Characteristics of closed and vented explosions of gasoline-air mixture in a square tube

-

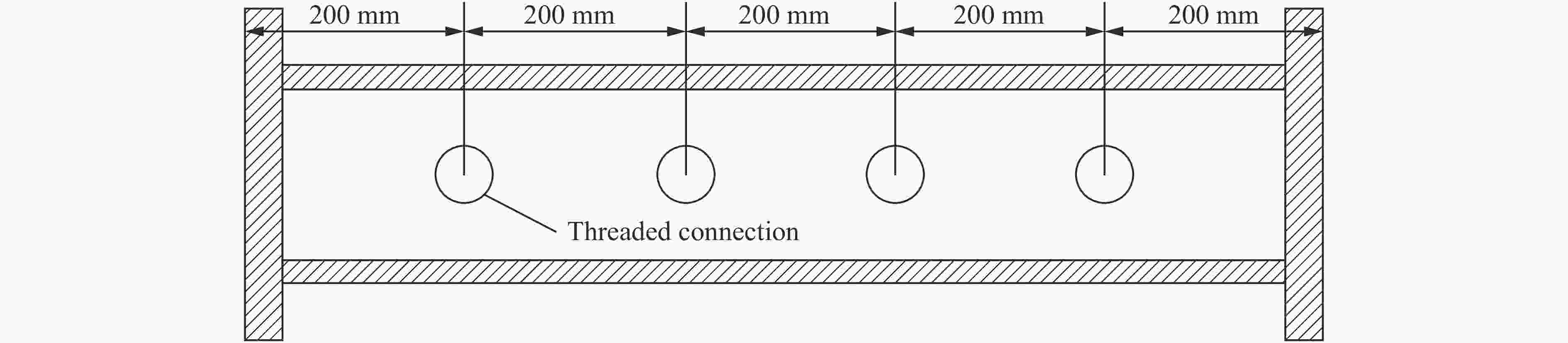

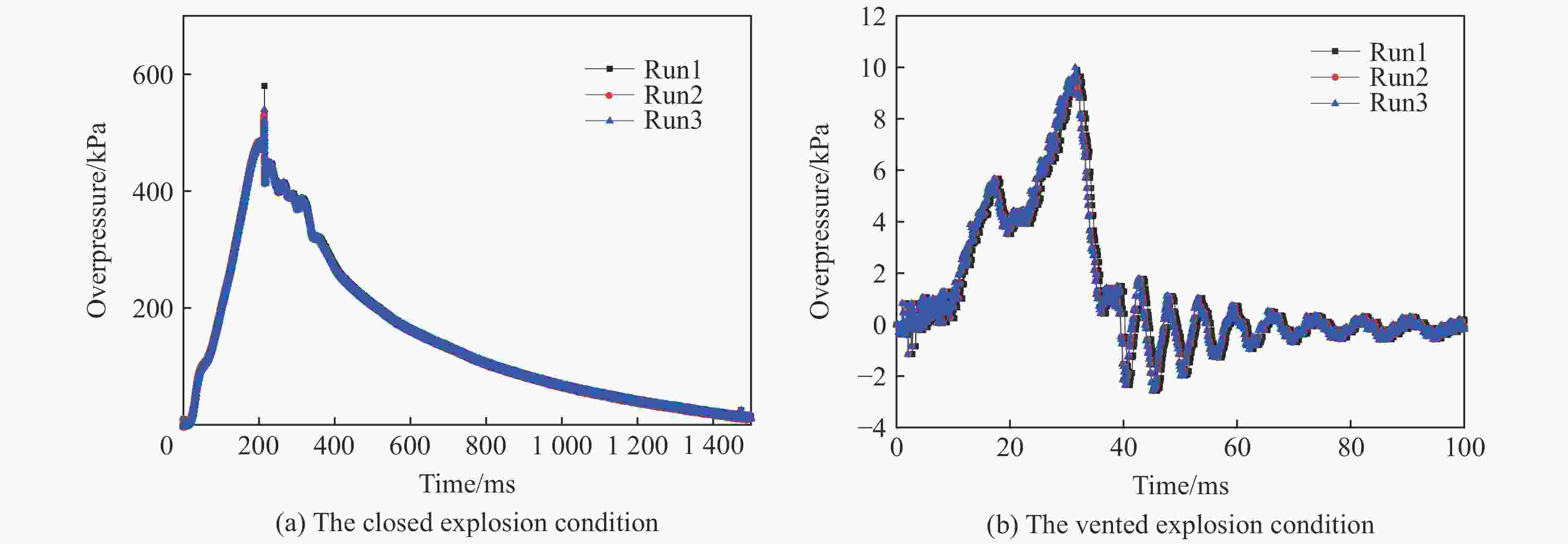

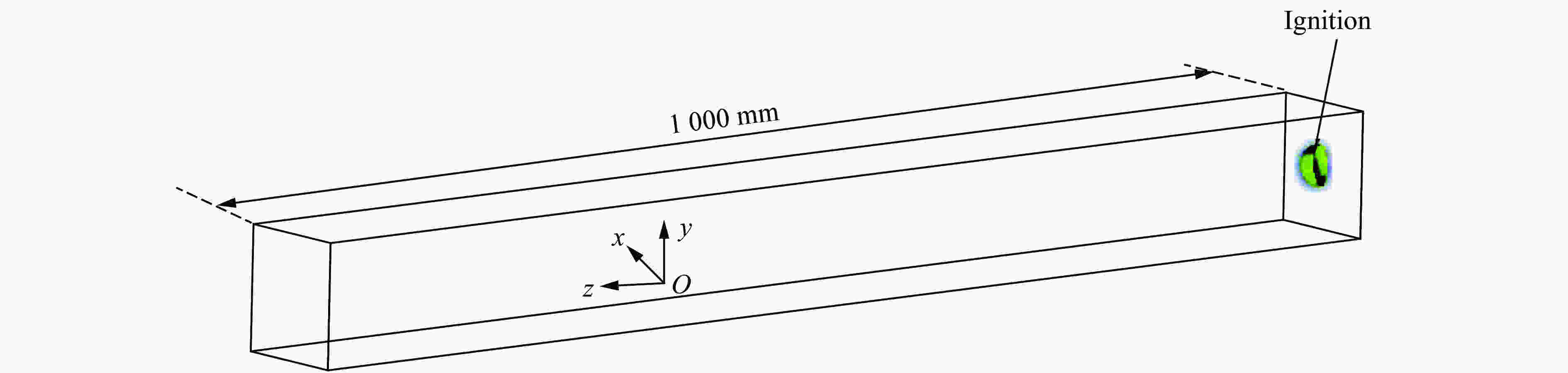

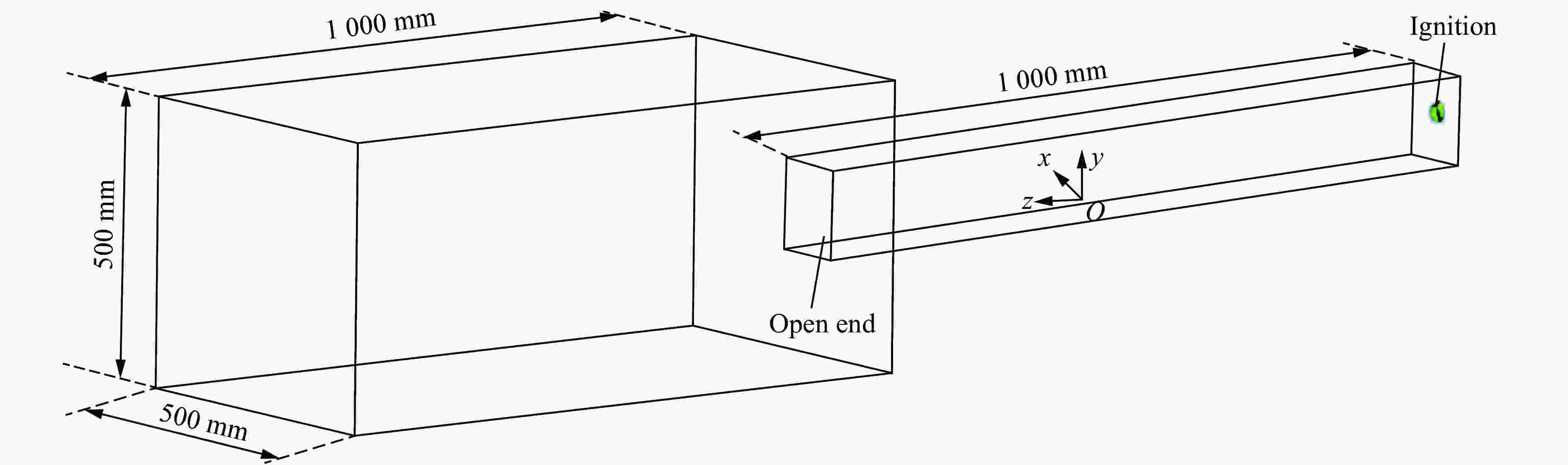

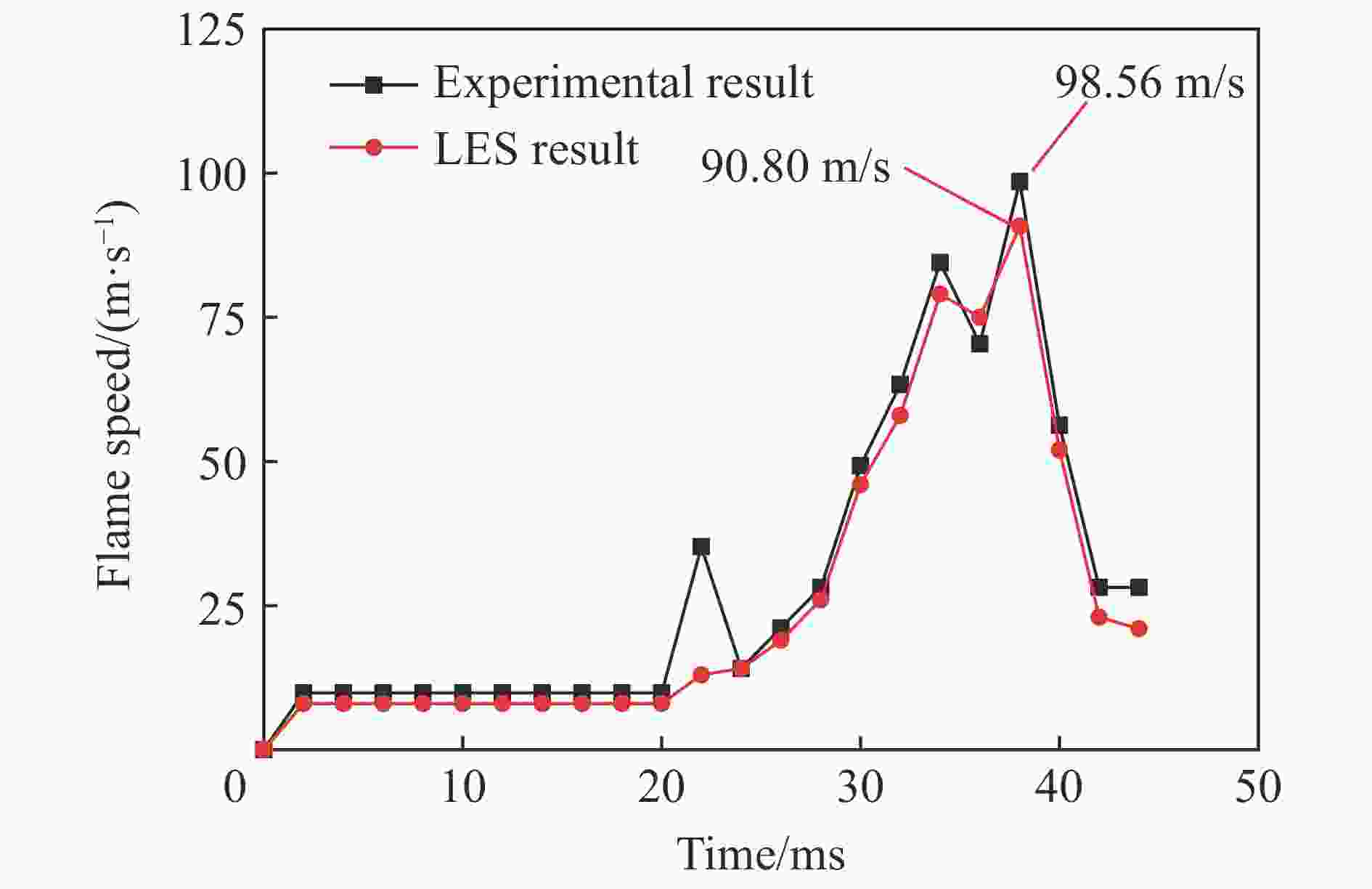

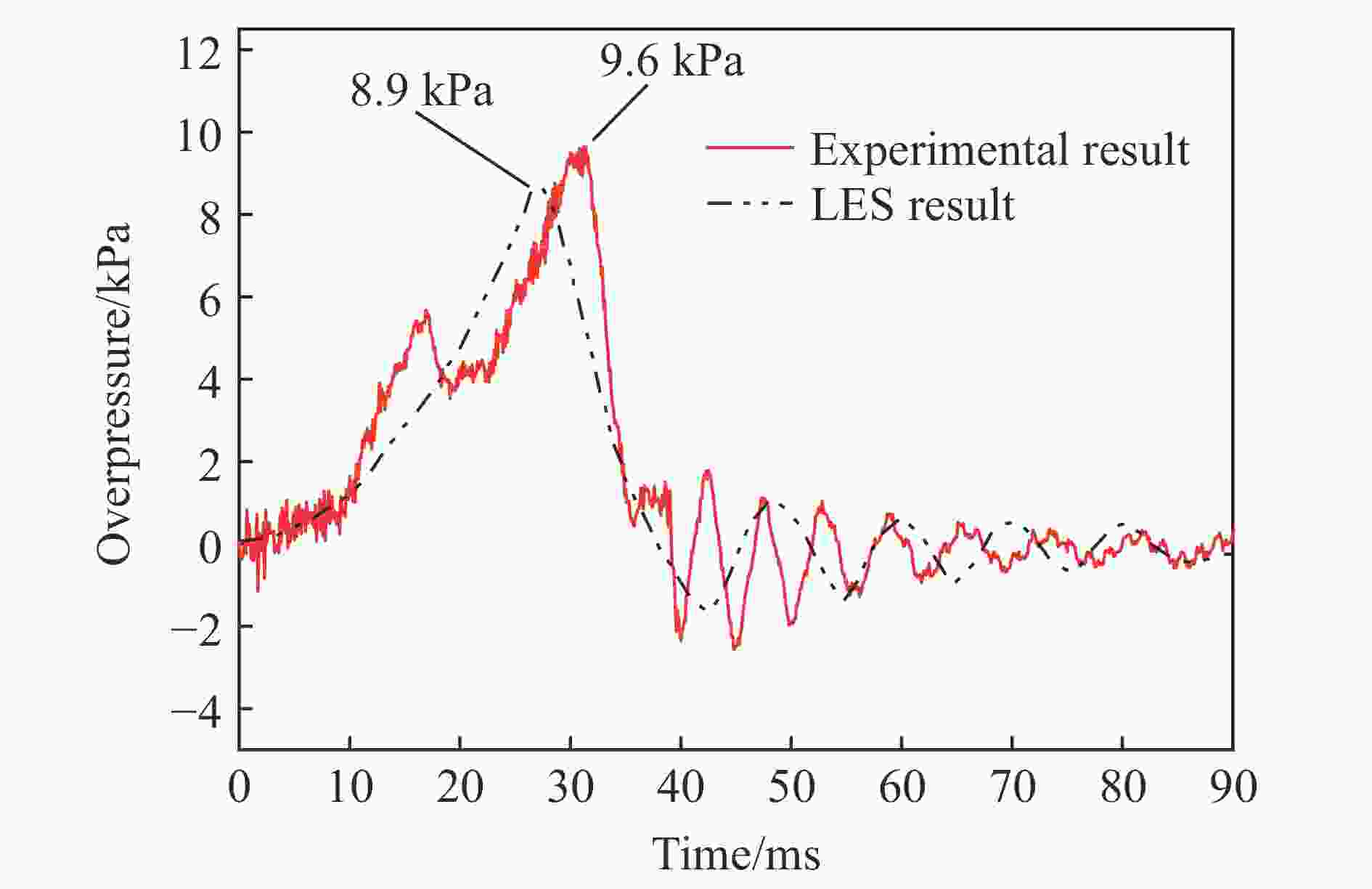

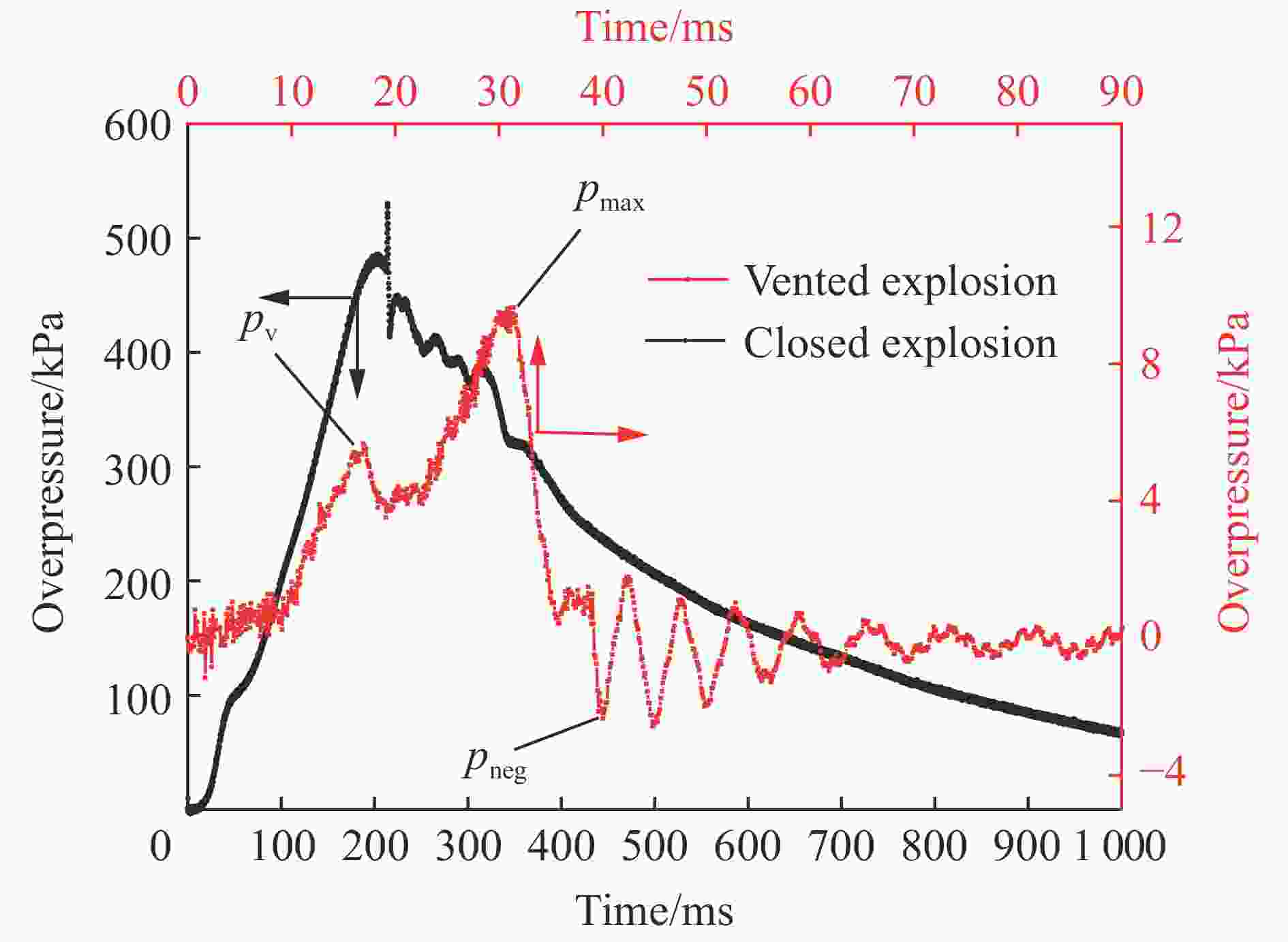

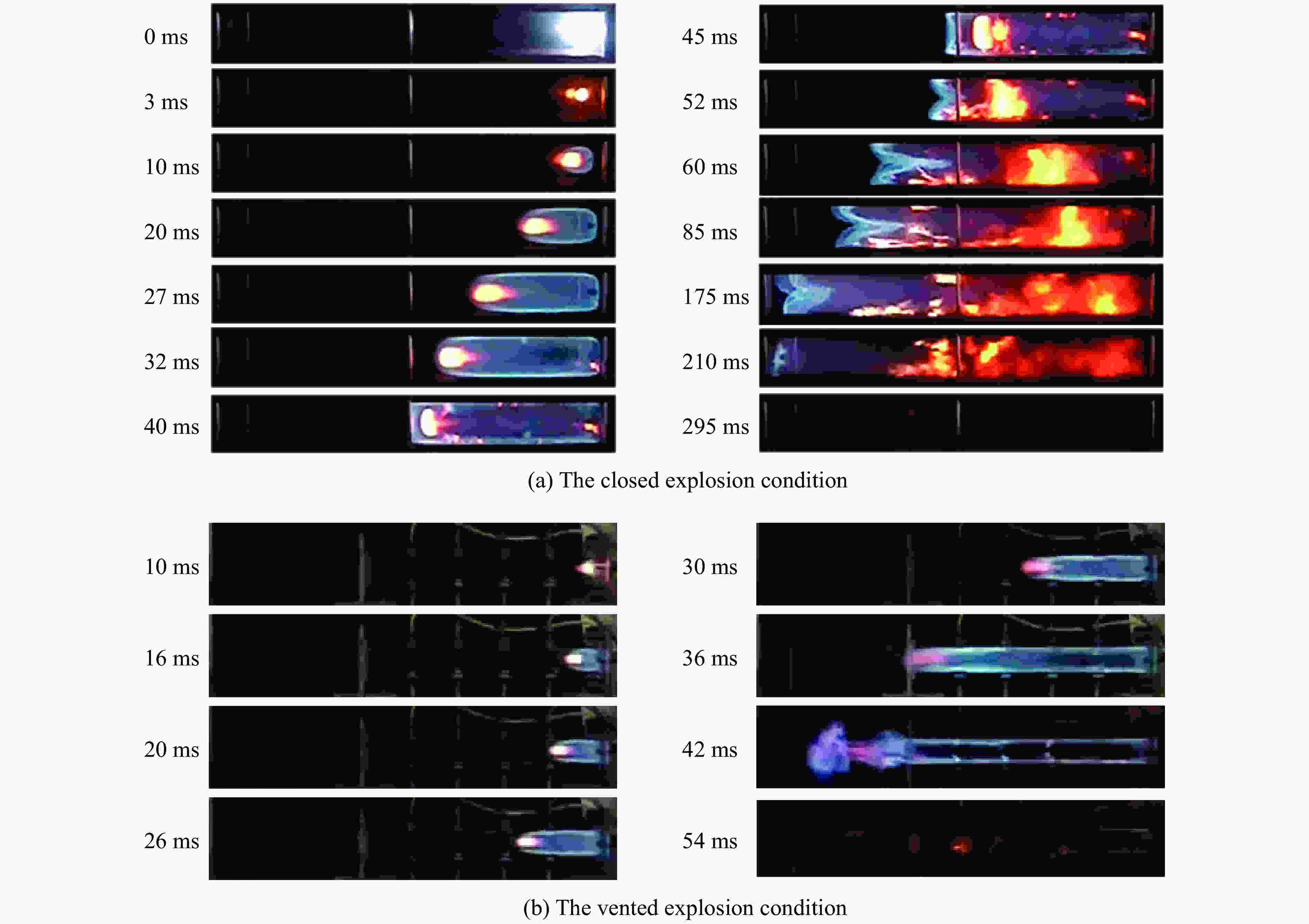

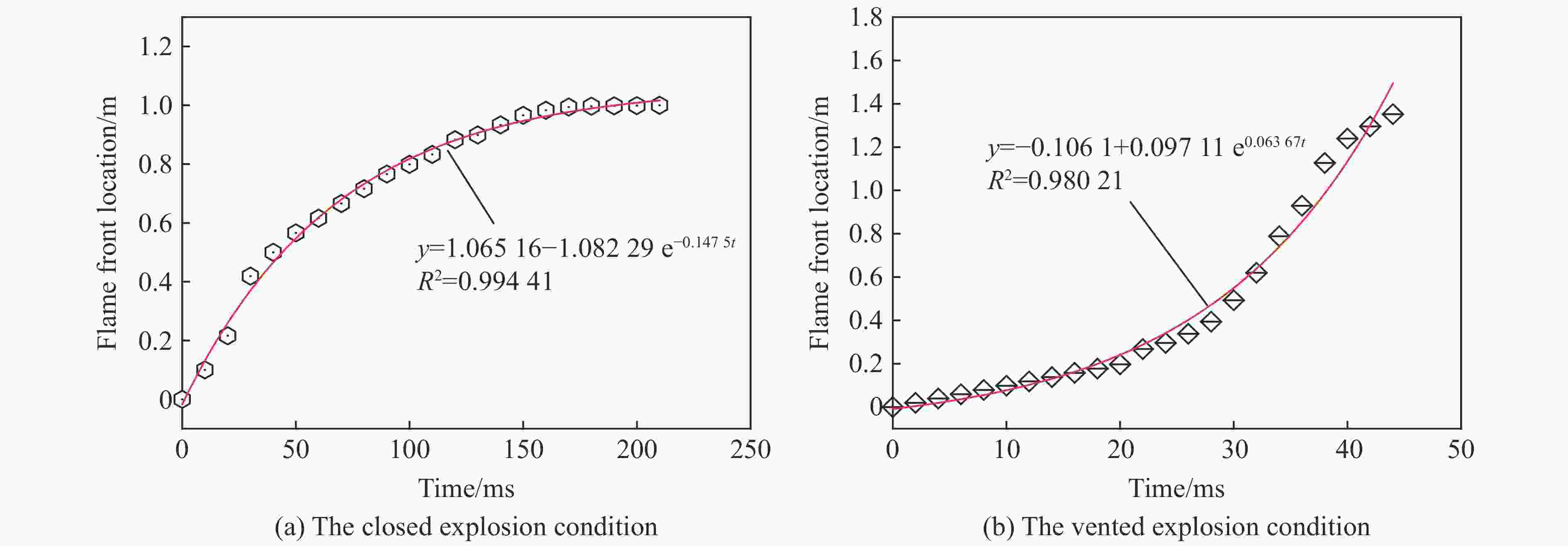

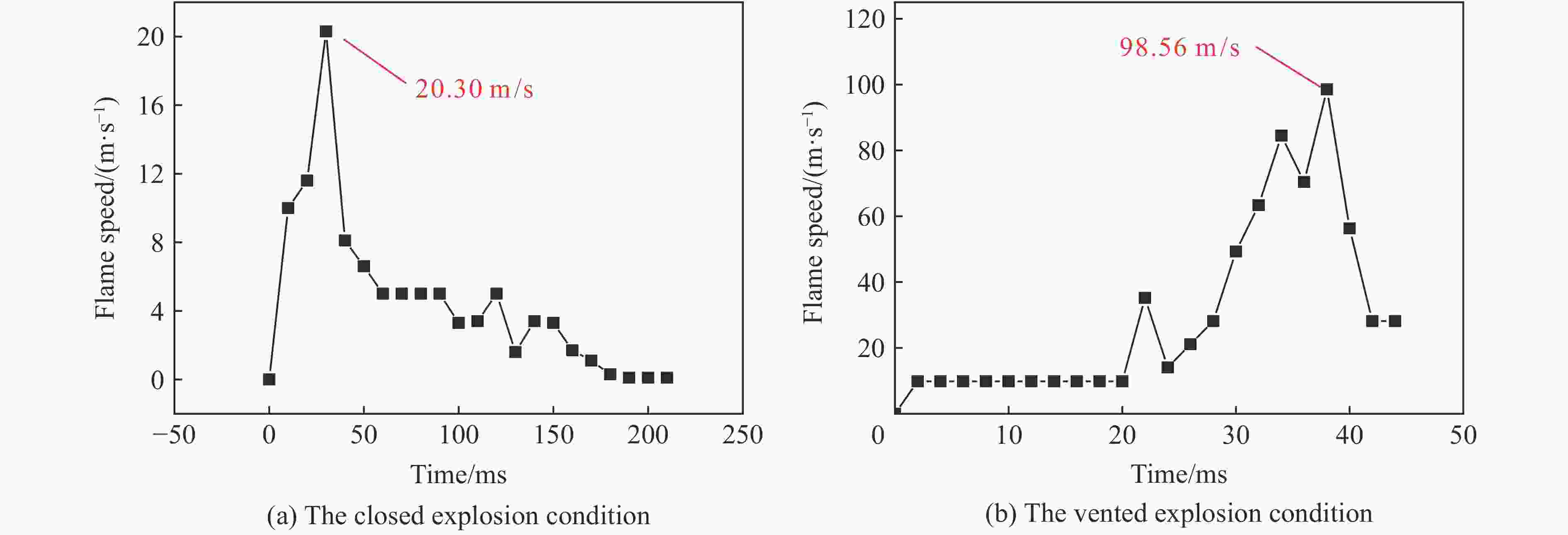

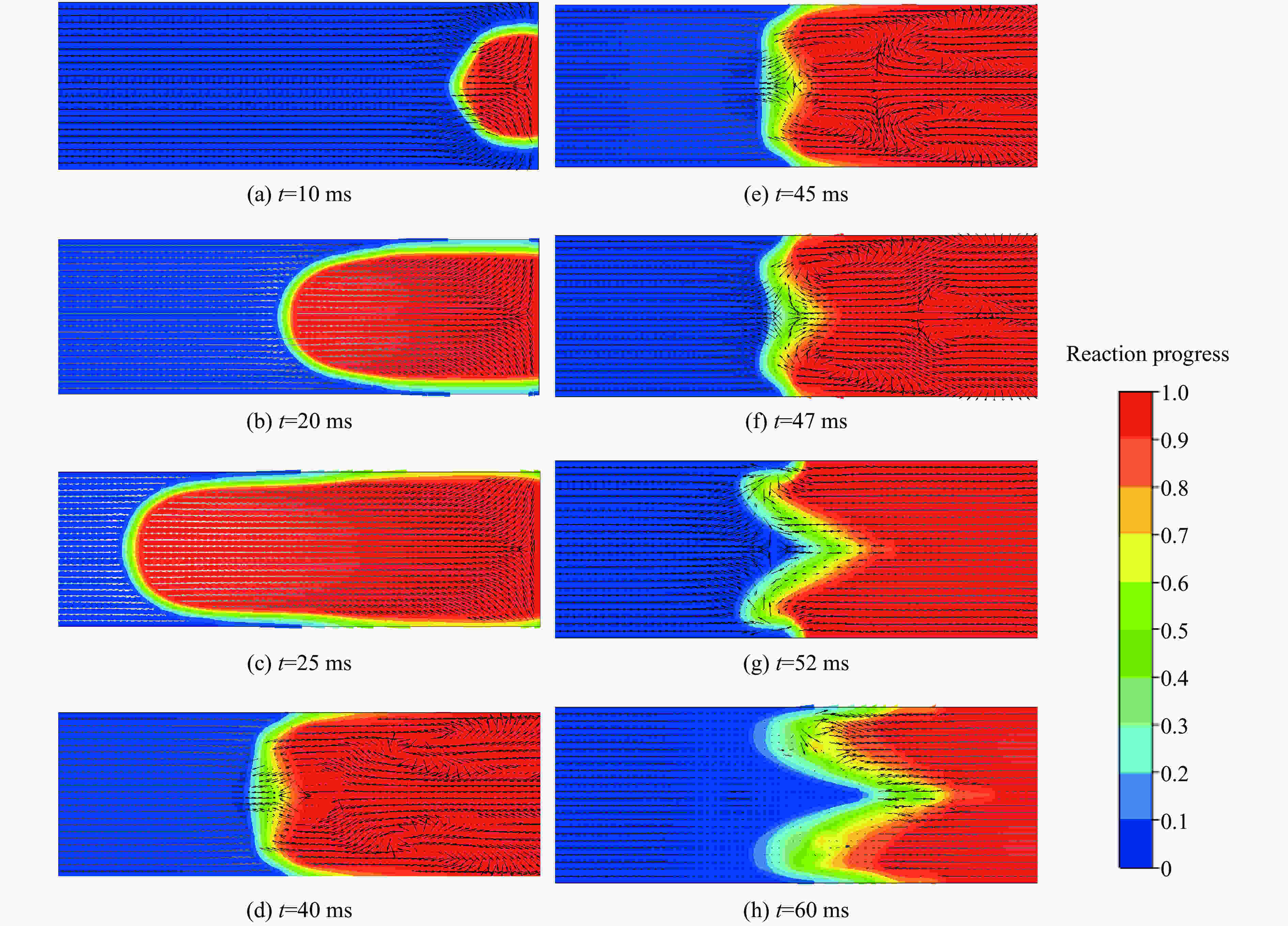

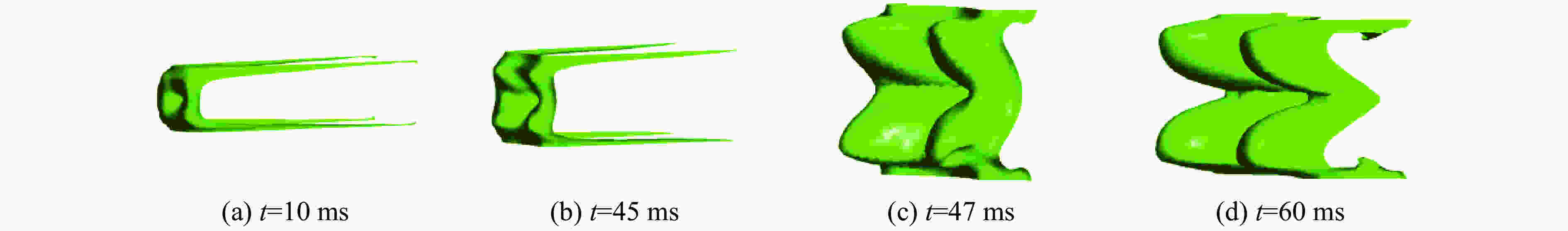

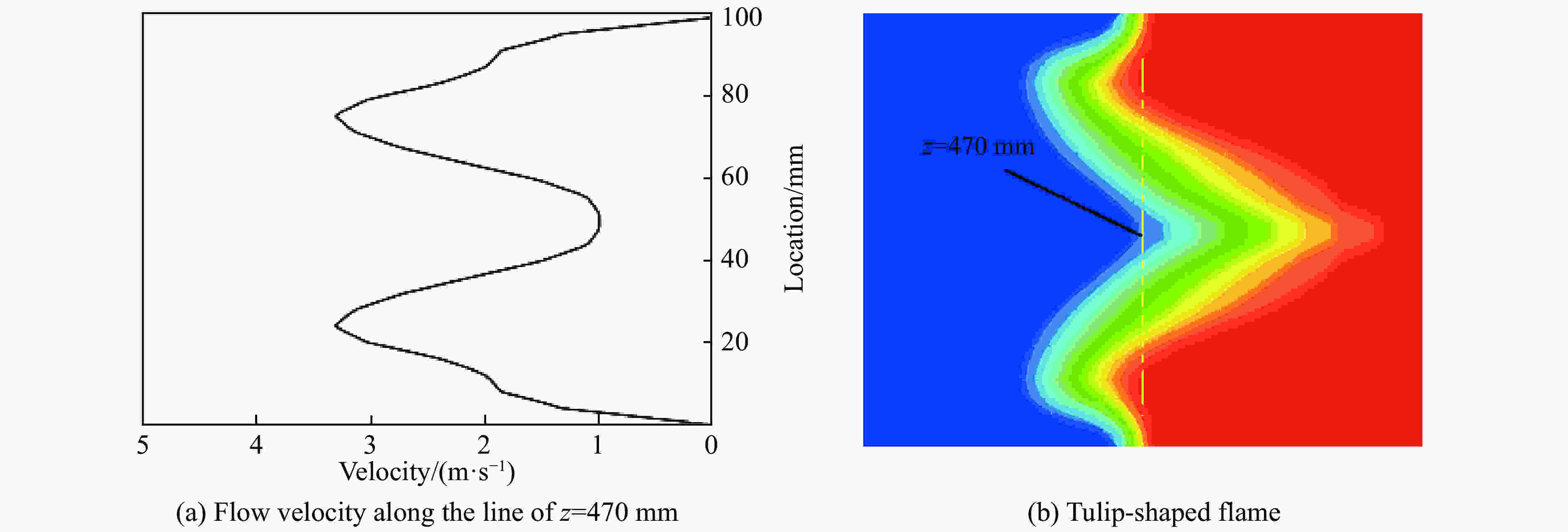

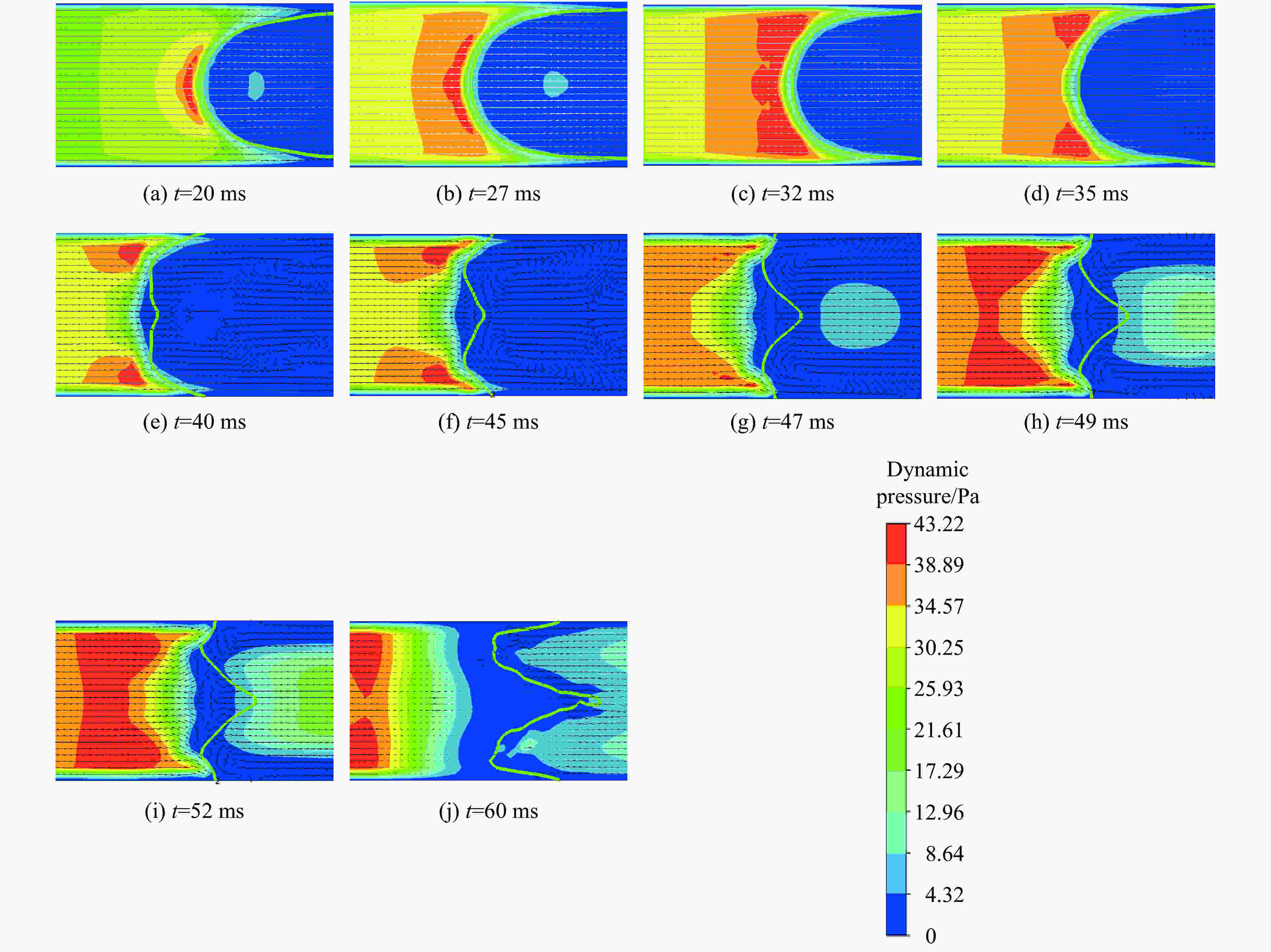

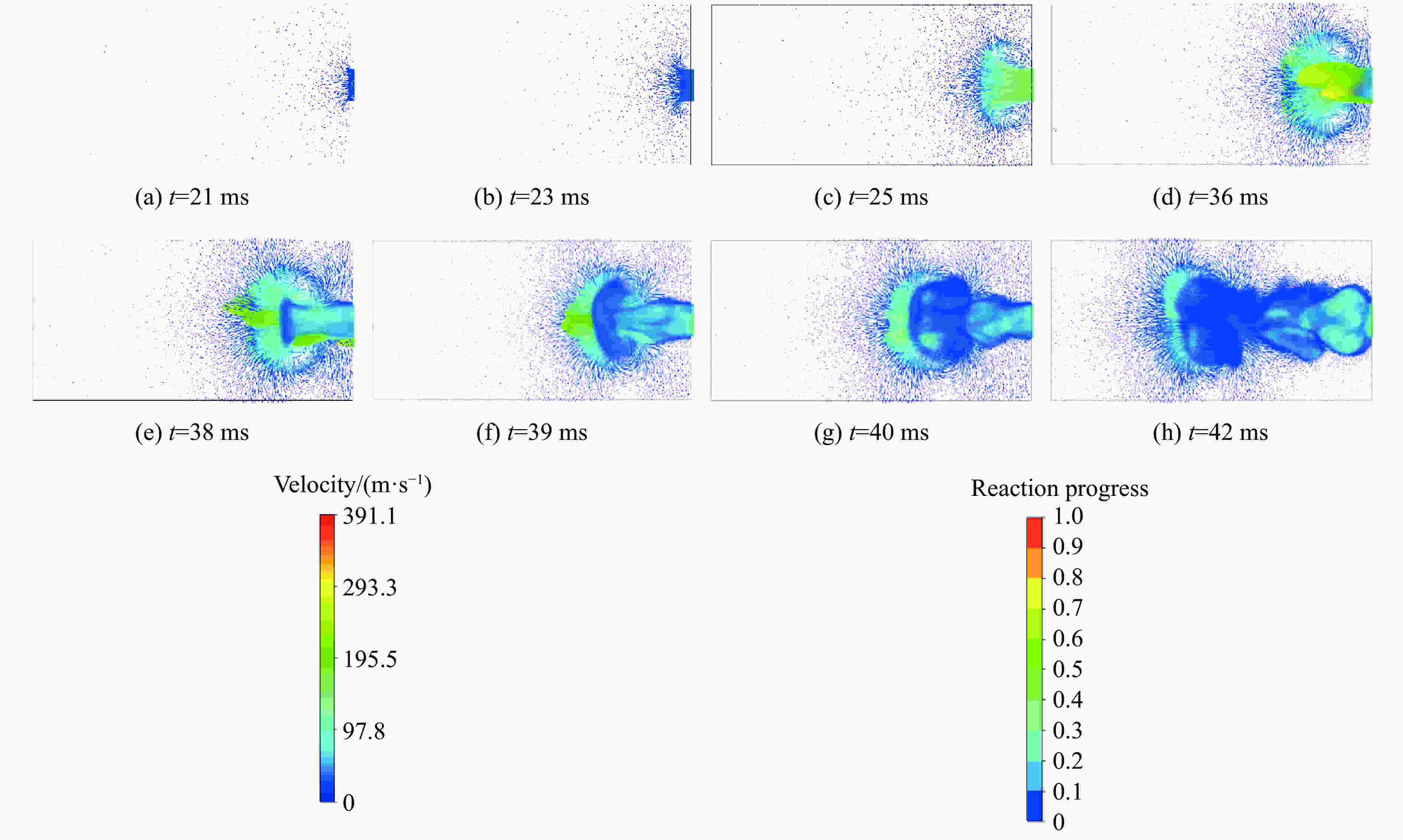

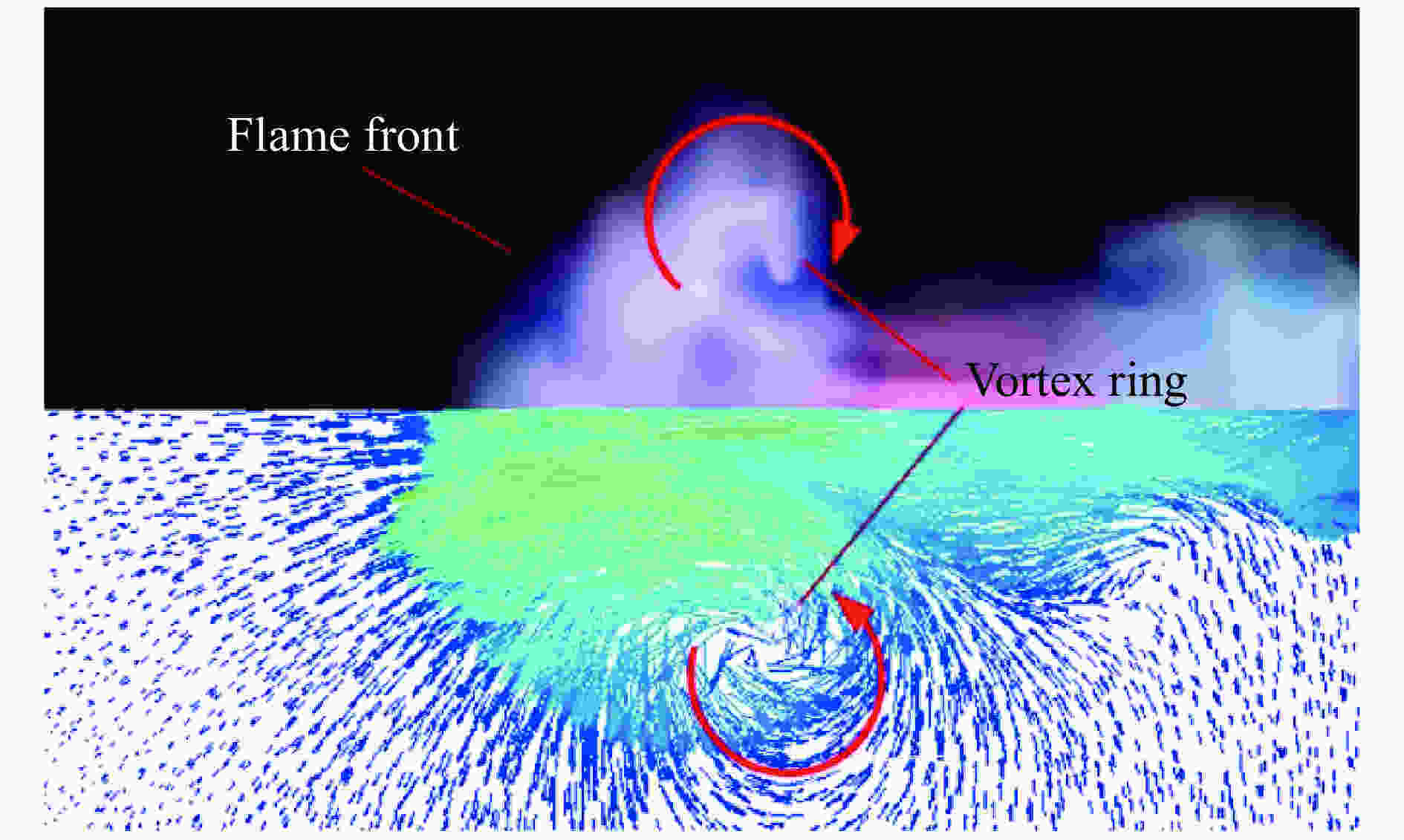

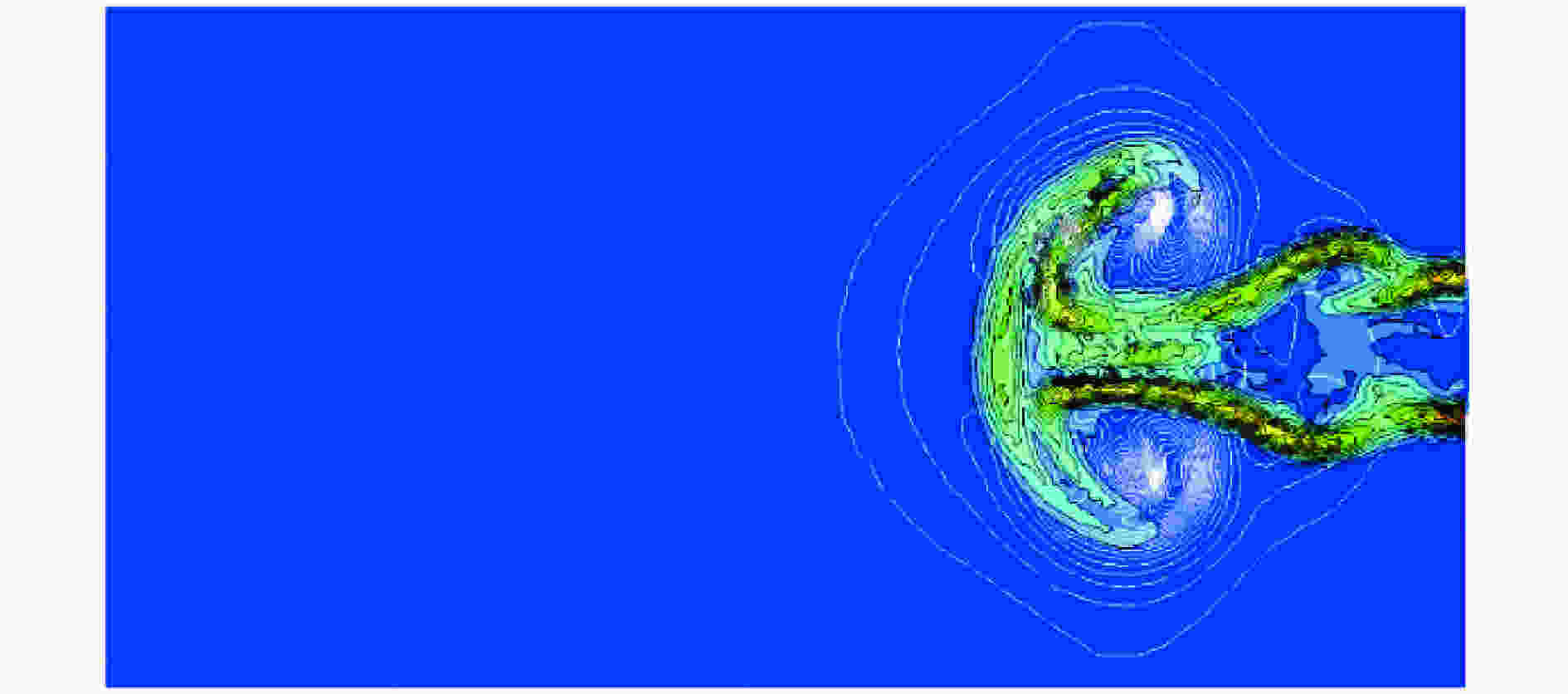

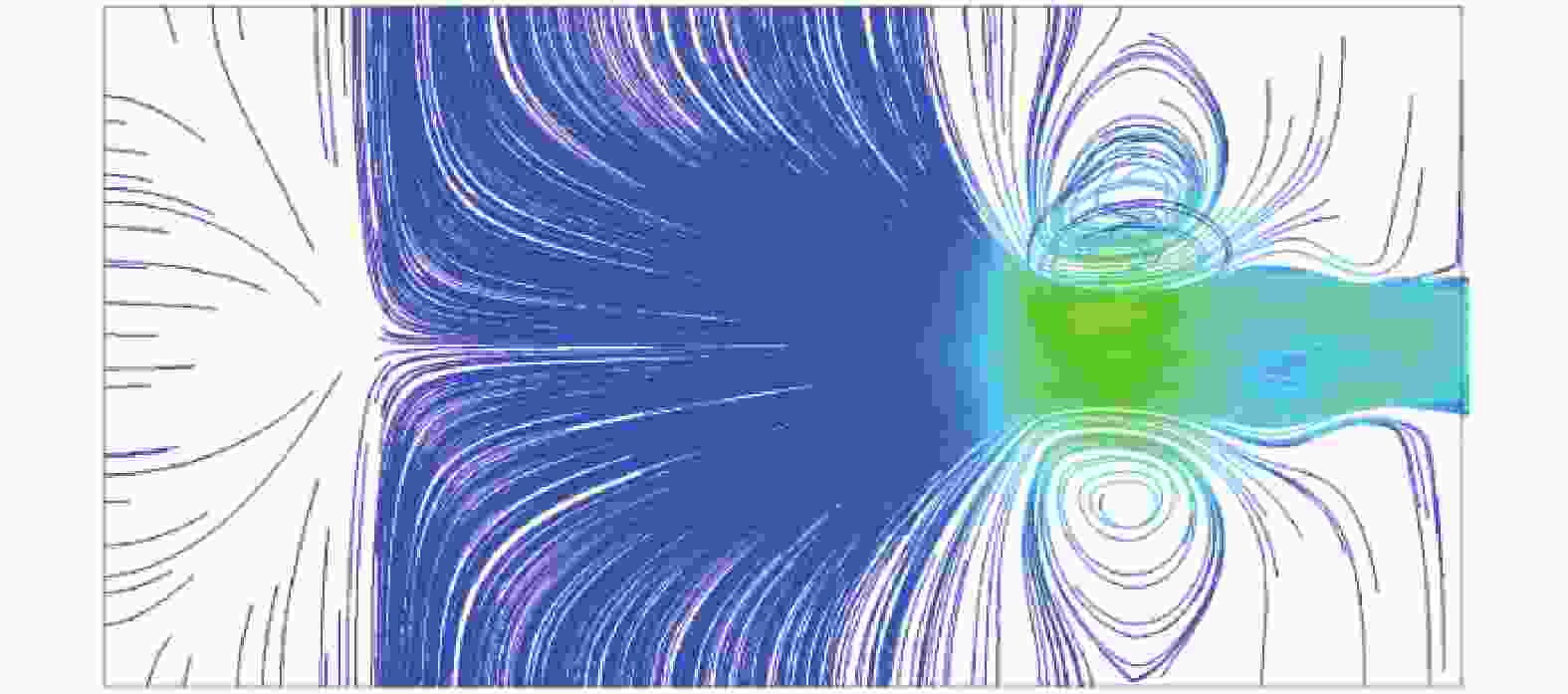

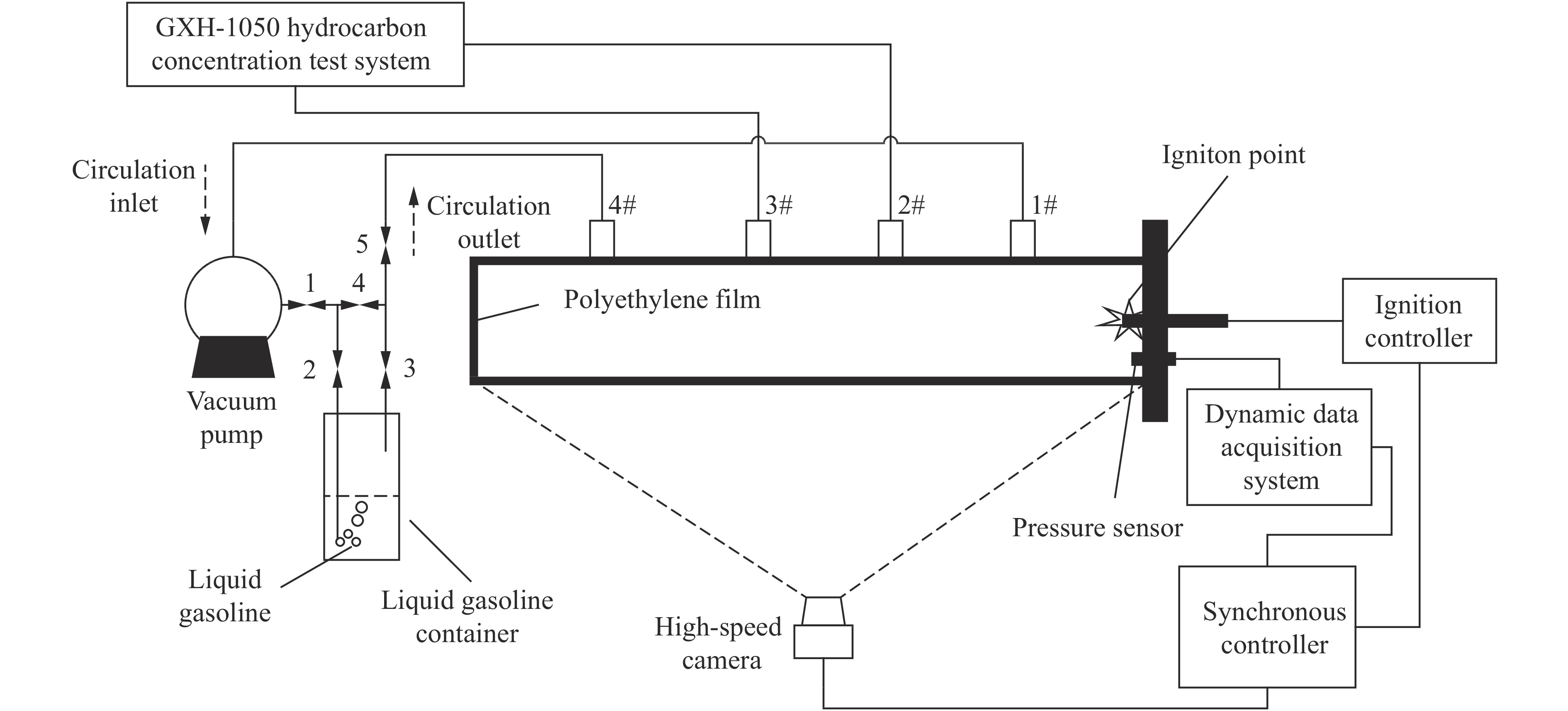

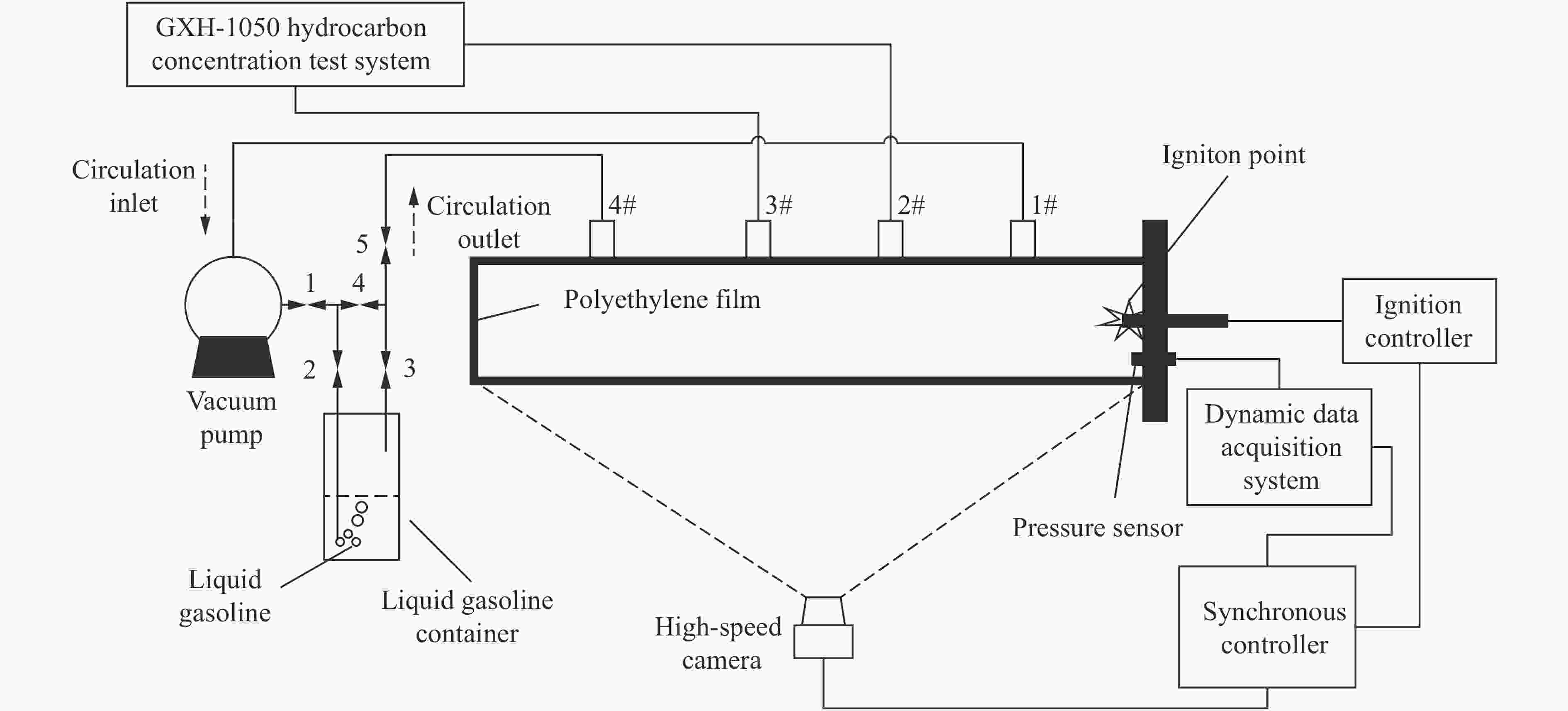

摘要: 为研究汽油-空气混合气体密闭爆炸和泄爆特性,采用可视化方管进行了两种爆炸模式实验研究,并基于壁面自适应局部涡黏(wall-adapting local eddy-viscosity,WALE)模型和Zimont预混火焰模型进行了数值模拟研究。结果表明:(1)泄爆工况超压-时序曲线峰值数量多于密闭爆炸工况,且泄爆工况超压-时序曲线存在剧烈的类似简谐振动的振荡,而密闭爆炸工况的爆炸超压特征参数显著高于泄爆工况;(2)密闭爆炸工况最大火焰传播速度明显小于泄爆工况,但前者在火焰传播初期即达到最大值,而后者在火焰传播末期才达到最大值;(3)密闭爆炸工况出现郁金香形火焰,而泄爆工况出现蘑菇形火焰,郁金香火焰的形成与管道内火焰锋面、流场和流场动压三者之间耦合效应相关,蘑菇形火焰由外部流场湍流和斜压效应的共同作用引起。Abstract: In order to investigate the closed explosion and venting characteristics of gasoline-air mixture, two kinds of explosion modes were studied by using a visualized square tube, and numerical simulation was carried out based on the wall-adapting local eddy-viscosity (WALE) model and Zimont premixed flame model. The results show the followings. (1) The number of the peaks on the overpressure time series curve for the vented explosion is greater than that for the closed explosion, and there is a violent oscillation similar to a simple harmonic vibration on the overpressure time series curve of the vented explosion, while the characteristic parameters of explosion overpressure in the closed explosion are significantly higher than those in the vented explosion. (2) The maximum flame propagation speed in the closed explosion is significantly lower than that in the vented explosion, but the former reaches the maximum at the beginning of flame propagation, while the latter reaches the maximum at the end of flame propagation. (3) Tulip-shaped flame appears in the closed explosion condition, while mushroom-shaped flame appears in the venting condition. The formation of the tulip-shaped flame is related to the coupling effects of flame front, flow field and dynamic pressure of flow field in the pipe, while the mushroom-shaped flame is caused by the combined action of turbulence and baroclinic effect in the external flow field.

-

Key words:

- closed explosion /

- vented explosion /

- gasoline-air mixture /

- explosion overpressure /

- flame propagation

-

表 1 密闭爆炸和泄爆工况下管道内最大爆炸超压峰值、形成最大爆炸超压峰值时间、平均升压速率和最大升压速率

Table 1. Maximum explosion overpressure peaks, arrival times of maximum explosion overpressures peaks, average pressure increasing rate and maximum pressure increasing rate in the tube under closed and vented explosions

工况 pmax/kPa tmax/ms (dp/dt)ave/(kPa·s−1) (dp/dt)max/(MPa·s−1) 密闭爆炸 523.0 215.0 310 24.40 泄爆 9.6 30.6 240 6.81 -

[1] HASSLBERGER J, KIM H K, KIM B J, et al. Three-dimensional CFD analysis of hydrogen-air-steam explosions in APR1400 containment [J]. Nuclear Engineering and Design, 2017, 320: 386–399. DOI: 10.1016/j.nucengdes.2017.06.014. [2] LI H W, GUO J, TANG Z S, et al. Effects of ignition, obstacle, and side vent locations on vented hydrogen-air explosions in an obstructed duct [J]. International Journal of Hydrogen Energy, 2019, 44(36): 20598–20605. DOI: 10.1016/j.ijhydene.2019.06.029. [3] MUKHIM E D, ABBASI T, TAUSEEF S M, et al. A method for the estimation of overpressure generated by open air hydrogen explosions [J]. Journal of Loss Prevention in the Process Industries, 2018, 52: 99–107. DOI: 10.1016/j.jlp.2018.01.009. [4] VAAGSAETHER K, GAATHAUG A V, BJERKETVEDT D. PIV-measurements of reactant flow in hydrogen-air explosions [J]. International Journal of Hydrogen Energy, 2019, 44(17): 8799–8806. DOI: 10.1016/j.ijhydene.2018.10.025. [5] WANG L Q, MA H H, SHEN Z W. On the explosion characteristics of hydrogen-air mixtures in a constant volume vessel with an orifice plate [J]. International Journal of Hydrogen Energy, 2019, 44(12): 6271–6277. DOI: 10.1016/j.ijhydene.2019.01.074. [6] 郑凯. 管道中氢气/甲烷混合燃料爆燃预混火焰传播特征研究[D]. 重庆: 重庆大学, 2017.ZHENG K. Study on the propagation characteristics of premixed flame of hydrogen/methane deflagration in ducts [D]. Chongqing: Chongqing University, 2017. [7] XIAO H H, MAKAROV D, SUN J H, et al. Experimental and numerical investigation of premixed flame propagation with distorted tulip shape in a closed duct [J]. Combustion and Flame, 2012, 159(4): 1523–1538. DOI: 10.1016/j.combustflame.2011.12.003. [8] ZHANG S H, ZHANG Q. Effect of vent size on vented hydrogen-air explosion [J]. International Journal of Hydrogen Energy, 2018, 43(37): 17788–17799. DOI: 10.1016/j.ijhydene.2018.07.194. [9] ZHANG Y, JIAO F Y, HUANG Q, et al. Experimental and numerical studies on the closed and vented explosion behaviors of premixed methane-hydrogen/air mixtures [J]. Applied Thermal Engineering, 2019, 159: 113907. DOI: 10.1016/j.applthermaleng.2019.113907. [10] ZHENG L G, DOU Z G, DU D P, et al. Study on explosion characteristics of premixed hydrogen/biogas/air mixture in a duct [J]. International Journal of Hydrogen Energy, 2019, 44(49): 27159–27173. DOI: 10.1016/j.ijhydene.2019.08.156. [11] HJERTAGER B H, FUHRE K, BJØRKHAUG M. Concentration effects on flame acceleration by obstacles in large-scale methane-air and propane-air vented explosions [J]. Combustion Science and Technology, 1988, 62(4−6): 239–256. DOI: 10.1080/00102208808924011. [12] KUNDU S, ZANGANEH J, MOGHTADERI B. A review on understanding explosions from methane-air mixture [J]. Journal of Loss Prevention in the Process Industries, 2016, 40: 507–523. DOI: 10.1016/j.jlp.2016.02.004. [13] BAUWENS C R, CHAO J, DOROFEEV S B. Effect of hydrogen concentration on vented explosion overpressures from lean hydrogen-air deflagrations [J]. International Journal of Hydrogen Energy, 2012, 37(22): 17599–17605. DOI: 10.1016/j.ijhydene.2012.04.053. [14] HISKEN H, ENSTAD G A, MIDDHA P, et al. Investigation of concentration effects on the flame acceleration in vented channels [J]. Journal of Loss Prevention in the Process Industries, 2015, 36: 447–459. DOI: 10.1016/j.jlp.2015.04.005. [15] QI S, DU Y, ZHANG P L, et al. Effects of concentration, temperature, humidity, and nitrogen inert dilution on the gasoline vapor explosion [J]. Journal of Hazardous Materials, 2017, 323: 593–601. DOI: 10.1016/j.jhazmat.2016.06.040. [16] 黄子超, 司荣军, 张延松, 等. 初始温度对瓦斯爆炸特性影响的数值模拟 [J]. 煤矿安全, 2012, 43(5): 5–7; 11. DOI: 10.13347/j.cnki.mkaq.2012.05.009.HUANG Z C, SI R J, ZHANG Y S, et al. Numerical simulation of the influence of initial temperature on gas explosion characteristics [J]. Safety in Coal Mines, 2012, 43(5): 5–7; 11. DOI: 10.13347/j.cnki.mkaq.2012.05.009. [17] 姚洁, 蒋军成, 潘勇. 初始温度对可燃气体爆炸下限影响的研究 [J]. 工业安全与环保, 2012, 38(2): 48–50. DOI: 10.3969/j.issn.1001-425X.2012.02.017.YAO J, JIANG J C, PAN Y. The effect of initial temperature on lower explosion limit of flammable gas [J]. Industrial Safety and Environmental Protection, 2012, 38(2): 48–50. DOI: 10.3969/j.issn.1001-425X.2012.02.017. [18] GAO N. Effect of initial temperature on free radicals of gas explosion in restricted space [J]. Advanced Materials Research, 2013, 798−799: 138–142. DOI: 10.4028/www.scientific.net/AMR.798-799.138. [19] GRABARCZYK M, TEODORCZYK A, DI SARLI V, et al. Effect of initial temperature on the explosion pressure of various liquid fuels and their blends [J]. Journal of Loss Prevention in the Process Industries, 2016, 44: 775–779. DOI: 10.1016/j.jlp.2016.08.013. [20] 高娜. 初始温度和初始压力对瓦斯爆炸特性的影响研究[D]. 南京: 南京理工大学, 2016.GAO N. Study on influence of initial temperature and pressure on gas explosion characteristics [D]. Nanjing: Nanjing University of Science and Technology, 2016. [21] 杜扬, 李国庆, 吴松林, 等. T型分支管道对油气爆炸强度的影响 [J]. 爆炸与冲击, 2015, 35(5): 729–734. DOI: 10.11883/1001-1455(2015)05-0729-06.DU Y, LI G Q, WU S L, et al. Explosion intensity of gasoline-air mixture in the pipeline containing a T-shaped branch pipe [J]. Explosion and Shock Waves, 2015, 35(5): 729–734. DOI: 10.11883/1001-1455(2015)05-0729-06. [22] 陈鹏, 李艳超, 黄福军, 等. 方孔障碍物对瓦斯火焰传播影响的实验与大涡模拟 [J]. 爆炸与冲击, 2017, 37(1): 21–26. DOI: 10.11883/1001-1455(2017)01-0021-06.CHEN P, LI Y C, HUANG F J, et al. LES approach to premixed methane/air flame propagating in the closed duct with a square-hole obstacle [J]. Explosion and Shock Waves, 2017, 37(1): 21–26. DOI: 10.11883/1001-1455(2017)01-0021-06. [23] 王公忠, 张建华, 李登科, 等. 障碍物对预混火焰特性影响的大涡数值模拟 [J]. 爆炸与冲击, 2017, 37(1): 68–76. DOI: 10.11883/1001-1455(2017)01-0068-09.WANG G Z, ZHANG J H, LI D K, et al. Large eddy simulation of impacted obstacles’ effects on premixed flame’s characteristics [J]. Explosion and Shock Waves, 2017, 37(1): 68–76. DOI: 10.11883/1001-1455(2017)01-0068-09. [24] 王亚磊, 郑立刚, 于水军, 等. 约束端面对管内甲烷爆炸特性的影响 [J]. 爆炸与冲击, 2019, 39(9): 095401. DOI: 10.11883/bzycj-2018-0249.WANG Y L, ZHENG L G, YU S J, et al. Effect of vented end faces on characteristics of methane explosion in duct [J]. Explosion and Shock Waves, 2019, 39(9): 095401. DOI: 10.11883/bzycj-2018-0249. [25] 杜扬, 李国庆, 王世茂, 等. 障碍物数量对油气泄压爆炸特性的影响 [J]. 化工学报, 2017, 68(7): 2946–2955.DU Y, LI G Q, WANG S M, et al. Effects of obstacle number on characteristics of vented gasoline-air mixture explosions [J]. CIESC Journal, 2017, 68(7): 2946–2955. [26] LI G Q, DU Y, WANG S M, et al. Large eddy simulation and experimental study on vented gasoline-air mixture explosions in a semi-confined obstructed pipe [J]. Journal of Hazardous Materials, 2017, 339: 131–142. DOI: 10.1016/j.jhazmat.2017.06.018. [27] 解茂昭, 贾明. 内燃机计算燃烧学[M]. 3版. 北京: 科学出版社, 2017. [28] 温小萍, 余明高, 邓浩鑫, 等. 小尺度受限空间内瓦斯湍流爆燃大涡模拟 [J]. 化工学报, 2016, 5(5): 1837–1843. DOI: 10.11949/j.issn.0438-1157.20151219.WEN X P, YU M G, DENG H X, et al. Large eddy simulation of gas turbulent deflagration in small-scale confined space [J]. CIESC Journal, 2016, 5(5): 1837–1843. DOI: 10.11949/j.issn.0438-1157.20151219. [29] WEN X P, YU M G, LIU Z C, et al. Large eddy simulation of methane-air deflagration in an obstructed chamber using different combustion models [J]. Journal of Loss Prevention in the Process Industries, 2012, 25(4): 730–738. DOI: 10.1016/j.jlp.2012.04.008. [30] LI G Q, DU Y, QI S, et al. Explosions of gasoline-air mixtures in a closed pipe containing a T-shaped branch structure [J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 529–536. DOI: 10.1016/j.jlp.2016.07.022. [31] MANNAA O, MANSOUR M S, ROBERTS W L, et al. Laminar burning velocities at elevated pressures for gasoline and gasoline surrogates associated with RON [J]. Combustion and Flame, 2015, 162(6): 2311–2321. DOI: 10.1016/j.combustflame.2015.01.004. [32] WEN X P, YU M G, JI W T, et al. Methane-air explosion characteristics with different obstacle configurations [J]. International Journal of Mining Science and Technology, 2015, 25(2): 213–218. DOI: 10.1016/j.ijmst.2015.02.008. [33] QI S, DU Y, WANG S M, et al. The effect of vent size and concentration in vented gasoline-air explosions [J]. Journal of Loss Prevention in the Process Industries, 2016, 44: 88–94. DOI: 10.1016/j.jlp.2016.08.005. [34] 温小萍. 瓦斯湍流爆燃火焰特性与多孔介质淬熄抑爆机理研究[D]. 大连: 大连理工大学, 2014.WEN X P. Mechanism study on flame characteristics and porous media quenching suppression of gas turbulent deflagration [D]. Dalian: Dalian University of Technology, 2014. [35] DUNN-RANKIN D, BARR P K, SAWYER R F. Numerical and experimental study of “tulip” flame formation in a closed vessel [J]. Symposium (International) on Combustion, 1988, 21(1): 1291–1301. DOI: 10.1016/S0082-0784(88)80360-6. [36] GONZALEZ M, BORGHI R, SAOUAB A. Interaction of a flame front with its self-generated flow in an enclosure: the “tulip flame” phenomenon [J]. Combustion and Flame, 1992, 88(2): 201–220. DOI: 10.1016/0010-2180(92)90052-Q. [37] 肖华华. 管道中氢-空气预混火焰传播动力学实验与数值模拟研究[D]. 合肥: 中国科学技术大学, 2013.XIAO H H. Experimental and numerical study of dynamics of premixed hydrogen-air flame propagating in ducts [D]. Hefei: University of Science and Technology of China, 2013. [38] ZHOU B, SOBIESIAK A, QUAN P. Flame behavior and flame-induced flow in a closed rectangular duct with a 90° bend [J]. International Journal of Thermal Sciences, 2006, 45(5): 457–474. DOI: 10.1016/j.ijthermalsci.2005.07.001. [39] 姜孝海. 泄爆外流场的动力学机理研究[D]. 南京: 南京理工大学, 2004.JIANG X H. Study on the dynamics of the external flowfield during venting [D]. Nanjing: Nanjing University of Science and Technology, 2004. -

下载:

下载: