Research on explosion-proof characteristics and optimization design of negative Poisson’s ratio honeycomb material

-

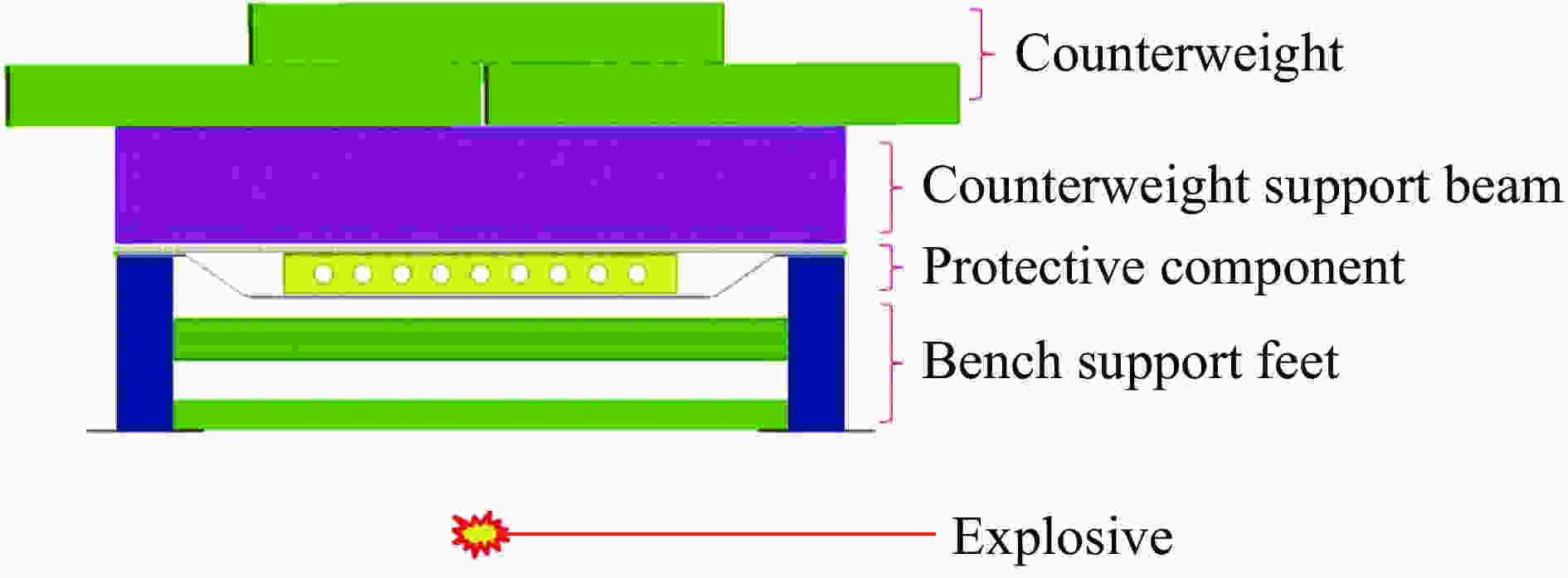

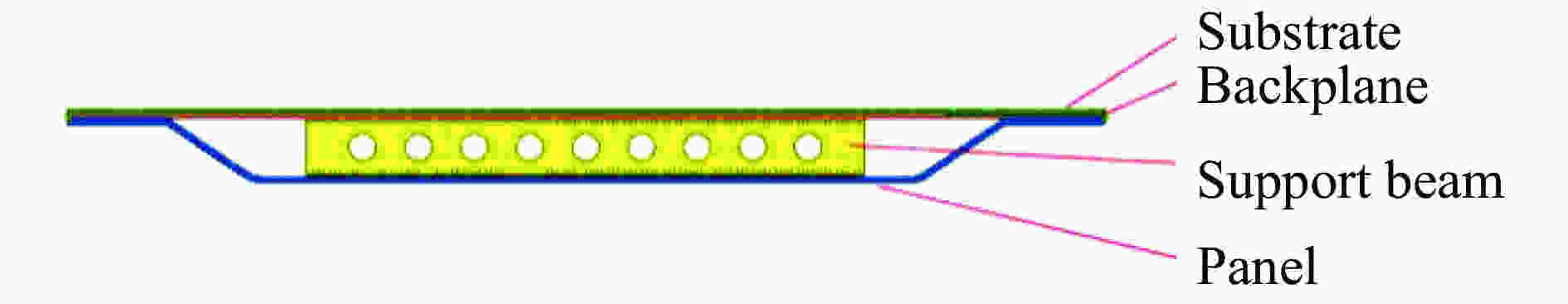

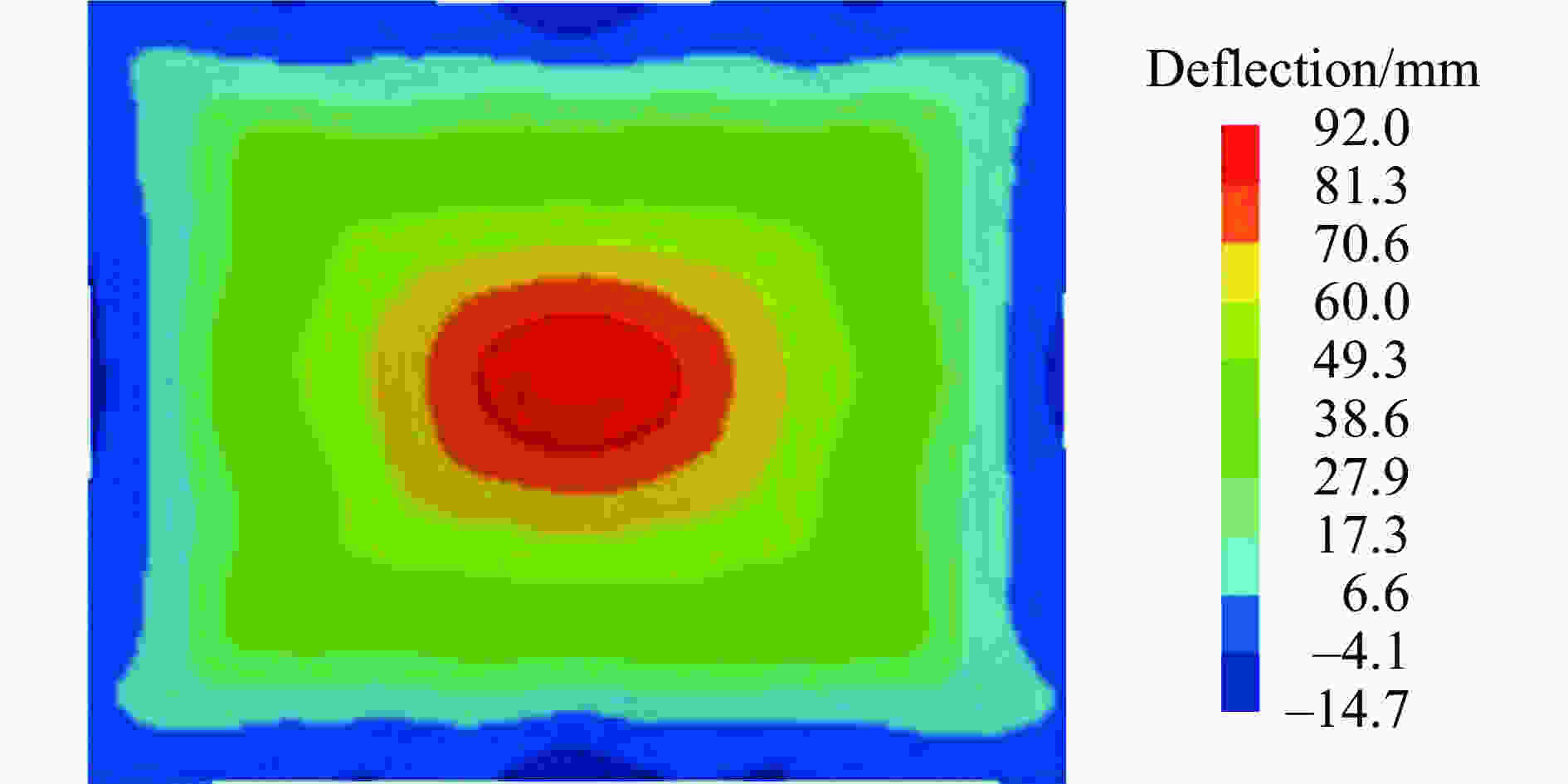

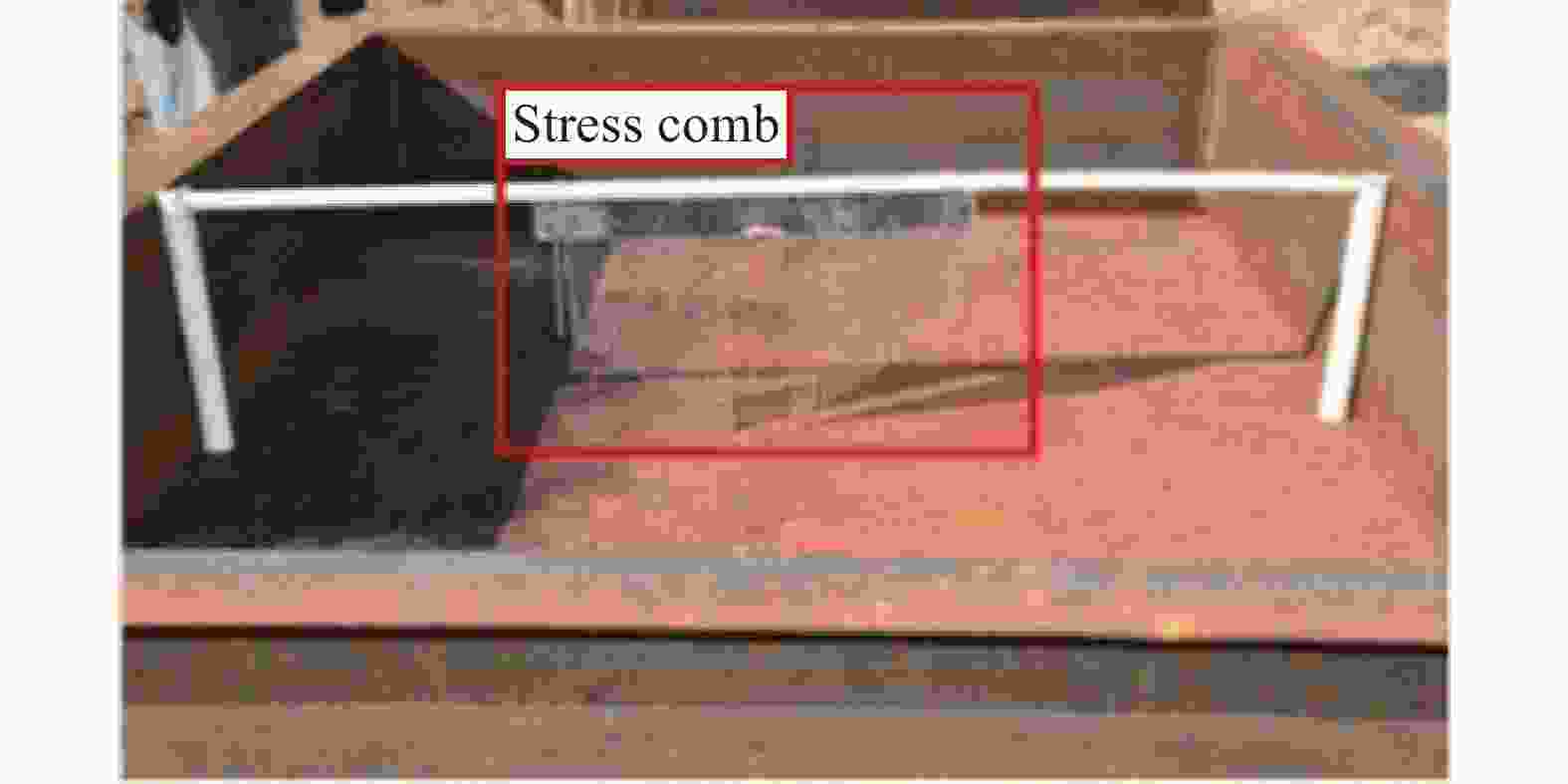

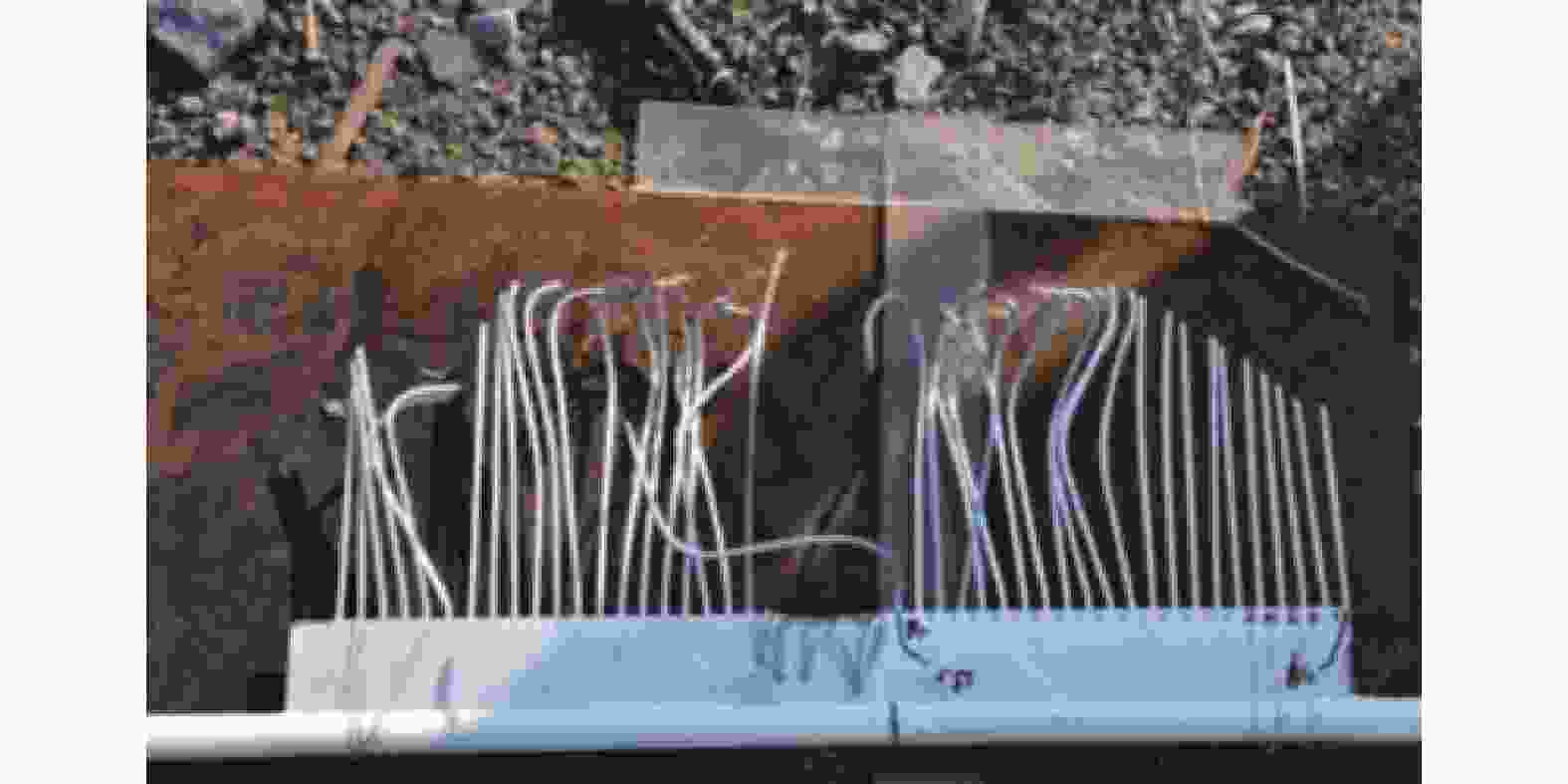

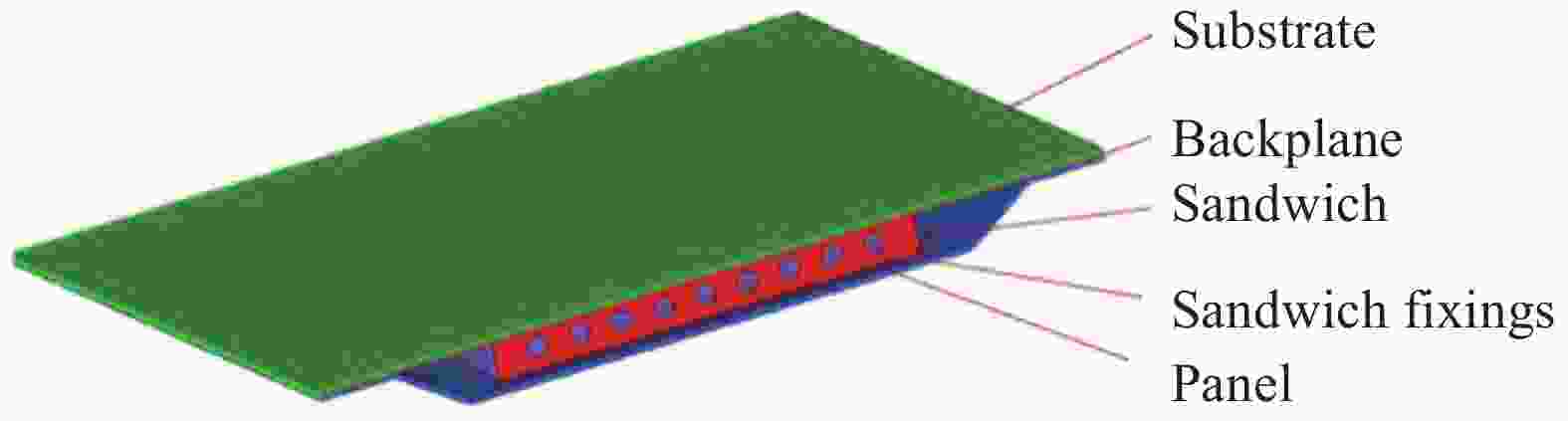

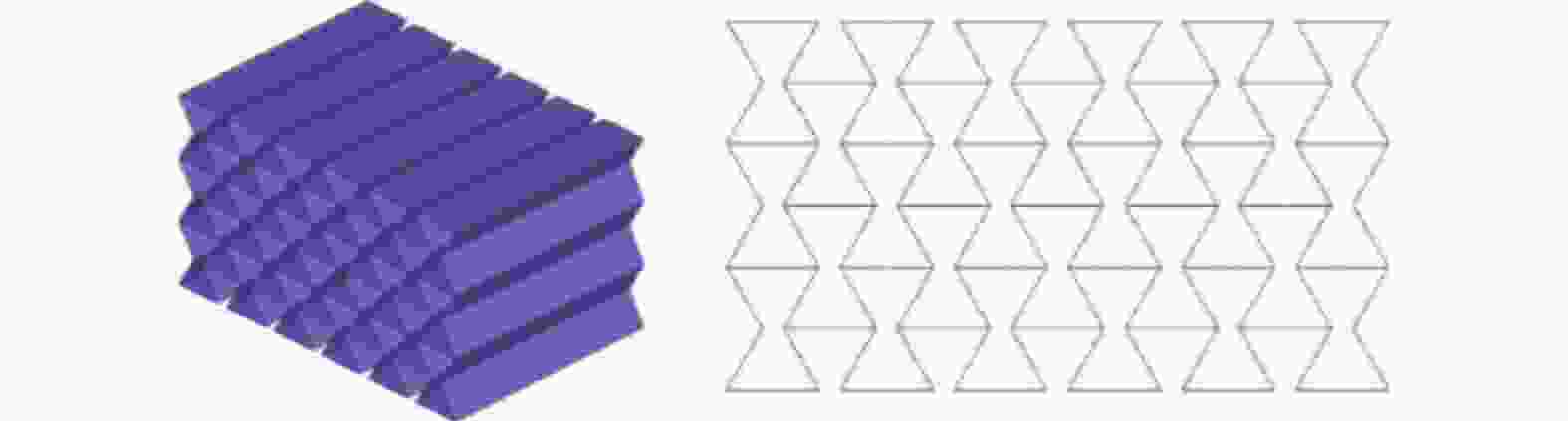

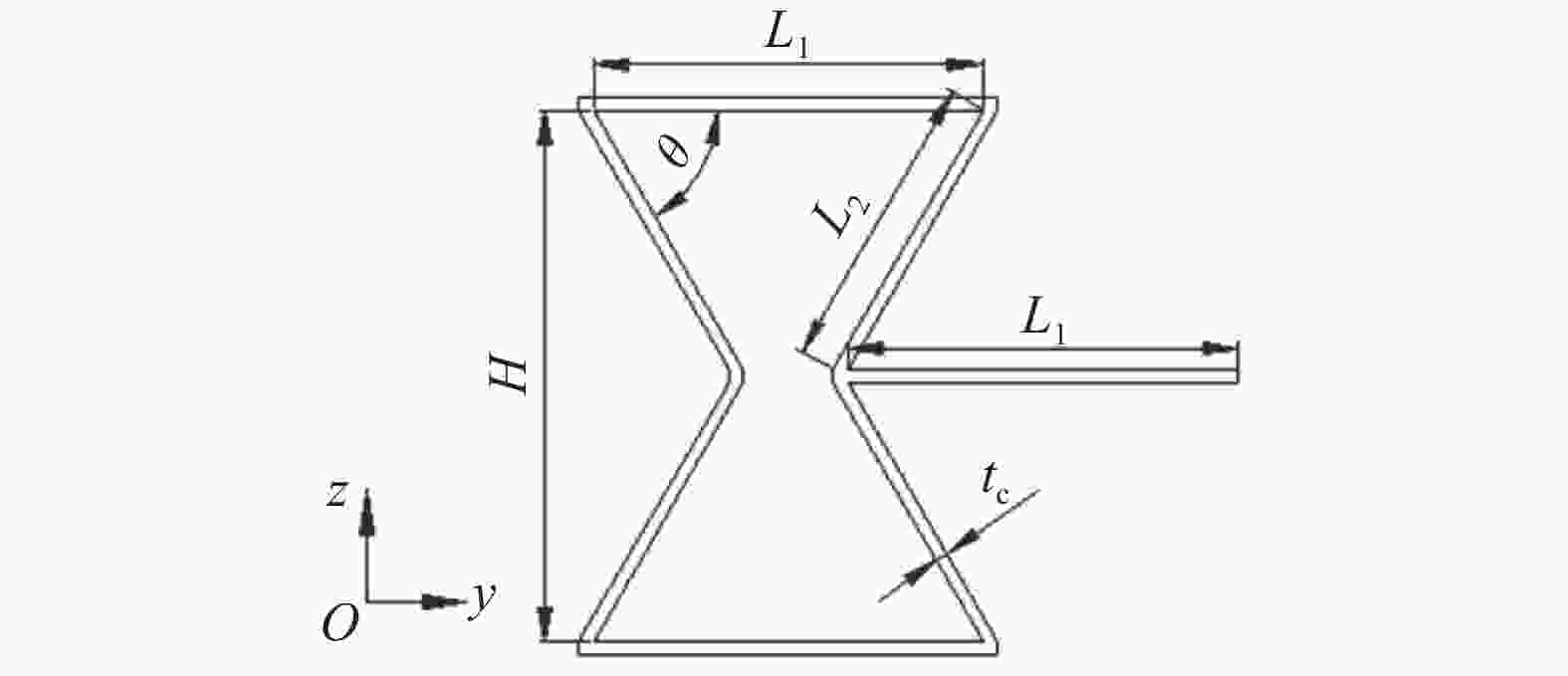

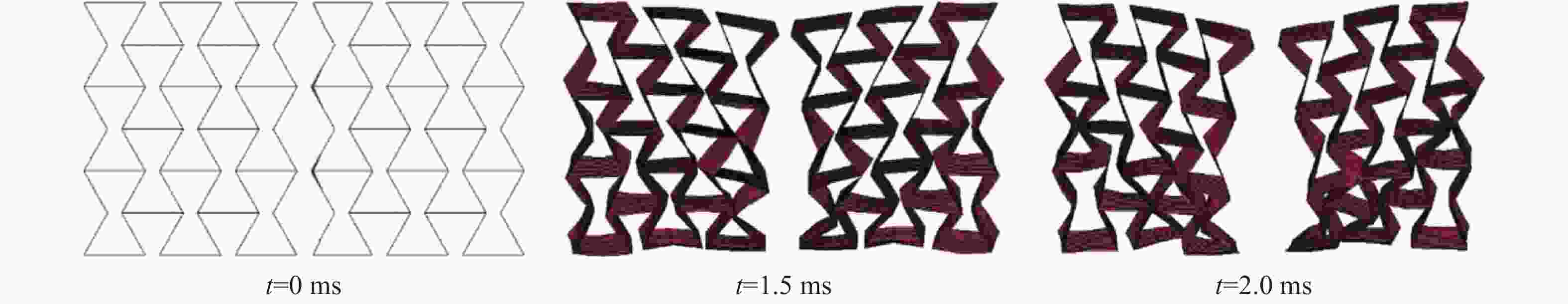

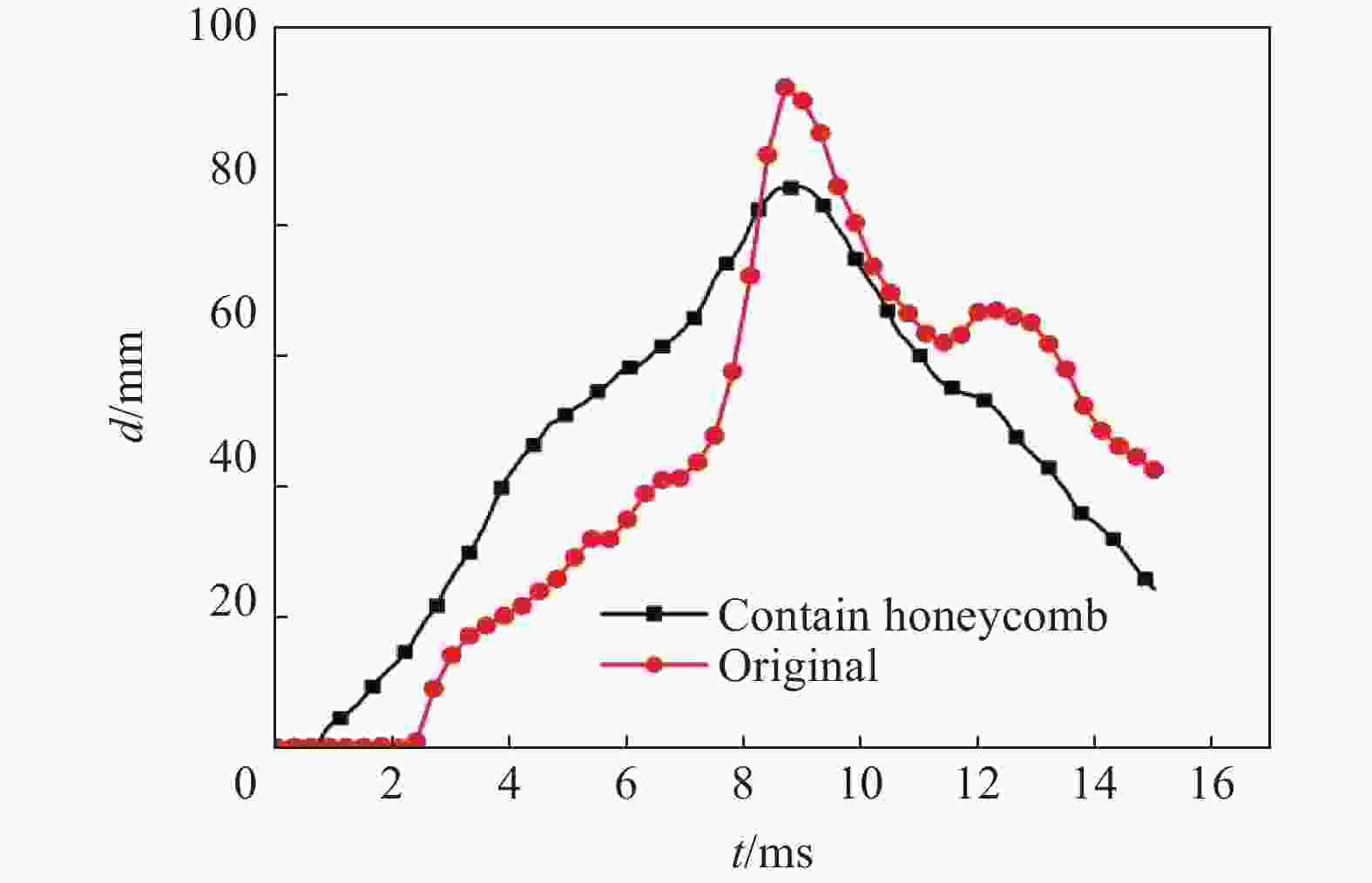

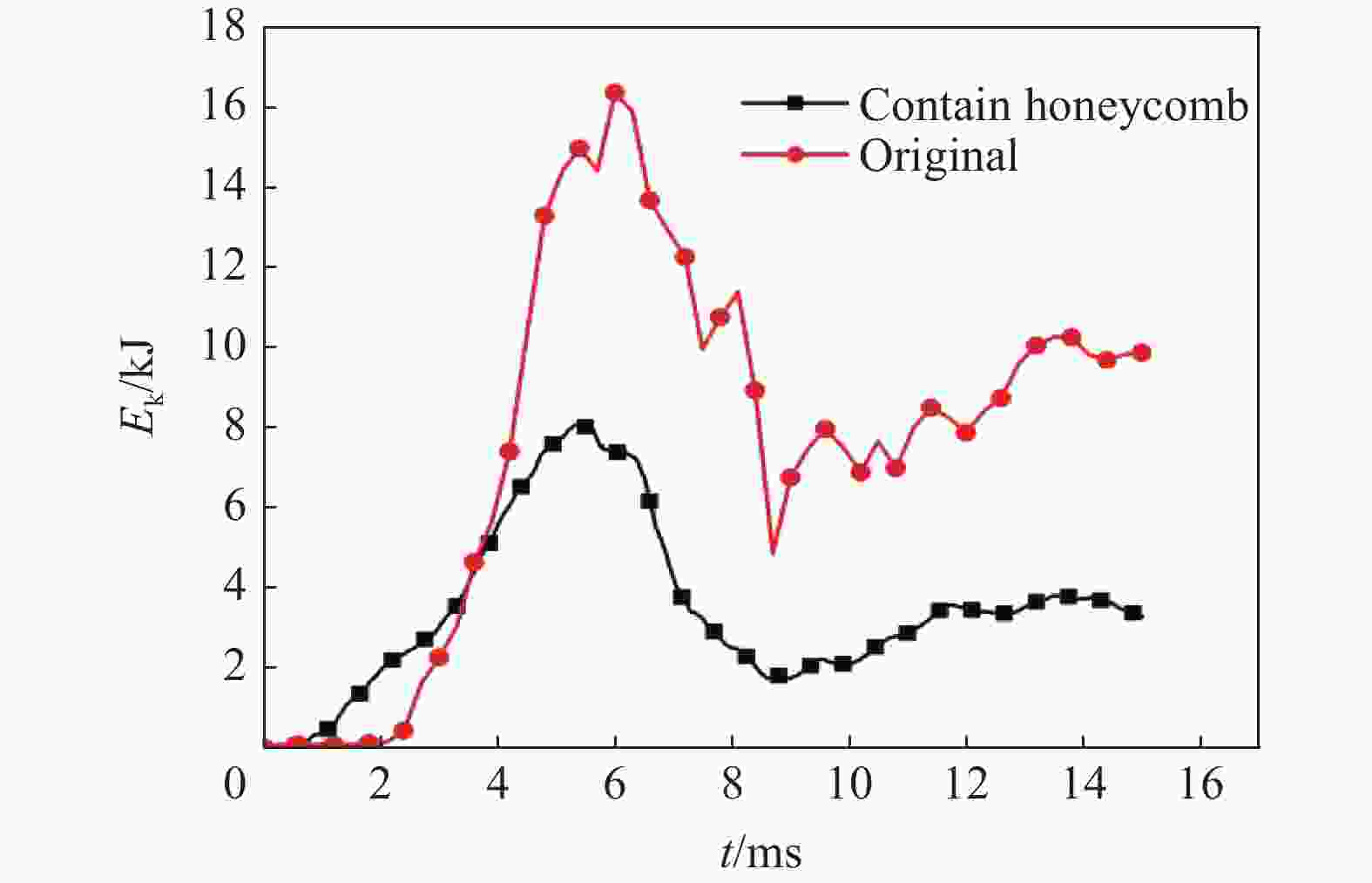

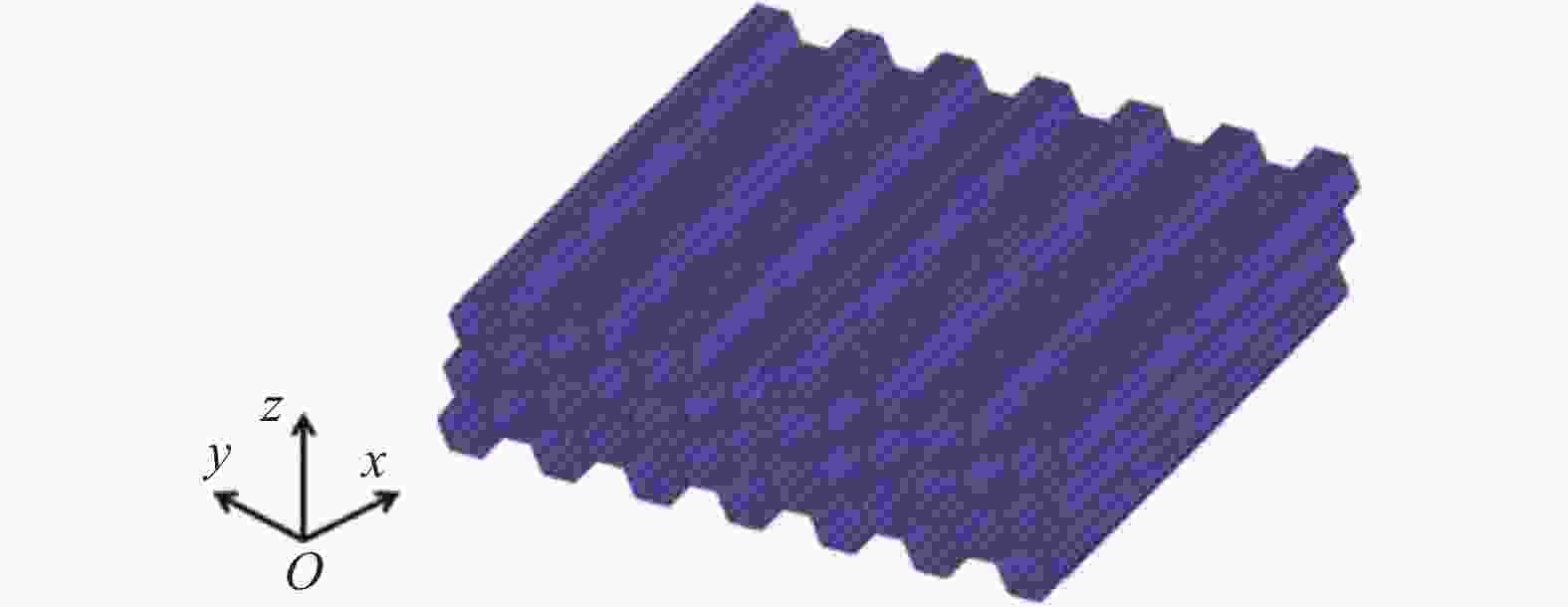

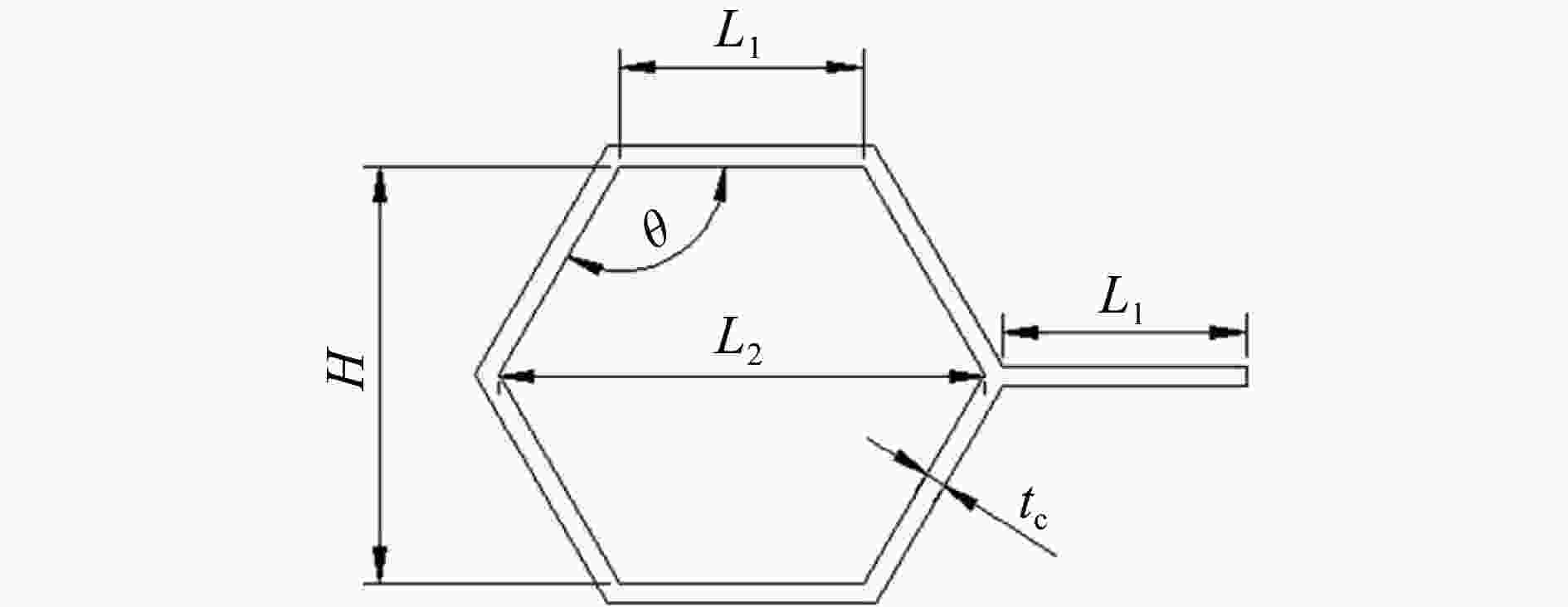

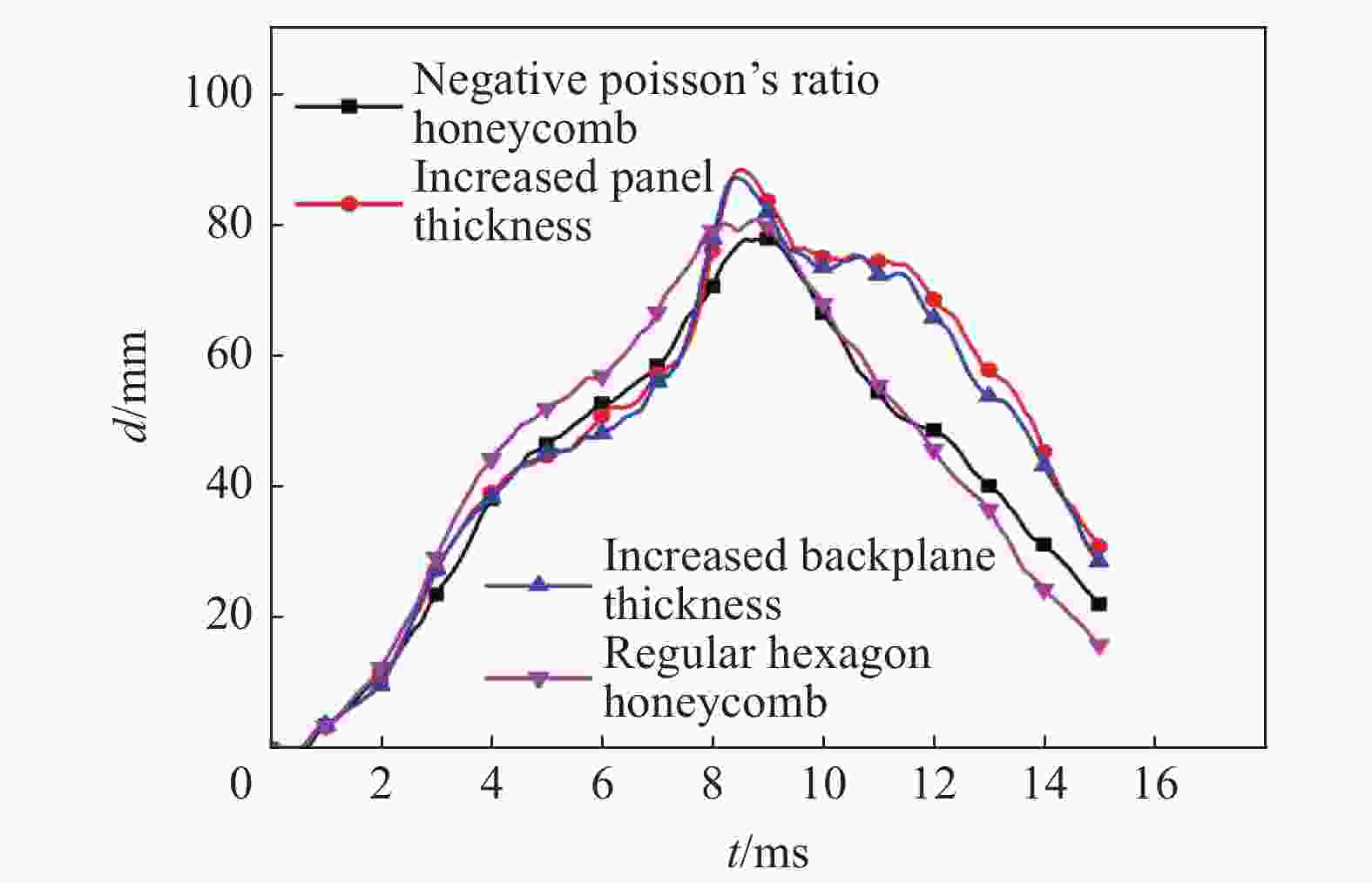

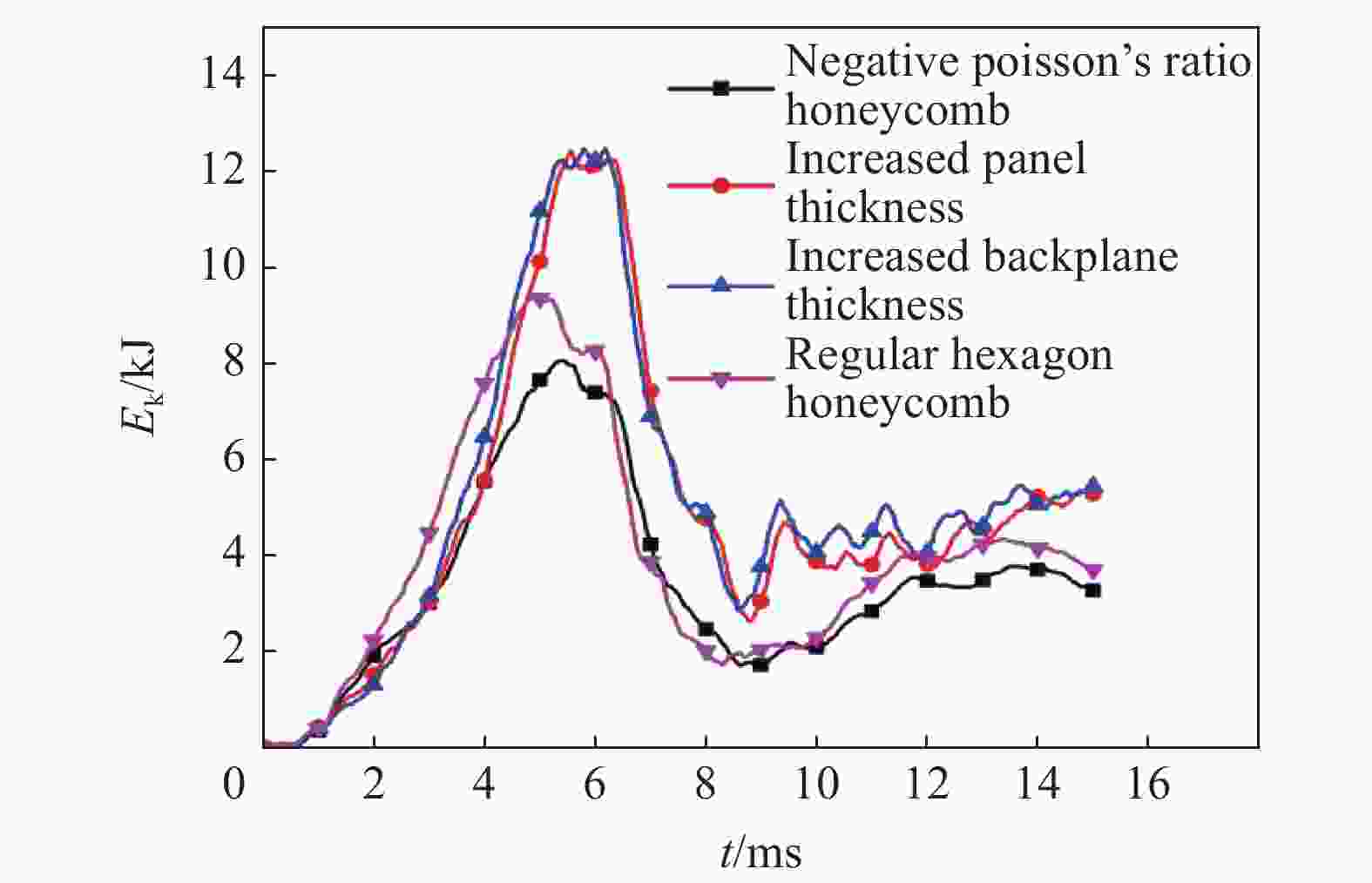

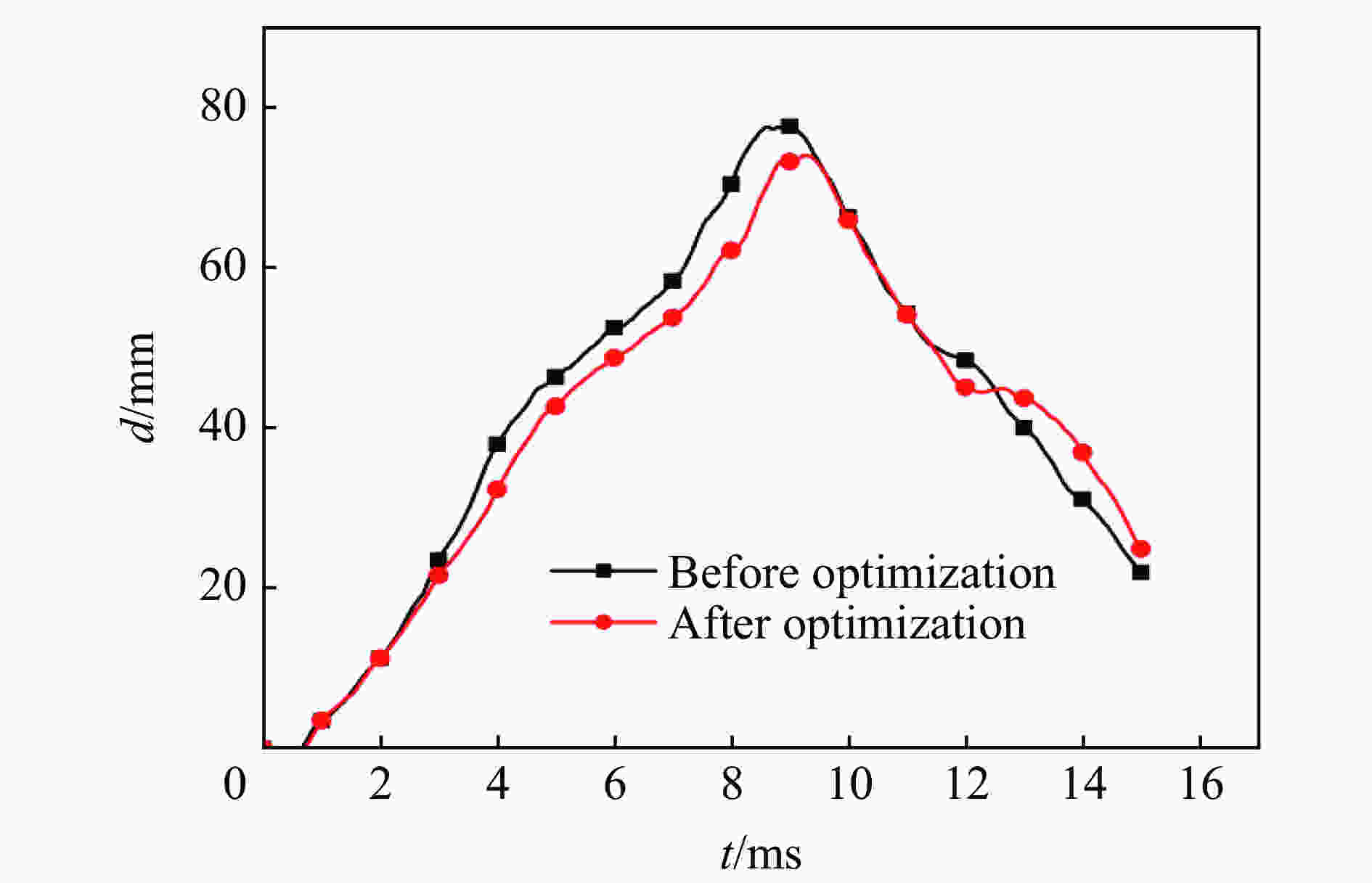

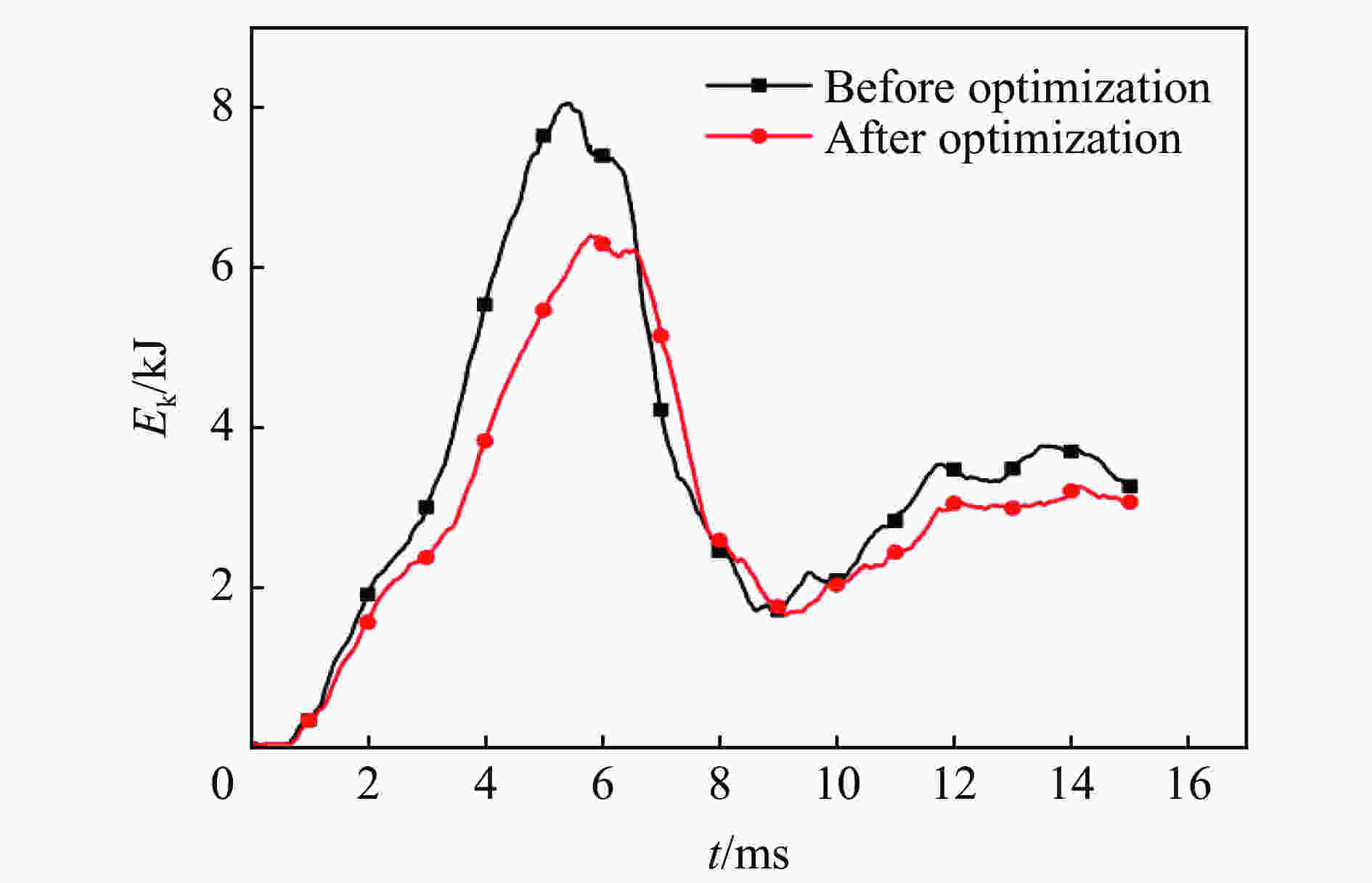

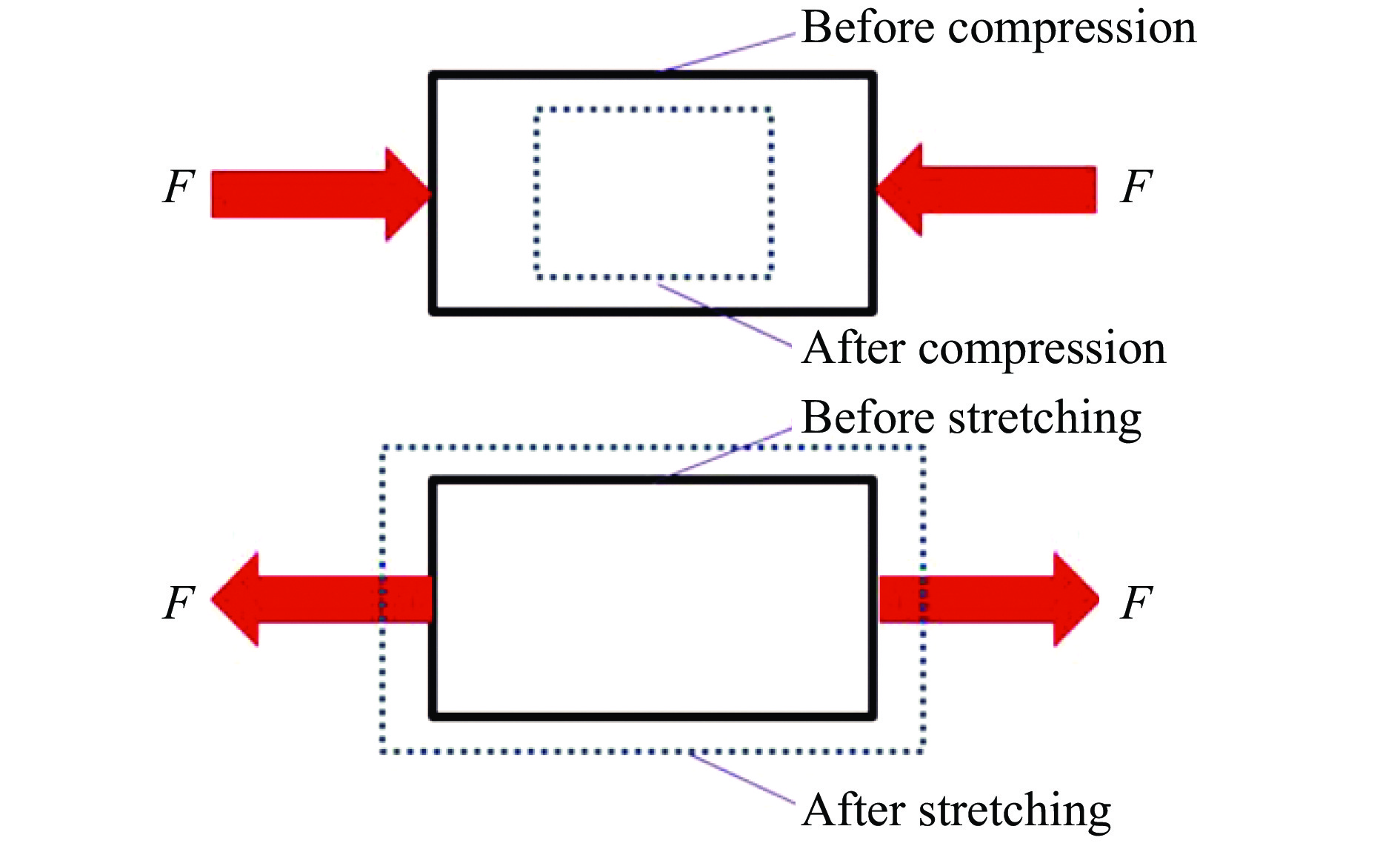

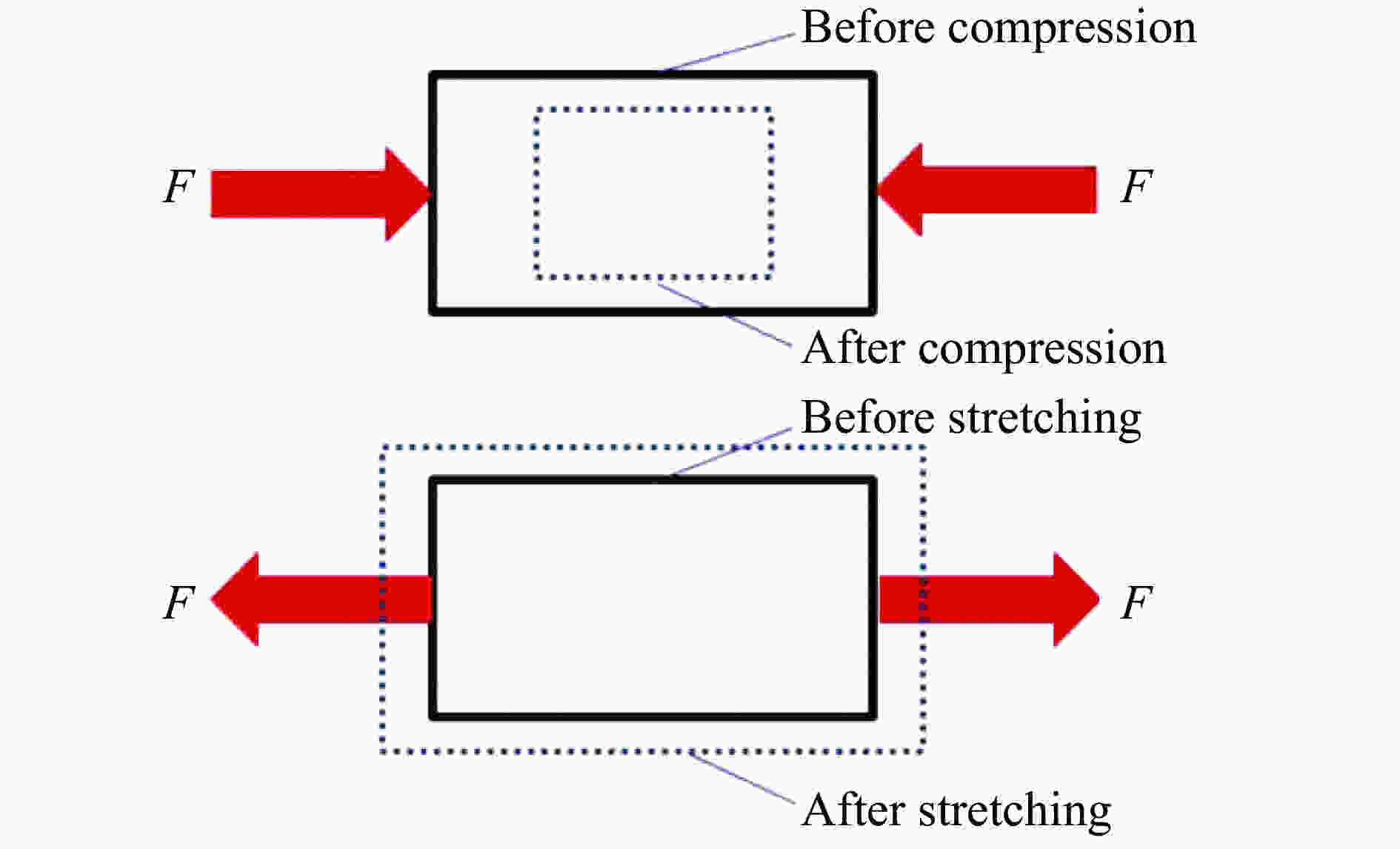

摘要: 为了深入研究车辆底部防护组件爆炸冲击下的结构响应,提高防护型车辆的抗爆炸冲击性能,建立了某车辆底部防护组件在爆炸冲击下的有限元模型,并进行爆炸冲击台架试验验证了有限元模拟的可靠性;将内凹六边形负泊松比蜂窝材料作为防护组件的夹芯部分,分析负泊松比蜂窝材料在爆炸冲击下的变形模式,并对比了同等质量的其他3种防护组件的抗爆炸冲击性能。结果表明,含有负泊松比蜂窝夹芯的防护组件具有更优的抗爆性能。建立了以内凹六边形负泊松比蜂窝胞元尺寸参数为设计变量的多目标优化问题的数学模型,采用多目标遗传算法获得胞元几何参数的最优方案,有效降低了防护组件基板的最大挠度和最大动能。Abstract: In order to study in depth the structural response of the bottom protective component of the vehicles under blast loading and improve the blast resistant performance of the protective vehicles, a finite element model of the bottom protective component of a vehicle under blast loading was established, and the reliability of the finite element simulation was verified by the explosion impact bench test; the concave hexagonal negative Poisson’s ratio honeycomb material was used as the core layer of the protective component, the deformation mode of the negative Poisson’s ratio honeycomb material under blast loading was analyzed, and the blast resistant performance was compared with the other three protective components of the same mass. The results show that the protective component containing negative Poisson’s ratio honeycomb core has better resistance to blast loading. A mathematical model was established for multi-objective optimization problems with the cell size parameters of the honeycomb material as design variables, and the multi-objective genetic algorithm was used to obtain the optimal solution of the cell geometric parameters, which effectively reduces the maximum deflection and maximum kinetic energy of the protective component substrate.

-

表 1 防护组件各部分材料参数

Table 1. Material parameters for each part of the protective component

材料 密度ρ/(kg·m−3) 杨氏模量E/GPa 屈服强度σy/MPa 泊松比µ 抗拉强度σt/MPa np500钢 7.8 × 103 210 1382 0.3 1757 960E钢 7.8 × 103 210 986 0.3 1150 KS700钢 7.8 × 103 210 700 0.3 752 表 2 防护组件的结构响应与能量

Table 2. Structural response and energy of protective component

结构 最大挠度d/mm 最大加速度a/g 最大动能$ {E}_{\rm k} $/kJ 最大内能$ {E}_{\rm i} $/kJ 面板 132.82 1018.15 123.28 69.39 背板 89.38 470.87 16.35 31.72 基板 91.68 448.52 16.81 35.14 表 3 H14铝材料参数

Table 3. H14 aluminum material parameters

材料 密度ρ/(kg·m−3) 杨氏模量E/GPa 屈服强度度σy/MPa 泊松比µ 抗拉强度σt/MPa H14铝 2.7×103 70 188 0.3 271 表 4 防护组件的结构响应与能量

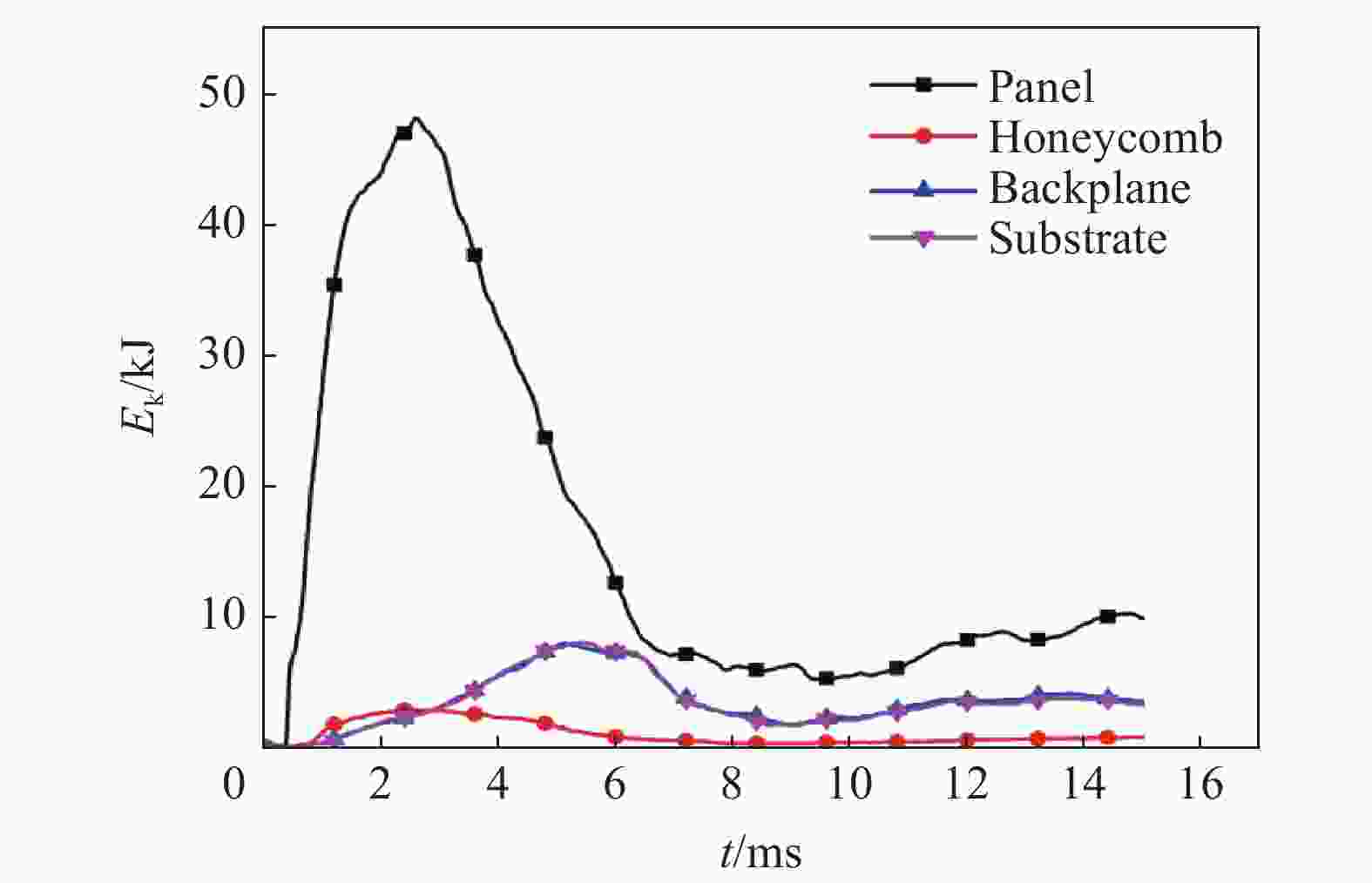

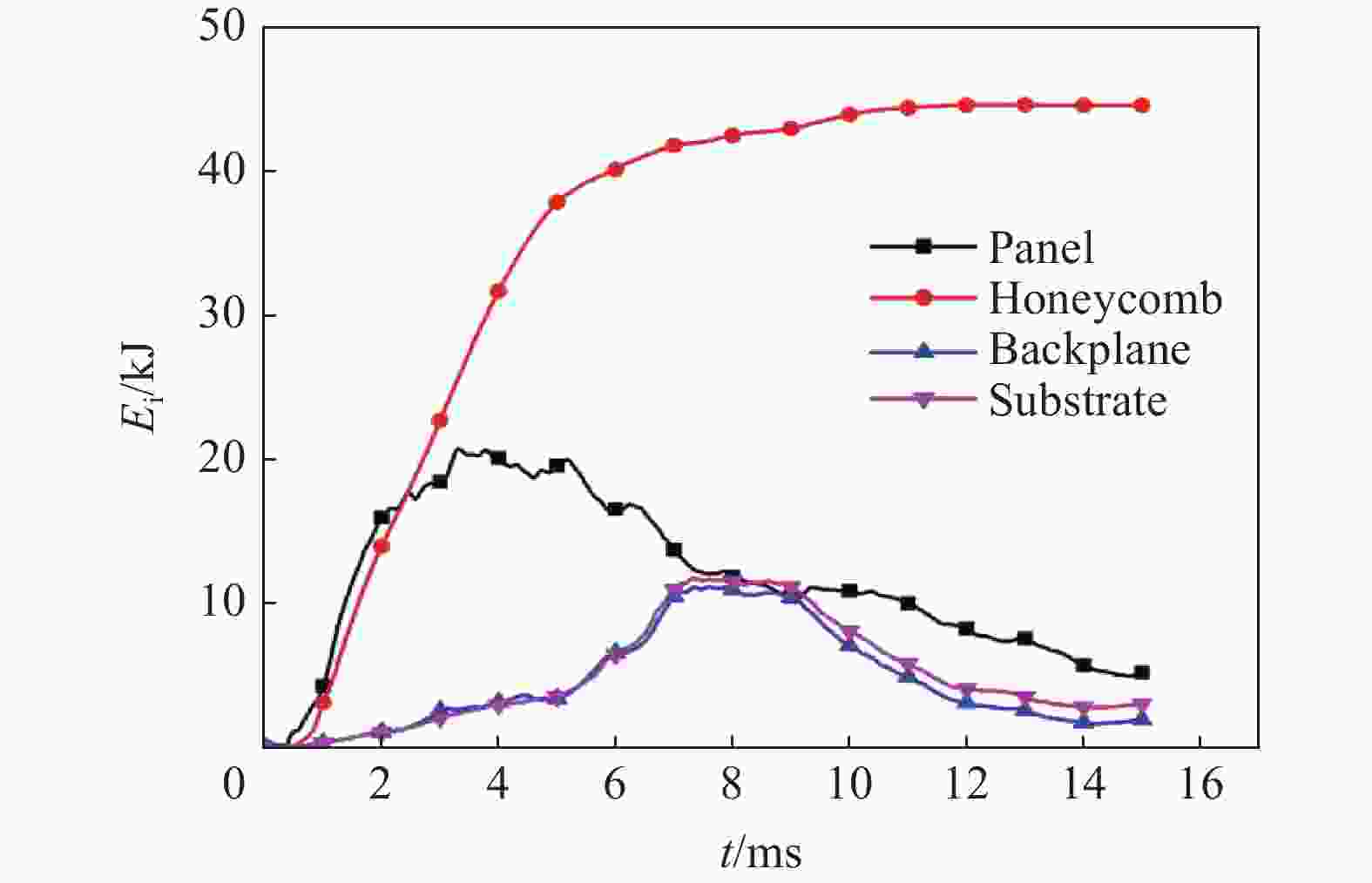

Table 4. Structural response and energy of protective components

结构 最大挠度d/mm 最大加速度a/g 最大动能Ek/kJ 最大内能Ei/kJ 比吸能η/(kJ·kg−1) 面板 130.4 1821.80 48.25 20.731 0.095 夹芯层 208.39 2.90 46.69 3.107 背板 78.35 350.67 7.98 10.99 0.063 基板 77.96 340.56 8.04 11.48 0.078 表 5 基于D-optimal采样的试验设计及结果

Table 5. Experimental design and results based on D-optimal sampling

序号 $ {L}_{1} $/mm $ {L}_{2} $/mm $ {t}_{\rm c} $/mm $ \theta $/(°) M/kg d/mm $ {E}_{\rm k} $/kJ 1 21.15 16.97 0.34 55 18.61 77.66 8.10 2 22.95 16.28 0.31 60 13.00 76.76 7.78 $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ 27 21.33 16.56 0.30 50 16.81 78.83 8.59 28 23.13 15.87 0.34 55 14.75 77.76 8.16 表 6 目标响应的决定系数

Table 6. Decision coefficients of target response

$ M $ $ {F}_{\rm d}\left(x\right) $ $ {F}_{\rm E}\left(x\right) $ $ {R}^{2} $ 0.963 0.987 0.959 表 7 第50代Pareto解集(部分)及变量参数

Table 7. The 50th generation Pareto solution set (part) and variable parameters

解集序号 L1/mm L2/mm $ {t}_{\rm c} $/mm $ \theta $/(°) M/kg d/mm $ {E}_{\rm k} $/kJ 1 24.35 15.78 0.33 60 12.41 74.56 7.99 2 22.36 15.78 0.32 50 12.47 76.64 7.84 $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ 155 24.44 15.79 0.31 55 12.53 75.83 7.70 156 20.43 18.11 0.32 50 18.18 76.23 6.52 $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ $ \vdots $ 857 21.27 17.85 0.32 60 17.89 76.16 6.96 858 20.78 17.44 0.34 50 16.23 76.17 6.99 -

[1] 李补莲, 原树兴. 现代军用车辆的防护措施 [J]. 国外坦克, 2011(5): 41–43. DOI: CNKI:SUN:GWTK.0.2011-05-019.LI B L, YUAN S X. Protective measures of modern military vehicles [J]. Foreign Tanks, 2011(5): 41–43. DOI: CNKI:SUN:GWTK.0.2011-05-019. [2] IMBALZANO G, LINFORTH S, NGO T D, et al. Blast resistance of auxetic and honeycomb sandwich panels: comparisons and parametric designs [J]. Composite Structures, 2018, 183: 242–261. DOI: 10.1016/j.compstruct.2017.03.018. [3] LI X, ZHANG P, WANG Z, et al. Dynamic behavior of aluminum honeycomb sandwich panels under air blast: experiment and numerical analysis [J]. Composite Structures, 2014, 108: 1001–1008. DOI: 10.1016/j.compstruct.2013.10.034. [4] 周冠. 新型负泊松比结构关键技术研究及其在车身设计中的应用[D]. 长沙: 湖南大学, 2015: 6−7. [5] QIAO J, CHEN C Q. Analyses on the in-plane impact resistance of auxetic double arrowhead honeycombs [J]. Journal of Applied Mechanics, 2015, 82(5): 051007. DOI: 10.1115/1.4030007. [6] ZHOU G, MA Z D, GU J, et al. Design optimization of a NPR structure based on HAM optimization method [J]. Structural and Multidisciplinary Optimization, 2016, 53(3): 635–643. DOI: 10.1007/s00158-015-1341-x. [7] 杨德庆, 吴秉鸿, 张相闻. 星型负泊松比超材料防护结构抗爆抗冲击性能研究 [J]. 爆炸与冲击, 2019, 39(6): 124–135. DOI: 10.11883/bjycj-2018-0060.YANG D Q, WU B H, ZHANG X W. Explosion and impact resistance of star negative Poisson’s ratio metamaterial protective structure [J]. Explosion and Shock Waves, 2019, 39(6): 124–135. DOI: 10.11883/bjycj-2018-0060. [8] 裴连政. 负泊松比夹芯板抗爆性能实验与仿真研究[D]. 大连: 大连理工大学, 2016: 11−34. [9] LAN X K, FENG S S, HUANG Q, et al. A comparative study of blast resistance of cylindrical sandwich panels with aluminum foam and auxetic honeycomb cores [J]. Aerospace Science and Technology, 2019, 87: 37–47. DOI: 10.1016/j.ast.2019.01.031. [10] JIN X C, WANG Z H, NING J G, et al. Dynamic response of sandwich structures with graded auxetic honeycomb cores under blast loading [J]. Composites Part B: Engineering, 2016, 106: 206–217. DOI: 10.1016/j.compositesb.2016.09.037. [11] 魏然. 爆炸冲击下车身结构防护机理及多学科优化研究[D]. 南京: 南京理工大学, 2019: 3−4. [12] 王陶. 负泊松比结构力学特性研究及其在商用车耐撞性优化设计中的应用[D]. 南京: 南京理工大学, 2018: 21−22. [13] ZHOU G, MA Z D, LI G, et al. Design optimization of a novel NPR crash box based on multi-objective genetic algorithm [J]. Structural and Multidisciplinary Optimization, 2016, 54(3): 673–684. DOI: 10.1007/s00158-016-1452-z. [14] 韩会龙, 张新春, 王鹏. 负泊松比蜂窝材料的动力学响应及能量吸收特性 [J]. 爆炸与冲击, 2019, 39(1): 47–57. DOI: 10.11883/bzycj-2017-0281.HAN H L, ZHANG X C, WANG P. Dynamic response and energy absorption characteristics of negative Poisson’s ratio honeycomb materials [J]. Explosion and Shock Waves, 2019, 39(1): 47–57. DOI: 10.11883/bzycj-2017-0281. [15] 田永军, 段国林, 夏晓光, 等. 响应面模型与混合优化算法相结合的锯片参数优化设计 [J]. 中国机械工程, 2016, 27(22): 3025–3031. DOI: 10.3969/j.issn.1004-132X.2016.22.008.TIAN Y J, DUAN G L, XIA X G, et al. Optimization design of saw blade parameters based on response surface model and hybrid optimization algorithm [J]. China Mechanical Engineering, 2016, 27(22): 3025–3031. DOI: 10.3969/j.issn.1004-132X.2016.22.008. [16] SIMPSON T W, MAUERY T M, KORTE J J, et al. Kriging models for global approximation in simulation-based multidisciplinary design optimization [J]. AIAA Journal, 2001, 39(12): 2233–2241. DOI: 10.2514/2.1234. [17] 任朋飞. 抗冲击型车身柔性底部结构防护技术研究[D]. 南京: 南京理工大学, 2018: 54−55. [18] 詹长书, 王清. 基于改进遗传算法电动汽车变速器参数设计与优化 [J]. 重庆理工大学学报(自然科学版), 2020, 34(2): 1–5. DOI: 10.3969/j.issn.1674-8425(z).2020.02.001.ZHAN C S, WANG Q. Design and optimization of transmission parameters of electric vehicle based on improved genetic algotithm [J]. Journal of Chongqing Institute of Technology (Natural Science), 2020, 34(2): 1–5. DOI: 10.3969/j.issn.1674-8425(z).2020.02.001. -

下载:

下载: