| [1] |

RICHARD H A, SANDER M. Damages caused by crack growth [M]//RICHARD H A, SANDER M. Fatigue Crack Growth. Cham: Springer, 2016. DOI: 10.1007/978-3-319-32534-7_2

|

| [2] |

RICHARD H A, FULLAND M, SANDER M. Theoretical crack path prediction [J]. Fatigue and Fracture of Engineering Materials and Structures, 2005, 28(1−2): 3–12. DOI: 10.1111/j.1460-2695.2004.00855.x.

|

| [3] |

杨仁树, 王雁冰, 侯丽冬, 等. 冲击荷载下缺陷介质裂纹扩展的DLDC试验 [J]. 岩石力学与工程学报, 2014, 33(10): 1971–1976. DOI: 10.13722/j.cnki.jrme.2014.10.004.YANG R S, WANG Y B, HOU L D, et al. DLDC experiment on crack propagation in defective medium under impact loading [J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(10): 1971–1976. DOI: 10.13722/j.cnki.jrme.2014.10.004.

|

| [4] |

杨仁树, 苏洪, 龚悦, 等. 冲击作用下静止裂纹与运动裂纹相互作用的试验研究 [J]. 振动与冲击, 2018, 37(8): 107–112. DOI: 10.13465/j.cnki.jvs.2018.08.017.YANG R S, SU H, GONG Y, et al. Experimental study of interaction between stationary crack and moving crack under impact [J]. Journal of Vibration and Shock, 2018, 37(8): 107–112. DOI: 10.13465/j.cnki.jvs.2018.08.017.

|

| [5] |

姚学锋, 熊春阳, 方竞. 含偏置裂纹三点弯曲梁的动态断裂行为研究 [J]. 力学学报, 1996, 28(6): 661–669. DOI: 10.3321/j.issn:0459-1879.1996.06.003.YAO X F, XIONG C Y, FANG J. Study of dynamic fracture behaviour on three-point-bend beam with off-center edge-crack [J]. Acta Mechanica Sinica, 1996, 28(6): 661–669. DOI: 10.3321/j.issn:0459-1879.1996.06.003.

|

| [6] |

YAO X F, XU W, XU M Q, et al. Experimental study of dynamic fracture behavior of PMMA with overlapping offset-parallel cracks [J]. Polymer Testing, 2003, 22(6): 663–670. DOI: 10.1016/S0142-9418(02)00173-3.

|

| [7] |

岳中文, 宋耀, 邱鹏, 等. 冲击载荷下双预置裂纹三点弯曲梁动态断裂实验 [J]. 振动与冲击, 2017, 36(4): 151–156, 177. DOI: 10.13465/j.cnki.jvs.2017.04.024.YUE Z W, SONG Y, QIU P, et al. A dynamic fracture experiment of a three-point-bend beam containing double pre-existing cracks under impact load [J]. Journal of Vibration and Shock, 2017, 36(4): 151–156, 177. DOI: 10.13465/j.cnki.jvs.2017.04.024.

|

| [8] |

GONG K Z, LI Z, QIN W Z. Influence of loading rate on dynamic fracture behavior of fiber-reinforced composites [J]. Acta Mechanica Solida Sinica, 2008, 21(5): 457–460. DOI: 10.1007/s10338-008-0855-9.

|

| [9] |

杨立云, 张勇进, 孙金超, 等. 偏置裂纹对含双裂纹PMMA试件动态断裂影响效应研究 [J]. 矿业科学学报, 2017, 2(4): 330–335. DOI: 10.19606/j.cnki.jmst.2017.04.003.YANG L Y, ZHANG Y J, SUN J C, et al. The effect of offset distance on dynamic fracture behavior of PMMA with double cracks [J]. Journal of Mining Science and Technology, 2017, 2(4): 330–335. DOI: 10.19606/j.cnki.jmst.2017.04.003.

|

| [10] |

李清, 薛耀东, 于强, 等. 含预制裂纹L形梁柱试件动态断裂过程 [J]. 爆炸与冲击, 2018, 38(3): 491–500. DOI: 10.11883/bzycj-2017-0255.LI Q, XUE Y D, YU Q, et al. Dynamic fracture processes of L-shaped beam-column specimens with prefabricated cracks [J]. Explosion and Shock Waves, 2018, 38(3): 491–500. DOI: 10.11883/bzycj-2017-0255.

|

| [11] |

李清, 薛耀东, 于强, 等. 含预制裂纹的悬臂梁-柱试件冲击断裂实验 [J]. 矿业科学学报, 2018, 3(2): 139–147. DOI: 10.19606/j.cnki.jmst.2018.02.005.LI Q, XUE Y D, YU Q, et al. Experimental study on impact fracture of cantilever beam-column specimen with prefabricated crack [J]. Journal of Mining Science and Technology, 2018, 3(2): 139–147. DOI: 10.19606/j.cnki.jmst.2018.02.005.

|

| [12] |

GUO D M, ZHOU B W, LIU K, et al. Dynamic caustics test of blast load impact on neighboring different cross-section roadways [J]. International Journal of Mining Science and Technology, 2016, 26(5): 803–808. DOI: 10.1016/j.ijmst.2016.05.045.

|

| [13] |

沈世伟, 廖文旺, 徐燕, 等. 不同节理间距条件下岩体双孔爆破动焦散试验研究 [J]. 煤炭学报, 2018, 43(8): 2180–2186. DOI: 10.13225/j.cnki.jccs.2017.1223.SHEN S W, LIAO W W, XU Y, et al. Dynamic caustics test of rock mass under different joint spacing conditions with two-hole blasting [J]. Journal of China Coal Society, 2018, 43(8): 2180–2186. DOI: 10.13225/j.cnki.jccs.2017.1223.

|

| [14] |

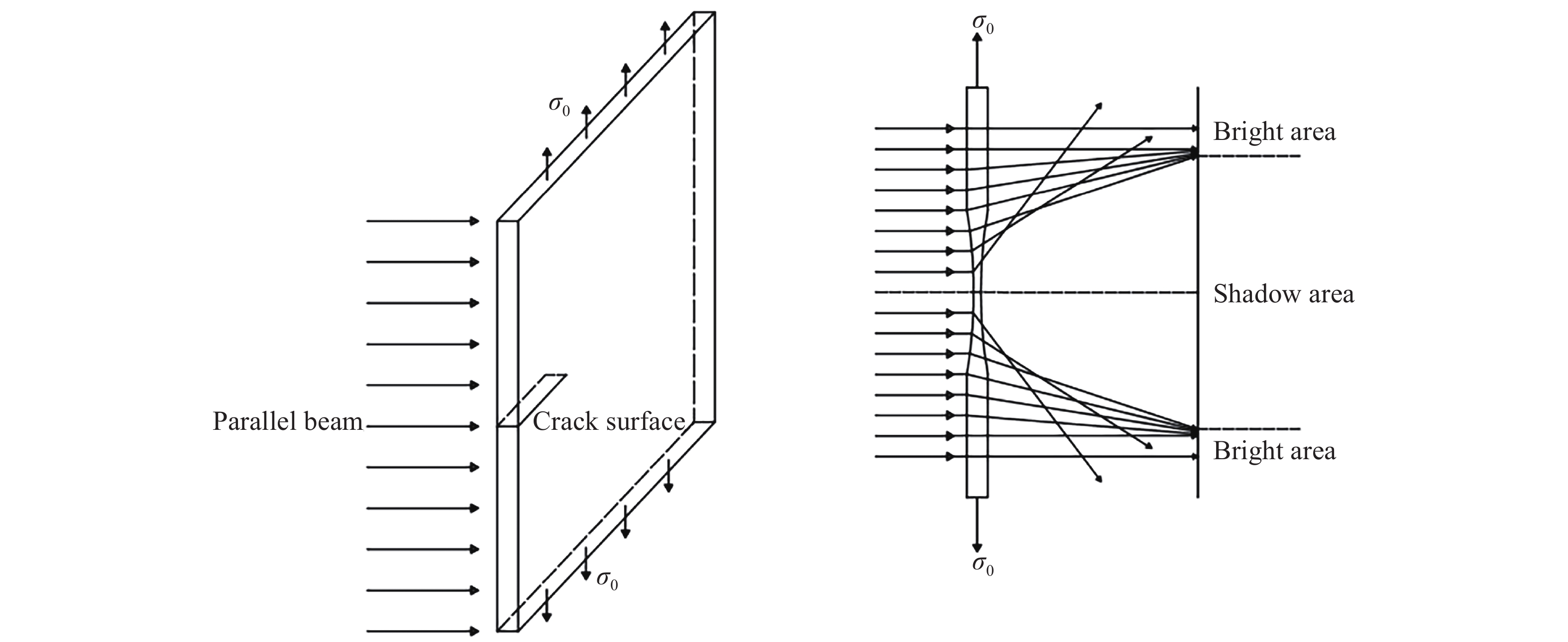

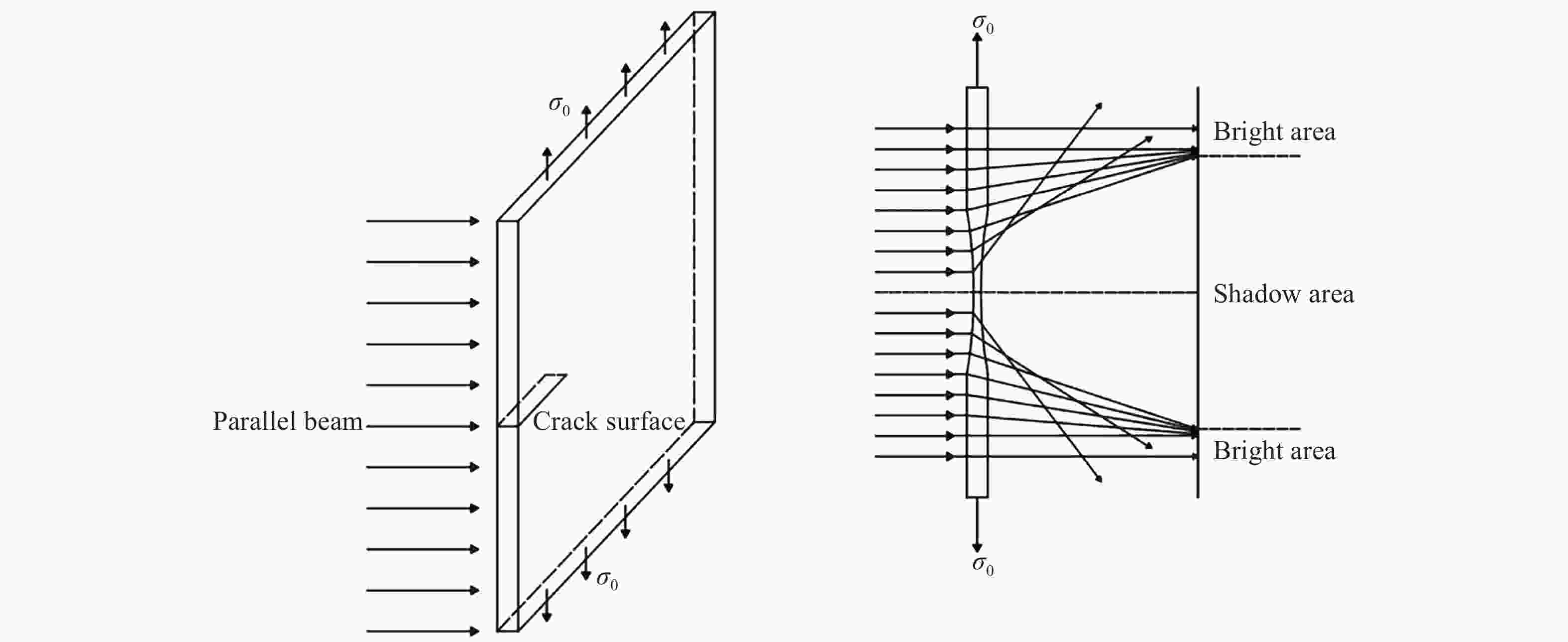

杨立云, 杨仁树, 许鹏. 新型数字激光动态焦散线实验系统及其应用 [J]. 中国矿业大学学报, 2013, 42(2): 188–194. DOI: 10.13247/j.cnki.jcumt.2013.02.005.YANG L Y, YANG R S, XU P. Caustics method combined with laser & digital high-speed camera and its applications [J]. Journal of China University of Mining and Technology, 2013, 42(2): 188–194. DOI: 10.13247/j.cnki.jcumt.2013.02.005.

|

| [15] |

杨仁树, 陈程, 赵勇, 等. 空孔-裂纹偏置方式对PMMA冲击断裂动态行为的影响 [J]. 振动与冲击, 2018, 37(20): 122–128. DOI: 10.13465/j.cnki.jvs.2018.20.019.YANG R S, CHEN C, ZHAO Y, et al. Influence of the void-crack offset method on the dynamic behavior of PMMA during impact fracture [J]. Journal of Vibration and Shock, 2018, 37(20): 122–128. DOI: 10.13465/j.cnki.jvs.2018.20.019.

|

| [16] |

YANG R S, DING C X, LI Y L, et al. Crack propagation behavior in slit charge blasting under high static stress conditions [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 119: 117–123. DOI: 10.1016/j.ijrmms.2019.05.002.

|

| [17] |

YANG L Y, DING C X. Fracture mechanism due to blast-imposed loading under high static stress conditions [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 107: 150–158. DOI: 10.1016/j.ijrmms.2018.04.039.

|

| [18] |

杨仁树, 许鹏, 岳中文, 等. 圆孔缺陷与I型运动裂纹相互作用的试验研究 [J]. 岩土力学, 2016, 37(6): 1597–1602. DOI: 10.16285/j.rsm.2016.06.009.YANG R S, XU P, YUE Z W, et al. Laboratory study of interaction between a circular hole defect and mode-I moving crack [J]. Rock and Soil Mechanics, 2016, 37(6): 1597–1602. DOI: 10.16285/j.rsm.2016.06.009.

|

| [19] |

杨立云. 岩石类材料的动态断裂与围压下爆生裂纹的实验研究[D]. 北京: 中国矿业大学(北京), 2011.YANG L Y. The experimental study on rock-type materials dynamic fracure and blasting crack propagation under confining pressure [D]. Beijing: China University of Mining and Technology-Beijing, 2011.

|

| [20] |

DAEHNKE A, ROSSMANITH H P, NAPIER J A L. Gas pressurisation of blast-induced conical cracks [J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(3/4): 263.e1–263.e17. DOI: 10.1016/S1365-1609(97)00282-7.

|

| [21] |

杨鑫. 爆炸作用下裂隙岩体裂纹扩展模拟试验研究[D]. 四川绵阳: 西南科技大学, 2015.YANG X. Simulation test study of fissured rock mass on crack progation under explosion [D]. Mianyang, Sichuan: Southwest University of Science and Technology, 2015.

|

| [22] |

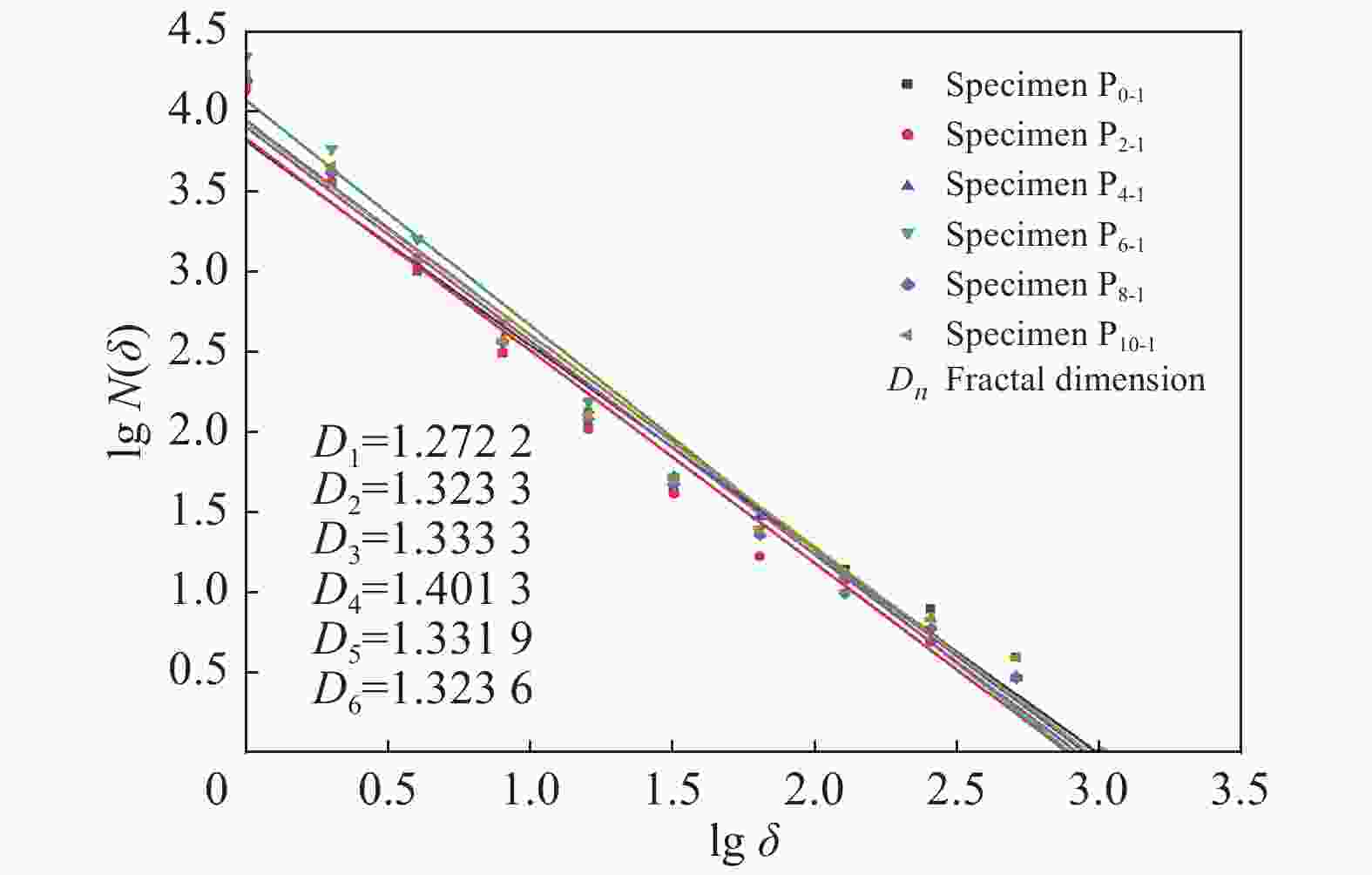

谢和平. 分形几何及其在岩土力学中的应用 [J]. 岩土工程学报, 1992, 14(1): 14–24. DOI: 10.3321/j.issn:1000-4548.1992.01.002.XIE H P. Fractal geometry and its application to rock and soil materials [J]. Chinese Journal of Geotechnical Engineering, 1992, 14(1): 14–24. DOI: 10.3321/j.issn:1000-4548.1992.01.002.

|

| [23] |

杨仁树, 肖成龙, 丁晨曦, 等. 空孔与运动裂纹相互作用的动焦散线实验研究 [J]. 爆炸与冲击, 2020, 40(5): 052202. DOI: 10.11883/bzycj-2019-0091.YANG R S, XIAO C L, DING C X, et al. Experimental study on dynamic caustics of interaction between void and running crack [J]. Explosion and Shock Waves, 2020, 40(5): 052202. DOI: 10.11883/bzycj-2019-0091.

|

| [24] |

李成杰, 徐颖, 张宇婷, 等. 冲击荷载下裂隙类煤岩组合体能量演化与分形特征研究 [J]. 岩石力学与工程学报, 2019, 38(11): 2231–2241. DOI: 10.13722/j.cnki.jrme.2019.0446.LI C J, XU Y, ZHANG Y T, et al. Study on energy evolution and fractal characteristics of cracked coal-rock-like combined body under impact loading [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(11): 2231–2241. DOI: 10.13722/j.cnki.jrme.2019.0446.

|

| [25] |

李柯萱, 李铁. 不同加载速率下砂岩弯曲破坏的细观机理 [J]. 爆炸与冲击, 2019, 39(4): 043101. DOI: 10.11883/bzycj-2018-0178.LI K X, LI T. Micro-mechanism of bending failure of sandstone under different loading rates [J]. Explosion and Shock Waves, 2019, 39(4): 043101. DOI: 10.11883/bzycj-2018-0178.

|

下载:

下载: