Mechanism of rock fragmentation by multi-hole blasting in highly-stressed rock masses

-

摘要: 深部岩体爆破破岩是爆炸荷载与高地应力共同作用的结果。基于一些简化假设,建立了一个高地应力岩体双孔爆破计算模型,采用光滑粒子流体力学-有限元方法耦合数值模拟方法,研究了高地应力作用下炮孔间裂纹的传播及贯通过程,分析了炮孔周围应力场动态演化过程与分布特征。研究结果表明:爆破引起的岩体开裂主要是环向动拉应力所致,地应力对岩体的压缩降低了炮孔周围环向动拉应力、缩短了环向动拉应力的作用时间,因而对爆炸致裂起抑制作用;静水地应力条件下多孔爆破时,垂直于炮孔连线方向传播的爆生裂纹更易受到地应力的抑制;对于高地应力岩体爆破,炮孔间的裂纹扩展长度随地应力水平的提高而减小,裂纹主要沿最大主应力方向扩展,因此沿最大主应力方向布置炮孔、缩短炮孔间距有利于炮孔间裂纹的连接贯通,形成良好的爆破开挖面。

-

关键词:

- 爆破 /

- 地应力 /

- 开裂 /

- 光滑粒子流体力学-有限元方法耦合数值模拟方法

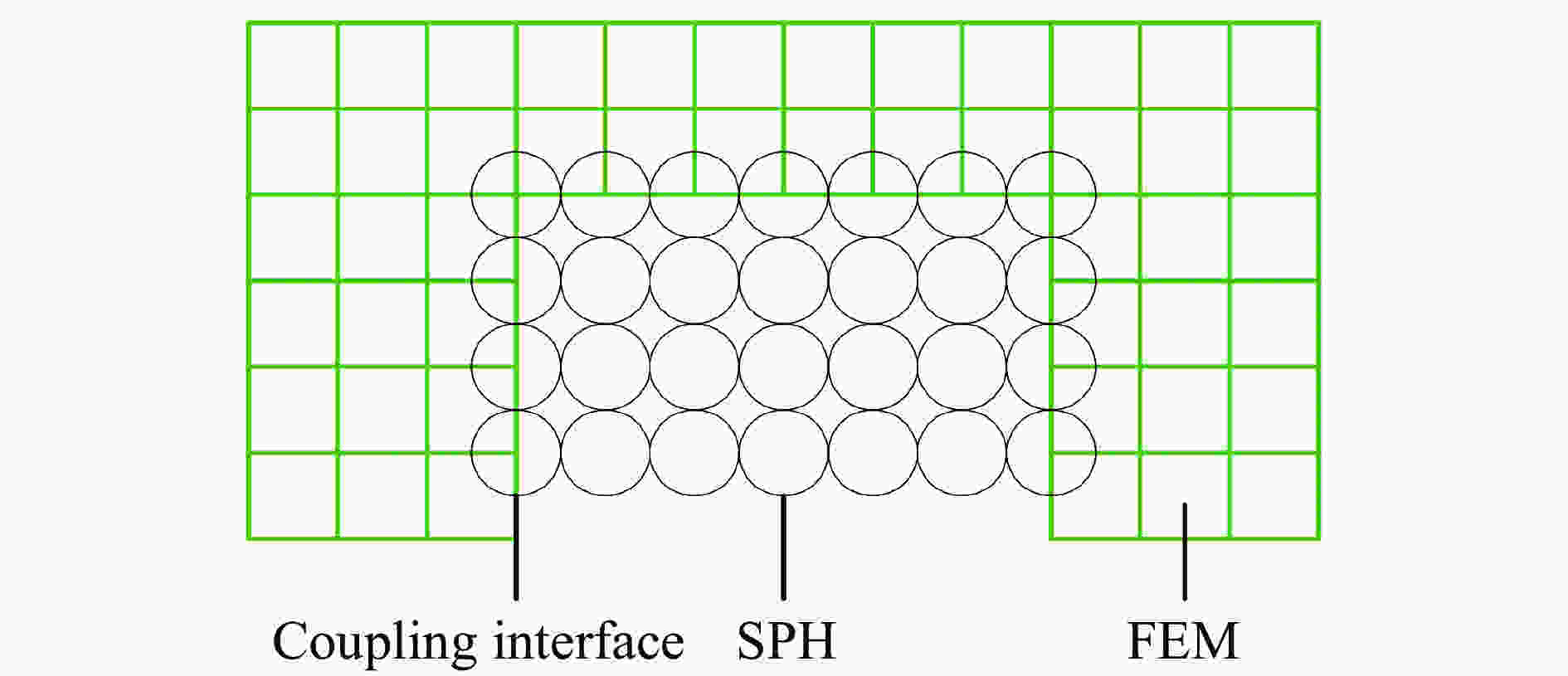

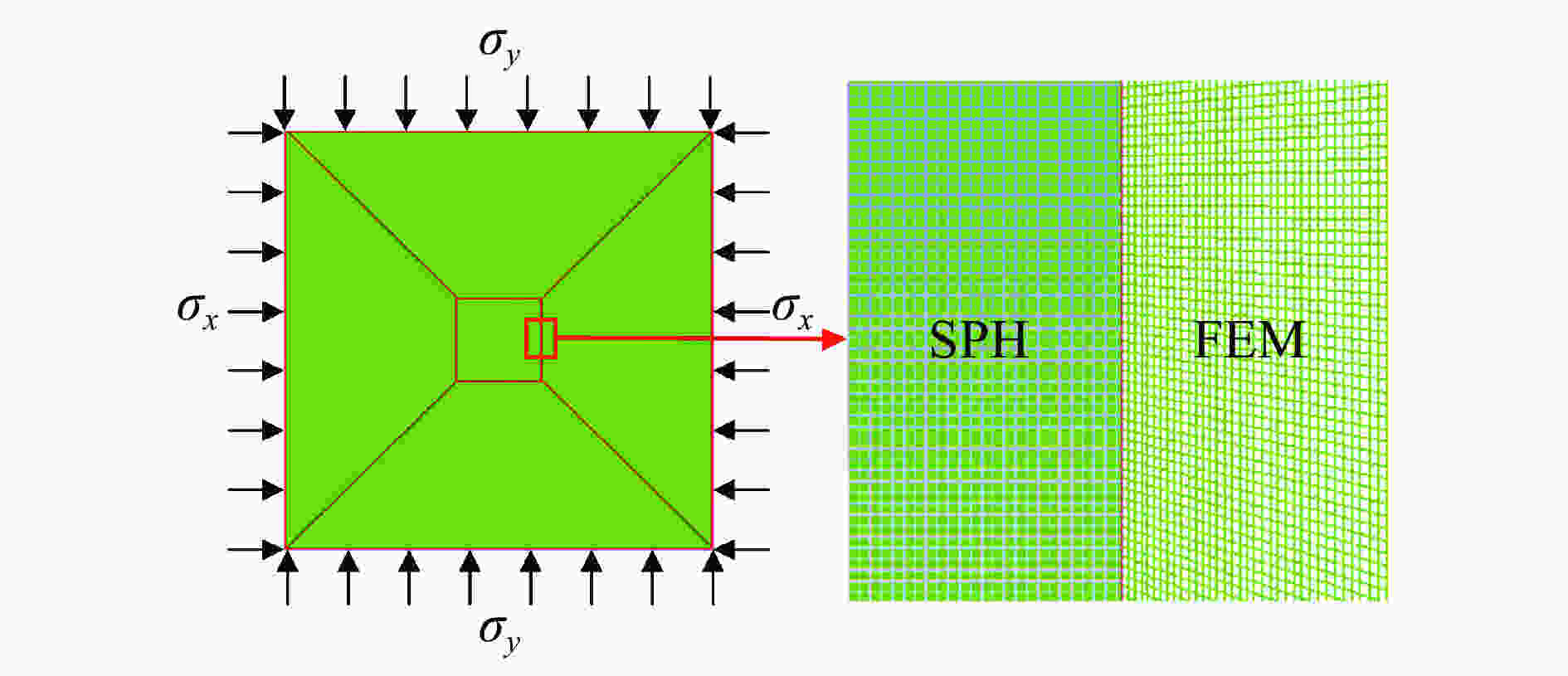

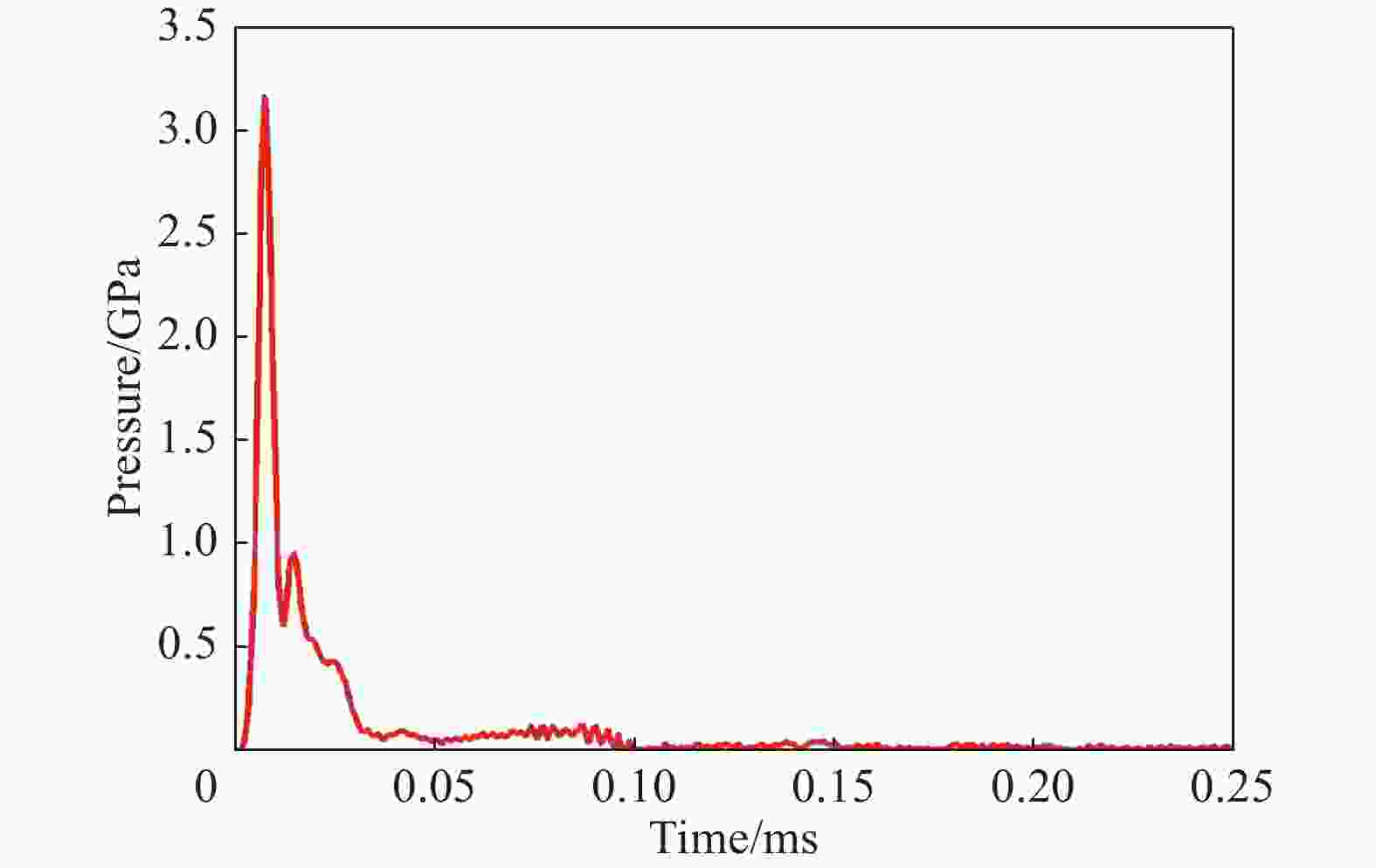

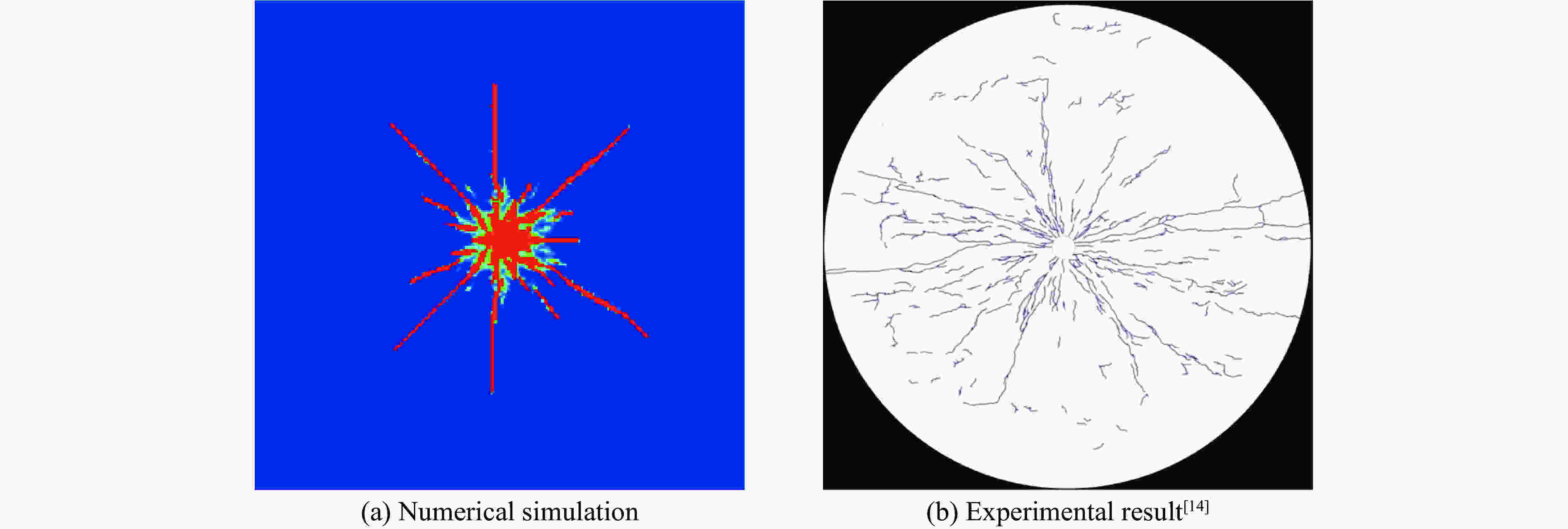

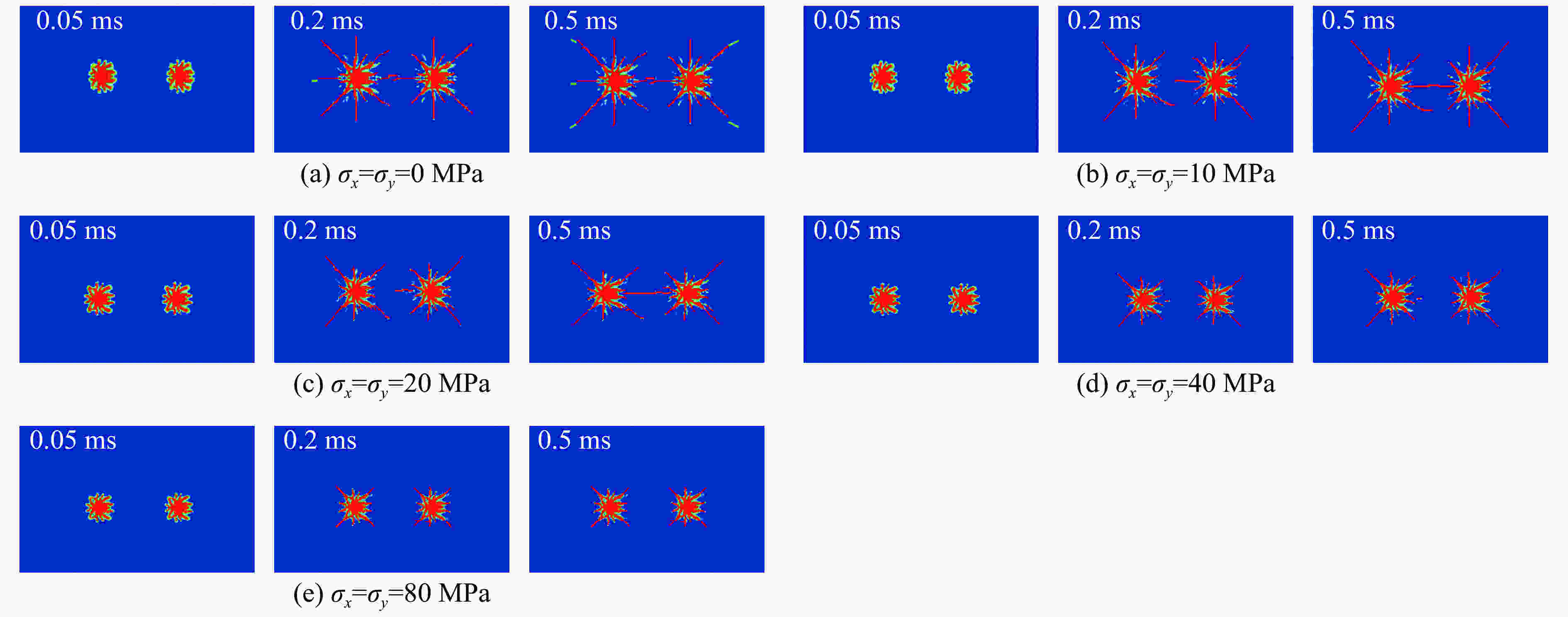

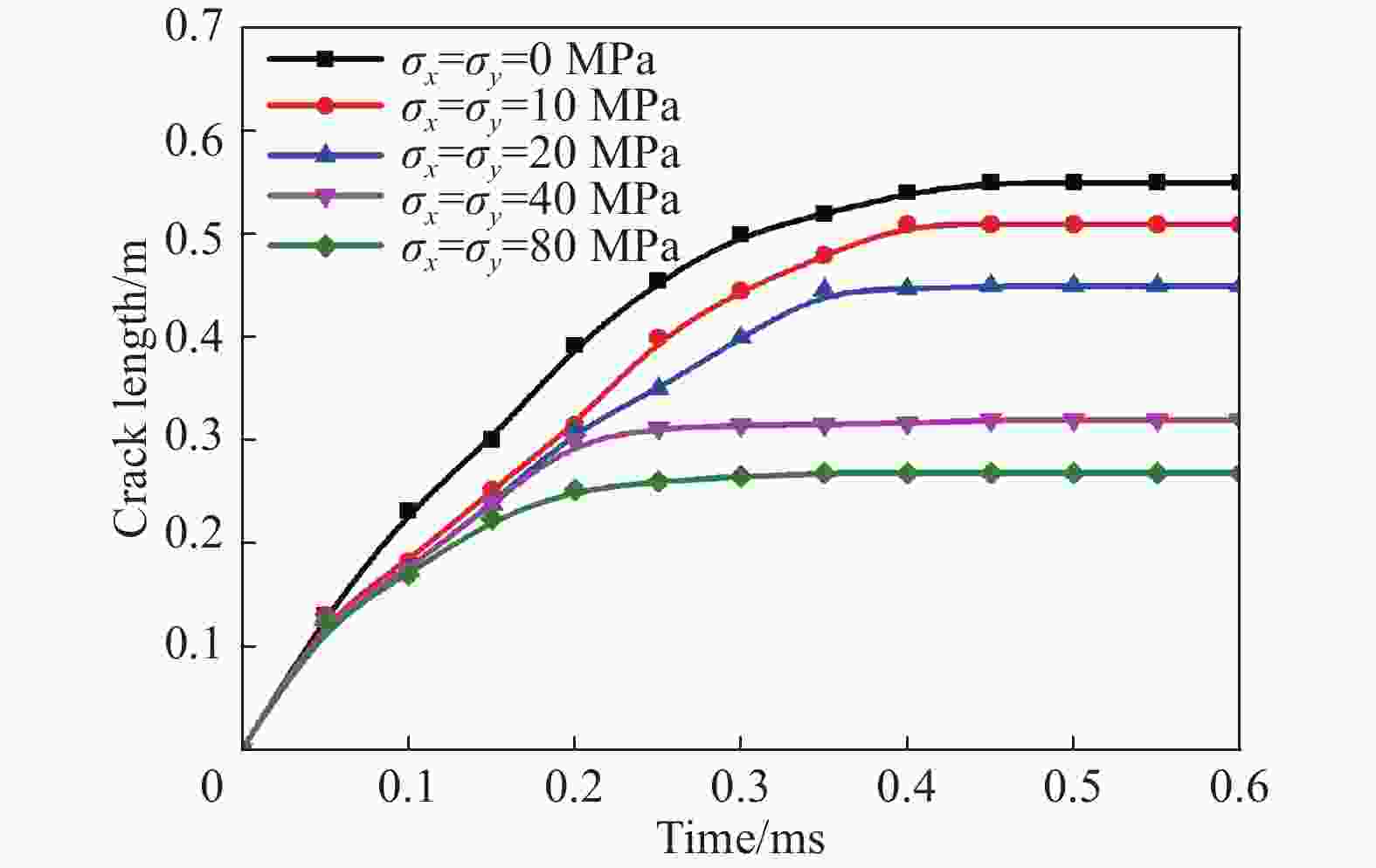

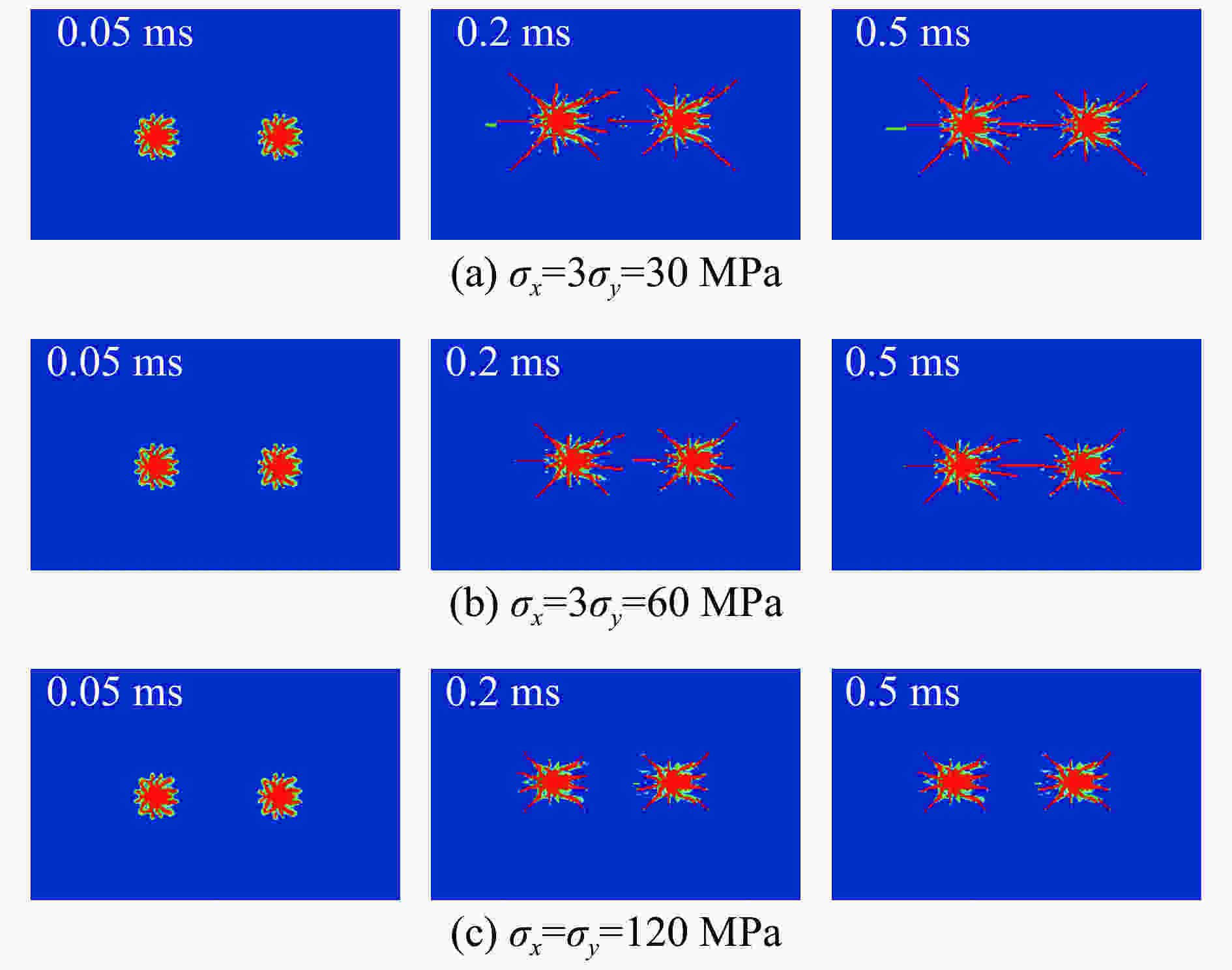

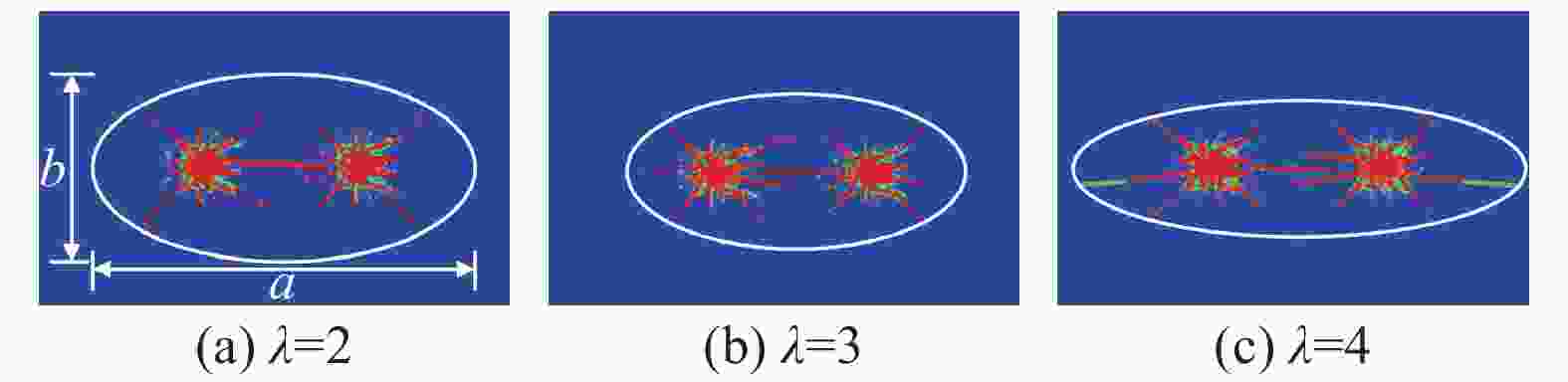

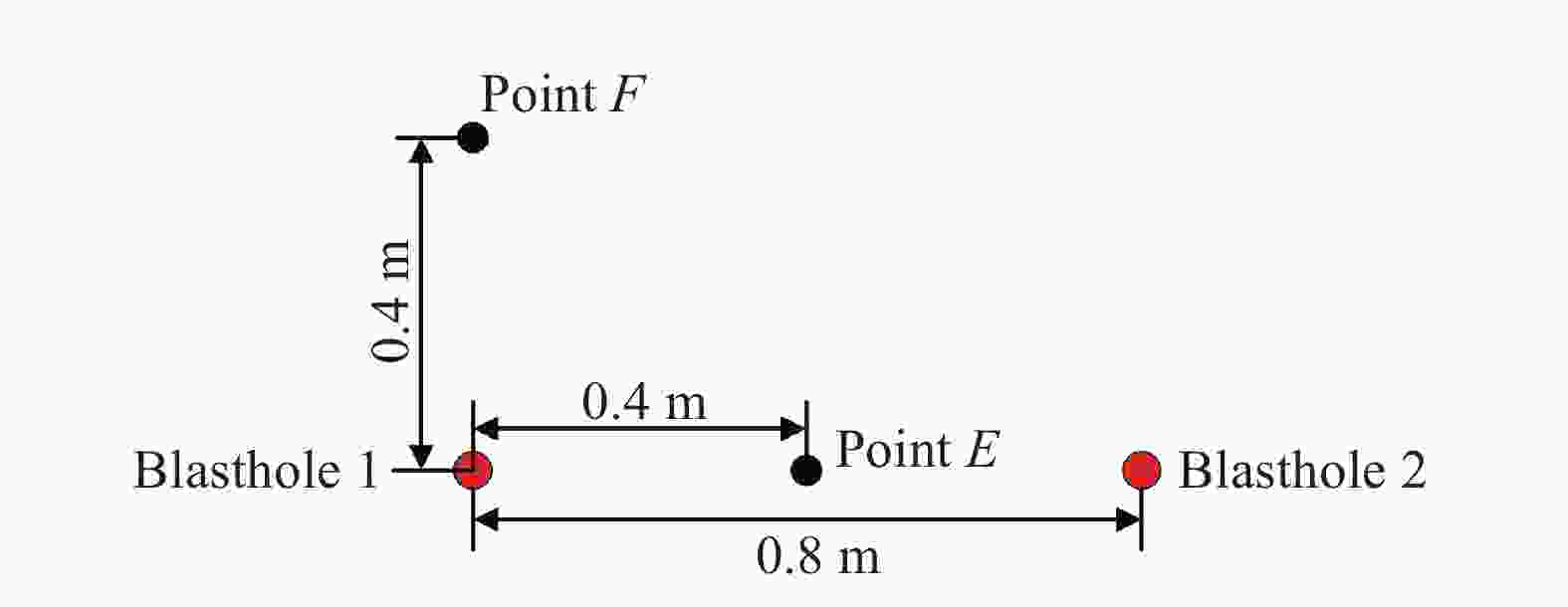

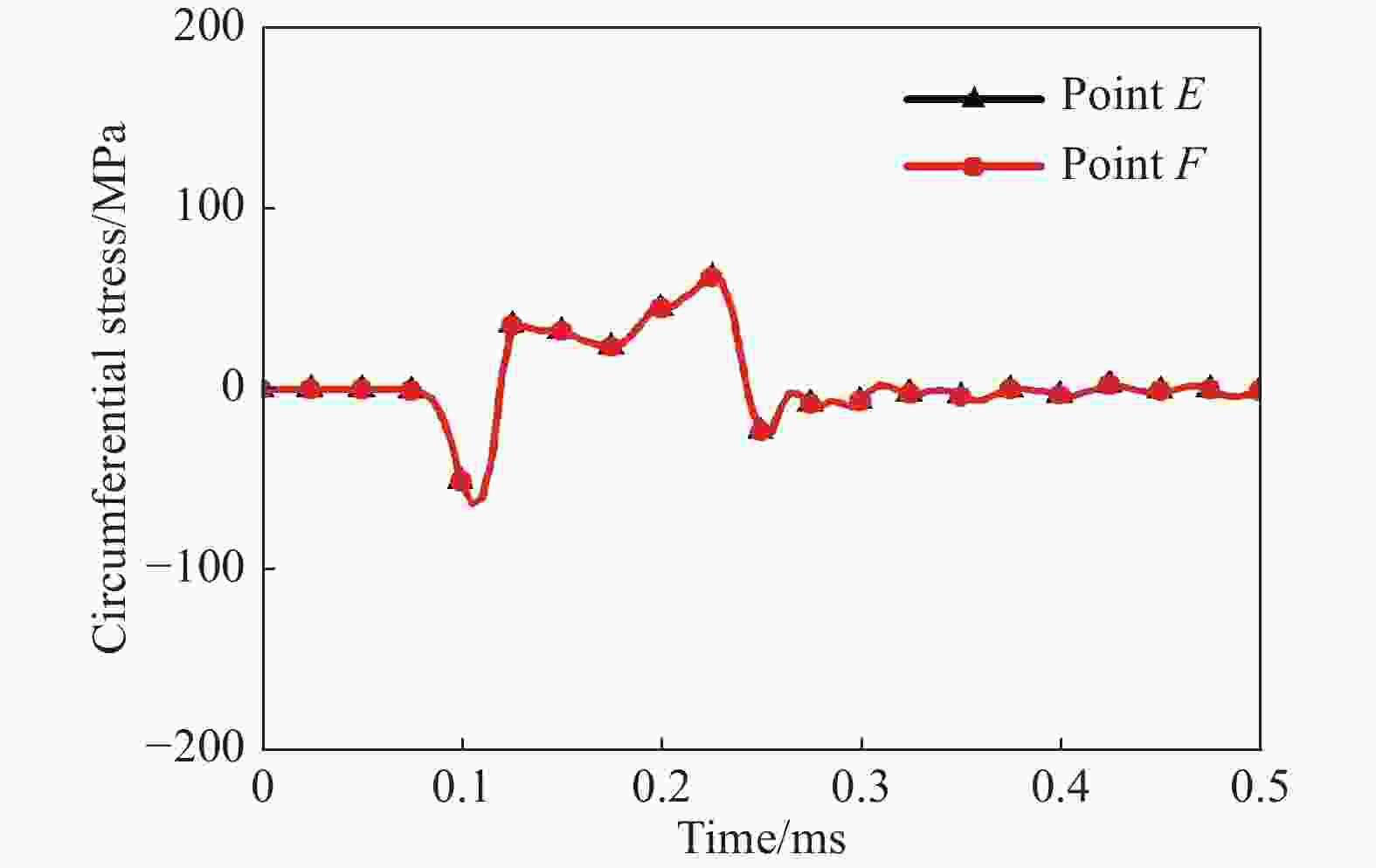

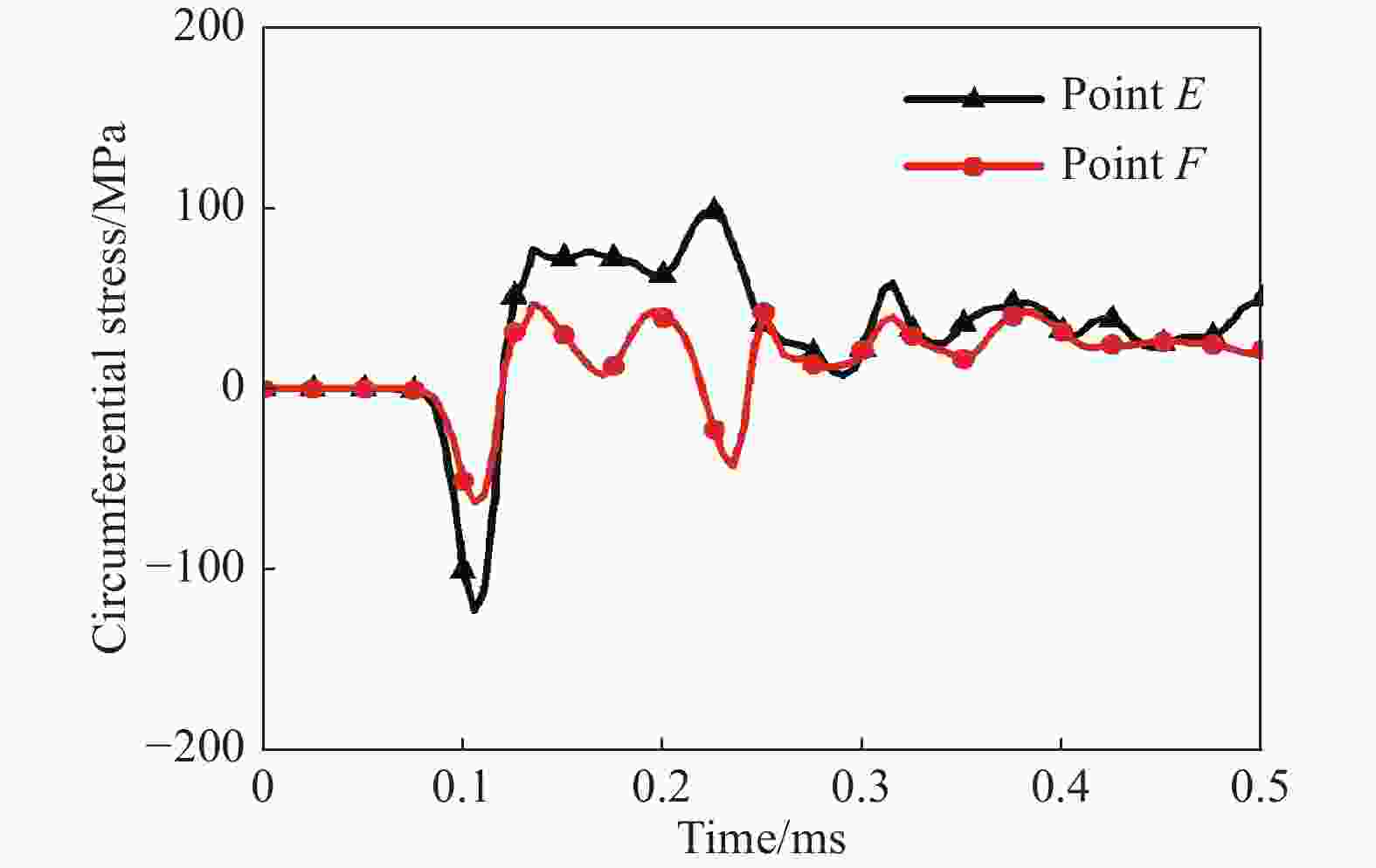

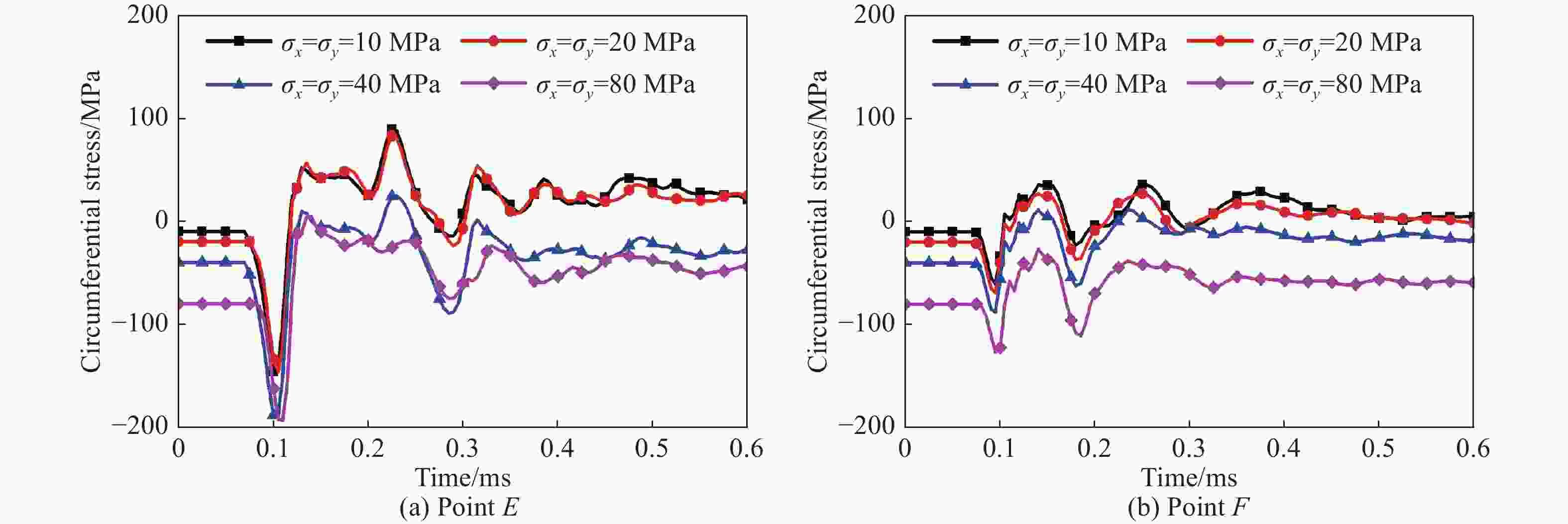

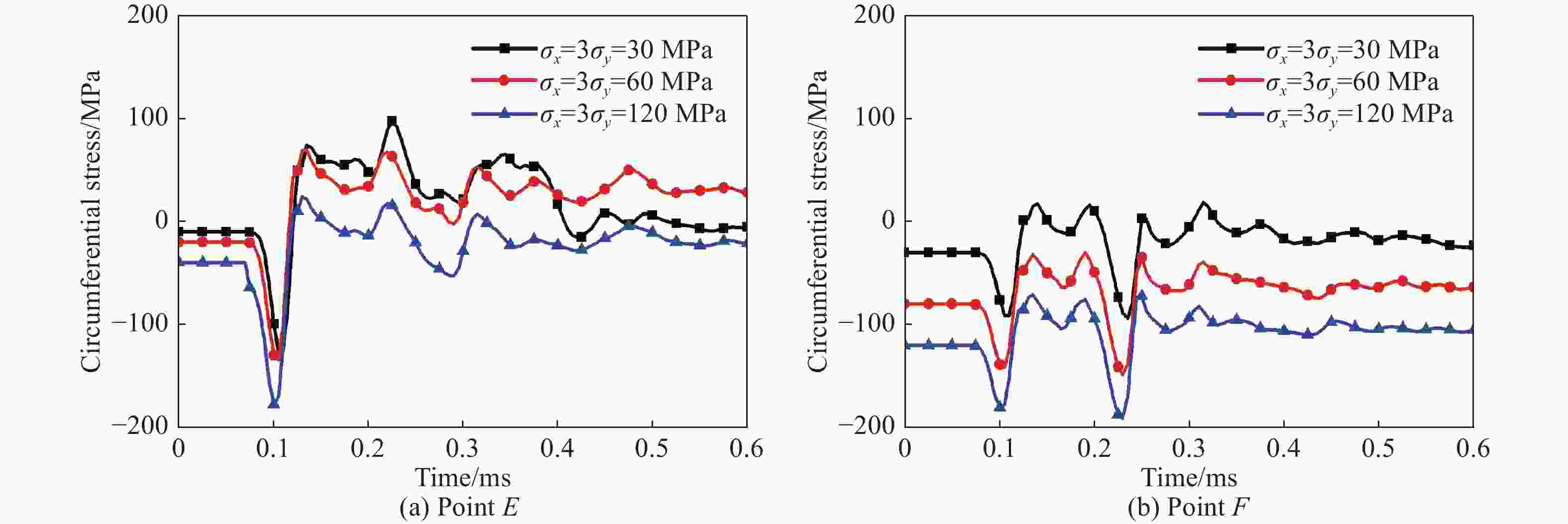

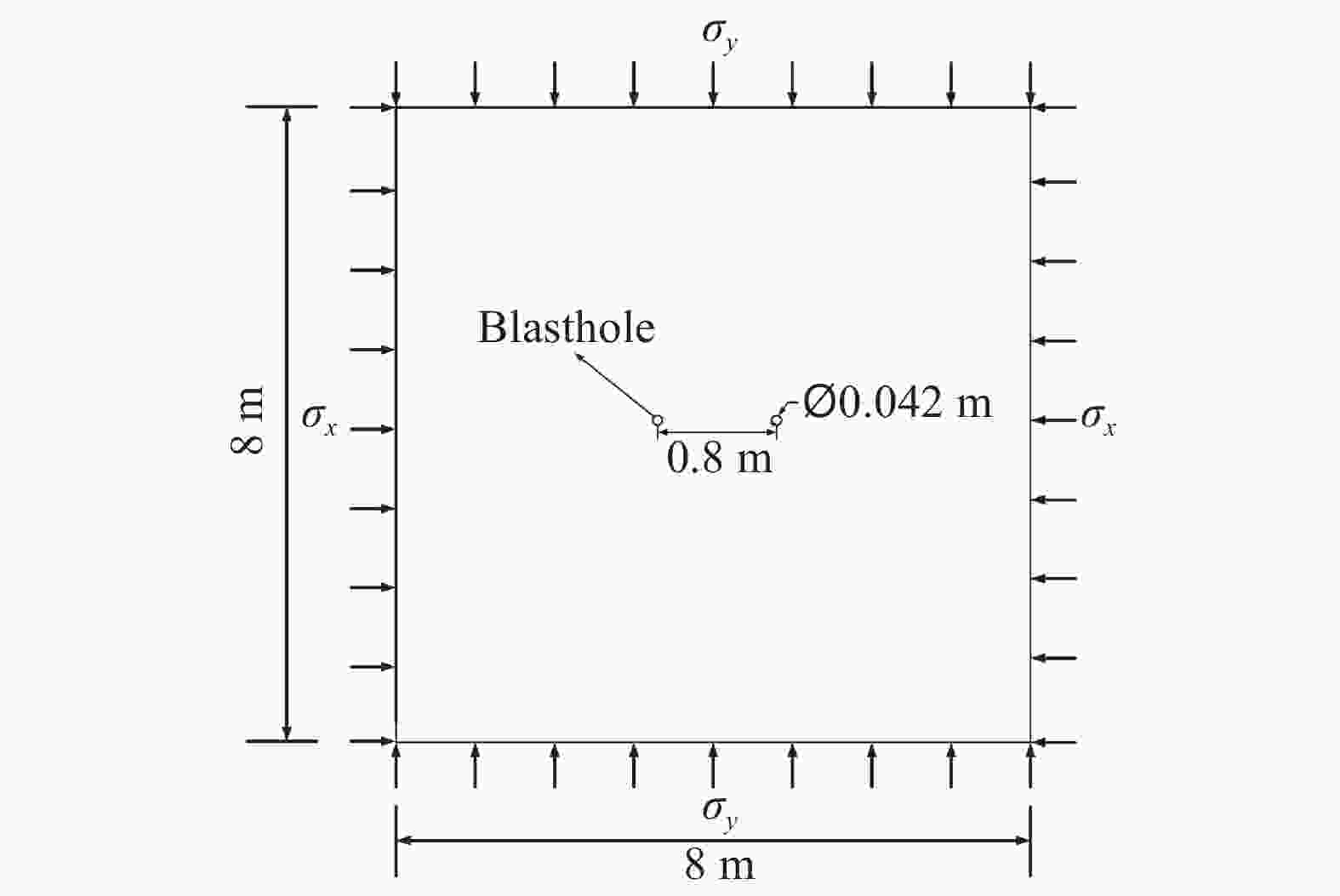

Abstract: During blasting in deep rock masses, the rock fragmentation is contributed to the combined effects of blast loading and high in-situ stress. An analysis model based on simplifying assumptions was developed for double-hole blasting in highly-stressed rock masses, and the crack propagation and dynamic stress evolution surrounding the blastholes were studied by using the coupled SPH (smoothed particle hydrodynamics)-FEM(finite element method) method. The results show that the blast-induced rock cracking is mainly caused by the dynamic circumferential tensile stress generated from blast loading. However, in the rock masses subjected to in-situ stress, the dynamic circumferential tensile stress is reduced in magnitude and duration due to the compressive effect of the in-situ stress. Therefore, the in-situ stress plays a role in inhibiting the rock fragmentation caused by blasting. For the case of multi-hole blasting in a hydrostatic in-situ stress field, the crack propagation perpendicular to the connecting line between the adjacent holes is more easily inhibited by the in-situ stress. The length of blast-induced crack growth decreases with an increase in the in-situ stress level. With regard to a non-hydrostatic in-situ stress field, the crack propagation along the direction of the minimum principal in-situ stress is most severely suppressed, and thus the cracks grow preferentially along the maximum principal stress direction. Therefore, arranging the blastholes along the maximum principal stress direction and shortening the spacing between the blastholes will facilitate the crack connections and the formation of excavation surfaces.-

Key words:

- blasting /

- in-situ stress /

- cracking /

- coupled SPH-FEM method

-

表 1 地应力加载工况

Table 1. In-situ stress conditions used in numerical calculations

应力场 工况 σx/MPa σy/MPa λ=σx/σy 无初始地应力场 1 0 0 静水地应力场 2 10 10 1 3 20 20 1 4 40 40 1 5 80 80 1 非静水地应力场 6 40 20 2 7 30 10 3 8 60 20 3 9 120 40 3 10 80 20 4 表 2 岩石材料物理力学参数

Table 2. Physical and mechanical parameters of the rock material

ρ/(g·cm-3) K/GPa G/GPa σHEL/GPa A N C B M D1 D2 2.66 25.7 21.9 4.5 0.76 0.62 0.005 0.25 0.62 0.005 0.7 -

[1] 谢和平. 深部岩体力学与开采理论”研究构想与预期成果展望 [J]. 工程科学与技术, 2017, 49(2): 1–16. DOI: 10.15961/j.jsuese.201700025.XIE H P. Research framework and anticipated results of deep rock mechanics and mining theory [J]. Advanced Engineering Sciences, 2017, 49(2): 1–16. DOI: 10.15961/j.jsuese.201700025. [2] CAI M F, BROWN E T. Challenges in the mining and utilization of deep mineral resources [J]. Engineering, 2017, 3(4): 432–433. DOI: 10.1016/J.ENG.2017.04.027. [3] MA G W, AN X M. Numerical simulation of blasting-induced rock fractures [J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(6): 966–975. DOI: 10.1016/j.ijrmms.2007.12.002. [4] 肖正学, 张志呈, 李端明. 初始应力场对爆破效果的影响 [J]. 煤炭学报, 1996, 21(5): 497–501. DOI: 10.15961/j.jsuese.201700025.XIAO Z X, ZHANG Z C, LI D M. The influence of initial stress field on blasting [J]. Journal of China Coal Society, 1996, 21(5): 497–501. DOI: 10.15961/j.jsuese.201700025. [5] 赵宝友, 王海东. 深孔爆破技术在高地应力低透气性高瓦斯煤层增透防突中的适用性 [J]. 爆炸与冲击, 2014, 34(2): 145–152. DOI: 10.11883/1001-1455(2014)02-0145-08.ZHAO B Y, WANG H D. Feasibility of deep-hole blasting technology for outburst prevention and permeability enhancement in high-gas-content coal seams with low-permeability subjected to high geo-stresses [J]. Explosion and Shock Waves, 2014, 34(2): 145–152. DOI: 10.11883/1001-1455(2014)02-0145-08. [6] 魏晨慧, 朱万成, 白羽, 等. 不同地应力条件下切缝药包爆破的数值模拟 [J]. 爆炸与冲击, 2016, 36(2): 161–169. DOI: 10.11883/1001-1455(2016)02-0161-09.WEI C H, ZHU W C, BAI Y, et al. Numerical simulation on cutting seam cartridge blasting under different in-situ stress conditions [J]. Explosion and Shock Waves, 2016, 36(2): 161–169. DOI: 10.11883/1001-1455(2016)02-0161-09. [7] YI C P, JOHANSSON D, GREBERG J. Effects of in-situ stresses on the fracturing of rock by blasting [J]. Computers and Geotechnics, 2018, 104: 321–330. DOI: 10.1016/j.compgeo.2017.12.004. [8] HE C L, YANG J. Experimental and numerical investigations of dynamic failure process in rock under blast loading [J]. Tunnelling and Underground Space Technology, 2019, 83: 552–564. DOI: 10.1016/j.tust.2018.08.047. [9] ZHAO J J, ZHANG Y, RANJITH P G. Numerical simulation of blasting-induced fracture expansion in coal masses [J]. International Journal of Rock Mechanics and Mining Sciences, 2017, 100: 28–39. DOI: 10.1016/j.ijrmms.2017.10.015. [10] 李洪伟, 雷战, 江向阳, 等. 不同炮孔间距对岩石爆炸裂纹扩展影响的数值分析 [J]. 高压物理学报, 2019, 33(4): 044103. DOI: 10.11858/gywlxb.20180683.LI H W, LEI Z, JIANG X Y, et al. Numerical analysis of impact of shot hole spacing on crack growth in rock [J]. Chinese Journal of High Pressure Physics, 2019, 33(4): 044103. DOI: 10.11858/gywlxb.20180683. [11] 徐涛龙, 梁博, 文霞, 等. 天然气泄漏爆炸冲击同沟并行邻管的模拟方法 [J]. 工程力学, 2019, 36(S1): 329–338. DOI: 10.6052/j.issn.1000-4750.2018.05.S061.XU T L, LIANG B, WEN X, et al. Explosion impact simulation methods for parallel pipeline laying in the same ditch after gas leakage [J]. Engineering Mechanics, 2019, 36(S1): 329–338. DOI: 10.6052/j.issn.1000-4750.2018.05.S061. [12] 王志亮, 毕程程, 李鸿儒. 混凝土爆破损伤的SPH-FEM耦合法数值模拟 [J]. 爆炸与冲击, 2018, 38(6): 1419–1428. DOI: 10.11883/bzycj-2017-0209.WANG Z L, BI C C, LI H R. Numerical simulation of blasting damage in concrete using a coupled SPH-FEM algorithm [J]. Explosion and Shock Waves, 2018, 38(6): 1419–1428. DOI: 10.11883/bzycj-2017-0209. [13] JOHNSON G R, HOLMQUIST T J. An improved computational constitutive model for brittle materials [J]. AIP Conference Proceedings, 1994, 309(1): 981–984. DOI: 10.1063/1.46199. [14] BANADAKI M M D, MOHANTY B. Numerical simulation of stress wave induced fractures in rock [J]. International Journal of Impact Engineering, 2012, 40−41: 16–25. DOI: 10.1016/j.ijimpeng.2011.08.010. [15] LEE E L, HORNIG H C, KURY J W. Adiabatic expansion of high explosive detonation products [R]. Livermore: Lawrence Radiation Laboratory, 1968. [16] GHAREHDASH S, BARZEGAR M, PALYMSKIY I B, et al. Blast induced fracture modelling using smoothed particle hydrodynamics [J]. International Journal of Impact Engineering, 2020, 135: 103235. DOI: 10.1016/j.ijimpeng.2019.02.001. -

下载:

下载: