Experimental study on dynamic response of high-density polyethylene bellows under blasting seismic load

-

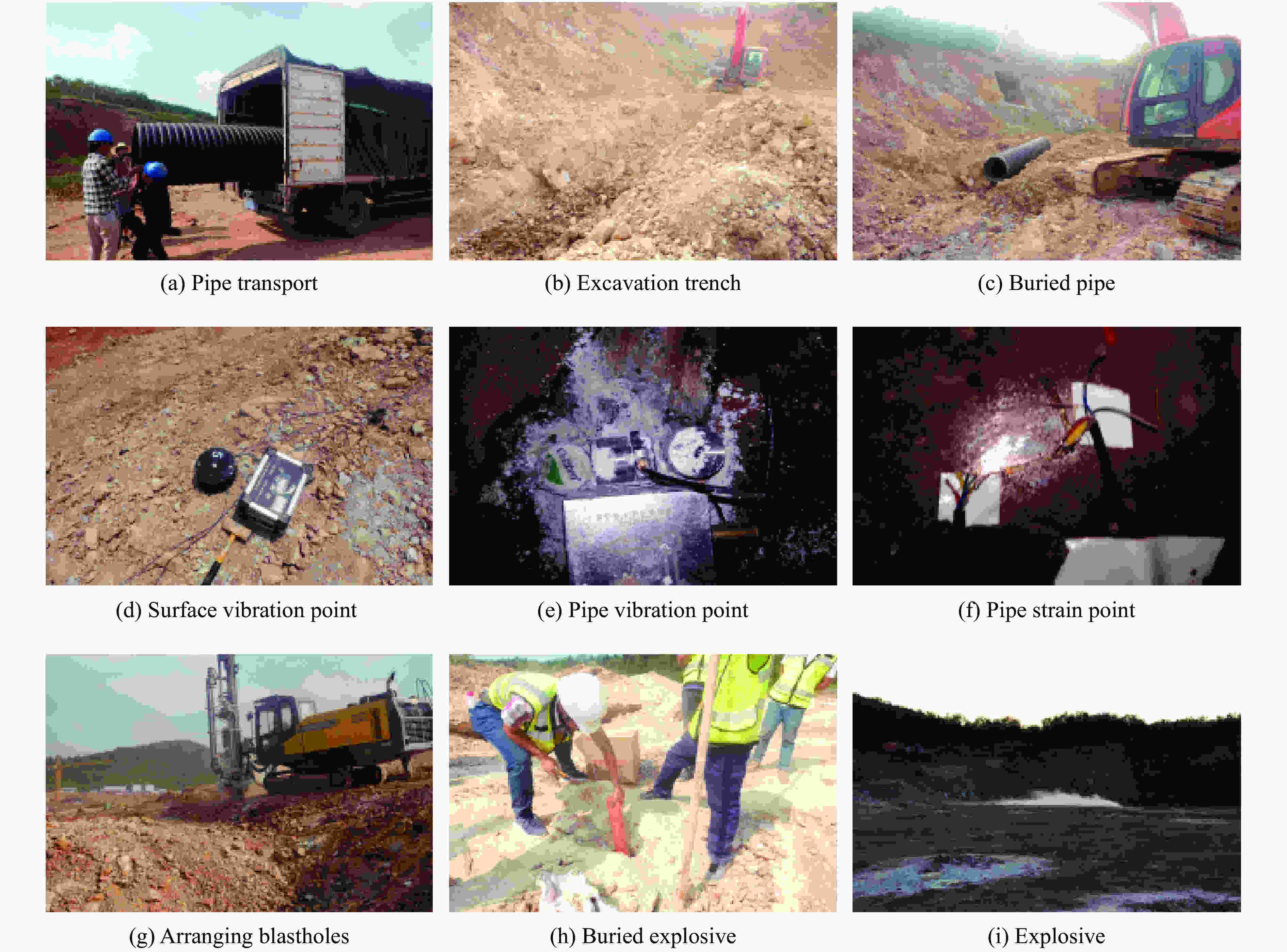

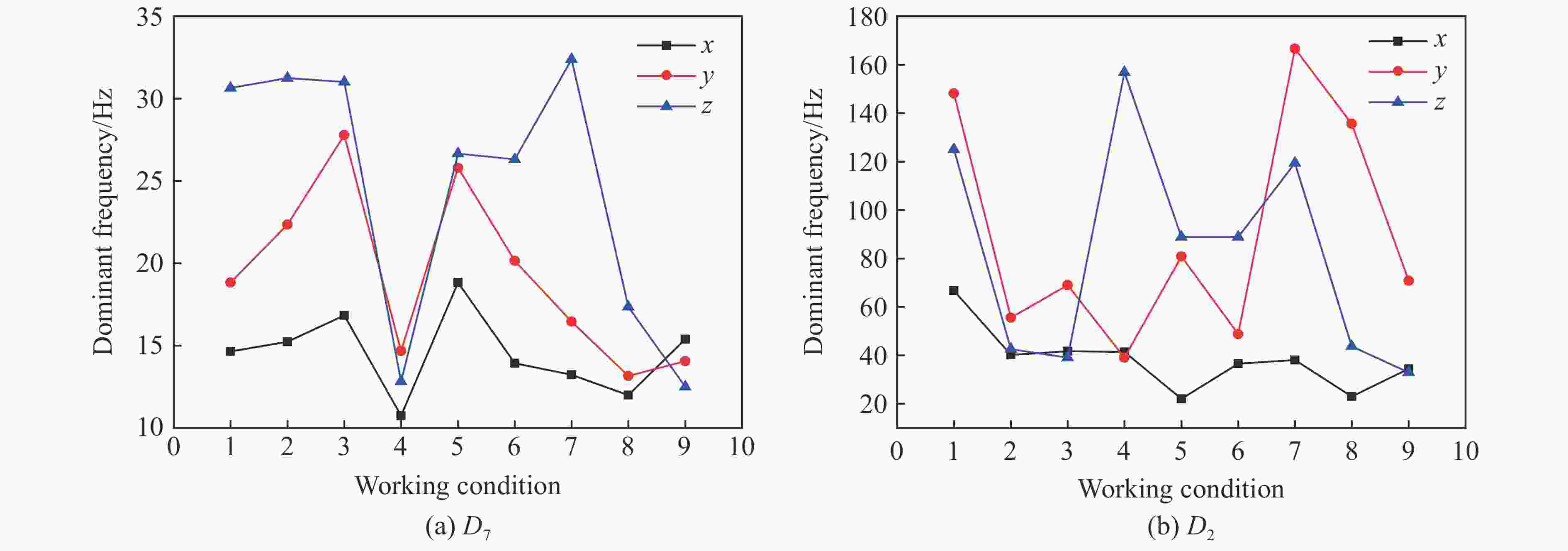

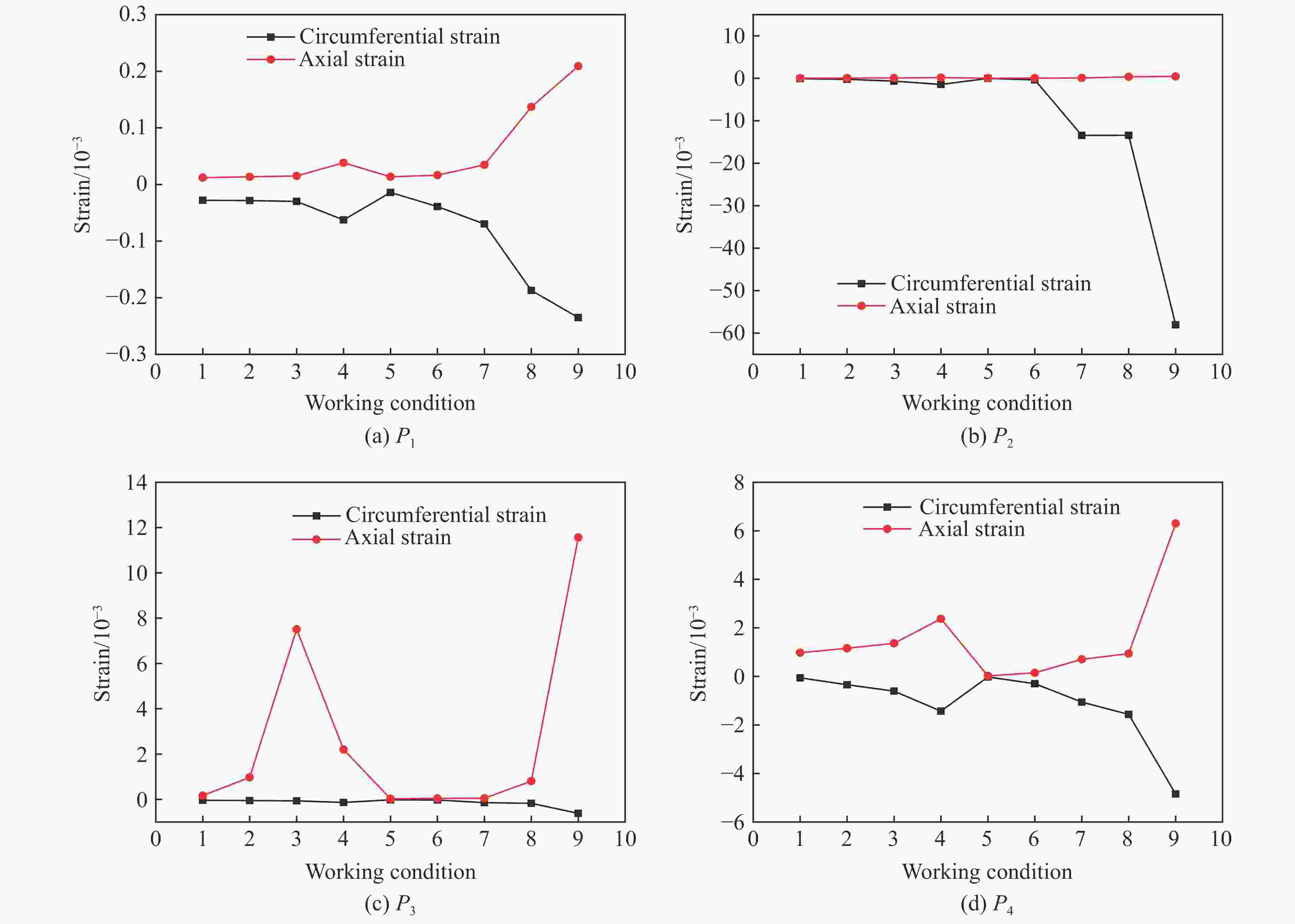

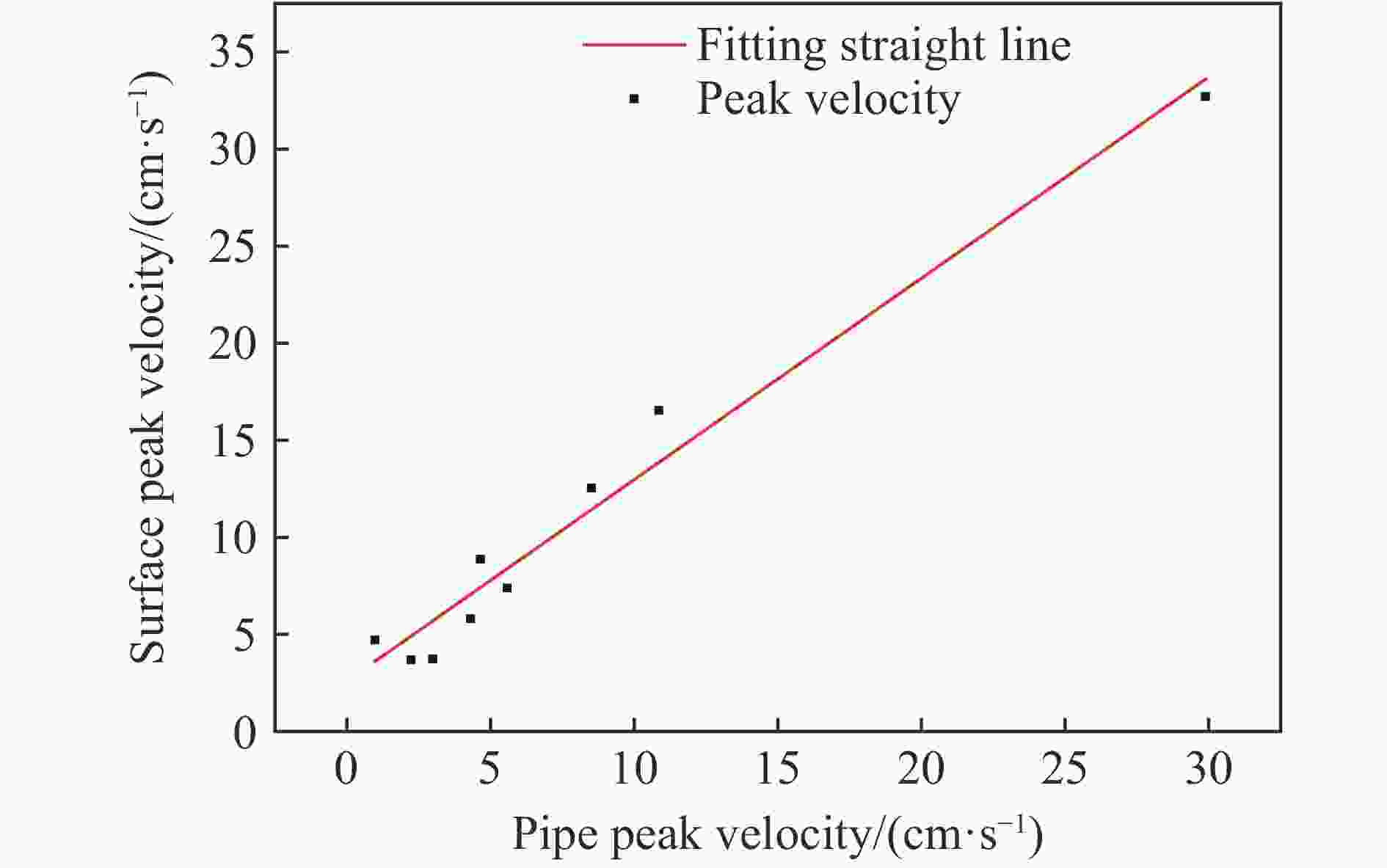

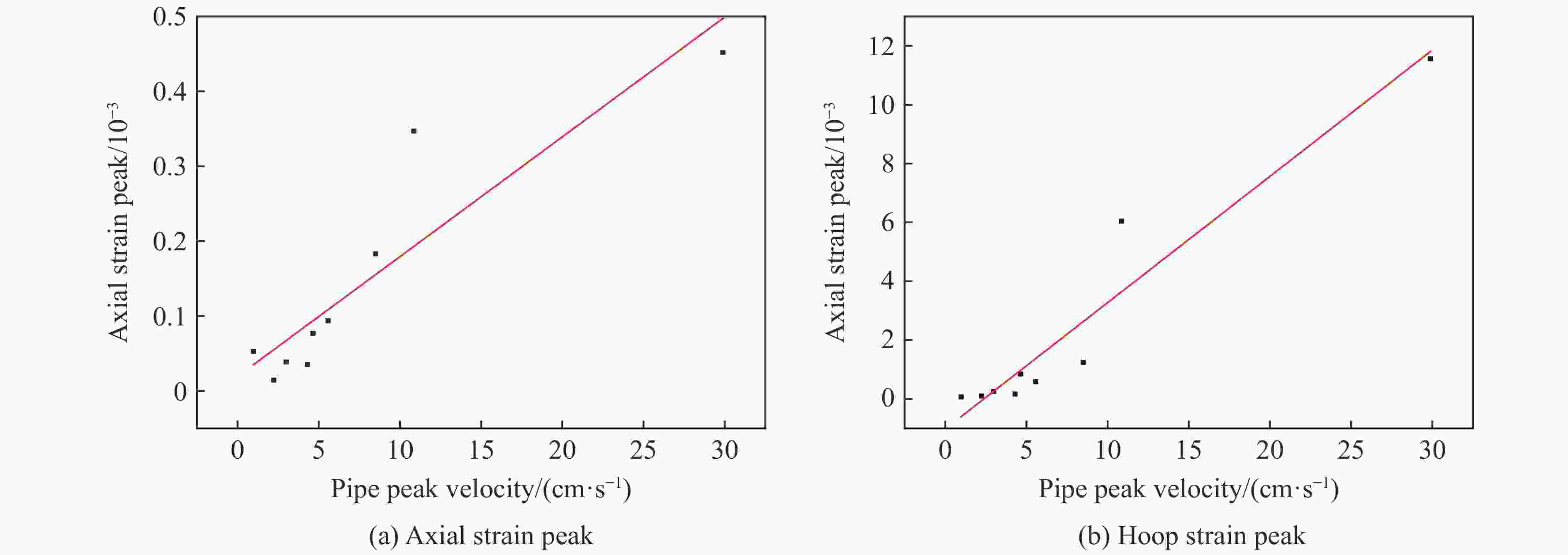

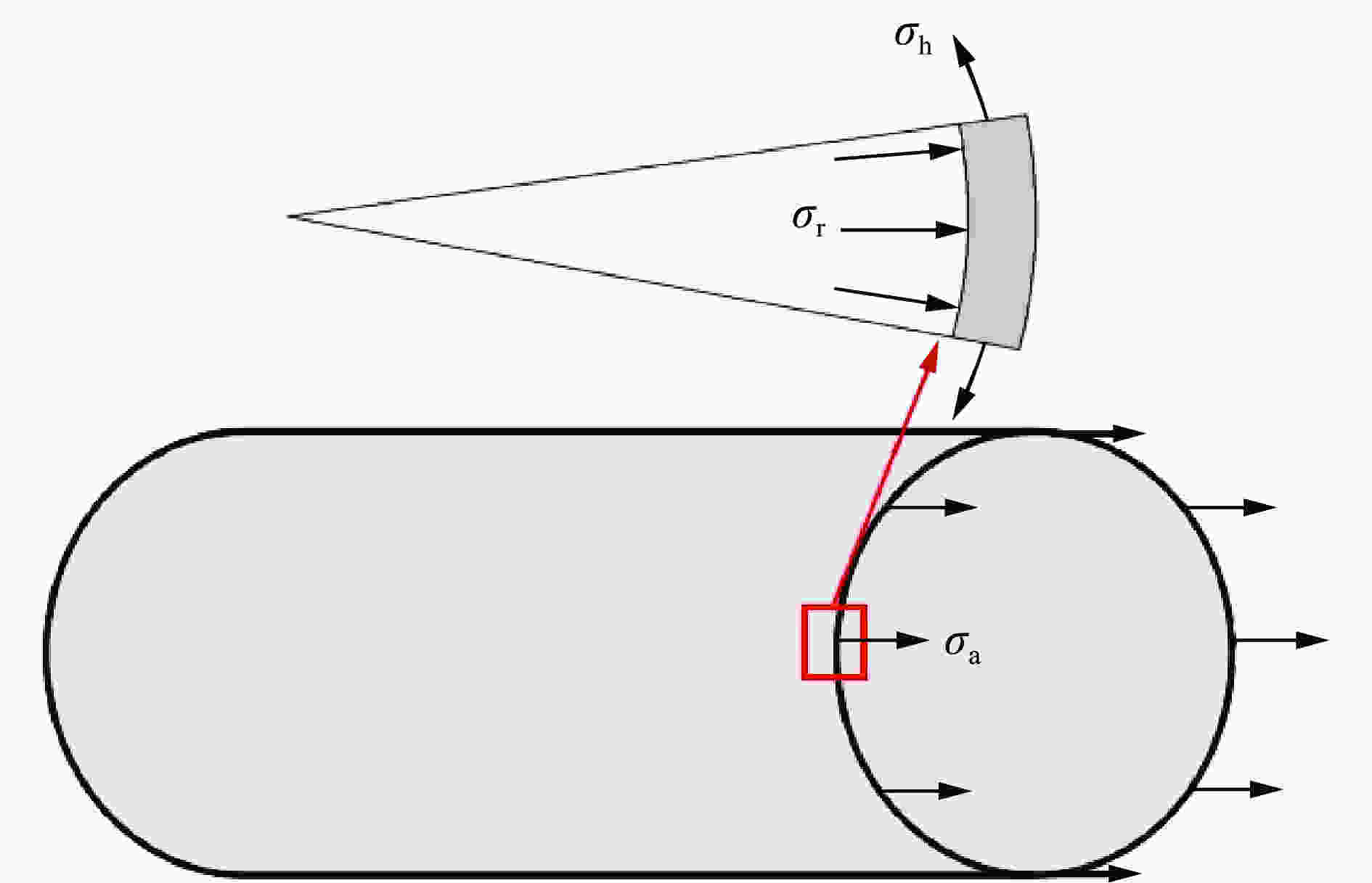

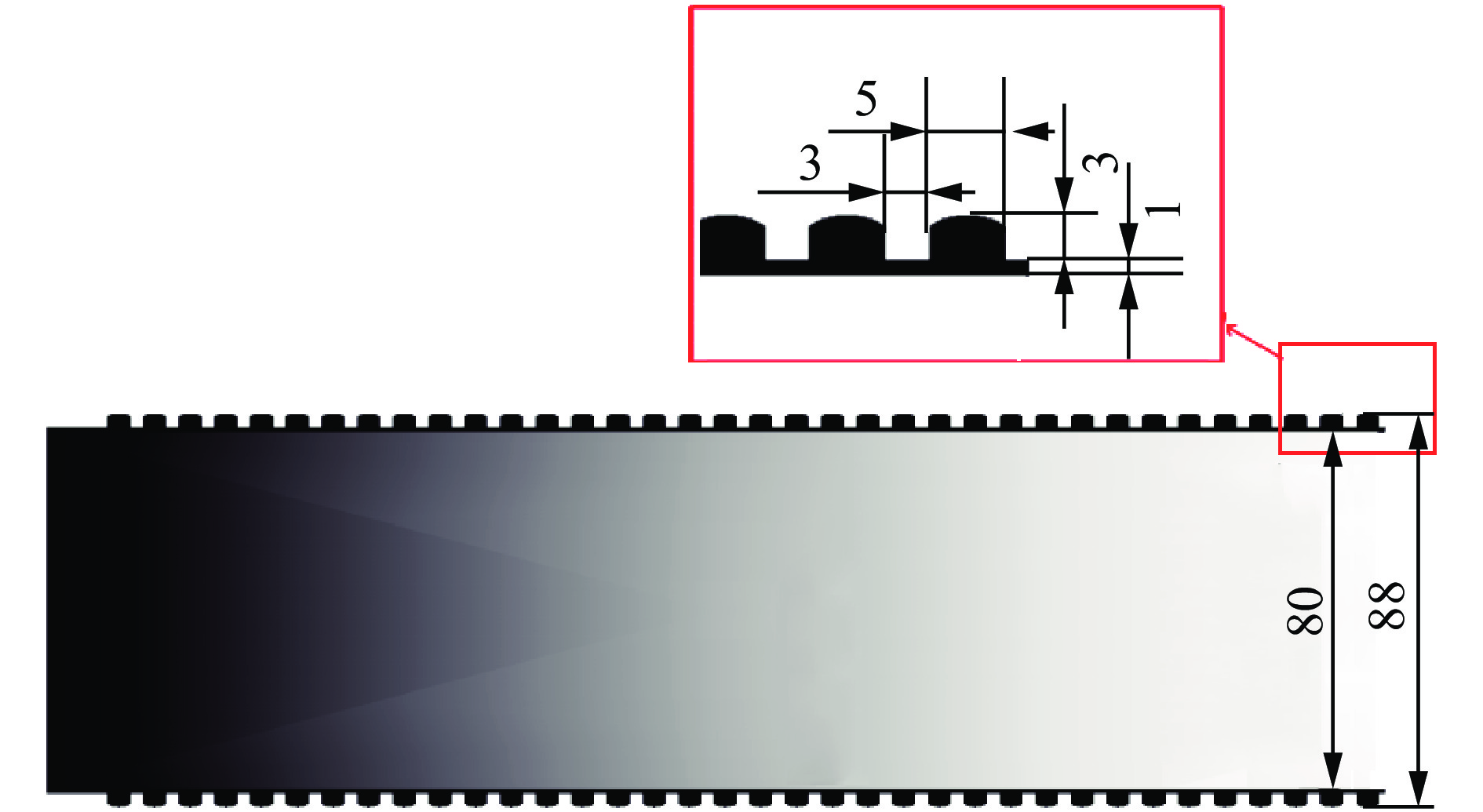

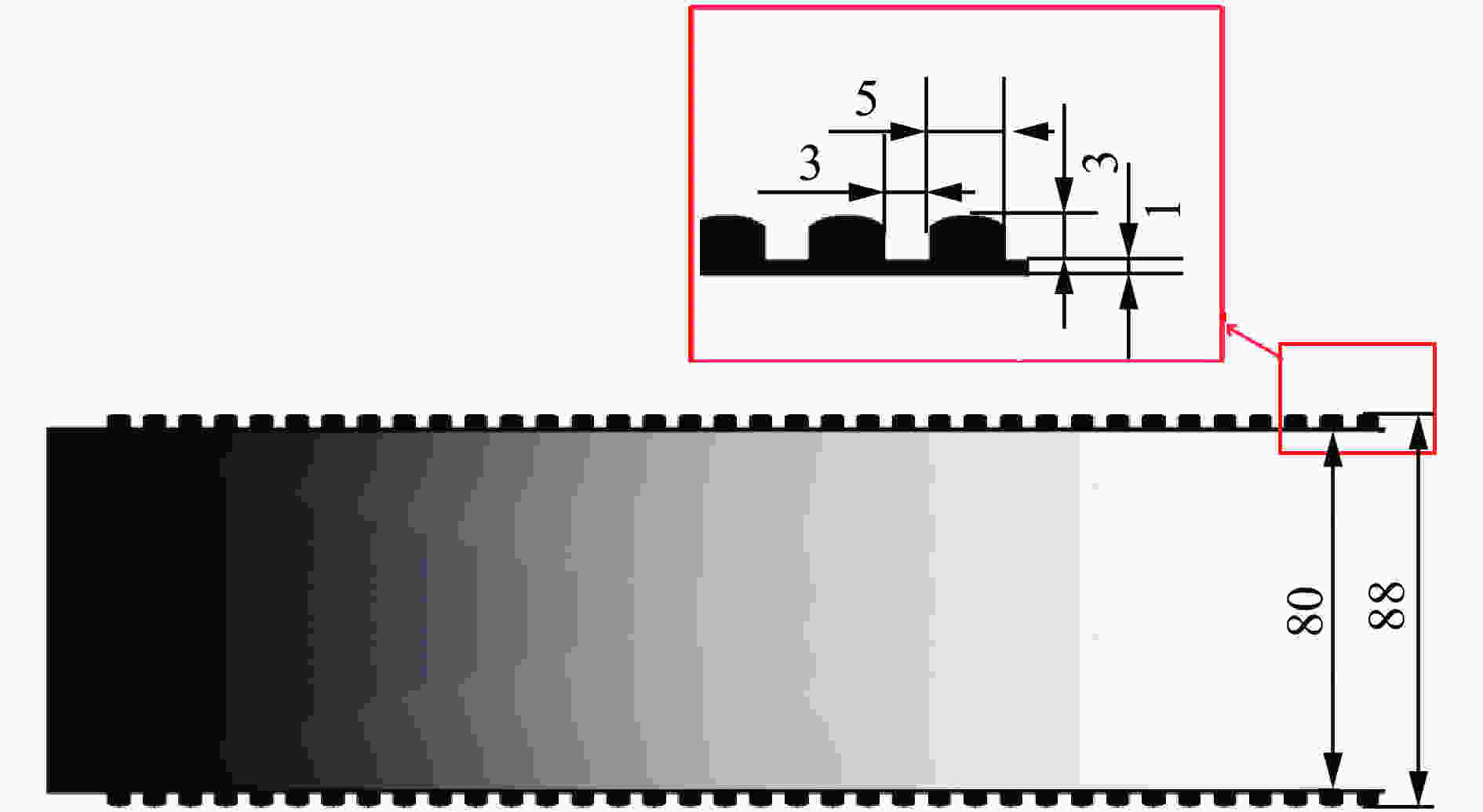

摘要: 为研究爆破地震荷载作用下埋地高密度聚乙烯(high-density polyethylene,HDPE)波纹管的动力响应规律,通过现场预埋管道的爆破试验,结合爆破地震与动态应变等测试手段,分析了爆破地震荷载作用下埋地管道的动力响应特征,研究了管道振动速度及动态应变的分布特征,基于von Mises屈服准则分析评价了管道安全性,提出了爆破振动速度控制标准。试验研究结果表明:试验中管道与地表振速以及管道动态应变随爆心距的减少,随炸药量的增加而增大;爆破地震波振动主频高,管道振动主频高于地表;相同爆破工况条件下,管道上方地表振速普遍大于管道振速;管道截面背爆侧峰值轴向应变以拉应变为主,迎爆侧峰值环向应变以压应变为主;本试验管道安全控制振速可取20 cm/s,此时管道处于安全状态。Abstract: The dynamic response of buried high density polyethylene (HDPE) bellows under blasting seismic load was studied. First, the blasting test of buried pipeline was carried out by combining the blasting seismic test and dynamic strain test. Secondly, the dynamic response characteristics of buried pipeline under blasting seismic load were analyzed. Then, the characteristics of vibration velocity and dynamic strain distribution were studied. Finally, the pipe safety was evaluated based on the von Mises yield criterion, and the blasting vibration velocity control standard was proposed. The experimental results show that the vibration velocity of pipeline and ground and the dynamic strain of pipeline increase with the decrease of core distance and the increase of explosive quantity. The dominant frequency of blasting seismic wave is higher. The dominant frequency of pipeline is higher than the surface. Under the same blasting condition, the ground vibration velocity above the pipeline is generally higher than that of the pipeline. The peak axial strain on the back explosion side of the pipeline section is mainly tensile strain, and the peak circumferential strain on the front explosion side is mainly compressive strain. The vibration velocity of the pipeline can be safely controlled by 20 cm·s−1, and the pipeline is in a safe state.

-

Key words:

- blasting earthquake /

- HDPE bellows /

- field test /

- response characteristics /

- safety control

-

表 1 工况参数

Table 1. Working condition parameter

工况 炸药埋深/m 炸药量/kg 水平距离/m 1 6.5 8 25 2 6.5 8 20 3 6.5 8 15 4 6.5 8 10 5 4 8 25 6 4 8 20 7 4 8 15 8 4 8 10 9 4 9.6 5 表 2 地表合振动速度峰值

Table 2. Resultant peak velocity at surface

工况 测点D6速度/(cm·s-1) 测点D7速度/(cm·s-1) 测点D3速度/(cm·s-1) 1 4.44 5.80 4.92 2 3.60 4.71 3.67 3 7.85 8.87 7.58 4 11.37 12.54 8.89 5 4.86 3.69 3.05 6 4.74 3.73 3.01 7 7.41 7.38 4.34 8 15.20 16.54 11.61 9 28.06 32.71 15.30 -

[1] 王栋, 何历超, 王凯. 钻爆法施工对邻近埋地管道影响的现场实测与数值模拟分析 [J]. 土木工程学报, 2017, 50(S2): 134–140. DOI: 10.15951/j.tmgcxb.2017.s2.021.WANG D, HE L C, WANG K. Field measurement and numerical simulation analysis for influence of blasting excavation on adjacent buried pipelines [J]. China Civil Engineering Journal, 2017, 50(S2): 134–140. DOI: 10.15951/j.tmgcxb.2017.s2.021. [2] GIANNAROS E, KOTZAKOLIOS T, KOSTOPOULOS V. Blast response of composite pipeline structure using finite element techniques [J]. Journal of Composite Materials, 2016, 50(25): 3459–3476. DOI: 10.1177/0021998315618768. [3] WON J H, KIM M K, KIM G, et al. Blast-induced dynamic response on the interface of a multilayered pipeline [J]. Structure and Infrastructure Engineering, 2014, 10(1): 80–92. DOI: 10.1080/15732479.2012.699532. [4] 夏宇磬, 蒋楠, 姚颖康, 等. 粉质黏土层预埋承插式混凝土管道对爆破振动的动力响应 [J]. 爆炸与冲击, 2020, 40(4): 043302. DOI: 10.11883/bzycj-2019-0207.XIA Y Q, JIANG N, YAO Y K, et al. Dynamic responses of a concrete pipeline with bell-and-spigot joints buried in a silty clay layer to blasting seismic waves [J]. Explosion and Shock Waves, 2020, 40(4): 043302. DOI: 10.11883/bzycj-2019-0207. [5] HA D, ABDOUN T H, O’ROURKE M J, et al. Centrifuge modeling of earthquake effects on buried high-density polyethylene (HDPE) pipelines crossing fault zones [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2008, 134(10): 1501–1515. DOI: 10.1061/(ASCE)1090-0241(2008)134:10(1501). [6] ABDOUN T H, HA D, O’ROURKE M J, et al. Factors influencing the behavior of buried pipelines subjected to earthquake faulting [J]. Soil Dynamics and Earthquake Engineering, 2009, 29(3): 415–427. DOI: 10.1016/j.soildyn.2008.04.006. [7] 王海涛, 金慧, 贾金青, 等. 地铁隧道钻爆法施工对邻近埋地管道影响的模型试验研究 [J]. 岩石力学与工程学报, 2018, 37(S1): 3332–3339. DOI: 10.13722/j.cnki.jrme.2016.1409.WANG H T, JIN H, JIA J Q, et al. Model test study on the influence of subway tunnel drilling and blasting method on adjacent buried pipeline [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(S1): 3332–3339. DOI: 10.13722/j.cnki.jrme.2016.1409. [8] ZHANG J, ZHANG L, LIANG Z. Buckling failure of a buried pipeline subjected to ground explosions [J]. Process Safety and Environmental Protection, 2018, 114: 36–47. DOI: 10.1016/j.psep.2017.11.017. [9] PARVIZ M, AMINNEJAD B, FIOUZ A. Numerical simulation of dynamic response of water in buried pipeline under explosion [J]. KSCE Journal of Civil Engineering, 2017, 21(7): 2798–2806. DOI: 10.1007/s12205-017-0889-y. [10] 娄敏, 明海芹. 基于LS-DYNA海底悬空管道受坠物碰撞动力响应分析 [J]. 海洋通报, 2015, 34(1): 113–120. DOI: 10.11840/j.issn.1001-6392.2015.01.017.LOU M, MING H Q. The dynamic response analysis of submarine suspended pipeline impacted by dropped objects based on LS-DYNA [J]. Marine Science Bulletin, 2015, 34(1): 113–120. DOI: 10.11840/j.issn.1001-6392.2015.01.017. [11] FRANCINI R B, BALTZ W N. Blasting and construction vibrations near existing pipelines: what are appropriate levels? [J]. Journal of Pipeline Engineering, 2009, 8(4): 519–531. [12] JIANG N, GAO T, ZHOU C B, et al. Effect of excavation blasting vibration on adjacent buried gas pipeline in a metro tunnel [J]. Tunnelling and Underground Space Technology, 2018, 81: 590–601. DOI: 10.1016/j.tust.2018.08.022. [13] 张震, 周传波, 路世伟, 等. 爆破振动作用下邻近埋地混凝土管道动力响应特性 [J]. 哈尔滨工业大学学报, 2017, 46(9): 79–84. DOI: 10.11918/j.issn.0367-6234.201611089.ZHANG Z, ZHOU C B, LU S W, et al. Dynamic response characteristic of adjacent buried concrete pipeline subjected to blasting vibration [J]. Journal of Harbin Institute of Technology, 2017, 46(9): 79–84. DOI: 10.11918/j.issn.0367-6234.201611089. [14] 朱斌, 蒋楠, 贾永胜, 等. 下穿燃气管道爆破振动效应现场试验研究 [J]. 岩石力学与工程学报, 2019, 38(12): 2582–2592. DOI: 10.13722/j.cnki.jrme.2019.0183.ZHU B, JIANG N, JIA Y S, et al. Field experiment on blasting vibration effect of underpass gas pipelines [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(12): 2582–2592. DOI: 10.13722/j.cnki.jrme.2019.0183. [15] 贾永胜, 钟冬望, 姚颖康, 等. 基坑爆破预留层对围护桩的保护作用数值分析 [J]. 工程爆破, 2017, 23(5): 1–4, 21. DOI: 10.3969/j.issn.1006-7051.2017.05.001.JIA Y S, ZHONG D W, YAO Y K, et al. Numerical calculation of the barrier effect of the pre-protective layer on bored piles in deep foundation pit blasting [J]. Engineering Blasting, 2017, 23(5): 1–4, 21. DOI: 10.3969/j.issn.1006-7051.2017.05.001. [16] 张震, 周传波, 路世伟, 等. 超浅埋地铁站通道爆破暗挖地表振动传播特征 [J]. 中南大学学报(自然科学版), 2017, 48(8): 2119–2125. DOI: 10.11817/j.issn.1672-7207.2017.08.020.ZHANG Z, ZHOU C B, LU S W, et al. Propagation characteristics of ground vibration induced by subsurface blasting excavation in an ultra-shallow buried underpass [J]. Journal of Central South University (Science and Technology), 2017, 48(8): 2119–2125. DOI: 10.11817/j.issn.1672-7207.2017.08.020. [17] 肖文芳. 地铁隧道掘进爆破振动测试与数值模拟研究 [D]. 武汉: 武汉理工大学, 2011.XIAO W F. Study of vibration testing and numerical simulation on metro tunnel excavation blasting[D]. Wuhan: Wuhan University of Technology, 2011. [18] 武卫星, 郭晓刚, 朱敏. 武汉轨道交通广虎区间隧道爆破施工方案优化 [J]. 人民长江, 2010, 41(10): 30–33. DOI: 10.16232/j.cnki.1001-4179.2010.10.009.WU W X, GUO X G, ZHU M. Optimization of blasting construction scheme of Guang-Hu section subway tunnels in Wuhan [J]. Yangtze River, 2010, 41(10): 30–33. DOI: 10.16232/j.cnki.1001-4179.2010.10.009. [19] 钟冬望, 卢哲, 黄雄, 等. 爆破荷载下埋地PE管道动力响应的试验研究 [J]. 爆破, 2018, 35(4): 1–5; 89. DOI: 10.3963/j.issn.1001-487X.2018.04.001.ZHONG D W, LU Z, HUANG X. Experimental study on buried PE pipeline under blasting loads [J]. Blasting, 2018, 35(4): 1–5; 89. DOI: 10.3963/j.issn.1001-487X.2018.04.001. [20] 钟冬望, 龚相超, 涂圣武, 等. 高饱和黏土中爆炸波作用下直埋聚乙烯管的动力响应 [J]. 爆炸与冲击, 2019, 39(3): 033102. DOI: 10.11883/bzycj-2017-0334.ZHONG D W, GONG X C, TU S W, et al. Dynamic responses of PE pipes directly buried in high saturated clay to blast wave [J]. Explosion and Shock Waves, 2019, 39(3): 033102. DOI: 10.11883/bzycj-2017-0334. [21] 贵州省住房和城乡建设厅. DBJ52/T039-2017 室外埋地聚乙烯(PE)给水管道工程技术规程[S]. 2018. [22] 罗利, 马燕, 张永军, 等. 地基沉降作用下埋地聚乙烯管强度失效的数值模拟 [J]. 建筑材料学报, 2020, 23(2): 473–478.LUO L, MA Y, ZHANG Y J, et al. Numerical simulation of strength failure of buried polyethylene pipes under foundation settlement [J]. Journal of Building Materials, 2020, 23(2): 473–478. [23] 何平笙. 高聚物的力学性能[M]. 2版. 合肥: 中国科学技术大学出版社, 2008: 232−235. [24] 舒亚俐. 既有给排水管线的震害及管道抗震能力关键问题综合分析 [J]. 城市道桥与防洪, 2013(3): 111–114. DOI: 10.16799/j.cnki.csdqyfh.2013.03.032.SHU Y L. Comprehensive analysis of seismic hazard to existing water and wastewater pipelines and key issues of seismic capacity of pipelines [J]. Urban Roads Bridges & Flood Control, 2013(3): 111–114. DOI: 10.16799/j.cnki.csdqyfh.2013.03.032. -

下载:

下载: