Penetration mechanism of a high-speed projectile into a shelter made of spherical aggregates

-

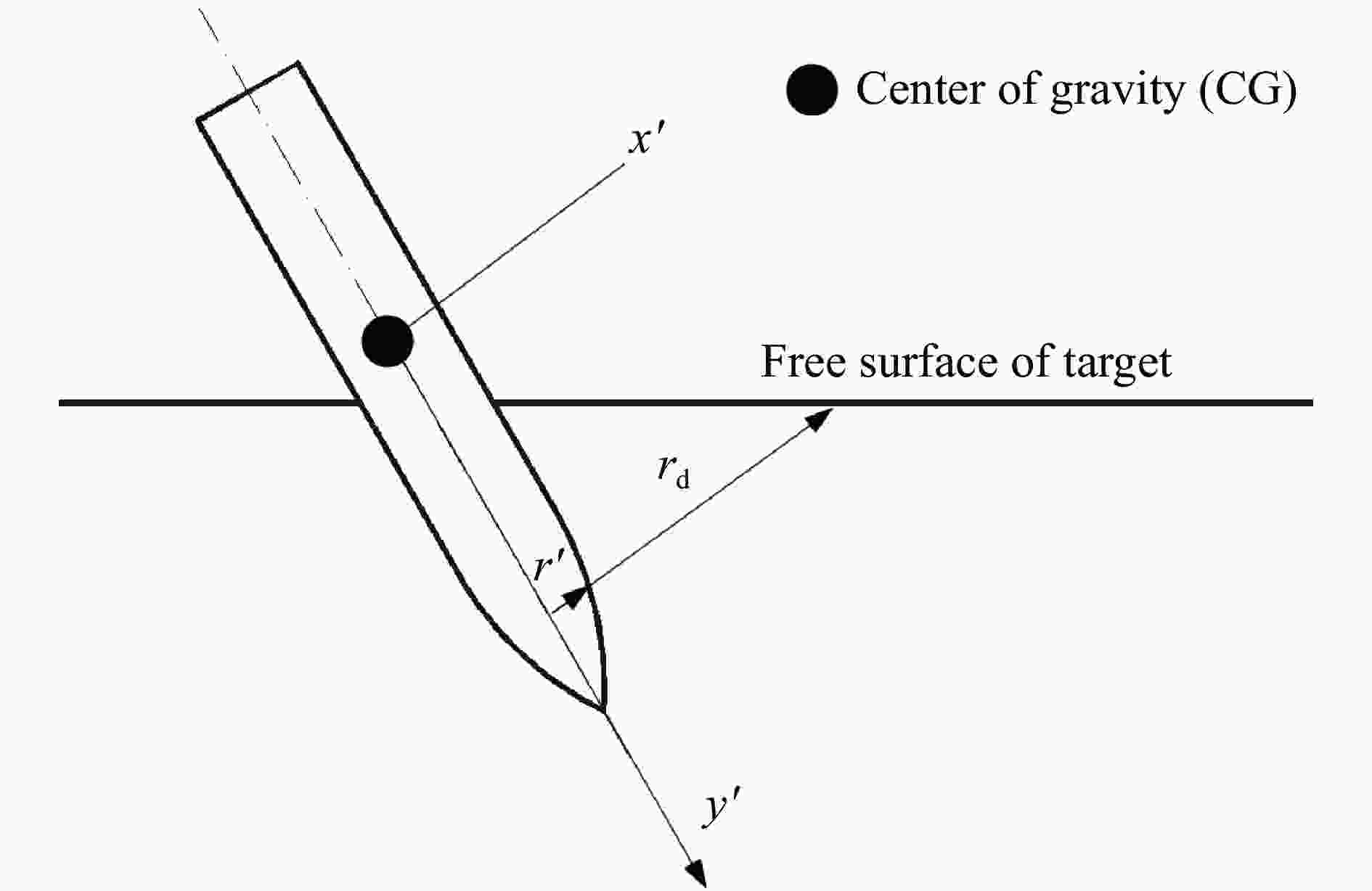

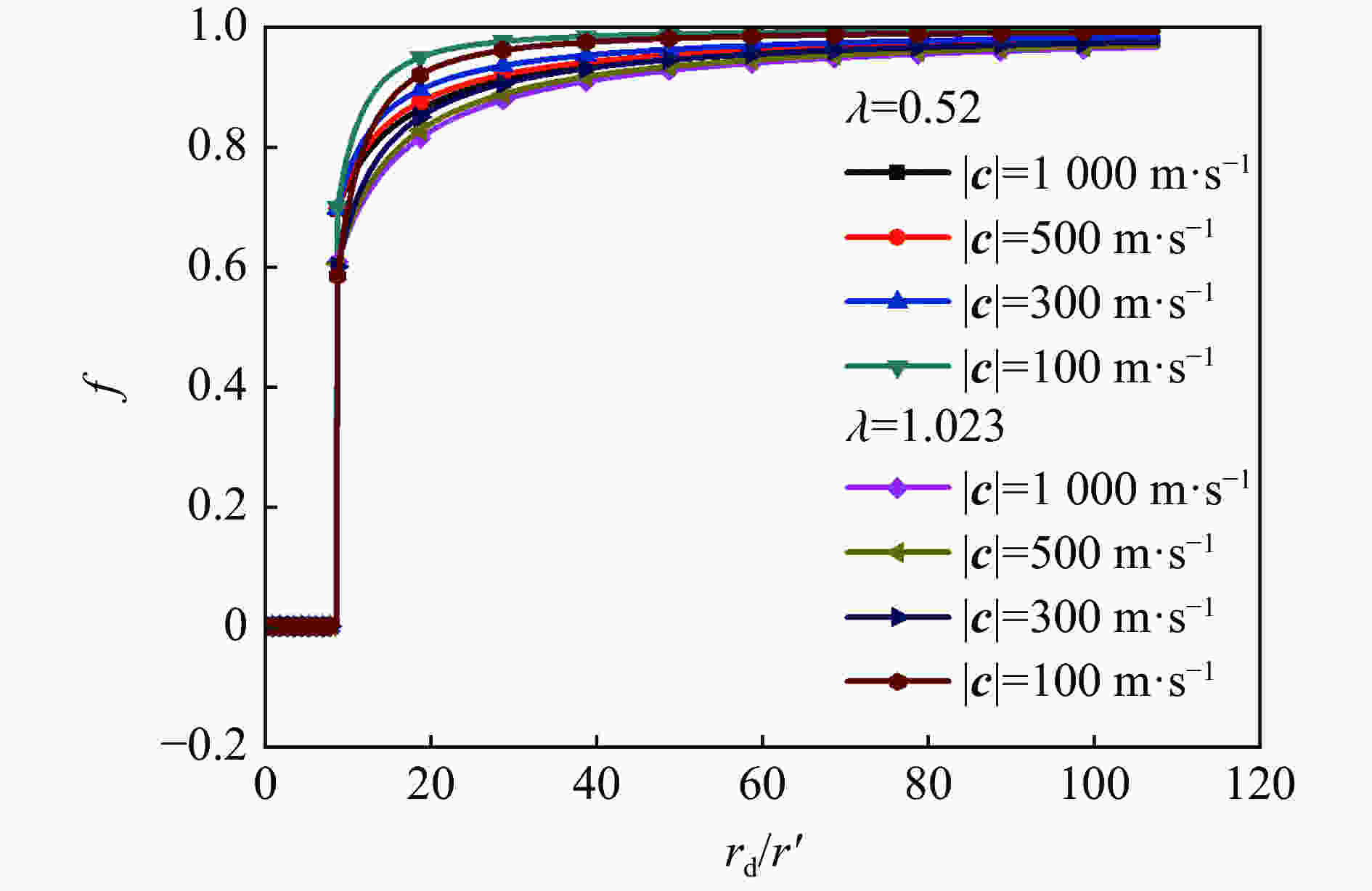

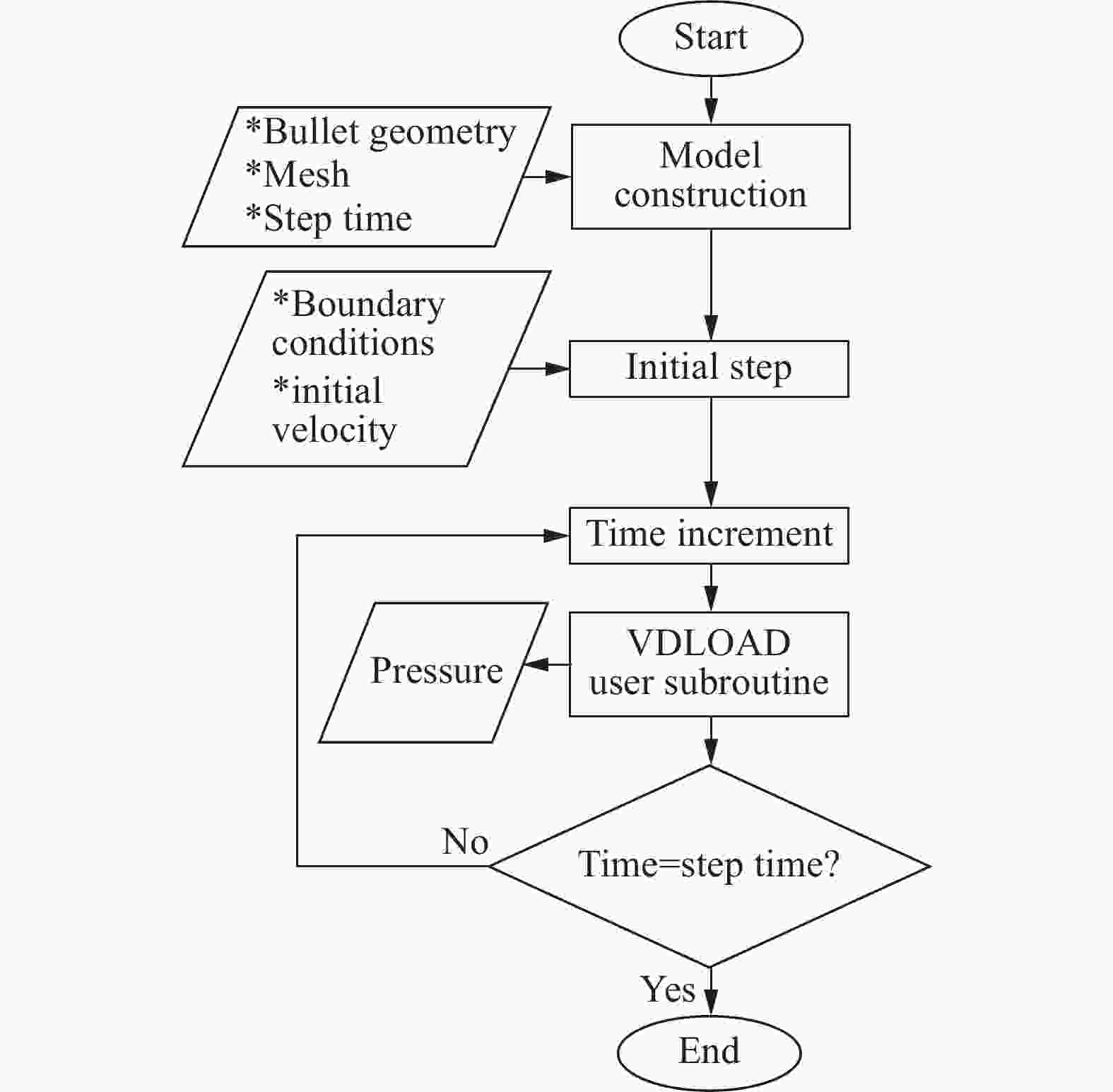

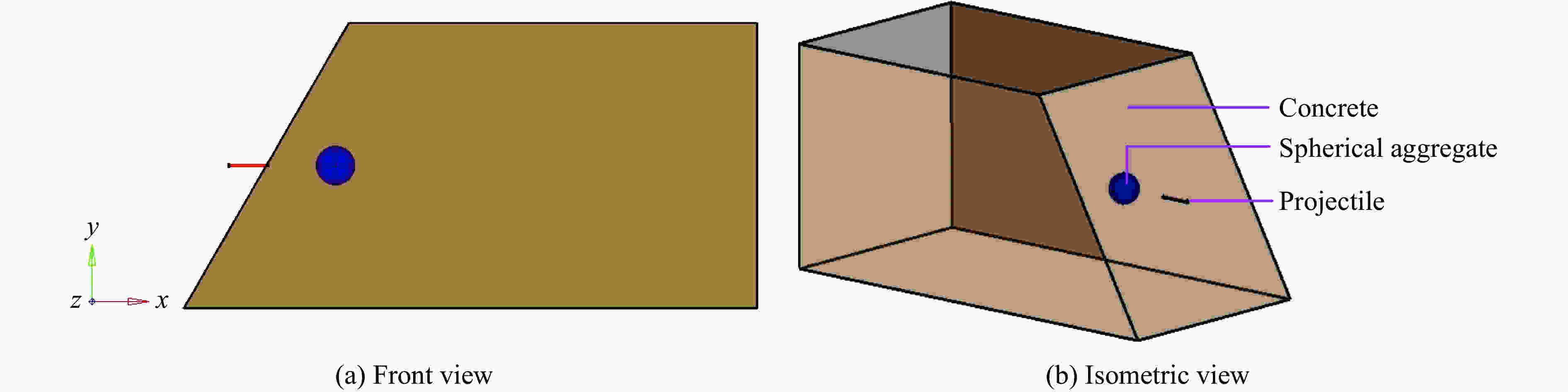

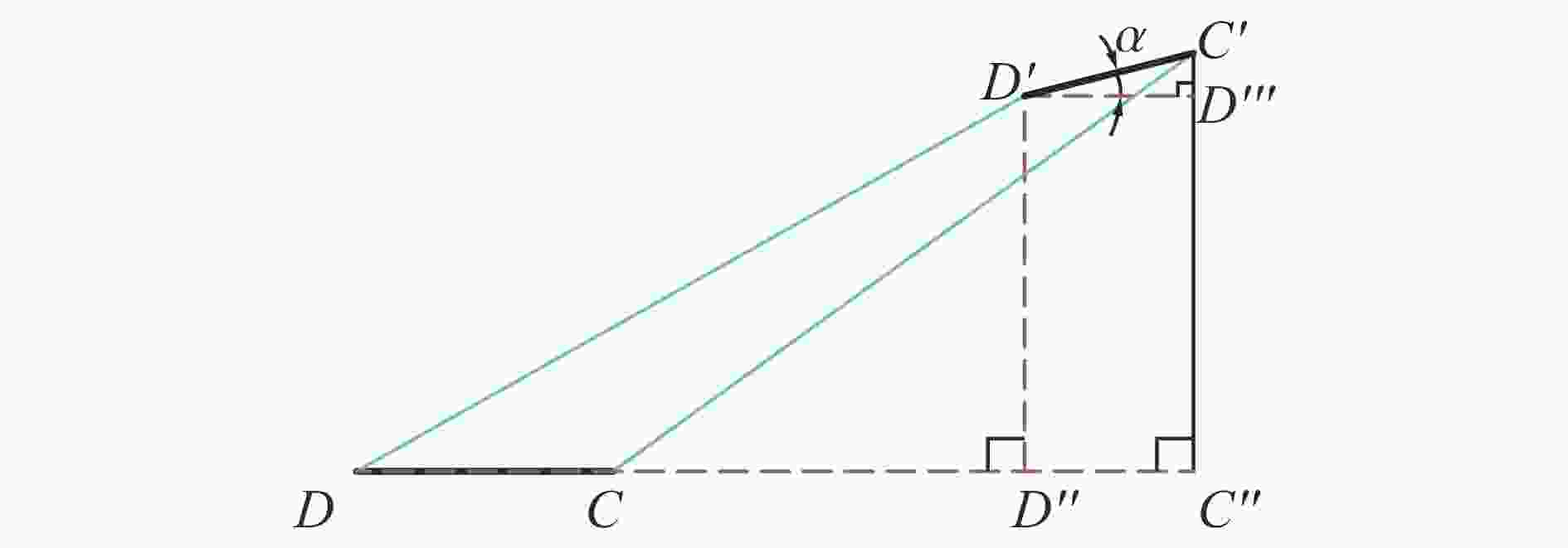

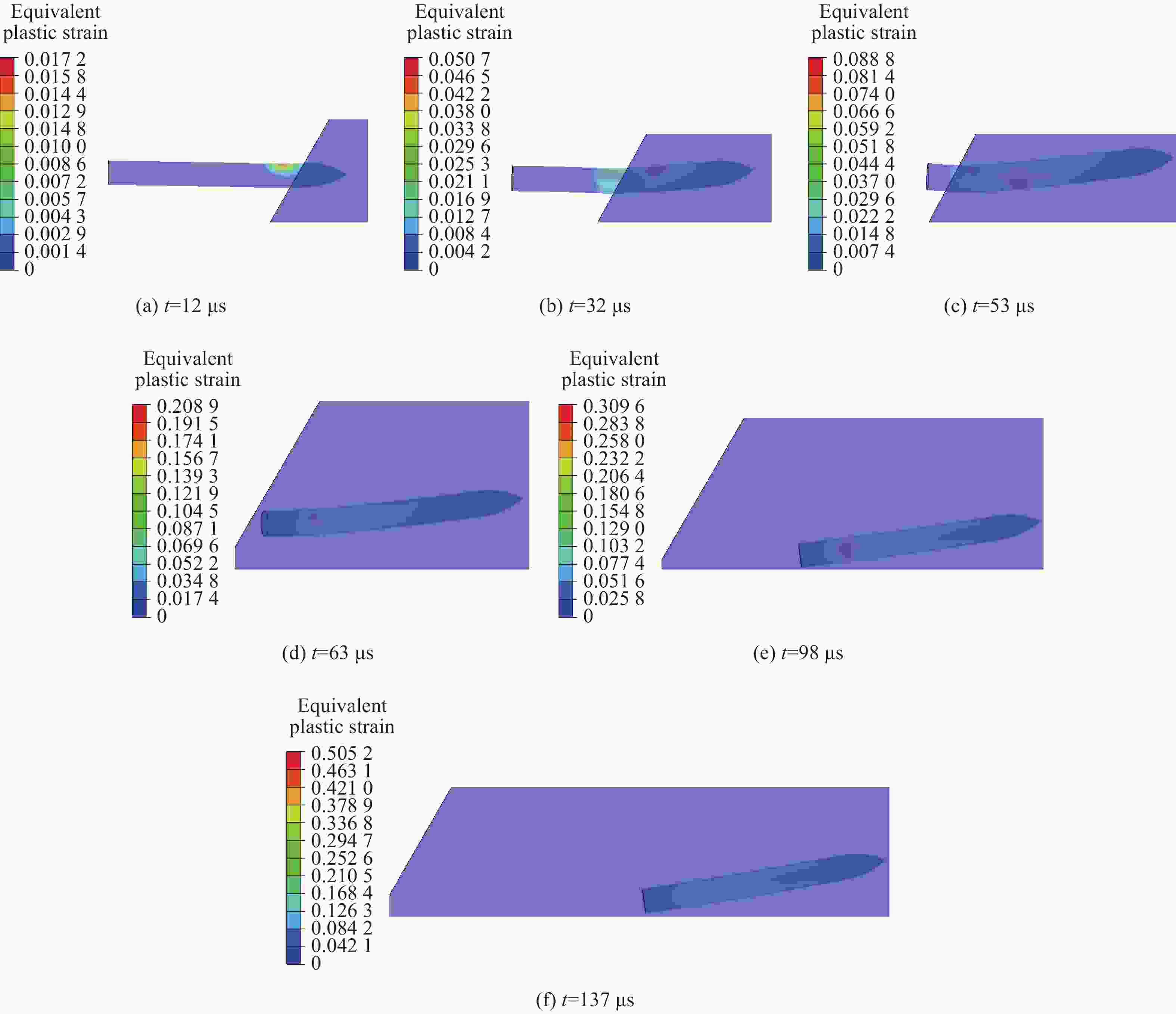

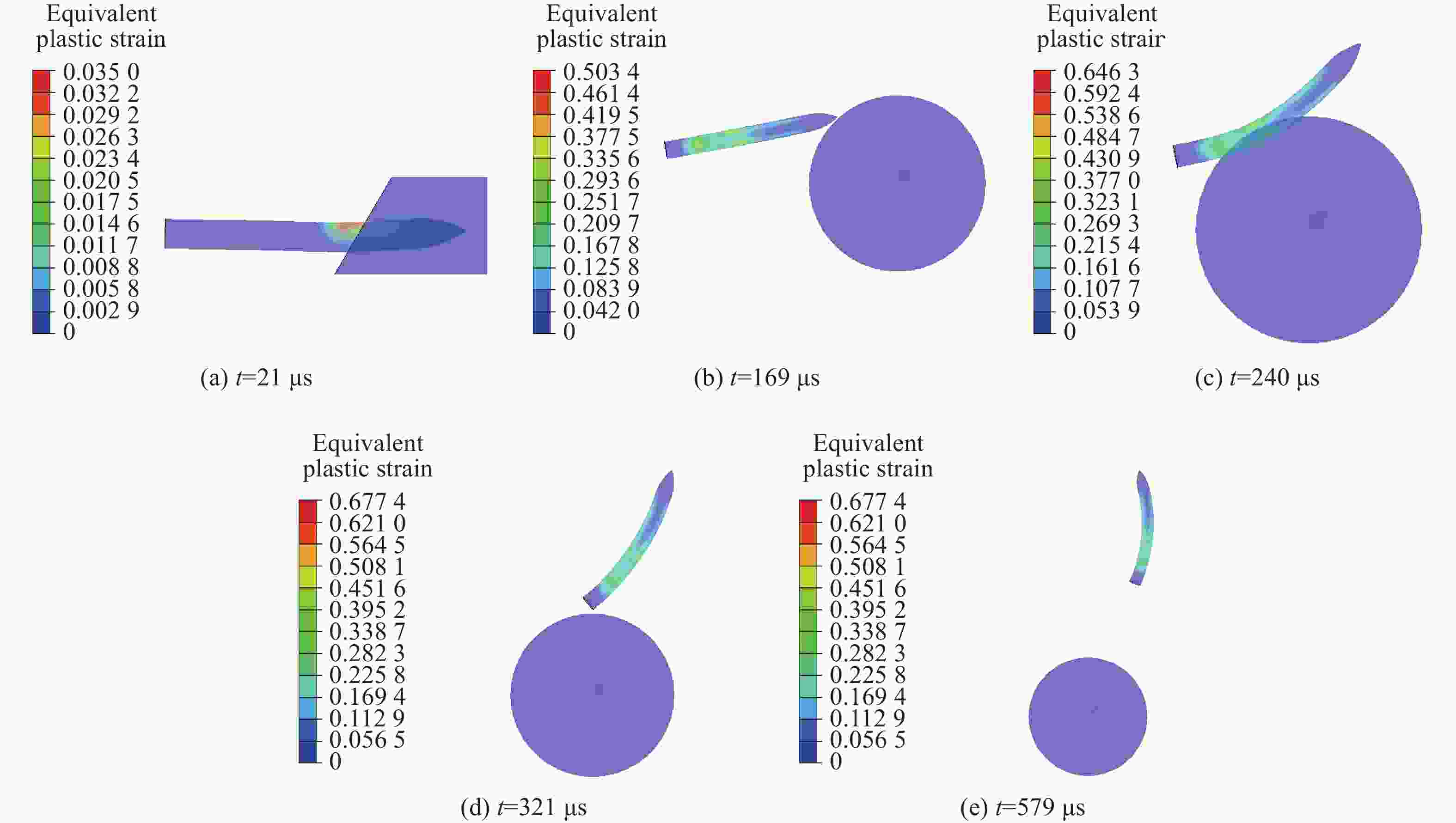

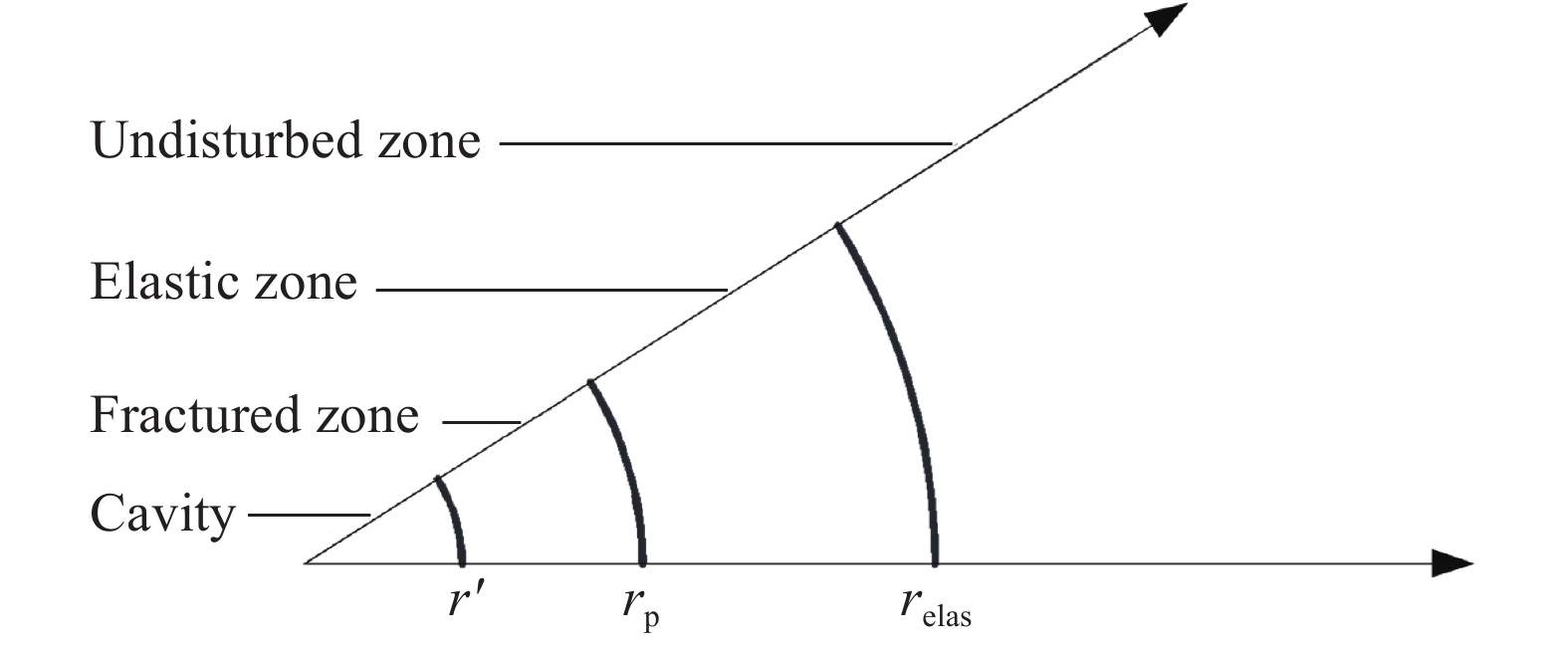

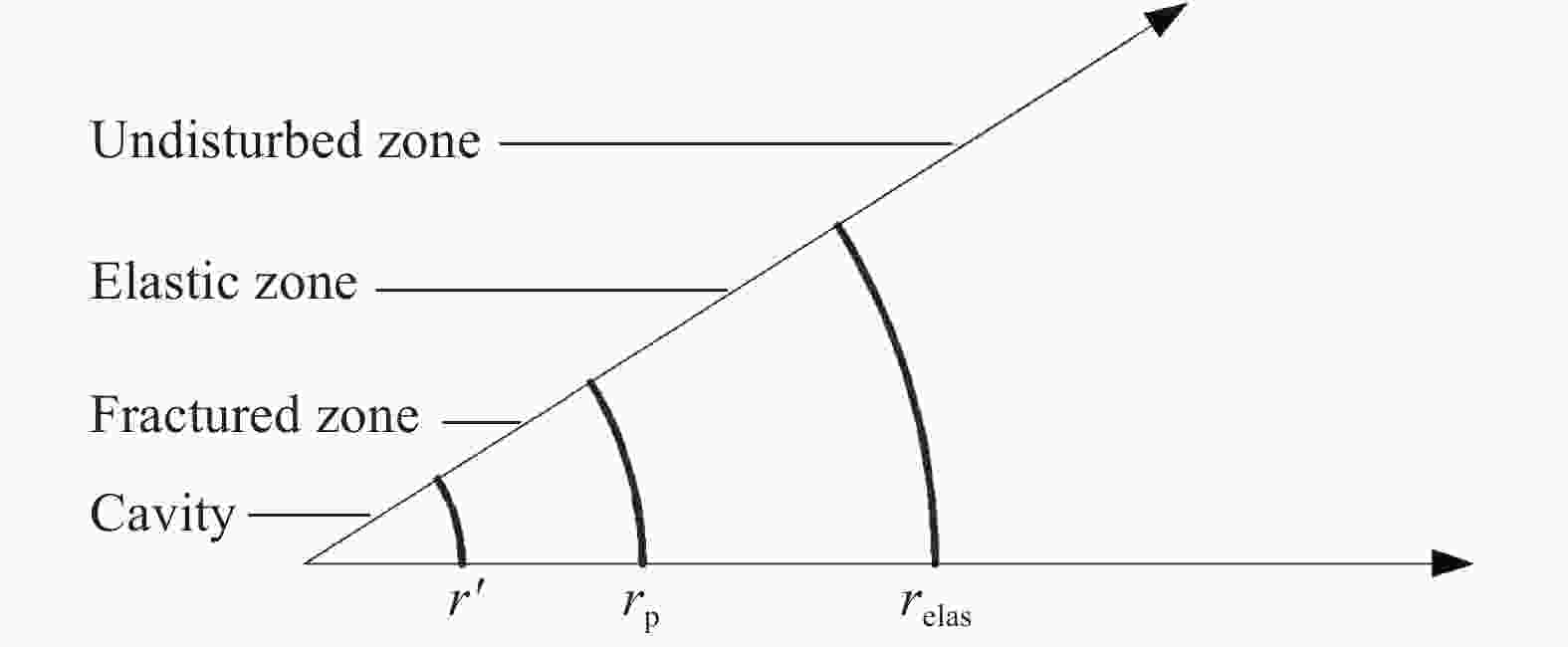

摘要: 在钻地弹威慑之下,重要目标工事外覆盖遮弹层是常见加固和防护手段。硬质球形颗粒(以下简称颗粒)是常见的遮弹层组成结构。本文中将研究高速侵彻弹体与颗粒作用机理,分析遮弹效率的控制因素。首先,基于动态空腔膨胀理论,计及靶的自由面效应和颗粒强度差异,建立了靶对弹体侵彻阻力的表征模型。然后,采用弹靶分离计算方法,模拟并分析了斜侵彻含球形颗粒有限大高强混凝土时弹体的运动与变形,研究颗粒的强度、位置及尺寸对来袭弹侵彻行为的影响规律。结果表明,颗粒的遮弹作用主要取决于与其作用时弹体的姿态,其随颗粒位置变化无明显规律;颗粒强度越高,遮弹效果越好;颗粒半径从1倍到10倍弹径变化时,颗粒对弹体的作用机理从弹道偏转为主转变为弹道偏转与侵彻阻力增加两者耦合。因此,为达到良好的遮弹效果,单层球形颗粒密排遮弹层的颗粒半径建议在5倍弹体直径之上;若采用较小颗粒制作遮弹层,建议采用多层错排方式,且遮弹层厚度须在10倍弹径之上。Abstract: Under the threat of earth penetration weapons (EPWs), the protective fortification should be further enhanced. The bursting layer is commonly used to increase the protective strength of the fortification. A hard spherical aggregate (aggregate for short) is often used to construct the bursting layer. The mechanism of a high-speed projectile into the aggregate was studied, and the dominant factors were investigated in the present paper. Based on the dynamic spherical cavity expansion theory, the model for the drag force of the projectile was constructed considering the free surface effect of the target and the strength of the aggregate. Detaching the projectile response from the target, the resistant force of the target was loaded on the projectile surface as a force boundary. The deformation and movement of the projectile was numerically researched when it obliquely penetrated into the high-strength concrete target including aggregates. The influences of aggregate strength, location and dimensions upon the projectile response were investigated. It indicates that the sheltering effect of the aggregate is mainly dominated by the gesture of the projectile impacting on the aggregate. However, the variation of the gesture does not follow a distinct law. It is shown that the higher the strength of the aggregate, the better the sheltering effect of the aggregate. The main sheltering mechanism transforms from ballistic trajectory deflection into combination of ballistic trajectory deflection and augment of the drag force of the projectile, when the radius of the aggregate increases from 1 time of projectile diameter to 10 times. Based on the above analyses, for the bursting layer made of one layer, the diameter of the aggregate should be larger than 10 times of the projectile diameter. However, when the size of the aggregate decreases, the bursting layers should be constructed by multiple and staggered layers of aggregates with total layer thickness larger than 10 times of the projectile diameter, in order to achieve the effective sheltering effect.

-

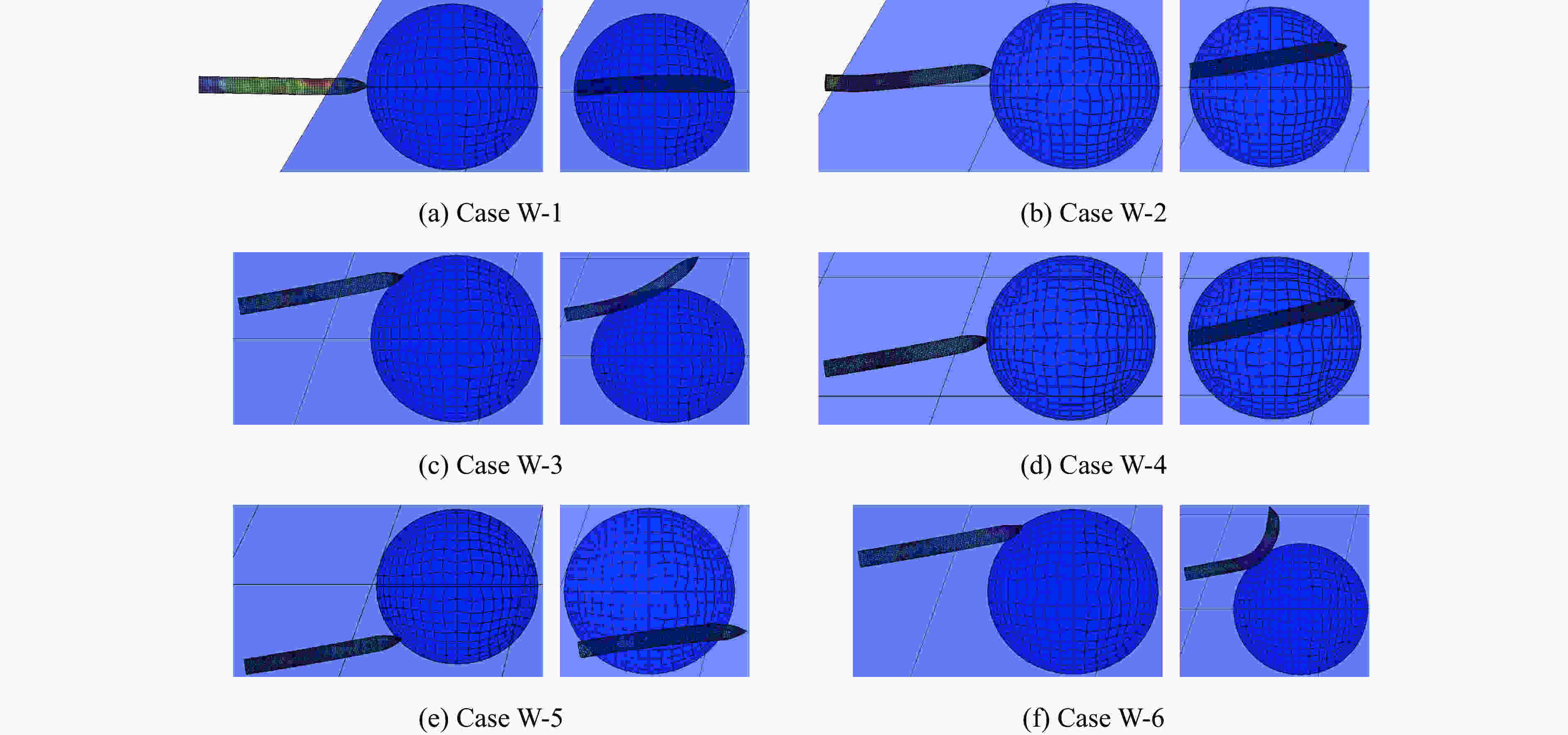

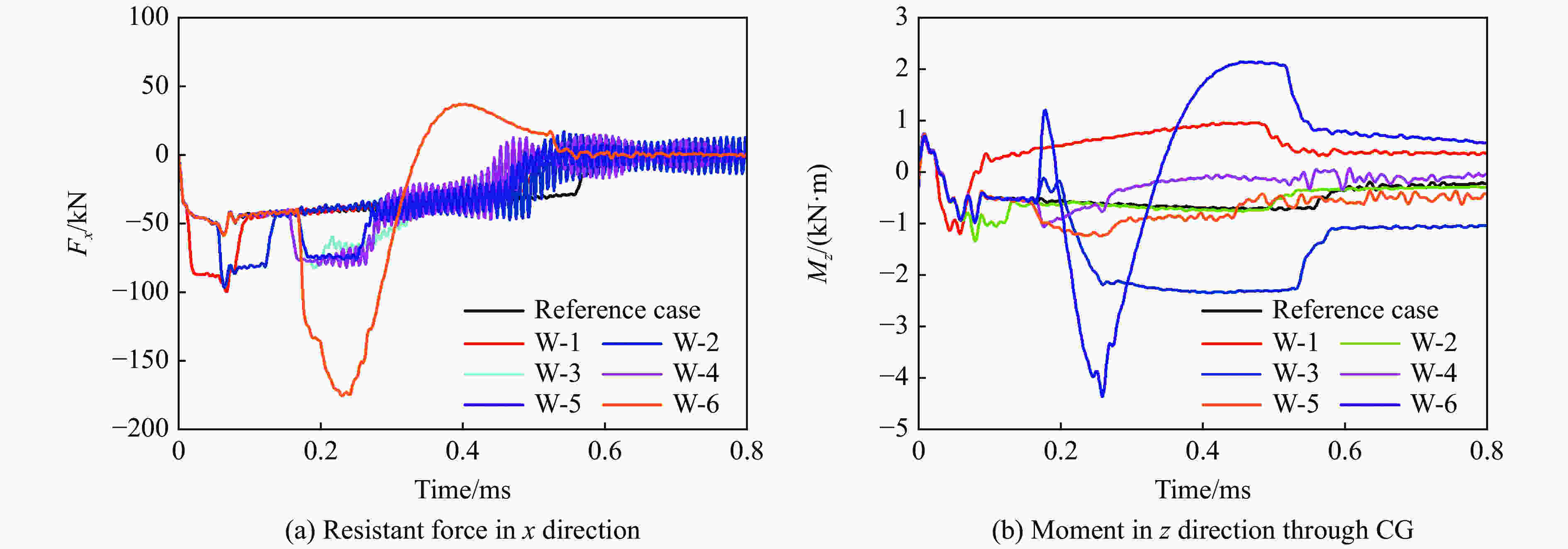

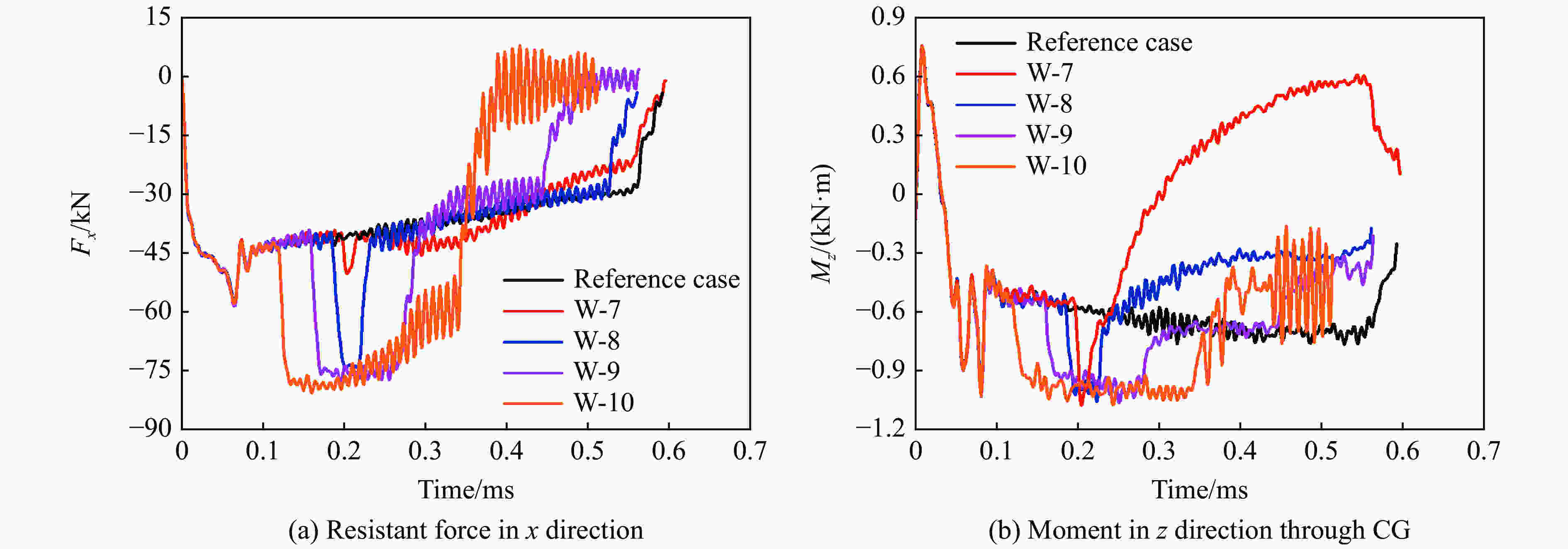

图 11 颗粒位置及强度变化时,弹体质心x向阻力及过质心z向力矩的时间历程(125 kHz低通滤波)

Figure 11. Time histories of x-directional resistant force and z-directional moment through projectile mass center for projectile with variation of location and strength of spherical aggregate (filtered by low pass filter with cutoff frequency 125 kHz)

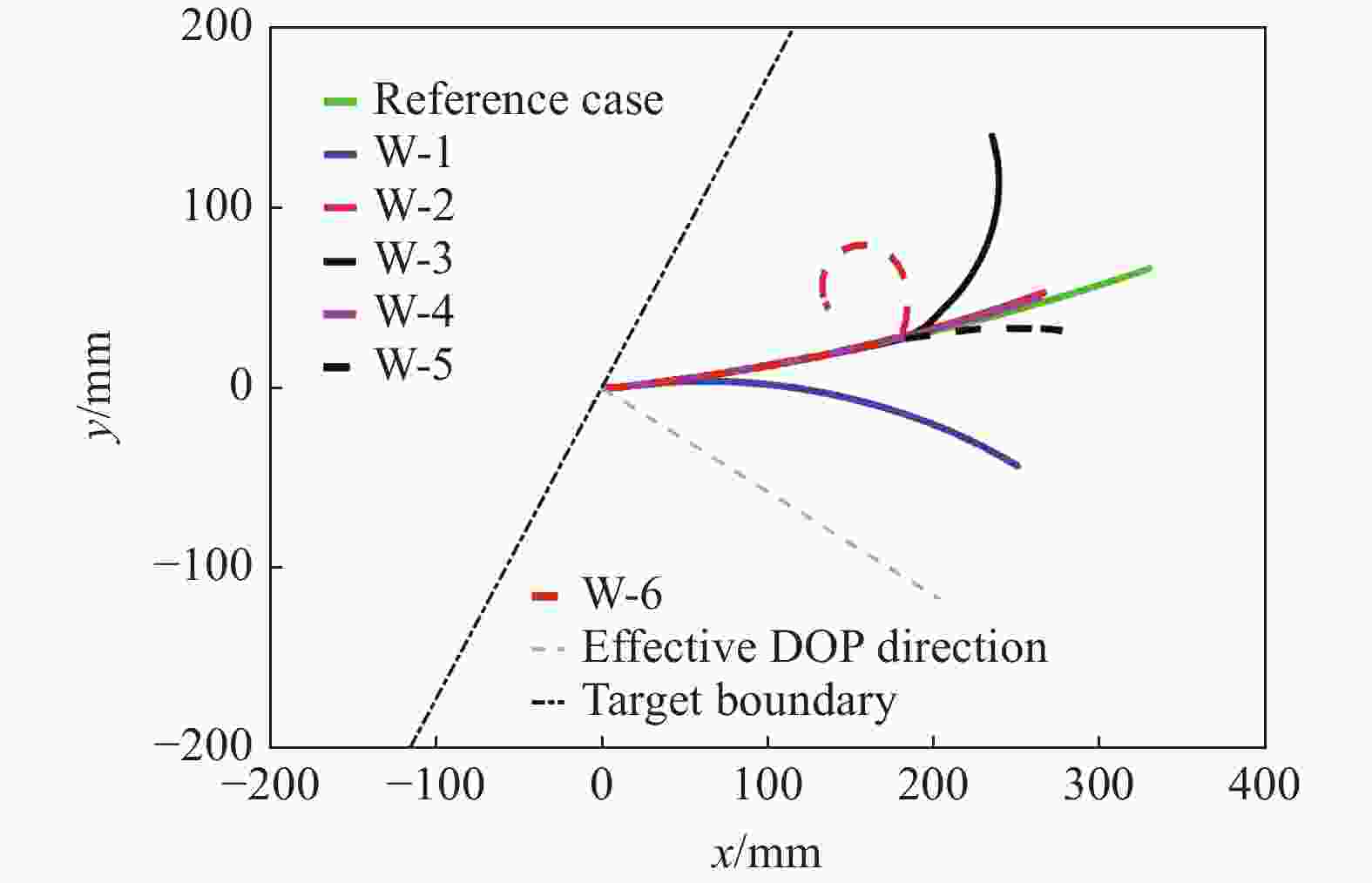

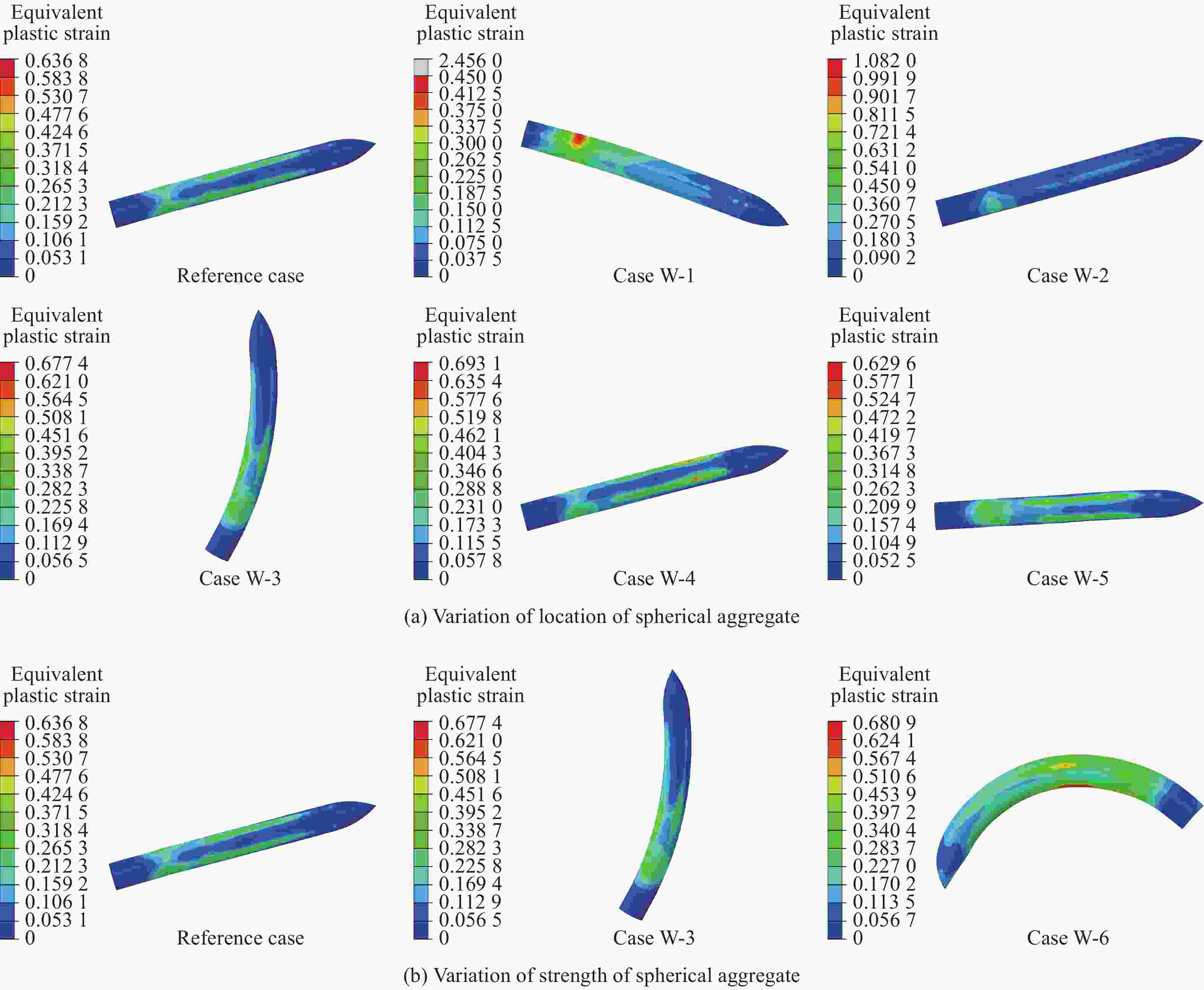

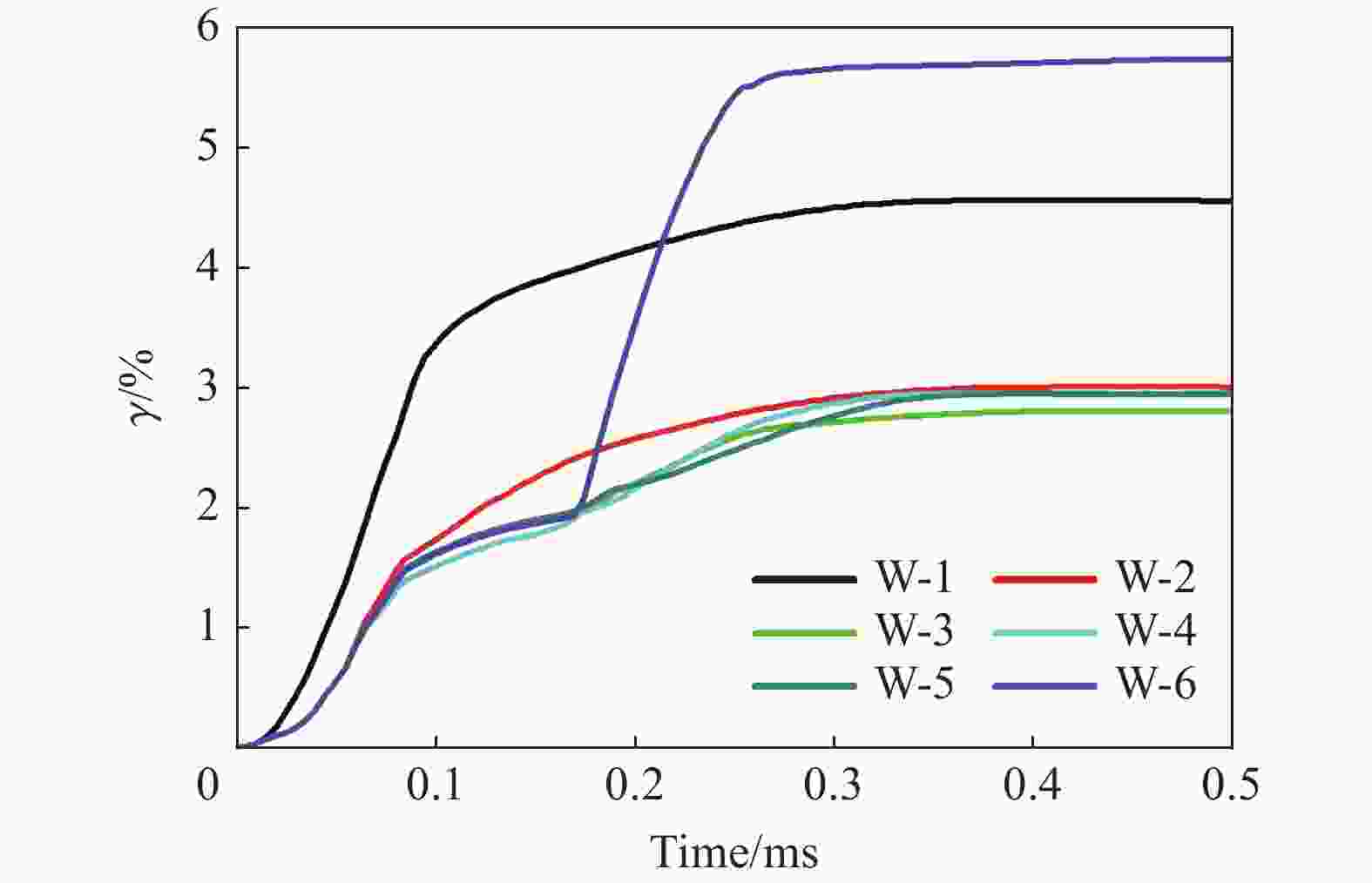

表 1 半径为5倍弹径球体嵌埋位置及强度对弹体运动和变形的影响

Table 1. Movement and deformation of the projectile with the location and strength variation of the aggregate whose radius is 5 times of the projectile diameter

工况 速度/(m·s−1) 斜角/(°) 攻角/(°) 球形颗粒 |弹尖位移|max/mm 有效侵深/

mm最大转角/(°) 弹体变形 向下 向右 球心坐标/mm g1 x y z z 轴 y 轴 Ref. 1266 30 1.0 1.5 329 66 8 252 17.2 2.5 完整 W-1 1266 30 1.0 1.5 (50, 0, 0) 2 250 44 2 239 −21.2 −1.8 轻微弯曲 W-2 1266 30 1.0 1.5 (100, 0, 0) 2 266 53 13 204 17.4 2.5 完整 W-3 1266 30 1.0 1.5 (200, 0, 0) 2 239 140 27 163 84.2 59.6 弯曲 W-4 1266 30 1.0 1.5 (200, 25, 0) 2 263 50 8 203 16.2 2.5 完整 W-5 1266 30 1.0 1.5 (200, 50, 0) 2 277 33 12 223 11.6 2.7 轻微弯曲 W-6 1266 30 1.0 1.5 (200, 0, 0) 4 184 79 13 143 232.4 203.1 弯曲 注:(1)表中Ref.是Reference case的简称,表 2中Ref.与此内涵一致,不再赘述。

(2)观察方向沿弹体运动方向,从弹尾至弹尖。

(3)|弹尖位移|max表示弹尖位移最大值,表 2中|弹尖位移|max与此内涵一致。

(4)最大转角表示转角绝对值最大时的转角,正值表示逆时针方向转动,负值表示顺时针方向转动,表 2中内涵与此一致。表 2 球心(200,35,0)处球体半径对弹体运动的影响

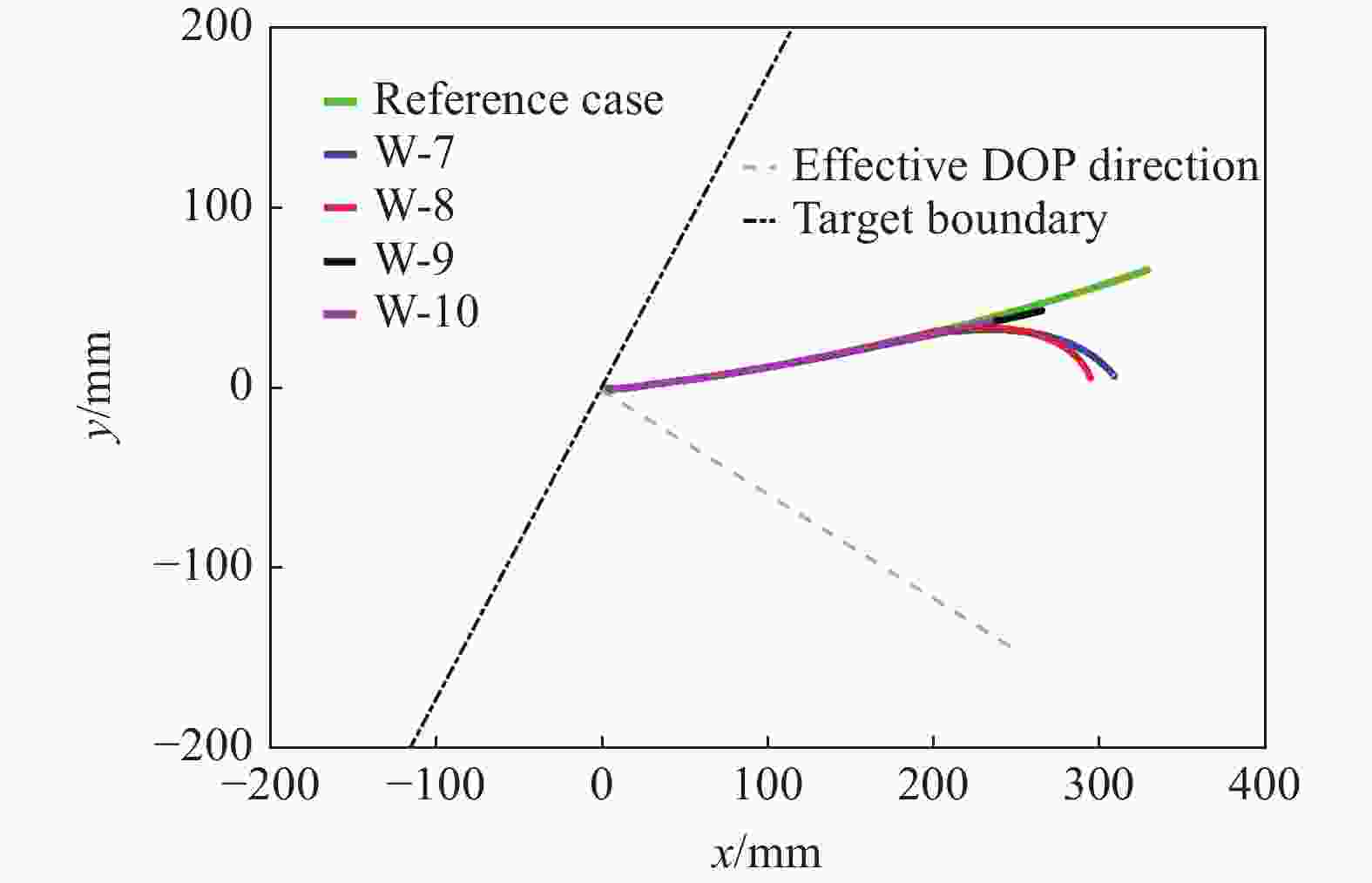

Table 2. Movement of the projectile when spherical aggregates with different radii located at (200,35,0)

工况 速度/(m·s−1) 斜角/(°) 攻角/(°) 球形颗粒 |弹尖位移|max/mm 有效侵深/mm 绕z轴最大转角/(°) 向下 向右 半径/mm g1 x y Ref. 1 266 30 1.0 1.5 329 66 252 17.2 W-7 1 266 30 1.0 1.5 7.1 2 310 33 264 −24.1 W-8 1 266 30 1.0 1.5 14.2 2 295 34 251 −31.0 W-9 1 266 30 1.0 1.5 35.5 2 266 44 208 12.3 W-10 1 266 30 1.0 1.5 71.0 2 235 38 185 12.0 -

[1] 任辉启, 穆朝民, 刘瑞朝, 等. 精确制导武器侵彻效应与工程防护[M]. 北京: 科学出版社, 2016: 1−19. [2] 郭志昆, 陈万祥, 袁正如, 等. 新型偏航遮弹层选型分析与试验 [J]. 解放军理工大学学报(自然科学版), 2007, 8(5): 505–512.GUO Z K, CHEN W X, YUAN Z R, et al. Structural selection and testing of new yaw-inducing bursting layer [J]. Journal of PLA University of Science and Technology (Natural Science Edition), 2007, 8(5): 505–512. [3] 孙岩, 汤文辉, 张若棋. 单层密排刚玉球对深层侵彻弹防护效应的试验研究 [J]. 强度与环境, 2005, 32(1): 56–58. DOI: 10.3969/j.issn.1006-3919.2005.01.009.SUN Y, TANG W H, ZHANG R Q. A study on the protective ability of tightly arrayed corundum spheres for deeply penetrating projectile [J]. Structure and Environment Engineering, 2005, 32(1): 56–58. DOI: 10.3969/j.issn.1006-3919.2005.01.009. [4] PENG Y, WU H, FANG Q, et al. Impact resistance of basalt aggregated UHP-SFRC/fabric composite panel against small caliber arm [J]. International Journal of Impact Engineering, 2016, 88: 201–213. DOI: 10.1016/j.ijimpeng.2015.10.011. [5] 国盛兵, 潘越峰, 高培正, 等. 防护工程遮弹层研究新进展 [J]. 防护工程, 2005, 27(1): 30–34. [6] 周布奎, 周早生, 唐德高. 单层紧密排列刚玉球遮弹层刚玉球几何尺寸对弹丸侵彻效应的影响 [J]. 防护工程, 2003, 25(1): 35–39. [7] 穆朝民, 施鹏, 辛凯. 射弹侵彻块石遮弹层的数值模拟 [J]. 兵器材料科学与工程, 2012, 35(5): 4–8. DOI: 10.3969/j.issn.1004-244X.2012.05.002.MU C M, SHI P, XIN K. Numerical simulation on rock anti-penetration layer against penetrating [J]. Ordnance Material Science and Engineering, 2012, 35(5): 4–8. DOI: 10.3969/j.issn.1004-244X.2012.05.002. [8] LONGCOPE Jr D B, TABBARA M R, JUNG J. Modeling of oblique penetration into geologic targets using cavity expansion penetrator loading with target free-surface effects [R]. Albuquerque: Sandia National Laboratories, 1999. DOI: 10.2172/7224. [9] MACEK R W, DUFFEY T A. Finite cavity expansion method for near-surface effects and layering during earth penetration [J]. International Journal of Impact Engineering, 2000, 24(3): 239–258. DOI: 10.1016/S0734-743X(99)00156-6. [10] WARREN T L, POORMON K L. Penetration of 6061-T6511 aluminum targets by ogive-nosed VAR 4340 steel projectiles at oblique angles: experiments and simulations [J]. International Journal of Impact Engineering, 2001, 25(10): 993–1022. DOI: 10.1016/S0734-743X(01)00024-0. [11] WARREN T L. Simulations of the penetration of limestone targets by ogive-nose 4340 steel projectiles [J]. International Journal of Impact Engineering, 2002, 27(5): 475–496. DOI: 10.1016/S0734-743X(01)00154-3. [12] WARREN T L, HANCHAK S J, POORMON K L. Penetration of limestone targets by ogive-nosed VAR 4340 steel projectiles at oblique angles: experiments and simulations [J]. International Journal of Impact Engineering, 2004, 30(10): 1307–1331. DOI: 10.1016/j.ijimpeng.2003.09.047. [13] 何涛, 文鹤鸣. 球形弹对金属靶板侵彻问题的数值模拟 [J]. 爆炸与冲击, 2006, 26(5): 456–461.HE T, WEN H M. Computer simulations of the penetration of metal targets by spherical-nosed projectiles [J]. Explosion and Shock Waves, 2006, 26(5): 456–461. [14] 何涛, 文鹤鸣. 靶体响应力函数的确定方法及其在侵彻力学中的应用 [J]. 中国科学技术大学学报, 2007, 37(10): 1249–1261. DOI: 10.3969/j.issn.0253-2778.2007.10.017.HE T, WEN H M. Determination of the analytical forcing function of target response and its applications in penetration mechanics [J]. Journal of University of Science and Technology of China, 2007, 37(10): 1249–1261. DOI: 10.3969/j.issn.0253-2778.2007.10.017. [15] 孔祥振, 方秦, 吴昊. 考虑靶体自由表面和开裂区影响的可变形弹体斜侵彻脆性材料的终点弹道分析 [J]. 兵工学报, 2014, 35(6): 814–821.KONG X Z, FANG Q, WU H. Terminal ballistics study of deformable projectile penetrating brittle material targets for free-surface and crack region effects [J]. Acta Armamentarii, 2014, 35(6): 814–821. [16] LI Q M, FLORES-JOHNSON E A. Hard projectile penetration and trajectory stability [J]. International Journal of Impact Engineering, 2011, 38(10): 815–823. DOI: 10.1016/j.ijimpeng.2011.05.005. [17] FORRESTAL M J, LUK V K. Dynamic spherical cavity-expansion in a compressible elastic-plastic solid [J]. Journal of Applied Mechanics, 1988, 55(2): 275–279. DOI: 10.1115/1.3173672. [18] FREW D J, FORRESTAL M J, HANCHAK S J. Penetration experiments with limestone targets and ogive-nose steel projectiles [J]. Journal of Applied Mechanics, 2000, 67(4): 841–845. DOI: 10.1115/1.1331283. [19] WU H, FANG Q, GONG J, et al. Projectile impact resistance of corundum aggregated UHP-SFRC [J]. International Journal of Impact Engineering, 2015, 84: 38–53. DOI: 10.1016/j.ijimpeng.2015.05.007. [20] LI Q M, REID S R, WEN H M, et al. Local impact effects of hard missiles on concrete targets [J]. International Journal of Impact Engineering, 2005, 32(1−4): 224–284. DOI: 10.1016/j.ijimpeng.2005.04.005. -

下载:

下载: