The lateral impact performance of concrete-filled steel tubular (CFST) members at high temperatures

-

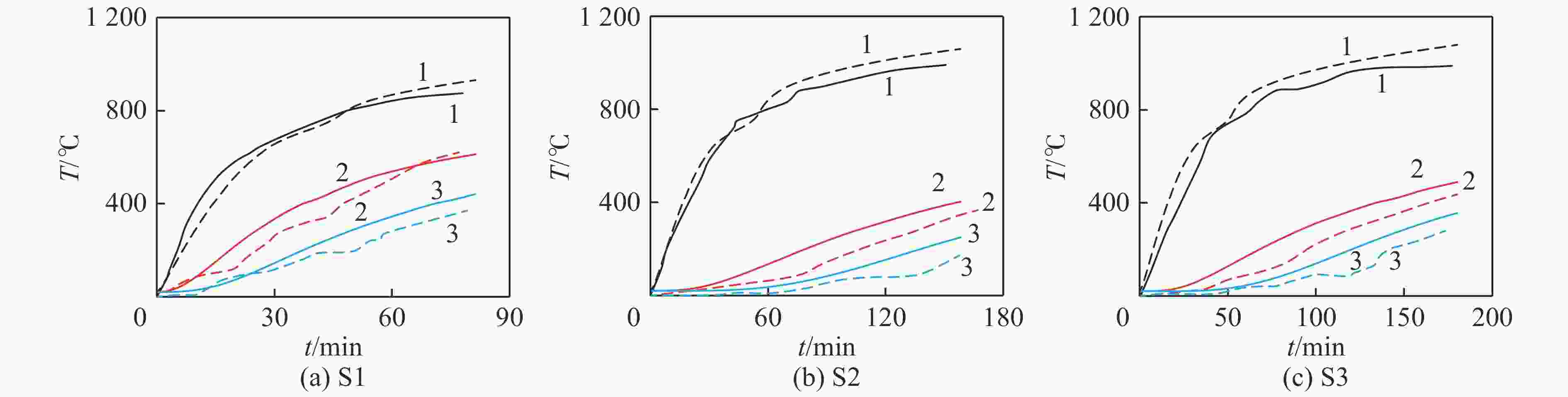

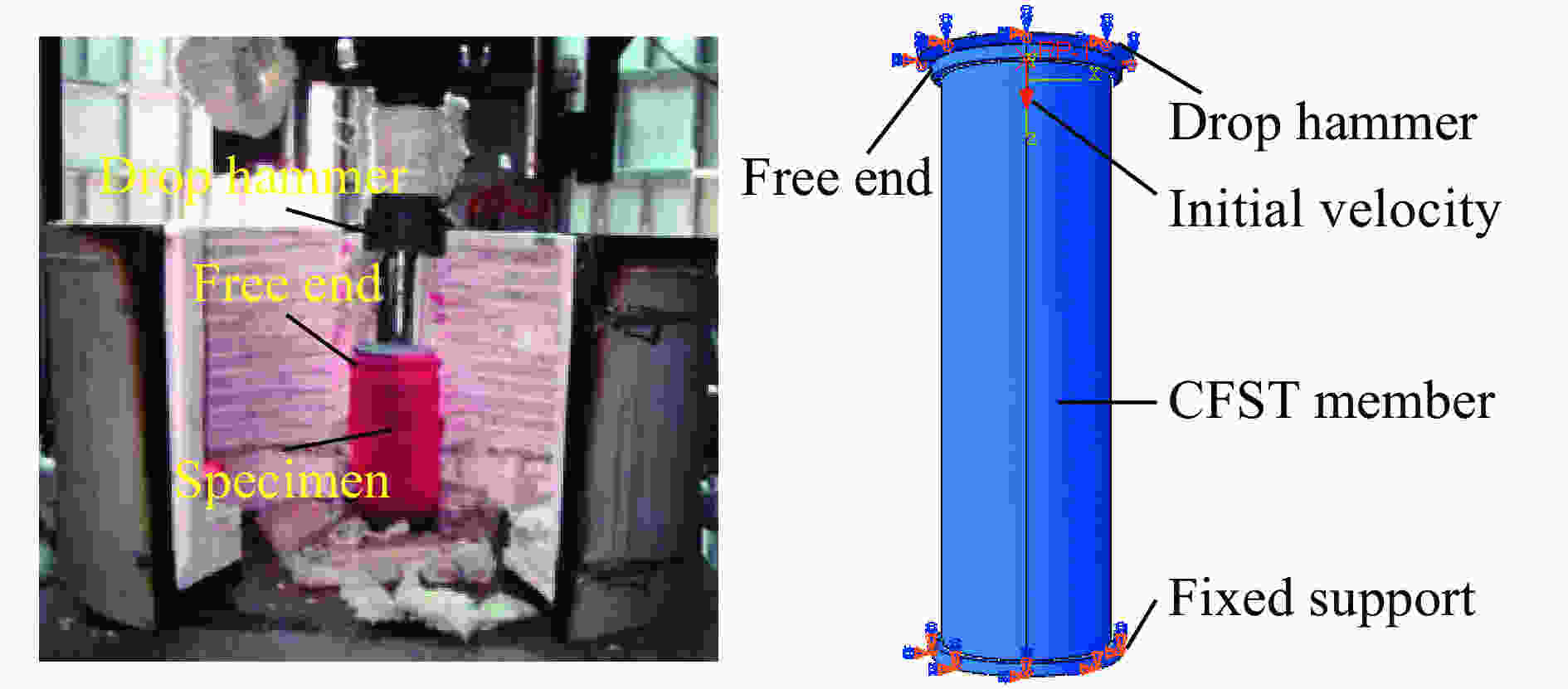

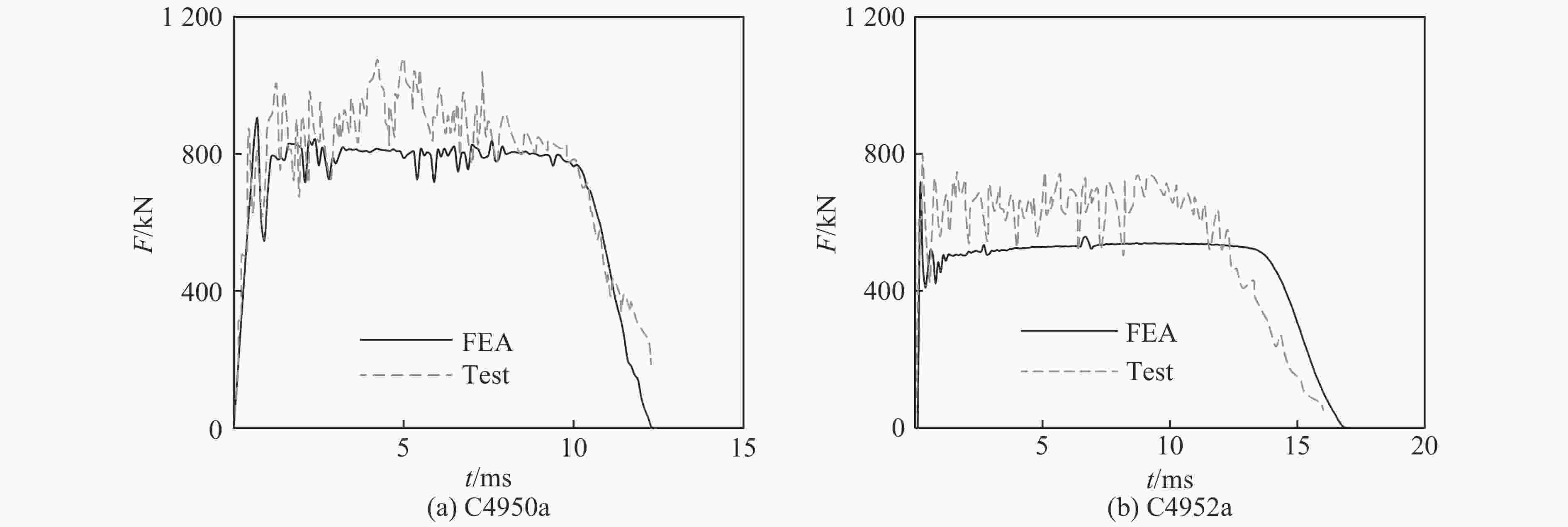

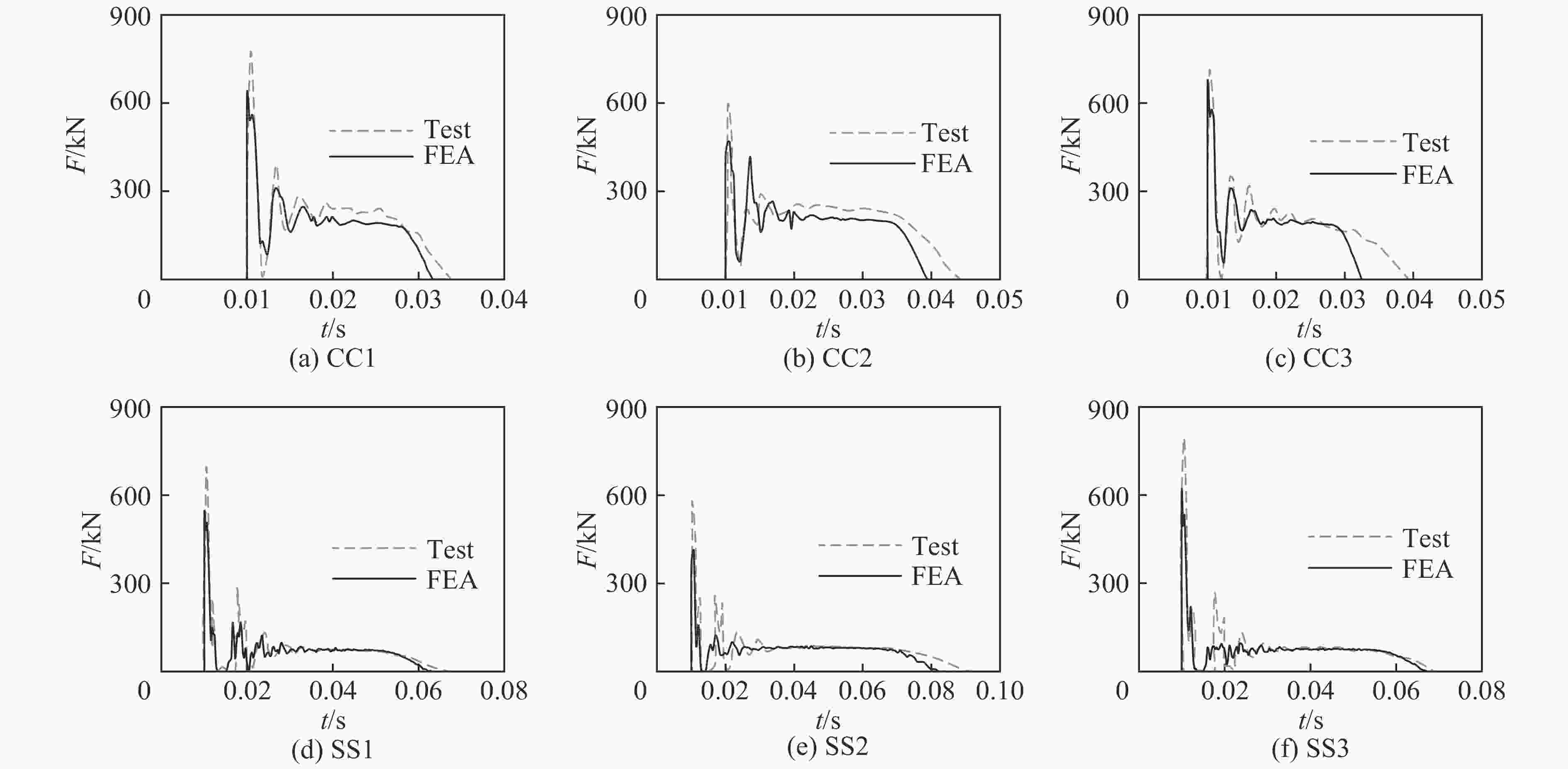

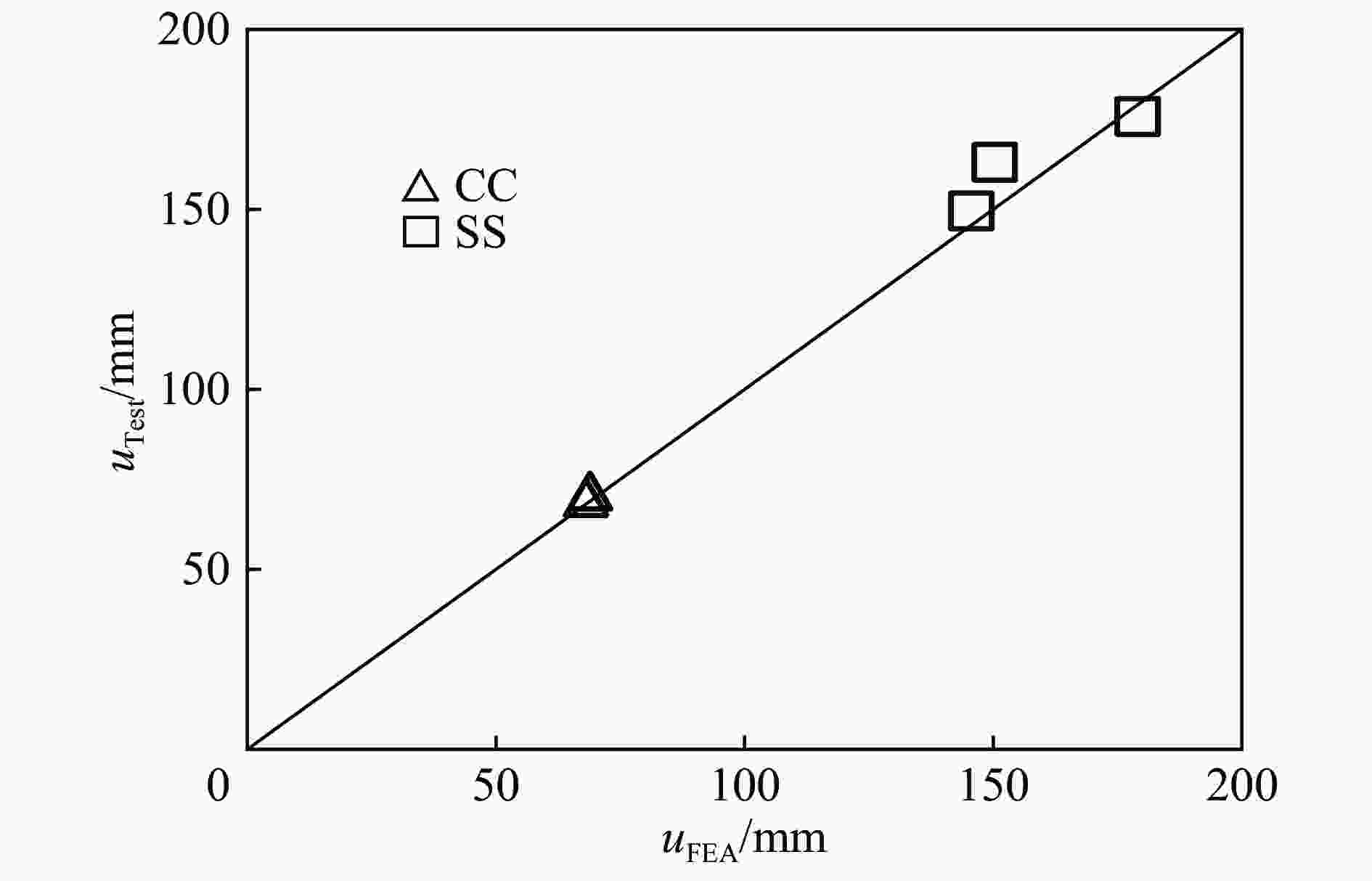

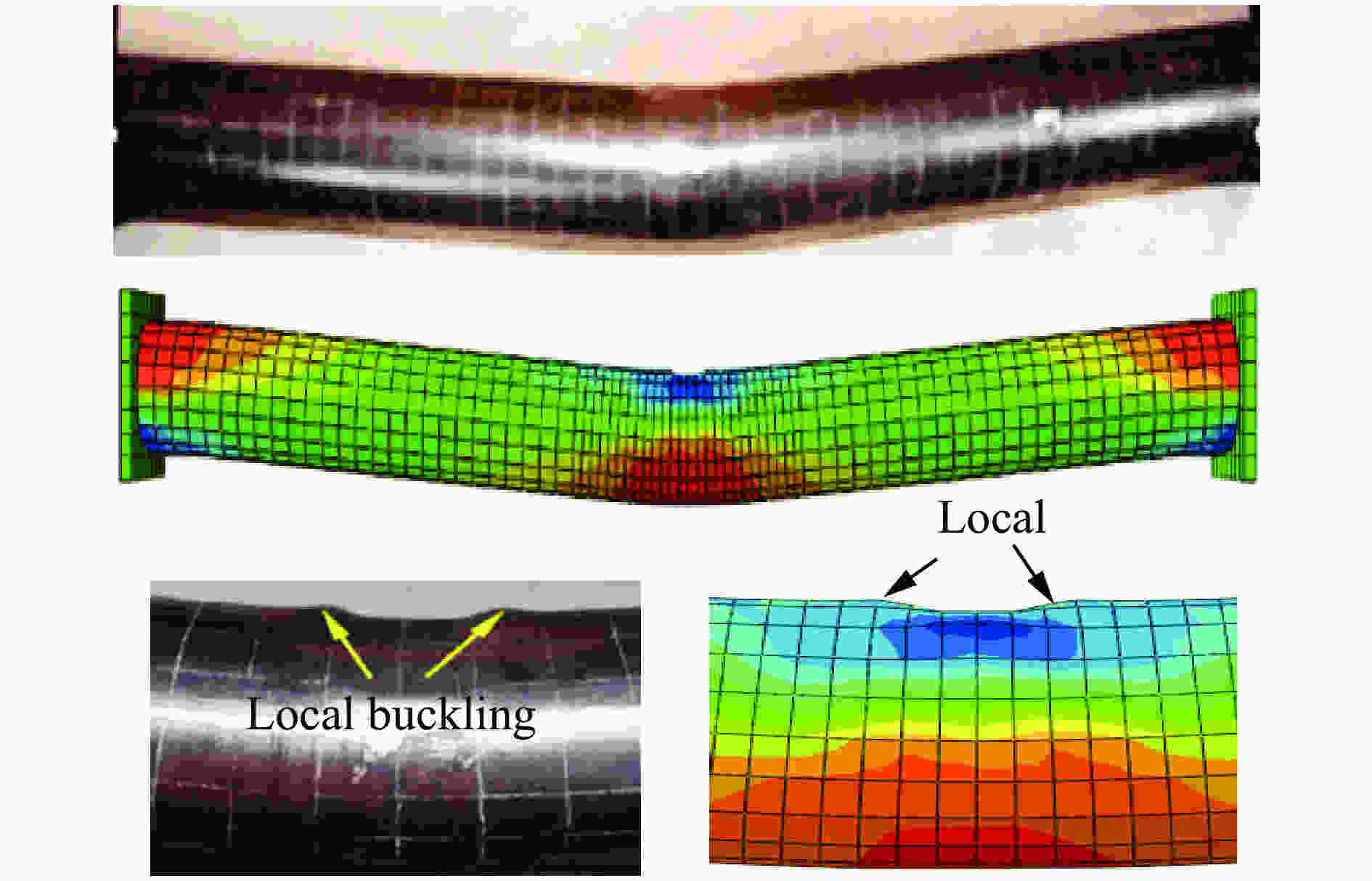

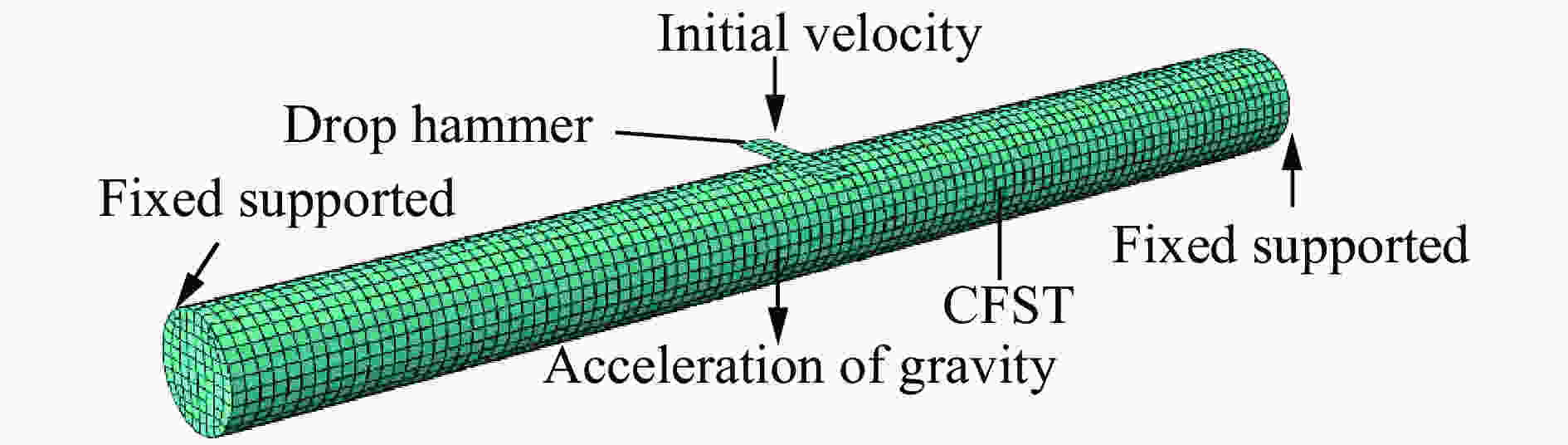

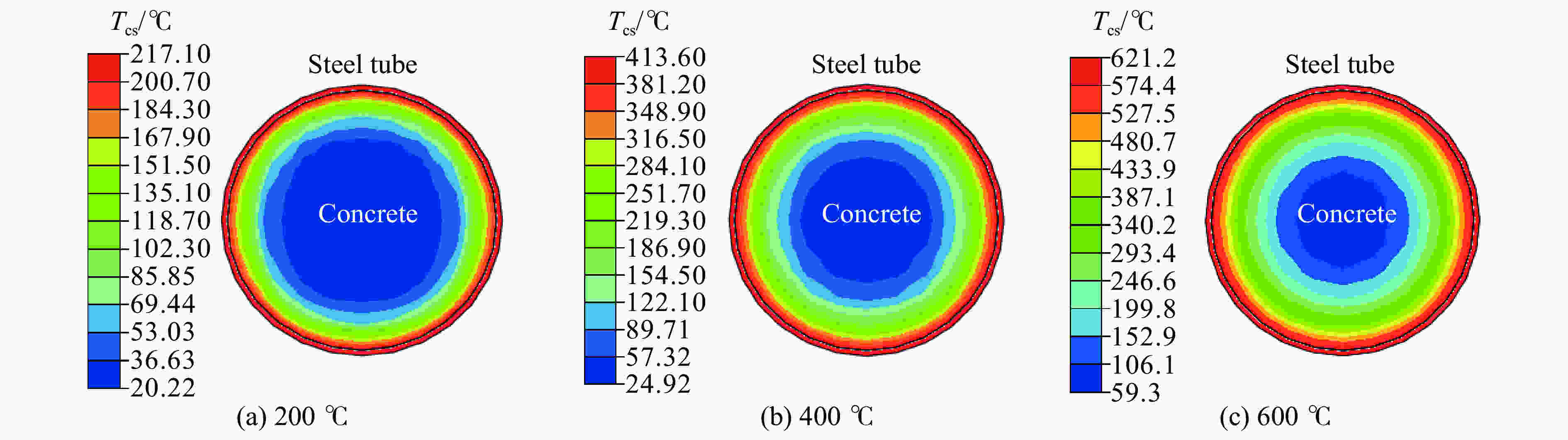

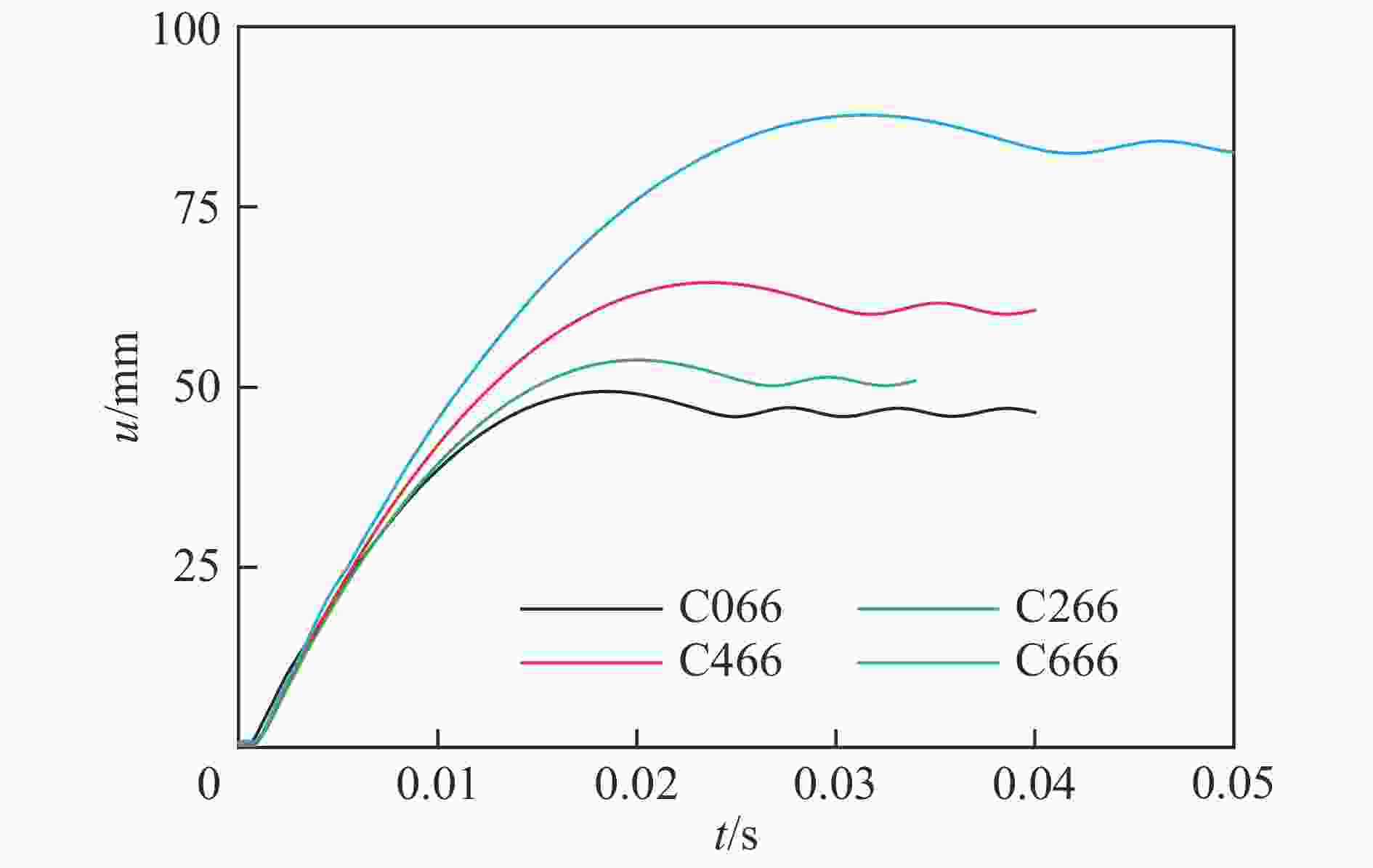

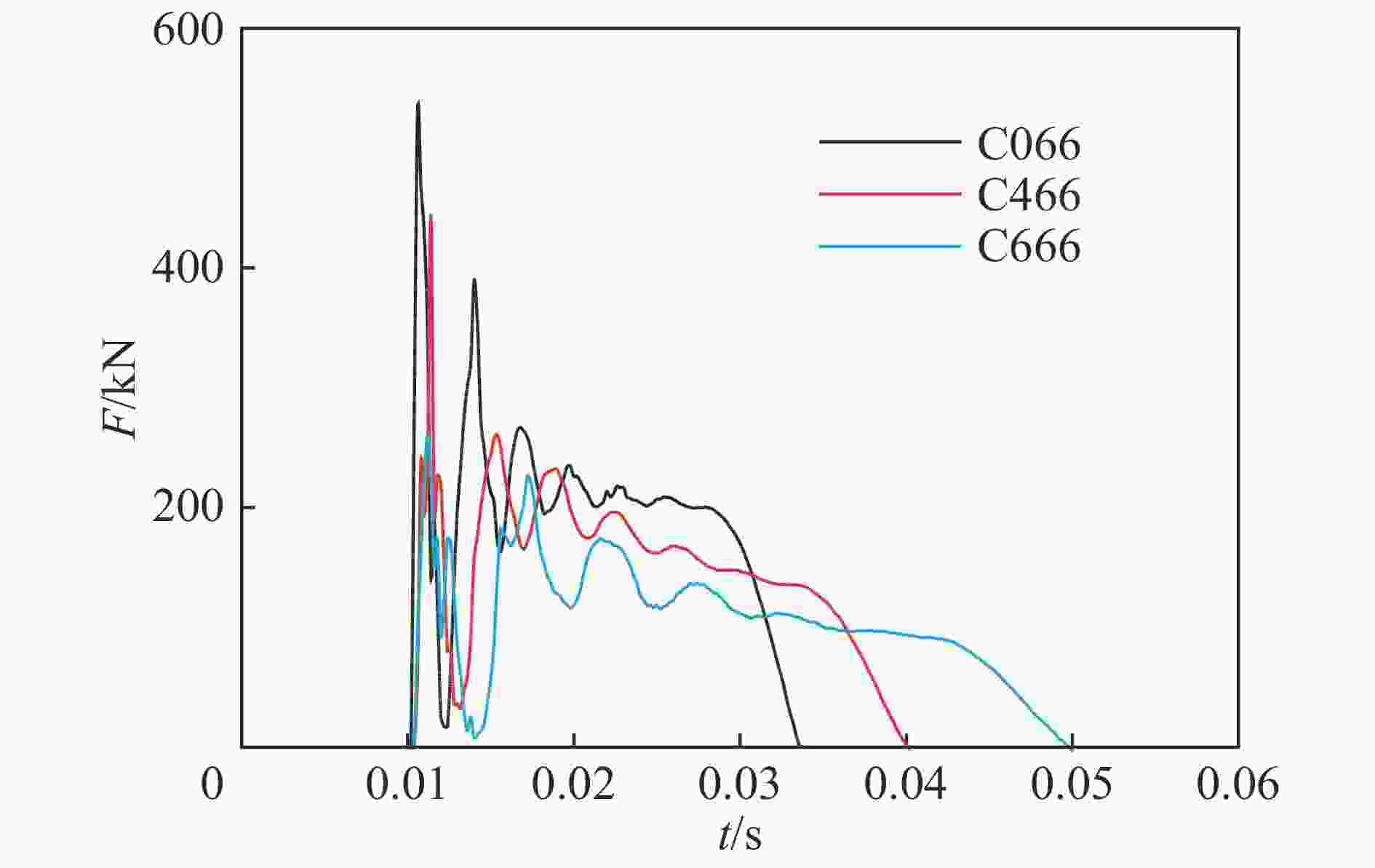

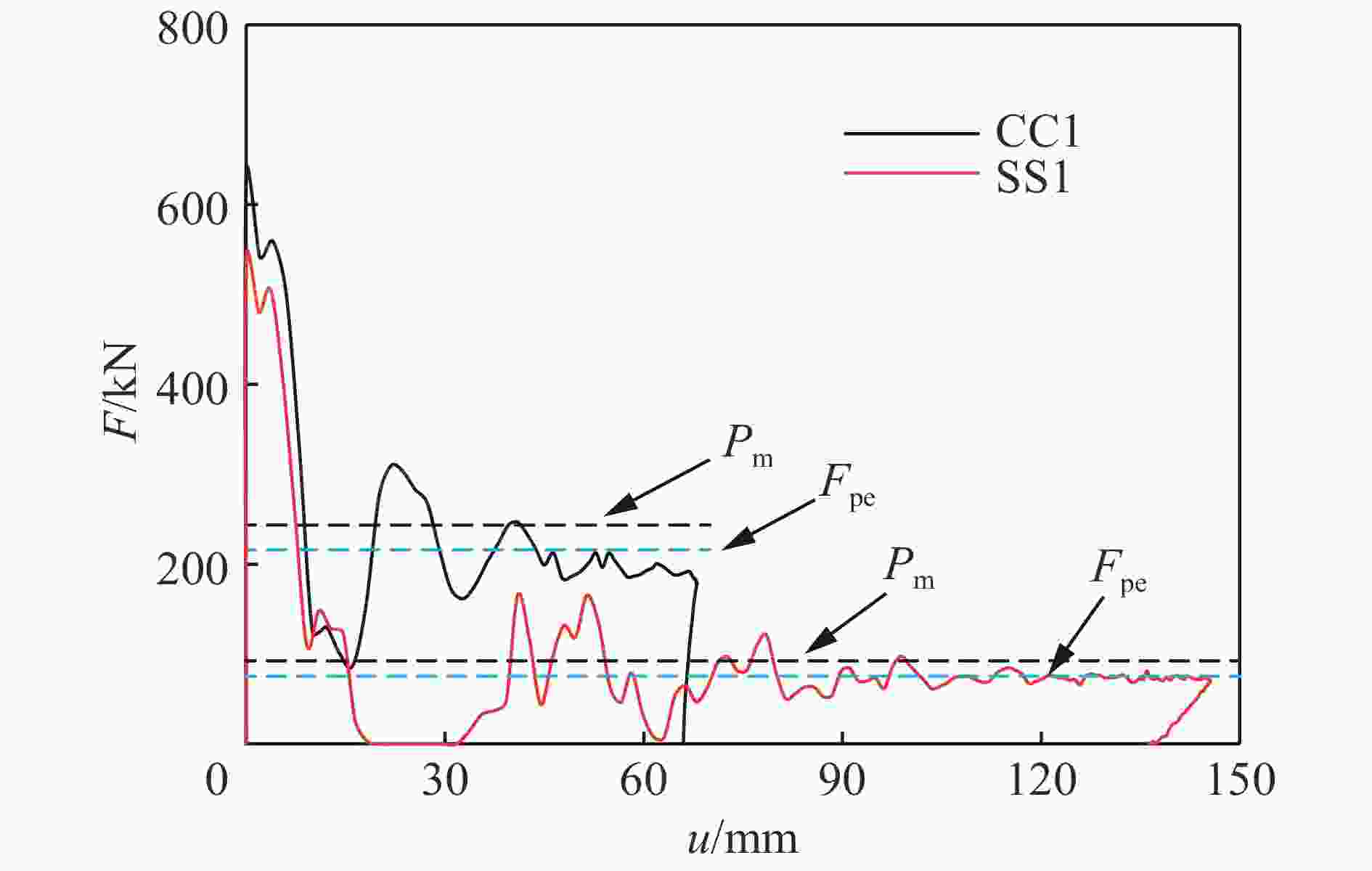

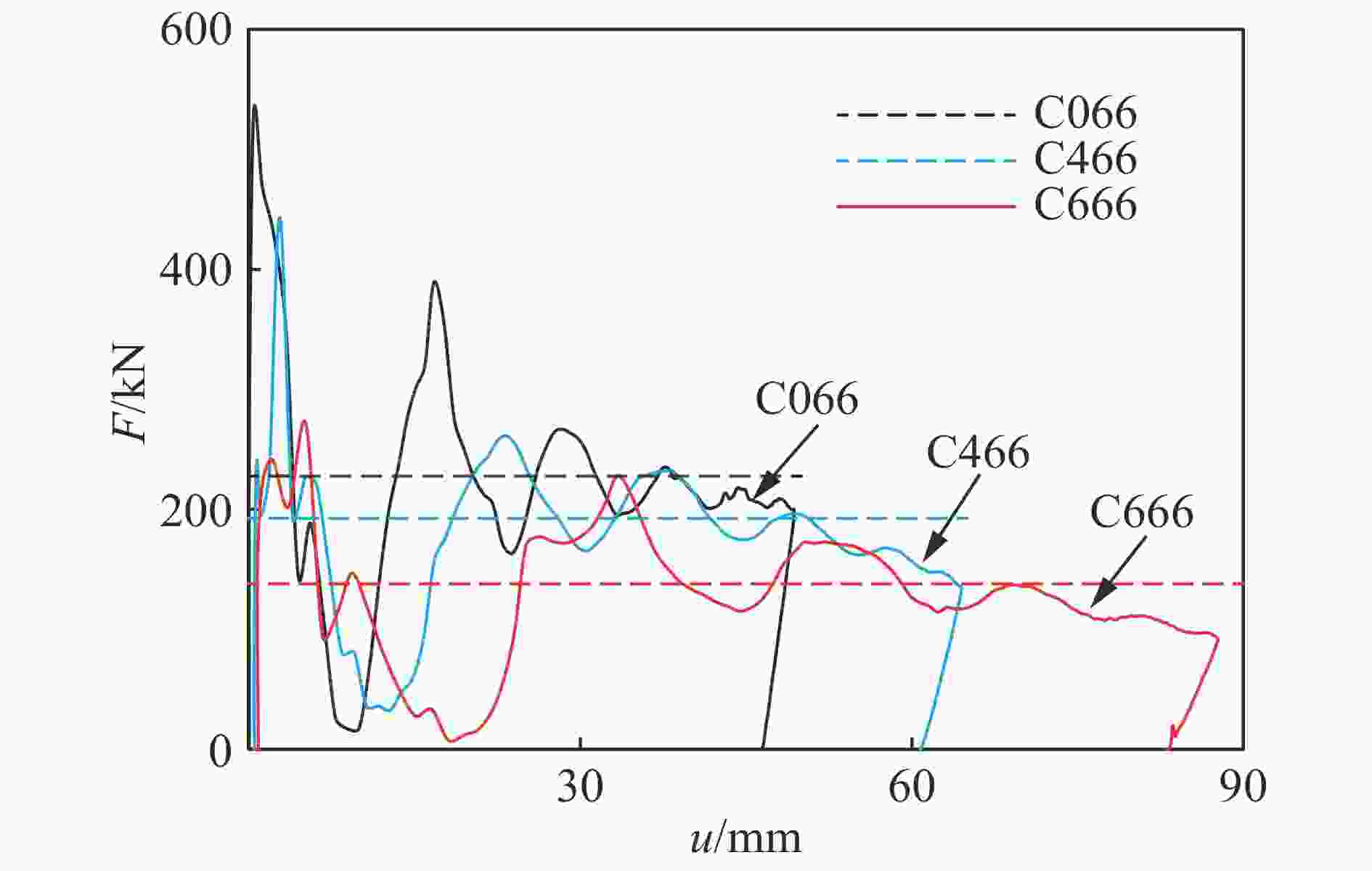

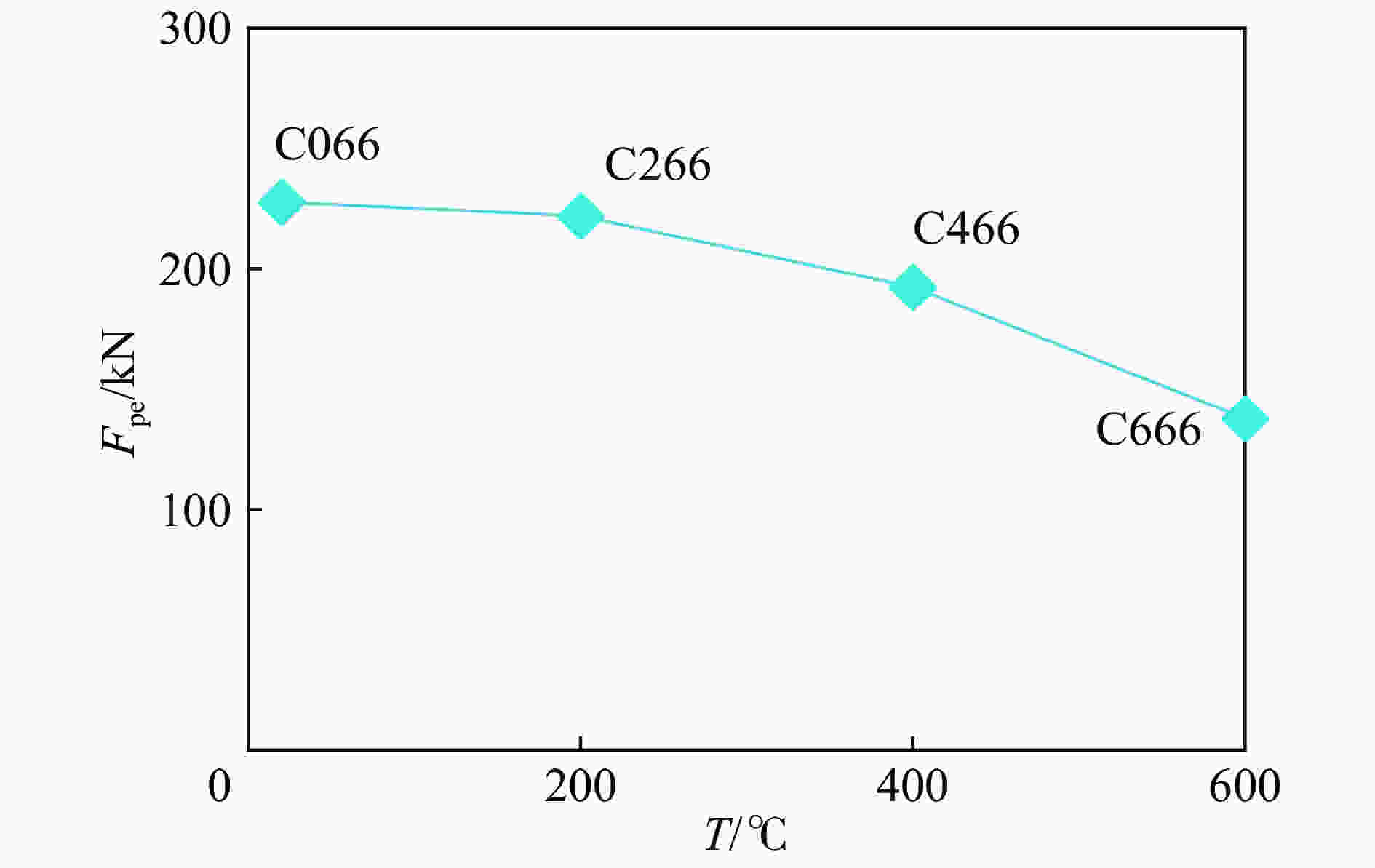

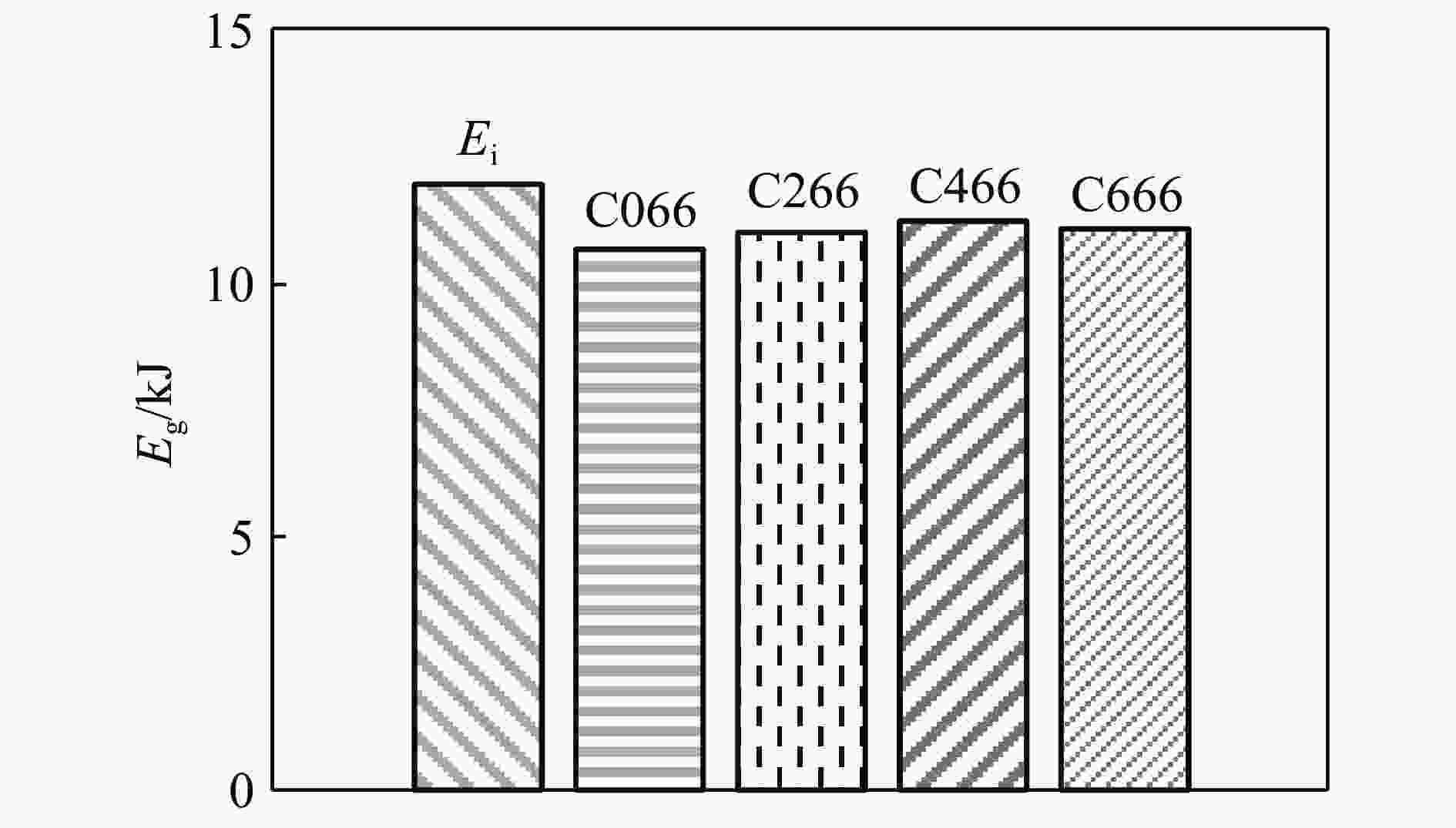

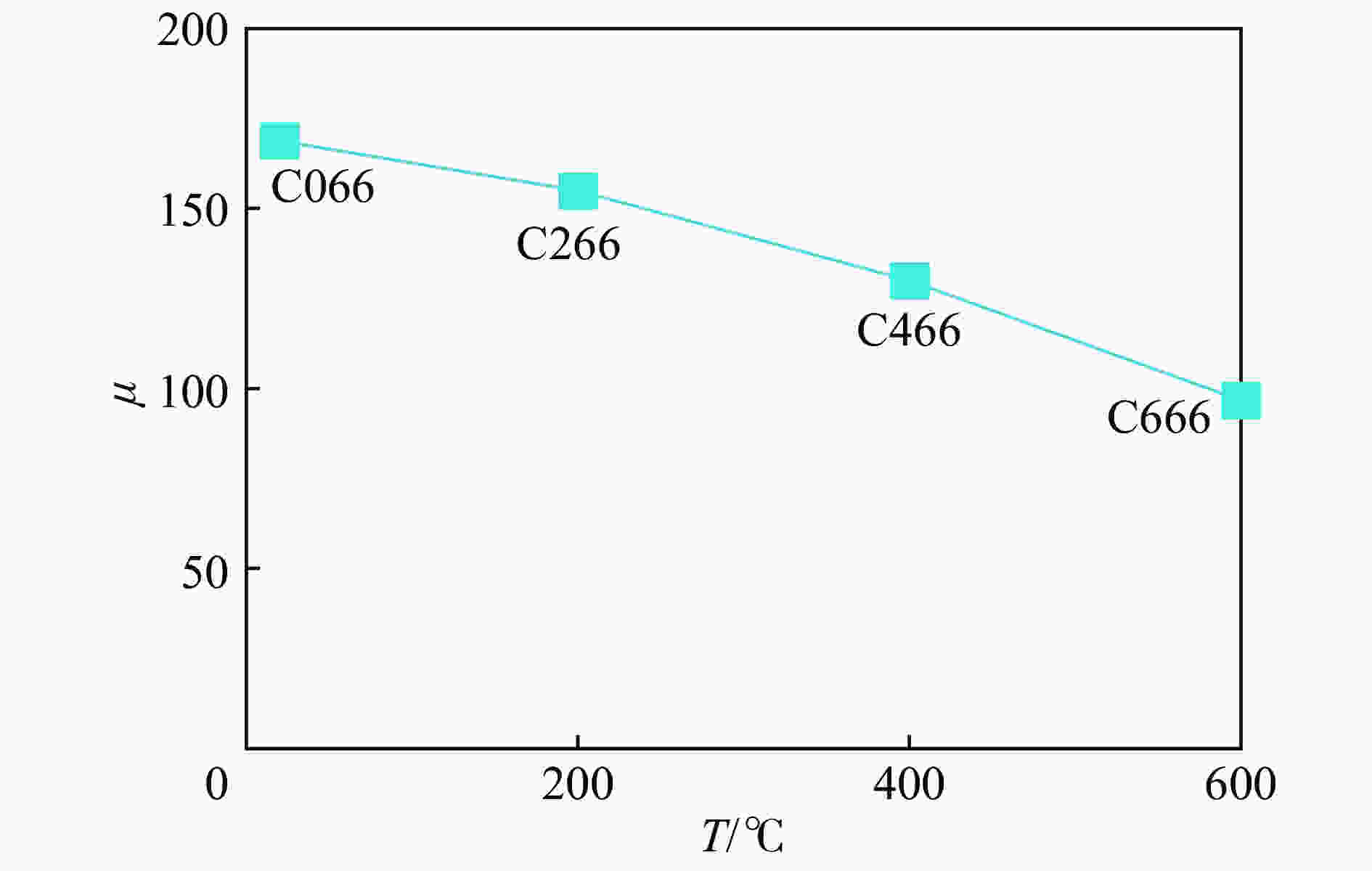

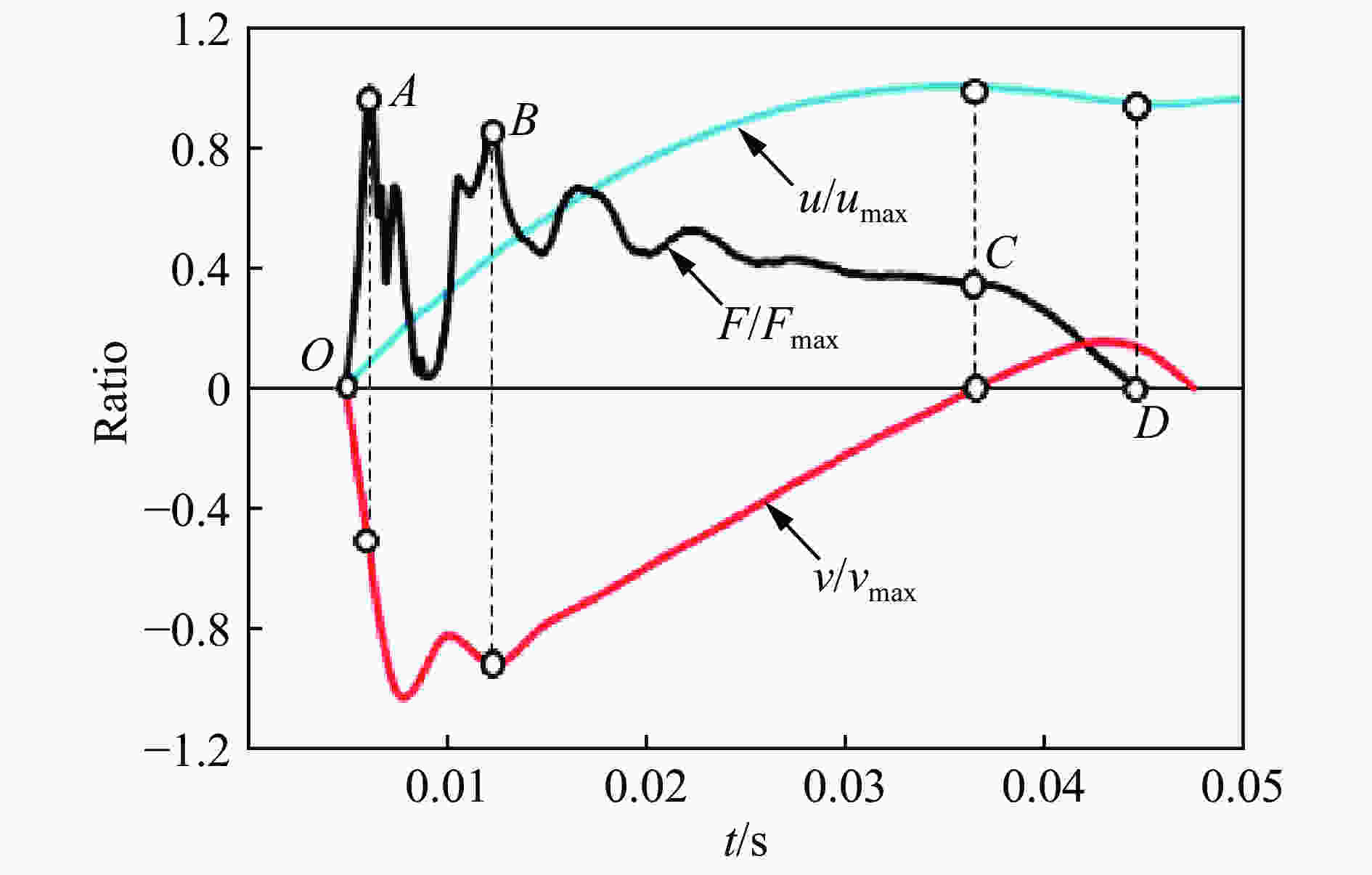

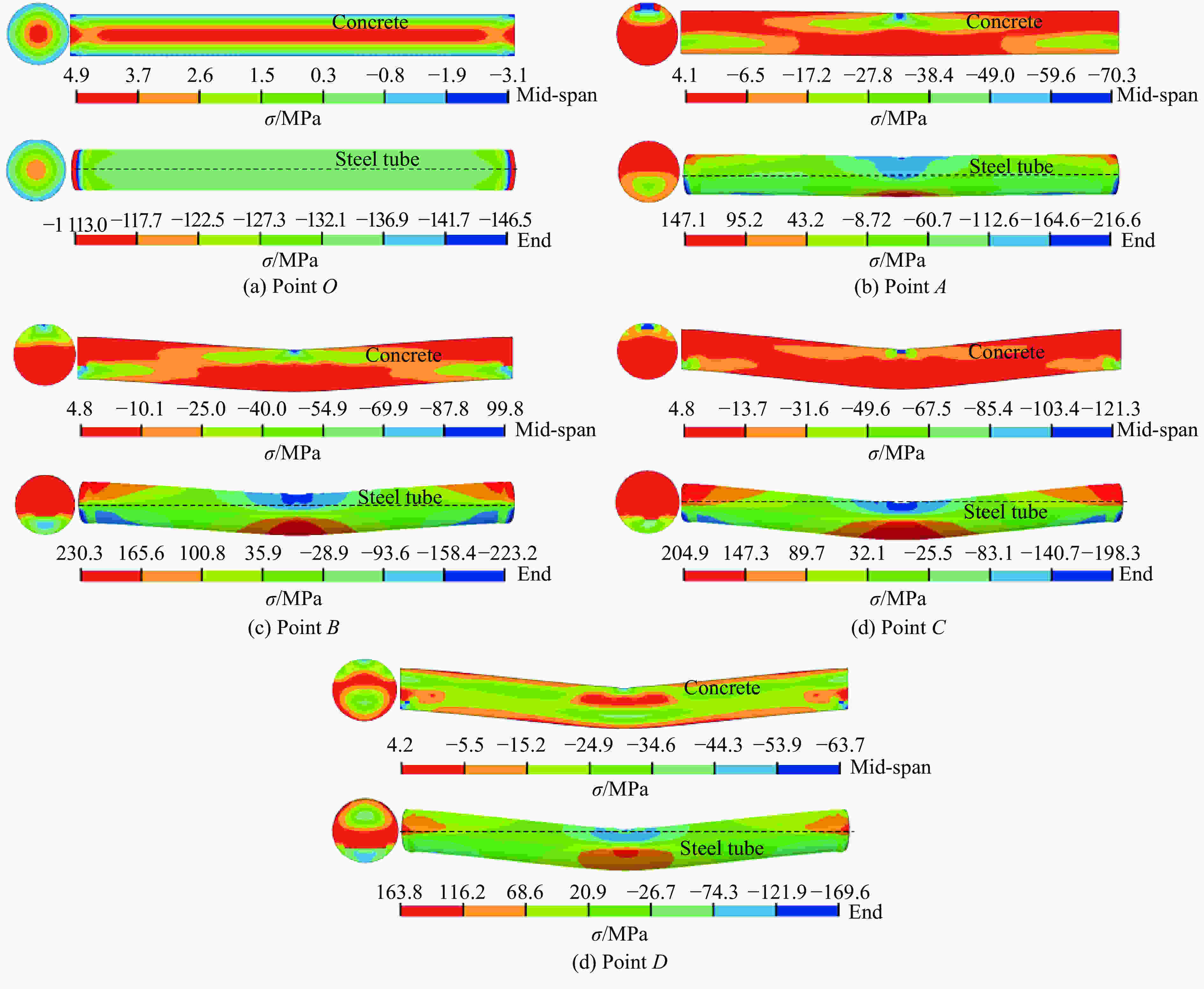

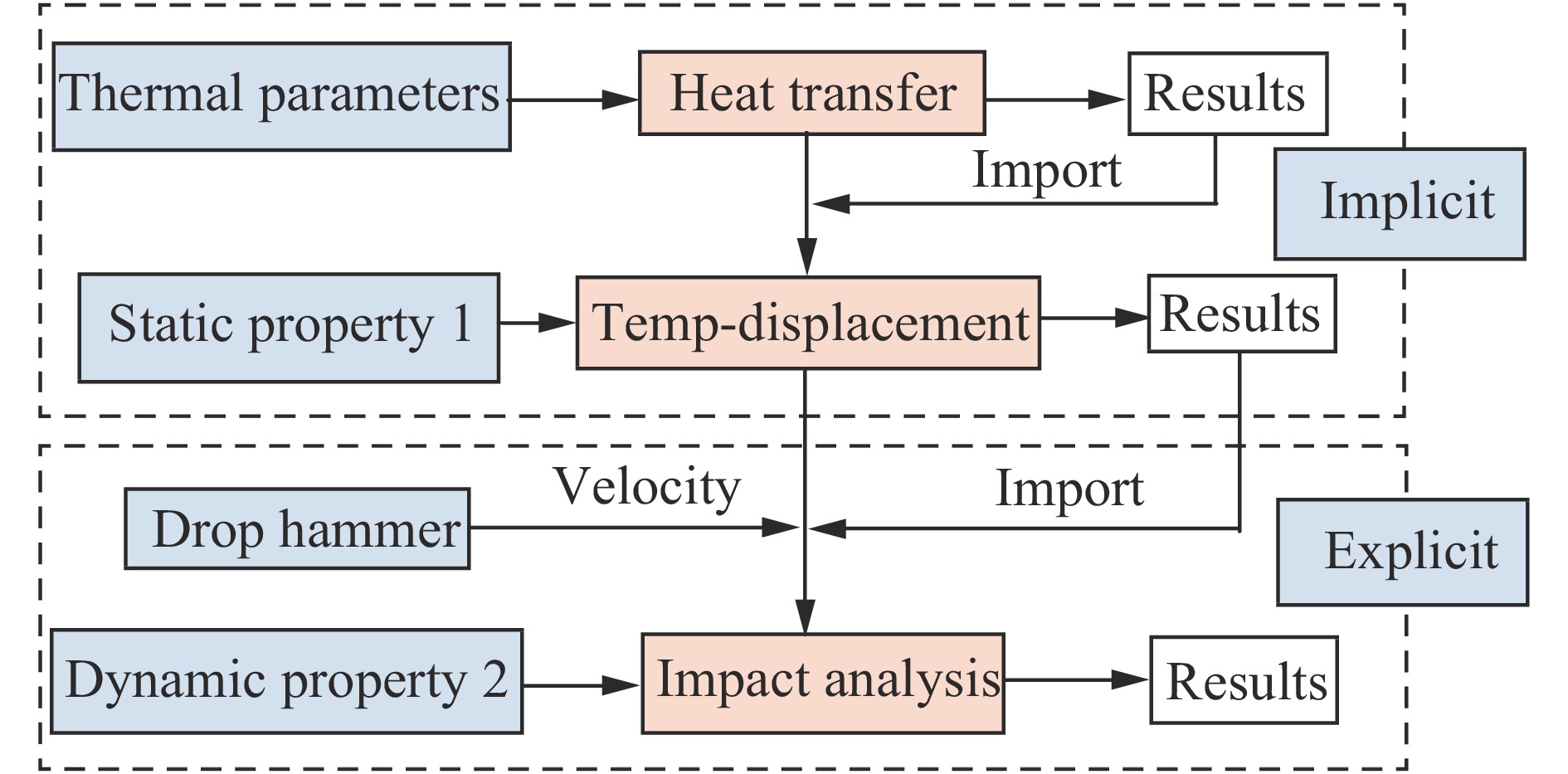

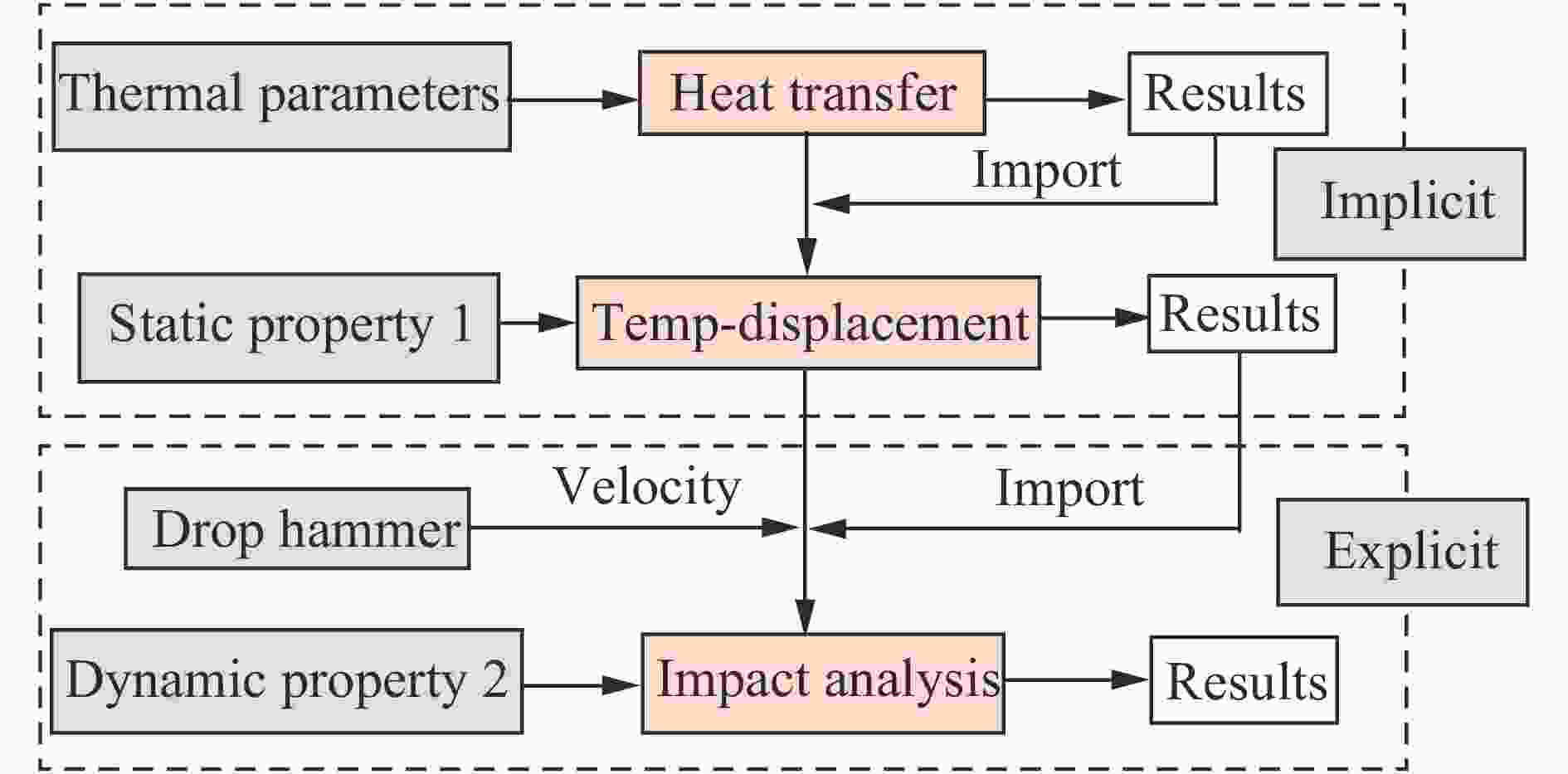

摘要: 通过耦合ABAQUS有限元软件中的隐式静态分析和显示动态分析,提出钢管混凝土构件在火灾与撞击联合作用下的数值计算方法,分别对已有钢管混凝土构件的温度场试验、火灾下轴向撞击试验和常温下侧向撞击试验进行数值模拟,以验证本文方法的合理性。在此基础上建立了钢管混凝土构件在不同温度下的侧向撞击有限元模型,分别对不同温度下的挠度和撞击力时程曲线进行对比,采用极值后平均撞击力和吸能系数对高温作用下构件的抗侧向撞击性能进行量化分析,并分析了600 ℃下构件撞击全过程。结果表明:温度对钢管混凝土构件的侧向撞击性能影响明显,随着温度升高,构件跨中挠度大幅增加,撞击时程变长;高温下构件的撞击力时程曲线与常温下差异明显,高温下曲线可分为震荡阶段、下降阶段和卸载阶段;构件主要通过整体弯曲变形吸收落锤的动能,随着温度升高,极值后平均撞击力和吸能系数逐渐降低,表明构件的抗撞击性能逐渐降低,当温度超过400 ℃后,构件抗撞击性能损失严重。Abstract: By coupling the implicit static analysis and the explicit dynamic analysis in ABAQUS, a numerical method to simulate the lateral impact process of concrete filled steel tubular (CFST) member in fire is presented. The tests about temperature field, the axial impact under fire and lateral impact at ambient temperature of CFST members are simulated to verify the feasibility of the method, respectively. Based on the proposed method, the finite element analysis (FEA) model of lateral impact of CFST members at different temperatures is developed. The time history curves of mid-span deflection and impact force at different temperatures are compared respectively. The post-extremumequal impact force (Fpe) and energy absorption capacity (μ) are used to quantitatively analyze the lateral impact resistance of the member. Finally, the impact process of the member at 600 °C is analyzed. The results show that the temperature has a significant influence on the lateral impact performance of the member. With the increase of temperature, the mid-span deflection increases and the impact duration is longer. The time history curve of impact force at high temperature is obviously different from that at ambient temperature. And the curve at high temperature can be divided into three stages, including the oscillating phase, the descending phase and the unloading phase. The kinetic energy of the drop hammer is mainly absorbed by the overall bending deformation of the member. The Fpe and μ decrease with the increase of temperature, indicating that the impact resistance of the member decreases. When the temperature of exceeds 400 °C, the impact resistance of the member is seriously lost.

-

表 1 试件温度场信息表

Table 1. The information of temperature field for the specimens

构件编号 d/mm $\varDelta $/mm s1/mm s2/mm s3/mm S1 219.0 4.78 0 26 52 S2 355.6 6.35 0 86 172 S3 323.9 6.35 0 78 155 表 2 试件试验信息表

Table 2. Information of the tested specimens

编号 d/mm $\varDelta $/mm L/mm 边界条件 速度/

(m∙s−1)质量/kg CC1 180 3.65 1 940 固支 9.21 465 CC2 180 3.65 1 940 固支 6.40 920 CC3 180 3.65 1 940 固支 9.66 465 SS1 180 3.65 2 800 简支 8.05 465 SS2 180 3.65 2 800 简支 5.69 920 SS3 180 3.65 2 800 简支 8.93 465 表 3 构件基本参数与结果

Table 3. Parameters and results of the members

构件编号 T/℃ Eg/kJ Ei/Eg tmax/s Fpe/kN μ umax/mm ut,max/mm C066 20 10.69 0.89 0.024 227.7 168.8 49.4 51.2 C266 200 11.03 0.92 0.025 222.0 154.9 53.8 56.2 C466 400 11.25 0.94 0.030 192.4 129.9 64.5 67.0 C666 600 11.09 0.93 0.040 137.9 96.7 87.7 90.6 -

[1] XI F, LI Q M, TAN Y H. Dynamic response and critical temperature of a steel beam subjected to fire and subsequent impulsive loading [J]. Computers and Structures, 2014, 135: 100–108. DOI: 10.1016/j.compstruc.2014.01.014. [2] RUAN Z, CHEN L, FANG Q. Numerical investigation into dynamic responses of RC columns subjected for fire and blast [J]. Journal of Loss Prevention in the Process Industries, 2015, 34: 10–21. DOI: 10.1016/j.jlp.2015.01.009. [3] TAN Y H, XI F, LI S C, et al. Pulse shape effects on the dynamic response of a steel beam under combined action of fire and explosion loads [J]. Journal of Constructional Steel Research, 2017, 139: 484–492. DOI: 10.1016/j.jcsr.2017.10.001. [4] YU X, CHEN L, FANG Q, et al. A concrete constitutive model considering coupled effects of high temperature and high strain rate [J]. International Journal of Impact Engineering, 2017, 101: 66–77. DOI: 10.1016/j.ijimpeng.2016.11.009. [5] CHEN L, FANG Q, JIANG X Q, et al. Combined effects of high temperature and high strain rate on normal weight concrete [J]. International Journal of Impact Engineering, 2015, 86: 40–56. DOI: 10.1016/j.ijimpeng.2015.07.002. [6] 韩林海. 钢管混凝土结构: 理论与实践[M]. 3版. 北京: 科学出版社, 2016. [7] WANG R, HAN L H, HOU C C. Behavior of concrete filled steel tubular (CFST) members under lateral impact: experiment and FEA model [J]. Journal of Constructional Steel Research, 2013, 80: 188–201. DOI: 10.1016/j.jcsr.2012.09.003. [8] HAN L H, HOU C C, ZHAO X L, et al. Behaviour of high-strength concrete filled steel tubes under transverse impact loading [J]. Journal of Constructional Steel Research, 2014, 92: 25–39. DOI: 10.1016/j.jcsr.2013.09.003. [9] 王蕊, 李珠, 任够平, 等. 钢管混凝土梁在侧向冲击荷载作用下动力响应的试验研究和数值模拟 [J]. 土木工程学报, 2007, 40(10): 34–40. DOI: 10.3321/j.issn:1000-131x.2007.10.006.WANG R, LI Z, REN G P, et al. Experimental study and numerical simulation of the dynamic response of concrete filled steel tubes under lateral impact load [J]. China Civil Engineering Journal, 2007, 40(10): 34–40. DOI: 10.3321/j.issn:1000-131x.2007.10.006. [10] WANG R, HAN L H, TAO Z. Behavior of FRP-concrete-steel double skin tubular members under lateral impact: experimental study [J]. Thin-Walled Structures, 2015, 95: 363–373. DOI: 10.1016/j.tws.2015.06.022. [11] WANG R, HAN L H, ZHAO X L, et al. Analytical behavior of concrete filled double steel tubular (CFDST) members under lateral impact [J]. Thin-Walled Structures, 2016, 101: 129–140. DOI: 10.1016/j.tws.2015.12.006. [12] HU M C, HAN L H, HOU C C. Concrete-encased CFST members with circular sections under laterally low velocity impact: analytical behaviour [J]. Journal of Constructional Steel Research, 2018, 146: 135–154. DOI: 10.1016/j.jcsr.2018.03.017. [13] 史艳莉, 何佳星, 王文达, 等. 内配圆钢管的圆钢管混凝土构件耐撞性能分析 [J]. 振动与冲击, 2019, 38(9): 123–132. DOI: 10.13465/j.cnki.jvs.2019.09.017.SHI Y L, HE J X, WANG W D, et al. Anti-impact performance analysis for circular CFST members with inner circular steel tube [J]. Journal of Vibration and Shock, 2019, 38(9): 123–132. DOI: 10.13465/j.cnki.jvs.2019.09.017. [14] 史艳莉, 鲜威, 王蕊, 等. 方套圆中空夹层钢管混凝土组合构件横向撞击试验研究 [J]. 土木工程学报, 2019, 52(12): 11–21, 35. DOI: 10.15951/j.tmgcxb.2019.12.002.SHI Y L, XIAN W, WANG R, et al. Experimental study on circular-in-square concrete filled double-skin steel tubular (CFDST) composite components under lateral impact [J]. China Civil Engineering Journal, 2019, 52(12): 11–21, 35. DOI: 10.15951/j.tmgcxb.2019.12.002. [15] HUO J S, ZHENG Q, CHEN B S, et al. Tests on impact behaviour of micro-concrete-filled steel tubes at elevated temperatures up to 400 ℃ [J]. Materials and Structures, 2009, 42(10): 1325–1334. DOI: 10.1617/s11527-008-9452-0. [16] HUO J S, HE Y M, CHEN B S. Experimental study on impact behaviour of concrete-filled steel tubes at elevated temperatures up to 800 ℃ [J]. Materials and Structures, 2014, 47(1−2): 263–283. DOI: 10.1617/s11527-013-0059-8. [17] CHEN W X, LUO L S, GUO Z K, et al. Strain rate effects on dynamic strength of high temperature-damaged RPC-FST [J]. Journal of Constructional Steel Research, 2018, 147: 324–339. DOI: 10.1016/j.jcsr.2018.04.025. [18] 霍静思, 任晓虎, 肖岩. 标准火灾作用下钢管混凝土短柱落锤动态冲击试验研究 [J]. 土木工程学报, 2012, 45(4): 9–20. DOI: 10.15951/j.tmgcxb.2012.04.009.HUO J S, REN X H, XIAO Y. Impact behavior of concrete-filled steel tubular stub columns under ISO-834 standard fire [J]. China Civil Engineering Journal, 2012, 45(4): 9–20. DOI: 10.15951/j.tmgcxb.2012.04.009. [19] CHEN H, LIEW J Y. Explosion and fire analysis of steel frames using mixed element approach [J]. Journal of Engineering Mechanics, 2005, 131(6): 606–616. DOI: 10.1061/(ASCE)0733-9399(2005)131:6(606). [20] LIE T T, CHABOT M. Experimental studies on the fire resistance of hollow steel columns filled with plain concrete: NRC-IRC-4196[R]. Ottawa: National Research Council of Canada, 1992. DOI: 10.4224/20358480. [21] WANG Y, QIAN X D, LIEW J Y R, et al. Experimental behavior of cement filled pipe-in-pipe composite structures under transverse impact [J]. International Journal of Impact Engineering, 2014, 72: 1–16. DOI: 10.1016/j.ijimpeng.2014.05.004. -

下载:

下载: