Experimental study on influence of weak dynamic disturbance on rockburst of granite in a circular tunnel

-

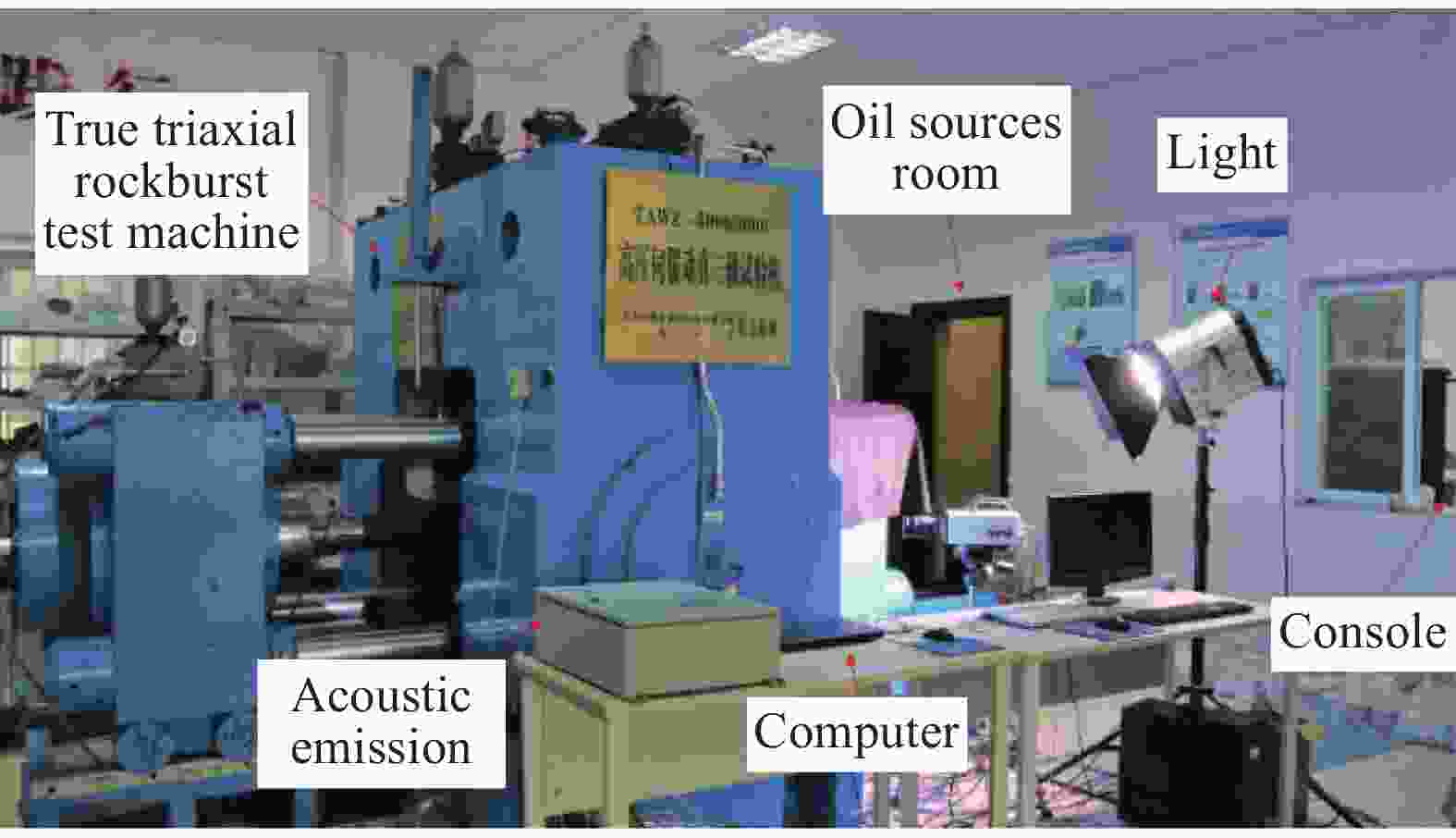

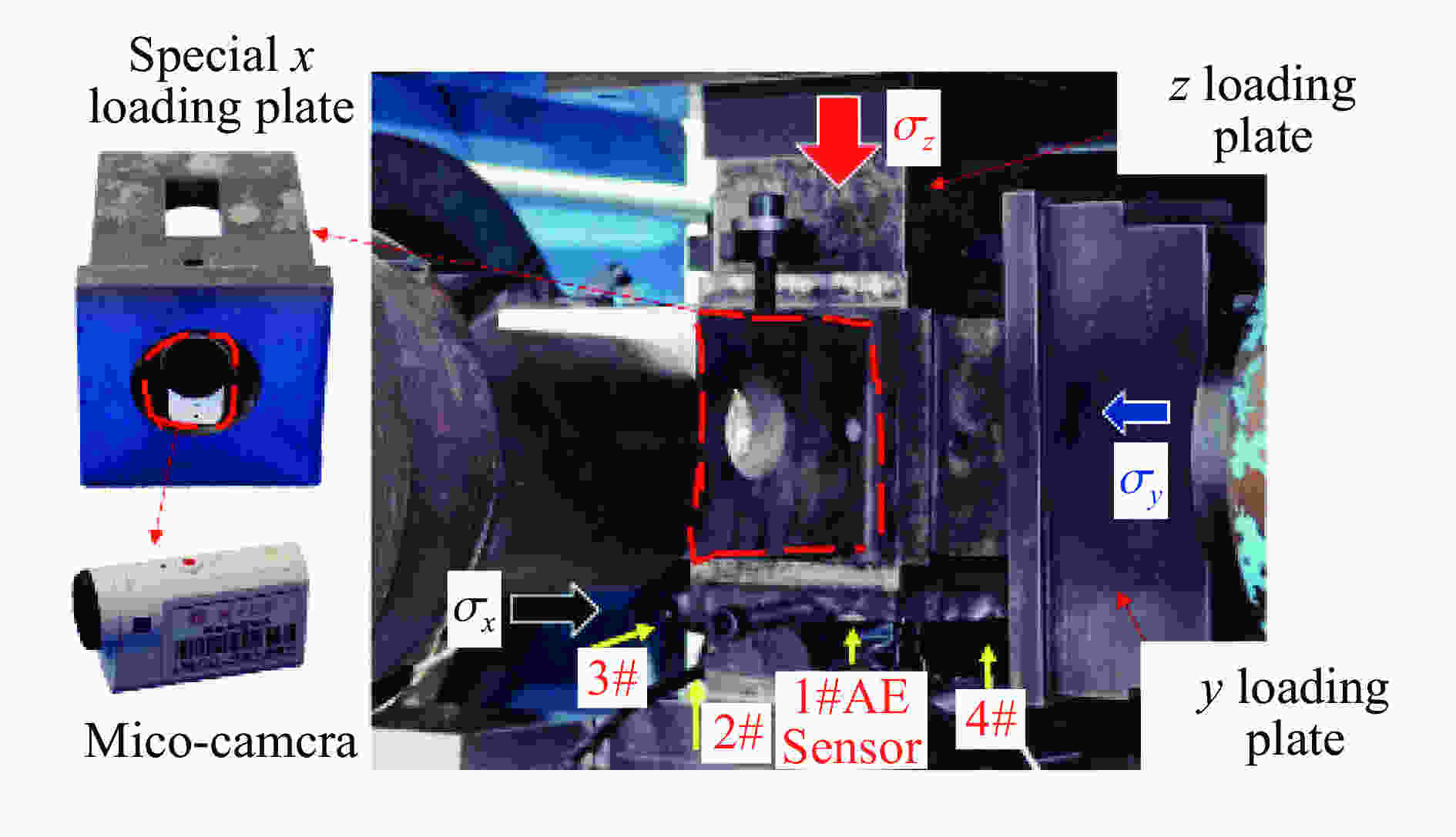

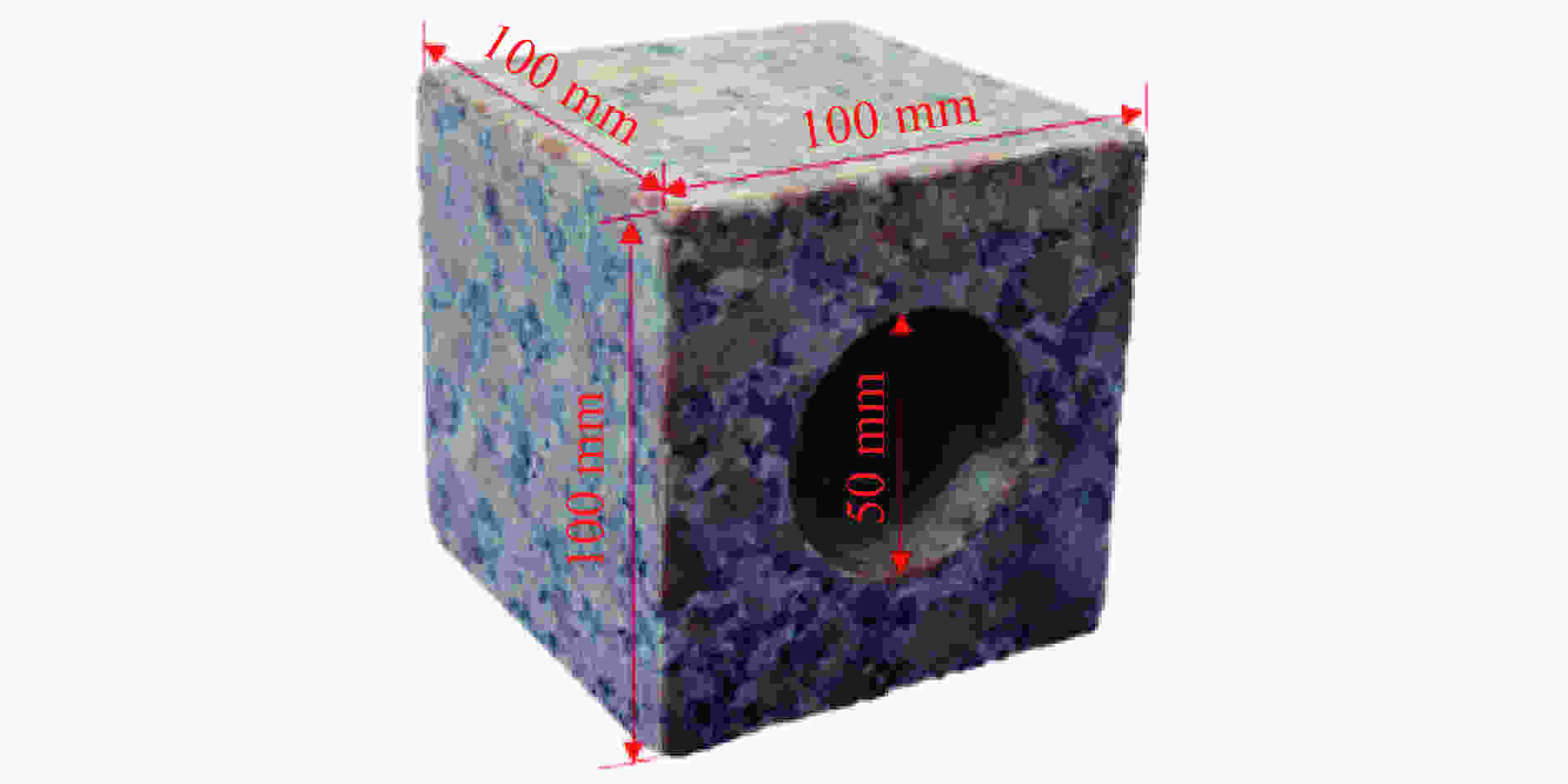

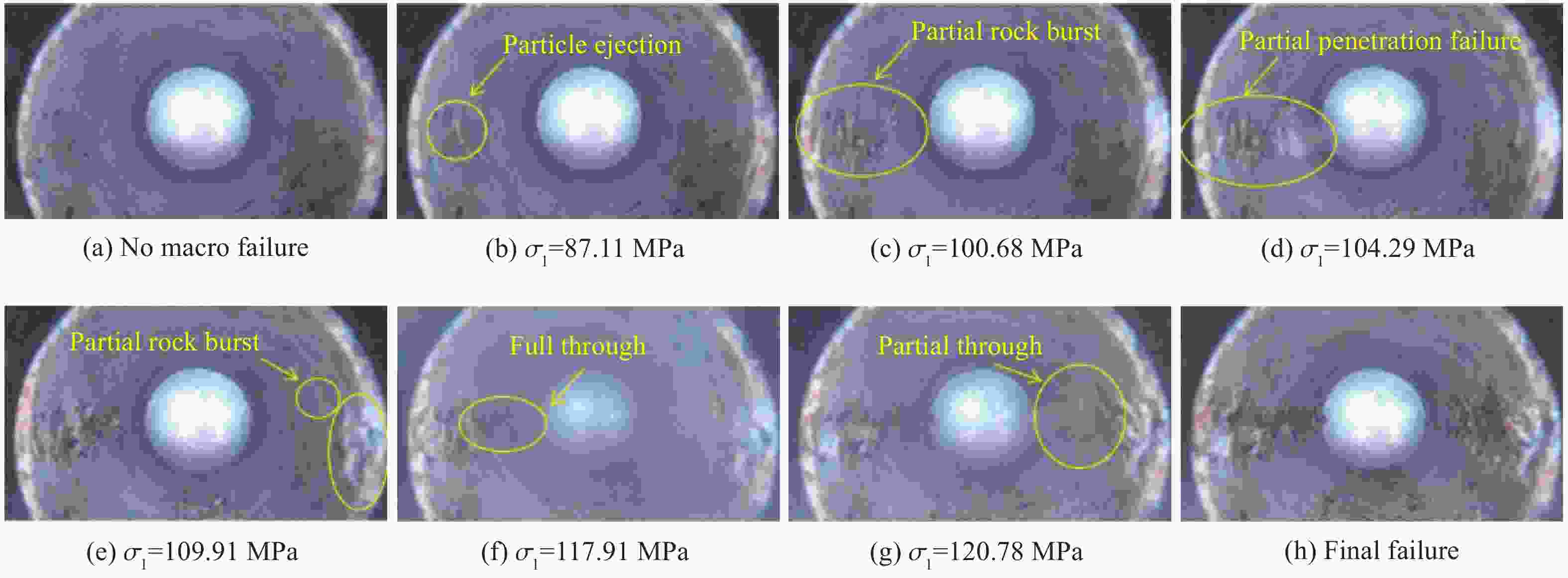

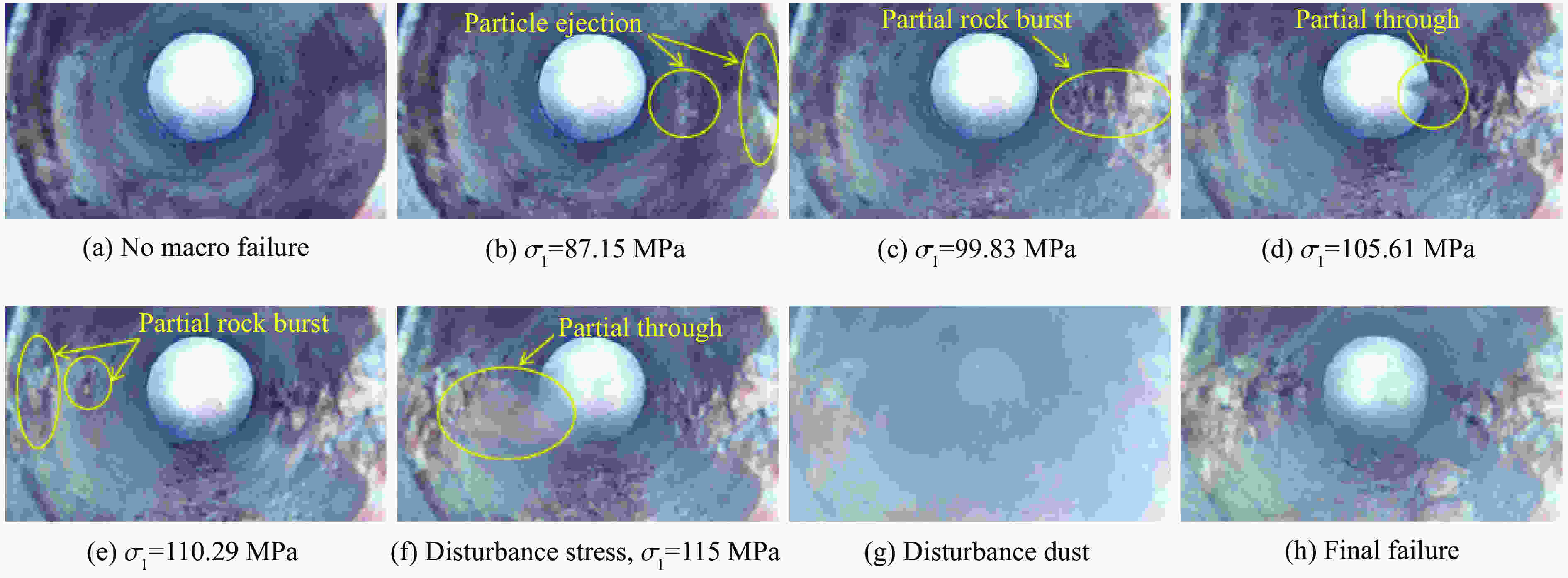

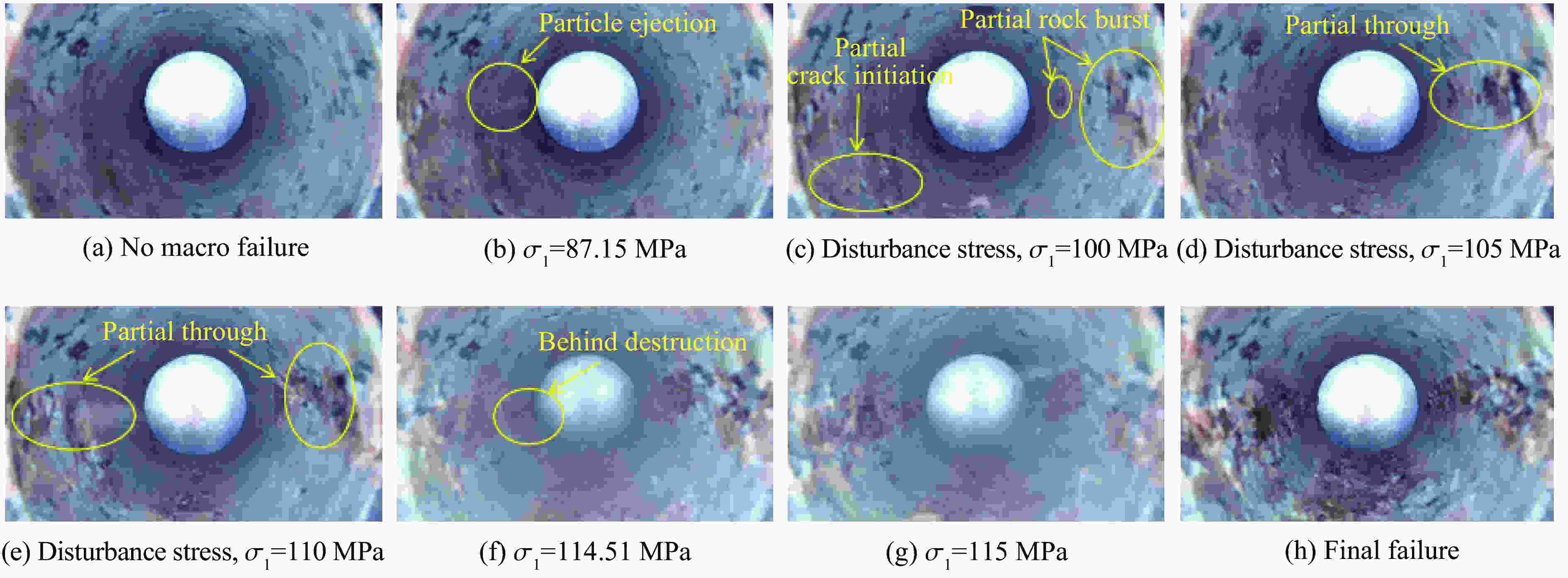

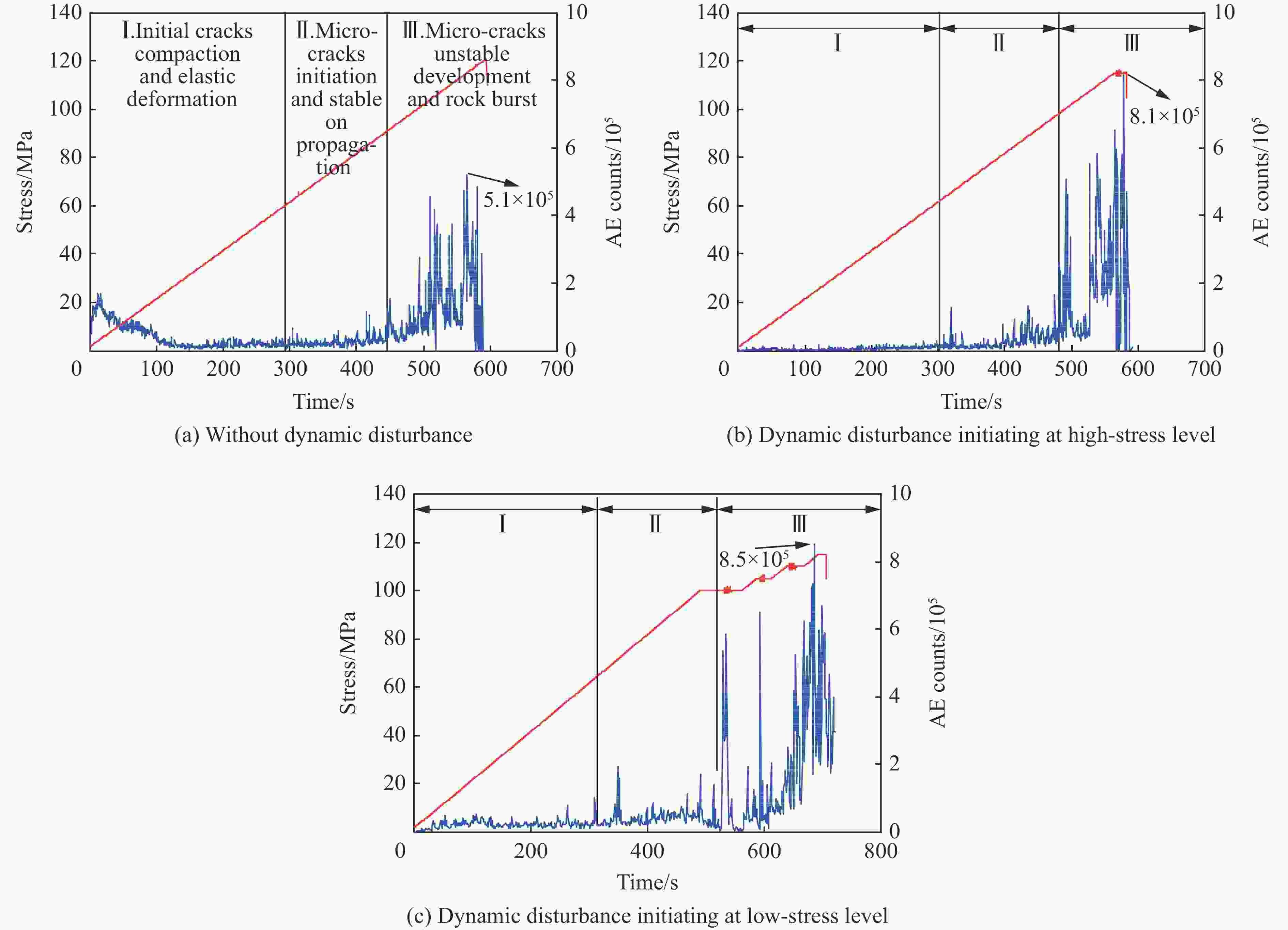

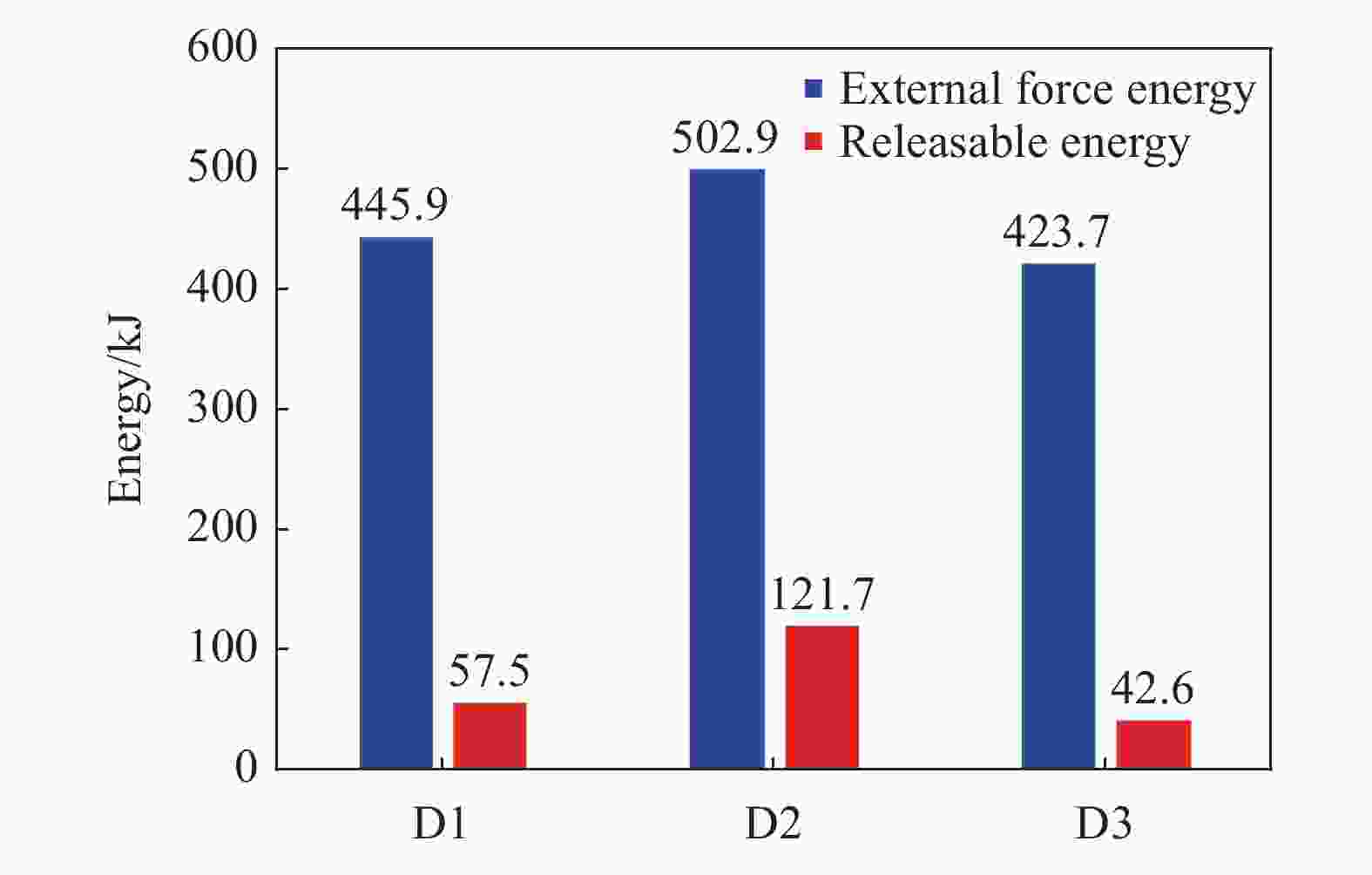

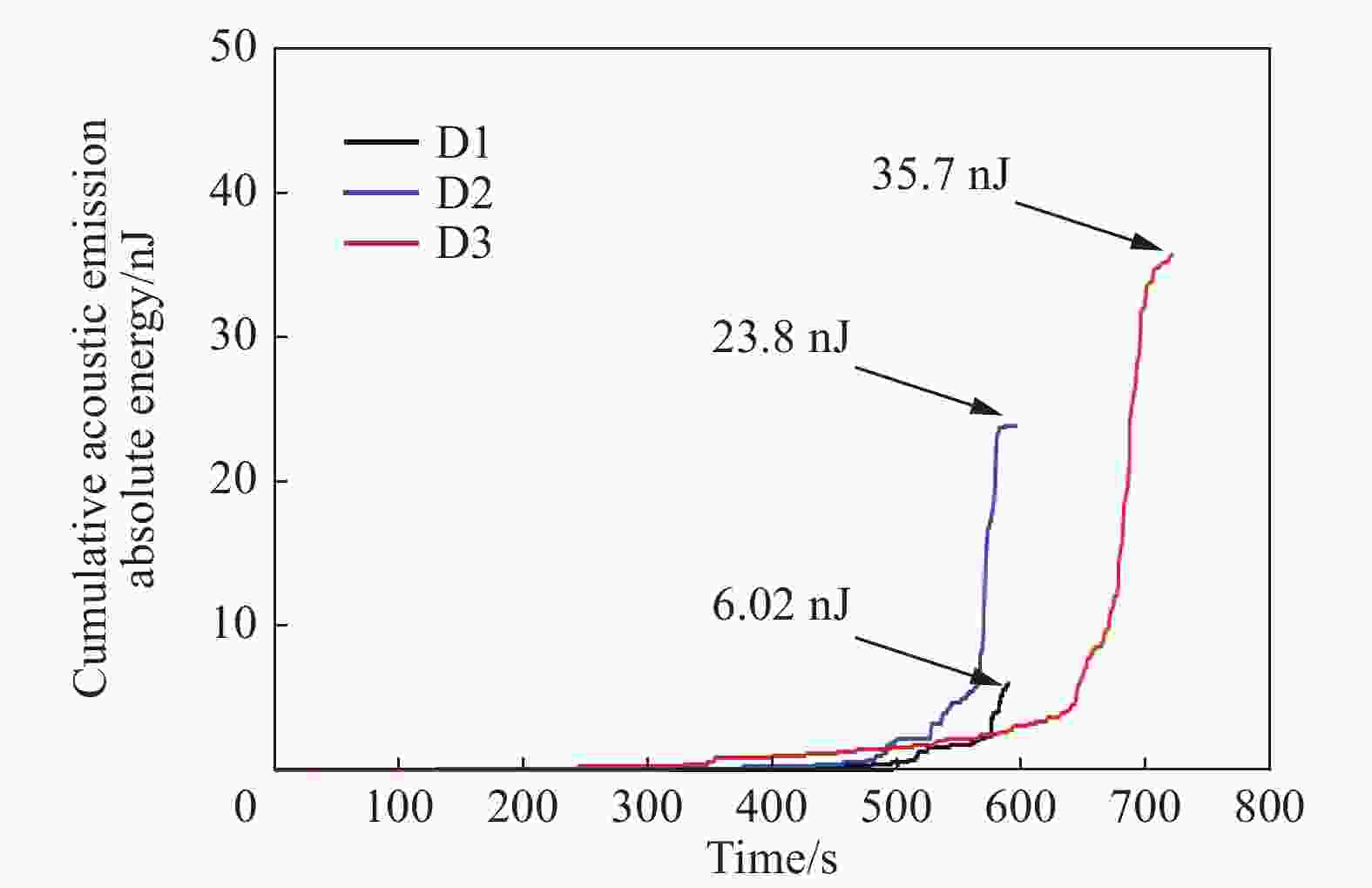

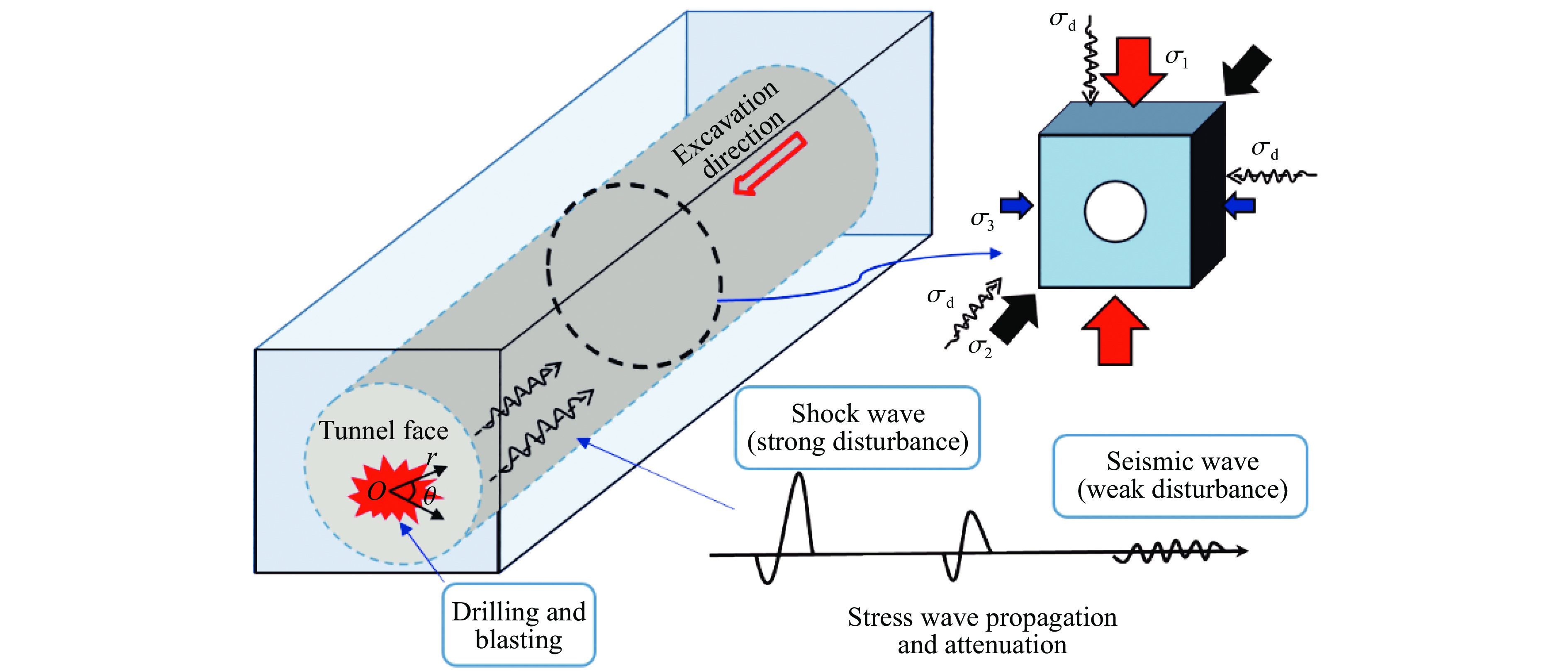

摘要: 为探究弱动力扰动对岩爆的影响,利用高压伺服动真三轴试验机,对含预制圆形贯穿孔洞的红色中粗晶粒立方体花岗岩试样进行弱动力扰动荷载条件下的岩爆模型试验,模拟隧洞洞壁围岩的岩爆弹射破坏过程,并采用声发射系统和视频观测系统对其进行监测、记录。基于无扰动、高应力下开始施加扰动和低应力下开始施加扰动3种加载路径的试验数据,从岩爆弹射破坏、岩爆坑破坏形态、声发射信号特征及岩爆烈度4个方面,详细分析弱动力扰动条件下的岩爆特征。研究结果表明:弱动力扰动会降低洞壁围岩发生岩爆时所需要的应力水平,增大岩爆破坏发生的范围。高应力下开始施加的扰动荷载会促进最终岩爆快速发生;而在低应力下开始施加的扰动荷载,岩爆的发生过程较为缓慢。相比与静应力条件下的岩爆,高应力下开始施加扰动触发的岩爆更剧烈,低应力下开始施加扰动触发的岩爆剧烈程度较弱。这主要是因为在高应力下开始施加的扰动对能量释放起到了激发和放大的作用,低应力下开始施加的扰动对能量释放仅起到激发的作用。Abstract: In order to study the influence of weak dynamic disturbance on rockburst, test on cubic medium-coarse grained granite specimen with a circle hole was conducted to simulate the rockburst ejection process in circle tunnel subjected to weak dynamic disturbance. Three loading paths, namely, no disturbance, weak dynamic disturbance starting at high-stress level, and weak dynamic disturbance beginning at a low-stress level were considered. The testing process was recorded using AE and video monitoring system. The ejection failure process, characteristics of rockburst pit, acoustic emission signal characteristics and rockburst intensity were investigated. The testing results show that the weak dynamic disturbance can reduce the stress level at the occurrence of rockburst and increase the range of rockburst. The applied dynamic disturbance at a high-stress level leads to a rapid occurrence of rockburst. In contrast, when the weak dynamic disturbance is applied at a low-stress level, rockburst will occur in a gradual manner. In addition, compared with that without dynamic disturbance, rockburst with the weak dynamic disturbance starting at high-stress level has a higher intensity, while that with weak dynamic disturbance starting at low high-stress level has a lower intensity. This is because that weak dynamic disturbance starting at high-stress level is capable of stimulating and amplifying the energy release process, while weak dynamic disturbance starting at a low-stress level is only capable of stimulating the energy release process.

-

Key words:

- rockburst /

- dynamic disturbance /

- ture triaxial /

- tunnel model

-

表 1 岩爆坑的尺寸

Table 1. Dimensions of rockburst notch

编号 扰动情况 左侧岩爆坑 右侧岩爆坑 长度/mm 最大宽度/mm 最大深度/mm 长度/mm 最大宽度/mm 最大深度/mm D1 无 100 15 6 47 15 3 D2 有 100 19 11 100 22 7 D3 多次 100 24 9 89 17 8 表 2 不同粒径岩爆碎屑质量分布(单位:g )

Table 2. Mass distribution of rockburst debris with different particle sizes (unit: g )

编号 >4.75 mm >2.38 mm >1.18 mm >0.6 mm >0.3 mm 盘底 总计 D1 0.35 1.06 1.29 1.01 1.51 1.28 6.5 D2 1.49 1.63 1.79 1.69 3.33 2.71 12.64 D3 0.93 2.26 2.23 1.72 2.96 2.35 12.45 -

[1] 钱七虎. 岩爆、冲击地压的定义、机制、分类及其定量预测模型 [J]. 岩土力学, 2014, 35(1): 1–6. DOI: CNKI:SUN:YTLX.0.2014-01001.QIAN Q H. Definition, mechanism, classification and quantitative forecast model for rockburst and pressure bump [J]. Rock and Soil Mechanics, 2014, 35(1): 1–6. DOI: CNKI:SUN:YTLX.0.2014-01001. [2] 冯夏庭. 岩爆孕育过程的机制、预警与动态调控[M]. 北京: 科学出版社, 2013: 159−167. [3] 谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则 [J]. 岩石力学与工程学报, 2005, 24(17): 3003–3010. DOI: 10.3321/j.issn:1000-6915.2005.17.001.XIE H P, JU Y, LI L Y. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(17): 3003–3010. DOI: 10.3321/j.issn:1000-6915.2005.17.001. [4] 谭以安. 岩爆形成机理研究 [J]. 水文地质工程地质, 1989(1): 38–42. DOI: CNKI:SUN:SWDG.0.1989-01-011. [5] KAISER P K, MCCREATH D, TANNANT D. Canadian rockbust support handbook [M]. Geomechanics Research Centre, 1996. 66−81. [6] KAISER P K, CAI M. Design of rock support system under rockburst condition [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2012, 4(3): 215–227. DOI: 10.3724/SP.J.1235.2012.00215. [7] HUANG R Q, WANG X N. Analysis of dynamic disturbance on rock burst [J]. Bulletin of Engineering Geology and the Environment, 1999, 57(3): 281–284. DOI: 10.1007/s100640050046. [8] 陈炳瑞, 冯夏庭, 明华军, 等. 深埋隧洞岩爆孕育规律与机制: 时滞型岩爆 [J]. 岩石力学与工程学报, 2012, 31(3): 561–569. DOI: 10.3969/j.issn.1000-6915.2012.03.014.CHEN B R, FENG X T, MING H J, et al. Evolution law and mechanism of rockburst in deep tunnel: time delayed rockburst [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(3): 561–569. DOI: 10.3969/j.issn.1000-6915.2012.03.014. [9] 何满潮, 苗金丽, 李德建, 等. 深部花岗岩试样岩爆过程实验研究 [J]. 岩石力学与工程学报, 2007, 26(5): 865–876. DOI: 10.3321/j.issn:1000-6915.2007.05.001.HE M C, MIAO J L, LI D J, et al. Experimental study on rockburst processes of granite specimen at great depth [J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(5): 865–876. DOI: 10.3321/j.issn:1000-6915.2007.05.001. [10] ZHAO X G, WANG J, CAI M, et al. Influence of unloading rate on the strainburst characteristics of Beishan granite under true-triaxial unloading conditions [J]. Rock Mechanics and Rock Engineering, 2014, 47(2): 467–483. DOI: 10.1007/s00603-013-0443-2. [11] SU G S, JIANG J Q, ZHAI S B, et al. Influence of tunnel axis stress on strainburst: an experimental study [J]. Rock Mechanics and Rock Engineering, 2017, 50(6): 1551–1567. DOI: 10.1007/s00603-017-1181-7. [12] HU X C, SU G S, CHEN G Y, et al. Experiment on rockburst process of borehole and its acoustic emission characteristics [J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 783–802. DOI: 10.1007/s00603-018-1613-z. [13] 苏国韶, 刘鑫锦, 闫召富, 等. 岩爆预警与烈度评价的声音信号分析 [J]. 爆炸与冲击, 2018, 38(4): 13–21. DOI: 10.11883/bzycj-2017-0383.SU G S, LIU X J, YAN Z F, et al. Sound signal analysis for warning and intensity evaluation of rockburst [J]. Explosion and Shock Waves, 2018, 38(4): 13–21. DOI: 10.11883/bzycj-2017-0383. [14] 苏国韶, 陈冠言, 胡小川, 等. 花岗岩晶粒尺寸对岩爆影响的试验研究 [J]. 爆炸与冲击, 2019, 39(12): 123103. DOI: 10.11883/bzycj-2018-0419.SU G S, CHEN G Y, HU X C, et al. Experimental study on influence of granite grain size on rockburst [J]. Explosion and Shock Waves, 2019, 39(12): 123103. DOI: 10.11883/bzycj-2018-0419. [15] 宫凤强, 罗勇, 司雪峰, 等. 深部圆形隧洞板裂屈曲岩爆的模拟试验研究 [J]. 岩石力学与工程学报, 2017, 36(7): 1633–1648. DOI: CNKI:SUN:YSLX.0.2017-07-008.GONG F Q, LUO Y, SI X F, et al. Experimental modelling on rockburst in deep hard rock circal tunnels [J]. Chinese Journal of Rock Mechanicsand Engineering, 2017, 36(7): 1633–1648. DOI: CNKI:SUN:YSLX.0.2017-07-008. [16] 李夕兵, 周子龙, 叶州元, 等. 岩石动静组合加载力学特性研究 [J]. 岩石力学与工程学报, 2008, 27(7): 1387–1395. DOI: 10.3321/j.issn:1000-6915.2008.07.011.LI X B, ZHOU Z L, YE Z Y, et al. Study of rock mechanical characteristics under coupled static and dynamic loads [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(7): 1387–1395. DOI: 10.3321/j.issn:1000-6915.2008.07.011. [17] ZUO Y J, LI X B, ZHOU Z L, et al. Damage and failure rule of rock undergoing uniaxial compressive load and dynamic load [J]. Journal of Central South University of Technology, 2005, 12(6): 742–748. DOI: 10.1007/s11771-005-0080-3. [18] 何满潮, 刘冬桥, 宫伟力, 等. 冲击岩爆试验系统研发及试验 [J]. 岩石力学与工程学报, 2014, 33(9): 1729–1739. DOI: 10.13722/j.cnki.jrme.2014.09.001.HE M C, LIU D Q, GONG W L, et al. Development of a testing system for impact rockbursts [J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(9): 1729–1739. DOI: 10.13722/j.cnki.jrme.2014.09.001. [19] 苏国韶, 胡李华, 冯夏庭, 等. 低频周期扰动荷载与静载联合作用下岩爆过程的真三轴试验研究 [J]. 岩石力学与工程学报, 2016, 35(7): 1309–1322. DOI: 10.13722/j.cnki.jrme.2015.1249.SU G S, HU L H, FENG X T, et al. True triaxial experimental study of rockburst process under low frequency cyclic disturbance load combined with static load [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(7): 1309–1322. DOI: 10.13722/j.cnki.jrme.2015.1249. [20] SU G S, FENG X T, WANG J H, et al. Experimental study of remotely triggered rockburst induced by a tunnel axial dynamic disturbance under true-triaxial conditions [J]. Rock Mechanics and Rock Engineering, 2017, 50(8): 2207–2226. DOI: 10.1007/s00603-017-1218-y. [21] DU K, TAO M, LI X B, et al. Experimental study of slabbing and rockburst induced by true-triaxial unloading and local dynamic disturbance [J]. Rock Mechanics and Rock Engineering, 2016, 49(9): 3437–3453. DOI: 10.1007/s00603-016-0990-4. [22] READ R S. 20 years of excavation response studies at AECL’s underground research laboratory [J]. Rock Mechanics and Rock Engineering, 2004, 41(8): 1251–1275. DOI: 10.1016/j.ijrmms.2004.09.012. [23] 黄润秋, 黄达. 卸荷条件下花岗岩力学特性试验研究 [J]. 岩石力学与工程学报, 2008, 27(11): 2205–2213. DOI: 10.3321/j.issn:1000-6915.2008.11.005.HUANG R Q, HUANG D. Experimental research on mechanical properties of granites under unloading condition [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(11): 2205–2213. DOI: 10.3321/j.issn:1000-6915.2008.11.005. [24] 许金余, 刘石. 大理岩冲击加载试验碎块的分形特征分析 [J]. 岩土力学, 2012, 33(11): 3225–3229. DOI: 10.16285/j.rsm.2012.11.005.XU J Y, LIU S. Research on fractal characteristics of marble fragments subjected to impact loading [J]. Rock and Soil Mechanics, 2012, 33(11): 3225–3229. DOI: 10.16285/j.rsm.2012.11.005. [25] 沈功田. 声发射检测技术及应用[M]. 北京: 科学出版社, 2015: 53−56. -

下载:

下载: