Dynamic mechanical properties of basalt fiber engineered cementitious composites

-

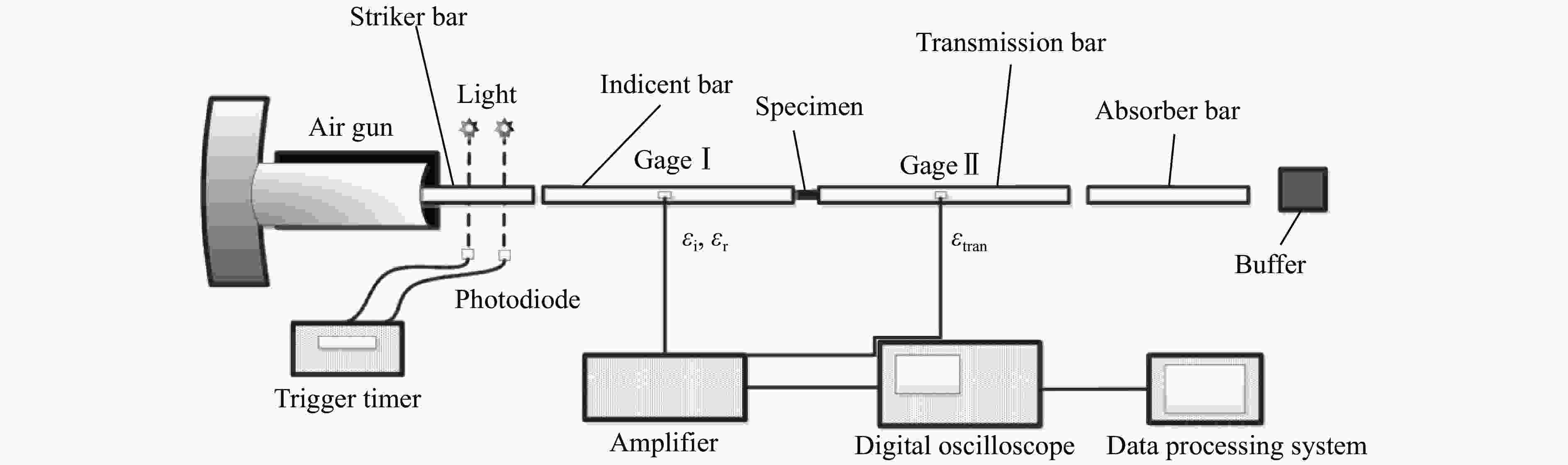

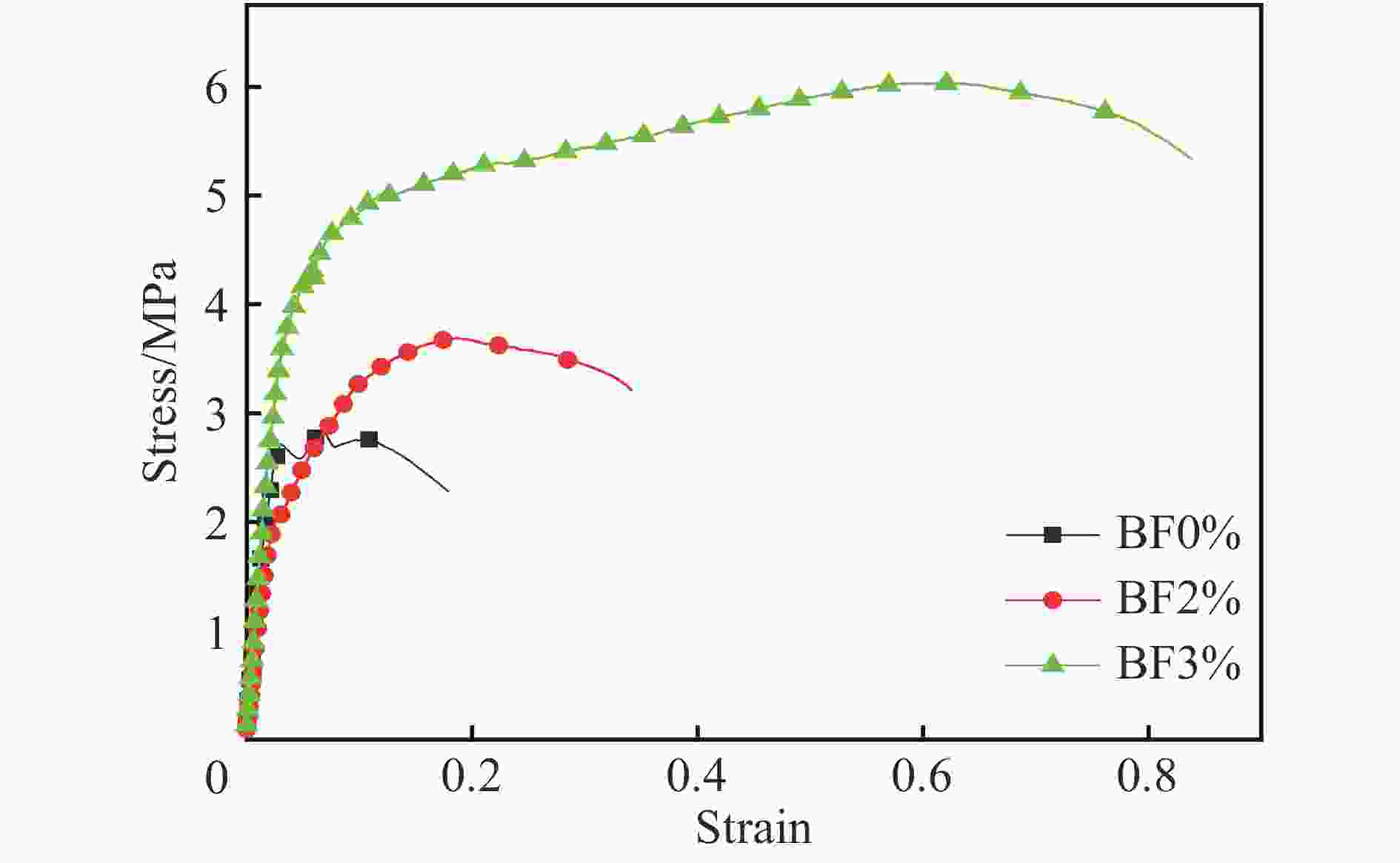

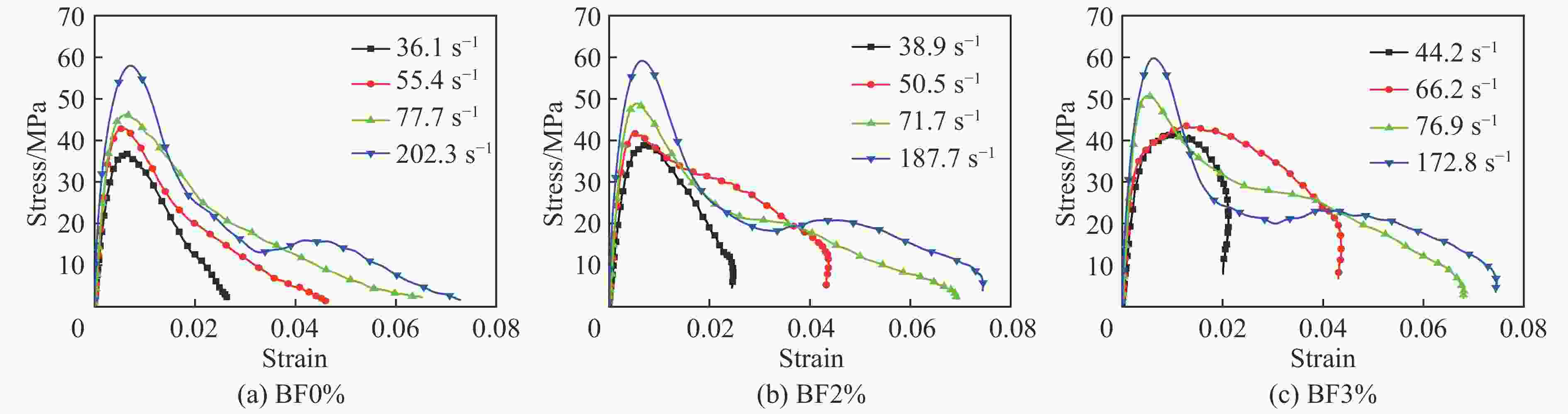

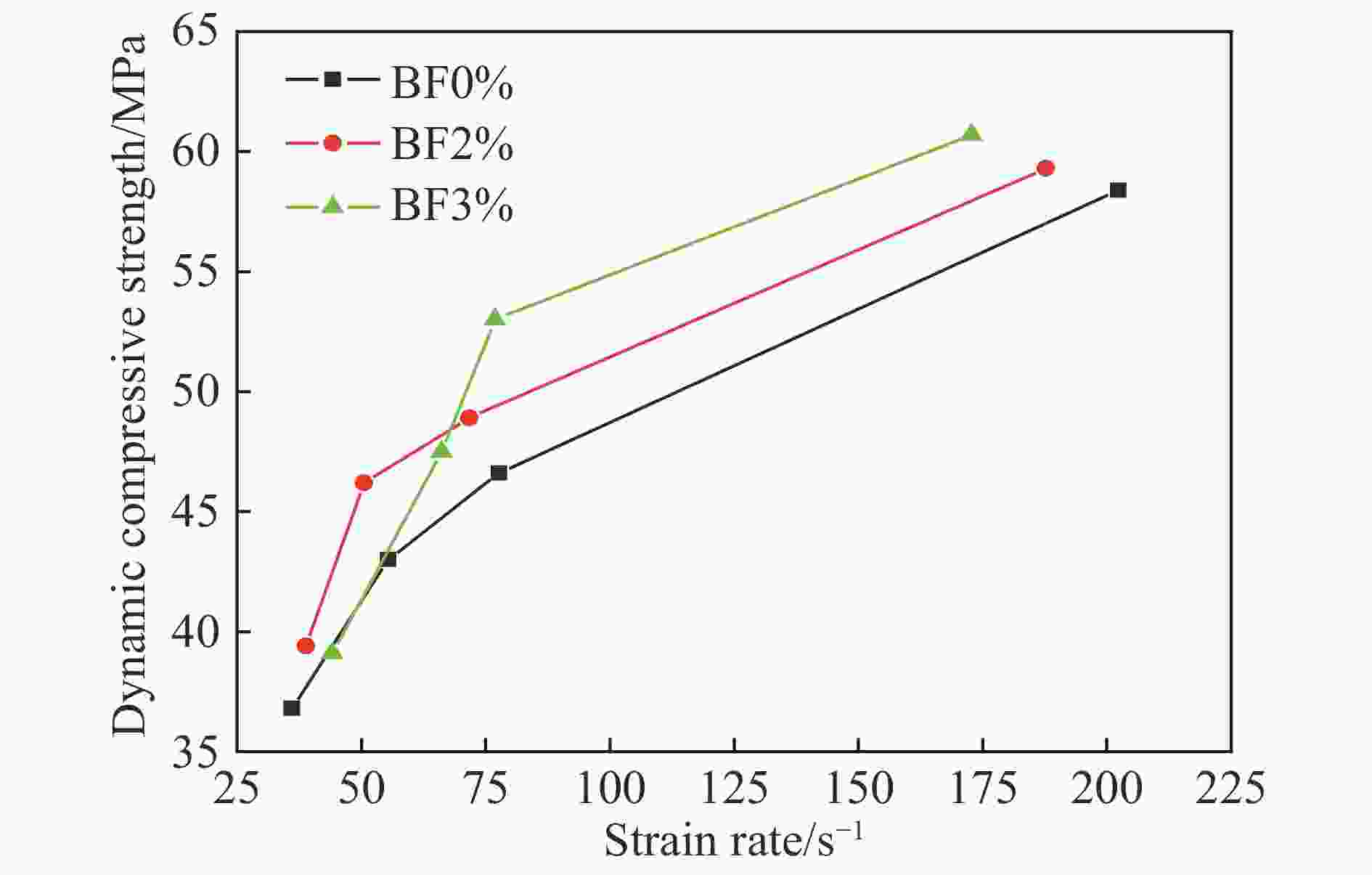

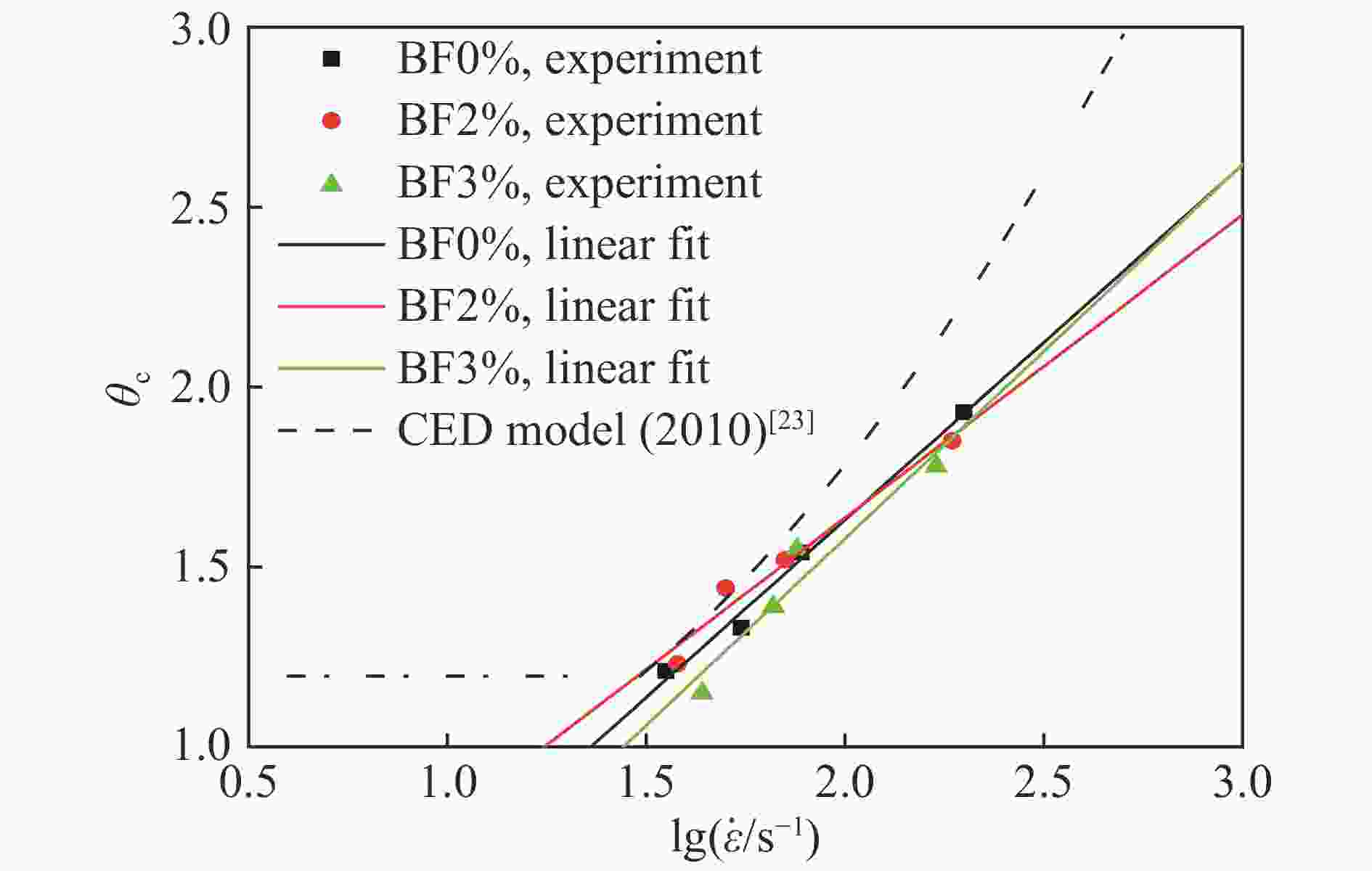

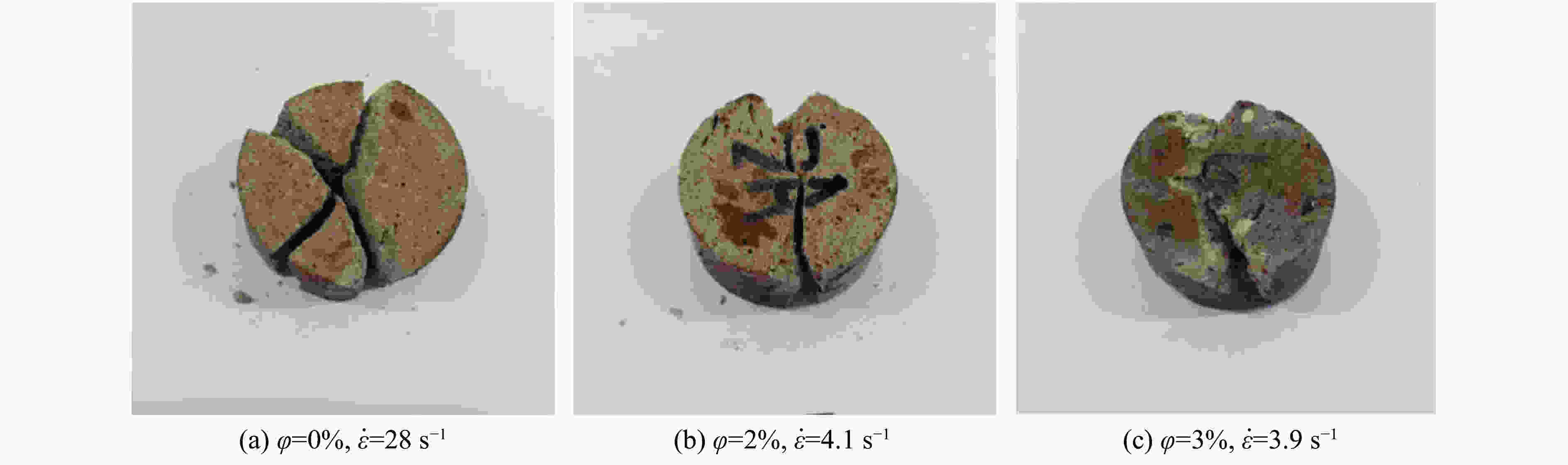

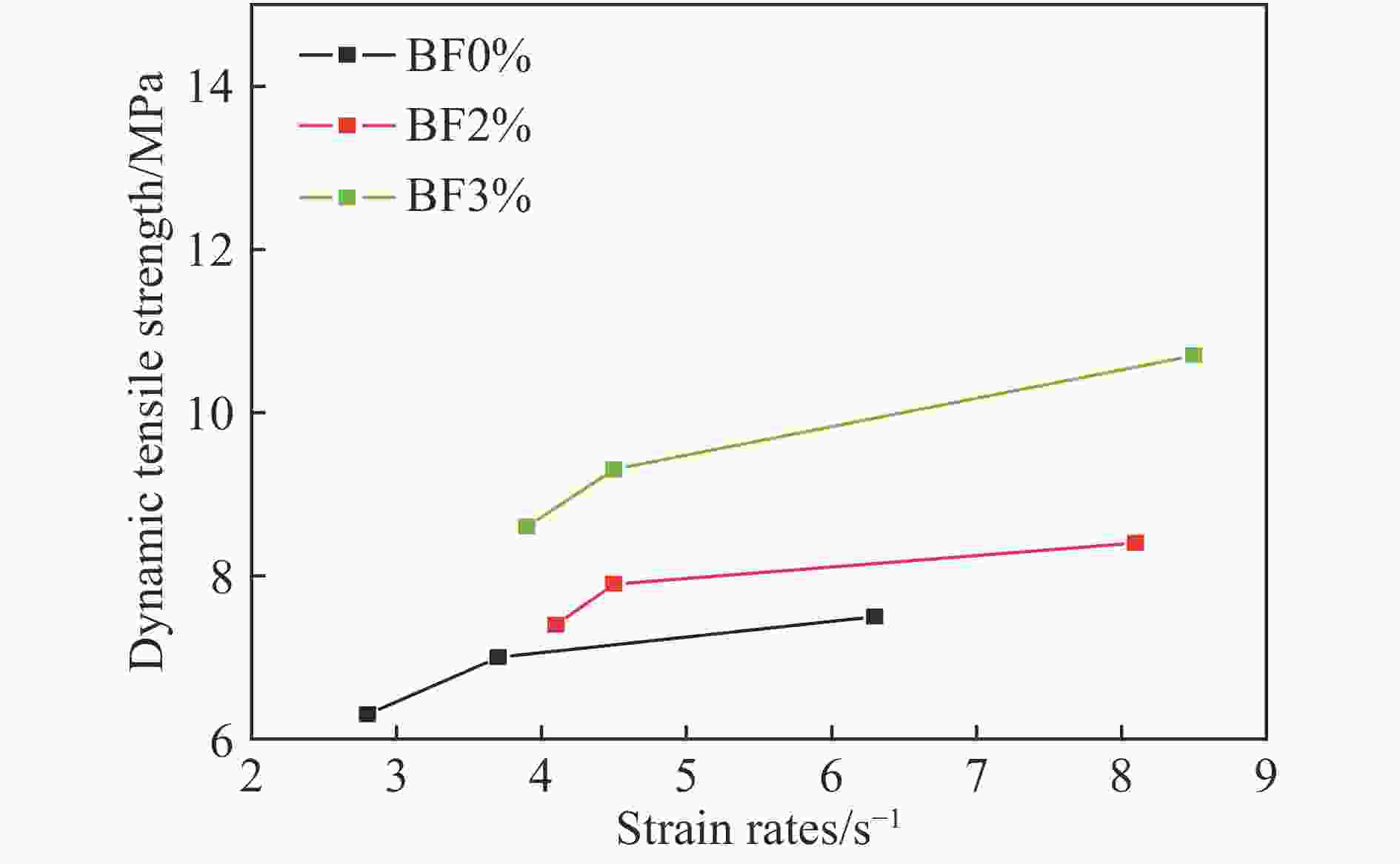

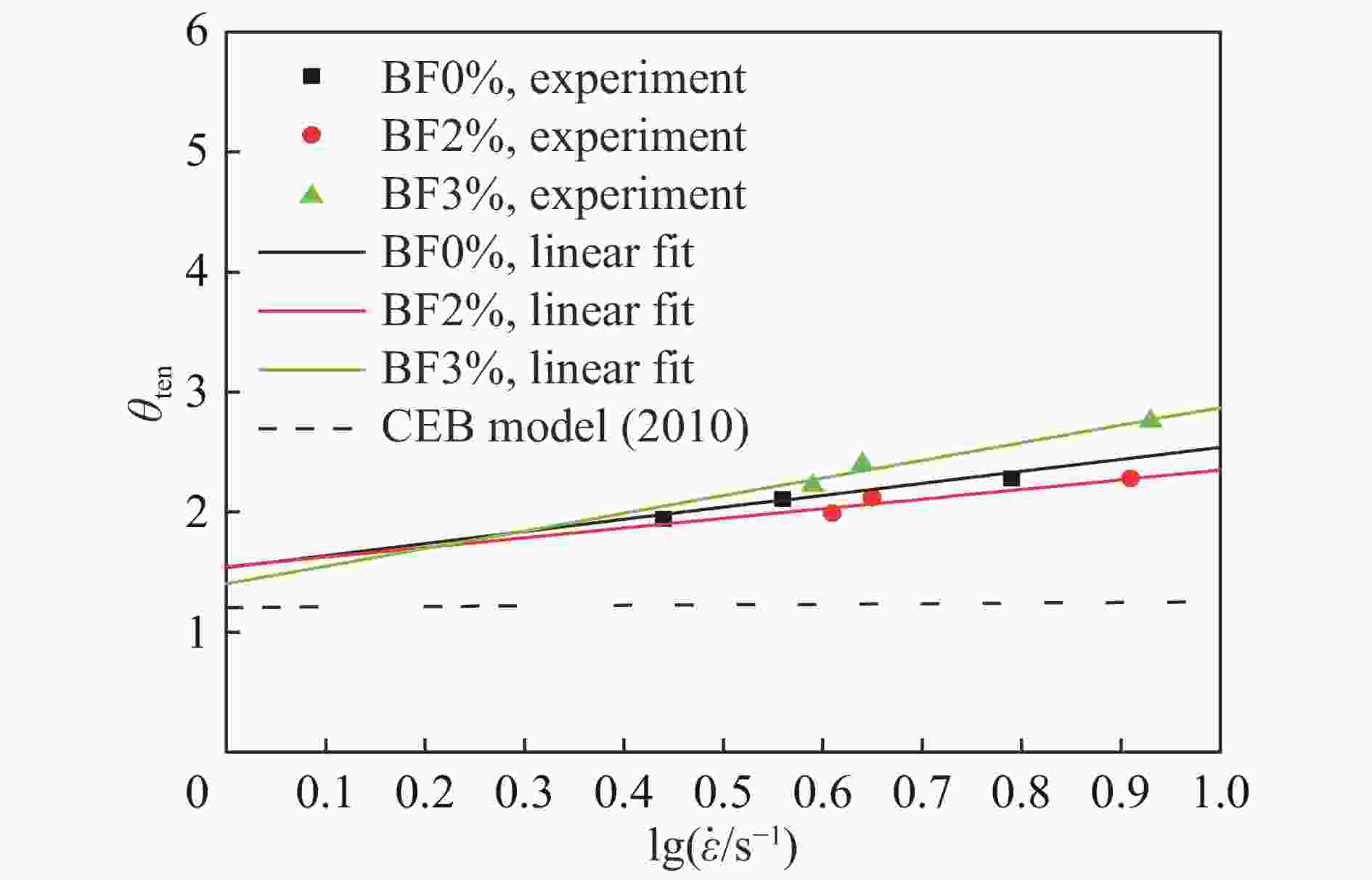

摘要: 利用玄武岩纤维和水泥基材料,通过一定配比融合制成了在静态拉伸试验中呈现多缝开裂、应变硬化、极限拉伸应变0.5%以上的玄武岩纤维高延性水泥基复合材料(basalt fiber engineered cementitious composites, BF-ECCs)。用分离式霍普金森压杆(split Hopkinson pressure bar, SHPB)装置对不同玄武岩纤维掺量的水泥基复合材料进行动态压缩和动态劈裂试验。结果表明:(1)在压、拉两种应力状态下,玄武岩纤维对水泥基复合材料的静态强度、动态强度均有增强,且高应变率下玄武岩纤维对抗压强度动态增幅较小,对劈裂强度动态增幅较大;(2) BF-ECC的抗压强度和劈裂强度均随应变率升高而显著提高,两者均可以采用动态增强因子(dynamic increase factor, DIF)反映动态强度的增幅,但劈裂强度的应变率敏感性强于抗压强度;(3)依据试验得到的普通水泥混凝土速率敏感性的CEB-FIP方程(2010)不适用于BF-ECCs。Abstract: Basalt fiber engineered cementitious composites (BF-ECCs) were prepared by using a certain ratio of basalt fiber and cement-based material. The prepared material showed multiple cracks in static tensile test and its tensile strain was above 0.5%. For the cementitious composites with different basalt fiber contents, dynamic compression and dynamic splitting tests were carried out by using a split Hopkinson pressure bar (SHPB) device. The results show the followings. (1) Both the static and dynamic strengths are enhanced under compression and tension conditions by basalt fiber. At high strain rates, the dynamic increase in compressive strength is small, and the dynamic increase in the splitting strength is large. (2) The compressive and splitting strengths of the BF-ECCs increase significantly with increasing strain rate, both of which can use a dynamic increase factor (DIF) to reflect the increase in dynamic strength, but the strain rate sensitivity of the splitting strength is stronger than that of the compressive strength. (3) According to the test, the CEB-FIP equation (2010) of ordinary cement concrete rate sensitivity is not applicable to the BF-ECCs.

-

Key words:

- basalt fibers /

- BF-ECC /

- static compression /

- static stretching /

- impact compression /

- dynamic splitting

-

表 1 主要原材料中不同化学成分的质量分数

Table 1. Mass fractions of different chemical ingredients in main raw materials

原材料 质量分数/% 二氧化硅 氧化铝 氧化铁 氧化钙 氧化镁 三氧化硫 烧失量 总计 铝酸盐水泥 7.95 50.33 2.38 32.6 2.03 − 0.57 95.86 粉煤灰 48.63 37.37 3.78 3.05 1.60 0.84 3.61 98.88 硅灰 87.28 1.09 0.75 0.87 1.76 1.47 4.74 97.96 表 2 不同试样的材料质量配合比

Table 2. Material mix proportions in the different specimens

试样编号 质量分数/% 减水剂与固体质量之比 φ/% 水固质量之比 水泥 粉煤灰 硅灰 BF0% 40 50 10 1∶250 0 1∶5 BF2% 40 50 10 1∶250 2 1∶5 BF3% 40 50 10 1∶250 3 1∶5 表 3 静态抗压和抗拉强度

Table 3. Static compression and tensile strength

φ/% fsta,c/MPa fsta,ten/MPa εlim,ten/% 0 30.2±0.23 3.24±0.029 0.09±0.001 2 32.1±0.19 3.71±0.009 0.20±0.003 3 34.1±0.25 3.87±0.008 0.66±0.002 表 4 BF-ECC试样动态压缩下的主要力学参数

Table 4. Main mechanical parameters of BF-ECC specimens under dynamic compression

φ/% ${\dot \varepsilon _0}/{{\rm{s}}^{ - 1}}$ fd,c/MPa εlim,c/10-6 φ/% ${\dot \varepsilon _0}/{{\rm{s}}^{ - 1}}$ fd,c/MPa εlim,c/10-6 φ/% ${\dot \varepsilon _0}/{{\rm{s}}^{ - 1}}$ fd,c/MPa εlim,c/10-6 0 36.1 36.8±0.73 6 530±173 2 38.9 39.4±2.38 7 113±242 3 44.2 39.1±1.93 8 550±189 55.4 43.0±1.82 5 693±221 50.5 46.2±1.93 5 160±233 66.2 47.5±2.53 8 047±245 77.7 46.6±1.41 6 043±194 71.7 48.9±1.91 5 497±201 76.9 53.0±1.82 5 320±267 202.3 58.4±1.52 7 253±203 187.7 59.3±2.63 6 637±196 172.8 60.7±2.56 5 967±234 表 5 动态劈裂试验结果

Table 5. Dynamic splitting test results

φ/% ${\dot \varepsilon _0}/{{\rm{s}}^{ - 1}}$ fd,ten/MPa φ/% ${\dot \varepsilon _0}/{{\rm{s}}^{ - 1}}$ fd,ten/MPa φ/% ${\dot \varepsilon _0}/{{\rm{s}}^{ - 1}}$ fd,ten/MPa 2.8 6.3±0.31 4.1 7.4±0.07 3.9 8.6±0.26 0 3.7 7.0±0.10 2 4.5 7.9±0.31 3 4.5 9.3±0.45 6.3 7.5±0.20 8.1 8.4±0.12 8.5 10.7±0.32 -

[1] LI V C, LEUNG C K Y. Steady-state and multiple cracking of short random fiber composites [J]. Journal of Engineering Mechanics, 1992, 118(11): 2246–2264. DOI: 10.1061/(ASCE)0733-9399(1992)118:11(2246). [2] MAALEJ M, LI V C. Flexural/tensile-strength ratio in engineered cementitious composites [J]. Journal of Materials in Civil Engineering, 1994, 6(4): 513–528. DOI: 10.1061/(ASCE)0899-1561(1994)6:4(513). [3] 徐世烺, 李庆华. 超高韧性水泥基复合材料在高性能建筑结构中的基本应用[M]. 北京: 科学出版社, 2010: 5−6. [4] 徐世烺, 李贺东. 超高韧性水泥基复合材料研究进展及其工程应用 [J]. 土木工程学报, 2008, 41(6): 45–60. DOI: 10.3321/j.issn:1000-131X.2008.06.008.XU S L, LI H D. A review on the development of research and application of ultra high toughness cementitious composites [J]. China Civil Engineering Journal, 2008, 41(6): 45–60. DOI: 10.3321/j.issn:1000-131X.2008.06.008. [5] 刘问. 超高韧性水泥基复合材料动态力学性能的试验研究[D]. 大连: 大连理工大学, 2011: 35−36. [6] YANG E H, LI V C. Rate dependence in engineered cementitious composites [C] // YANG E H, LI V C. International RILEM Workshop on High Performance Fiber Reinforced Cementitious Composites in Structural Applications. Honolulu, Hawaii, USA: RILEM Publications SARL, 2006: 83−92. [7] YANG E H, LI V C. Tailoring engineered cementitious composites for impact resistance [J]. Cement and Concrete Research, 2012, 42(8): 1066–1071. DOI: 10.1016/j.cemconres.2012.04.006. [8] MAALEJ M, QUEK S T, ZHANG J. Behaviour of hybrid-fiber engineered cementitious composites subjected to dynamic tensile loading and projectile impact [J]. Journal of Materials in Civil Engineering, 2005, 17(2): 143–152. DOI: 10.1061/(ASCE)0899-1561(2005)17:2(143). [9] ZHANG J, MAALEJ M, QUEK S T. Performance of hybrid-fiber ECC blast/shelter panels subjected to drop weight impact [J]. Journal of Materials in Civil Engineering, 2007, 19(10): 855–863. DOI: 10.1061/(ASCE)0899-1561(2007)19:10(855). [10] MECHTCHERINE V, MILLON O, BUTLE M, et al. Mechanical behaviour of strain hardening cement-based composites under impact loading [J]. Cement and Concrete Composites, 2011, 33(1): 1–11. DOI: 10.1016/j.cemconcomp.2010.09.018. [11] SOE K T, ZHANG Y X, ZHANG L C. Impact resistance of hybrid-fiber engineered cementitious composite panels [J]. Composite Structures, 2013, 104: 320–330. DOI: 10.1016/j.compstruct.2013.01.029. [12] LI V C, MISHRA D K, WU H C. Matrix design for Pseudo-strain-hardening fibre reinforced cementitious composites [J]. Materials and Structures, 1995, 28(10): 586–595. DOI: 10.1007/BF02473191. [13] LI V C, WANG S X, WU C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC) [J]. ACI Materials Journal, 2001, 98(6): 483–492. [14] ZHOU J, QIAN S Z, BELTRAN M G S., et al Development of engineered cementitious composites with limestone powder and blast furnace slag [J]. Materials and Structures, 2010, 43(6): 803–814. DOI: 10.1617/s11527-009-9549-0. [15] PAKRAVAN H R, JAMSHIDI M, LATIFI M. Study on fiber hybridization effect of engineered cementitious composites with low- and high-modulus polymeric fibers [J]. Construction and Building Materials, 2016, 112: 739–746. DOI: 10.1016/j.conbuildmat.2016.02.112. [16] 成涛华, 李玉香. 玄武岩纤维增强混凝土力学性能研究 [J]. 混凝土与水泥制品, 2017(1): 53–56. DOI: 10.3969/j.issn.1000-4637.2017.01.012.CHEN T H, LI Y X. Study on mechanical performance of basalt fiber reinforced concrete [J]. China Concrete and Cement Products, 2017(1): 53–56. DOI: 10.3969/j.issn.1000-4637.2017.01.012. [17] 葛浩军. 玄武岩纤维混凝土力学性能及耐久性研究[D]. 大连: 大连理工大学, 2019. [18] SUN X J, GAO Z, CAO P, et al. Mechanical properties tests and multiscale numerical simulations for basalt fiber reinforced concrete [J]. Construction and Building Materials, 2019, 202: 58–72. DOI: 10.1016/j.conbuildmat.2019.01.018. [19] 李为民, 许金余. 玄武岩纤维混凝土的冲击力学行为及本构模型 [J]. 工程力学, 2009, 26(1): 86–91.LI W M, XU J Y. Dynamic behavior and constitutive model of basalt fiber reinforced concrete under impact loading [J]. Engineering Mechanics, 2009, 26(1): 86–91. [20] 朱涵, 刘昂, 于泳. 低温下玄武岩纤维混凝土的抗冲击性能 [J]. 材料科学与工程学报, 2018, 36(4): 600–604.ZHU H, LIU A, YU Y. Low temperature impact performance of basalt fiber reinforced concrete [J]. Journal of Materials Science and Engineering, 2018, 36(4): 600–604. [21] ZHANG H, WANG B, XIE A Y, et al. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete [J]. Construction and Building Materials, 2017, 152: 154–167. DOI: 10.1016/j.conbuildmat.2017.06.177. [22] 工业和信息化部. 高延性纤维增强水泥基复合材料力学性能试验方法: JC/T 2461-2018 [S]. 北京: 建材工业出版社, 2018. [23] CEB, FIP. FIB model code 2010 [S]. 2011. -

下载:

下载: