Energy absorption capacity of regular polygon-based multi-cell tubes

-

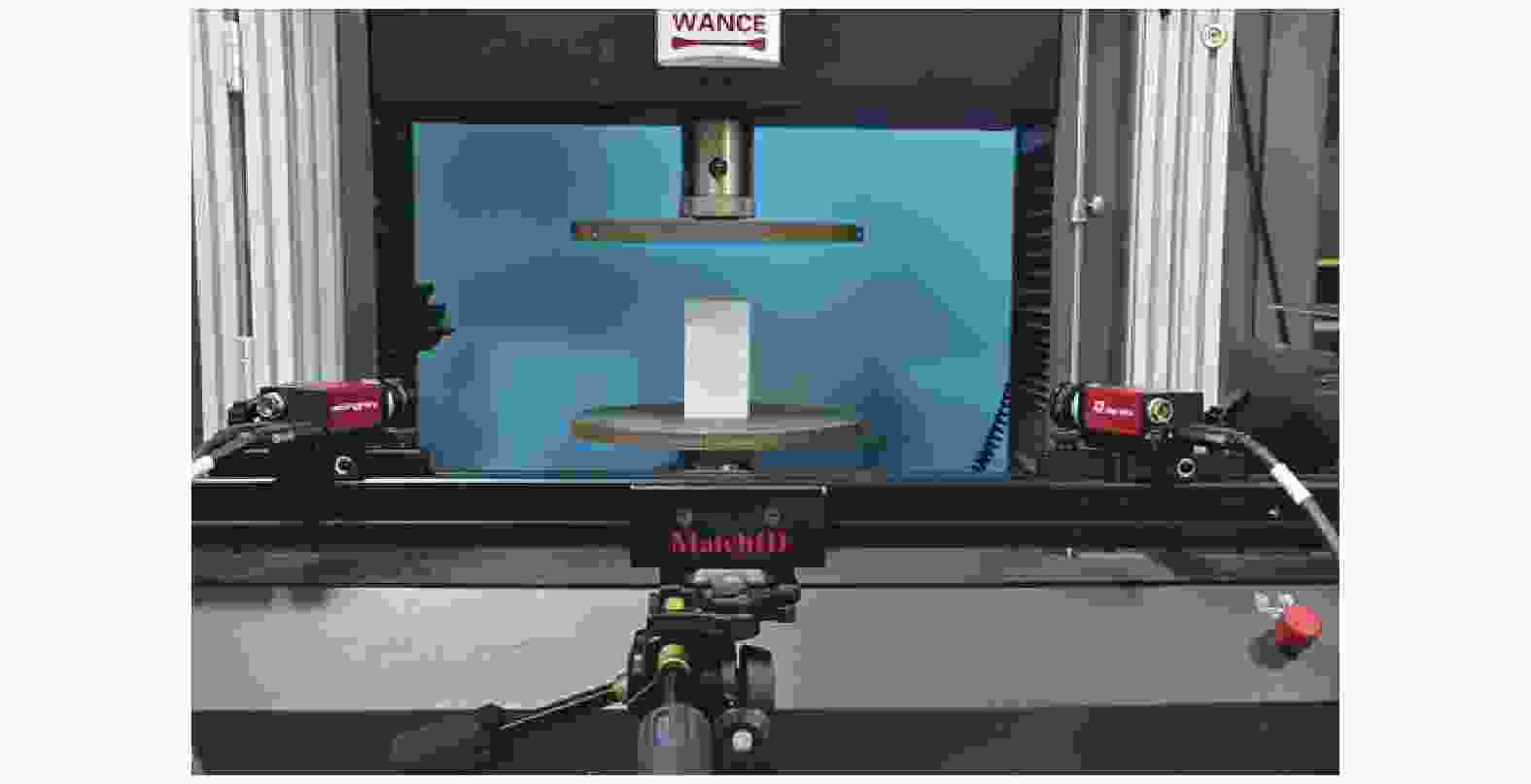

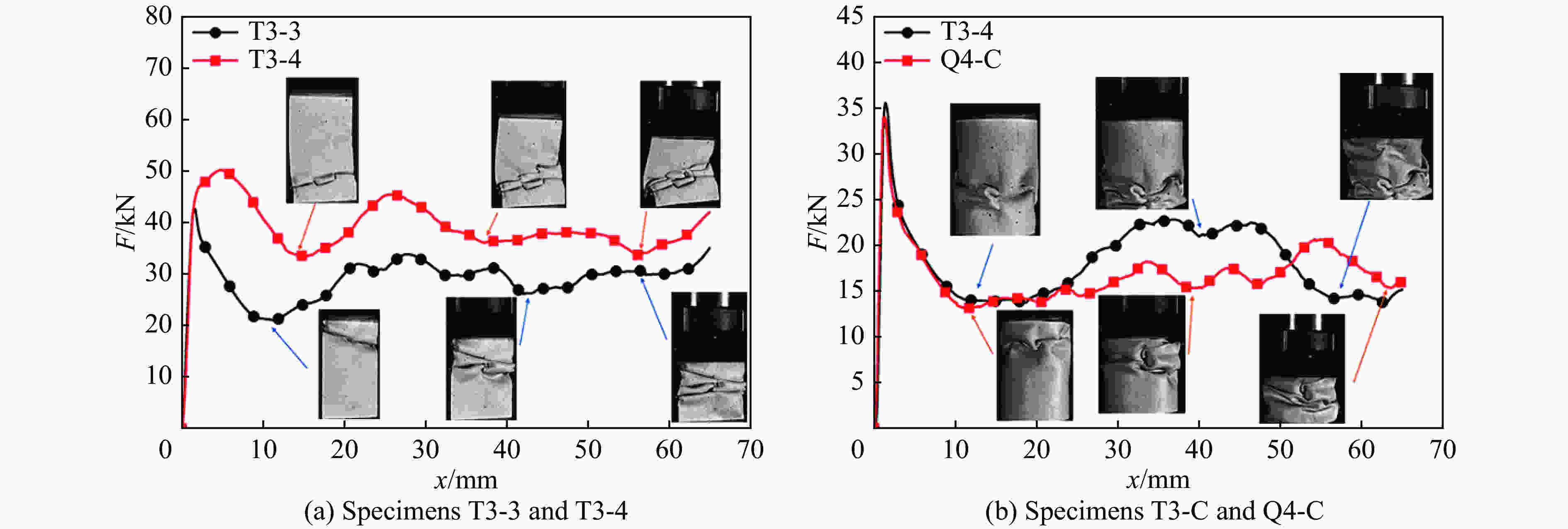

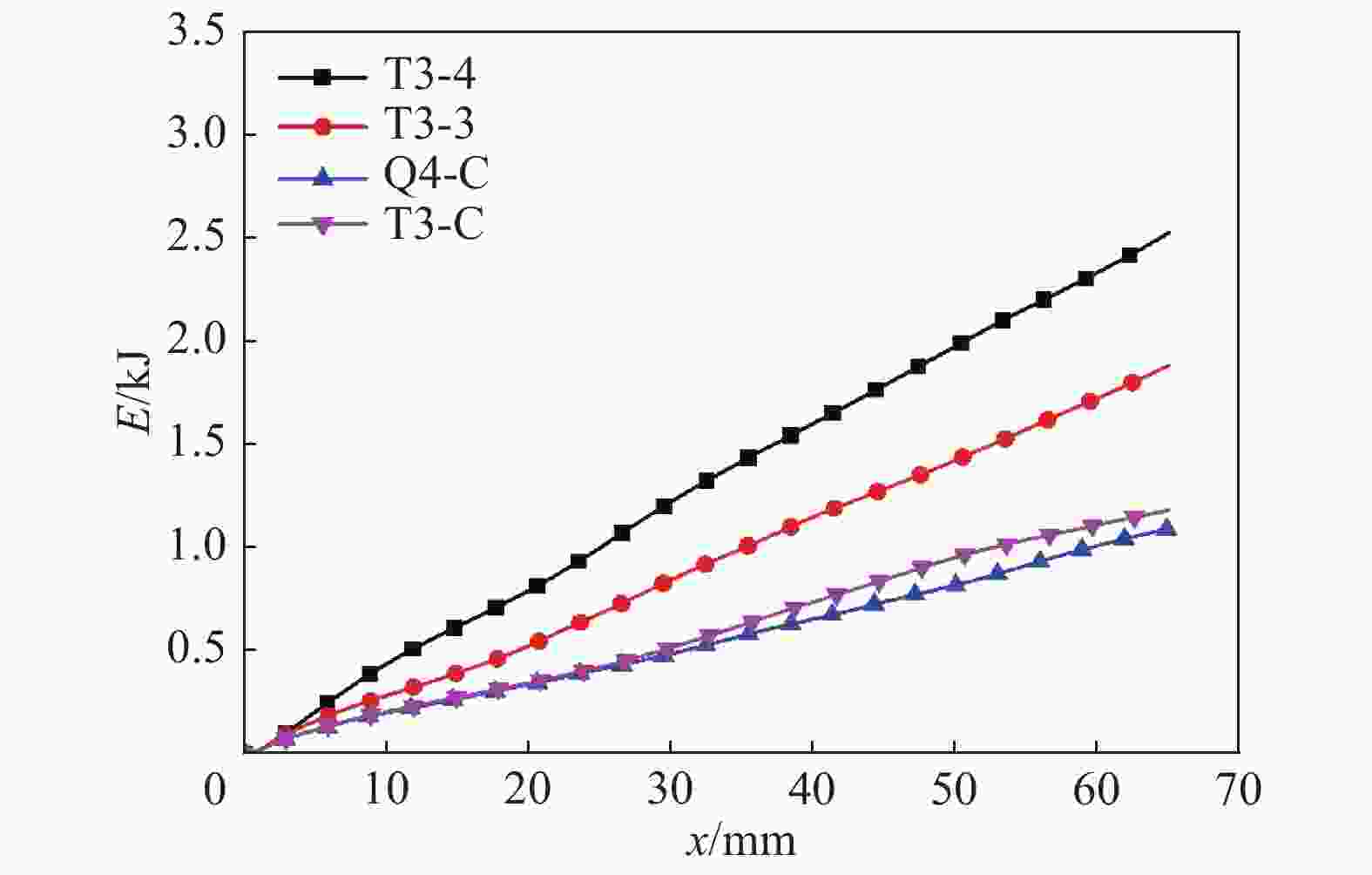

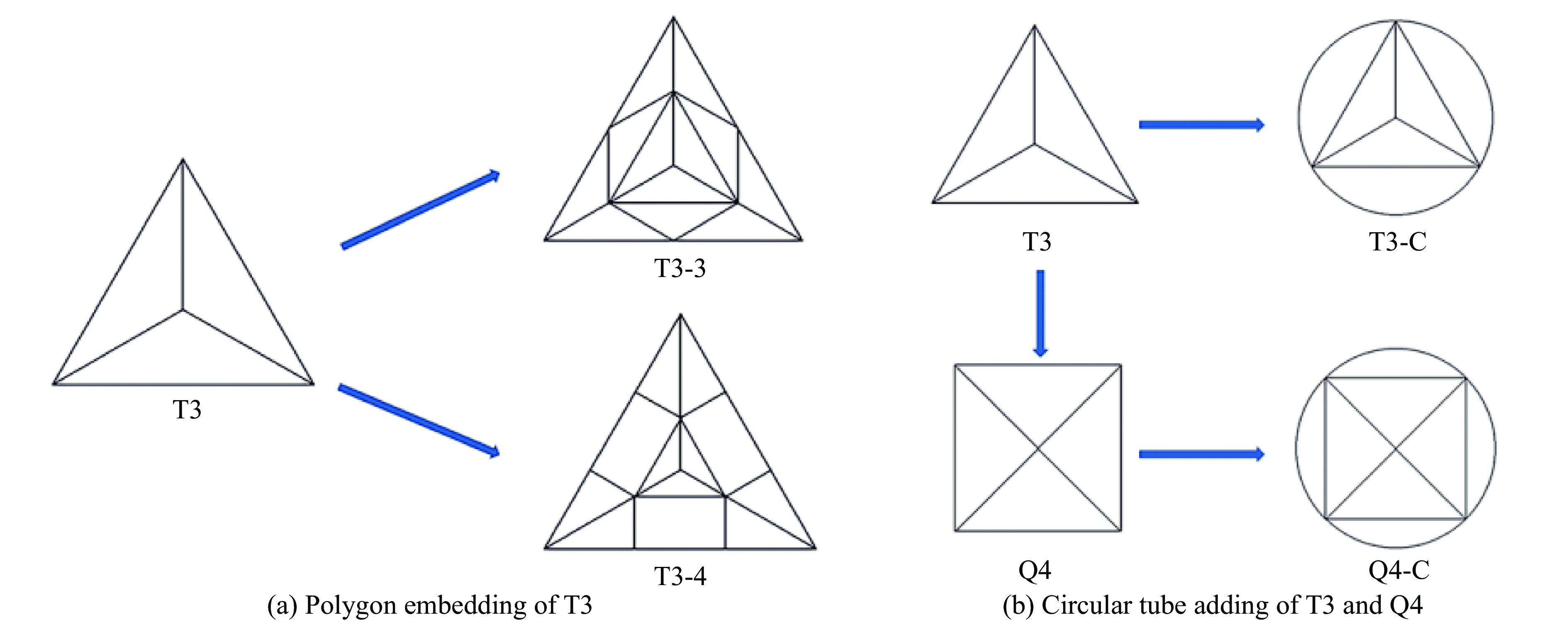

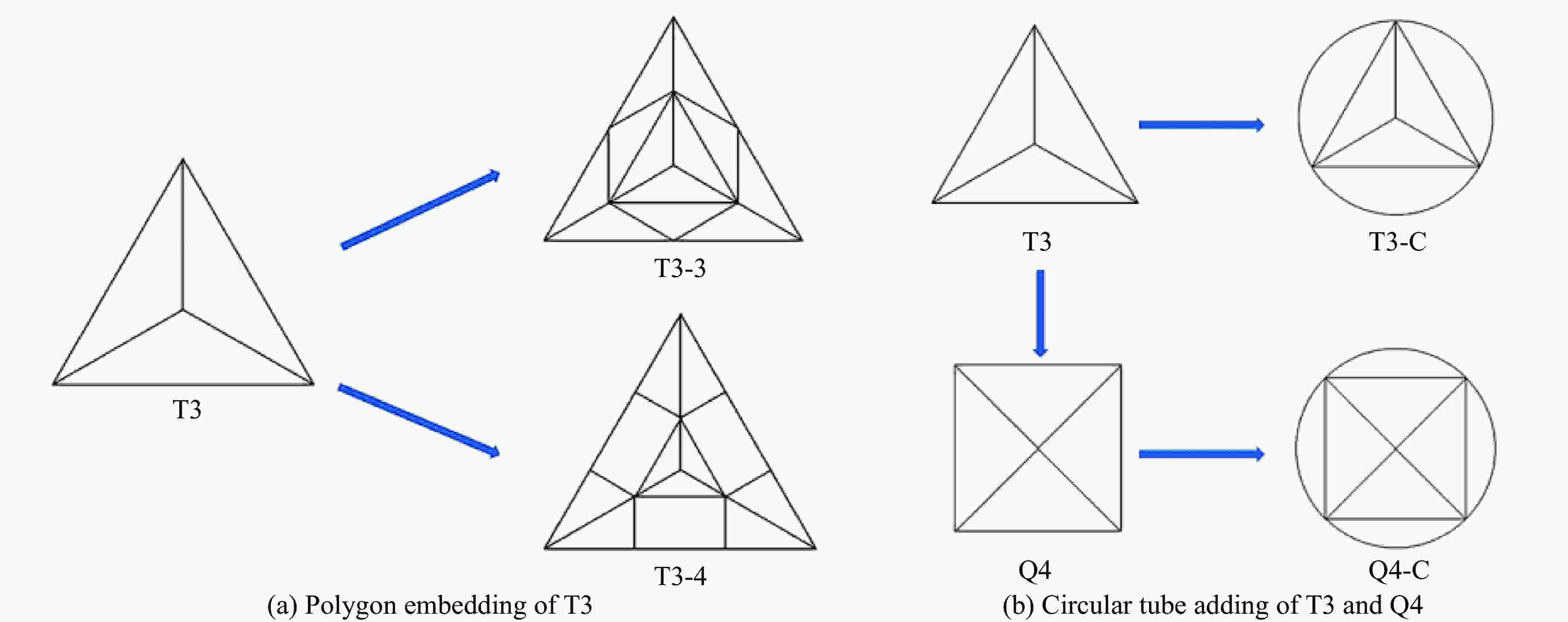

摘要: 多胞薄壁结构具有轻量化、高比吸能的特点,在汽车、轮船、航空航天等领域得到了广泛的应用。已有研究表明结构的耐撞性与结构的拓扑方式及胞元数量密切相关。为了研究结构形状和拓扑优化对其吸能效果的影响,基于正多边形结构,通过内嵌多边形和外接圆管的方式设计了两类新型多胞薄壁结构,并对这两类多胞薄壁结构进行准静态和落锤冲击实验,利用高速相机记录结构的变形模式,并定量分析了结构的吸能特性。实验结果表明:除正三角形二级内嵌四边形所得结构在准静态加载实验后期出现了局部失稳现象外,其余结构在准静态和落锤冲击实验过程中均保持垂直受压,结构变形模式与吸能效果较好。通过比较两类结构的实验结果得出:不论是在准静态加载还是在落锤冲击的情况下,内嵌多边形结构的各项吸能指标都明显优于外接圆管的结构;同等质量的情况下,内嵌四边形结构的吸能效果明显优于内嵌三角形的结构。Abstract: With the characteristics of light weight and high specific energy absorption, multi-cell thin-wall structures have been widely used in automobile, ship, aerospace and other fields. Previous studies have shown that the crashworthiness of a structure is closely related to its topology and cell number. In order to study the influence of the structural shape and topology optimization on energy absorption, based on regular polygon structures, two kinds of new multi-cell thin-wall structures were designed by embedding polygons in the basic structures given and circumscribing circular tubes to them, respectively. Meanwhile, quasi-static compression and drop-hammer impact tests were carried out on the two kinds of multi-cell thin-wall structures. The deformation modes of the structures were captured by high-speed cameras, and their energy absorption characteristics were studied quantitatively. The experimental results show that local instability occurred in the structures obtained by second-order embedding quadrangles into the basic regular triangle tubes in the later stage of the quasi-static loading test; the other structures were compressed vertically in the quasi-static compression and drop hammer impact tests, and their corresponding deformation modes and energy absorption capacities were excellent. By comparing the experimental results of two kinds of structures, following conclusions are drawn: the energy absorption of the polygon-embedded structures is obviously higher than that of the structures by externally circumscribing a circular tube under quasi-static loading and drop hammer impact tests; the energy absorption performance of the quadrangle-embedded structure is obviously better than that of the triangle-embedded structure with the same mass.

-

表 1 准静态加载下的吸能性能指标(加载速度为5 mm/min,压缩位移为65 mm)

Table 1. Energy absorption parameters under quasi-static axial compression (the loading speed is 5 mm/min and the final displacement is 65 mm)

试件编号 试件质量/kg 总吸能/kJ 峰值力/kN 平均压缩力/kN 压缩力效率 比吸能/(kJ·kg−1) T3-3 0.107 1.88 42.74 28.92 0.68 17.57 T3-4 0.107 2.53 50.19 38.92 0.78 23.64 T3-C 0.113 1.18 35.61 18.15 0.51 10.44 Q4-C 0.113 1.09 34.06 16.77 0.49 9.65 表 2 落锤实验能量数据

Table 2. Energy data in axial impact tests

试件编号 落锤初始高度/mm 落锤重力势能/kJ 试件被压缩高度/mm 重力势能增量/kJ 总能量/kJ T3-3 1450 1.86 54.96 0.07 1.93 T3-4 2240 2.87 57.43 0.07 2.94 T3-C 733 0.94 44.98 0.06 1.00 Q4-C 954 1.22 55.01 0.07 1.29 表 3 落锤实验吸能性能指标

Table 3. Energy absorption parameters under axial impact

试件编号 质量/kg 总吸能/kJ 峰值力/kN 平均压缩力/kN 压缩力效率 单位位移比吸能/(kJ·kg−1·mm−1) T3-3 0.108 1.93 51.52 35.12 0.68 0.325 T3-4 0.107 2.94 70.20 51.19 0.73 0.478 T3-C 0.114 1.00 38.94 22.43 0.58 0.195 Q4-C 0.113 1.29 39.82 23.45 0.59 0.208 -

[1] 张涛, 吴英友, 朱显明, 等. 多边形截面薄壁管撕裂卷曲吸能研究 [J]. 爆炸与冲击, 2007, 27(3): 223–229. DOI: 10.11883/1001-1455(2007)03-0223-07.ZHANG T, WU Y Y, ZHU X M, et al. Energy absorption in splitting metal tubes with polygonal section [J]. Explosion and Shock Waves, 2007, 27(3): 223–229. DOI: 10.11883/1001-1455(2007)03-0223-07. [2] ALEXANDER J M. An approximate analysis of the collapse of thin cylindrical shells under axial loading [J]. The Quarterly Journal of Mechanics and Applied Mathematics, 1960, 13(1): 10–15. DOI: 10.1093/qjmam/13.1.10. [3] WIERZBICKI T, ABRAMOWICZ W. On the crushing mechanics of thin-walled structures [J]. Journal of Applied Mechanics, 1983, 50(4a): 727–734. DOI: 10.1115/1.3167137. [4] ABRAMOWICZ W, JONES N. Dynamic axial crushing of square tubes [J]. International Journal of Impact Engineering, 1984, 2(2): 179–208. DOI: 10.1016/0734-743X(84)90005-8. [5] ABRAMOWICZ W, JONES N. Dynamic progressive buckling of circular and square tubes [J]. International Journal of Impact Engineering, 1986, 4(4): 243–270. DOI: 10.1016/0734-743X(86)90017-5. [6] LANGSETH M, HOPPERSTAD O S. Static and dynamic axial crushing of square thin-walled aluminum extrusions [J]. International Journal of Impact Engineering, 1996, 18(7−8): 949–968. DOI: 10.1016/S0734-743x(96)00025-5. [7] CHEN W G, WIERZBICKI T. Relative merits of single-cell, multi-cell and foam-filled thin-walled structures in energy absorption [J]. Thin-Walled Structures, 2001, 39(4): 287–306. DOI: 10.1016/S0263-8231(01)00006-4. [8] KIM H S. New extruded multi-cell aluminum profile for maximum crash energy absorption and weight efficiency [J]. Thin-Walled Structures, 2002, 40(4): 311–327. DOI: 10.1016/S0263-8231(01)00069-6. [9] ZHANG X, CHENG G D, ZHANG H. Theoretical prediction and numerical simulation of multi-cell square thin-walled structures [J]. Thin-Walled Structures, 2006, 44(11): 1185–1191. DOI: 10.1016/j.tws.2006.09.002. [10] NAJAFI A, RAIS-ROHANI M. Mechanics of axial plastic collapse in multi-cell, multi-corner crush tubes [J]. Thin-Walled Structures, 2011, 49(1): 1–12. DOI: 10.1016/j.tws.2010.07.002. [11] TANG Z L, LIU S T, ZHANG Z H. Analysis of energy absorption characteristics of cylindrical multi-cell columns [J]. Thin-Walled Structures, 2013, 62: 75–84. DOI: 10.1016/j.tws.2012.05.019. [12] ALAVI NIA A, PARSAPOUR M. An investigation on the energy absorption characteristics of multi-cell square tubes [J]. Thin-Walled Structures, 2013, 68: 26–34. DOI: 10.1016/j.tws.2013.01.010. [13] HONG W, FAN H L, XIA Z C, et al. Axial crushing behaviors of multi-cell tubes with triangular lattices [J]. International Journal of Impact Engineering, 2014, 63: 106–117. DOI: 10.1016/j.ijimpeng.2013.08.007. [14] ZHANG X, ZHANG H. Axial crushing of circular multi-cell columns [J]. International Journal of Impact Engineering, 2014, 65: 110–125. DOI: 10.1016/j.ijimpeng.2013.12.002. [15] WU S Z, ZHENG G, SUN G Y, et al. On design of multi-cell thin-wall structures for crashworthiness [J]. International Journal of Impact Engineering, 2016, 88: 102–117. DOI: 10.1016/j.ijimpeng.2015.09.003. -

下载:

下载: