Characteristics of gas explosion to diffusion combustion under porous materials

-

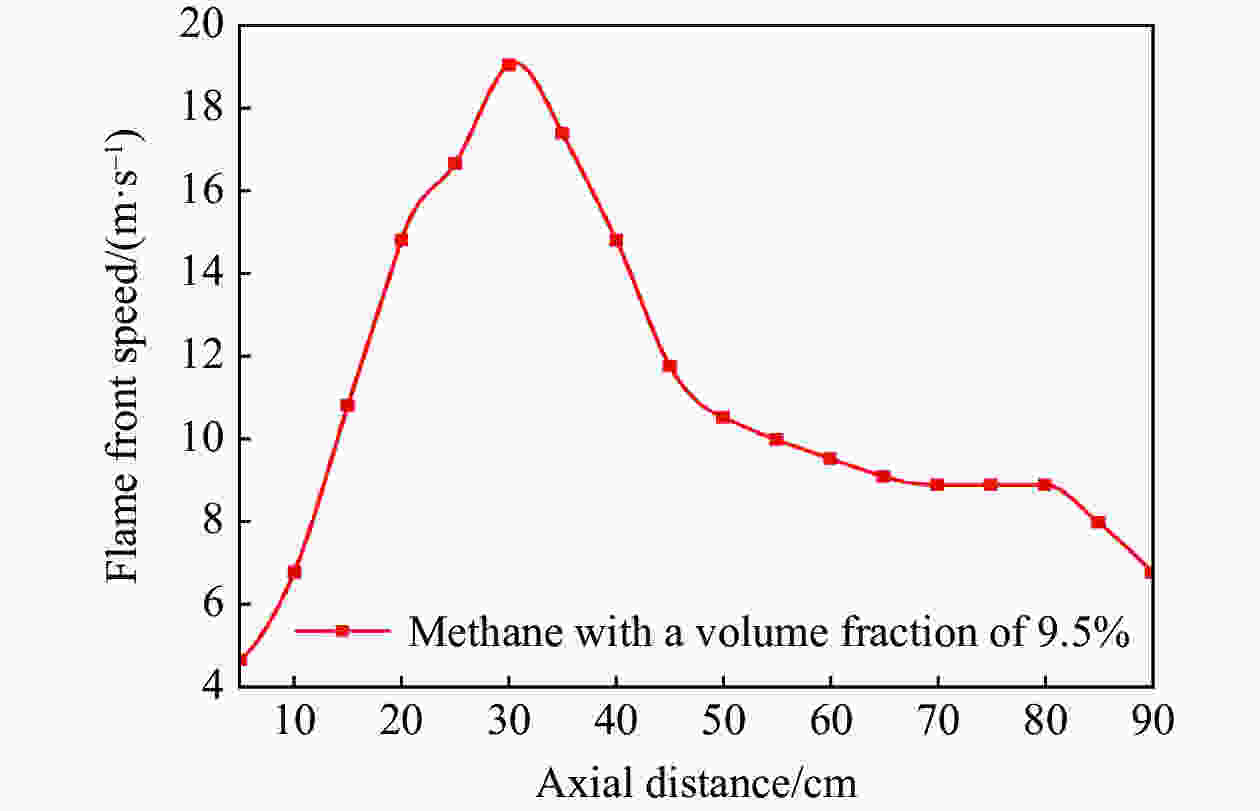

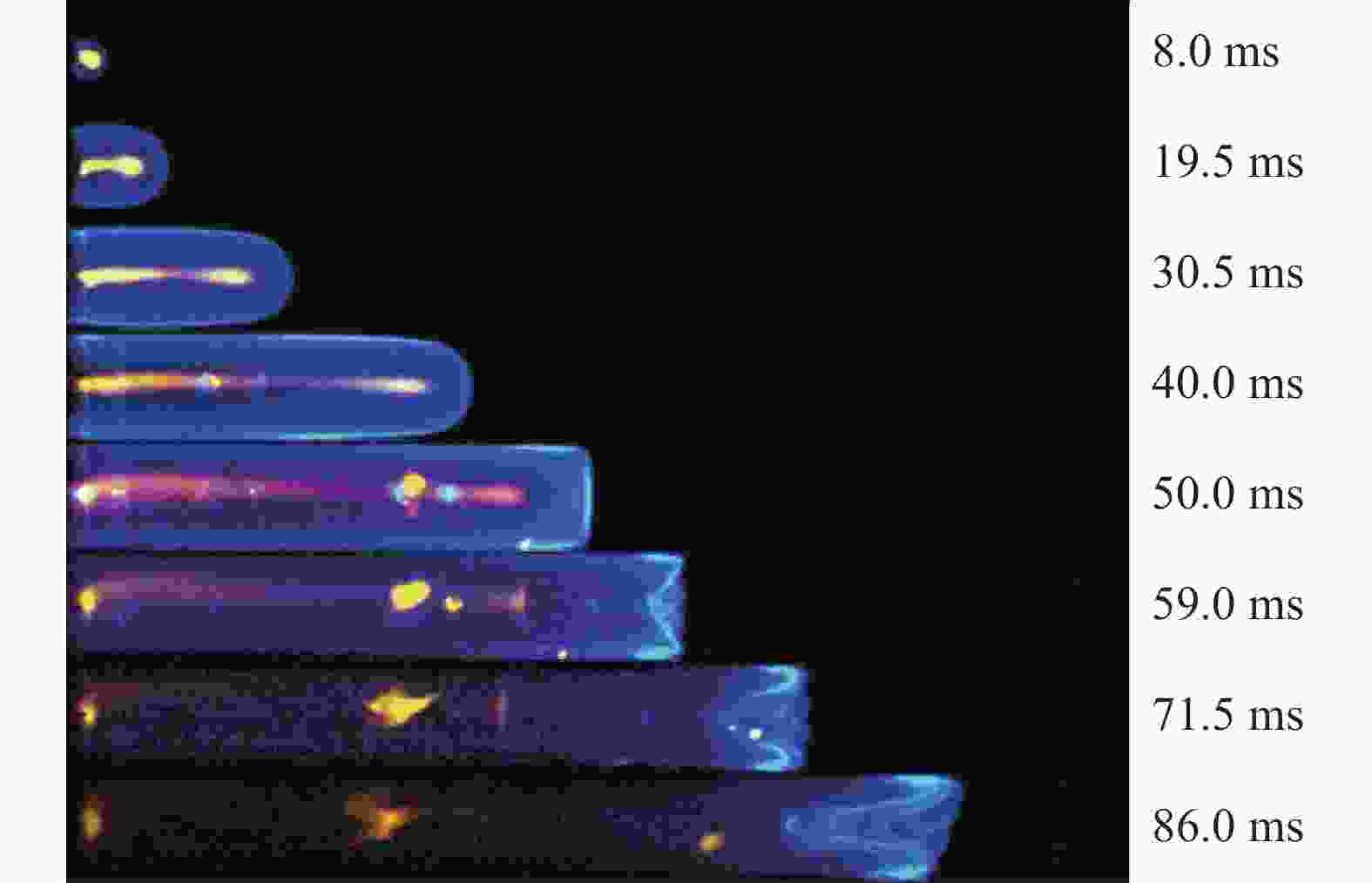

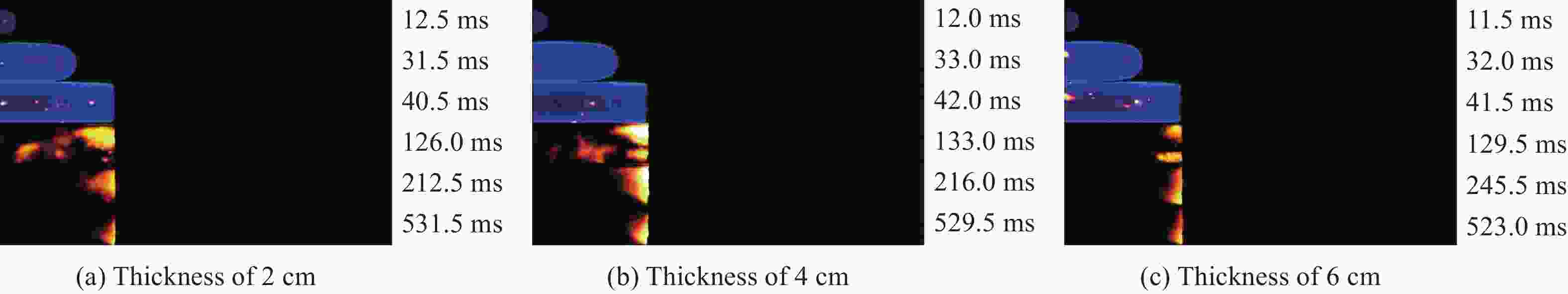

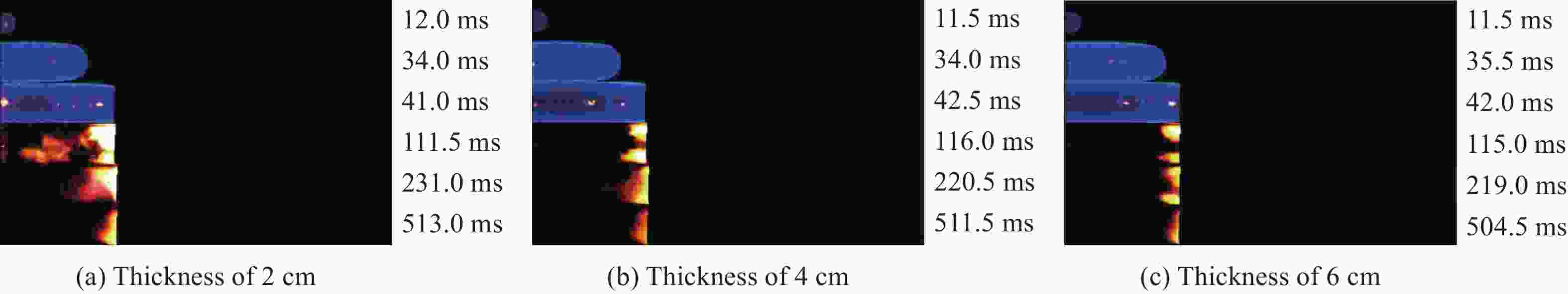

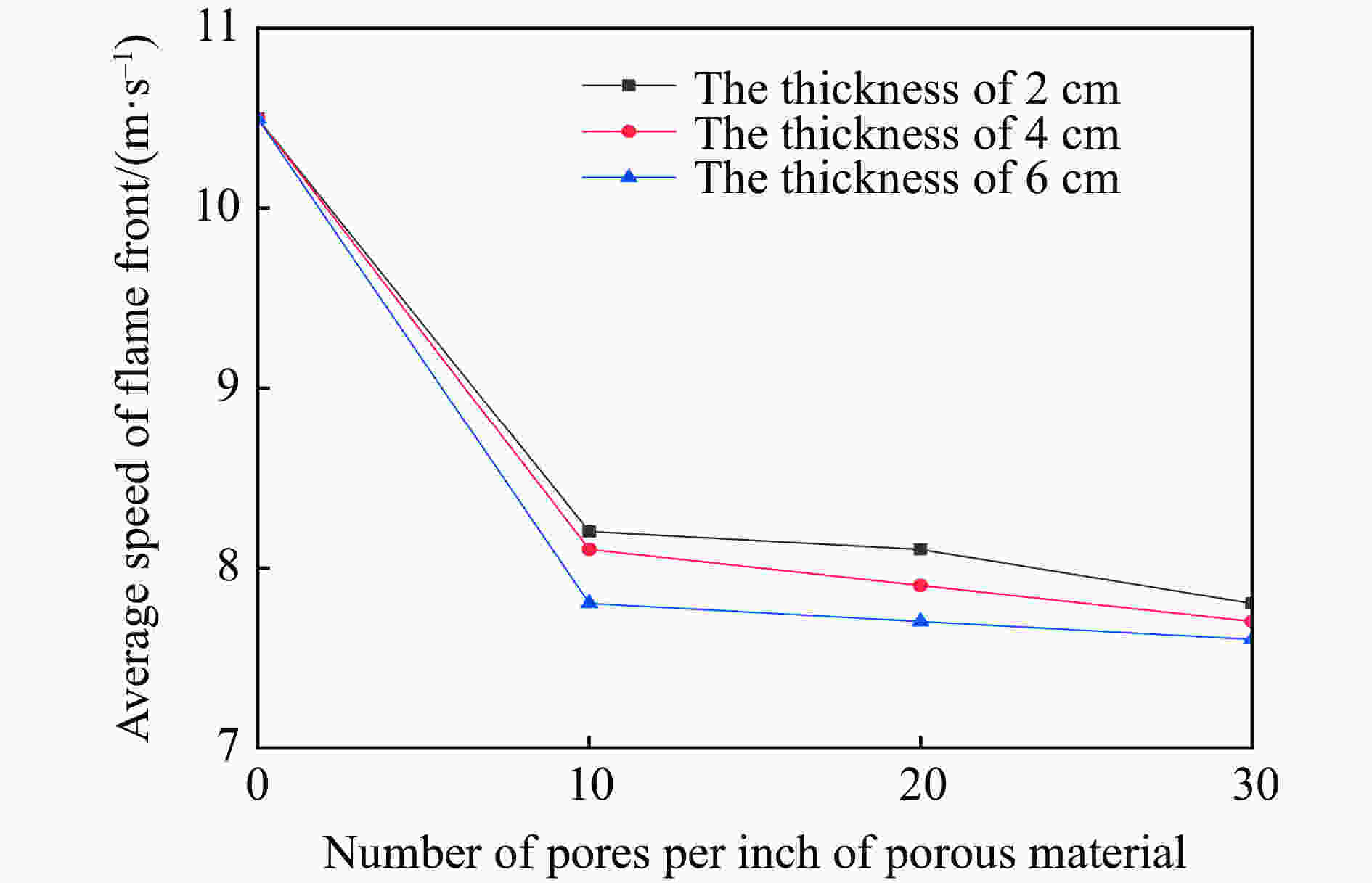

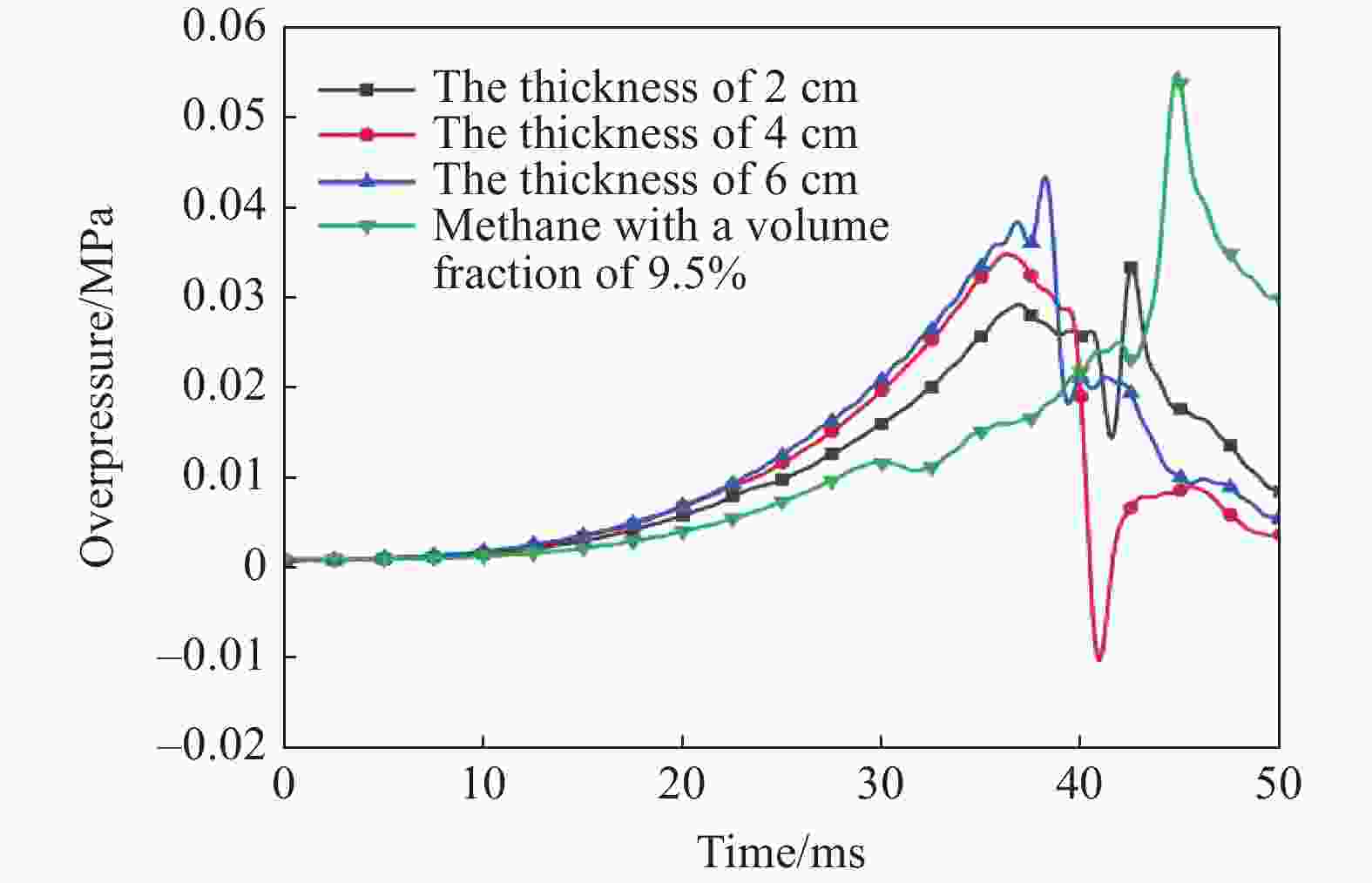

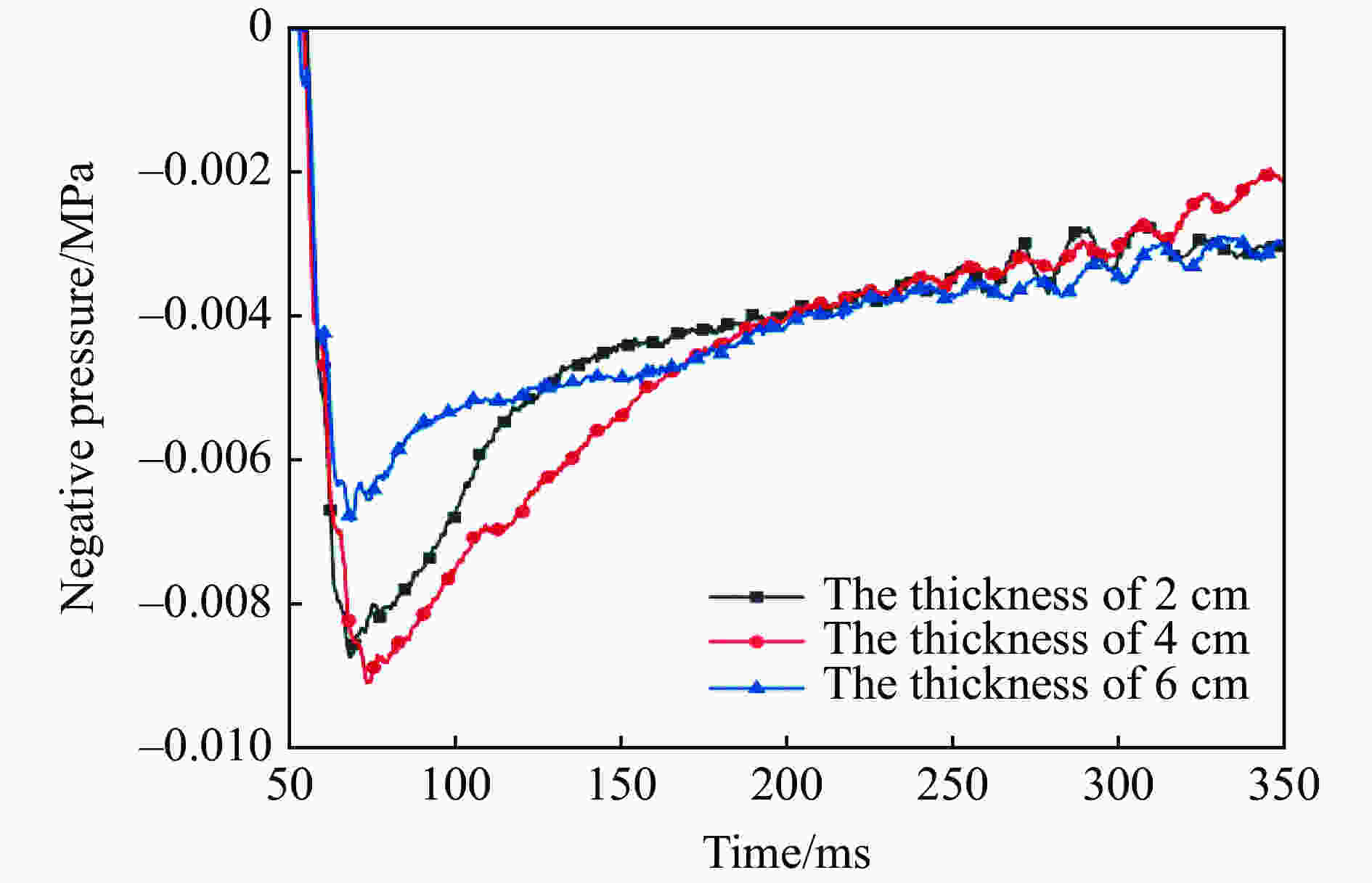

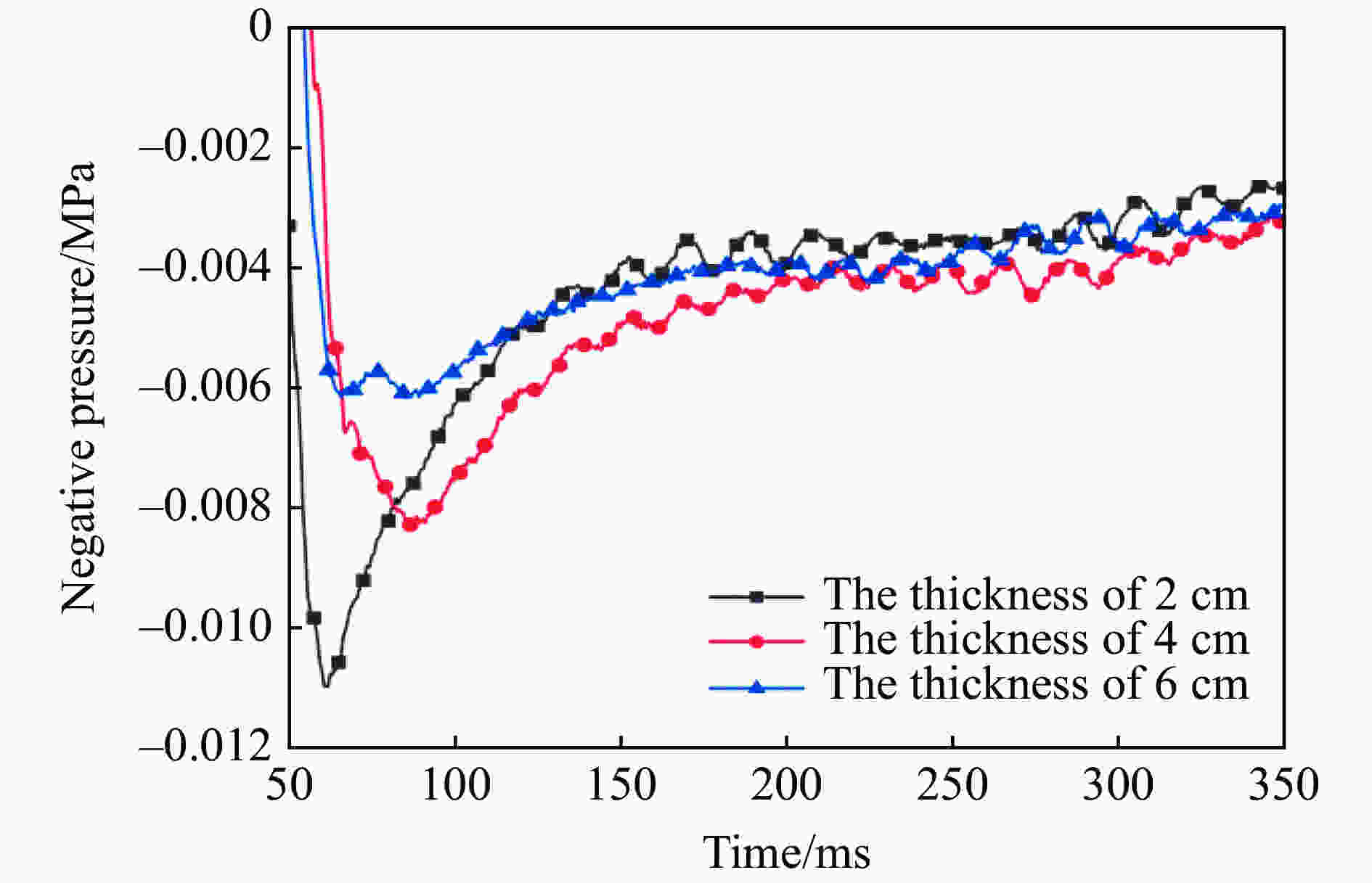

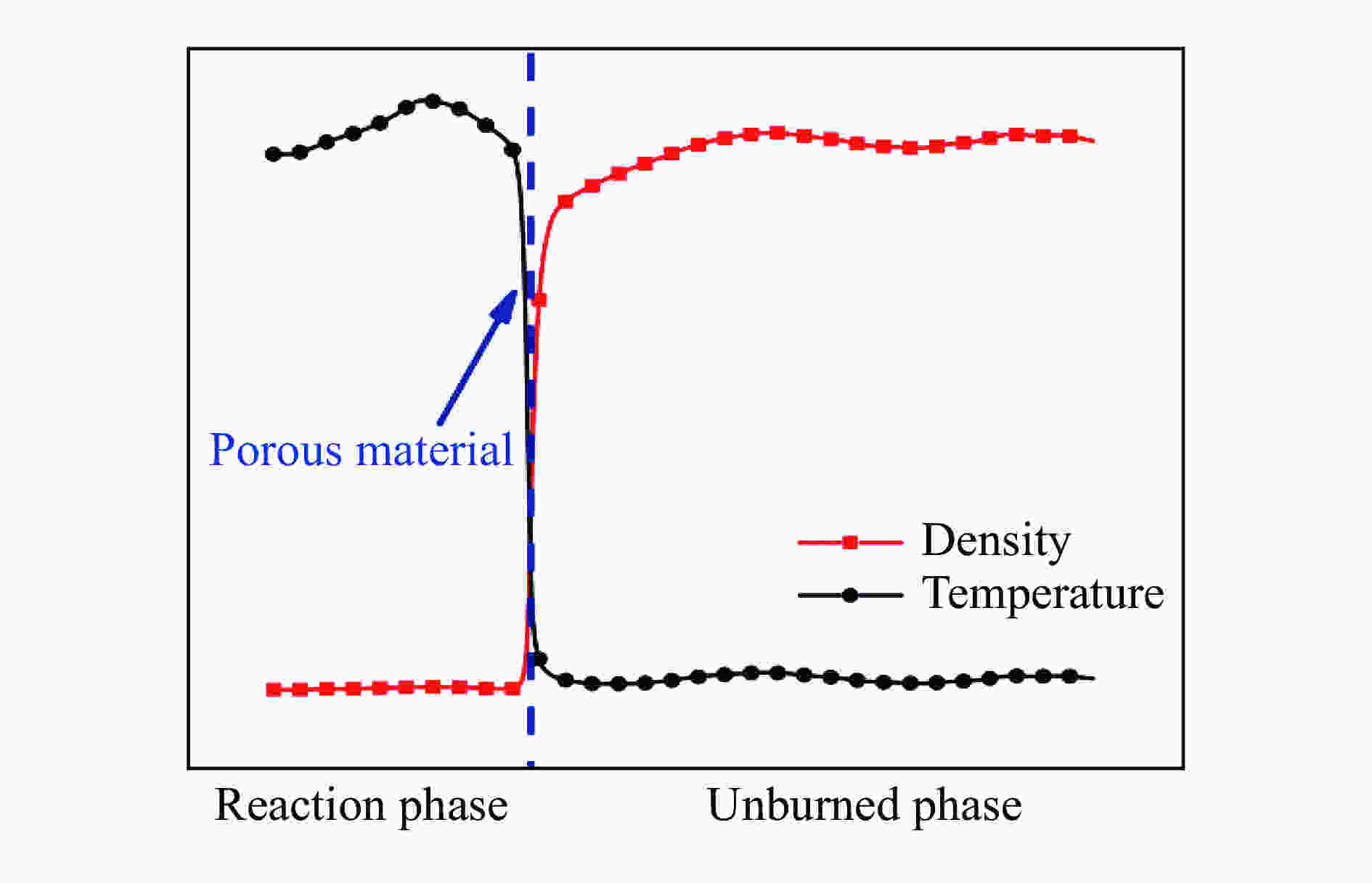

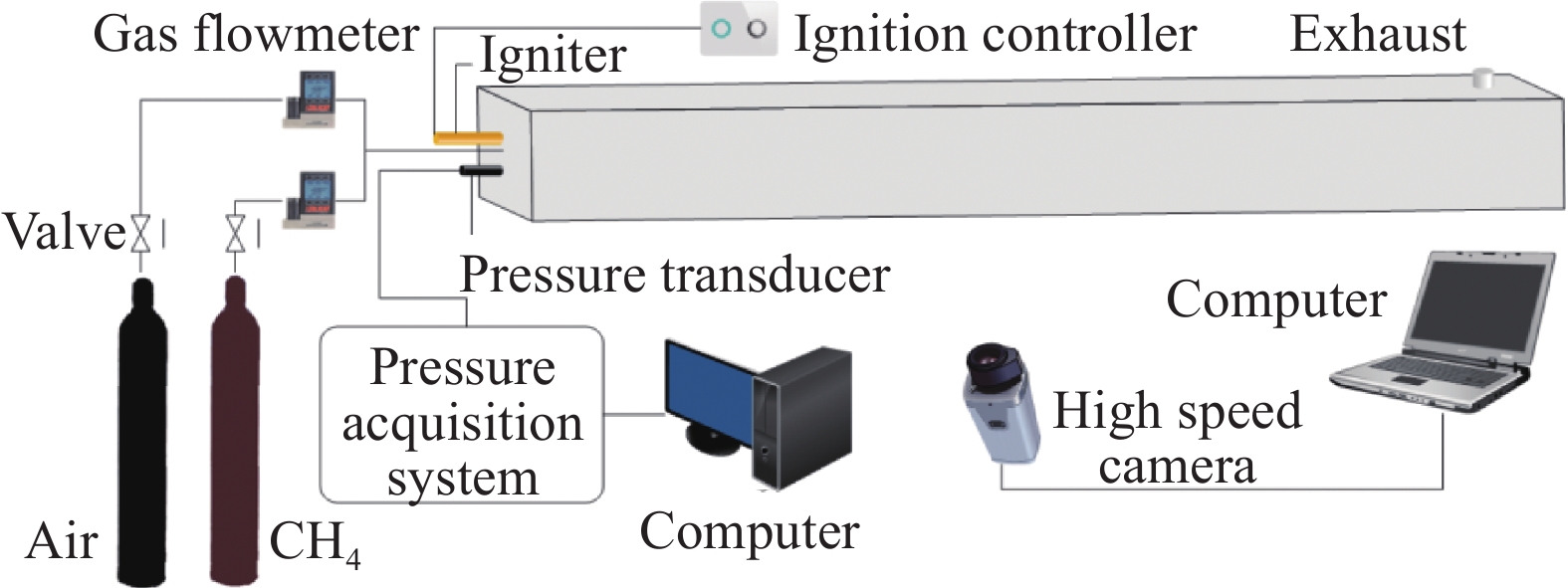

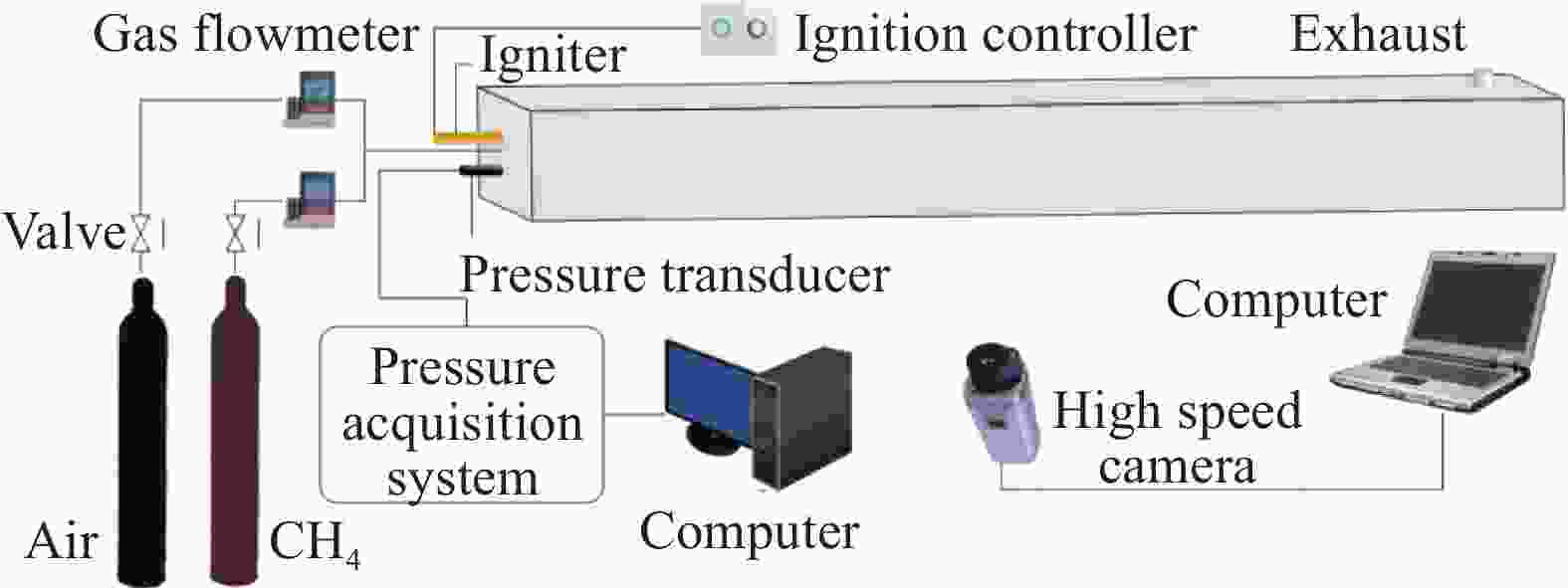

摘要: 为分析多孔材料对预混气体爆炸特性参数的影响效果,采用自主搭建的爆炸实验平台,探究不同孔隙度和厚度的多孔材料对当量比为1的甲烷/空气预混气体爆炸的作用行为。实验研究表明,不同孔隙度的多孔材料对爆炸火焰和超压具有促进或抑制两种不同的影响。孔隙度较小时,爆燃火焰传播速度随着材料厚度的增大而降低,并在厚度较大时,火焰有短暂的传播延时现象。孔隙度较大时,预混火焰冲击多孔材料时发生淬熄,但随后一段时间内,由于负压抽吸作用,在已爆区域一侧的材料表面产生扩散燃烧现象,且扩散燃烧程度与材料厚度成反比关系。多孔材料的固相结构能降低压力的泄放效率,同时可吸收能量,进而提高爆炸超压的上升速率,降低超压峰值。当每英寸长度孔数δ=10的多孔材料促进火焰传播时,与当量比为1的预混气体爆炸相比,超压峰值最大可提高约2倍,造成更严重的后果。火焰冲击δ=20的多孔材料时发生淬熄,最大超压衰减可达47.17%,δ=30时最大超压衰减了24.62%。Abstract: To analyze the effect of porous materials on the explosion characteristics of premixed gas, a self-built explosion experiment platform was used to investigate the behavior of porous materials with different porosities and thicknesses on premixed methane/air gas explosion with a stoichiometric ratio of 1. Experimental studies have shown that porous materials with different porosities can either promote or suppress the explosive flame and overpressure. When the porosity was low, the propagation speed of the deflagration flame decreased with the increase of material thickness, and when the thickness was large, the flame had a short propagation delay. When the porosity was high, the quenching effect occurred when the premixed flame impacted the porous material. However, in the following period, due to negative pressure suction, diffusion combustion occurred on the surface of the material towards the side of the exploded area, and the degree of diffusion combustion was inversely proportional to the thickness of the material. The solid phase structure of porous materials could reduce the efficiency of pressure release and absorb energy, resulting in increasing the rate of explosion overpressure rise and reducing the overpressure peak. When the porous material with δ=10 were used to promote flame propagation, compared with premixed gas explosions with a stoichiometric ratio of 1, the peak overpressure could be increased by about 2 times at most, causing more serious consequences. Quenching occurred when flame impacted the porous material with δ=20, and the maximum overpressure attenuation was 47.17%. The maximum overpressure decreased by 24.62% at the porous material with δ=30.

-

Key words:

- gas explosion /

- porous materials /

- quenching /

- diffusion combustion /

- explosion suppression

-

表 1 实验工况

Table 1. Experimental conditions

序号 δ 厚度/cm 1 10 2 2 10 4 3 10 6 4 20 2 5 20 4 6 20 6 7 30 2 8 30 4 9 30 6 -

[1] SUN J H, ZHAO Y, WEI C R, et al. The comparative experimental study of the porous materials suppressing the gas explosion [J]. Procedia Engineering, 2011, 26: 954–960. DOI: 10.1016/j.proeng.2011.11.2262. [2] PRAMOD B, Prudhvi R J, PARASHAR C H, et al. Attenuation of shock waves by using porous media [C]//AIP Conference Proceedings. Karnataka, India, 2019: 030015. DOI: 10.1063/1.5092918. [3] OLIM M, DONGEN M, KITAMURA T, et al. Numerical simulation of the propagation of shock waves in compressible open-cell porous foams [J]. International Journal of Multiphase Flow, 1994, 20(3): 557–568. DOI: 10.1016/0301-9322(94)90029-9. [4] KITAGAWA K, YASUHARA M, TAKAYAMA K. Attenuation of shock waves propagating in polyurethane foams [J]. Shock Waves, 2006, 15(6): 437–445. DOI: 10.1007/s00193-006-0042-1. [5] 邵继伟, 庄春吉, 王志荣, 等. 组合型多孔材料对容器管道系统内甲烷/空气的抑爆效果 [J]. 爆炸与冲击, 2018, 38(4): 905–912. DOI: 10.11883/bzycj-2017-0064.SHAO J W, ZHUANG C J, WANG Z R, et al. Explosion suppression effect of CH4/air by combined porous materials in a container piping system [J]. Explosion and Shock Waves, 2018, 38(4): 905–912. DOI: 10.11883/bzycj-2017-0064. [6] 梁滔, 孙永夺, 杨锡军. 泡沫镍对甲烷-空气预混气体爆燃超压影响的研究 [J]. 中国安全生产科学技术, 2017, 13(8): 170–174. DOI: 10.11731/j.issn.1673-193x.2017.08.027.LIANG T, SUN Y D, YANG X J. Study on effect of nickel foam on deflagration overpressure of methane-air premixed gas [J]. Journal of Safety Science and Technology, 2017, 13(8): 170–174. DOI: 10.11731/j.issn.1673-193x.2017.08.027. [7] 陈鹏, 黄福军, 何昕, 等. 多孔材料对管道内甲烷-空气预混火焰传播的影响 [J]. 工业安全与环保, 2016, 42(1): 49–52. DOI: 10.3969/j.issn.1001-425X.2016.01.015.CHEN P, HUANG F J, HE X, et al. Effects of different porous foam upon premixed methane/air flame propagation in closed ducts [J]. Industrial Safety and Environmental Protection, 2016, 42(1): 49–52. DOI: 10.3969/j.issn.1001-425X.2016.01.015. [8] 陈鹏, 孙永夺. 泡沫金属对甲烷/空气爆燃火焰的淬熄实验研究 [J]. 中国安全生产科学技术, 2017, 13(7): 37–41. DOI: 10.11731/j.issn.1673-193x.2017.07.006.CHEN P, SUN Y D. Experiment study on quenching effect of foam metal on methane-air deflagration flame [J]. Journal of Safety Science and Technology, 2017, 13(7): 37–41. DOI: 10.11731/j.issn.1673-193x.2017.07.006. [9] 魏春荣, 徐敏强, 王树桐, 等. 多孔材料抑制瓦斯爆炸火焰波的实验研究 [J]. 中国矿业大学学报, 2013, 42(2): 206–213. DOI: 10.13247/j.cnki.jcumt.2013.02.008.WEI C R, XU M Q, WANG S T, et al. Experiment of porous materials for suppressing the gas explosion flame wave [J]. Journal of China University of Mining & Technology, 2013, 42(2): 206–213. DOI: 10.13247/j.cnki.jcumt.2013.02.008. [10] 魏春荣, 徐敏强, 孙建华, 等. 多孔材料抑制瓦斯爆炸传播的实验及机理 [J]. 功能材料, 2012, 43(16): 2247–2250;2255. DOI: 10.3969/j.issn.1001-9731.2012.16.031.WEI C R, XU M Q, SUN J H, et al. Experiment and mechanism of porous materials for suppressing the gas explosion [J]. Journal of Functional Materials, 2012, 43(16): 2247–2250;2255. DOI: 10.3969/j.issn.1001-9731.2012.16.031. [11] 孙建华, 赵益, 魏春荣, 等. 金属丝网和泡沫陶瓷组合体抑制瓦斯爆炸的实验研究 [J]. 煤炭学报, 2012, 37(7): 1156–1160. DOI: 10.13225/j.cnki.jccs.2012.07.018.SUN J H, ZHAO Y, WEI C R, et al. Experimental study of combination of metal wire mesh and foam ceramic for suppressing the gas explosion [J]. Journal of China Coal Society, 2012, 37(7): 1156–1160. DOI: 10.13225/j.cnki.jccs.2012.07.018. [12] 聂百胜, 何学秋, 张金锋, 等. 泡沫陶瓷对瓦斯爆炸过程影响的实验及机理 [J]. 煤炭学报, 2008(8): 903–907. DOI: 10.3321/j.issn:0253-9993.2008.08.013.NIE B S, HE X Q, ZHANG J F, et al. The experiments and mechanism of foam ceramics affecting gas explosion process [J]. Journal of China Coal Society, 2008(8): 903–907. DOI: 10.3321/j.issn:0253-9993.2008.08.013. [13] 聂百胜, 何学秋, 张金锋, 等. 泡沫陶瓷对瓦斯爆炸火焰传播的影响 [J]. 北京理工大学学报, 2008(7): 573–576. DOI: 10.15918/j.tbit1001-0645.2008.07.001.NIE B S, HE X Q, ZHANG J F, et al. Effect of foam ceramics upon gas explosion flame propagation [J]. Transactions of Beijing Institute of Technology, 2008(7): 573–576. DOI: 10.15918/j.tbit1001-0645.2008.07.001. [14] 蒋新生, 谢威, 杨卫, 等. 网状材料抑制中尺度密闭空间爆炸试验研究 [J]. 中国安全科学学报, 2017, 27(12): 20–25. DOI: 10.16265/j.cnki.issn1003-3033.2017.12.004.JIANG X S, XIE W, YANG W, et al. Experimental study on suppression of gasoline-air mixture explosion in narrow-confined space using polymer mesh [J]. China Safety Science Journal, 2017, 27(12): 20–25. DOI: 10.16265/j.cnki.issn1003-3033.2017.12.004. [15] 温小萍, 郭志东, 王发辉, 等. 一维多孔介质和超细水雾协同抑制瓦斯爆炸试验 [J]. 安全与环境学报, 2020, 20(2): 539–547. DOI: 10.13637/j.issn.1009-6094.2019.0114.WEN X P, GUO Z D, WANG F H, et al. Experimental approach to the synergistic inhibition of the gas explosion through the one-D porous media and the ultrafine water mist [J]. Journal of Safety and Environment, 2020, 20(2): 539–547. DOI: 10.13637/j.issn.1009-6094.2019.0114. [16] 余明高, 刘梦茹, 温小萍, 等. 超细水雾-多孔材料协同抑制瓦斯爆炸实验研究 [J]. 煤炭学报, 2019, 44(5): 1562–1569. DOI: 10.13225/j.cnki.jccs.2018.0795.YU M G, LIU M R, WEN X P, et al. Synergistic inhibition of gas explosion by ultrafine water mist-porous materials [J]. Journal of China Coal Society, 2019, 44(5): 1562–1569. DOI: 10.13225/j.cnki.jccs.2018.0795. [17] 王大龙, 周心权, 张玉龙, 等. 煤矿瓦斯爆炸火焰波和冲击波传播规律的理论研究与实验分析 [J]. 矿业安全与环保, 2007(2): 1–3;89. DOI: 10.3969/j.issn.1008-4495.2007.02.001.WANG D L, ZHOU X Q, ZHANG Y L, et al. Theoretic study and experimental analysis of propagation law of mine gas explosion flame wave and shock wave [J]. Mining Safety & Environmental Protection, 2007(2): 1–3;89. DOI: 10.3969/j.issn.1008-4495.2007.02.001. [18] 段玉龙, 王海燕, 程彩霞, 等. 瓦斯爆炸火焰波热作用下巷道煤壁温度变化规律的探讨与分析 [J]. 煤矿安全, 2010, 41(9): 100–104. DOI: 10.13347/j.cnki.mkaq.2010.09.024.DUAN Y L, WANG H Y, CHEN C X, et al. Discussion and analysis on the variation law of coal wall temperature under the action of flame wave heat of gas explosion [J]. Safety in Coal Mines, 2010, 41(9): 100–104. DOI: 10.13347/j.cnki.mkaq.2010.09.024. [19] ZHANG D, NIE B S, WANG C, et al. Preliminary research on porous foam ceramics against gas explosions in goaf [J]. Procedia Engineering, 2011, 26: 1330–1336. DOI: 10.1016/j.proeng.2011.11.2308. [20] NIE B S, ZHANG R M, HE X Q, et al. Potential applications of foam ceramics in gas explosion prevention [J]. Advanced Materials Research, 2011: 284–286. DOI: 10.4028/www.scientific.net/amr.284-286.1330. [21] 肖华华. 管道中氢-空气预混火焰传播动力学实验与数值模拟研究[D].合肥: 中国科学技术大学, 2013: 5−6. -

下载:

下载: