Vibration prediction and energy analysis of slope under blasting load in underpass tunnel

-

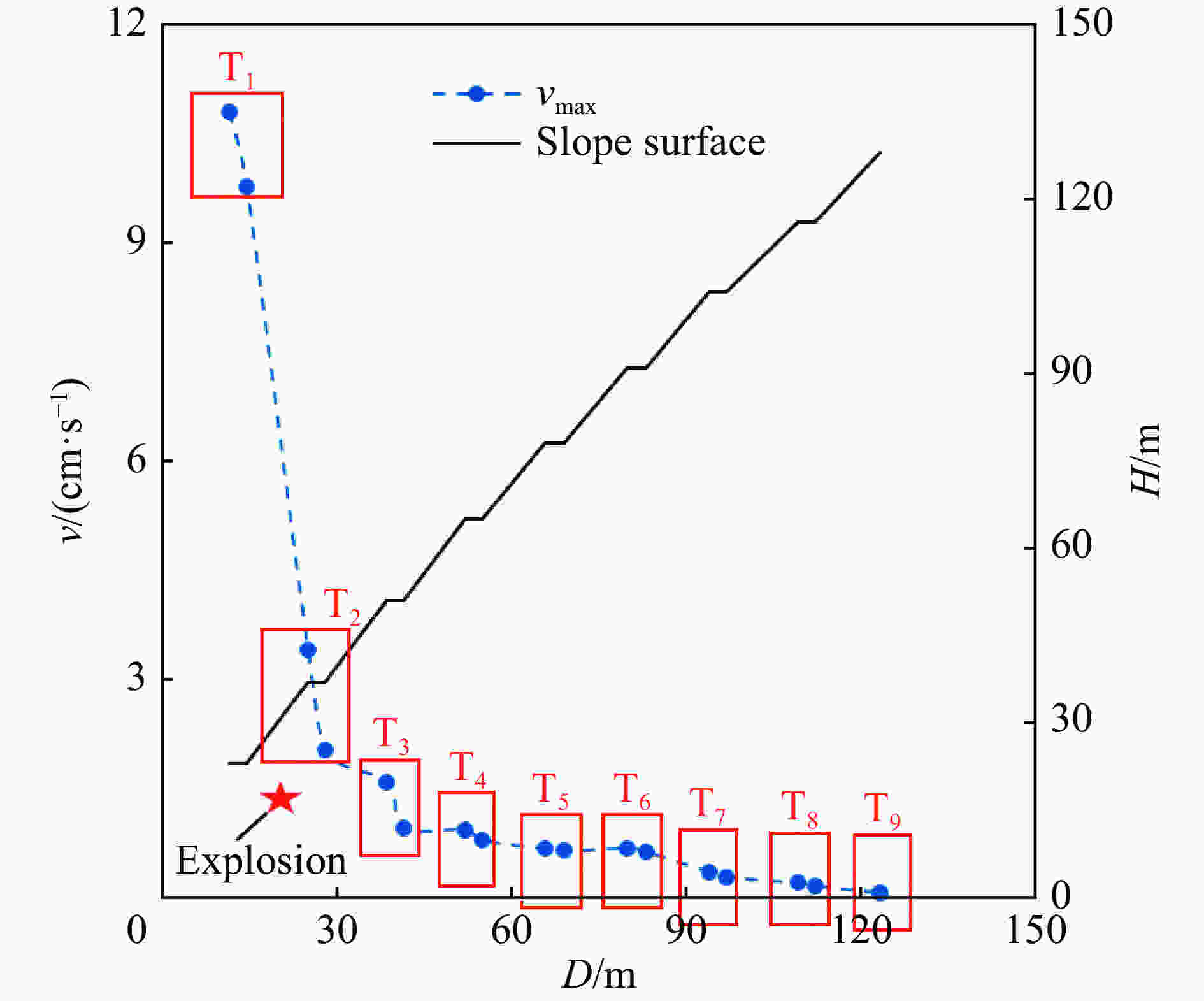

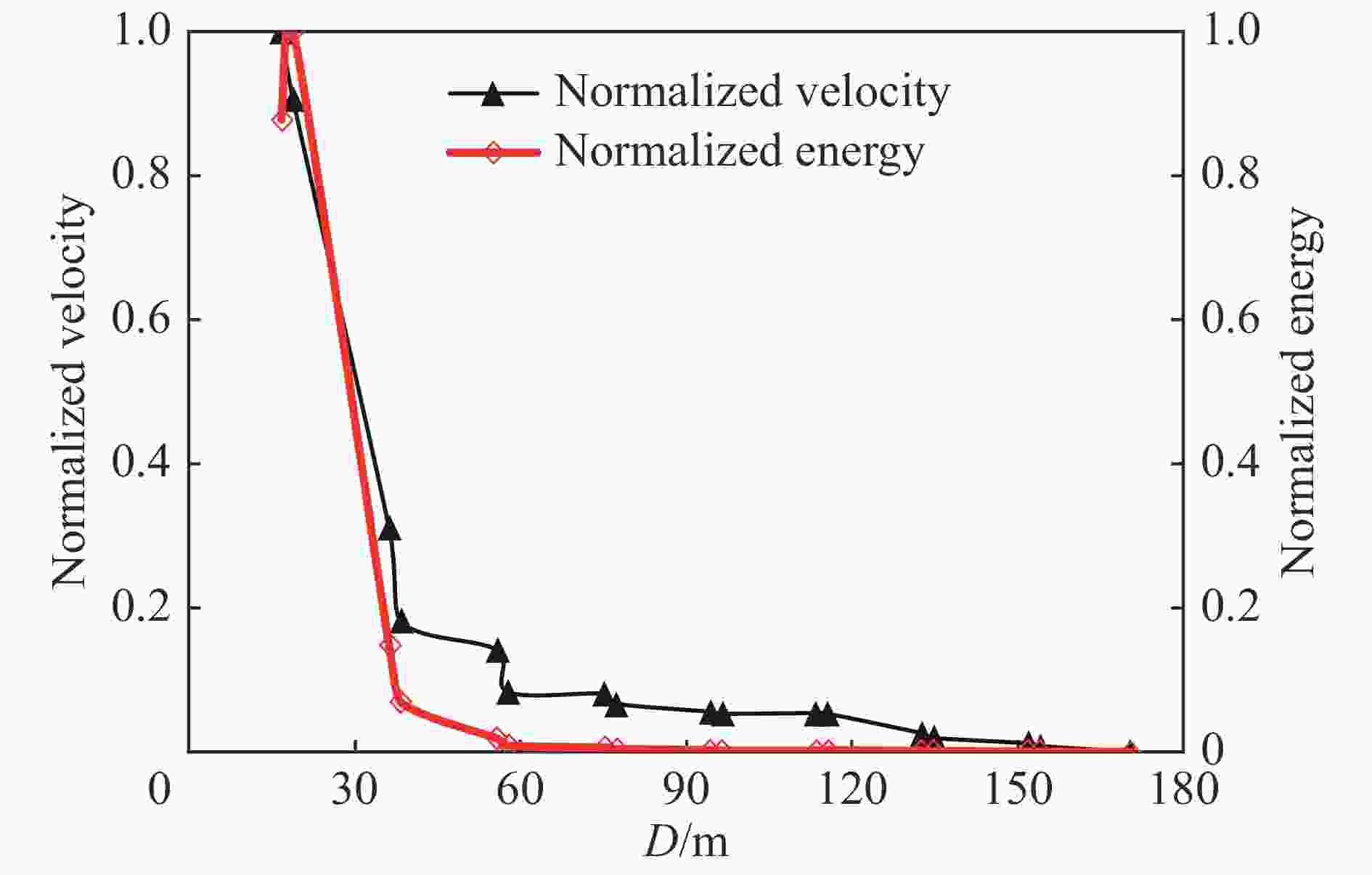

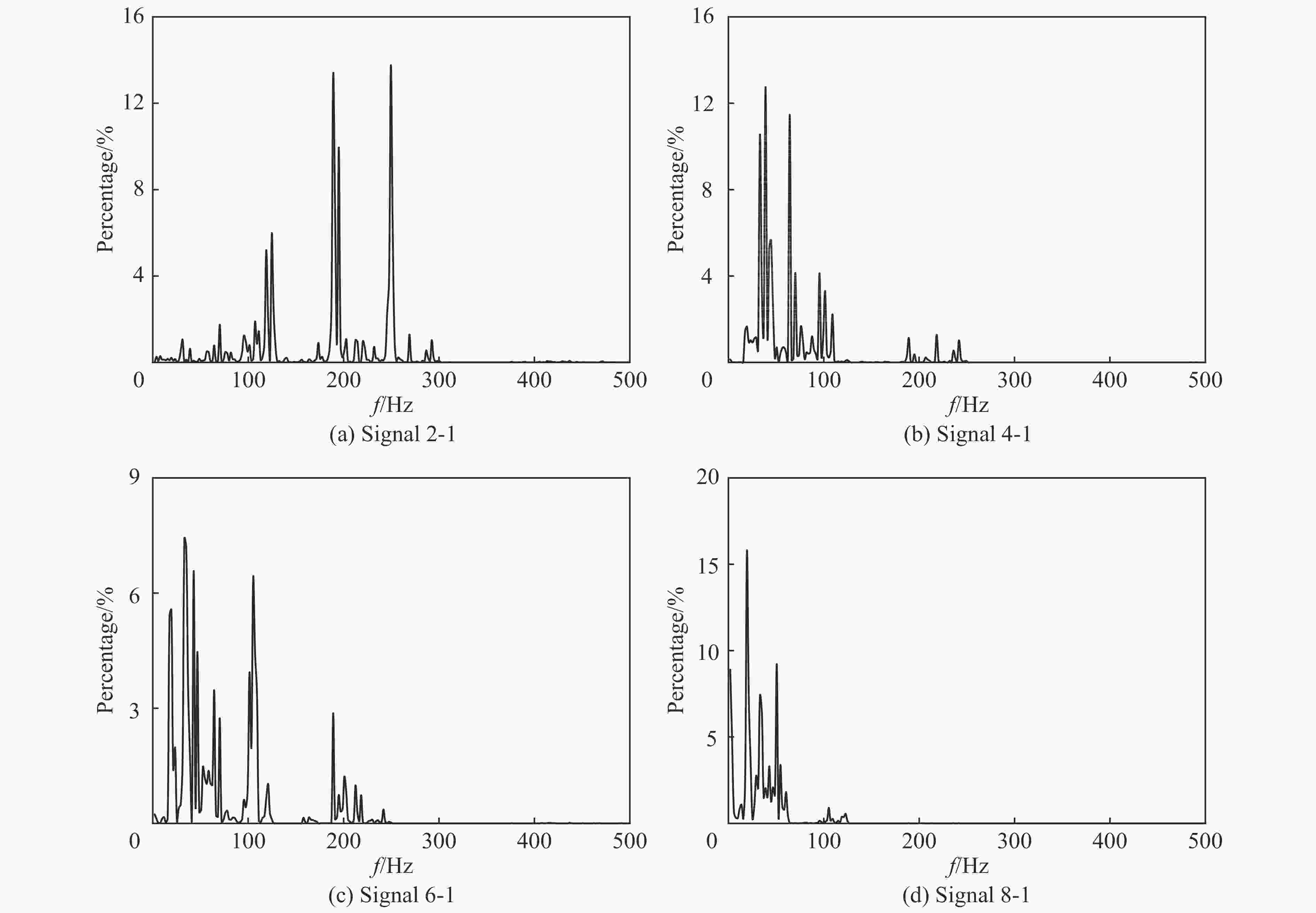

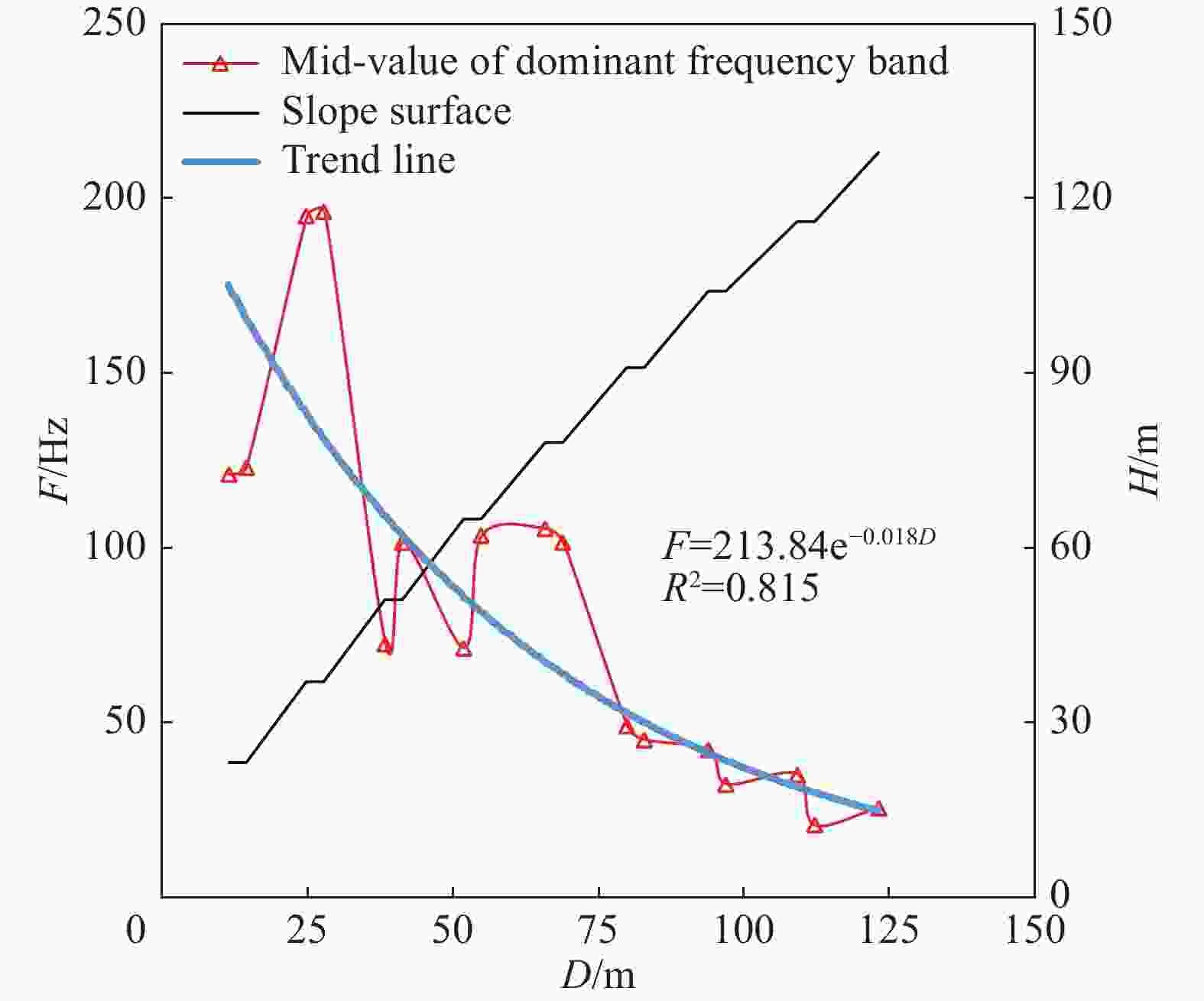

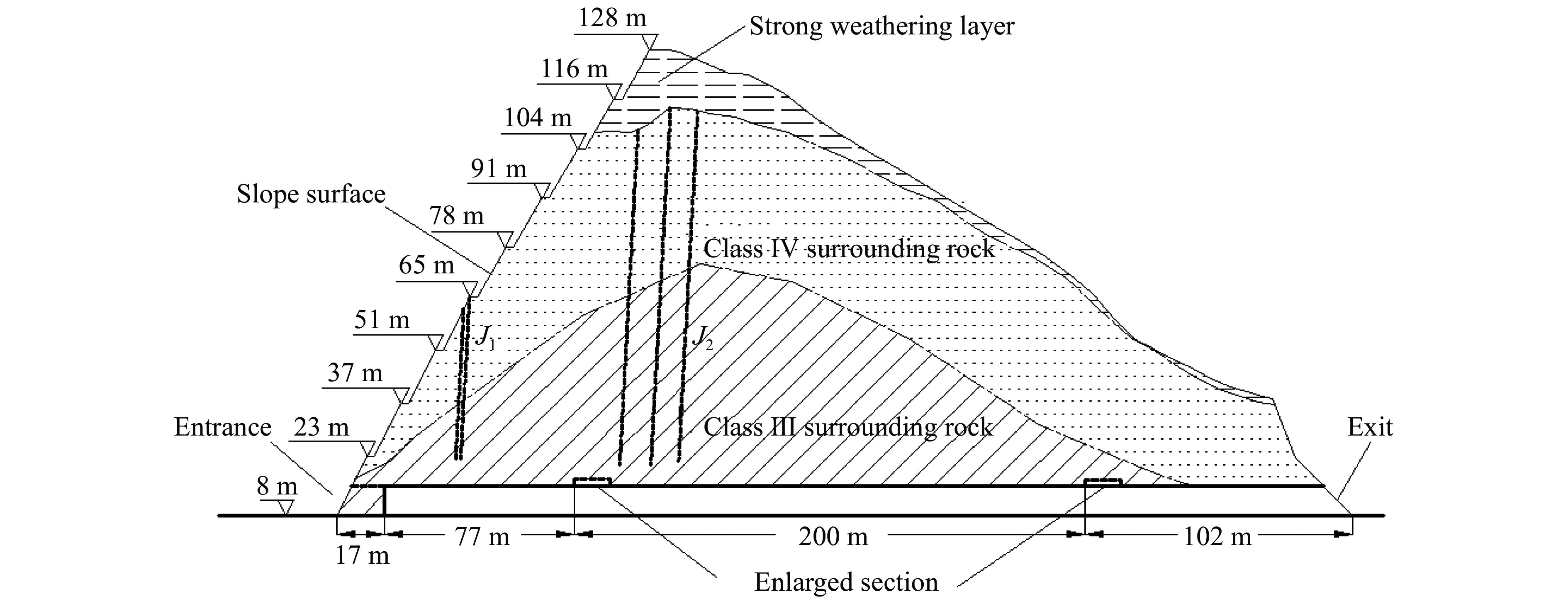

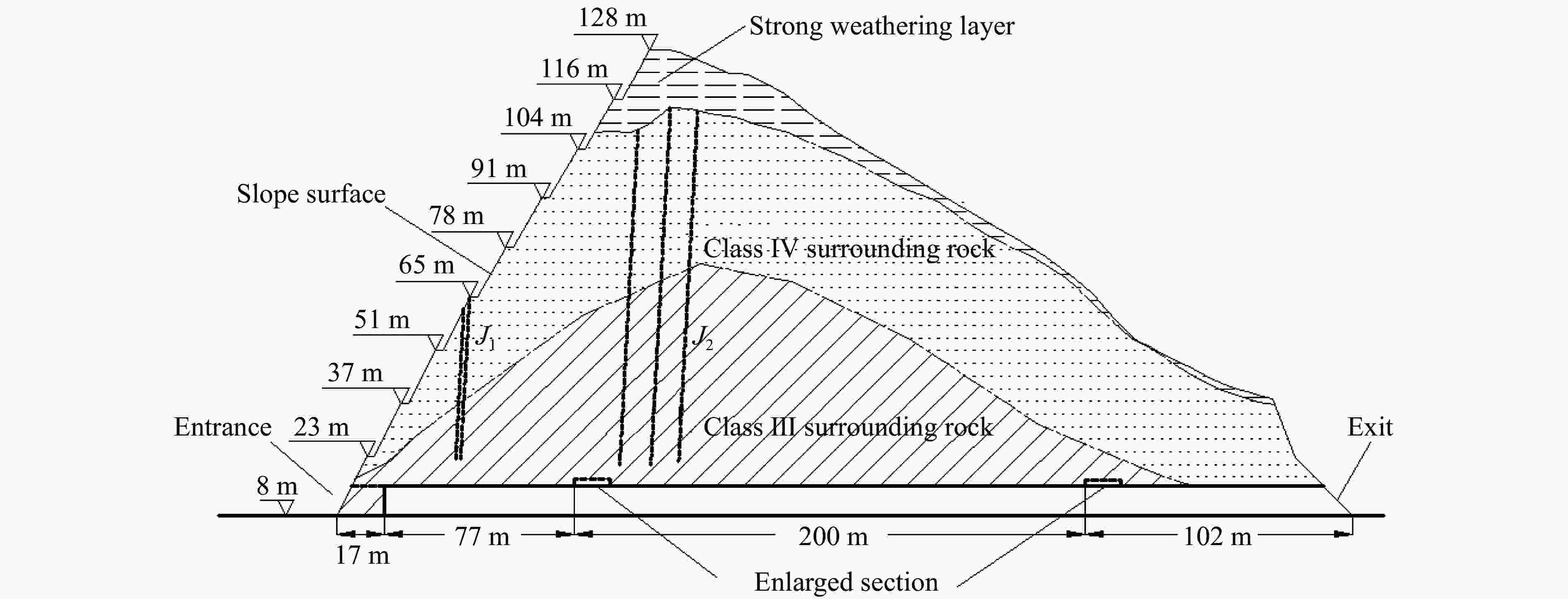

摘要: 为解决边坡与下穿近接隧道协同爆破施工安全难题,结合某石油储备基地扩建项目,运用量纲推导、现场实验与信号分析相结合的方法,构建考虑高程影响的振动峰值速度公式,研究隧道爆破振动能量沿坡面的衰减机制。结果显示,边坡同台阶边沿处质点振速峰值大于坡脚处,坡面局部存在振动速度高程放大效应;引入相对坡度H/D的爆破振动模型对坡面质点振速预测精度高,可反映边坡角对高程放大效应的影响;振动速度及能量沿坡面均呈现出近区衰减快、远区衰减慢的传播特性,同时隧道爆破振动能量集中分布在0~300 Hz范围的多个子振频带,且高频能量沿坡面衰减更快,能量卓越频带中值以指数形式衰减,能量最终向低频带集中。Abstract: In order to solve the safety problem in the construction of slope and underpass adjacent tunnel by cooperative blasting, based on the expansion project of a domestic petroleum reserve base, the formula of peak vibration velocity considering elevation effect was established, and the vibration energy attenuation mechanism of tunnel blasting along the slope surface was systematically studied by using method combining dimension derivation, field test and signal analysis. The results show that the peak value of particle velocity at the edge of the same step is larger than that at the foot of the inner slope, and there is an elevation amplification effect of vibration velocity on the local slope surface. The blasting vibration formula with relative slope H/D has high accuracy in predicting the particle vibration velocity on the slope, and can reflect the influence of slope angle on the elevation amplification effect of vibration velocity. The vibration velocity and energy decay faster in the near region and slower in the far region with the increase of propagation distance. The energy of tunnel blasting vibration is concentrated in several Sub-vibration frequency bands in the range of 0-300 Hz, and the high frequency energy decays faster along slope surface. The median of dominant frequency band decays exponentially, and the energy concentrates in the low frequency band eventually.

-

Key words:

- slope /

- tunnel blasting /

- dimensional analysis /

- peak velocity /

- vibration energy /

- elevation amplification effect /

- relative slope

-

表 1 坡面质点振动速度

Table 1. Particle vibration velocity on slope surface

振动信号 D/m H/m vmax/(cm·s−1) 1-1 5.6 12.5 10.81 1-2 2.6 9.78 2-1 7.9 26.5 3.41 2-2 10.9 2.02 3-1 21.4 40.5 1.59 3-2 24.4 0.96 4-1 34.9 54.5 0.94 4-2 37.9 0.79 5-1 48.9 67.5 0.67 5-2 51.9 0.64 6-1 63.0 80.5 0.68 6-2 66.0 0.63 7-1 77.0 93.5 0.35 7-2 80.0 0.28 8-1 92.1 105.5 0.20 8-2 95.1 0.16 9 146.2 117.5 0.07 注:D为水平爆心距;H为垂直爆心距;vmax为质点振动速度峰值;信号编号m-n,m表示台阶级数,m=1, 2, 3, …, 9;n=1表示台阶边沿处监测点,n=2表示内侧坡脚处监测点。 表 2 各变量量纲

Table 2. Dimension of variables

量纲 Q D Cp H E μ ρ f V M 1 0 0 0 1 0 1 0 0 L 0 1 1 1 −1 0 −3 0 1 T 0 0 −1 0 −2 0 0 −1 −1 注:表2中M为质量量纲,L为长度量纲,T为时间量纲。 表 3 振动速度预测模型及拟合系数

Table 3. Prediction model and correlation coefficient of vibration velocity

公式形式 振动速度预测模型 相关系数 $v = K{\left( {\dfrac{{\sqrt[3]{Q}}}{R}} \right)^\alpha }$ $v = 139.7{\left( {\dfrac{{\sqrt[3]{Q}}}{R}} \right)^{1.62}}$ 0.939 $v = K{\left( {\dfrac{{\sqrt[3]{Q}}}{D}} \right)^\alpha }{\left( {\dfrac{{\sqrt[3]{Q}}}{H}} \right)^\beta }$ $v = 62.2{\left( {\dfrac{{\sqrt[3]{Q}}}{D}} \right)^{0.51}}{\left( {\dfrac{{\sqrt[3]{Q}}}{H}} \right)^{1.02}}$ 0.927 $v = K{\left( {\dfrac{{\sqrt[3]{Q}}}{R}} \right)^\alpha }{\left( {\dfrac{R}{D}} \right)^\beta }$ $v = 208.5{\left( {\dfrac{{\sqrt[3]{Q}}}{R}} \right)^{1.69}}{\left( {\dfrac{R}{D}} \right)^{ - 0.21}}$ 0.941 $v = K{\left( {\dfrac{{\sqrt[3]{Q}}}{R}} \right)^\alpha }{\left( {\dfrac{{\sqrt[3]{Q}}}{H}} \right)^\beta }$ $v = 70.1{\left( {\dfrac{{\sqrt[3]{Q}}}{R}} \right)^{4.61}}{\left( {\dfrac{{\sqrt[3]{Q}}}{H}} \right)^{ - 3.49}}$ 0.954 $v = K'{\left( {\dfrac{{\sqrt[3]{Q}}}{D}} \right)^\alpha }{\left( {\dfrac{R}{D}} \right)^\beta }{\left( {\dfrac{H}{D}} \right)^\gamma }$ $v = 204.4{\left( {\dfrac{{\sqrt[3]{Q}}}{D}} \right)^{1.34}}{\left( {\dfrac{R}{D}} \right)^{ - 6.16}}{\left( {\dfrac{H}{D}} \right)^{4.17}}$ 0.958 表 4 各振动信号总能量

Table 4. Total energy of vibration signals

信号编号 1-1 1-2 2-1 2-2 3-1 3-2 4-1 4-2 5-1 5-2 6-1 6-2 7-1 7-2 8-1 8-2 9 总能量/mJ 1518.2 1770.9 262.3 122.9 33.3 15.8 11.2 7.6 5.0 3.8 3.8 4.9 2.8 1.8 1.5 1.2 0.2 表 5 信号能量集中频带的分布

Table 5. Energy distribution in energy concentrated bands

信号 能量集中频带1 能量集中频带2 能量集中频带3 能量集中频带4 卓越频带/Hz 频率/Hz 能量占比/% 频率/Hz 能量占比/% 频率/Hz 能量占比/% 频率/Hz 能量占比/% 1-1 54.6~64.35 17.1 115.05~126.75 24.6 179.40~202.80 20.7 232.05~251.55 17.4 115.05~126.75 1-2 39.00~62.40 24.9 118.95~126.75 44.6 187.20~196.95 18.2 − − 118.95~126.75 2-1 107.25~126.75 20.4 187.20~202.80 36.1 243.75~251.55 26.2 − − 187.20~202.80 2-2 62.40~78.00 11.1 189.15~202.80 21.9 235.95~249.60 18.7 − − 189.15~202.80 3-1 31.20~48.75 17.3 62.40~81.90 22.9 93.60~105.30 9.1 189.15~202.80 10.8 62.40~81.90 3-2 21.45~50.70 21.4 62.40~81.90 26.9 93.60~109.20 28.7 − − 93.60~109.20 4-1 33.15~109.20 81.7 187.20~241.80 5.9 − − − − 33.15~109.20 4-2 17.55~46.80 31.1 60.45~78.00 11.3 95.55~111.15 35.7 − − 95.55~111.15 5-1 29.25~64.35 34.7 93.6~117.00 42.4 189.15~202.80 8.6 − − 93.60~117.00 5-2 29.25~54.60 22.6 93.6~109.20 43.4 189.15~195.00 10.4 − − 93.60~109.20 6-1 17.55~23.40 14.3 33.15~64.35 42.6 101.40~109.20 20.2 − − 33.15~64.35 6-2 17.55~23.40 11.3 31.2~58.50 72.3 93.60~101.40 5.2 − − 31.20~58.50 7-1 29.25~54.60 71.9 93.6~105.30 9.4 − − − − 29.25~54.60 7-2 17.55~46.80 69.8 95.55~101.4 11.4 − − − − 17.55~46.80 8-1 0~3.90 13.7 19.50~50.70 68.9 − − − − 19.5~50.70 8-2 0~3.90 19.9 17.55~23.40 22.9 29.25~35.10 17.7 42.90~54.60 21.7 17.55~23.40 9 17.55~33.15 62.1 48.75~62.40 26.2 − − − − 17.55~33.15 -

[1] 吴亮, 金沐, 钟冬望, 等. 一种边坡与近接隧道协同爆破施工的爆破控制方法: CN201510023750.5[P]. 2015-05-27. [2] 黄志强, 吴立. 爆破振动对隧道洞口顺层岩质边坡稳定性影响研究 [J]. 爆破, 2012, 29(1): 110–114, 118. DOI: 10.3963/j.issn.1001-487X.2012.01.029.HUANG Z Q, WU L. Effects of blasting vibration on stability of bedding rock slope at tunnel entrance [J]. Blasting, 2012, 29(1): 110–114, 118. DOI: 10.3963/j.issn.1001-487X.2012.01.029. [3] 宋杰. 傍山隧道施工爆破震动效应与测试技术研究[D]. 长沙: 中南大学, 2013.SONG J. Research on Construction blasting vibration effects and testing technology of mountain-adjacent tunnel [D]. Changsha: Central South University, 2013. [4] 金华东, 邓鹏飞, 徐伟健. 傍山隧道施工爆破方案研究 [J]. 中外公路, 2014, 34(6): 202–205. DOI: 10.3969/j.issn.1671-2579.2014.06.049.JIN H D, DENG P F, XU W J. Study on blasting scheme for construction of mountain-adjacent tunnel [J]. Journal of China and Foreign Highway, 2014, 34(6): 202–205. DOI: 10.3969/j.issn.1671-2579.2014.06.049. [5] 黄诗渊. 水工隧洞爆破施工振动对邻近边坡的影响研究[D]. 重庆: 重庆交通大学, 2016.HUNAG S Y. The influence research of hydraulic tunnel blasting vibration on adjacent slope [D]. Chongqing: Chongqing Jiaotong University, 2016. [6] 徐金贵, 蒲传金, 贺高威, 等. 傍山隧道爆破振动边坡传播规律试验研究 [J]. 有色金属(矿山部分), 2018, 70(3): 51–58, 112. DOI: 10.3969/j.issn.1671-4172.2018.03.012.XU J G, PU C J, HE G W, et al. Experimental study on propagation of side slope of blasting vibration of mountain-adjacent tunnel [J]. Nonferrous Metals (Mining Section), 2018, 70(3): 51–58, 112. DOI: 10.3969/j.issn.1671-4172.2018.03.012. [7] 贾党育. 隧道爆破开挖对洞口段边坡稳定性影响的数值分析 [J]. 矿冶工程, 2017, 37(1): 25–28. DOI: 10.3969/j.issn.0253-6099.2017.01.007.JIA D Y. Numerical analysis for effect of tunnel excavation by blasting on slope stability of portal section [J]. Mining and Metallurgical Engineering, 2017, 37(1): 25–28. DOI: 10.3969/j.issn.0253-6099.2017.01.007. [8] 兰明雄, 林从谋. 小净距隧道爆破振动传播规律小波包分析 [J]. 煤矿爆破, 2009(3): 1–4.LAN M X, LIN C M. Wavelet packet analysis of vibration caused by blasting high rock slope [J]. Coal Mine Blasting, 2009(3): 1–4. [9] 蒋丽丽, 林从谋, 陈泽观, 等. 岩石高边坡爆破振动传播规律小波包分析 [J]. 有色金属(矿山部分), 2009, 61(2): 43–45, 52. DOI: 10.3969/j.issn.1671-4172.2009.02.014.JIANG L L, LIN C M, CHEN Z G, et al. Wavelet packet analysis of vibration caused by high rock slope blasting [J]. Nonferrous Metals (Mining Section), 2009, 61(2): 43–45, 52. DOI: 10.3969/j.issn.1671-4172.2009.02.014. [10] 张声辉, 刘连生, 钟清亮, 等. 露天边坡爆破地震波能量分布特征研究 [J]. 振动与冲击, 2019, 38(7): 224–232. DOI: 10.13465/j.cnki.jvs.2019.07.032.ZHANG S H, LIU L S, ZHONG Q L, et al. Energy distribution characteristics of blast seismic wave on open pit slope [J]. Journal of Vibration and Shock, 2019, 38(7): 224–232. DOI: 10.13465/j.cnki.jvs.2019.07.032. [11] 周建敏. 爆破振动对含结构面边坡稳定性影响研究[D]. 重庆: 重庆大学, 2015.ZHOU J M. Influence of blasting vibration on the stability of slope with structure planes [D]. Chongqing: Chongqing University, 2015. [12] 何理, 钟冬望, 陈晨, 等. 岩质高边坡开挖施工的爆破振动监测与分析 [J]. 金属矿山, 2017, 46(1): 6–10. DOI: 10.3969/j.issn.1001-1250.2017.01.002.HE L, ZHONG D W, CHEN C, et al. Monitoring and analysis of blasting vibration in high rocky slope excavation [J]. Metal Mine, 2017, 46(1): 6–10. DOI: 10.3969/j.issn.1001-1250.2017.01.002. [13] 周文海, 梁瑞, 余建平, 等. 边坡抛掷爆破峰值质点振动速度的无量纲分析 [J]. 爆炸与冲击, 2019, 39(5): 054201. DOI: 10.11883/bzycj-2017-0373.ZHOU W H, LIANG R, YU J P, et al. Dimensionless analysis on peak particle vibration velocity induced by slope casting blast [J]. Explosion and Shock Waves, 2019, 39(5): 054201. DOI: 10.11883/bzycj-2017-0373. [14] 韩亮, 辛崇伟, 梁书锋, 等. 深孔台阶爆破近远区振动特征的试验研究 [J]. 振动与冲击, 2017, 36(8): 65–70. DOI: 10.13465/j.cnki.jvs.2017.08.011.HAN L, XIN C W, LIANG S F, et al. Experimental study on vibration characteristics of deep hole bench blasting in both near and far field [J]. Journal of Vibration and Shock, 2017, 36(8): 65–70. DOI: 10.13465/j.cnki.jvs.2017.08.011. [15] 何理, 钟冬望, 刘建程, 等. 微差爆破试验及爆破振动能量的小波包分析 [J]. 金属矿山, 2014, 43(6): 10–15.HE L, ZHONG D W, LIU J C, et al. Millisecond blasting tests and wavelet packet analysis of blasting vibration energy [J]. Metal Mine, 2014, 43(6): 10–15. [16] SINGH P K, ROY M P. Damage to surface structures due to blast vibration [J]. International Journal of Rock Mechanics and Mining Sciences, 2010, 47(6): 949–961. DOI: 10.1016/j.ijrmms.2010.06.010. [17] LU W B, LUO Y, CHEN M, et al. An introduction to Chinese safety regulations for blasting vibration [J]. Environmental Earth Sciences, 2012, 67(7): 1951–1959. DOI: 10.1007/s12665-012-1636-9. [18] 武旭, 张云鹏, 郭奇峰. 台阶地形爆破振动放大与衰减效应研究 [J]. 爆炸与冲击, 2017, 37(6): 1017–1022. DOI: 10.11883/1001-1455(2017)06-1017-06.WU X, ZHANG Y P, GUO Q F. Amplification and attenuation effect of blasting vibration on step topography [J]. Explosion and Shock Waves, 2017, 37(6): 1017–1022. DOI: 10.11883/1001-1455(2017)06-1017-06. [19] 陈明, 卢文波, 李鹏, 等. 岩质边坡爆破振动速度的高程放大效应研究 [J]. 岩石力学与工程学报, 2011, 30(11): 2189–2195.CHEN M, LU W B, LI P, et al. Elevation amplification effect of blasting vibration velocity in rock slope [J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(11): 2189–2195. [20] 叶海旺, 袁尔君, 雷涛, 等. 基于量纲分析的爆破振动质点峰值速度预测公式 [J]. 金属矿山, 2019, 48(5): 56–61. DOI: 10.19614/j.cnki.jsks.201905010.YE H W, YUAN E J, LEI T, et al. Blasting vibration peak particle velocity prediction formula based on dimensional analysis method [J]. Metal Mine, 2019, 48(5): 56–61. DOI: 10.19614/j.cnki.jsks.201905010. [21] 胡刚, 吴云龙. 爆破地震振动控制的一种方法 [J]. 煤炭技术, 2004, 23(4): 104–106. DOI: 10.3969/j.issn.1008-8725.2004.04.065.HU G, WU Y L. A new method of the control of the earthquake vibration caused by explosive [J]. Coal Technology, 2004, 23(4): 104–106. DOI: 10.3969/j.issn.1008-8725.2004.04.065. [22] 唐海, 李海波. 反映高程放大效应的爆破振动公式研究 [J]. 岩土力学, 2011, 32(3): 820–824. DOI: 10.3969/j.issn.1000-7598.2011.03.030.TANG H, LI H B. Study of blasting vibration formula of reflecting amplification effect on elevation [J]. Rock and Soil Mechanics, 2011, 32(3): 820–824. DOI: 10.3969/j.issn.1000-7598.2011.03.030. [23] 钟冬望, 何理, 操鹏, 等. 基于精确毫秒延时控制的爆破降振试验研究 [J]. 煤炭学报, 2015, 40(S1): 107–11. DOI: 10.13225/j.cnki.jccs.2014.1447.ZHONG D W, HE L, CAO P, et al. Experimental study of reducing vibration intensity based on controlled blasting with precise time delay [J]. Journal of China Coal Society, 2015, 40(S1): 107–11. DOI: 10.13225/j.cnki.jccs.2014.1447. [24] 杨巨文, 白润才, 于永江, 等. 含弱层岩质边坡自振周期反演试验及数值验证 [J]. 煤炭学报, 2015, 40(S1): 69–75. DOI: 10.13225/j.cnki.jccs.2014.1249.YANG J W, BAI R C, YU Y J, et al. Inversion test and numerical verification on natural period of rock slope with weak layers [J]. Journal of China Coal Society, 2015, 40(S1): 69–75. DOI: 10.13225/j.cnki.jccs.2014.1249. -

下载:

下载: