Impact resistance of thickness-graded arrow-shaped honeycomb pedestals with negative Poisson’s ratio

-

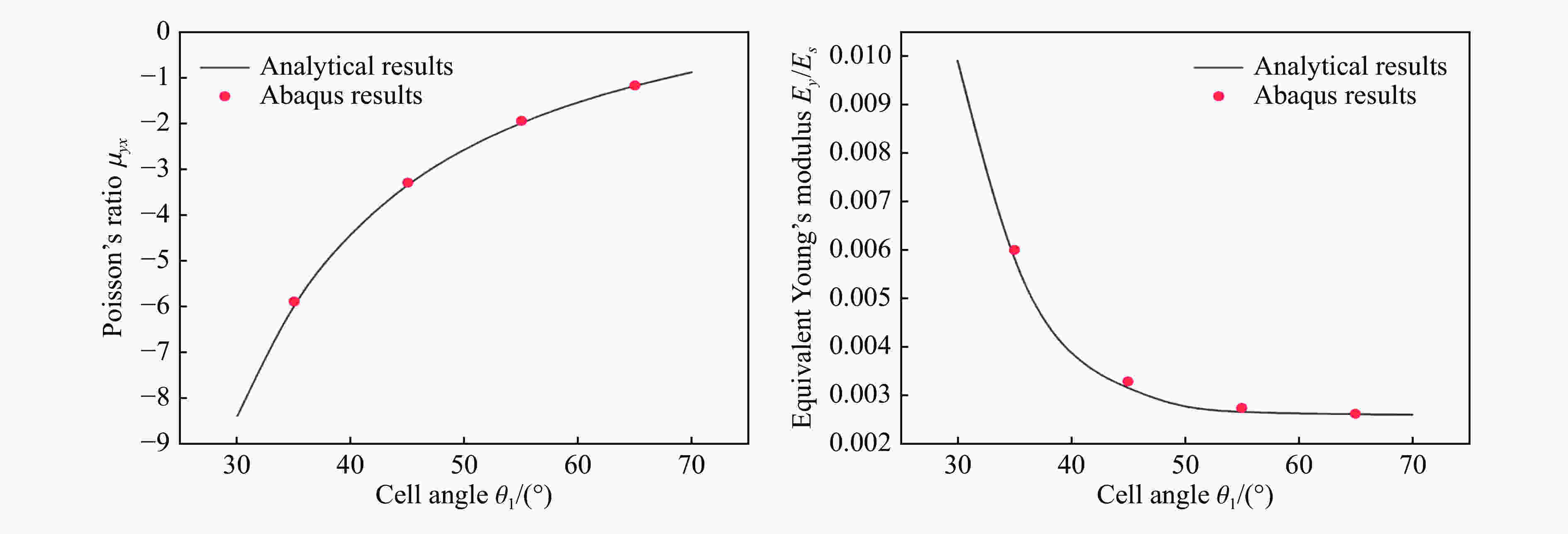

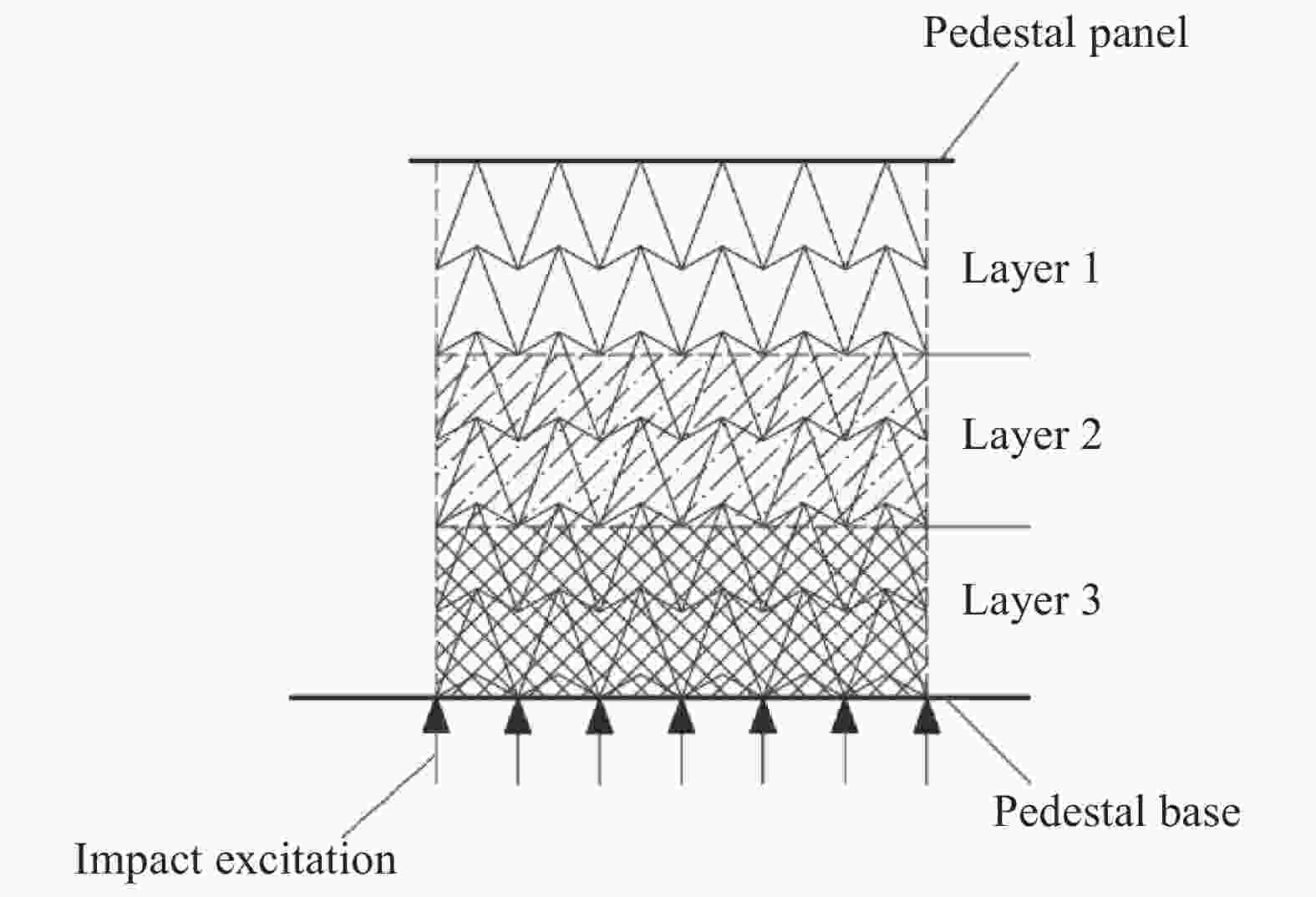

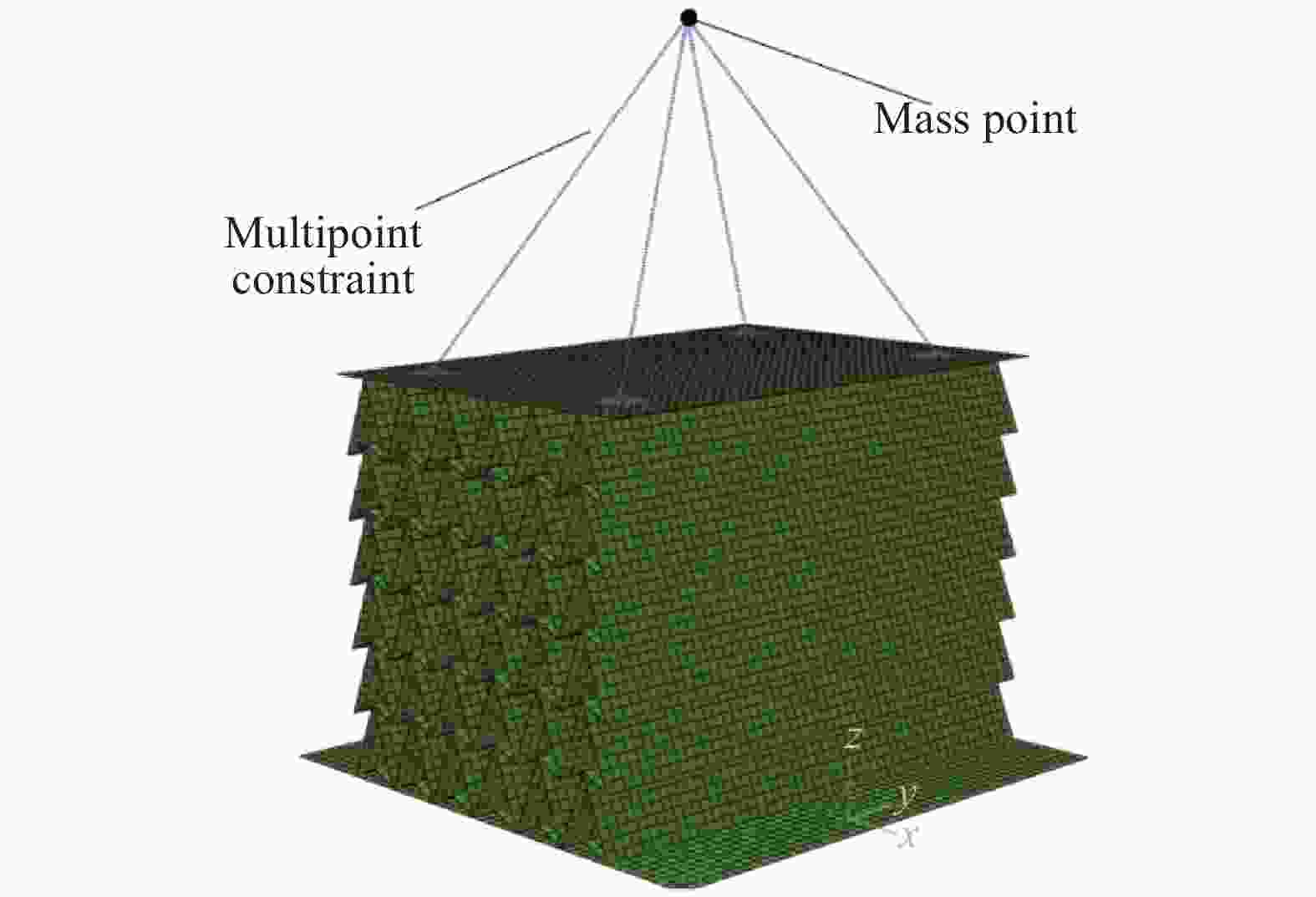

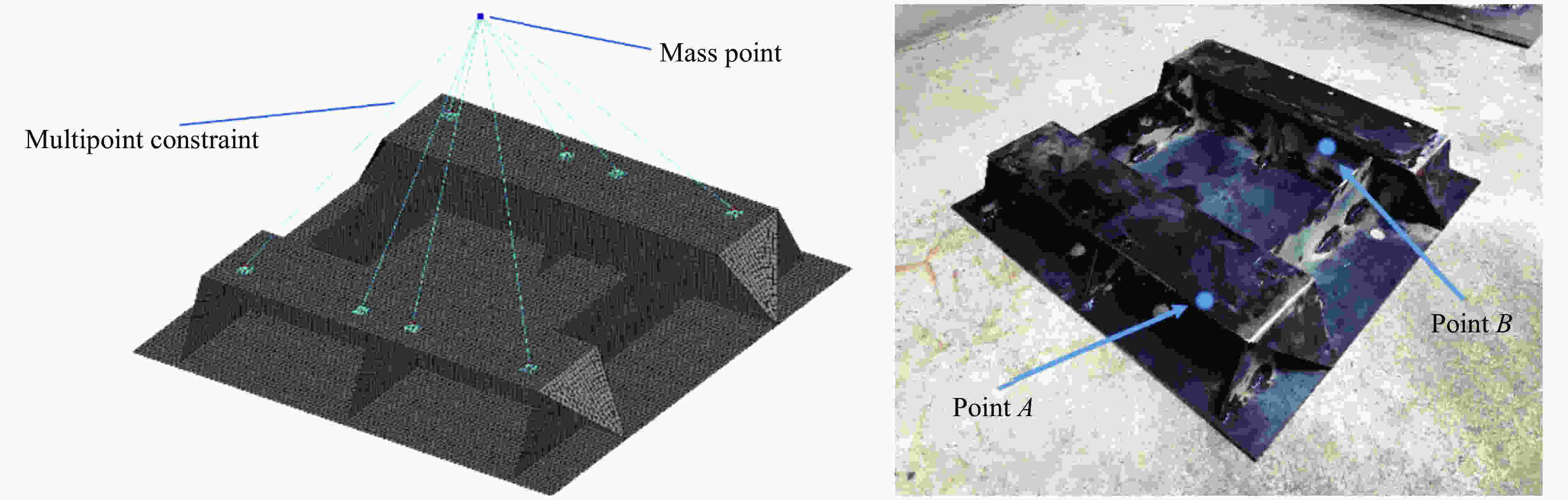

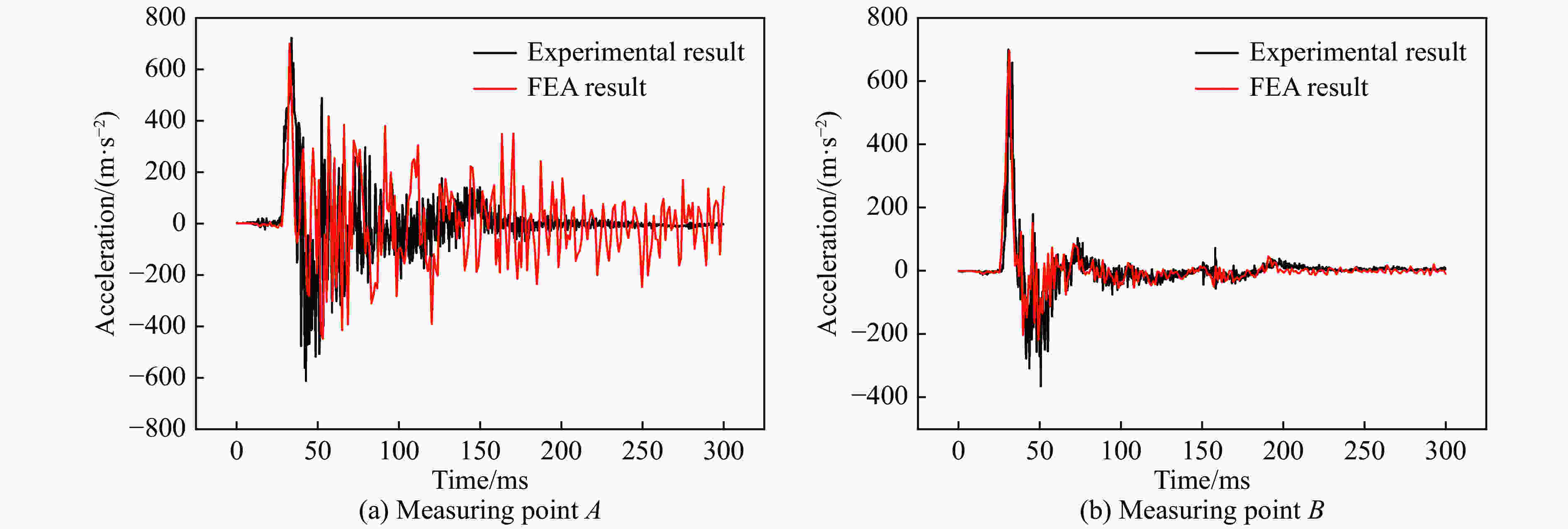

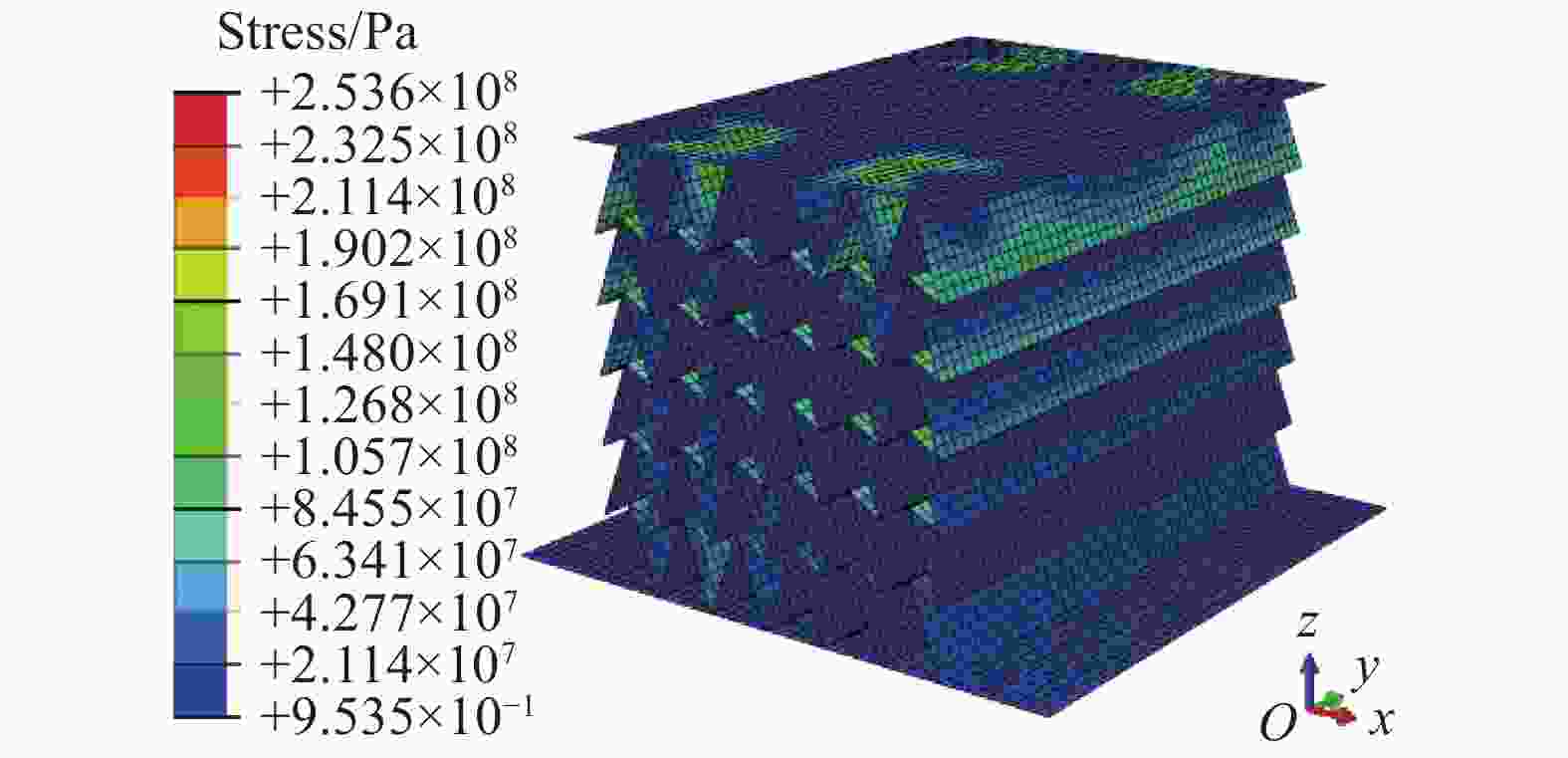

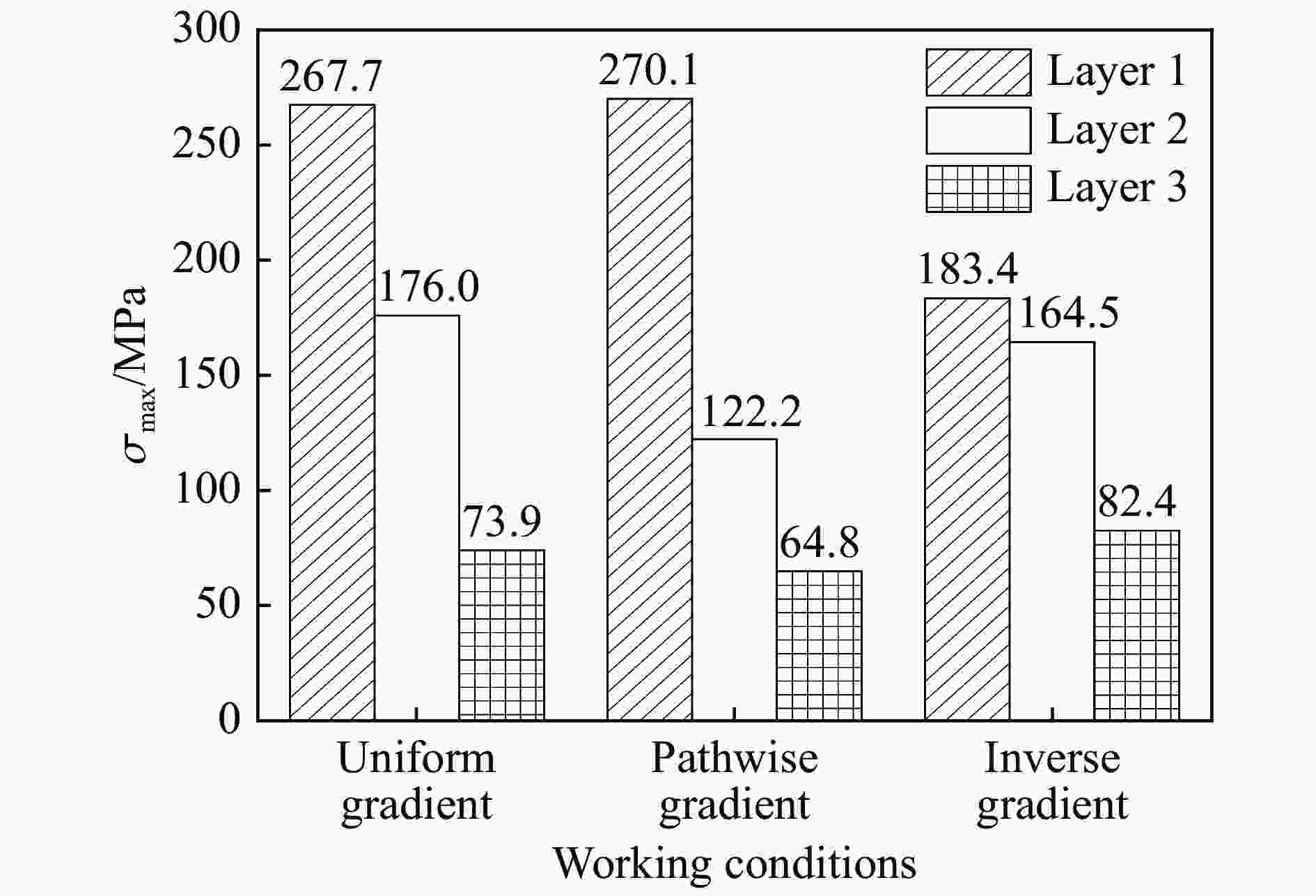

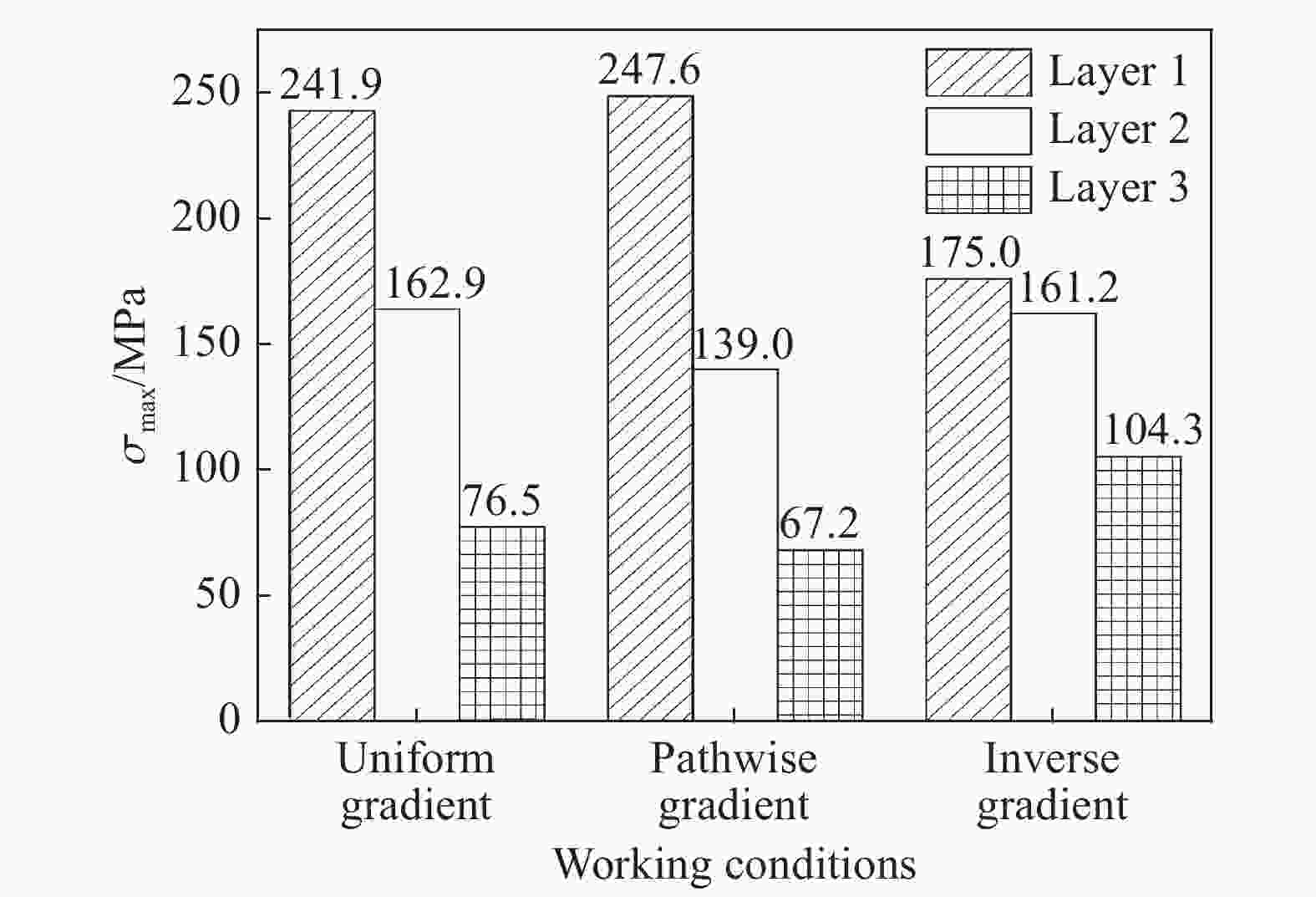

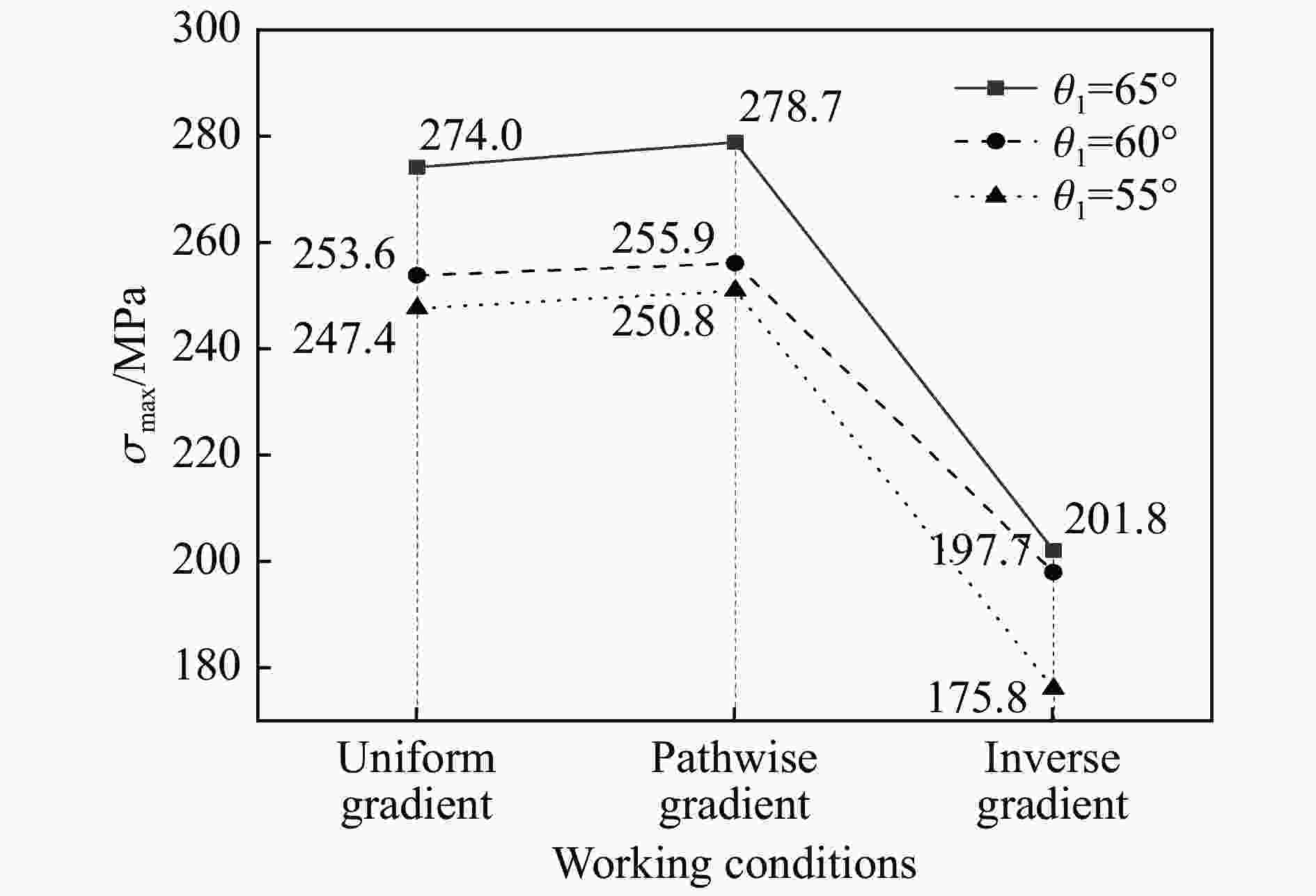

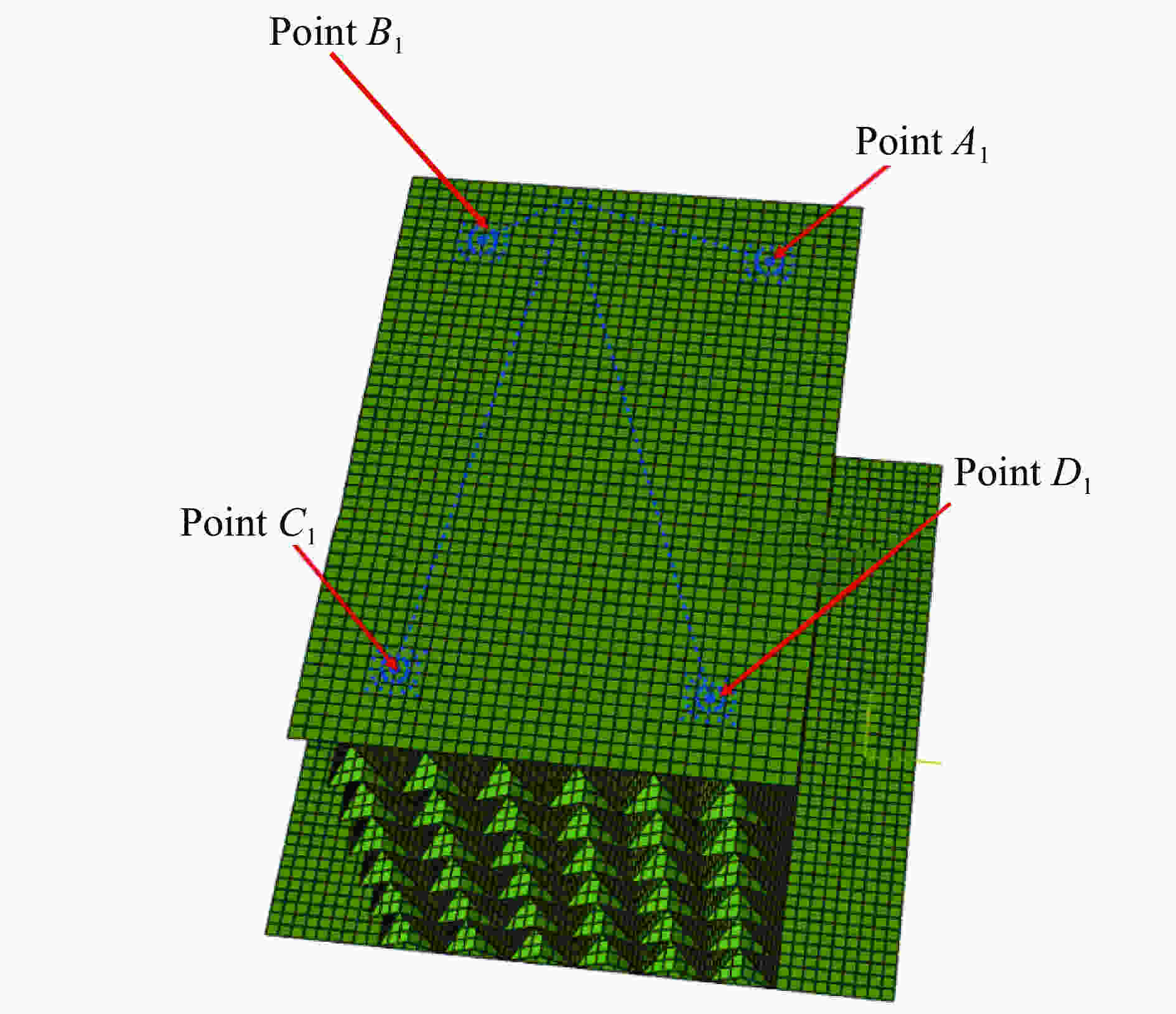

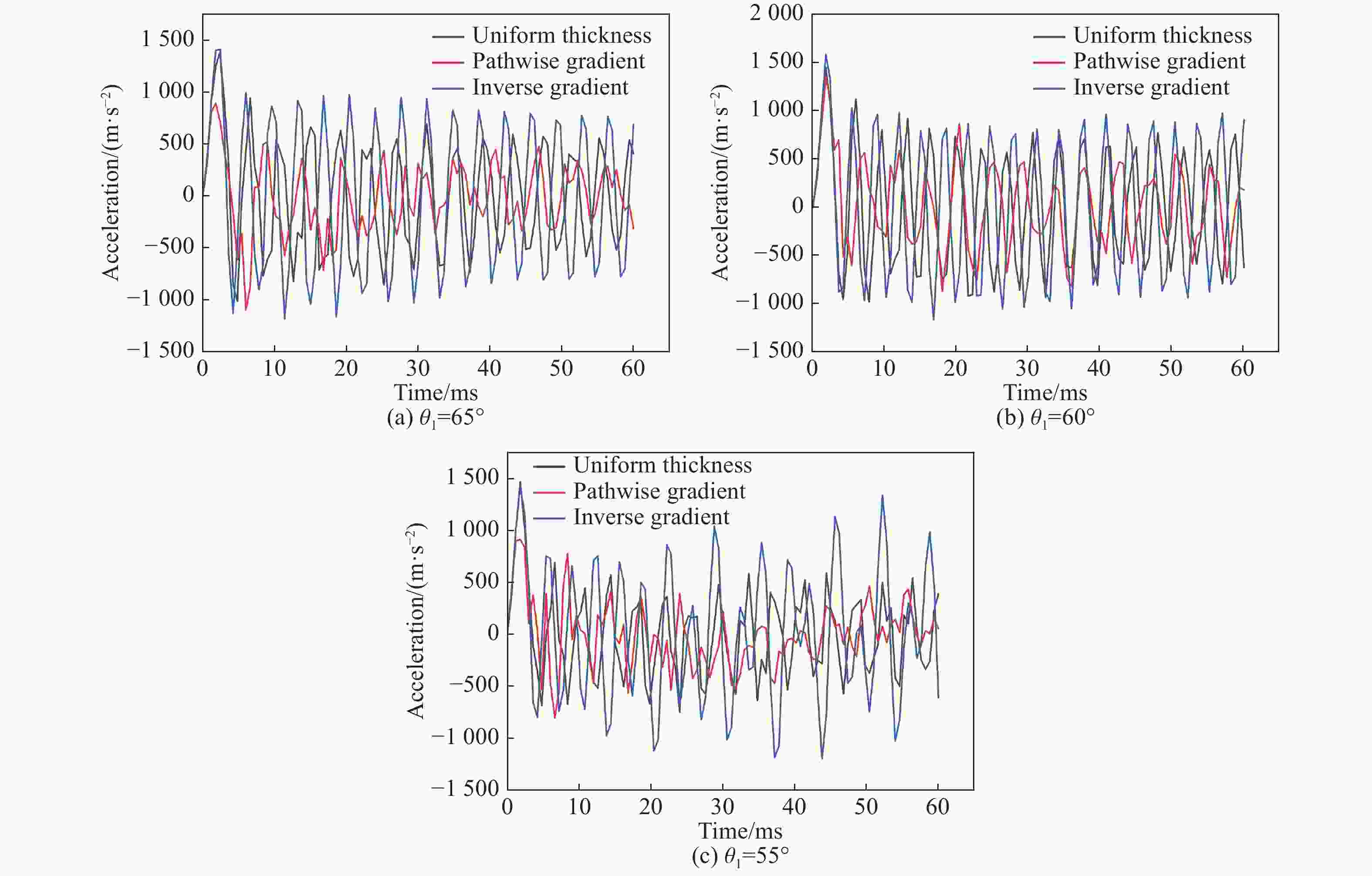

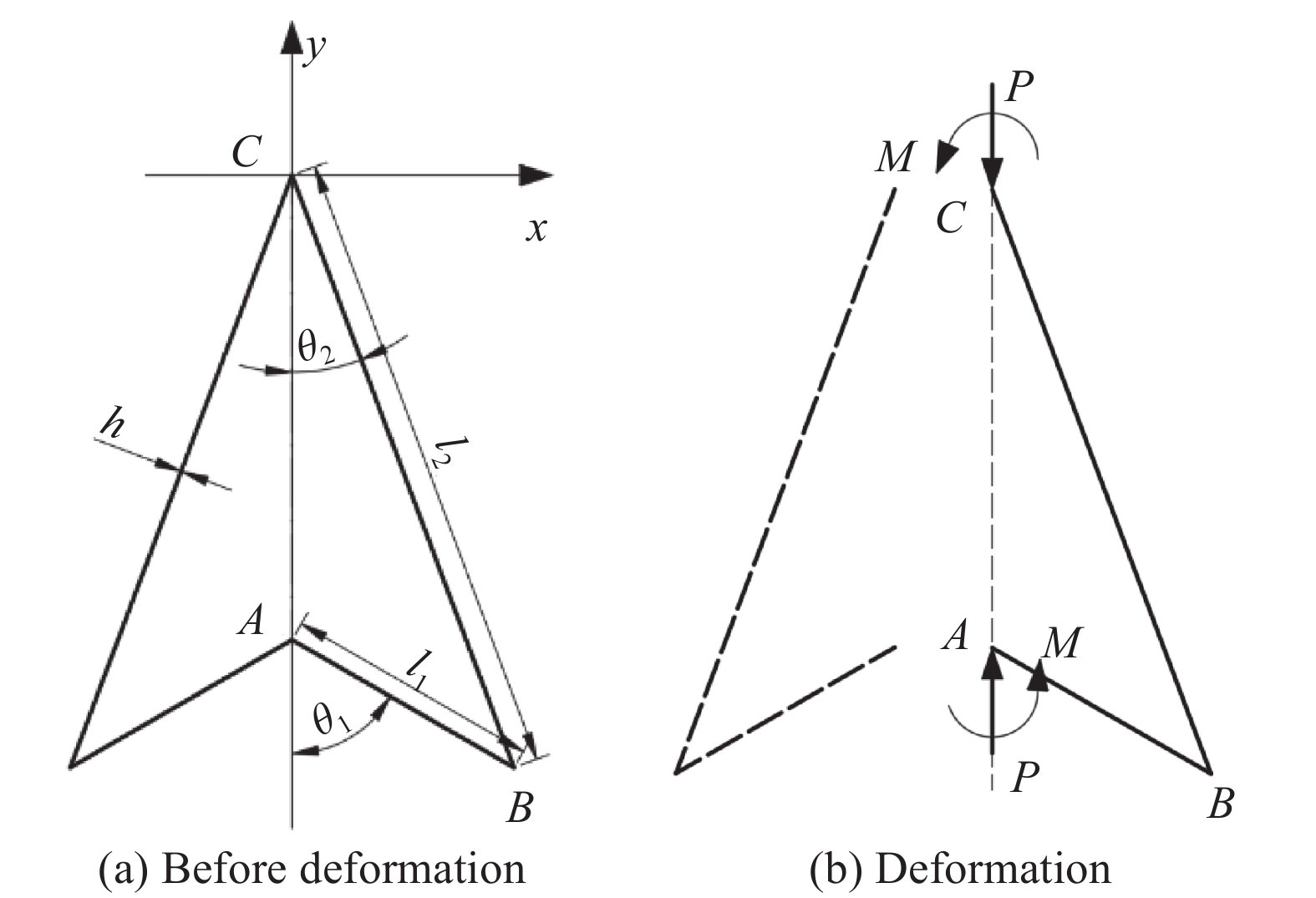

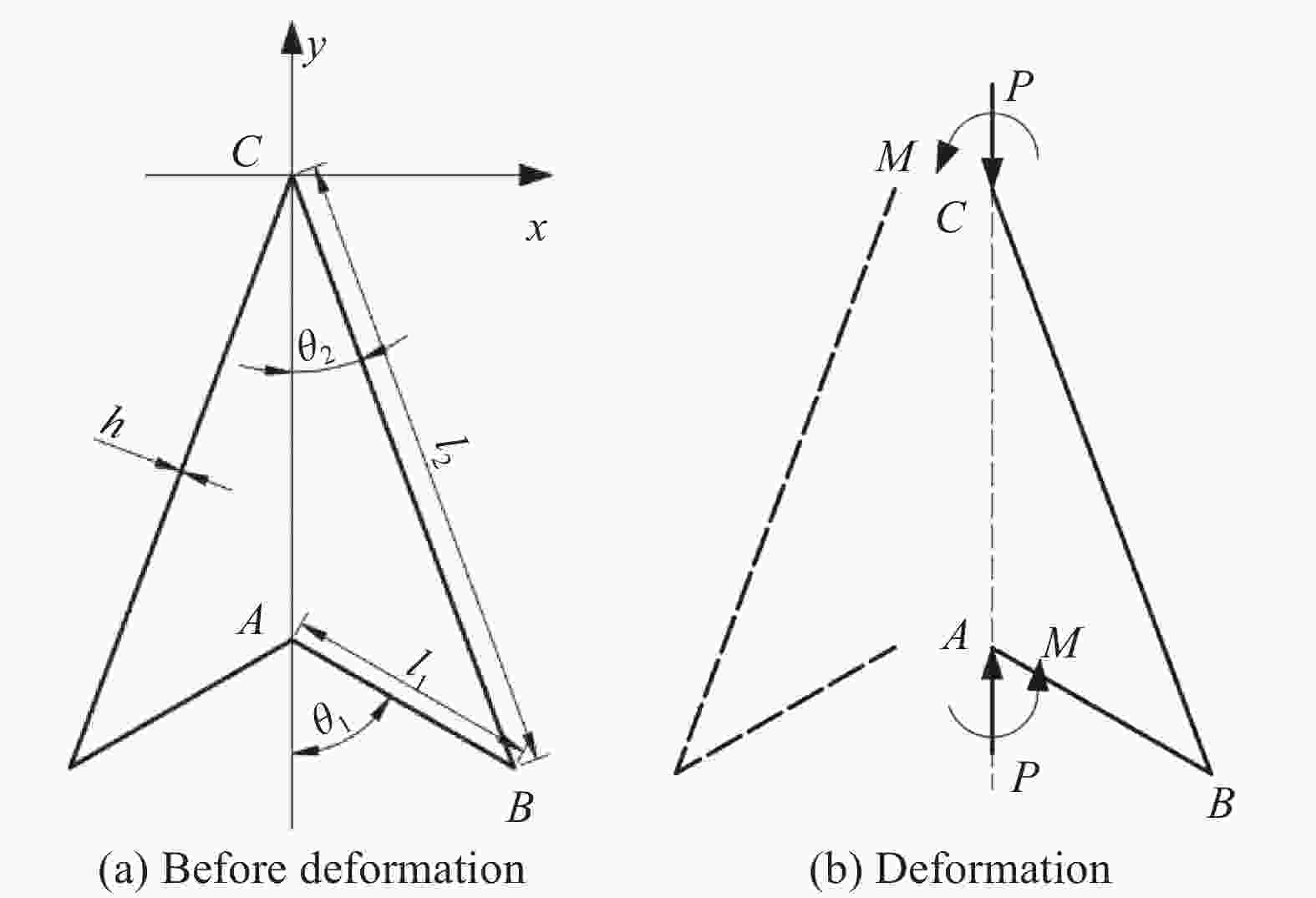

摘要: 设计了一种箭形负泊松比的蜂窝基座结构,推导了其胞元结构的力学性能解析公式,并利用有限元方法研究了具有厚度梯度箭形负泊松比蜂窝材料的抗冲击性能。基于功能梯度材料,其基体呈连续梯度变化的概念,以胞元壁厚为自变量,设计了顺厚度梯度、逆厚度梯度型和均匀厚度的蜂窝层,并建立基座模型。在基座质量不变的前提下具体讨论了蜂窝胞元凹角及厚度梯度的不同设置情况对基座抗冲击性能的影响。结果表明,相同梯度设置情况下,胞角的变化会引起蜂窝结构等效弹性模量的变化,进而改变基座的抗冲击性能,而将胞壁厚度较小的蜂窝层放置于迎冲端时,基座整体的应力水平明显降低;将壁厚较大的蜂窝层放置于迎冲端时,基座面板的输出冲击环境能够有效地得到控制。Abstract: An arrow-shaped honeycomb pedestal with negative Poisson’s ratio was designed. An analytical formula was derived for the mechanical properties of the cell structures, and the impact resistance of the thickness-graded arrow-shaped honeycomb materials with negative Poisson's ratio was numerically studied by the explicit dynamic finite element method. Based on the concept of functionally-graded materials, honeycomb layers with pathwise thickness gradient, inverse thickness gradient and uniform thickness were designed, by taking the thickness of the cell wall as the independent variable, the relevant model was established. The influence of thickness gradients on the impact resistance of the pedestal was discussed concretely under the premise of constant pedestal mass. The results show that, under the same gradient setting, the change of cell angle will cause the change of equivalent elastic modulus of the honeycomb structure, thus changing the impact resistance of the pedestal. When the honeycomb layer with a thinner cell wall is placed at the impact end, the stress level of the pedestal is significantly reduced. By placing a honeycomb layer with a thicker cell wall on the impact end, the output impact environment of the pedestal panel can be effectively controlled.

-

表 1 厚度梯度基座工况设置

Table 1. Condition settings for thickness gradient pedestals

胞角$ {\theta }_{1} $/(°) 工况 层1厚度/mm 层2厚度/mm 层3厚度/mm 55 均匀厚度 3 3 3 顺厚度梯度 2 3 4 逆厚度梯度 4 3 2 60 均匀厚度 3 3 3 顺厚度梯度 2 3 4 逆厚度梯度 4 3 2 65 均匀厚度 3 3 3 顺厚度梯度 2 3 4 逆厚度梯度 4 3 2 -

[1] 王军, 卢立新. 蜂窝纸板面内平台应力表征 [J]. 工程力学, 2012, 29(8): 354–359. DOI: 10.6052/j.issn.1000-4750.2010.11.0816.WANG J, LU L X. Characterization of in-plane platean stress for honeycomb paperboard [J]. Engineering Mechanics, 2012, 29(8): 354–359. DOI: 10.6052/j.issn.1000-4750.2010.11.0816. [2] 张伟. 三维负泊松比多胞结构的轴向压缩性能研究[D]. 大连: 大连理工大学, 2015. [3] CHOI J B, LAKES R S. Analysis of elastic modulus of conventional foams and of re-entrant foam materials with a negative Poisson’s ratio [J]. International Journal of Mechanical Sciences, 1995, 37(1): 51–59. DOI: 10.1016/0020-7403(94)00047-n. [4] LI Y, CORMIER D, WEST H, et al. Non-stochastic Ti-6Al-4V foam structures with negative Poisson’s ratio [J]. Materials Science and Engineering: A, 2012, 558: 579–585. DOI: 10.1016/j.msea.2012.08.053. [5] SCHULTZ J, GRIESE D, SHANKAR P, et al. Optimization of honeycomb cellular meso-structures for high speed impact energy absorption [C] // Proceedings of ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Washington: American Society of Mechanical Engineers, 2014: 955-965. DOI: 10.1115/DETC2011-48000. [6] 杨德庆, 马涛, 张梗林. 舰艇新型宏观负泊松比效应蜂窝舷侧防护结构 [J]. 爆炸与冲击, 2015, 35(2): 243–248. DOI: 10.11883/1001-1455(2015)02-0243-06.YANG D Q, MA T, ZHANG G L. A novel auxetic broadside defensive structure for naval ships [J]. Explosion and Shock Waves, 2015, 35(2): 243–248. DOI: 10.11883/1001-1455(2015)02-0243-06. [7] ZHANG X C, AN L Q, DING H M, et al. Influence of cell micro-structure on the in-plane dynamic crushing of honeycombs with negative Poisson’s ratio [J]. Journal of Sandwich Structures and Materials, 2015, 17(1): 26–55. DOI: 10.1177/1099636214554180. [8] KOIZUMI M. FGM activities in Japan [J]. Composites Part B: Engineering, 1997, 28(1−2): 1–4. [9] 何强, 马大为, 张震东, 等. 功能梯度蜂窝材料的面内冲击性能研究 [J]. 工程力学, 2016, 33(2): 172–178. DOI: 10.6052/j.issn.1000-4750.2014.05.0392.HE Q, MA D W, ZHANG Z D, et al. Research on the in-plane dynamic crushing of functionally graded honeycombs [J]. Engineering Mechanics, 2016, 33(2): 172–178. DOI: 10.6052/j.issn.1000-4750.2014.05.0392. [10] 吴鹤翔, 刘颖. 梯度分布对密度梯度金属空心球阵列动力学性能的影响 [J]. 工程力学, 2013, 30(1): 425–431. DOI: 10.6052/j.issn.1000-4750.2011.06.0335.WU H X, LIU Y. The influence of gradient profile on the dynamic properties of density graded metal hollow sphere arrays [J]. Engineering Mechanics, 2013, 30(1): 425–431. DOI: 10.6052/j.issn.1000-4750.2011.06.0335. [11] AJDARI A, CANAVAN P, NAYEB-HASHEMI H, et al. Mechanical properties of functionally graded 2-D cellular structures: a finite element simulation [J]. Materials Science and Engineering: A, 2009, 499(1−2): 434–439. DOI: 10.1016/j.msea.2008.08.040. [12] GUPTA N. A functionally graded syntactic foam material for high energy absorption under compression [J]. Materials Letters, 2007, 61(4−5): 979–982. DOI: 10.1016/j.matlet.2006.06.033. [13] LIANG C, KIERNAN S, GILCHRIST M D. Designing the energy absorption capacity of functionally graded foam materials [J]. Materials Science and Engineering: A, 2009, 507(1−2): 215–225. DOI: 10.1016/j.msea.2008.12.011. [14] 李营, 汪玉, 吴卫国, 等. 船用907A钢的动态力学性能和本构关系 [J]. 哈尔滨工程大学学报, 2015, 36(1): 127–129. DOI: 10.3969/j.issn.1006-7043.201311093.LI Y, WANG Y, WU W G, et al. Dynamic mechanical properties and constitutive relations of marine 907A steel [J]. Journal of Harbin Engineering University, 2015, 36(1): 127–129. DOI: 10.3969/j.issn.1006-7043.201311093. [15] 王军. 浮动冲击平台冲击动力特性研究[D]. 哈尔滨: 哈尔滨工程大学, 2015. [16] German Federal Office for Military Technology and Procurement. Shock resistance specification for bundeswehr ships: BV043[S]. 1985. [17] 卢子兴, 李康. 四边手性蜂窝动态压溃行为的数值模拟 [J]. 爆炸与冲击, 2014, 34(2): 181–187. DOI: 10.11883/1001-1455(2014)02-0181-07.LU Z X, LI K. Numerical simulation on dynamic crushing behaviors of tetrachiral honeycombs [J]. Explosion and Shock Waves, 2014, 34(2): 181–187. DOI: 10.11883/1001-1455(2014)02-0181-07. [18] 王军, 姚熊亮, 杨棣. 浮动冲击平台冲击环境对设备响应的影响 [J]. 爆炸与冲击, 2015, 35(2): 236–242. DOI: 10.11883/1001-1455(2015)02-0236-07.WANG J, YAO X L, YANG D. Impact analysis of shock environment from floating shock platform on equipment response [J]. Explosion and Shock Waves, 2015, 35(2): 236–242. DOI: 10.11883/1001-1455(2015)02-0236-07. -

下载:

下载: