Study on static and dynamic mechanical properties and fracture mechanism of cenospheres

-

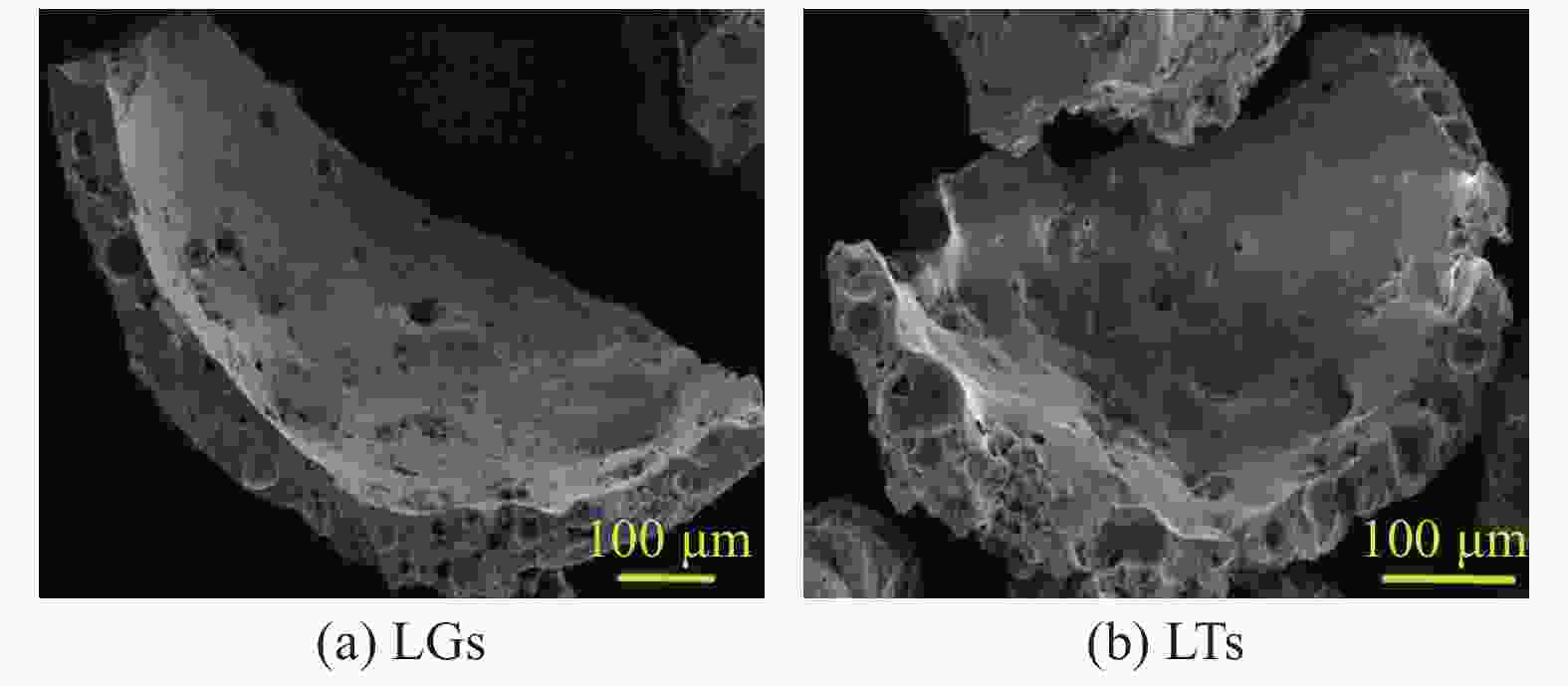

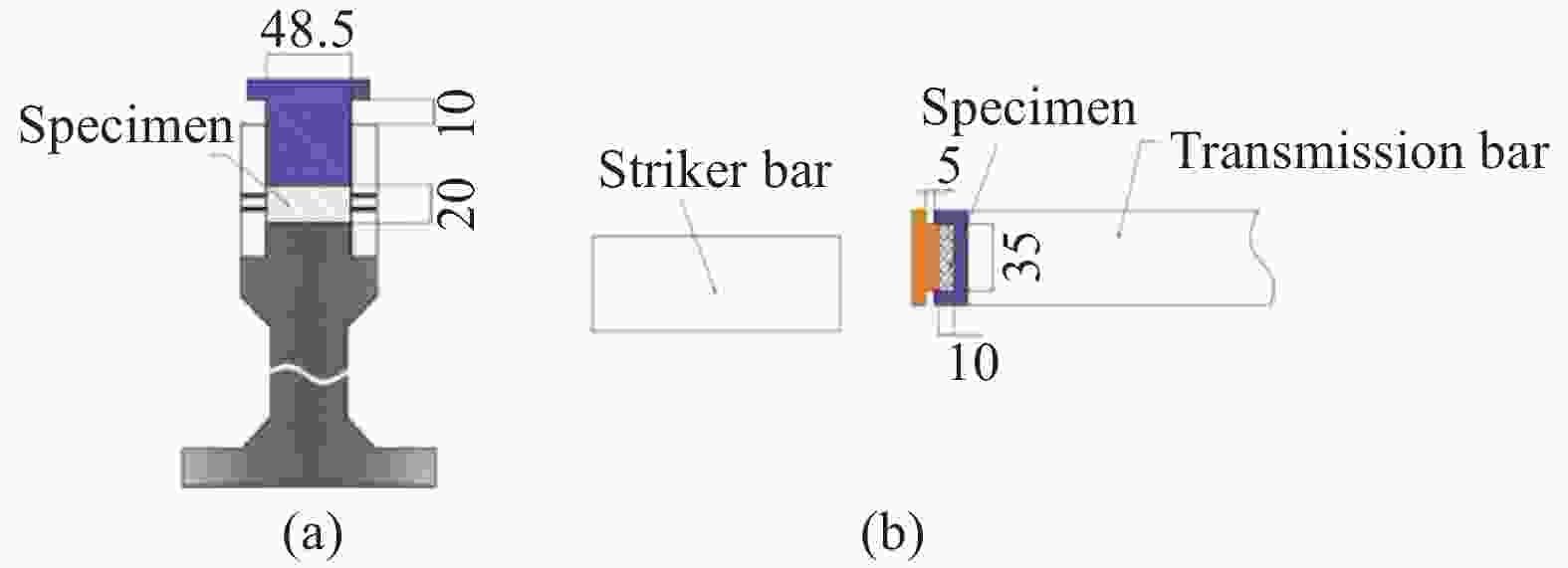

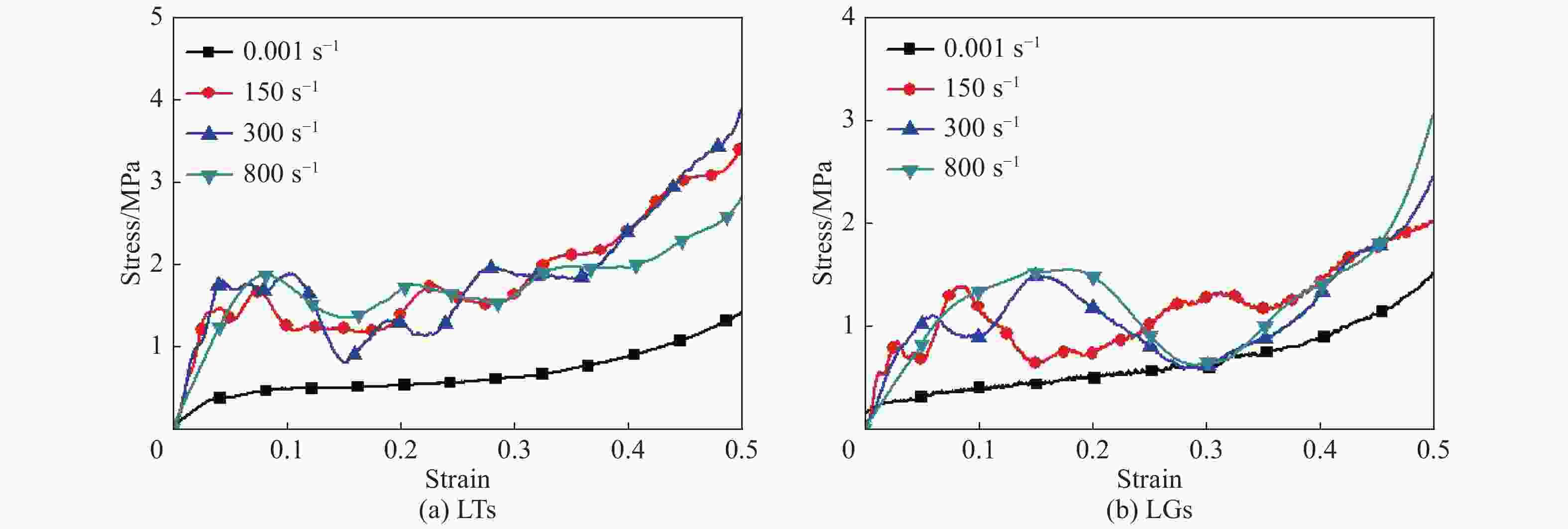

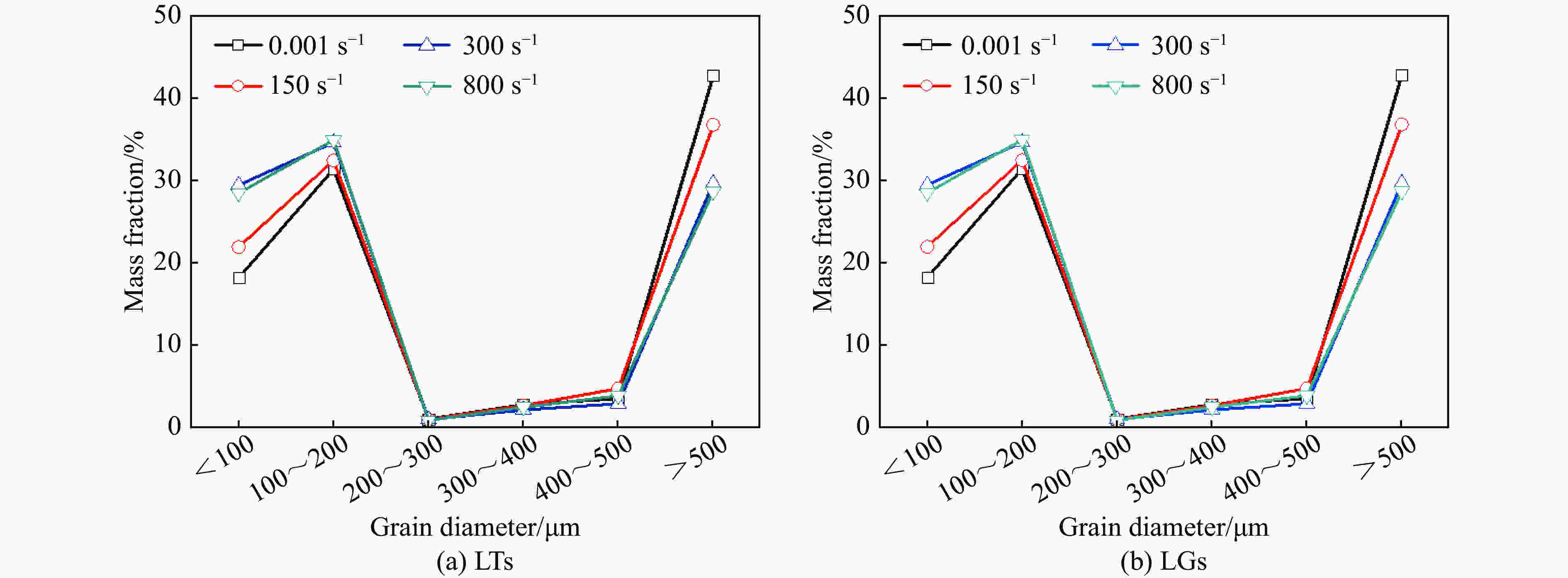

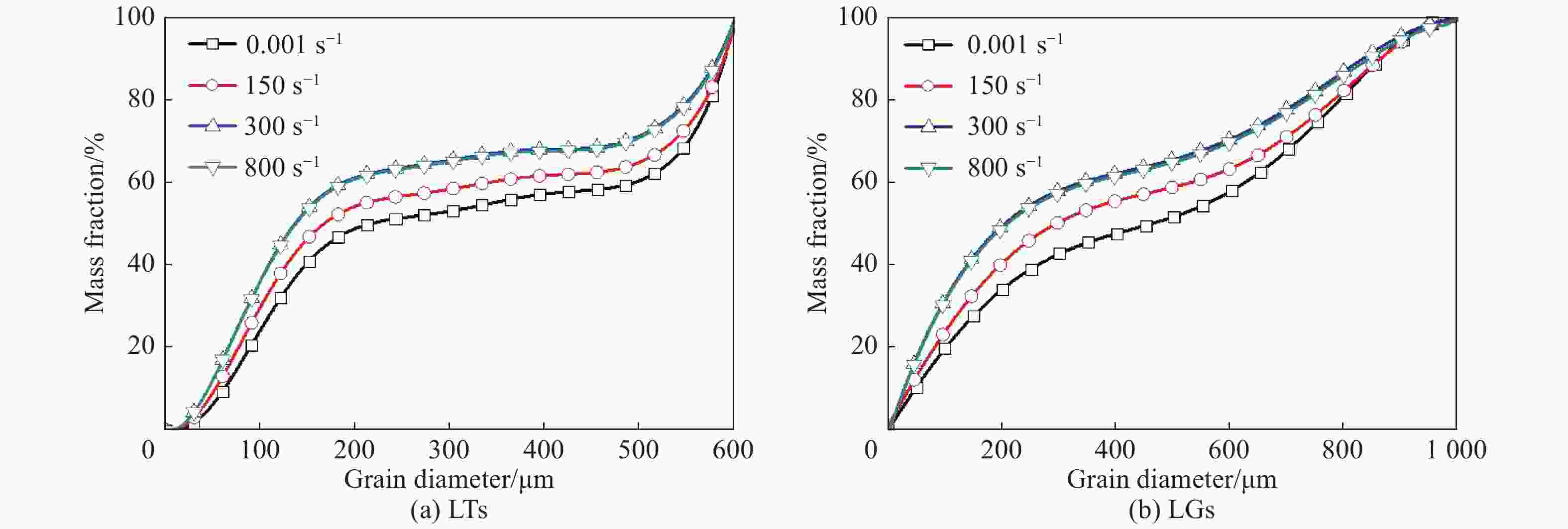

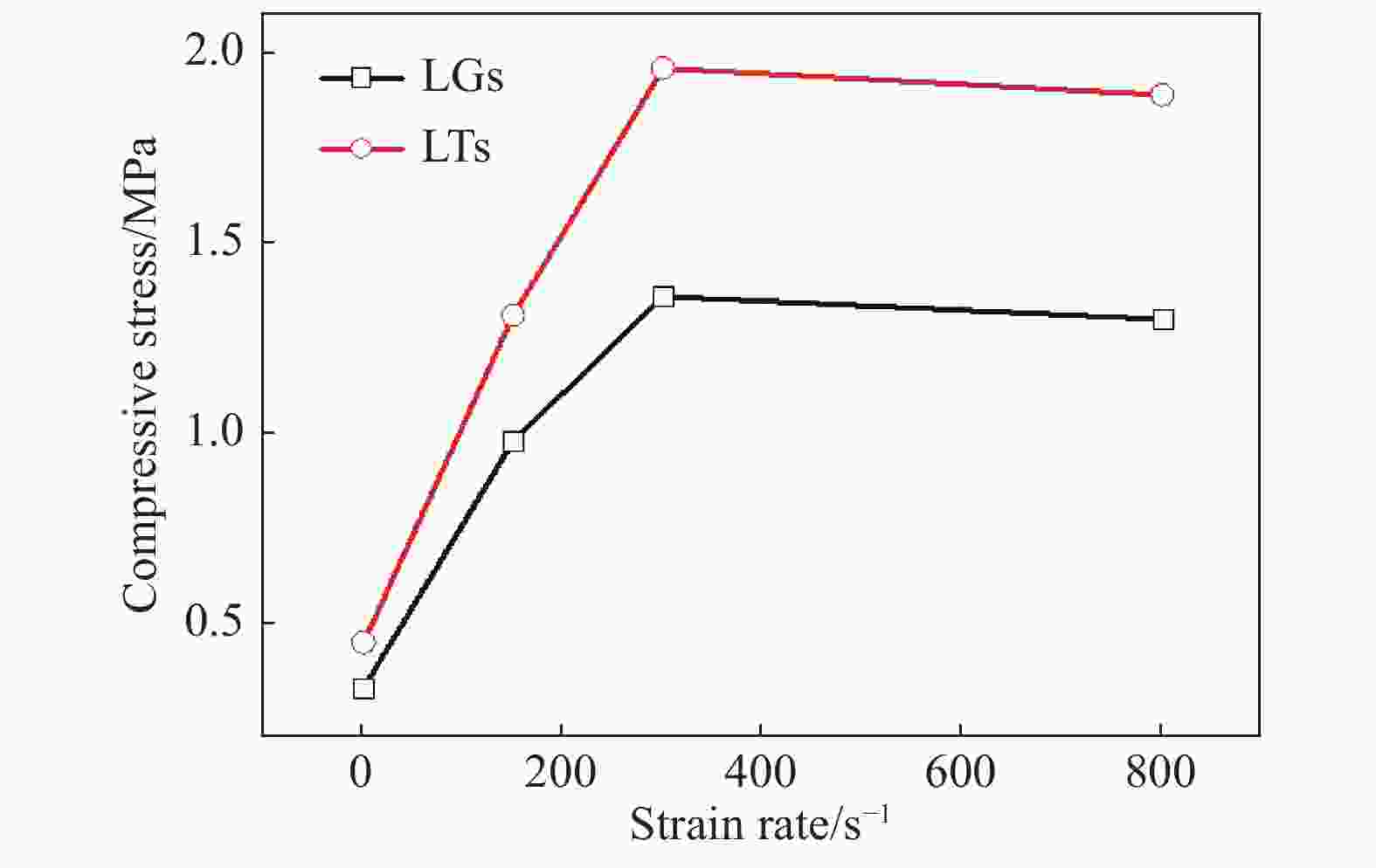

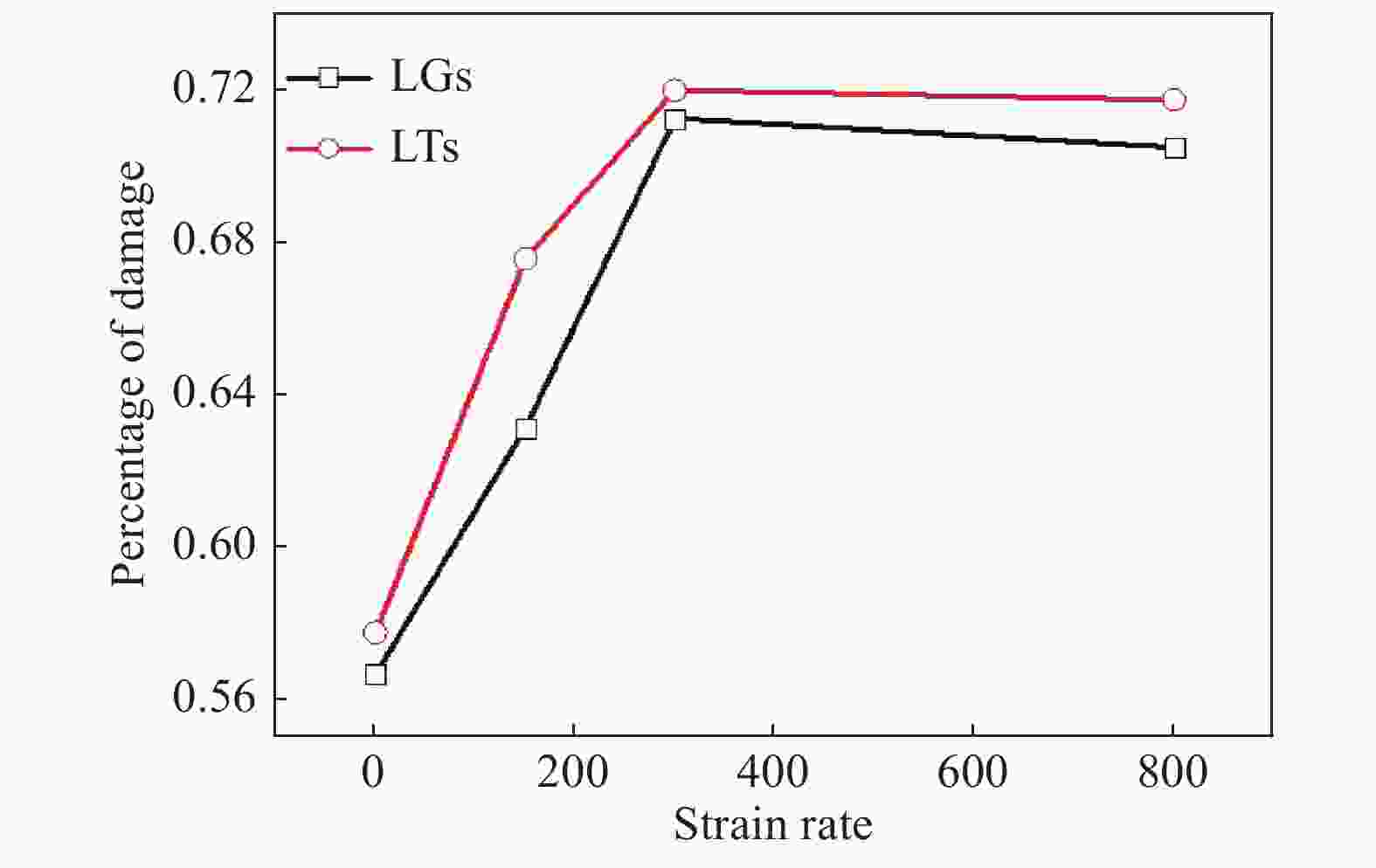

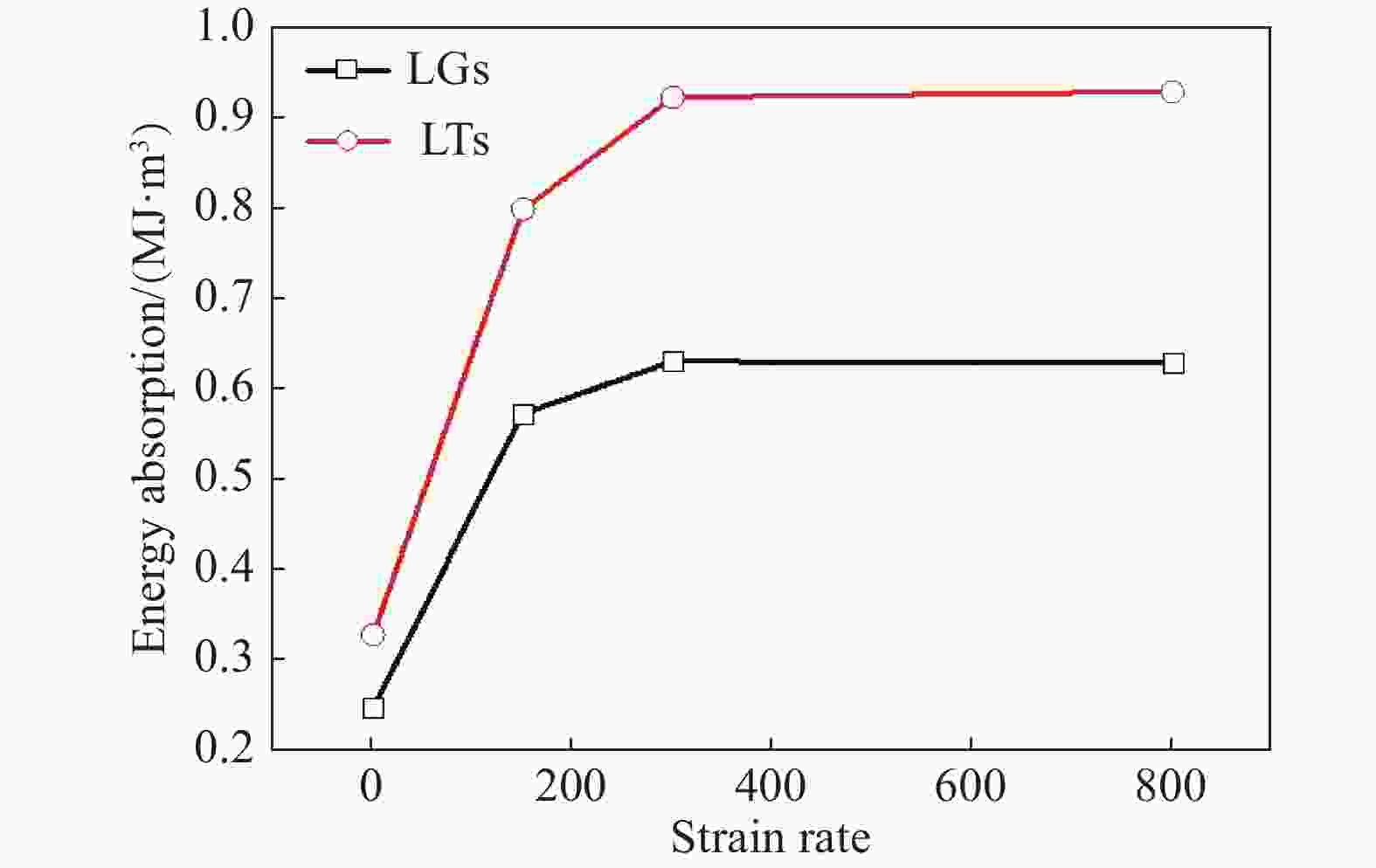

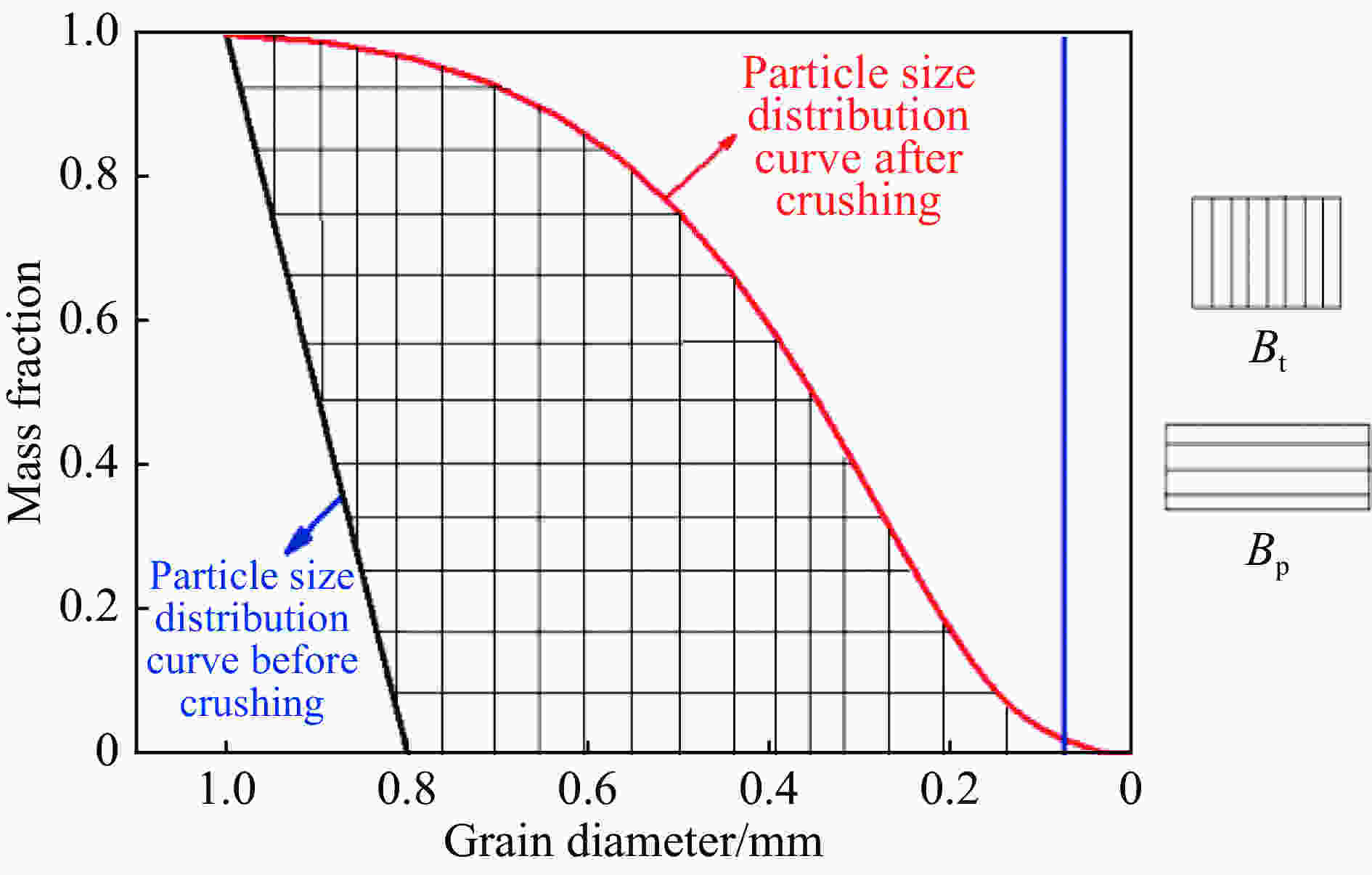

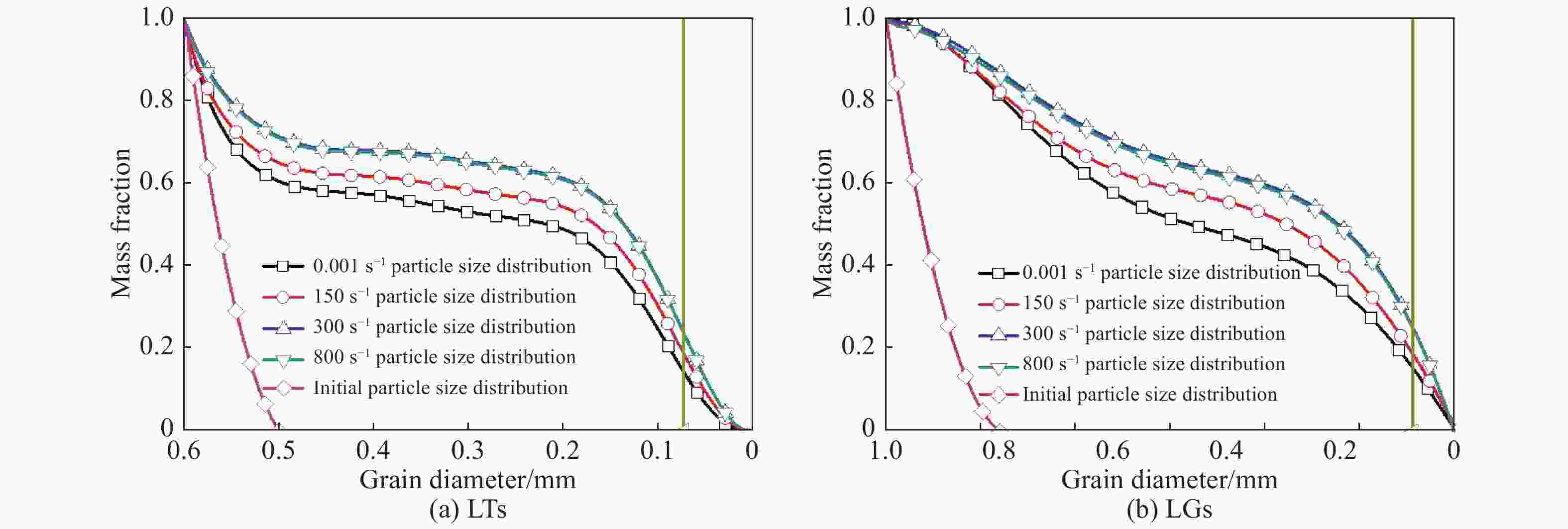

摘要: 为考察脆性空心颗粒材料冲击载荷下的力学特性,以具有不同粒径分布的粉煤灰漂珠为研究对象,对其静动态力学性能进行实验研究。通过限制颗粒材料压缩应变为50%,分析颗粒破碎率和破碎机理与材料宏观应变率效应的关系。结果表明:(1)不同粒径的漂珠颗粒材料在动态压缩下较准静态压缩下颗粒材料的强度均有明显的增强,在0.001和150 s−1大小颗粒的强度分别提高200%和195%,在150和300 s−1大小颗粒的强度分别提高39%和51.5%,在300和800 s−1大小颗粒的强度并未发生明显的变化;(2)在相同加载速度下粒径较小的颗粒比大粒径颗粒的强度和吸能效果分别提高35%~40%和35%~48%;(3)对破碎后颗粒粒径分布曲线分析可知,随着加载速度的增加,大小颗粒的破碎率和破碎程度都会增大,且在相同加载速度下大颗粒的破碎率较小颗粒的破碎率高;(4)Hardin破碎势分析表明,单位输入能量下颗粒的相对破碎势随冲击速度增大而减小,动态冲击下用于颗粒破碎的能量利用率降低,从而导致材料在相同压缩量下产生更高的能量耗散和应力水平,即表现为宏观的应变率效应。Abstract: To investigate the mechanical properties of brittle hollow particles (BHPs) under impact loading, Quasi-static and dynamic compressive tests were conducted on fly ash cenospheres (CPs) with two different particle size graduations. The breakage rate and fracture mechanism of the cenospheres and their effects on the strain rate sensitivity of the cenospheres accumulation were discussed based on the single loading experiments, which were implemented by limiting the compression strain of the particles accumulation to 50%. The results are as follows. (1) The dynamic strength of cenosphere materials was significantly enhanced as compared to the quasi-static compression results. In the strain rate range of 0.001-150 s−1, the strength of the cenosphere accumulations with large and small average particle sizes (marked LGs and LTs) increased by 200% and 195%, respectively. The strength of LGs and LTs increased 39% and 51.5% with the strain rate increased from 150 s−1 to 300 s−1. However, when the strain rate increased to 800 s−1, no obvious change on the strength of both LGs and LTs were observed. (2) At the same loading rate, the strength and energy absorption of particle accumulation with smaller average size were35%~40% and 35%~48% higher than that containing larger particles. (3) According to the particle fragments size distribution analysis, the broken rate of the particle accumulation and the broken severity of single particle both increased with the loading rate. In addition, the broken rate of LGs was higher than that of LTs at the same loading rate. (4) Based on Hardin fracture potential analysis, it can be concluded that the relative breaking potential of particles decreases with the increase of impact velocity under unit input energy, and the energy utilization rate for particle breaking decreases under dynamic impact, which leads to higher energy dissipation and stress level of materials under the same compression amount, namely, the macroscopic strain rate effect.

-

Key words:

- cenospheres /

- brittle hollow particles /

- mechanical properties /

- broken rate /

- strain rate effect

-

表 1 粉煤灰漂珠破碎势

Table 1. Cenospheres breaking potential

颗粒大小 应变率/s−1 Bp Bt Br 输入总能量/J 单位能量相对破碎势/J−1 LGs 0.001 0.826 0.430 0.520 4.610 0.113 150 0.490 0.593 10.600 0.056 300 0.530 0.642 11.670 0.055 800 0.530 0.641 11.630 0.055 LTs 0.001 0.476 0.237 0.497 6.085 0.082 150 0.268 0.562 14.770 0.038 300 0.294 0.617 17.062 0.036 800 0.290 0.609 17.170 0.036 -

[1] WANG Y, MA T H, ZHU J J. Analysis on cushion performance of quartz sand in high-g shock [J]. Computer Modelling & New Technologies, 2014, 18(12D): 367–370. [2] LING Y F, ZHANG Q, ZHANG F Y, et al. Microstructure and strength correlation of pure Al and Al-Mg syntactic foam composites subject to uniaxial compression [J]. Materials Science and Engineering: A, 2017, 696: 236–247. DOI: 10.1016/j.msea.2017.04.060. [3] FAN Z Q, MIAO Y Z, WANG Z Z, et al. Effect of the cenospheres size and internally lateral constraints on dynamic compressive behavior of fly ash cenospheres polyurethane syntactic foams [J]. Composites Part B: Engineering, 2019, 171: 329–338. DOI: 10.1016/j.compositesb.2019.05.008. [4] BRAGOV A M, LOMUNOV A K, SERGEICHEV I V, et al. Determination of physicomechanical properties of soft soils from medium to high strain rates [J]. International Journal of Impact Engineering, 2008, 35(9): 967–976. DOI: 10.1016/j.ijimpeng.2007.07.004. [5] SONG B, CHEN W N, LUK V. Impact compressive response of dry sand [J]. Mechanics of Materials, 2009, 41(6): 777–785. DOI: 10.1016/j.mechmat.2009.01.003. [6] FARR J V. One-dimensional loading-rate effects [J]. Journal of Geotechnical Engineering, 1990, 116(1): 119–135. DOI: 10.1061/(ASCE)0733-9410(1990)116:1(119). [7] YAMAMURO J A, ABRANTES A E, LADE P V. Effect of strain rate on the stress-strain behavior of sand [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2011, 137(12): 1169–1178. DOI: 10.1061/(ASCE)GT.1943-5606.0000542. [8] HUANG J Y, XU S L, HU S S. Influence of particle breakage on the dynamic compression responses of brittle granular materials [J]. Mechanics of Materials, 2014, 68: 15–28. DOI: 10.1016/j.mechmat.2013.08.002. [9] HUANG J, XU S, HU S. Effects of grain size and gradation on the dynamic responses of quartz sands [J]. International Journal of Impact Engineering, 2013, 59: 1–10. DOI: 10.1016/j.ijimpeng.2013.03.007. [10] HUANG J Y, LU L, FAN D, et al. Heterogeneity in deformation of granular ceramics under dynamic loading [J]. Scripta Materialia, 2016, 111: 114–118. DOI: 10.1016/j.scriptamat.2015.08.028. [11] MONDAL D P, JHA N, GULL B, et al. Microarchitecture and compressive deformation behaviour of Al-alloy (LM13)-cenosphere hybrid Al-foam prepared using CaCO3 as foaming agent [J]. Materials Science and Engineering: A, 2013, 560: 601–610. DOI: 10.1016/j.msea.2012.10.003. [12] LADE P V, YAMAMURO J A, BOPP P A. Significance of particle crushing in granular materials [J]. Journal of Geotechnical Engineering, 1996, 122(4): 309–316. DOI: 10.1061/(ASCE)0733-9410(1996)122:4(309). [13] LIU H Y, KOU S Q, LINDQVIST P A. Numerical studies on the inter-particle breakage of a confined particle assembly in rock crushing [J]. Mechanics of Materials, 2005, 37(9): 935–954. DOI: 10.1016/j.mechmat.2004.10.002. [14] 倪素环, 陈青果, 侯书军. 颗粒层受压破碎过程的试验研究 [J]. 金属矿山, 2011(1): 109–111, 127.NI S H, CHEN Q G, HOU S J. Experimental research on compression crushing process of granular layer [J]. Metal Mine, 2011(1): 109–111, 127. [15] HARDIN B O. Crushing of soil particles [J]. Journal of Geotechnical Engineering, 1985, 111(10): 1177–1192. DOI: 10.1061/(ASCE)0733-9410(1985)111:10(1177). [16] 池昌江. 准脆性颗粒材料的受压渐进破碎机制研究[D]. 北京: 清华大学, 2015. [17] 黄俊宇. 冲击载荷下脆性颗粒材料多尺度变形破碎特性研究[D]. 合肥: 中国科学技术大学, 2016. -

下载:

下载: