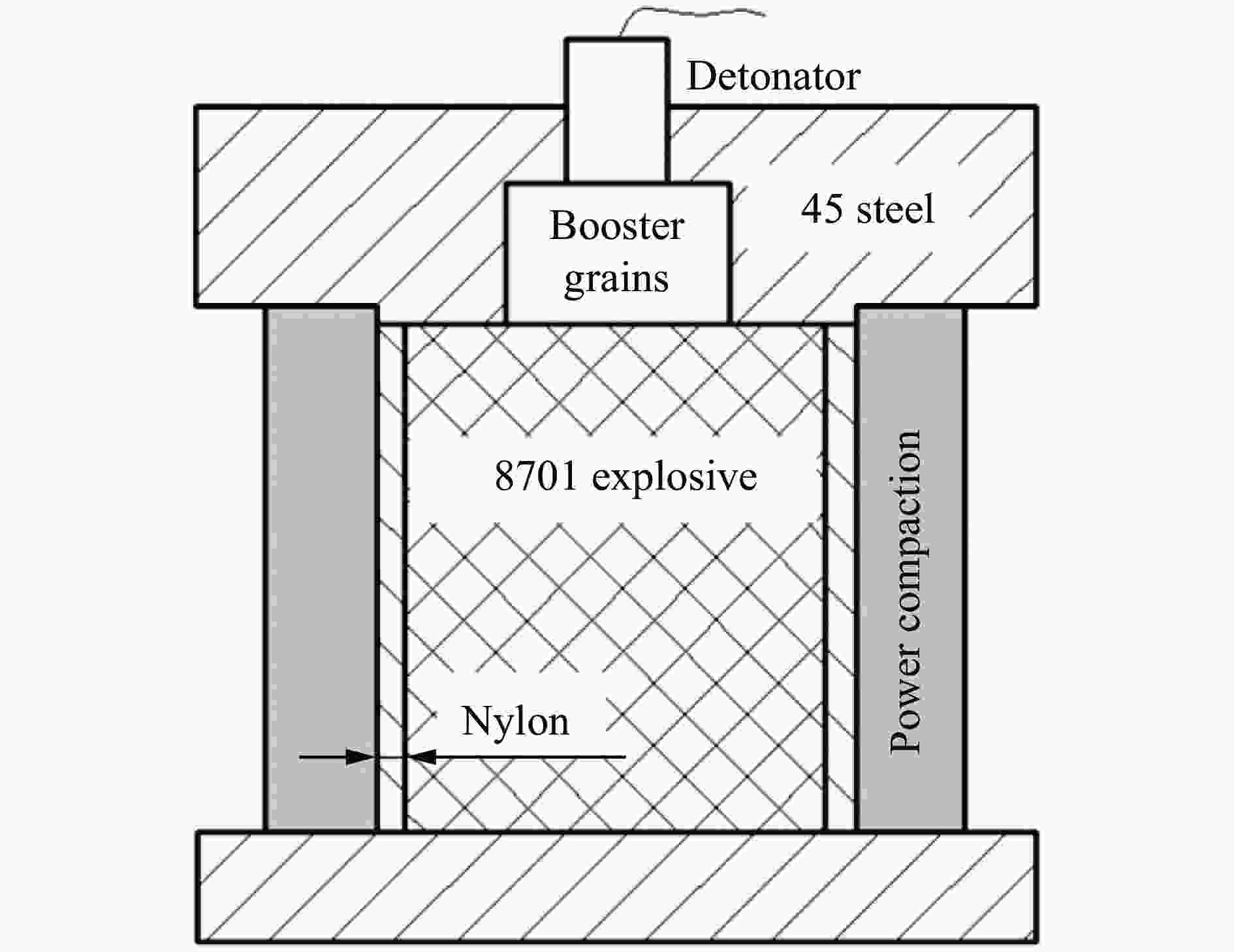

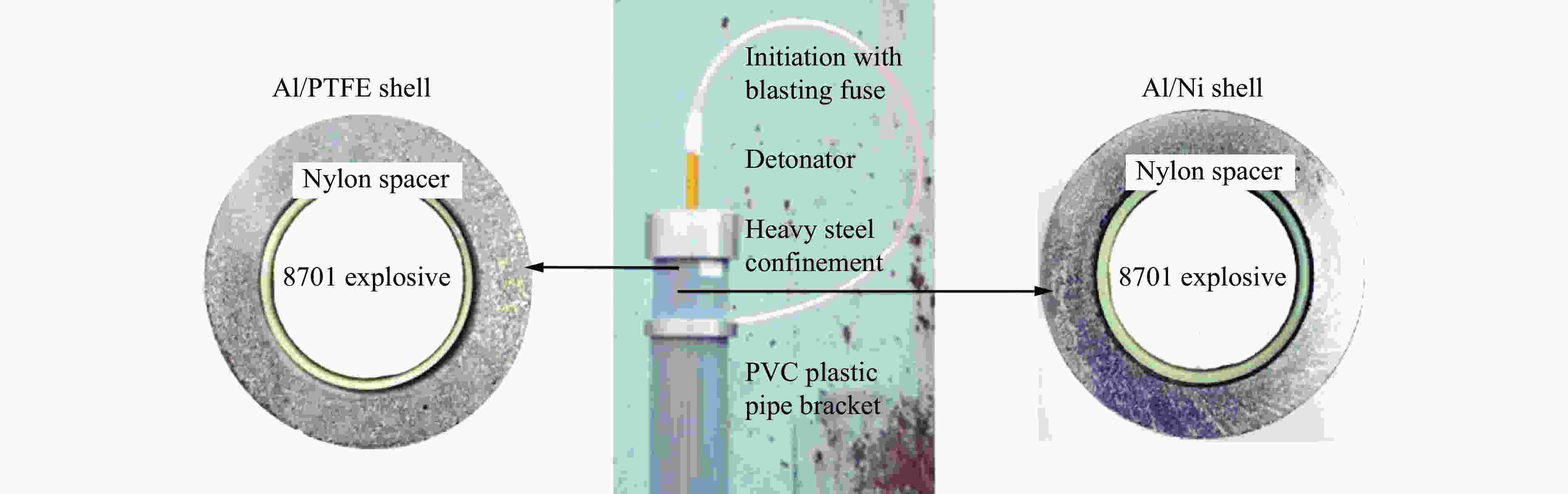

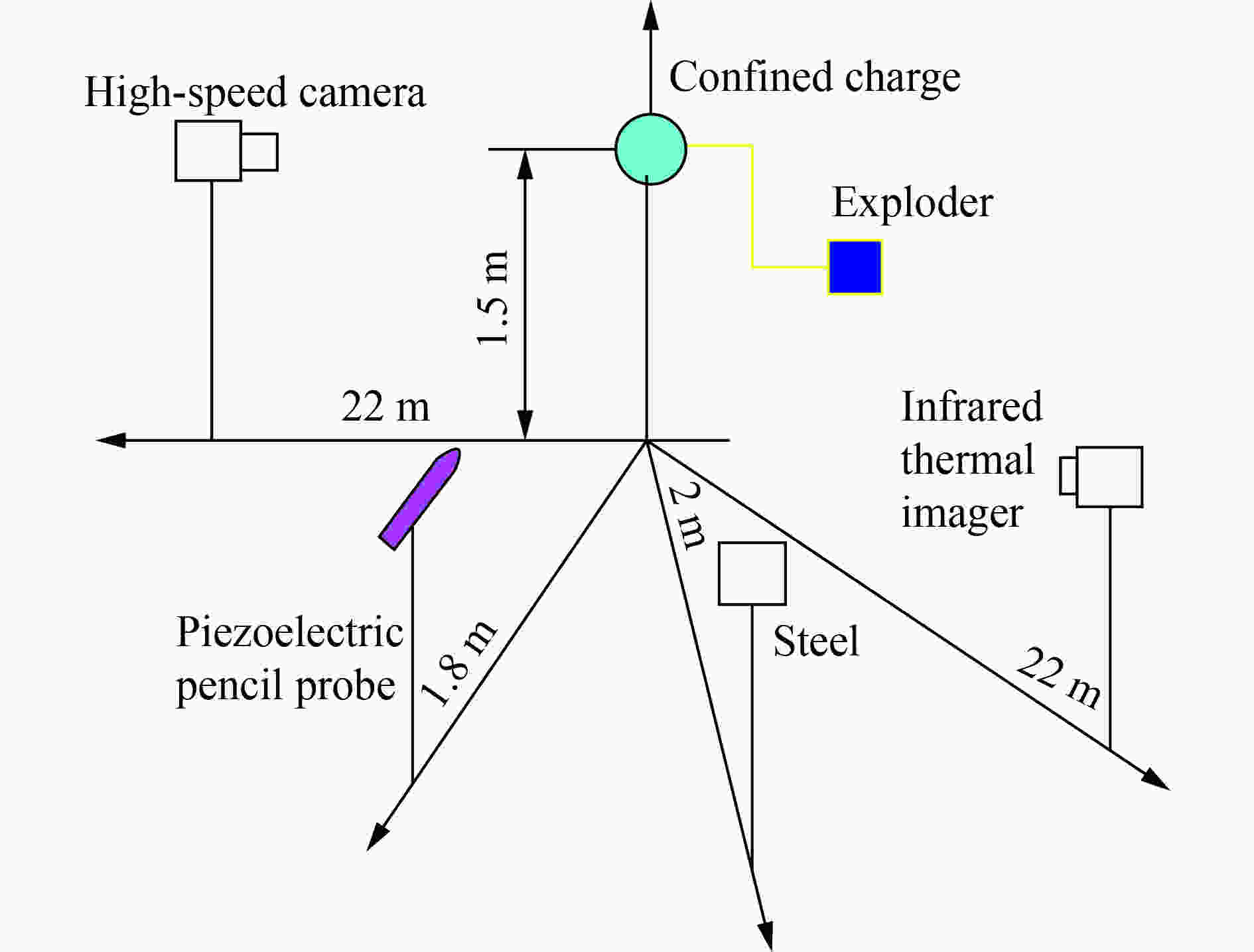

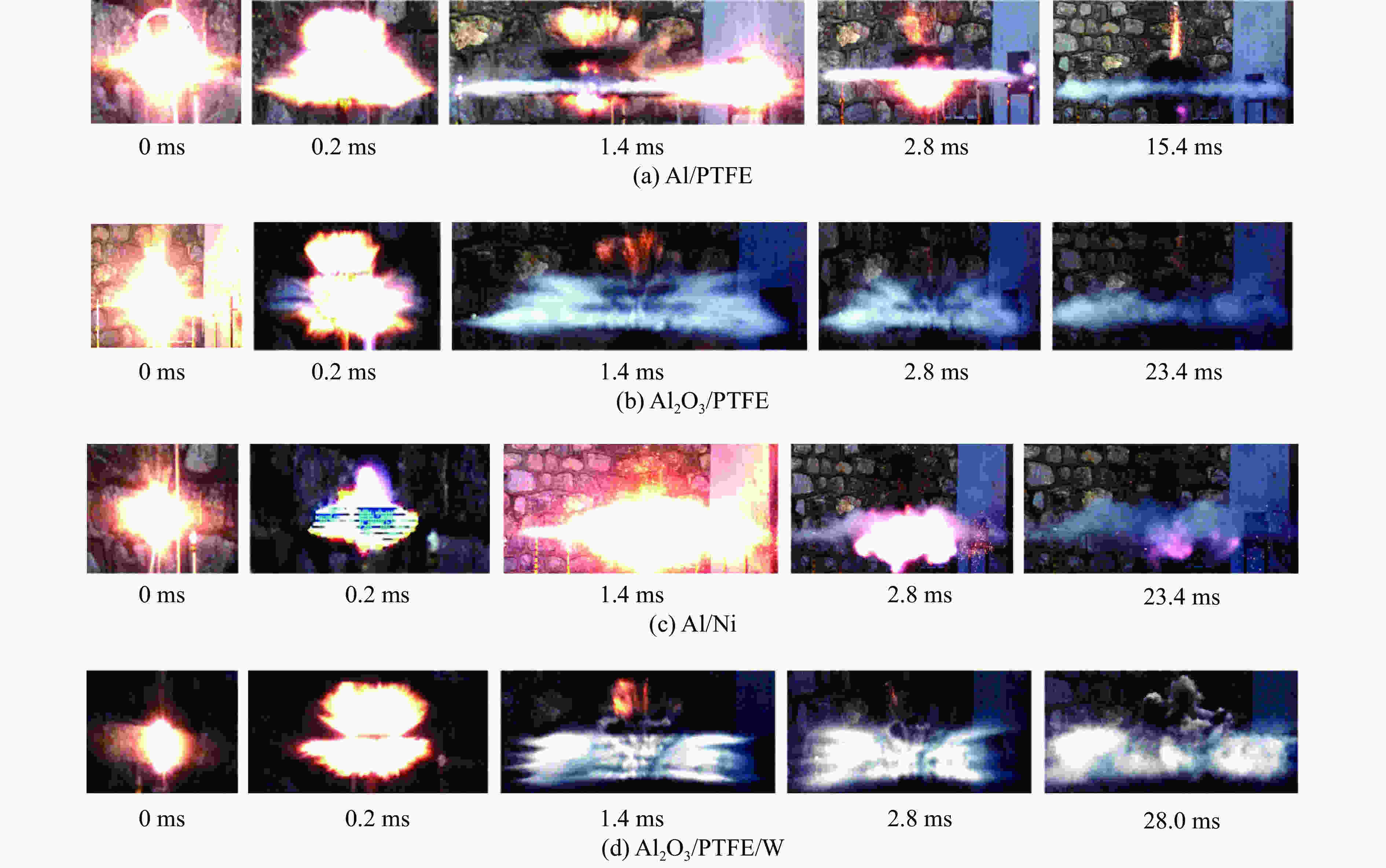

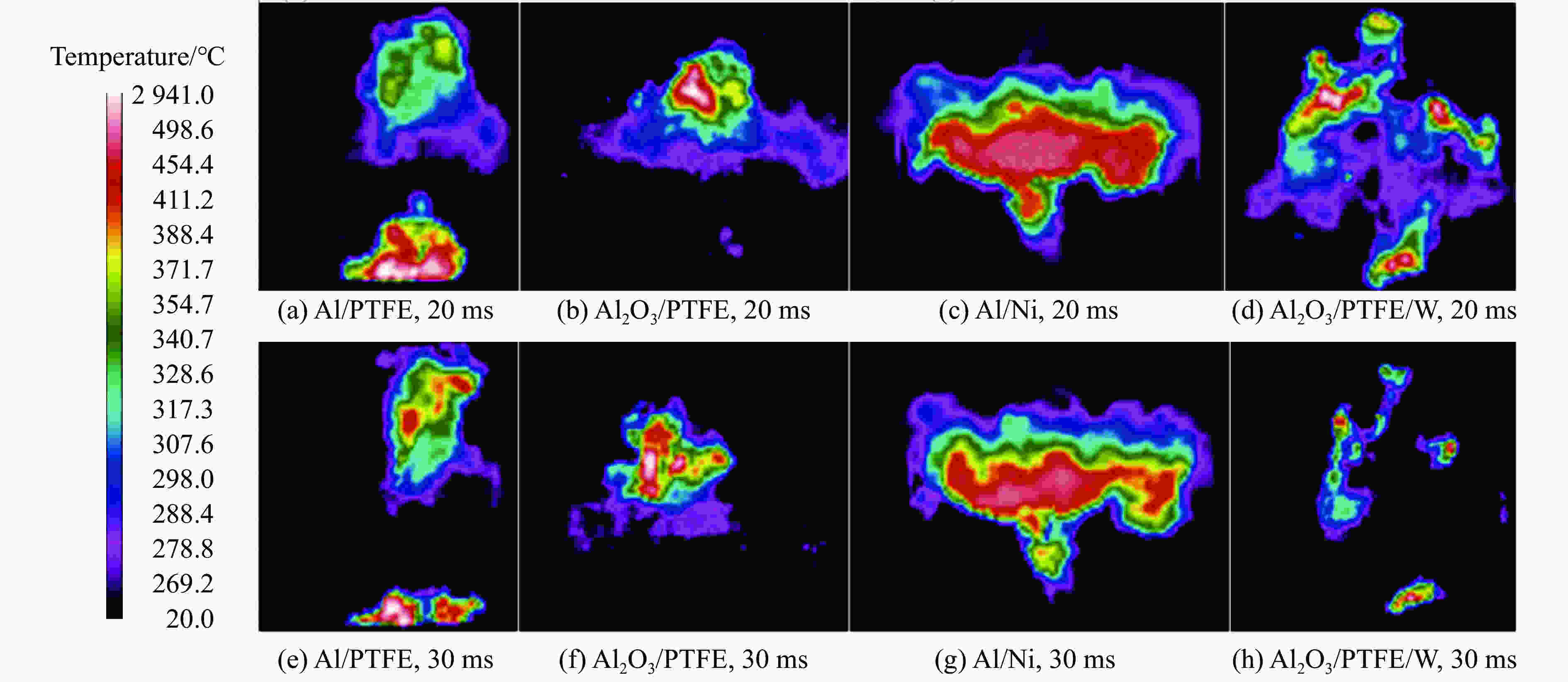

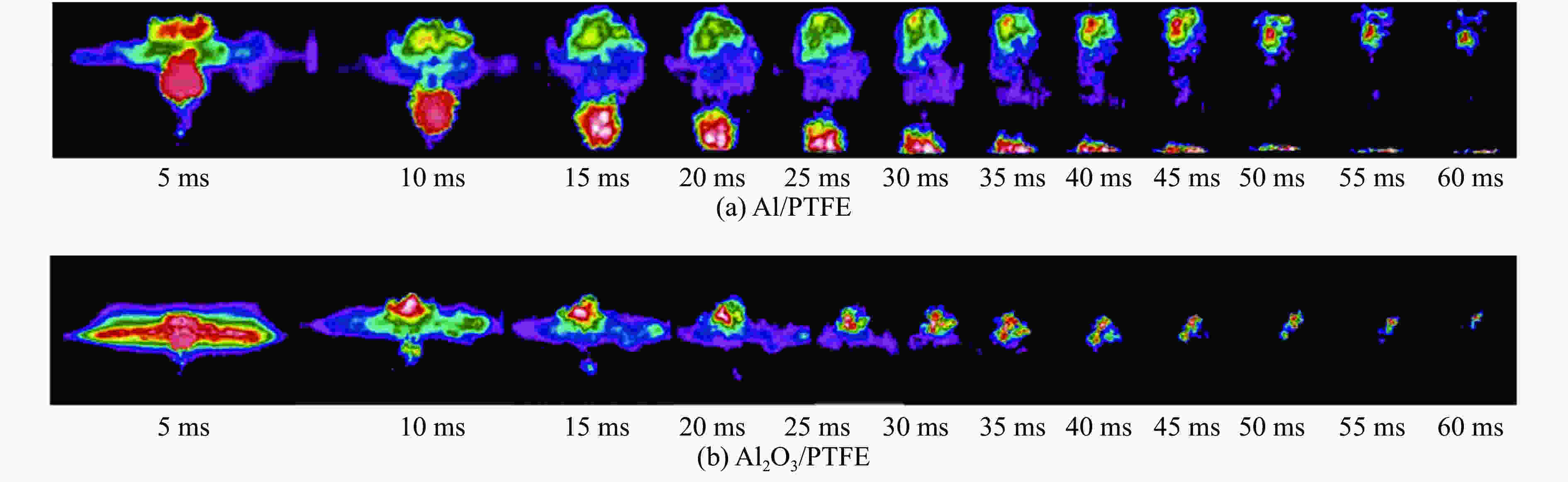

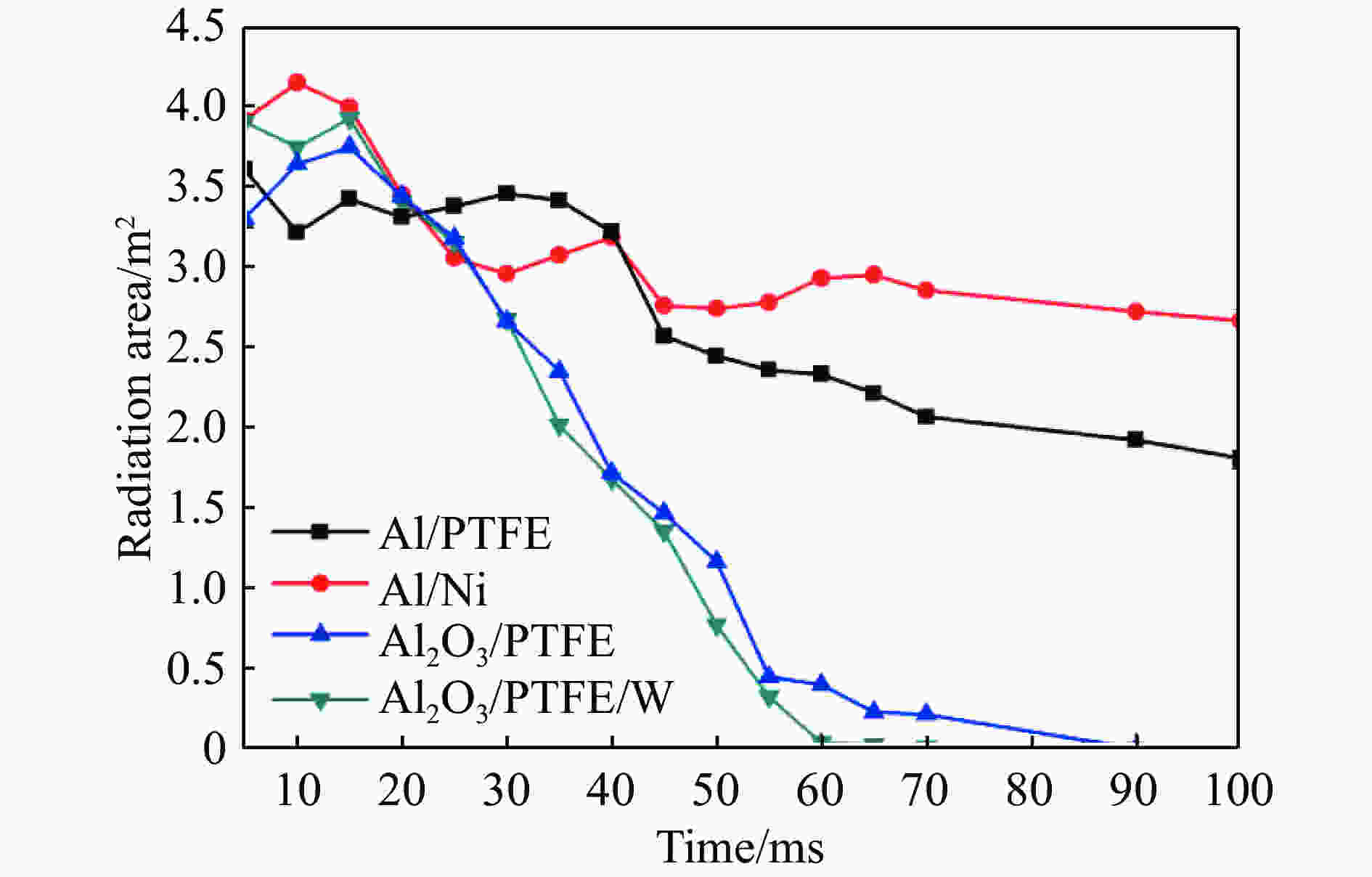

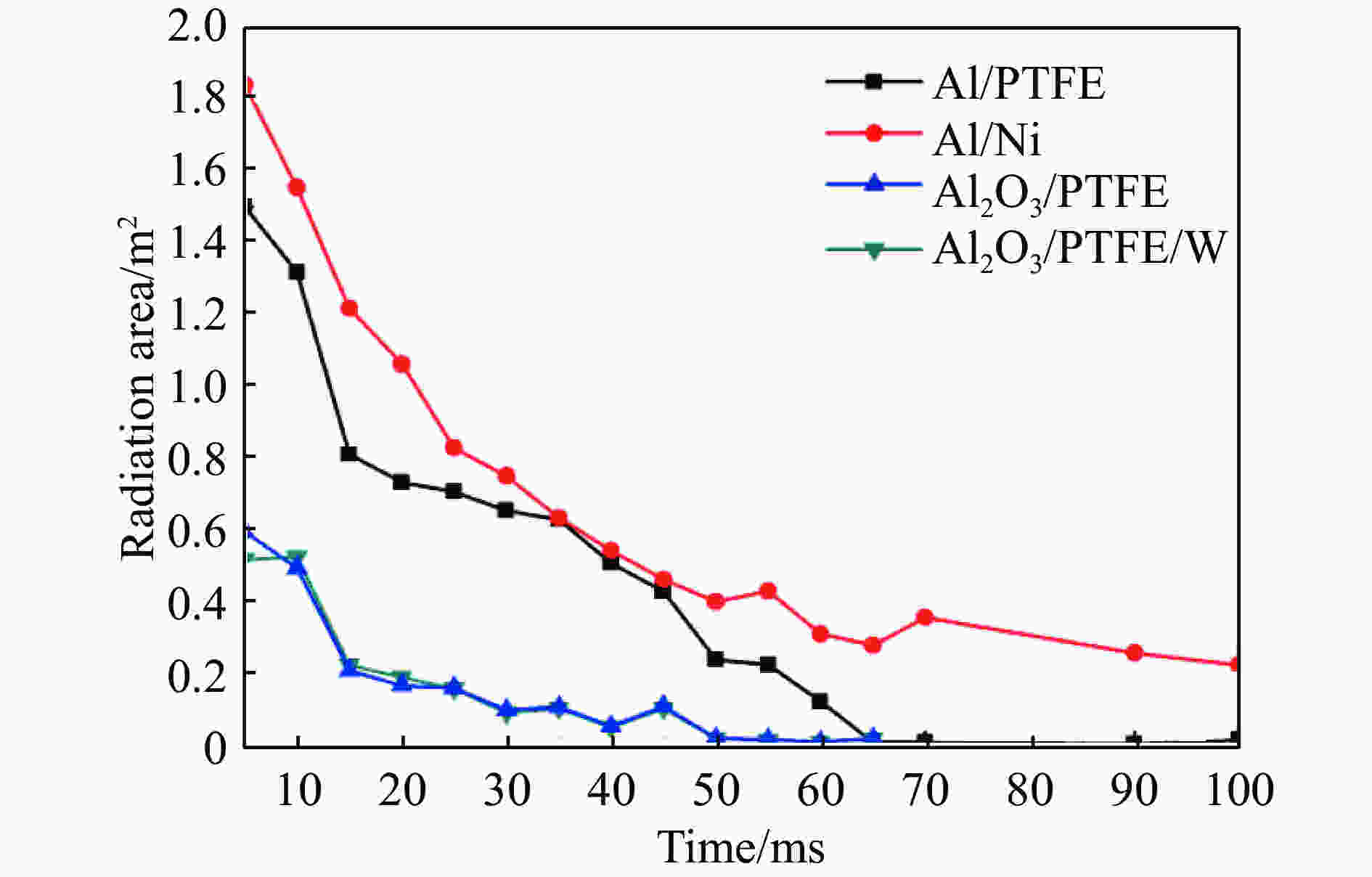

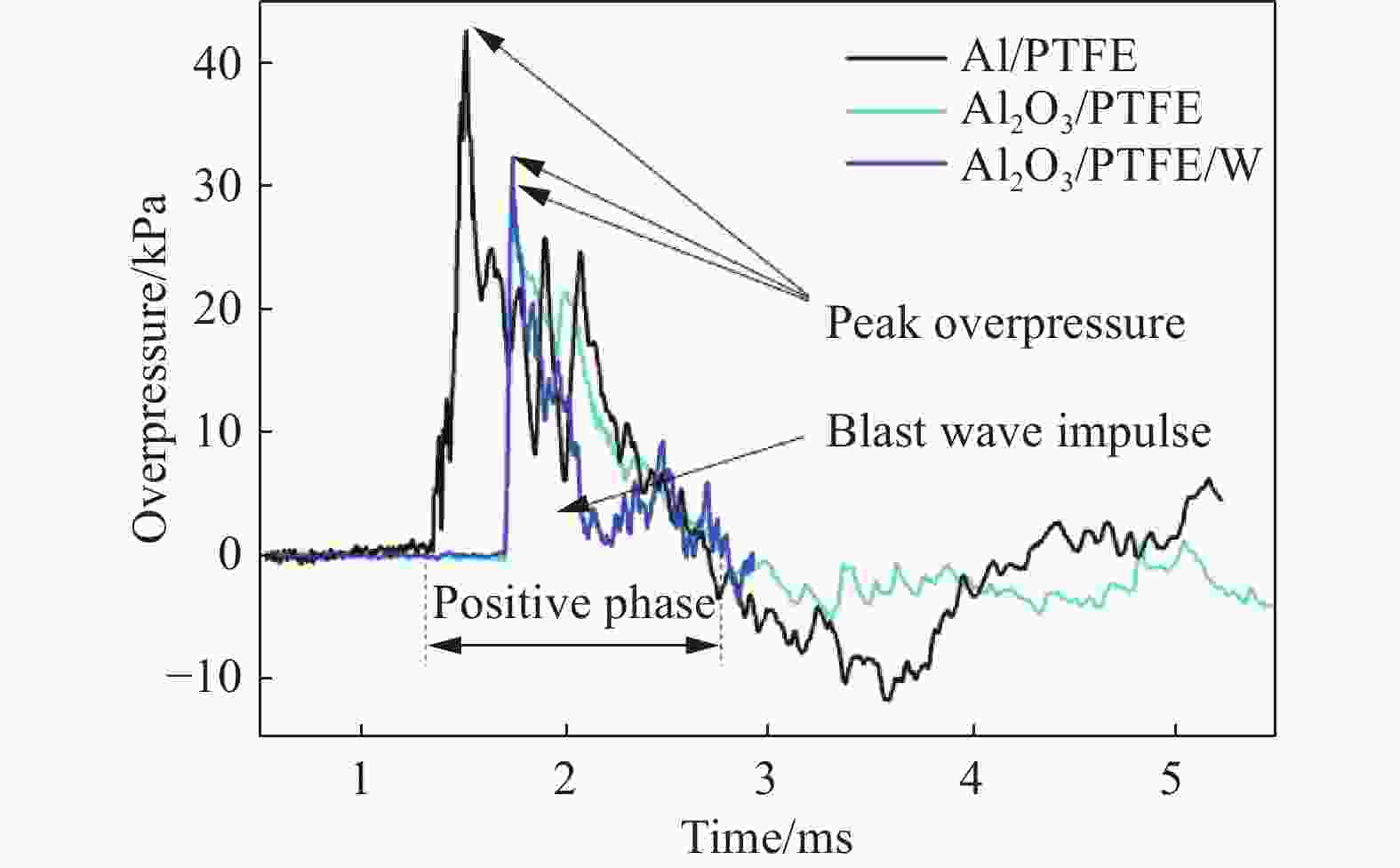

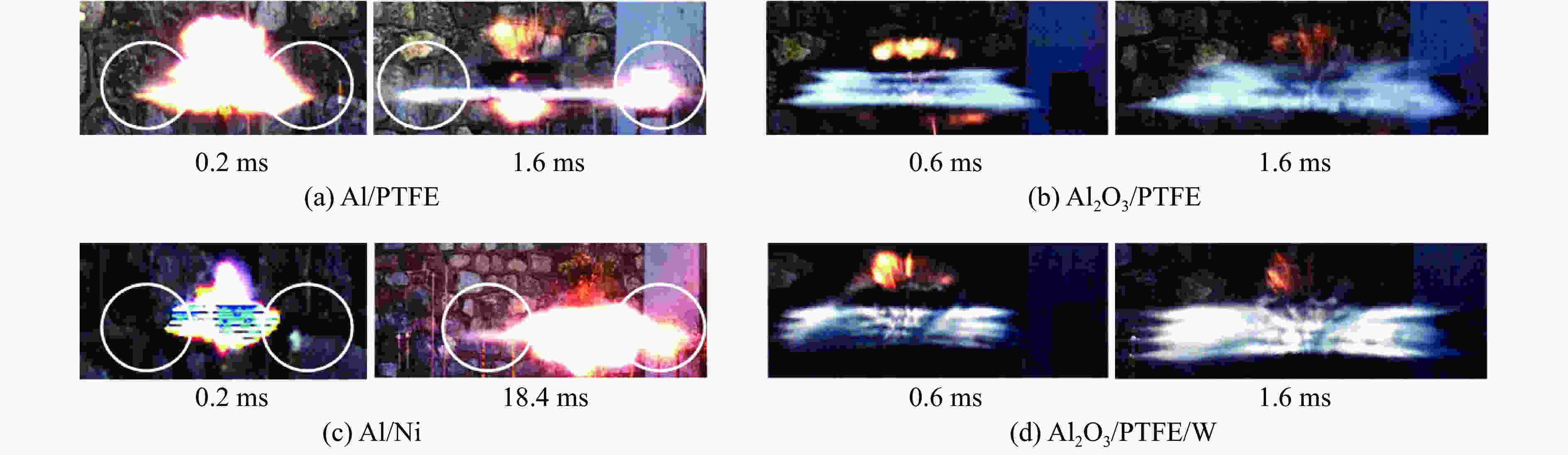

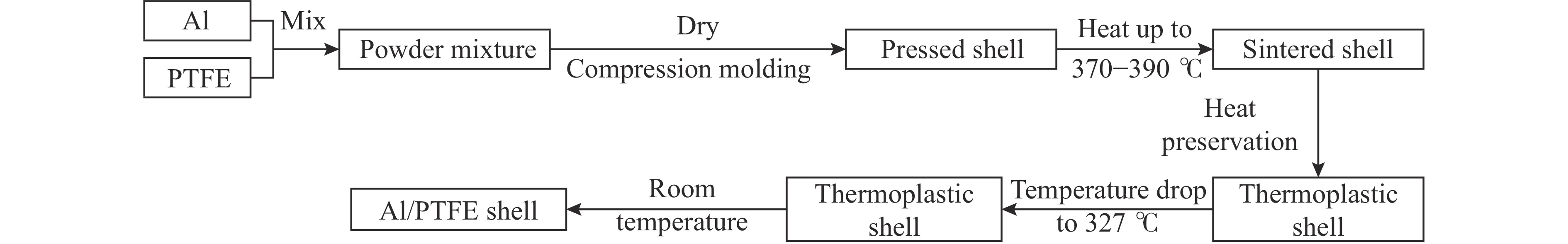

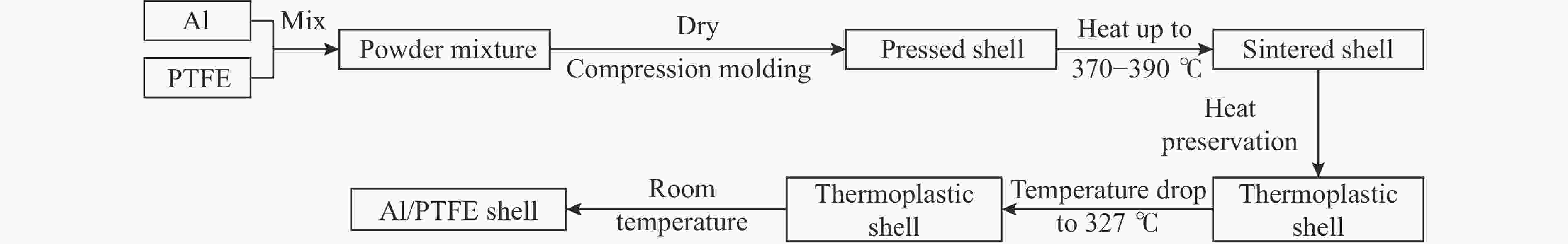

摘要: 为了研究活性材料爆炸驱动反应特性,基于粉末压制成型工艺,制备了Al/PTFE、Al/Ni两种典型的活性材料及Al2O3/PTFE、Al2O3/PTFE/W惰性材料。通过爆炸驱动试验,并结合高速摄影、远红外热像仪以及峰值超压测试技术,分析了不同活性材料壳体装药爆炸火球、温度场分布及空气冲击波峰值超压等特性。同时,在炸药爆炸空气冲击波峰值超压经验计算模型中考虑了活性材料释放的化学能,分析了反应释放能量对空气冲击波的影响规律。结果表明:活性材料在爆炸驱动过程中经历了强加载条件下反应、产生碎片并向四周飞散、撞击钢板及后续反应等阶段。活性材料对炸药爆炸产生的空气冲击波具有强化作用,爆炸加载瞬间材料仅发生了部分化学反应。Abstract: In order to study the reaction characteristics of reactive materials under explosive loading, two typical reactive materials, namely Al/PTFE and Al/Ni, as well as two inert materials, namely Al2O3/PTFE and Al2O3/PTFE/W, were manufactured by powder compaction. Explosion-driven tests were conducted on the four materials, by combining with the high-speed photography technology, far-infrared thermal imager testing technology and peak overpressure testing technology. The characteristics of explosive fireball, distribution of temperature and peak overpressure of blast shock waves were analyzed for different materials. Furthermore, the chemical energy released from the reactive materials was considered in the empirical calculation model to estimate the peak overpressure of blast shock waves. The influence of the released energy on the blast shock wave was analyzed by the model. The results show that during the explosion driving process, the reactive materials undergo such stages as reaction under strong loading, debris generation and scattering around, impact on steel plates and subsequent reaction. Reactive materials can strengthen the air shock wave produced by explosive explosion, and only part of the chemical reaction occurs at the moment of explosion loading.

-

表 1 材料性能参数

Table 1. The parameters of materials

材料 质量比 密实度/% Qm/(kJ·g−1) σ/MPa ρ/(g·cm−3) m/g Al/PTFE 26.5∶73.5 99.5 8.87 20.43 2.27 87.78 Al/Ni 23.9∶76.1 68.9 1.38 27.70 3.97 157.01 Al2O3/PTFE 13.6∶86.4 96.4 0 16.66 2.20 87.45 Al2O3/PTFE/W 20∶36.9∶43.1 67.9 0 18.47 3.91 154.72 表 2 压电传感器测试爆炸参数

Table 2. Test data by piezoelectric sensors

材料 测试编号 m/g M/g Qt/kJ Δ p/kPa y/% Al2O3/PTFE 2 87.45 44.0 0 30.2 0 Al2O3/PTFE/W 3 154.72 44.0 0 32.8 0 Al/PTFE 4 87.78 44.0 778.6 43.3 17.48 表 3 不同材料在爆炸驱动下反应度计算结果

Table 3. Calculation results of reactive efficiency of different materials under explosion loading

材料 编号 m/g M/g Qt/kJ Δ p/kPa y/% Alumina[12] Al2O3 8.91 5.53 0 91.5 0 Mechanically alloyed powder[12] Al·Mg (NJIT)-1 11.30 6.12 181.5 137.5 21.60 Al·Mg (NJIT)-2 9.95 5.71 163.2 139.9 26.32 Flake aluminum[12] Al (flake) 9.70 5.57 150.1 135.2 26.85 Spherical aluminum powder (repeats) [12] Al H-2-1 9.95 5.78 167.2 120.6 17.39 Al H-2-2 10.83 6.02 167.6 123.9 17.98 Al H-2-3 10.02 5.83 168.6 125.4 19.06 Atomized alloy powder[12] Al·Mg(Valimet) 9.62 5.73 176.4 130.6 20.56 -

[1] 门建兵, 蒋建伟, 帅俊峰, 等. 复合反应破片爆炸成型与毁伤实验研究 [J]. 北京理工大学学报, 2010, 30(10): 1143–1146. DOI: 10.1002/9783527628650.ch2.MEM J B, JIANG J W, SHUAI J F, et al. Experimental research on formation and terminal effect of explosively formed compound energetic structural fragments [J]. Transactions of Beijing Institute of Technology, 2010, 30(10): 1143–1146. DOI: 10.1002/9783527628650.ch2. [2] 张先锋, 赵晓宁. 多功能含能结构材料研究进展 [J]. 含能材料, 2009, 17(6): 731–739. DOI: 10.3969/j.issn.1006-9941.2009.06.021.ZHANG X F, ZHAO X N. Review on multifunctional energetic structural materials [J]. Chinese Journal of Energetic Materials, 2009, 17(6): 731–739. DOI: 10.3969/j.issn.1006-9941.2009.06.021. [3] 陈鹏, 卢芳云, 覃金贵, 等. 含钨活性材料动态压缩力学性能 [J]. 兵工学报, 2015, 36(10): 1861–1866. DOI: 10.3969/j.issn.1000-1093.2015.10.006.CHENG P, LU F Y, QIN J G, et al. Dynamic compressive mechanical properties of tungstenic reactive material [J]. Acta Armamentarii, 2015, 36(10): 1861–1866. DOI: 10.3969/j.issn.1000-1093.2015.10.006. [4] VARAS J M, PHILIPPENS M, MEIJIER S R, et al. Physics of IED blast shock tube simulations for mTBI research [J]. Frontiers in Neurology, 2011, 2(58): 1–14. DOI: 10.3389/fneur.2011.00058. [5] ZHANG F, WILSON W H. The effect of charge reactive metal cases on air blast [J]. American Institute of Physics Conference Proceedings, 2009, 1195(1): 149–152. DOI: 10.1063/1.3295089. [6] ARNOD W, ROTTENKOLBER E. Fragment mass distribution of metal cased explosive charges [J]. International Journal of Impact Engineering, 2008, 35(12): 1393–1398. DOI: 10.1016/j.ijimpeng.2008.07.049. [7] AMES R. Energy release characteristics of impact-initiated energetic materials [J]. MRS Proceedings, 2005, 896(3): 321–333. DOI: 10.1557/PROC-0896-H03-08. [8] KELLY S C, THADHANI N N. Shock compression response of highly reactive Ni+Al multilayered thin foils [J]. Journal of Applied Physics, 2016, 119(9): 095903. DOI: 10.1063/1.4942931. [9] CLEMENSON M. Enhancing reactivity of aluminum-based structural energetic materials [D]. Illinois: University of Illinois at Urbana-Champaign, 2015: 52−58. [10] FABIGNON Y, TRUBERT J F, LAMBERT D, et al. Combustion of aluminum particles in solid rocket motors [C] // 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. Huntsville, Alabama, USA: American Institute for Aeronautics and Astronautics, 2003: 1. DOI: 10.2514/6.2003-4807. [11] ORTH L, KRIER H. Shock physics for nonideal detonations of metallized energetic explosives [J]. Symposium on Combustion, 1998, 27(2): 2327–2333. DOI: 10.1016/S0082-0784(98)80083-0. [12] GUADARRAMA J, DREIZIN E L, GLUMAC N. Reactive liners prepared using powders of aluminum and aluminum-magnesium alloys [J]. Propellants, Explosives, Pyrotechnics, 2016, 41(4): 605–611. DOI: 10.1002/prep.201500230. [13] FROST D L, GOROSHIN S, JANIDLO S, et al. Fragmentation of reactive metallic particles during impact with a plate [J]. American Institute of Physics Conference Proceedings, 2004, 706(1): 451–454. DOI: 10.1063/1.1780275. [14] AMES R. Vented chamber calorimetry for impact-initiated energetic materials [C] // 43rd AIAA Aerospace Sciences Meeting and Exhibit. Reno, Nevada, USA: American Institute for Aeronautics and Astronautics, 2013: 10−13. DOI: 10.2514/6.2005-279. [15] XIONG W, ZHANG X, WU Y, et al. Influence of additives on microstructures, mechanical properties and shock-induced reaction characteristics of Al/Ni composites [J]. Journal of Alloys and Compounds, 2015, 648: 540–549. DOI: 10.1016/j.jallcom.2015.07.004. [16] WEI C T, VITALI E, JIANG F, et al. Quasi-static and dynamic response of explosively consolidated metal-aluminum powder mixtures [J]. Acta Materialia, 2012, 60(3): 1418–1432. DOI: 10.1016/j.actamat.2011.10.027. [17] ZHANG X F, SHI A S, QIAO L, et al. Experimental study on impact-initiated characters of multifunctional energetic structural materials [J]. Journal of Applied Physics, 2013, 113(8): 2129–1156. DOI: 10.1063/1.4793281. [18] 饶国宁. 爆炸能量输出特性及爆炸波与目标作用的研究[D]. 南京: 南京理工大学, 2007: 1−20. [19] KINNEY G F, GRAHAM K J. Explosive shocks in air [M]. 2nd ed. New York: Springer-Verlag, 1985: 35−49. [20] 任会兰, 李尉, 刘晓俊, 等. 钨颗粒增强铝/聚四氟乙烯材料的冲击反应特性 [J]. 兵工学报, 2016, 37(5): 872–878. DOI: 10.3969/j.issn.1000-1093.2016.05.014.REN H L, LI W, LIU X J, et al. Reaction behaviors of Al/PTFE materials enhanced by W particles [J]. Acta Armamentarii, 2016, 37(5): 872–878. DOI: 10.3969/j.issn.1000-1093.2016.05.014. [21] 张先锋, 李向东, 沈培辉, 等. 终点效应学[M]. 北京: 北京理工大学出版社, 2017: 67−72. [22] 张守中. 爆炸与冲击动力学[M]. 北京: 兵器工业出版社, 1993: 369−375. -

下载:

下载: