Static/dynamic mechanical properties and a constitutive model of a polyvinyl chloride elastomer

-

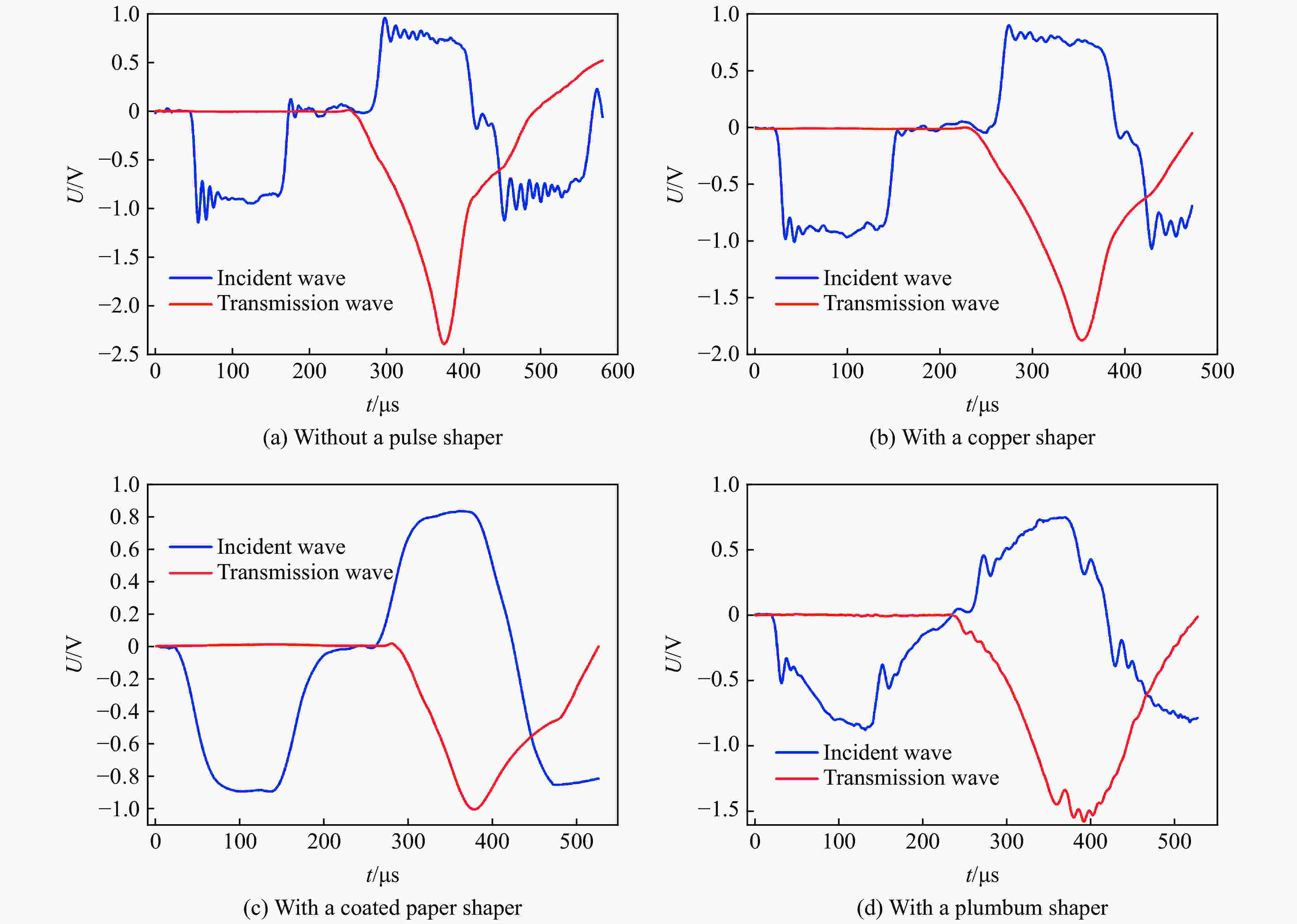

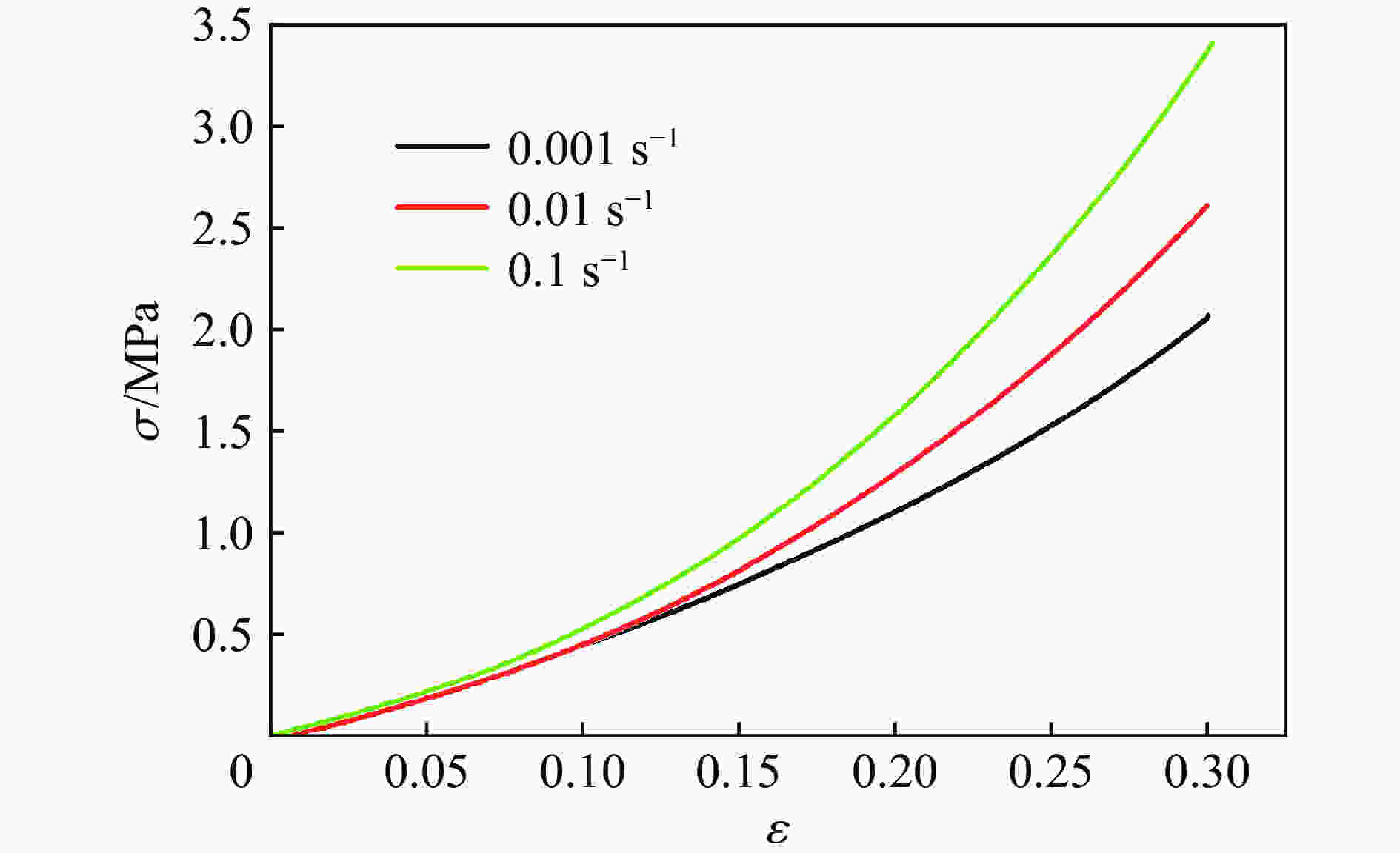

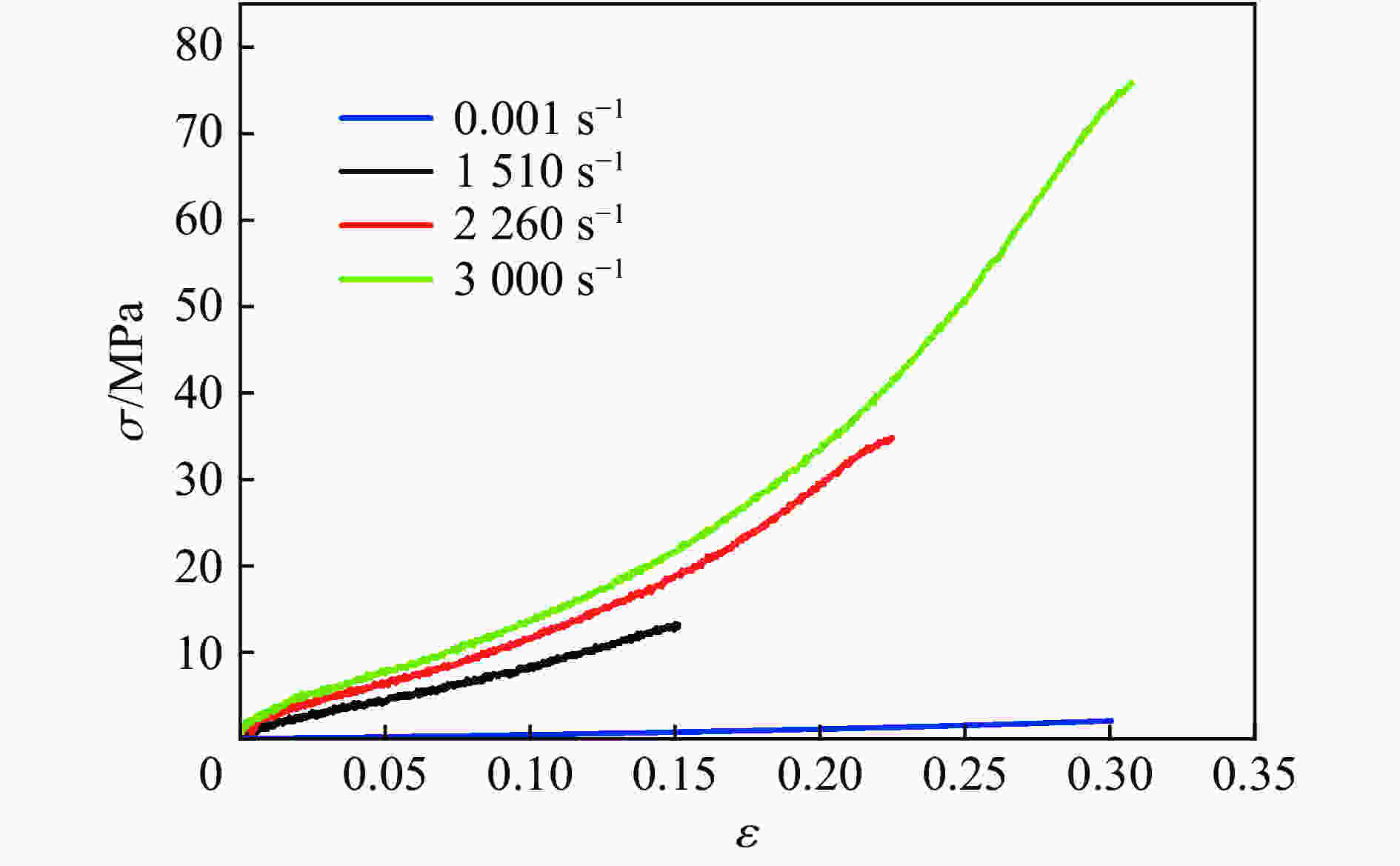

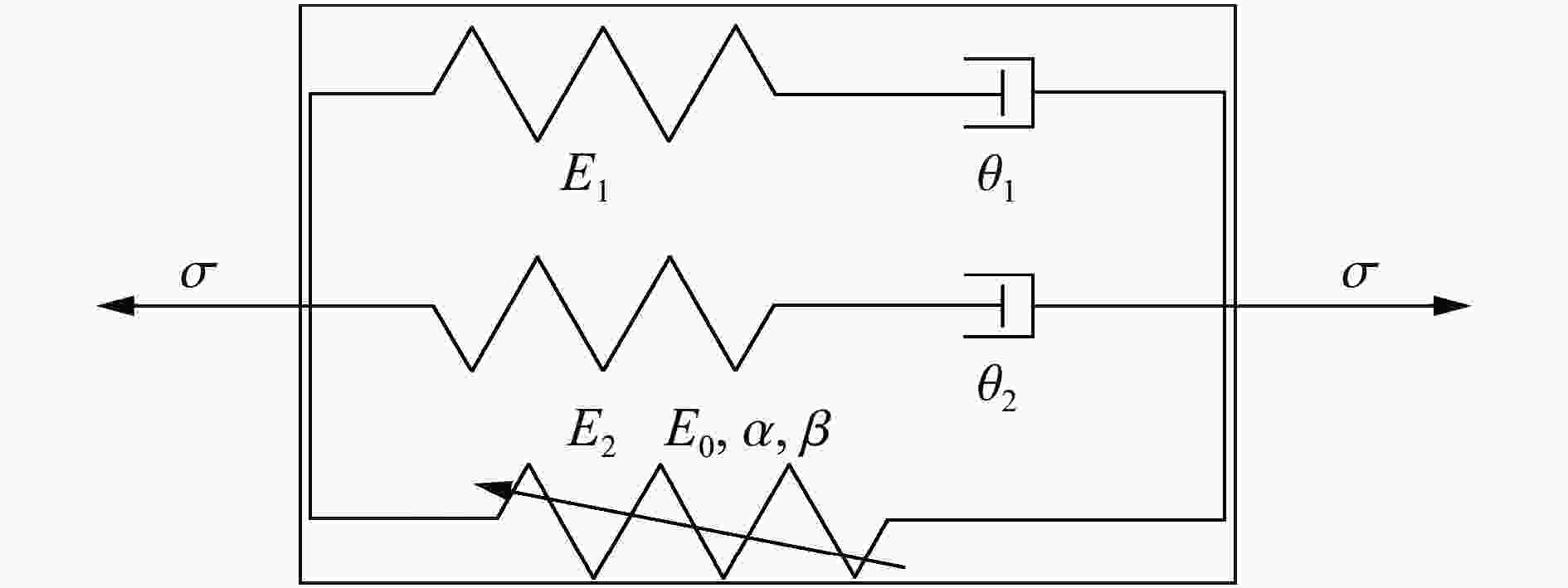

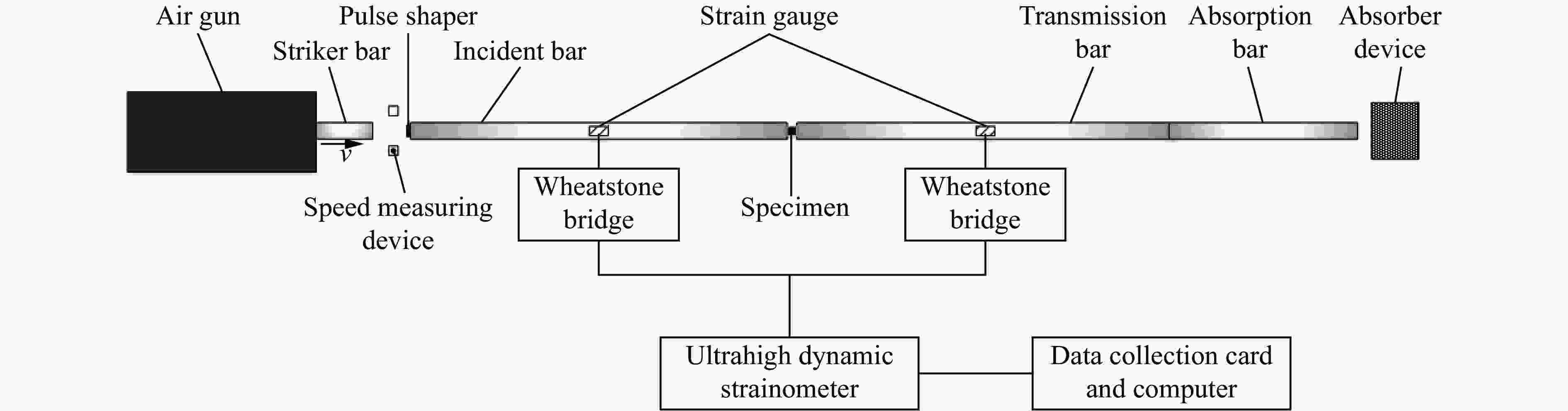

摘要: 为揭示聚氯乙烯弹性体在静、动态载荷下的力学性能,采用万能材料试验机和改进的分离式霍普金森压杆实验装置获得了材料在应变率为0.001、0.01、0.1、1 510、2 260和3 000 s−1下的应力应变曲线,并以屈服强度为整形器优选参数,对比了紫铜、铜版纸和铅等3种整形器材料的整形效果。使用修正的ZWT非线性黏弹性本构模型描述聚氯乙烯弹性体在静、动态载荷下的力学性能。结果表明:聚氯乙烯弹性体在静态载荷下具有应变率效应和显著的超弹性特性,动态载荷下表现出较明显的应变率效应和较强的抗变形能力,且静动态载荷下的力学行为受应变历史影响较大。3种整形器材料中铜版纸的整形效果最好。修正后的ZWT非线性黏弹性本构模型能够得到统一参数的本构表达式,且各应变率下的拟合结果与实验结果具有较好的一致性。

-

关键词:

- 聚氯乙烯弹性体 /

- 静、动态力学性能 /

- ZWT非线性黏弹性本构模型 /

- 整形器

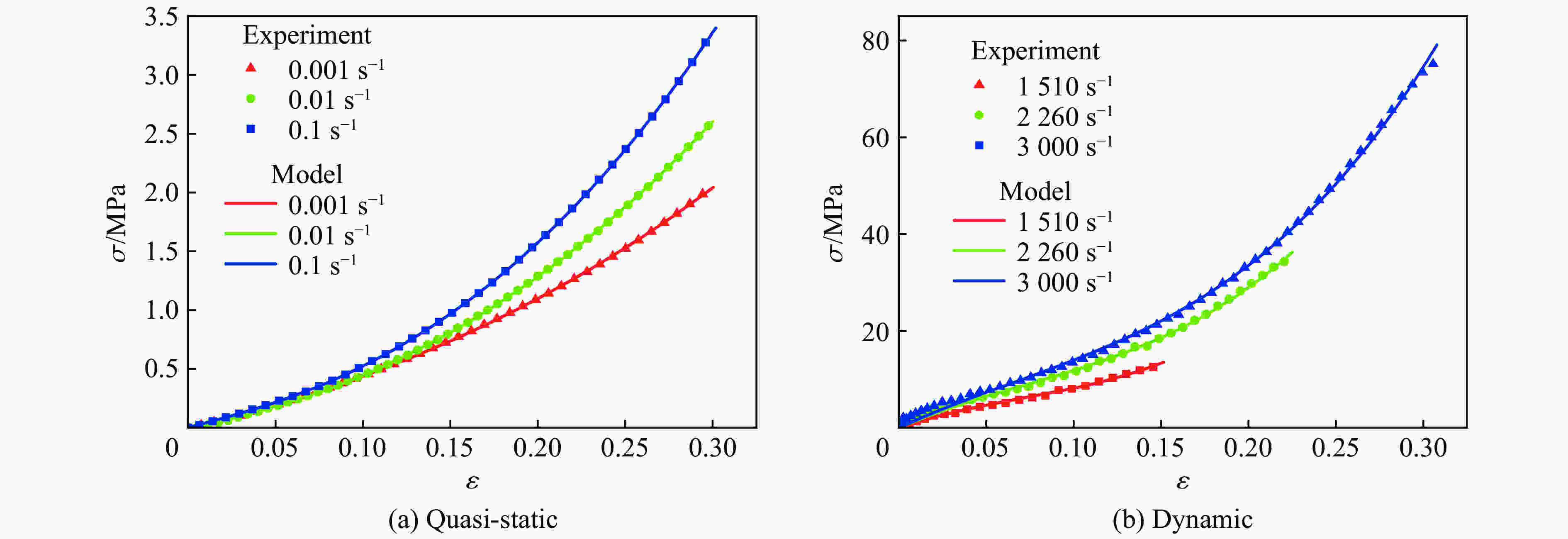

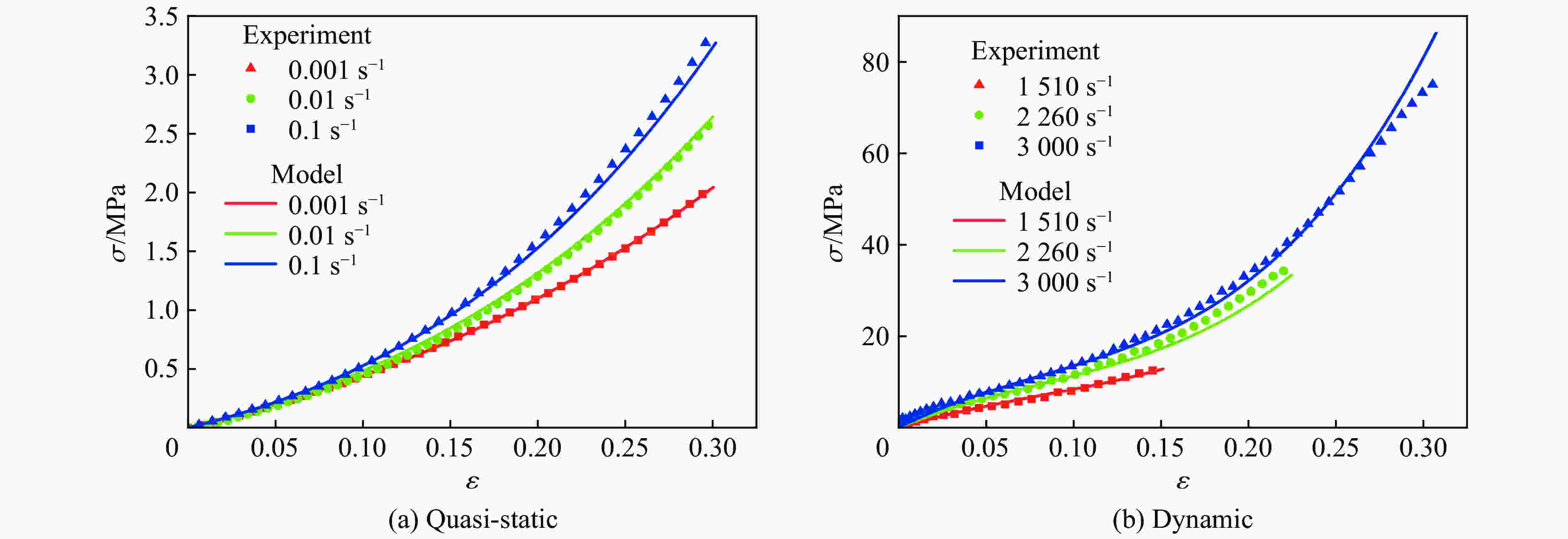

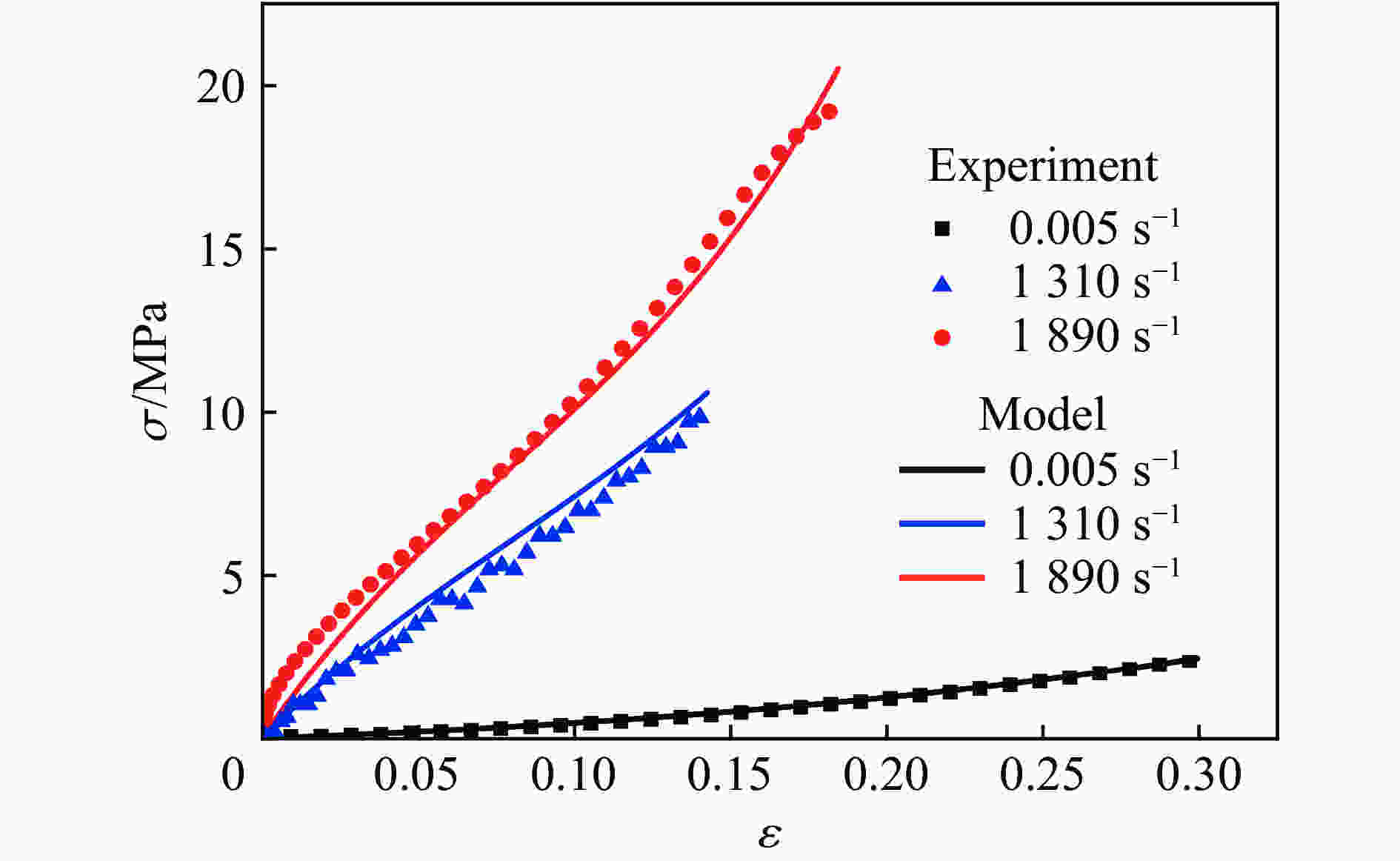

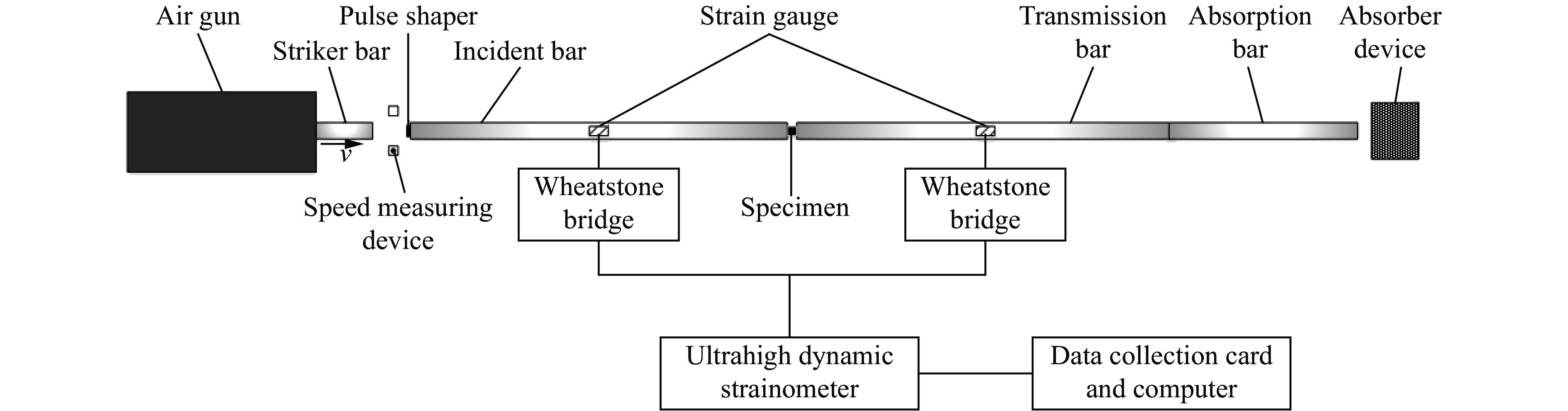

Abstract: In order to reveal the mechanical properties of a polyvinyl chloride elastomer under static and dynamic loading, the stress-strain curves of the polyvinyl chloride elastomer at six different strain rates (0.001, 0.01, 0.1, 1 510, 2 260 and 3 000 s−1) were obtained by using a universal material testing machine and a modified split Hopkinson pressure bar experimental device. The shaping effects of the three shaper materials including copper, coated paper and plumbum were compared by using the yield strength as the optimized parameter of the shapers. It is difficult to obtain a unified parametric constitutive expression directly using the original ZWT nonlinear viscoelastic constitutive model, and the constitutive model is less efficient in describing the mechanical properties of the materials under static and dynamic loading. Therefore, the modified ZWT nonlinear viscoelastic constitutive model was used to describe the mechanical properties of the material under static and dynamic loading. The results show that the polyvinyl chloride elastomer has a strain-rate effect and significant hyperelastic properties under static load. It exhibits a more obvious strain-rate effect and strong resistance to deformation under dynamic loading, and the mechanical behaviors under static and dynamic loading are greatly affected by the strain histories. Coated paper has the best shaping effect among the three shaper materials. The modified ZWT nonlinear viscoelastic constitutive model can obtain constitutive expressions with uniform parameters, and the fitting results at various strain rates are in good agreement with the experimental results. -

表 1 整形器材料参数

Table 1. Parameters of the pulse shaper material

整形器

材质整形器尺寸 屈服强度/

MPa撞击速度/

(m·s−1)紫铜 $\varnothing $10 mm×0.6 mm 70.0 8.12 铜版纸 10 mm×10 mm×0.6 mm

(双层厚)5.95 8.10 铅 $\varnothing $10 mm×0.6 mm 5.0 7.99 表 2 拟合参数值

Table 2. Fitted parameters

$\dot \varepsilon {\rm{/}}{{\rm{s}}^{{\rm{ - 1}}}}$ E0 or (E0+E1)/MPa α/MPa β/MPa E1 or E2/MPa θ1 or θ2/s 相关系数平方R2 0.001 3.14 7.619 10.97 0.419 7 2117 0.999 9 0.01 2.854 14.86 15.15 6.664×10−9 5.933×10−9 1 0.1 2.924 17.98 31.19 1.32 0.1775 1 1 510 −81.4 −748.8 3 580 202.7 134.6 0.995 5 2 260 138.2 −669.9 3 100 17.1 9552 0.997 3 3 000 90.1 −517.9 2 650 75.64 77.58 0.998 6 表 3 修正后的ZWT模型的拟合结果

Table 3. The fitting result of the modified ZWT model

$\dot \varepsilon {\rm{/}}{{\rm{s}}^{{\rm{ - 1}}}}$ 相关系数平方R2 $\dot \varepsilon {\rm{/}}{{\rm{s}}^{{\rm{ - 1}}}}$ 相关系数平方R2 0.001 0.999 9 1 510 0.997 3 0.01 0.998 3 2 260 0.993 0 0.1 0.997 4 3 000 0.996 1 表 4 修正后的ZWT模型的验证结果

Table 4. Verification result of the modified ZWT model

$\dot \varepsilon {\rm{/}}{{\rm{s}}^{{\rm{ - 1}}}}$ 相关系数平方R2 0.005 0.997 1 1 310 0.988 7 1 890 0.996 3 -

[1] BERNARD C A, BAHLOULI N, WAGNER-KOCHER C, et al. Multiscale description and prediction of the thermomechanical behavior of multilayered plasticized PVC under a wide range of strain rate [J]. Journal of Materials Science, 2018, 53(20): 14834–14849. DOI: 10.1007/s10853-018-2625-5. [2] JHA N K, NACKENHORST U, PAWAR V S, et al. On the constitutive modelling of fatigue damage in rubber-like materials [J]. International Journal of Solids and Structures, 2019, 159: 77–89. DOI: 10.1016/j.ijsolstr.2018.09.022. [3] KIDD T H, ZHUANG S, RAVICHANDRAN G. In situ mechanical characterization during deformation of PVC polymeric foams using ultrasonics and digital image correlation [J]. Mechanics of Materials, 2012, 55: 82–88. DOI: 10.1016/j.mechmat.2012.08.001. [4] 刘高冲, 金涛, 陈圣家, 等. 聚氨酯弹性体静动态加载条件下力学性能的研究 [J]. 材料导报, 2017, 31(S1): 315–318.LIU G C, JIN T, CHEN S J, et al. Study on mechanical properties of polyurethane elastomer under static/dynamic loading conditions [J]. Materials Review, 2017, 31(S1): 315–318. [5] 王宝珍, 胡时胜. 猪后腿肌肉的冲击压缩特性实验 [J]. 爆炸与冲击, 2010, 30(1): 33–38. DOI: 10.11883/1001-1455(2010)01-0033-06.WANG B Z, HU S S. Dynamic compression experiments of porcine ham muscle [J]. Explosion and Shock Waves, 2010, 30(1): 33–38. DOI: 10.11883/1001-1455(2010)01-0033-06. [6] 王宝珍, 胡时胜. 猪肝动态力学性能及本构模型研究 [J]. 力学学报, 2017, 49(6): 1399–1408. DOI: 10.6052/0459-1879-17-238.WANG B Z, HU S S. Research on dynamic mechanical response and constitutive model of porcine liver [J]. Chinese Journal of Theoretical and Applied Mechanics, 2017, 49(6): 1399–1408. DOI: 10.6052/0459-1879-17-238. [7] SONG B, CHEN W N, GE Y, et al. Dynamic and quasi-static compressive response of porcine muscle [J]. Journal of Biomechanics, 2007, 40(13): 2999–3005. DOI: 10.1016/j.jbiomech.2007.02.001. [8] NAIK N K, SHANKAR P J, KAVALA V R, et al. High strain rate mechanical behavior of epoxy under compressive loading: experimental and modeling studies [J]. Materials Science and Engineering: A, 2011, 528(3): 846–854. DOI: 10.1016/j.msea.2010.10.099. [9] SNEDEKER J G, NIEDERER P, SCHMIDLIN F R, et al. Strain-rate dependent material properties of the porcine and human kidney capsule [J]. Journal of Biomechanics, 2005, 38(5): 1011–1021. DOI: 10.1016/j.jbiomech.2004.05.036. [10] 马赛尔, 许进升, 童心, 等. 高密度聚乙烯单轴拉伸力学性能及本构关系研究 [J]. 中国塑料, 2016, 30(4): 88–92. DOI: 10.19491/j.issn.1001-9278.2016.04.015.MA S E, XU J S, TONG X, et al. Research on uniaxially tensile mechanical properties and constitutive model of high density polyethylene [J]. China Plastics, 2016, 30(4): 88–92. DOI: 10.19491/j.issn.1001-9278.2016.04.015. [11] GUO H, GUO W G, AMIRKHIZI A V, et al. Experimental investigation and modeling of mechanical behaviors of polyurea over wide ranges of strain rates and temperatures [J]. Polymer Testing, 2016, 53: 234–244. DOI: 10.1016/j.polymertesting.2016.06.004. [12] JIANG J, XU J S, ZHANG Z S, et al. Rate-dependent compressive behavior of EPDM insulation: experimental and constitutive analysis [J]. Mechanics of Materials, 2016, 96: 30–38. DOI: 10.1016/j.mechmat.2016.02.003. [13] 孙紫建, 王礼立. 高应变率大变形下的聚丙烯/尼龙共混高聚物损伤型本构特性 [J]. 爆炸与冲击, 2006, 26(6): 492–497. DOI: 10.11883/1001-1455(2006)06-0492-06.SUN Z J, WANG L L. The constitutive behavior of PP/PA polymer blends taking account of damage evolution at high strain rate and large deformation [J]. Explosion and Shock Waves, 2006, 26(6): 492–497. DOI: 10.11883/1001-1455(2006)06-0492-06. [14] XU X, GAO S Q, ZHANG D M, et al. Mechanical behavior of liquid nitrile rubber-modified epoxy resin: experiments, constitutive model and application [J]. International Journal of Mechanical Sciences, 2019, 151: 46–60. DOI: 10.1016/j.ijmecsci.2018.11.003. [15] LIU K, WU Z L, REN H L, et al. Strain rate sensitive compressive response of gelatine: experimental and constitutive analysis [J]. Polymer Testing, 2017, 64: 254–266. DOI: 10.1016/j.polymertesting.2017.09.008. [16] 周海霞, 李世鹏, 谢侃, 等. HTPB推进剂宽泛应变率下黏弹性本构模型研究 [J]. 固体火箭技术, 2017, 40(3): 325–329, 396. DOI: 10.7673/j.issn.1006-2793.2017.03.010.ZHOU H X, LI S P, XIE K, et al. Research on the viscoelastic constitutive model of HTPB propellant over a wide range of strain rates [J]. Journal of Solid Rocket Technology, 2017, 40(3): 325–329, 396. DOI: 10.7673/j.issn.1006-2793.2017.03.010. [17] 卢芳云, CHEN W, FREW D J. 软材料的SHPB实验设计 [J]. 爆炸与冲击, 2002, 22(1): 15–19.LU F Y, CHEN W, FREW D J. A design of SHPB experiments for soft materials [J]. Explosion and Shock Waves, 2002, 22(1): 15–19. -

下载:

下载: