Application of flame retardant medium in fuel dispersion driven by explosive

-

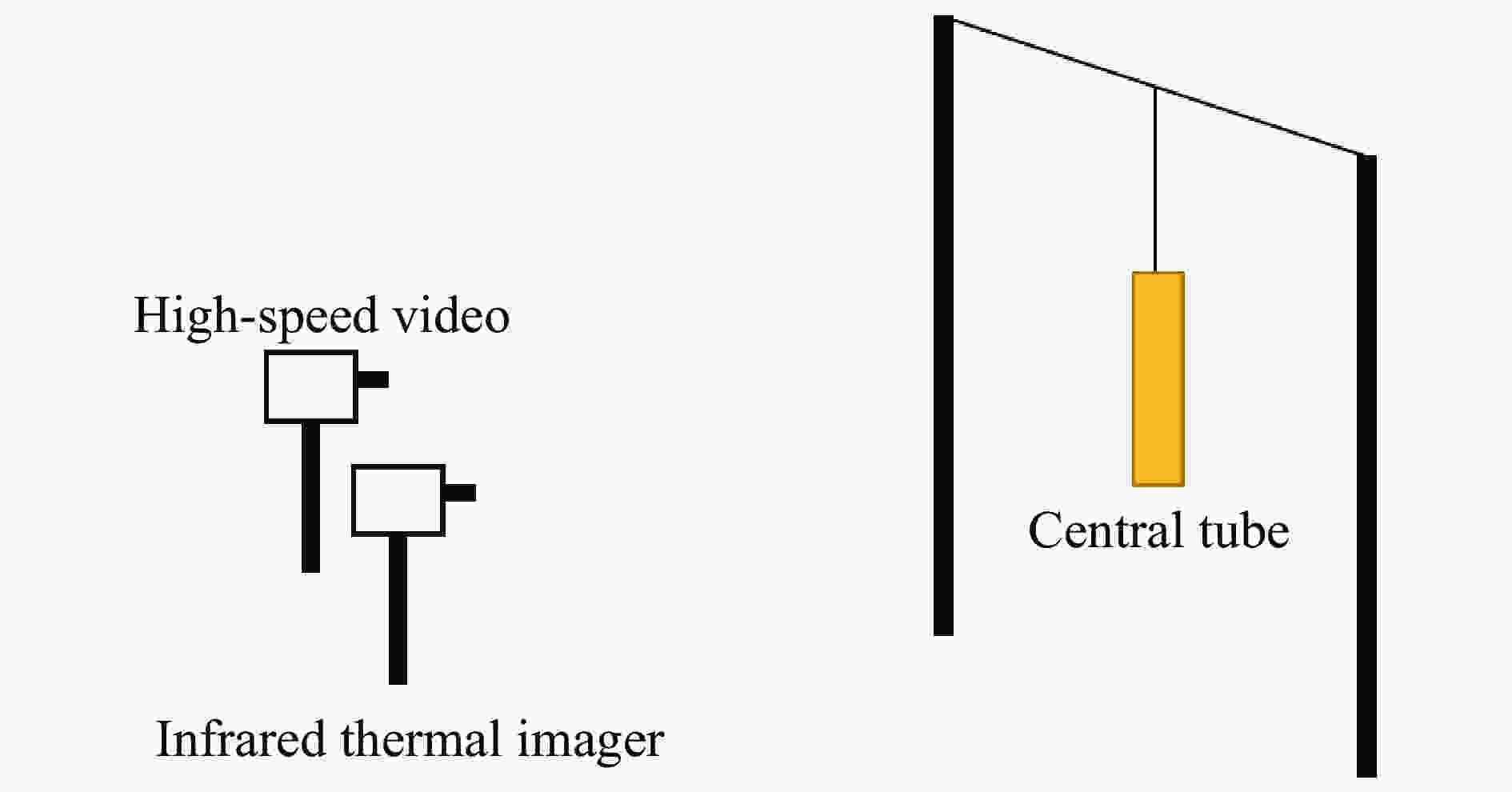

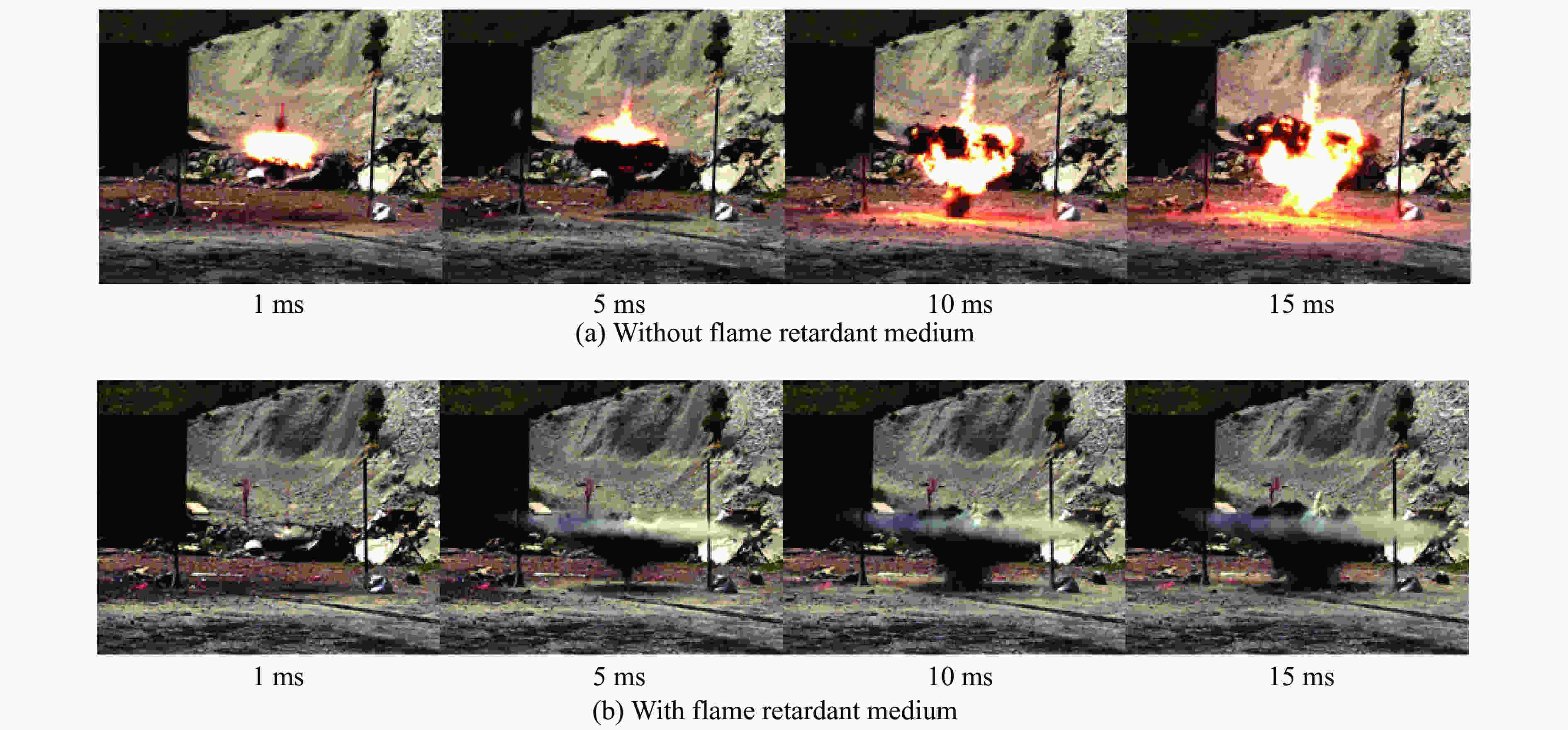

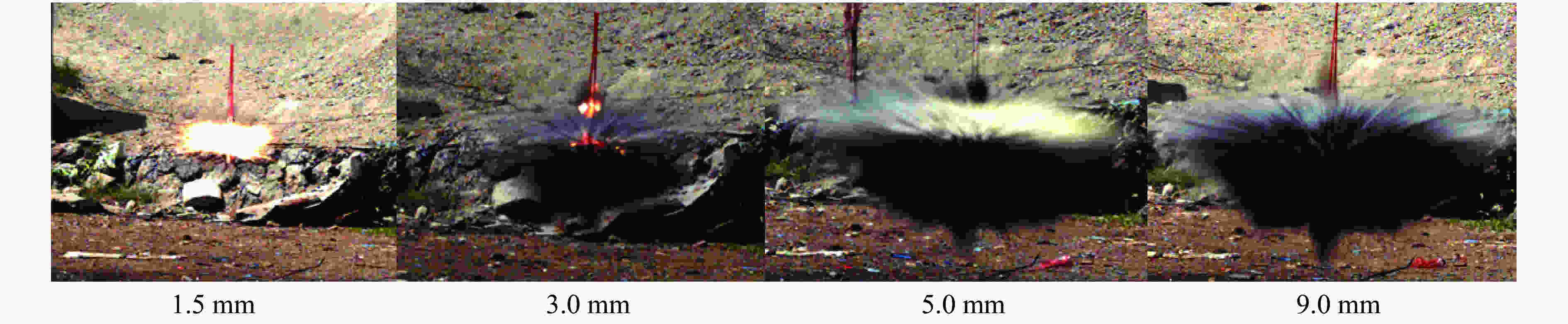

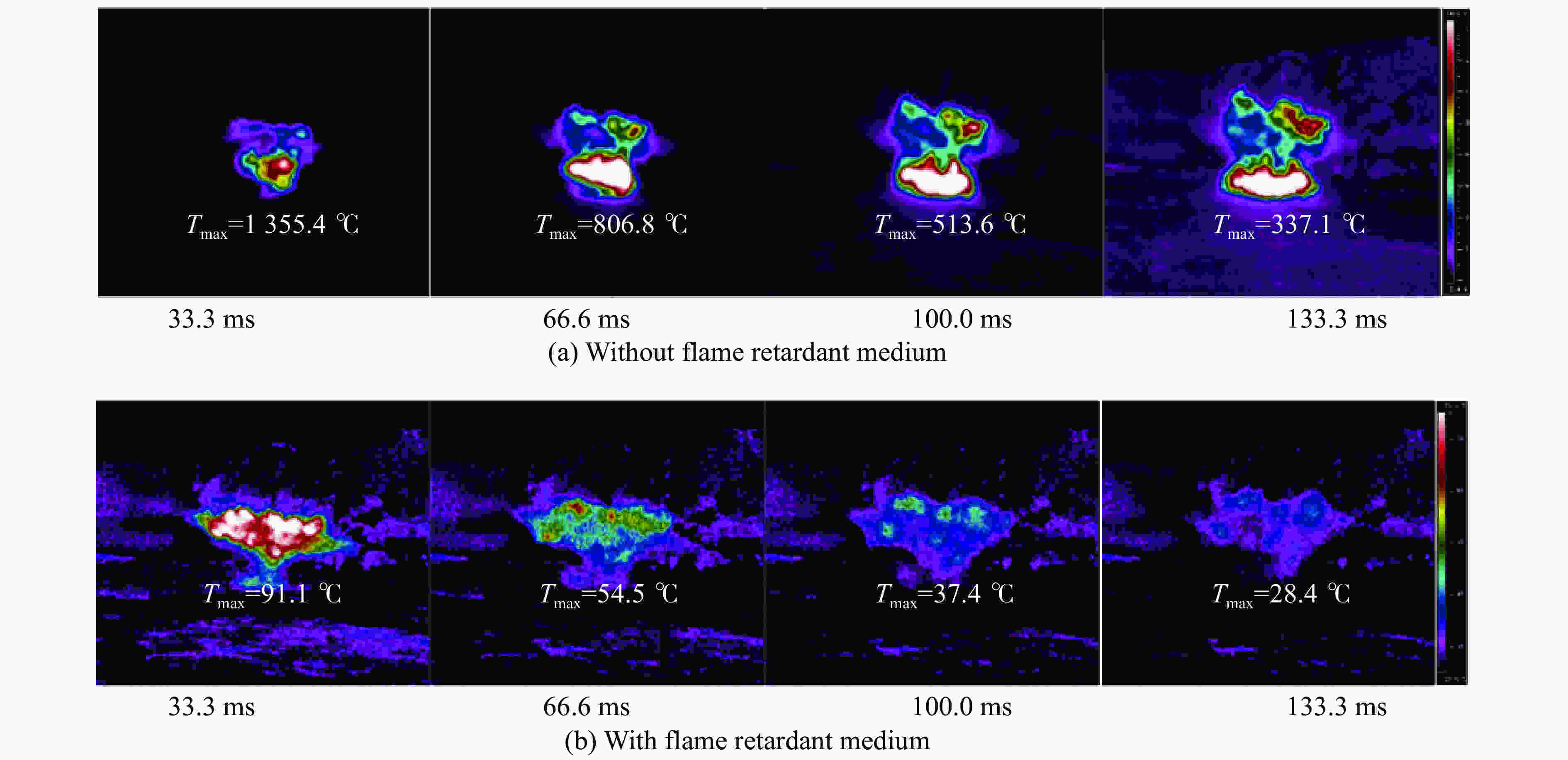

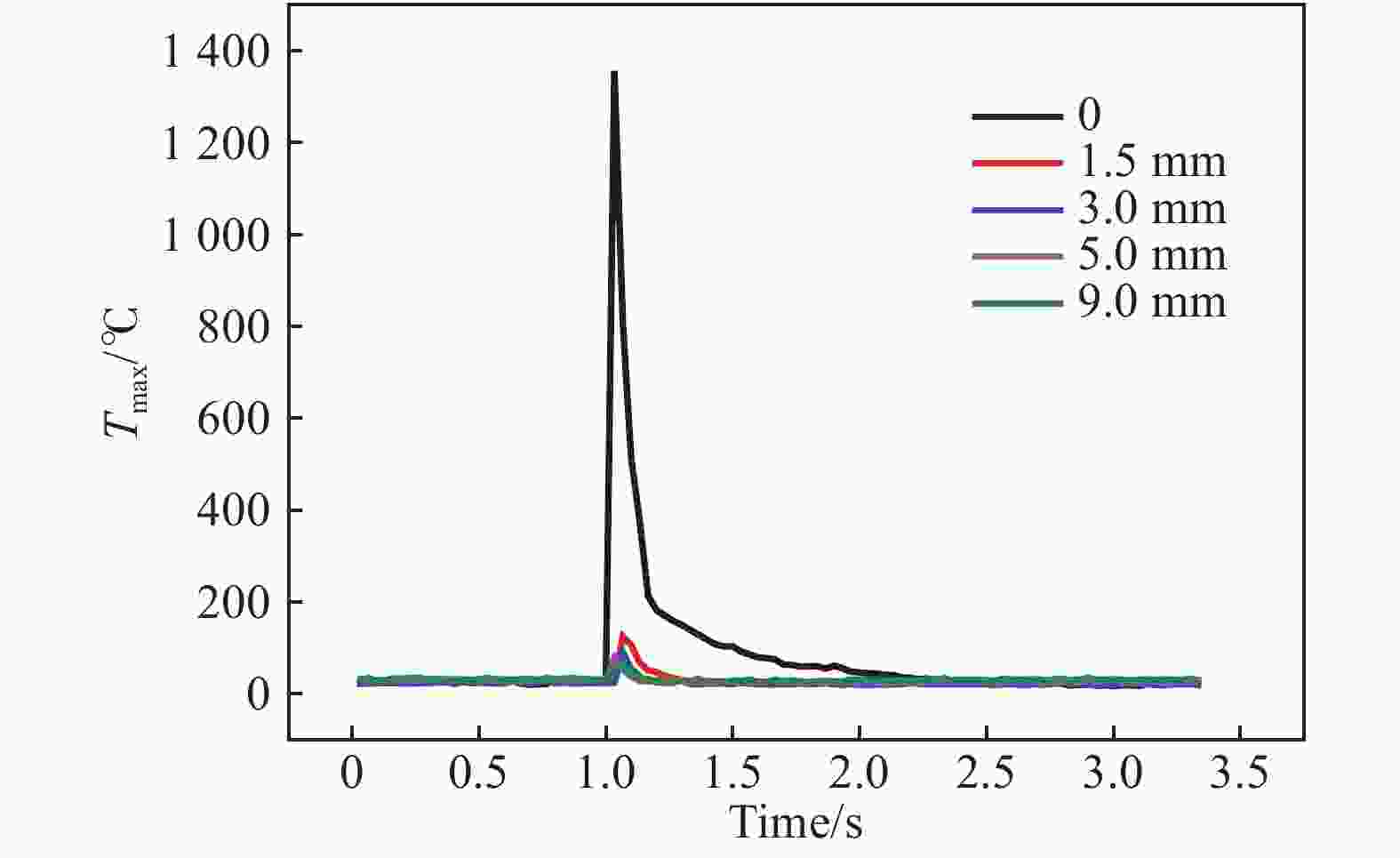

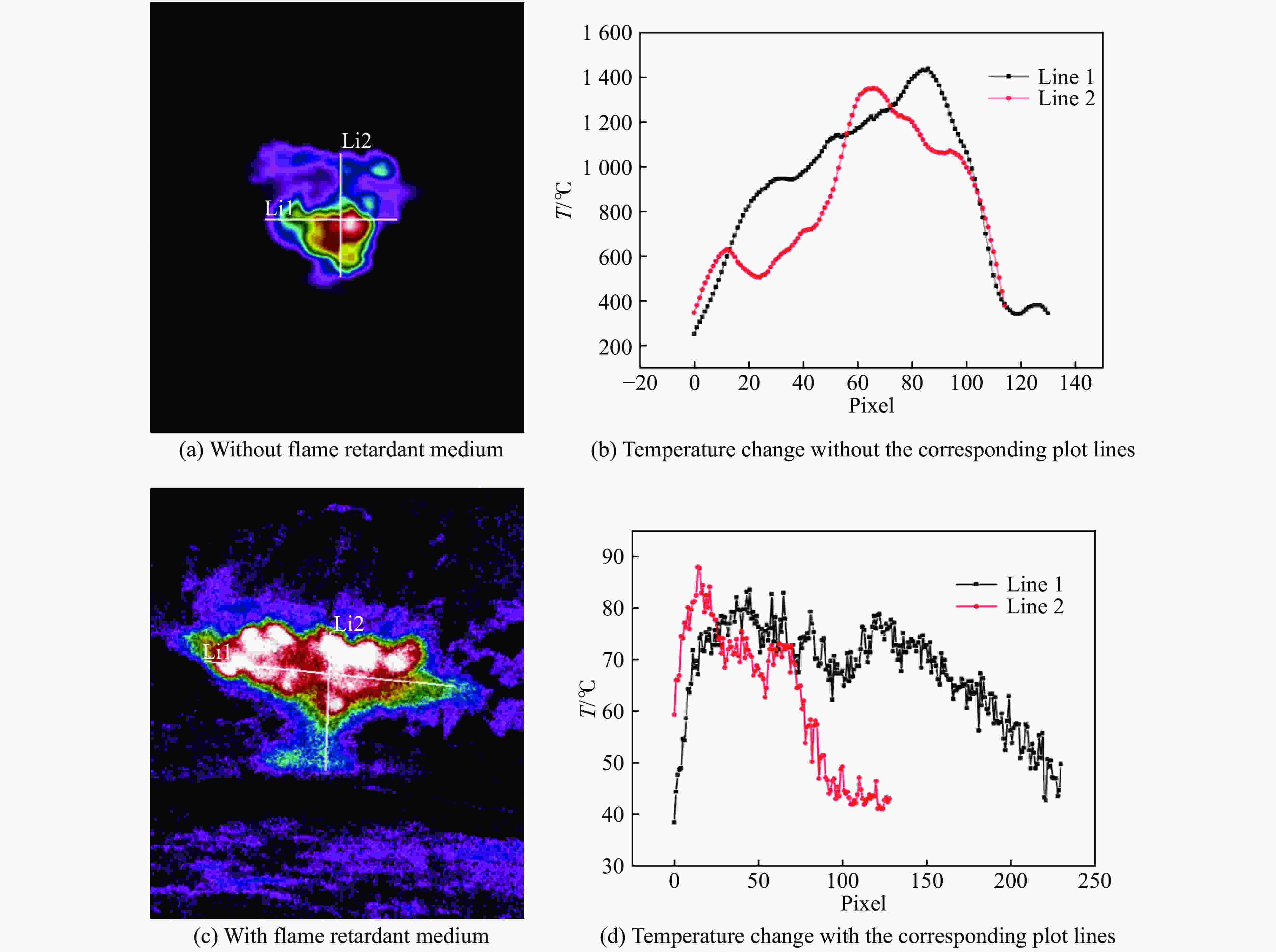

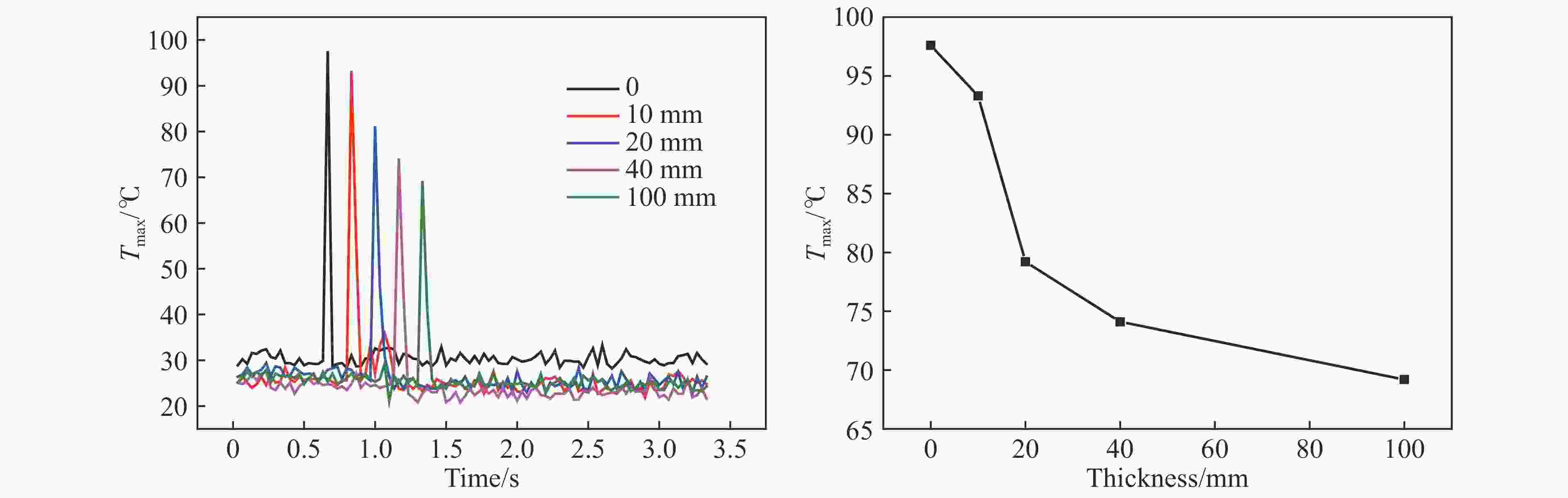

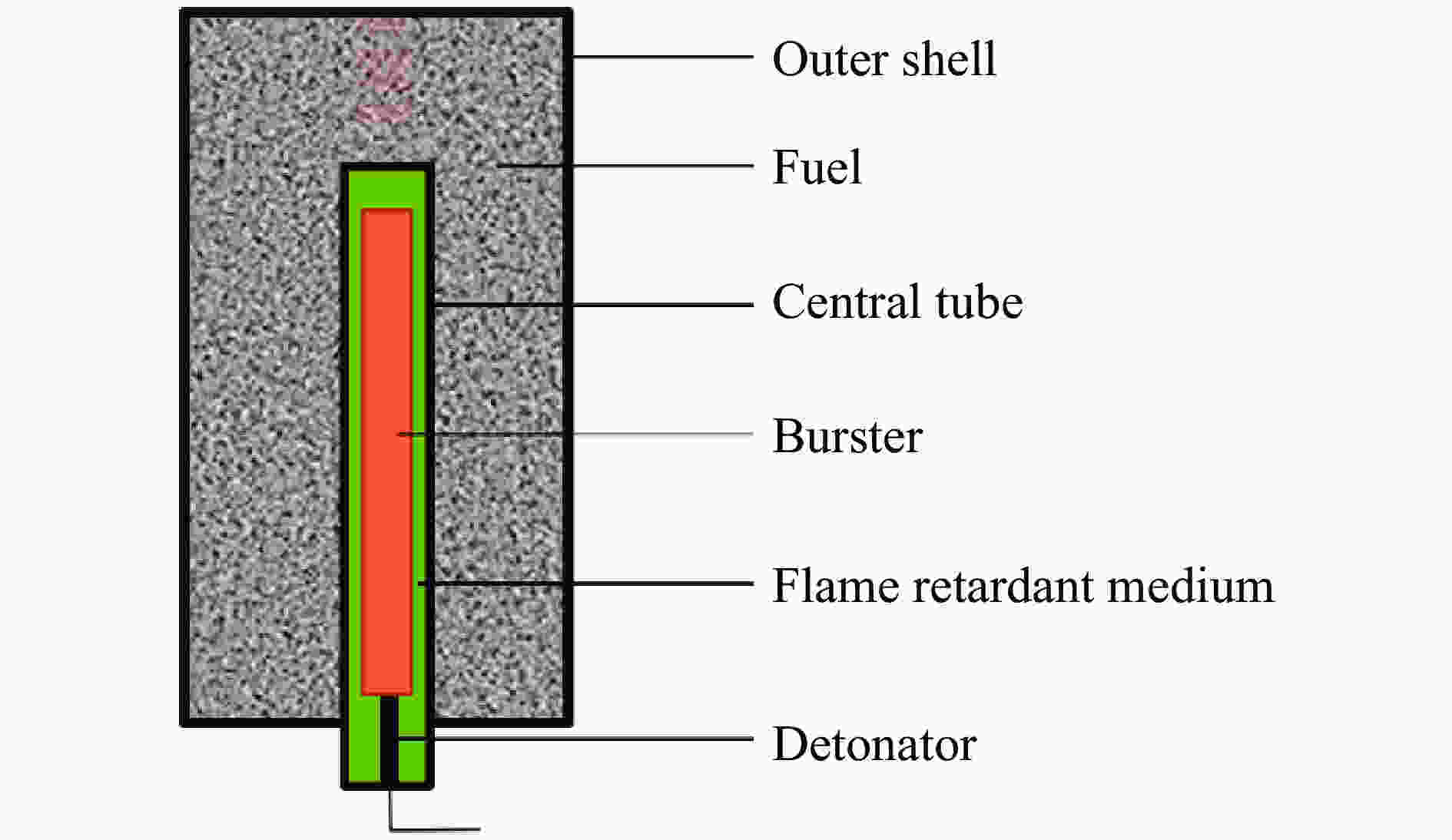

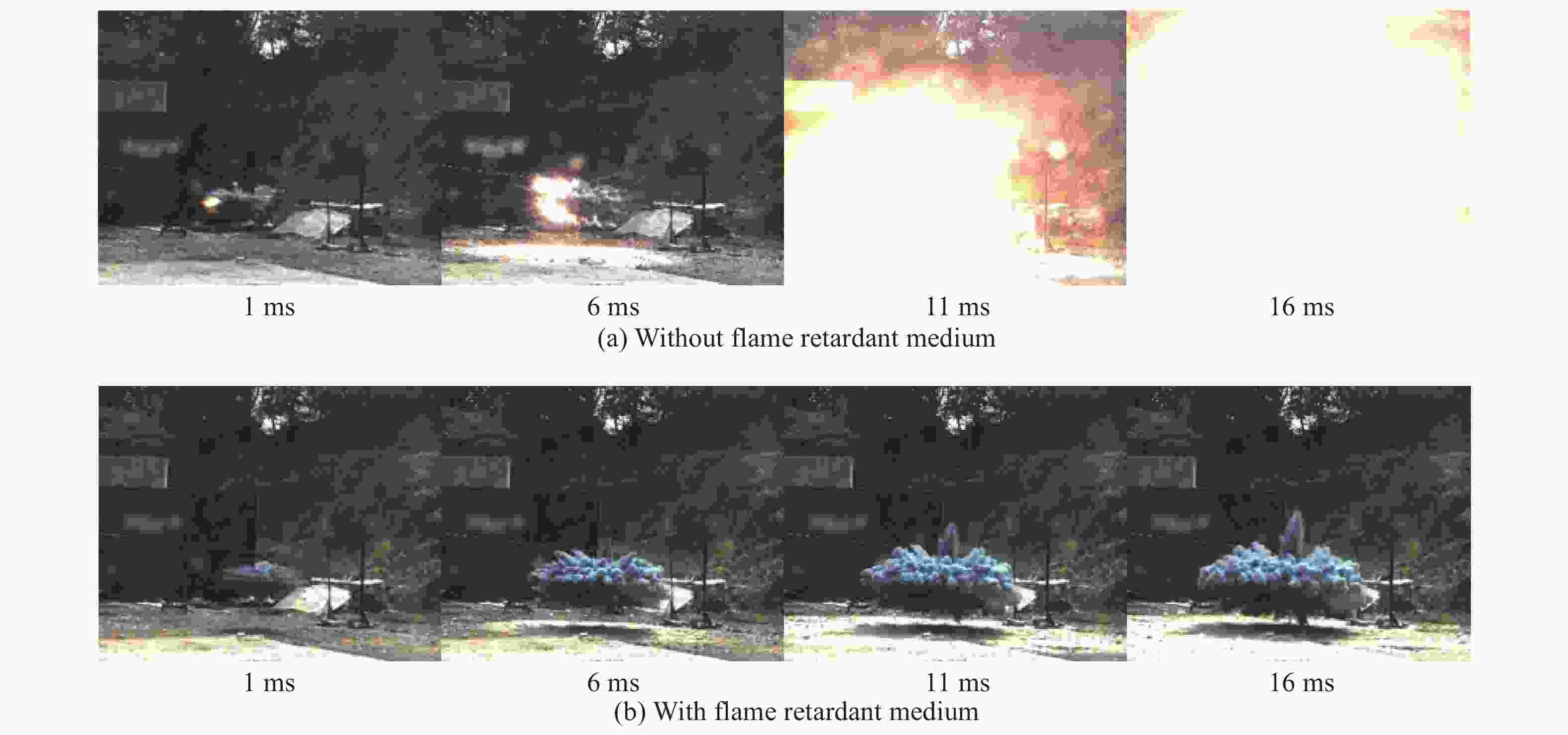

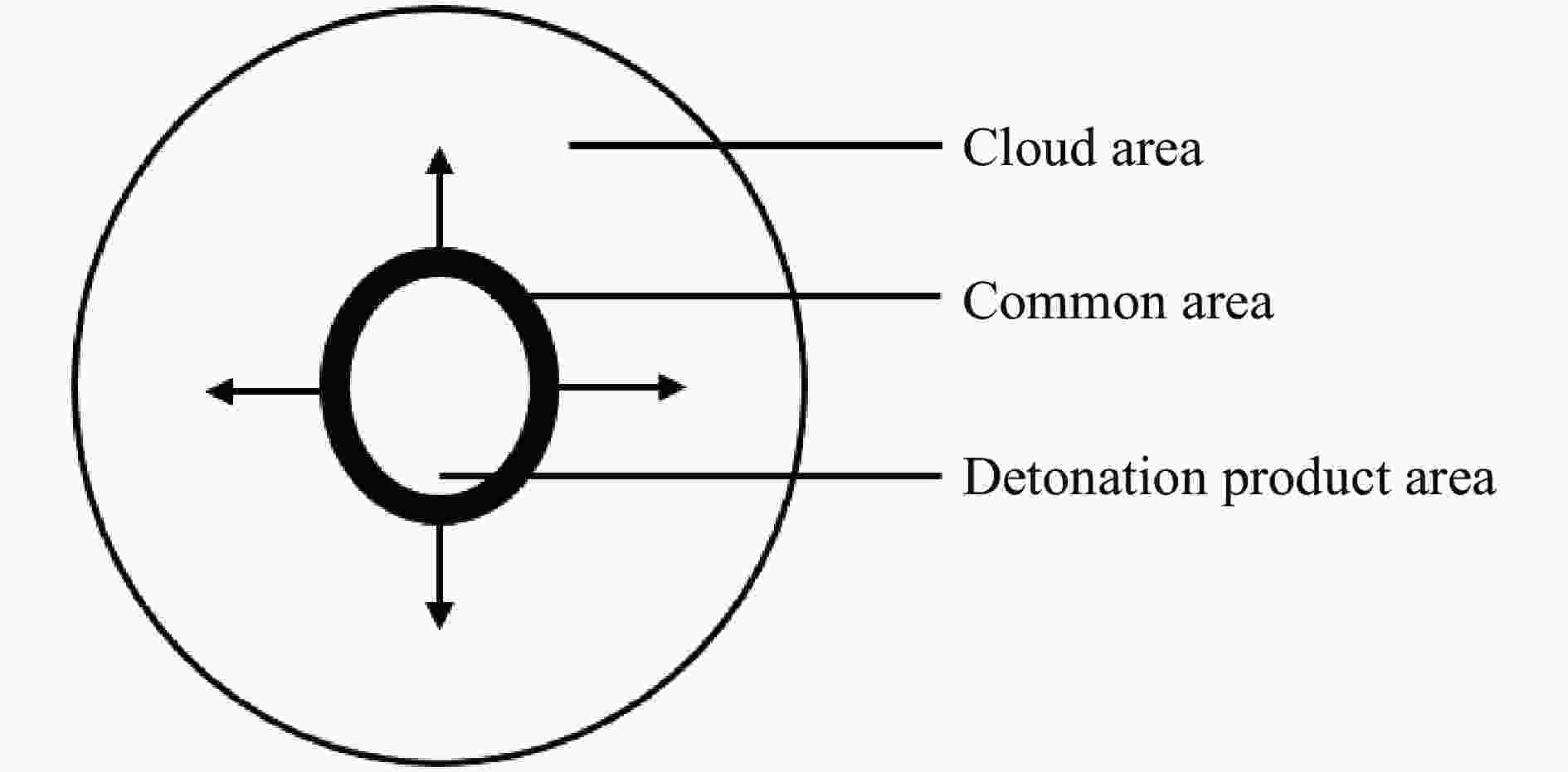

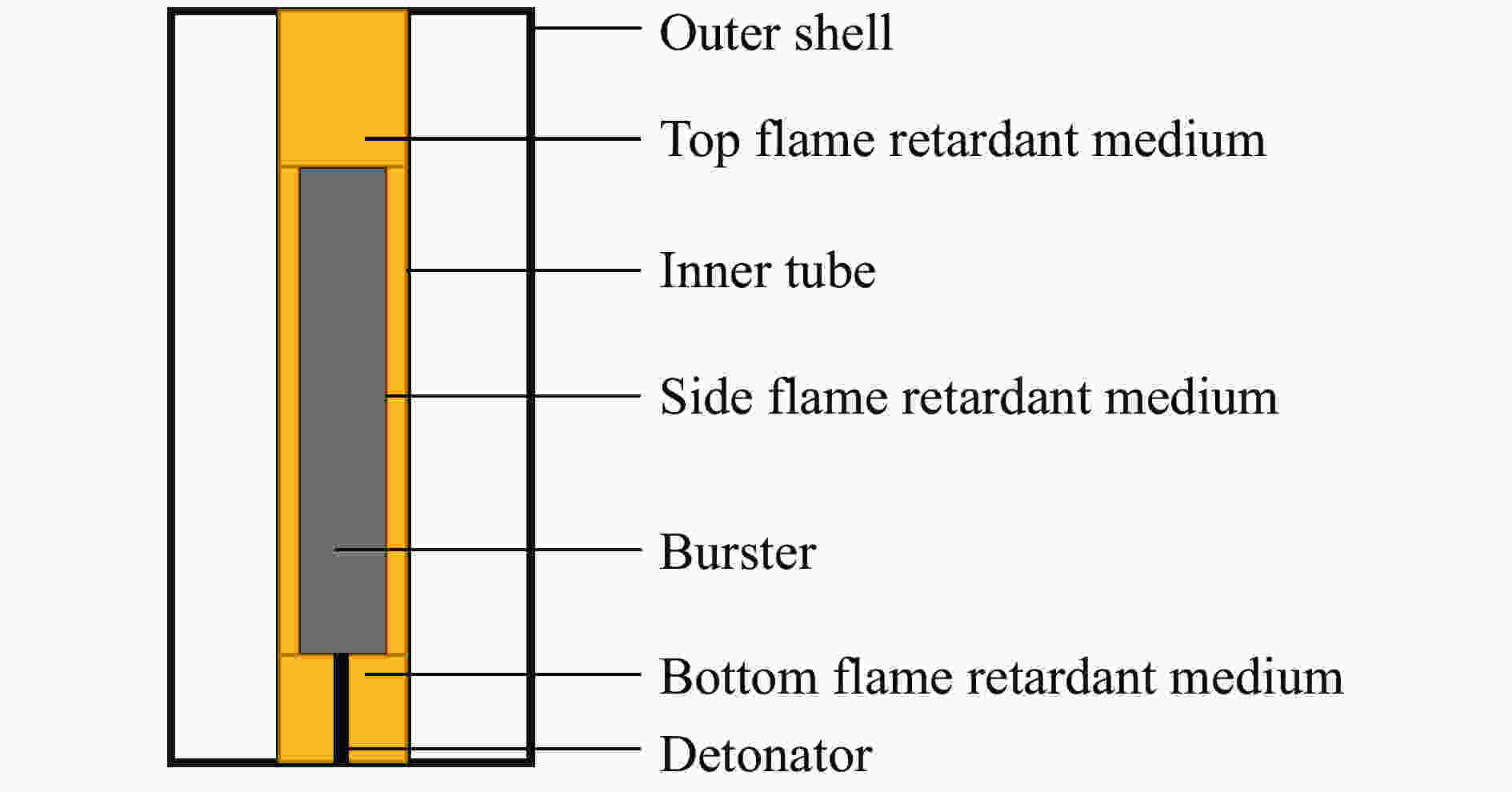

摘要: 为解决燃料空气炸药中的燃料在中心分散装药爆炸驱动抛撒过程中易发生的窜火问题,结合中心分散装药结构设计,引入以超细干粉灭火剂为主体的阻燃介质,采用高速录像和红外热成像仪研究了中心分散药外部填充阻燃介质的情况下,对中心分散药爆炸火球产生的高温及火焰的抑制情况。试验结果表明,中心分散药爆炸火球的最高温度为1 355.4 ℃,温度超过150 ℃的持续时间为264.8 ms。外部填充阻燃介质后,中心分散药爆炸产生的火焰基本消失,火球最高温度下降90%以上,火球表面温度分布不超过100 ℃。同时进行了验证试验,采用填充阻燃介质的中心分散药抛撒1 kg的乙醚和铝粉的混合燃料,分散药与燃料的质量比超过4%时,云雾仍未发生窜火。表明填充阻燃介质可以有效防止燃料在爆炸抛撒过程中发生窜火的问题。Abstract: To solve the premature-combustion problem of FAE fuel during the dispersal process by explosive, fire retardant medium with superfine ABC powder as the main component was introduced along with the structural design of central dispersed explosive. High-speed camera and infrared thermal imager were used to study the temperature and flame generated by the dispersed explosive. The experimental results show that the maximum temperature of the dispersed explosive fireball was 1355.4 °C, and the duration of the temperature exceeding 150 °C was 264.8 ms. The flame generated by the dispersed explosive almost completely disappears after the introduction of the flame retardant medium. The maximum temperature of the fireball decreases by more than 90%, and the surface temperature of the fireball does not exceed 100 °C. At the same time, the verification experiment was carried out. The mixture fuel of 1 kg ether and aluminum powder was dispersed by the dispersed explosive filled with flame retardant medium. When the mass ratio of dispersed explosive to fuel was more than 4%, the premature-combustion was restrained successfully. It shows that filling the flame retardant medium can effectively prevent the premature-combustion in the fuel dispersion process.

-

Key words:

- fuel air explosive /

- dispersed explosive /

- premature-combustion /

- flame retardant medium

-

表 1 内管直径和侧面阻燃介质厚度

Table 1. Inner tube diameter and side flame retardant medium thickness

内管直径/mm 20 23 26 30 38 阻燃介质厚度/mm 0 1.5 3.0 5.0 9.0 表 2 火球表面温度测试结果

Table 2. Fireball surface temperature test results

序号 阻燃介质厚度/

mm最高温度/

℃高温持续时间/ms

(大于150 ℃)1 0 1 355.4 264.8 2 1.5 124.1 0 3 3.0 91.1 0 4 5.0 77.2 0 5 9.0 59.9 0 -

[1] 白春华, 粱慧敏, 李建平, 等. 云雾爆轰[M]. 北京: 科学出版社, 2012. [2] 饶国宁,周莉,宋述忠,等. 云爆药剂爆炸超压测试及威力评价 [J]. 爆炸与冲击, 2018, 38(3): 579–585. DOI: 10.11883/bzycj-2016-0245.RAO G N, ZHOU L, SONG S Z, et al. Explosion overpressure measurement and power evaluation of FAE [J]. Explosion and Shock Waves, 2018, 38(3): 579–585. DOI: 10.11883/bzycj-2016-0245. [3] 王晔, 白春华, 李建平. 动态云雾形成及爆轰场特性 [J]. 含能材料, 2017, 25(6): 466–471. DOI: 10.11943/j.issn.1006-9941.2017.06.004.WANG Y, BAI C H, LI J P. Formation and blasting field characteristics of moving cloud detonation [J]. Chinese Journal of Energetic Materials, 2017, 25(6): 466–471. DOI: 10.11943/j.issn.1006-9941.2017.06.004. [4] 刘庆明, 白春华, 李建平. 多相燃料空气炸药爆炸压力场研究 [J]. 实验力学, 2008, 23(4): 360–370.LIU Q M, BAI C H, LI J P. Study on blast field characteristics of multiphase fuel air explosive [J]. Journal of Experimental Mechanics, 2008, 23(4): 360–370. [5] LIU G, HOU F, CAO B, et al. Experimental study of fuel-air explosive [J]. Combustion, Explosion, and Shock Waves, 2008, 44(2): 213–217. DOI: 10.1007/s10573-008-0028-7. [6] LI Y, SONG Z, LI Y. Theoretical analysis and numerical simulation for the spill procedure of liquid fuel of fuel air explosive with shell [J]. International Journal of Non-Linear Mechanics, 2010, 45(7): 699–703. DOI: 10.1016/j.ijnonlinmec.2010.04.004. [7] 史远通, 张奇. 爆炸驱动燃料抛散的非理想化特征 [J]. 含能材料, 2015, 23(4): 330–335. DOI: 10.11943/j.issn.1006-9941.2015.04.004.SHI Y T, ZHANG Q. Non-ideal characteristics of fuel dispersal driven by explosive [J]. Chinese Journal of Energetic Materials, 2015, 23(4): 330–335. DOI: 10.11943/j.issn.1006-9941.2015.04.004. [8] 吴德义, 杨基明. 强冲击波作用下液体抛撒的实验研究 [J]. 爆炸与冲击, 2003, 23(1): 91–95.WU D Y, YANG J M. Experimental investigation on liquid dispersal induced by explosions [J]. Explosion and Shock Waves, 2003, 23(1): 91–95. [9] APPARAO A, RAO C R, TEWARI S P. Studies on formation of unconfined detonable vapor cloud using explosive means [J]. Journal of Hazardous Materials, 2013, 254-255(6): 214–220. DOI: 10.1016/j.jhazmat.2013.02.056. [10] 方伟, 赵省向, 李文祥, 等. 爆炸抛撒过程中FAE云雾的运动特性 [J]. 含能材料, 2015, 23(11): 1061–1066. DOI: 10.11943/j.issn.1006-9941.2015.11.005.FANG W, ZHAO S X, LI W X, et al. Movement characteristics of fuel-air explosive (FAE) clouds in the explosion dispersal process [J]. Chinese Journal of Energetic Materials, 2015, 23(11): 1061–1066. DOI: 10.11943/j.issn.1006-9941.2015.11.005. [11] 郭学永, 惠君明. 装置参数对FAE云雾状态的影响 [J]. 含能材料, 2002, 10(4): 161.16–164.GUO X Y, HUI J M. Influence of equipment parameters on FAE cloud status [J]. Chinese Journal of Energetic Materials, 2002, 10(4): 161.16–164. [12] 丁珏, 刘家骢. 液体燃料爆炸抛撒和云雾形成全过程的数值研究 [J]. 火炸药学报, 2001, 24(1): 20–23. DOI: 10.3969/j.issn.1007-7812.2001.01.007.DING J, LIU J C. Numerical study on the whole process of explosive dispersal for forming liquid air cloud [J]. Chinese Journal of Explosives and Propellants, 2001, 24(1): 20–23. DOI: 10.3969/j.issn.1007-7812.2001.01.007. [13] SEDGWICK R T. Fuel air explosives: A parametric investigation: AD-A159177[R]. 1979. [14] ALEY M H. Surface-launched FAE mine field clearance round: USP4, 273, 048 [P]. 1981. [15] 肖绍清. 分散药T型装药控制二次引爆型FAE云雾研究 [J]. 火炸药学报, 2006, 29(2): 10–14. DOI: 10.3969/j.issn.1007-7812.2006.02.004.XIAO S Q. Study on control cloud of twice-detonating FAE by T-type charge of burster [J]. Chinese Journal of Explosives and Propellants, 2006, 29(2): 10–14. DOI: 10.3969/j.issn.1007-7812.2006.02.004. [16] 肖绍清. 复合分散药的性能及对FAE燃料分散的影响 [J]. 含能材料, 2006, 14(4): 244–247;256. DOI: 10.3969/j.issn.1006-9941.2006.04.002.XIAO S Q. Controlling fuel dispersion of FAE by combination burster [J]. Chinese Journal of Energetic Materials, 2006, 14(4): 244–247;256. DOI: 10.3969/j.issn.1006-9941.2006.04.002. [17] 徐晓楠. 气溶胶灭火剂的研究及发展现状 [J]. 消防技术与产品信息, 2002, 9(9): 26–30. DOI: 10.3969/j.issn.1002-784X.2002.09.010.XU X N. Research and development status of aerosol fire extinguishing agent [J]. Fire Technique and Products Information, 2002, 9(9): 26–30. DOI: 10.3969/j.issn.1002-784X.2002.09.010. [18] YANG M, CHEN X, WANG Y, et al. Comparative evaluation of thermal decomposition behavior and thermal stability ofpowdered ammonium nitrate under different atmosphere conditions [J]. Journal of Hazardous Materials, 2017, 33: 10–19. DOI: 10.1016/j.jhazmat.2017.04.063. -

下载:

下载: