Experimental study on the peak pressure of borehole wall in decoupling charge blasting

-

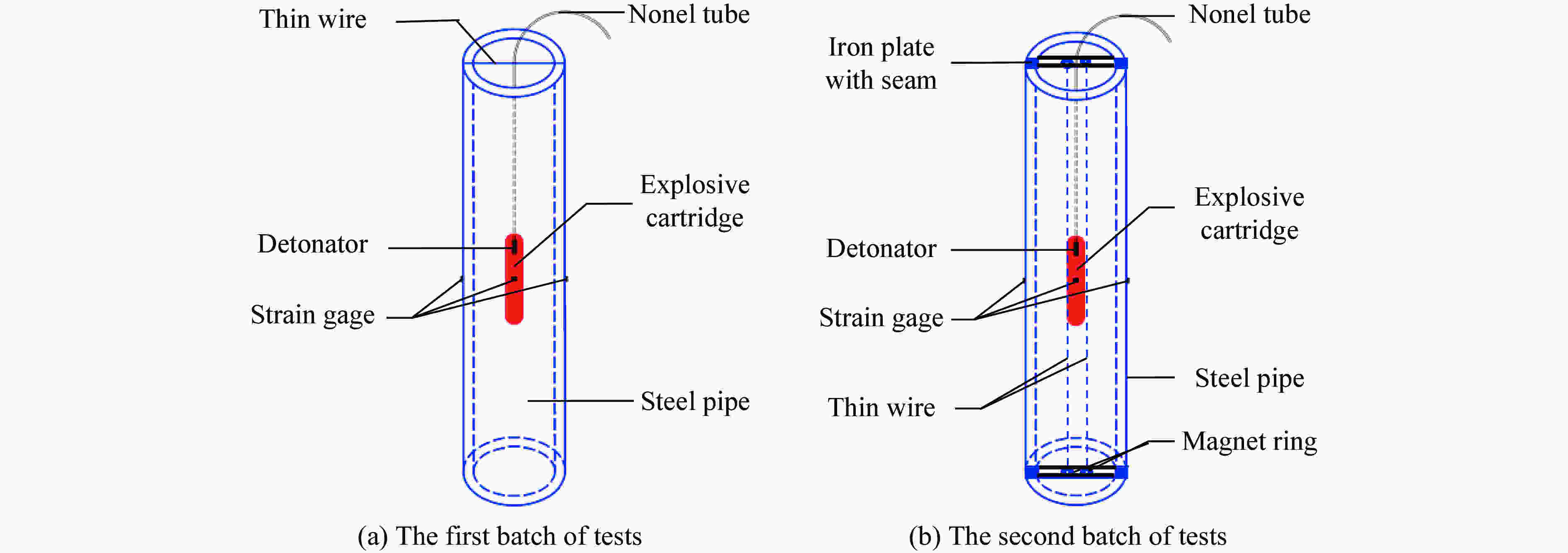

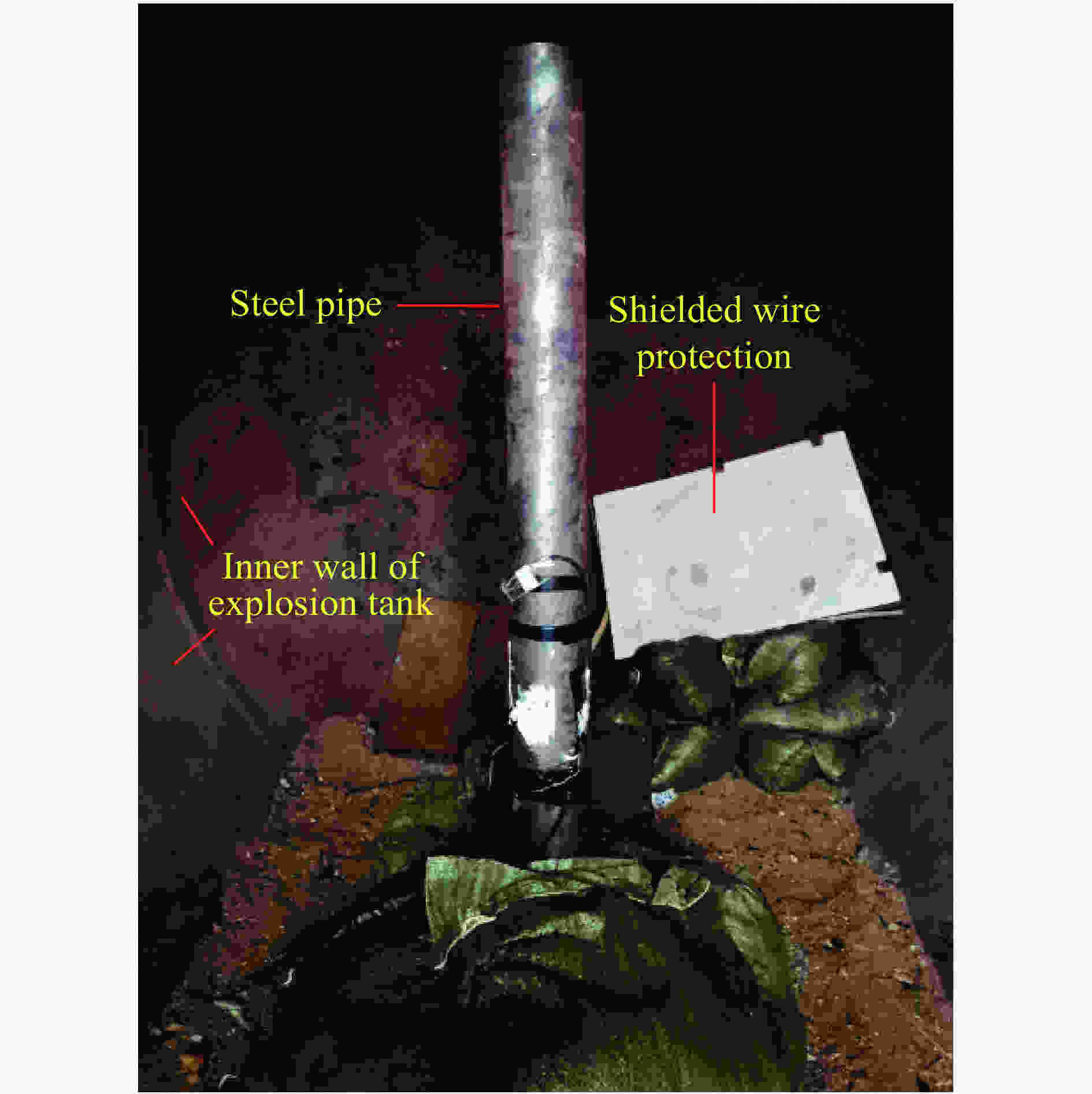

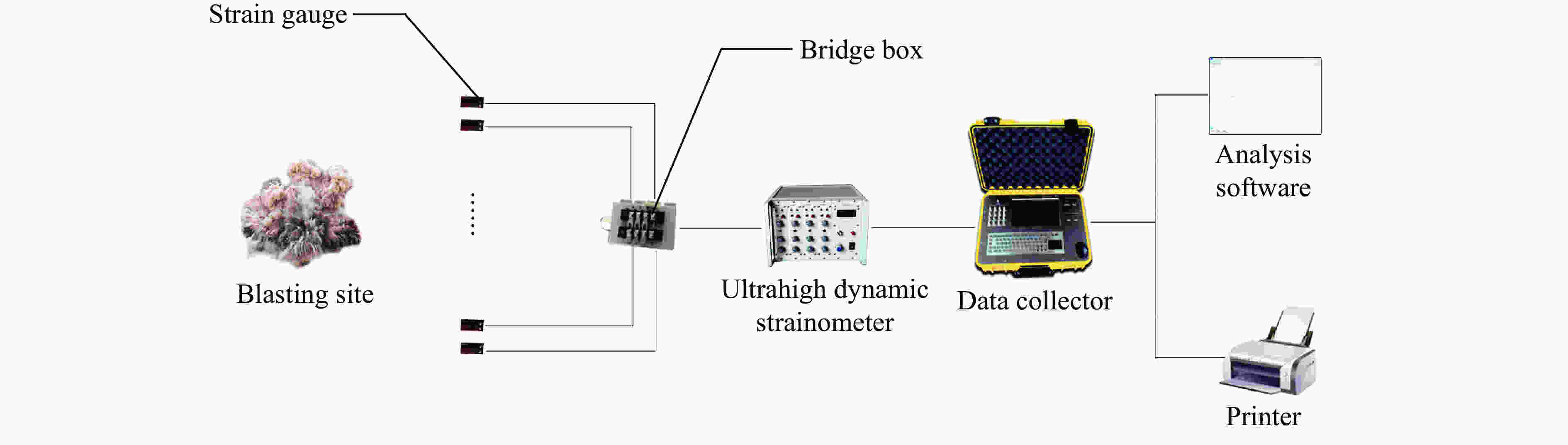

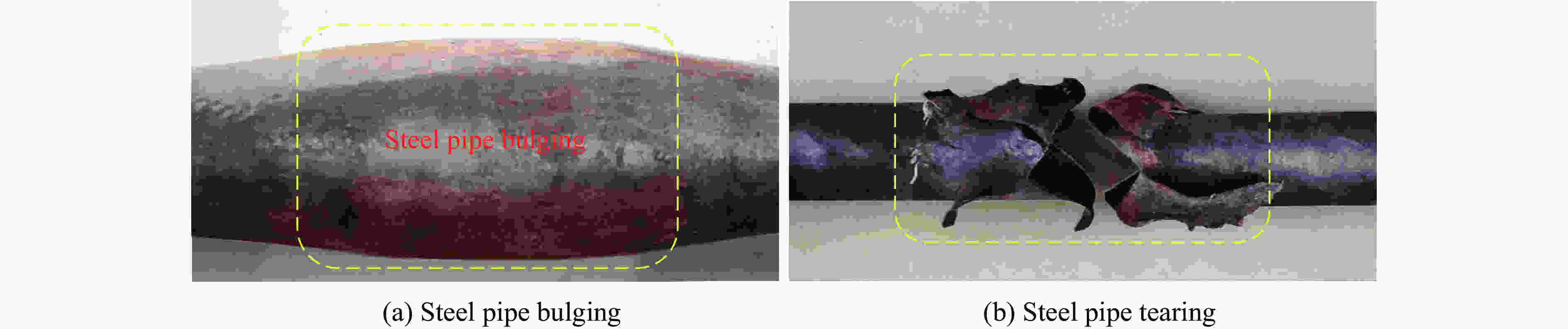

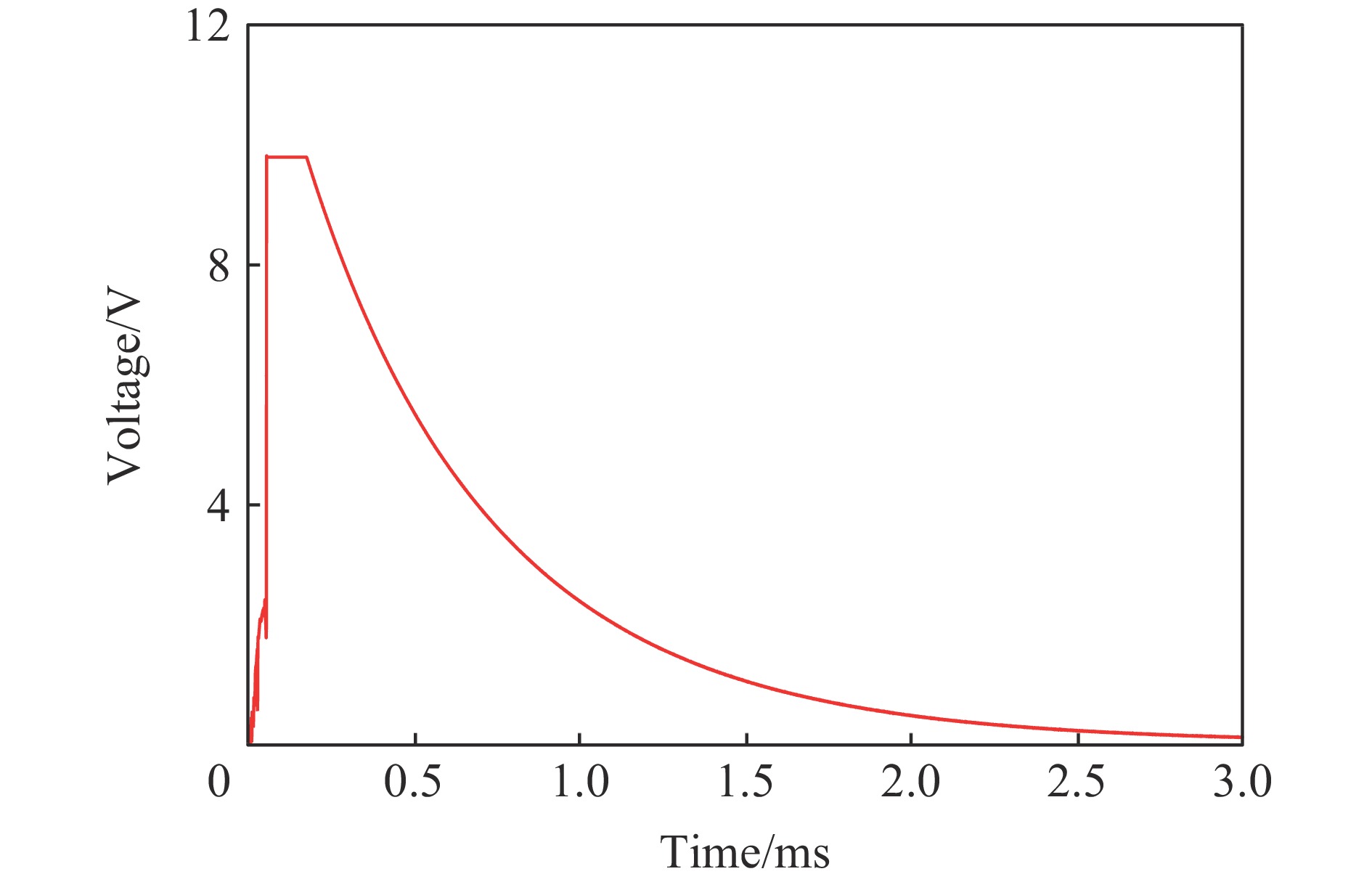

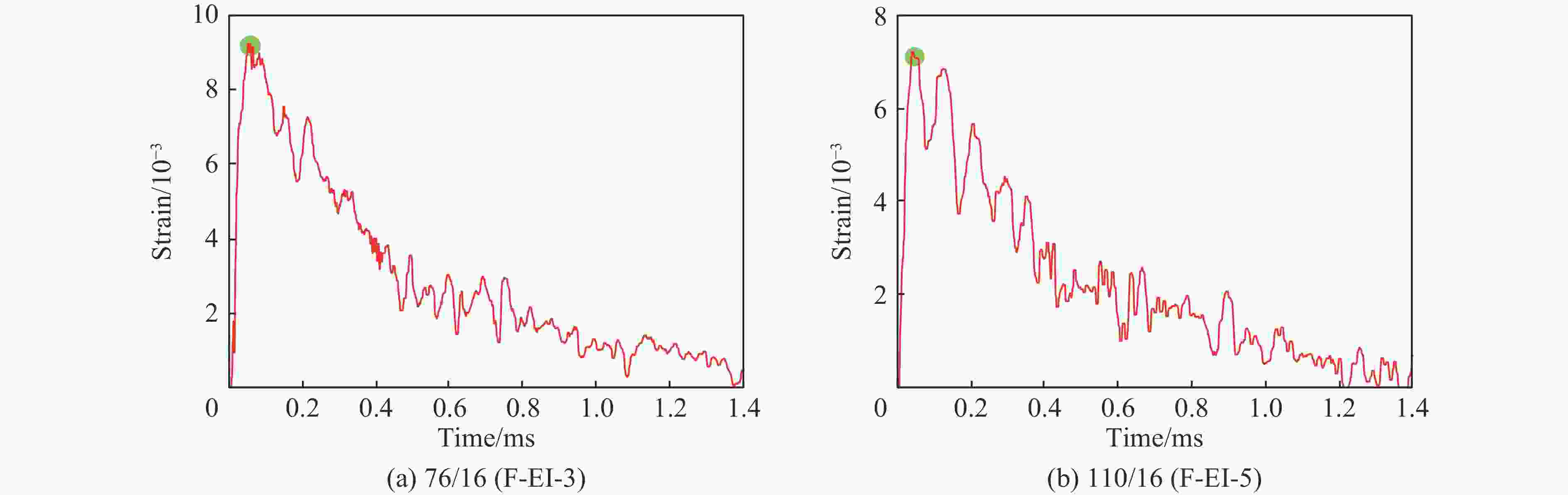

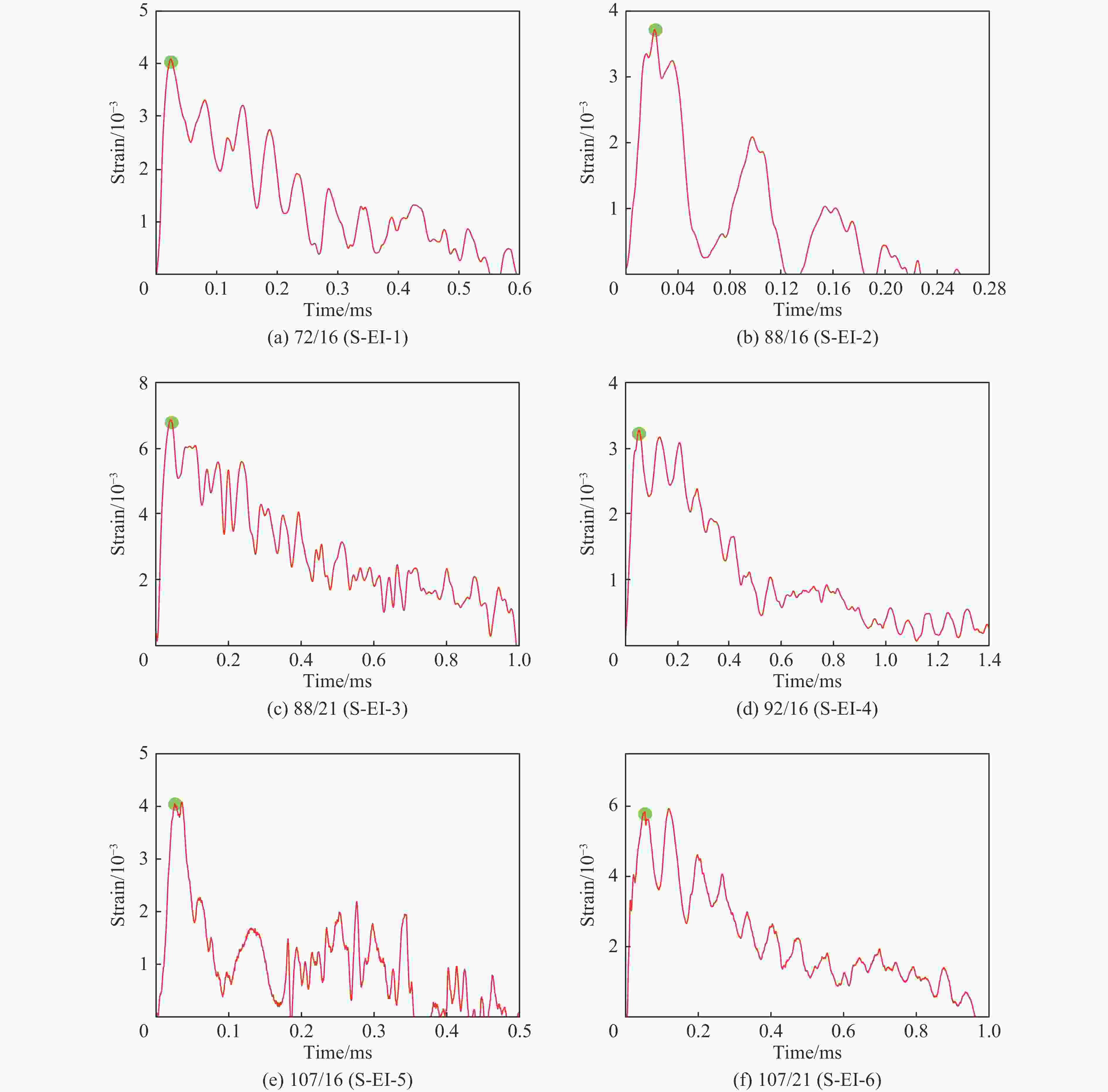

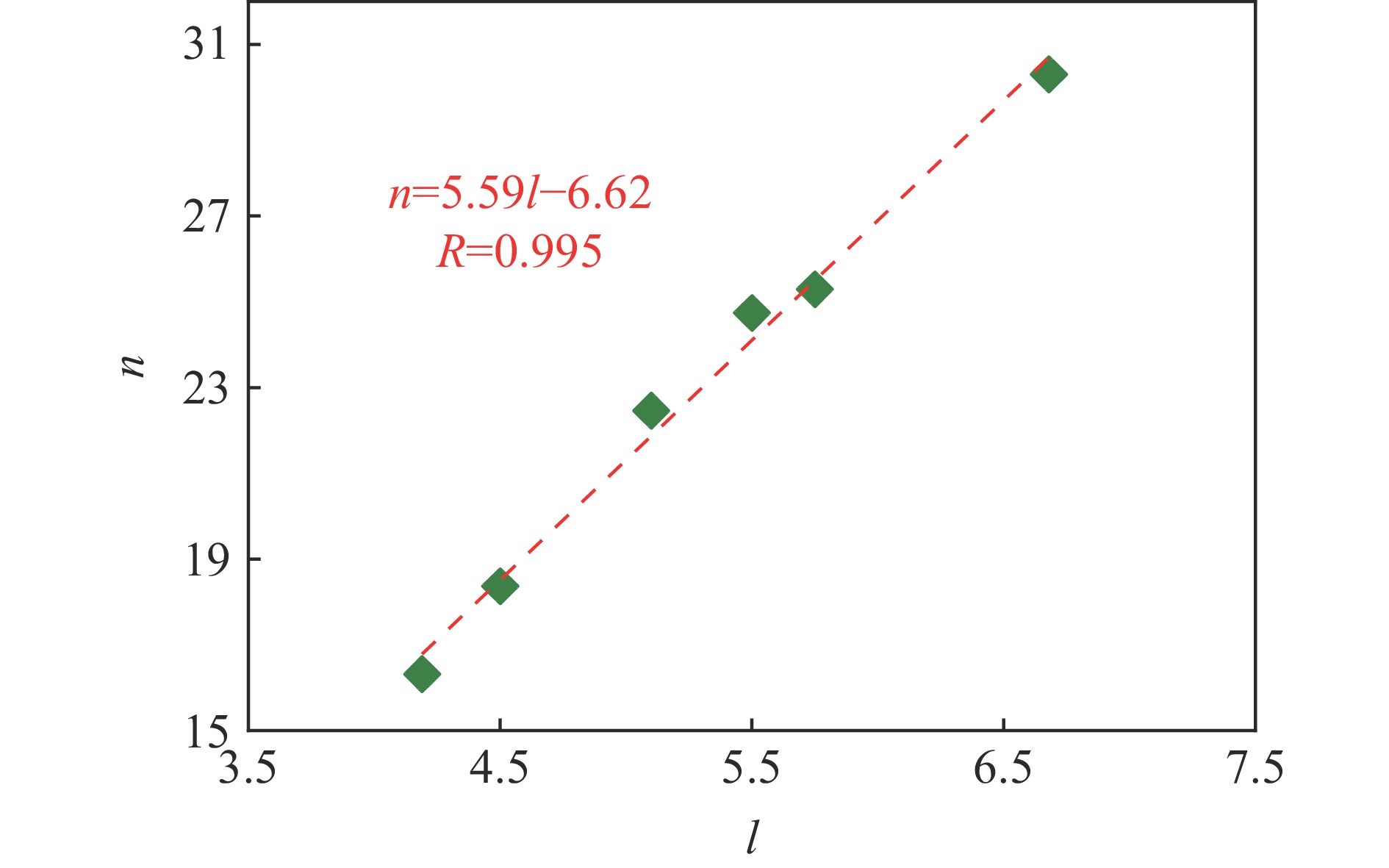

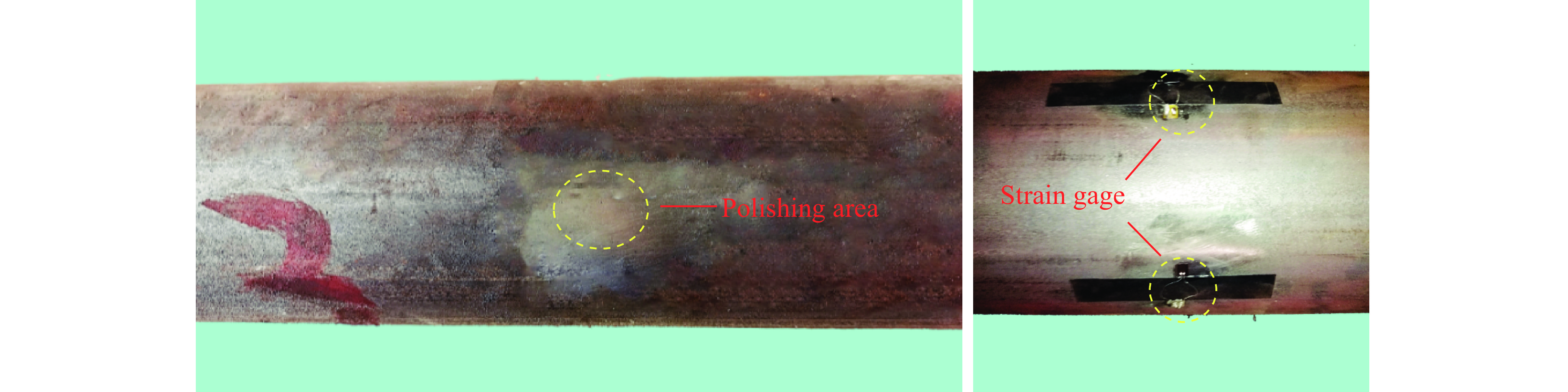

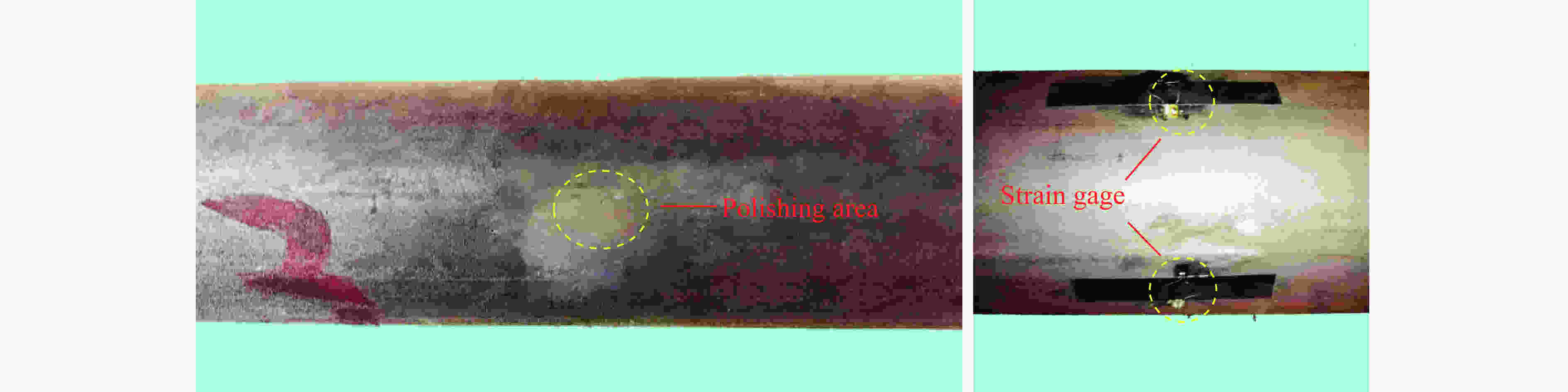

摘要: 不耦合装药爆破孔壁压力峰值是控制岩体轮廓成形质量及进行非流固耦合爆破振动响应数值模拟分析的重要参数,本文采用实验方法研究了不耦合装药爆破的孔壁压力峰值:利用材质为20钢的无缝薄壁钢管模拟不耦合装药爆破炮孔,以高灵敏度、高精度的应变片为传感器,选用超动态应变仪采集钢管内置柱状炸药卷爆炸过程中钢管外壁产生的环向应变,应用动荷载作用下薄壁圆筒的动力响应计算方法,反演分析采集的钢管外壁环向应变数据,得到了爆破过程中空气冲击波作用于钢管内壁的冲击荷载压力峰值,间接测量了不耦合装药爆炸后的孔壁压力峰值。实验获得了6种不耦合装药工况下的爆破孔壁压力峰值测试数据,并计算了相应工况下实验值较准静态爆生气体压力的增大倍数,拟合结果表明压力增大倍数随不耦合系数的增大近似呈线性增长。同时也分析了部分试验工况下爆炸测试结果不理想的原因,研究成果可为轮廓爆破孔壁压力峰值的测试与计算提供参考。Abstract: The peak pressure of borehole wall in decoupling charge blasting is an important parameter to control the quality of rock mass profile forming and to carry out numerical simulation analysis of blasting vibration response of non-fluid-solid coupling. In this paper, the peak pressure of borehole wall in decoupling charge blasting was studied from an experimental perspective. Based on the characteristics that the difference between the two higher wave impedance media, steel pipe and rock, has little effect on the peak pressure of borehole wall, the seamless thin-walled steel pipe made of 20# steel was used to simulate the borehole in decoupling blasting with high-sensitivity-high-precision strain gauge as sensor, four strain gauges arranged along the circumferential direction of a certain section of each steel pipe. Ultrahigh dynamic strainometer was used to collect the circumferential strain of steel pipe during the explosion process of built-in columnar explosive cartridge; the method of calculating the dynamic response of thin-walled cylinder under dynamic load is used to calculate the collected circumferential strain; the elastic dynamic formula of the thin-walled cylinder was used to deduce the collected circumferential strain; and the peak pressure on the borehole wall by the air shock wave has been measured indirectly. The peak pressure on the borehole wall under six working conditions was obtained, and calculated the ratio of the experimental values to the quasi-static gas-pressure under the corresponding working conditions to obtain increase multiples. The decoupling coefficient was taken as the abscissa and the pressure increase multiple as the ordinate for the fitting, the fitting results indicate that the pressure increase multiples increase approximately linearly with the increase of the decoupling coefficients, and the fitting correlation coefficient is as high as 0.99 or more.At the same time, the reasons why the experimental results under some working conditions are unsatisfactory have been analyzed, which can be referred to the measurement and calculation of the peak pressure of borehole wall in contour blasting.

-

Key words:

- decoupling charge /

- borehole peak pressure /

- circumferential strain /

- dynamic response

-

表 1 第一批次实验工况

Table 1. First batch experimental cases

实验工况 钢管内径/mm 钢管外径/mm 数量/根 药卷直径/mm F-EI-1 42 50 4 11、16、21、26 F-EI-2 50 60 4 11、16、21、26 F-EI-3 76 89 4 16、21、26、32 F-EI-4 90 102 4 16、21、26、32 F-EI-5 110 121 4 16、21、26、32 表 2 第二批次实验工况

Table 2. Second batch experimental cases

实验工况 钢管内径/mm 钢管外径/mm 数量/根 药卷直径/mm S-EI-1 72 88 3 16 S-EI-2 88 108 3 16 S-EI-3 88 108 4 21 S-EI-4 92 108 3 16 S-EI-5 107 121 3 16 S-EI-6 107 127 4 21 表 3 第二批次实验不同工况钢管内壁压力峰值(单位:MPa)

Table 3. Peak pressure of steel pipe inner wall under different conditions in the second bath experiment (units: MPa)

实验工况 实验序号 通道a 通道b 通道c 通道d 平均值 S-EI-1 (72/16) 1 280.79 303.46 251.44 245.00 270.17 2 261.73 346.04 231.87 214.72 263.59 3 275.59 288.43 262.36 231.92 264.58 S-EI-2 (88/16) 4 180.54 231.37 224.38 197.95 208.56 5 199.43 231.80 224.57 212.34 217.04 S-EI-3 (88/21) 6 损坏 277.69 259.54 287.26 274.83 7 321.77 284.25 299.88 272.16 294.51 S-EI-4 (92/16) 8 188.27 211.06 200.80 187.87 197.00 9 170.45 损坏 191.53 209.43 190.47 S-EI-5 (107/16) 10 156.42 173.19 163.86 损坏 164.49 11 126.06 157.26 损坏 172.74 152.02 12 143.53 146.93 158.72 171.28 155.12 S-EI-6 (107/21) 13 235.77 218.79 178.93 213.21 211.68 14 230.38 237.75 252.18 264.05 246.09 15 229.18 损坏 236.71 254.07 239.99 16 294.95 208.28 255.38 220.31 244.73 表 4 压力增大倍数

Table 4. Pressure increase factor

实验工况 不耦合系数 钢管内壁压力峰值/MPa 准静态压力/MPa 压力增大倍数 88/21 (S-EI-3) 4.19 284.67 17.44 16.32 72/16 (S-EI-1) 4.50 266.11 14.49 18.37 107/21 (S-EI-6) 5.10 235.62 10.49 22.46 88/16 (S-EI-2) 5.50 212.80 8.60 24.74 92/16 (S-EI-4) 5.75 193.74 7.66 25.29 107/16 (S-EI-5) 6.68 157.21 5.19 30.30 -

[1] 费鸿禄, 李守巨, 何庆志. 光面爆破装药不偶合系数的计算 [J]. 爆炸与冲击, 1992, 12(3): 270–274.FEI H L, LI S J, HE Q Z. Determintion of decouple coefficient and analysis of decouple action in the smooth blasting [J]. Explosion and Shock Waves, 1992, 12(3): 270–274. [2] 王伟, 李小春, 石露, 等. 深层岩体松动爆破中不耦合装药效应的探讨 [J]. 岩土力学, 2008, 29(10): 2837–2842. DOI: 10.16285/j.rsm.2008.10.009.WANG W, LI X C, SHI L, et al. Discussion on decoupled charge loosening blasting in deep rock mass [J]. Rock and Soil Mechanics, 2008, 29(10): 2837–2842. DOI: 10.16285/j.rsm.2008.10.009. [3] 刘云川, 汪旭光, 刘连生, 等. 不耦合装药条件下炮孔初始压力计算的能量方法 [J]. 中国矿业, 2009, 18(6): 104–107; 110. DOI: 10.3969/j.issn.1004-4051.2009.06.031.LIU Y C, WANG X G, LIU L S, et al. An energy method for calculate borehole pressure under decoupled charging [J]. China Mining Magazine, 2009, 18(6): 104–107; 110. DOI: 10.3969/j.issn.1004-4051.2009.06.031. [4] FRANCIS O. Measurements and prsesdictions of borehole pressure variations in model blasting system [C] // First International Symposium on Rock Fragmentation by Blasting. Lulea, Sweden, 1983. [5] HOMMERT P J, KUSZMAUL R L, PAR RISH R L. 爆破漏斗堵塞物作用的计算和试验研究[C] // 第2届爆破破岩国际会议译文集. 1990. [6] LI N. The numerical modelling of blasting loading, application of computer methods in rock mechanics [C] // Proceedings of International Symposium ACMIRME. Xi’an, China, 1993. [7] 闫国斌, 于亚伦. 空气与水介质不耦合装药爆破数值模拟 [J]. 工程爆破, 2009, 15(4): 13–19; 65. DOI: 10.3969/j.issn.1006-7051.2009.04.004.YAN G B, YU Y L. Numerical simulation of air and water medium decoupling charge blasting [J]. Engineering Blasting, 2009, 15(4): 13–19; 65. DOI: 10.3969/j.issn.1006-7051.2009.04.004. [8] 余德运, 刘殿书, 李洪超, 等. 柱状装药炮孔壁初始压力数值模拟及误差分析 [J]. 爆破, 2015, 32(4): 26–32. DOI: 10.3963/j.issn.1001-487X.2015.04.006.YU D Y, LIU D S, LI H C, et al. Numerical simulation and error analysis of preliminary shock pressure on borehole wall in columnar blasting [J]. Blasting, 2015, 32(4): 26–32. DOI: 10.3963/j.issn.1001-487X.2015.04.006. [9] FELDGUN V R, KARINSKI Y S, YANKELEVSKY D Z. Experimental simulation of blast loading on structural elements using rarefaction waves-theoretical analysis [J]. International Journal of Impact Engineering, 2017, 102: 86–101. DOI: 10.1016/j.ijimpeng.2016.12.010. [10] SAHARAN M R, MITRI H S. Numerical procedure for dynamic simulation of discrete fractures due to blasting [J]. Rock Mechanics and Rock Engineering, 2008, 41(5): 641–670. DOI: 10.1007/s00603-007-0136-9. [11] YILMAZ O, UNLU T. Three dimensional numerical rock damage analysis under blasting load [J]. Tunnelling and Underground Space Technology, 2013, 38: 266–278. DOI: 10.1016/j.tust.2013.07.007. [12] 朱振海, 曲广建, 孙强, 等. 不耦合装药爆炸应力场的动光弹研究 [J]. 爆炸与冲击, 1991, 11(3): 252–257.ZHU Z H, QU G J, SUN Q, et al. Dynamic photoelastic investigation of the action of decouple [J]. Explosion and Shock Waves, 1991, 11(3): 252–257. [13] 凌伟明. 岩石爆破炮孔孔壁压力的试验研究 [J]. 矿冶, 2004, 13(4): 13–16. DOI: 10.3969/j.issn.1005-7854.2004.04.004.LING W M. Experimental research on explosion pressure on the wall of a borehole in rock [J]. Mining & Metallurgy, 2004, 13(4): 13–16. DOI: 10.3969/j.issn.1005-7854.2004.04.004. [14] TALHI K, BENSAKER B. Design of a model blasting system to measure peak p-wave stress [J]. Soil Dynamics and Earthquake Engineering, 2003, 23(6): 513–519. DOI: 10.1016/S0267-7261(03)00018-6. [15] 宗琦, 罗强. 炮孔水耦合装药爆破应力分布特性试验研究 [J]. 实验力学, 2006, 21(3): 393–398. DOI: 10.3969/j.issn.1001-4888.2006.03.022.ZONG Q, LUO Q. Experimental study on distribution character of blasting stress when boreholes with water-couple charge [J]. Journal of Experimental Mechanics, 2006, 21(3): 393–398. DOI: 10.3969/j.issn.1001-4888.2006.03.022. [16] 陈明, 刘涛, 叶志伟, 等. 轮廓爆破孔壁压力峰值计算方法 [J]. 爆炸与冲击, 2019, 39(6): 064202. DOI: 10.11883/bzycj-2018-0171.CHEN M, LIU T, YE Z W, et al. Calculation methods for peak pressure on borehole wall of contour blasting [J]. Explosion and Shock Waves, 2019, 39(6): 064202. DOI: 10.11883/bzycj-2018-0171. [17] 罗兴柏, 张玉令, 丁玉奎. 爆炸力学理论教程[M]. 北京: 国防工业出版社, 2016: 254−259. [18] 陈勇军, 朱劲松, 孙国有, 等. 动载荷作用下区分厚壁圆筒和薄壁圆筒的一个准则 [J]. 压力容器, 2005, 22(6): 15–19. DOI: 10.3969/j.issn.1001-4837.2005.06.005.CHEN Y J, ZHU J S, SUN G Y, et al. A criterion to distinguish between thick-walled cylinder and thin-walled cylinder under dynamic loading [J]. Pressure Vessel Technology, 2005, 22(6): 15–19. DOI: 10.3969/j.issn.1001-4837.2005.06.005. [19] HENRYCH J. The dynamics of explosion and its use [M]. New York: Elsevier Scientific Publishing Company, 1979. -

下载:

下载: