A practical calculation method of steel plate concrete walls to resist perforation from missile impact in nuclear engineering

-

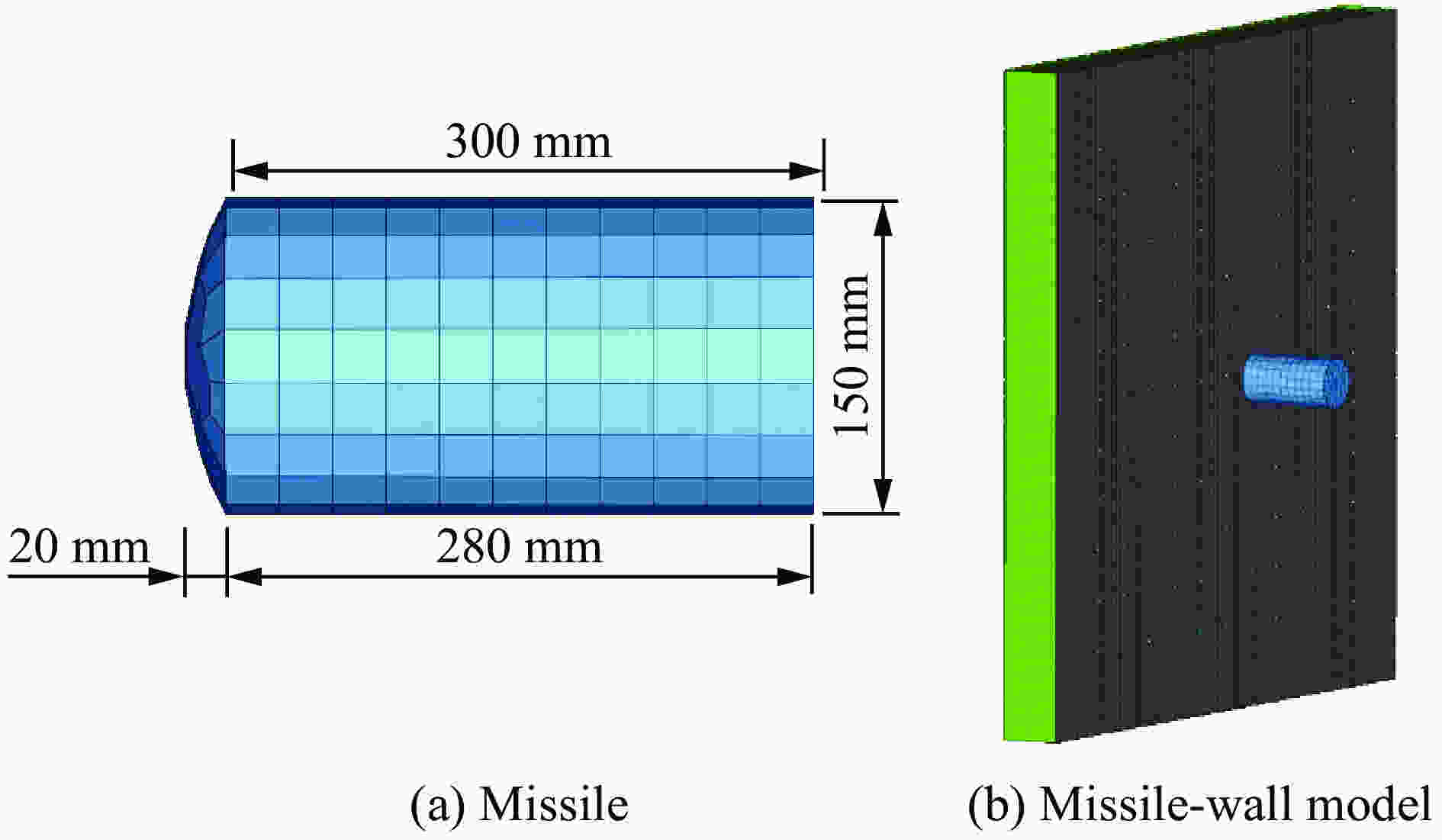

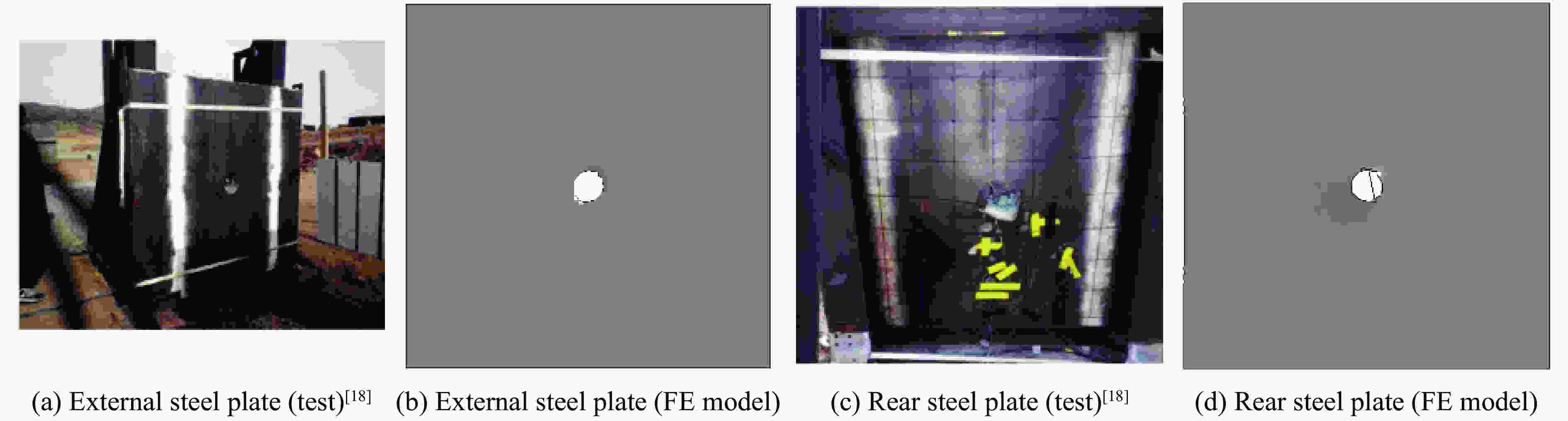

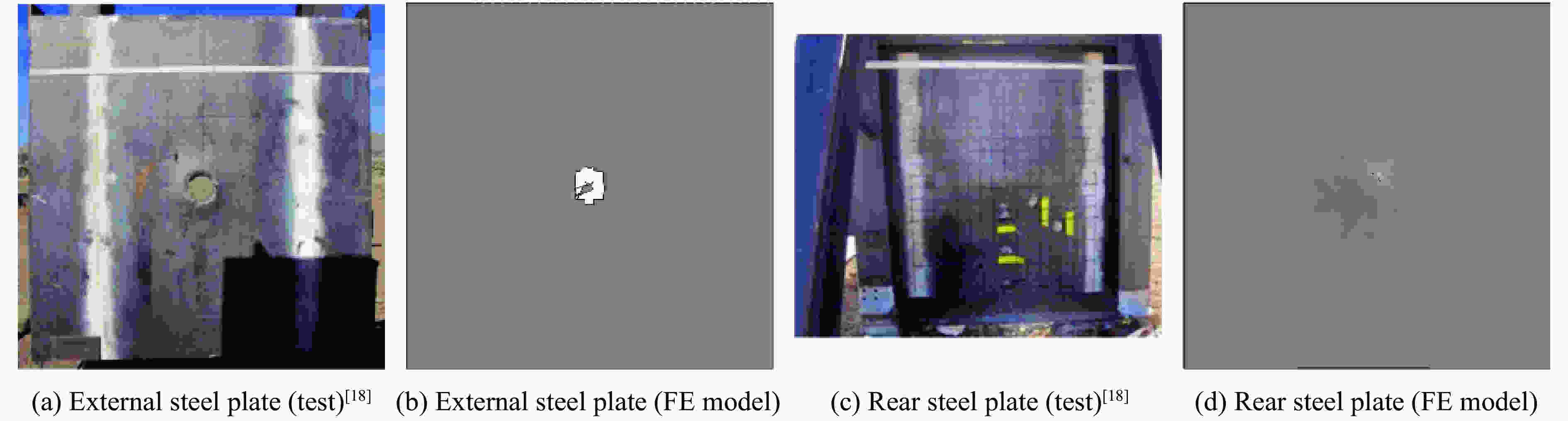

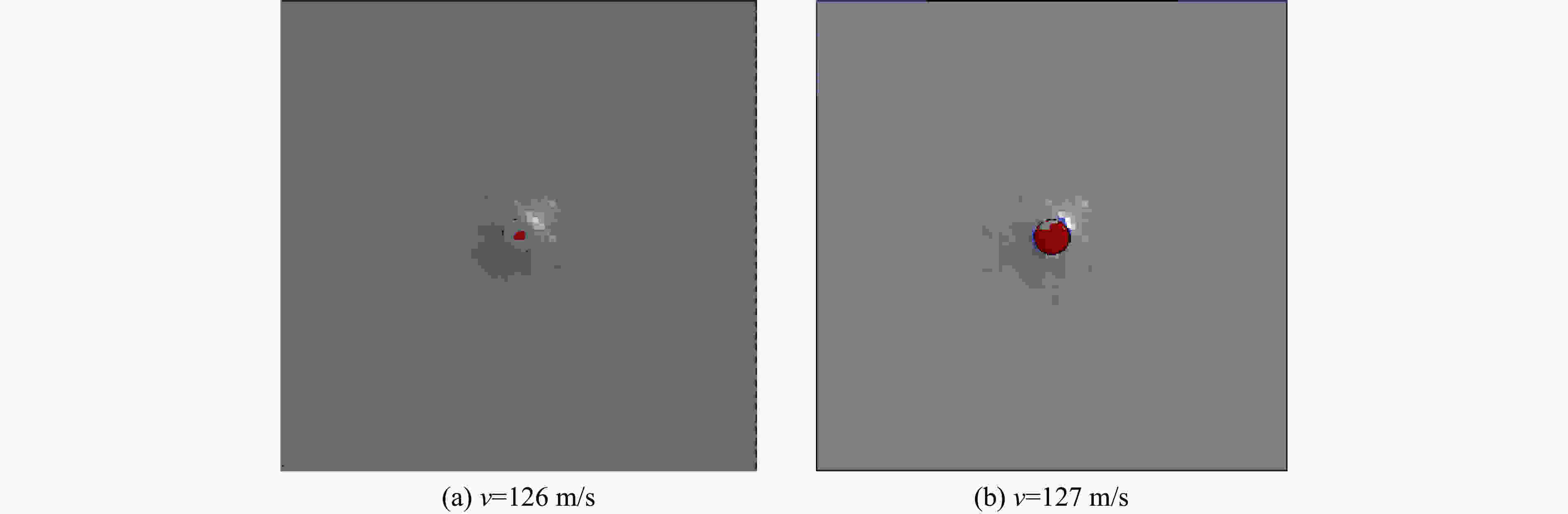

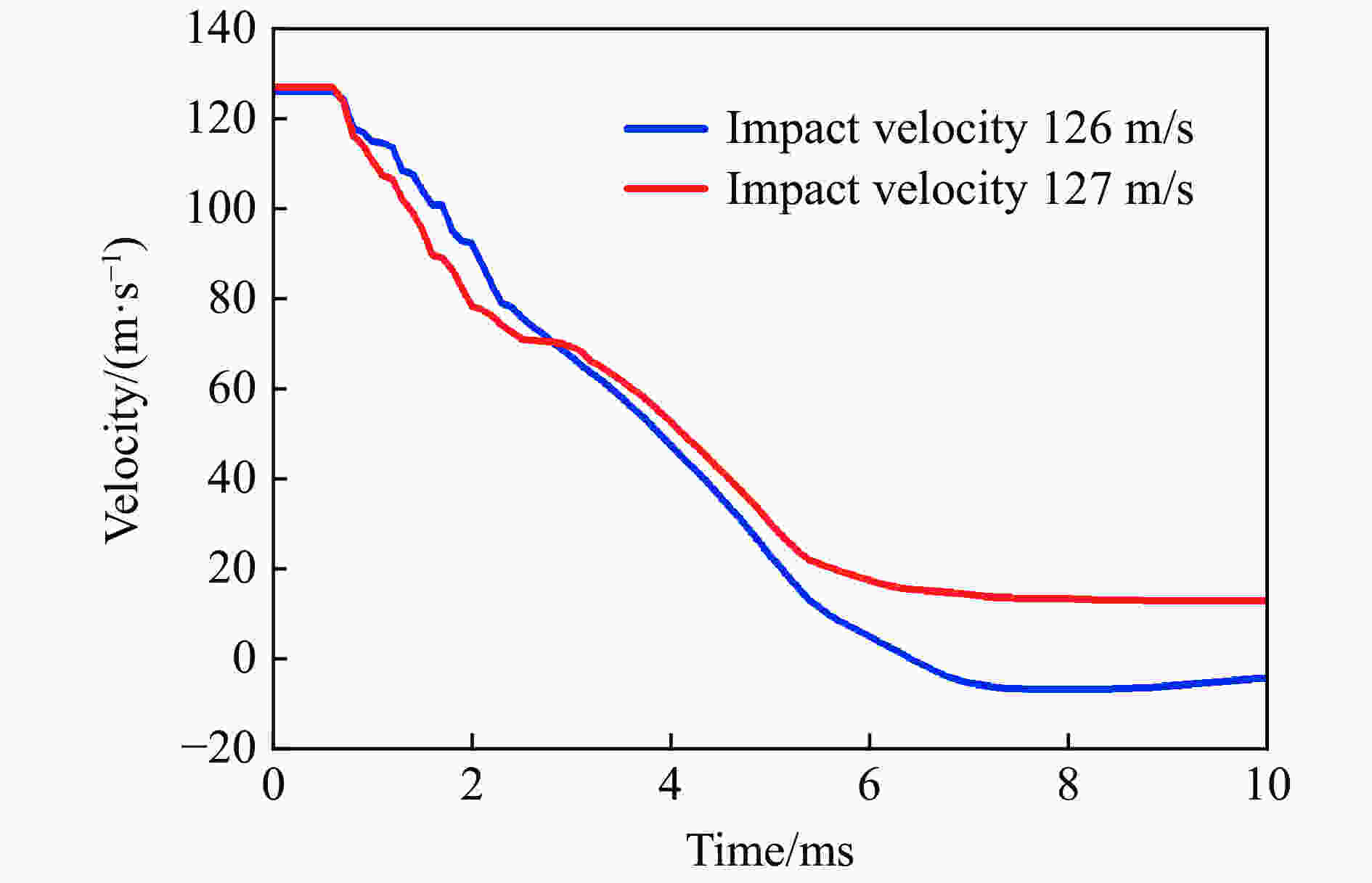

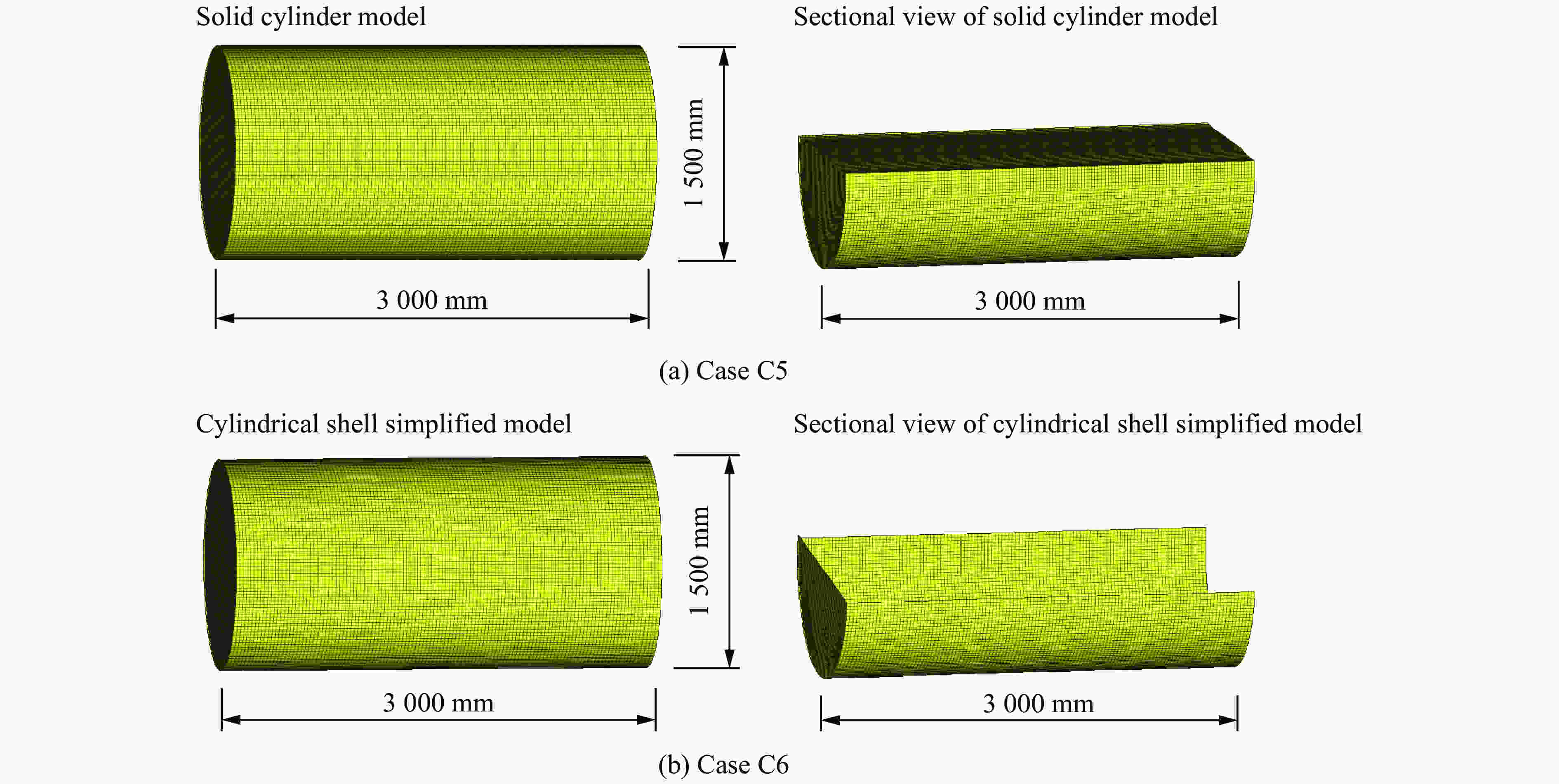

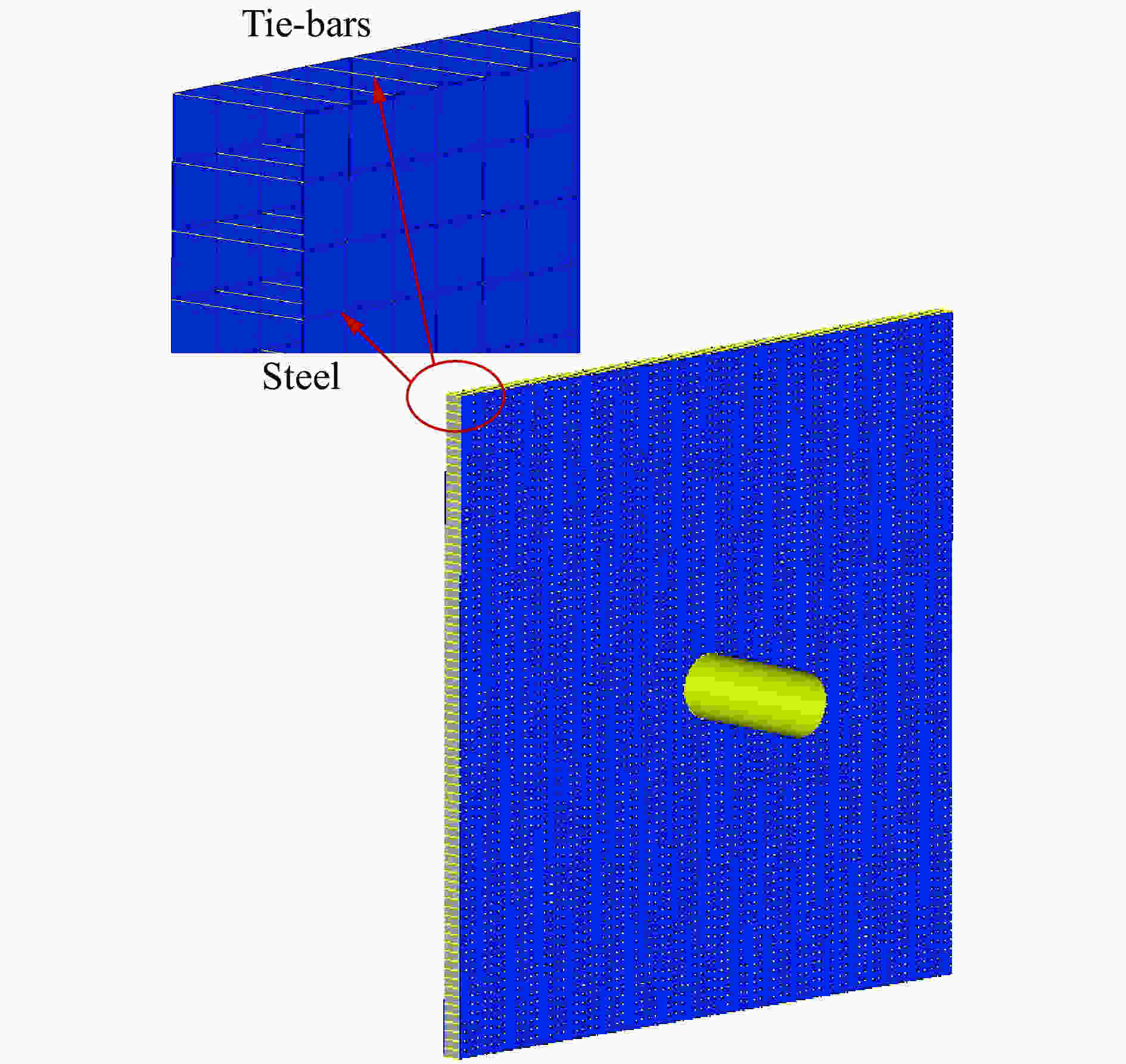

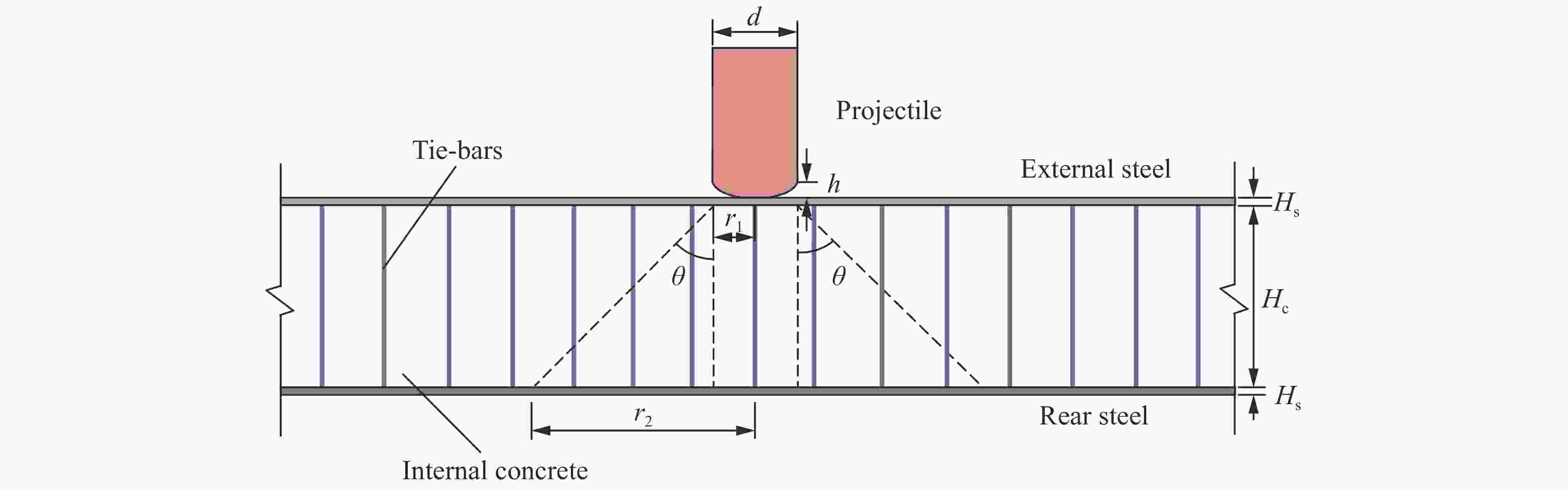

摘要: 针对带对拉钢筋的双钢板混凝土墙,研究了双钢板混凝土墙防贯穿计算方法,建立了基于能量法的防贯穿计算公式。在已知弹体和钢板混凝土墙体材料与几何相关参数时,利用防贯穿实用计算公式可对带对拉钢筋的核工程双钢板混凝土墙体贯穿速度以及弹体剩余速度进行计算,避免了复杂的结构抗撞击反应动力时程数值分析。为验证公式的可靠性,将公式计算结果与已有刚性弹体撞击双钢板混凝土墙实验结果及其动力有限元计算结果进行对比,结果表明:防贯穿实用计算公式可以正确判断双钢板混凝土墙的贯穿状态,实用计算公式给出的弹体剩余速度与实验结果符合良好。为进一步验证公式的适用范围,将公式计算结果与共10个工况的飞机发动机撞击双钢板混凝土墙的有限元计算结果进行了对比分析,结果表明:除1个工况计算结果偏差略超10%外,其余工况的偏差均在10%以内,说明该计算方法合理可行。Abstract: The calculation method based on the energy method for resisting perforation to the SC walls with tied bars was discussed. Based on the perforation mechanism of missile impacting on the SC walls, the dissipated energy was divided into four parts: the energy dissipated by the front and rear steel plates, the energy dissipated by internal concrete and tied bars, and a practical calculation formula of preventing perforation was proposed. The perforation velocity and the residual velocity of the SC walls with tied bars can be calculated by the practical calculation formula when the related parameters of the materials and geometry about the missile and SC walls are known, thus avoiding complex impacting numerical analysis of dynamic time history. In order to verify the reliability of the formula, the results calculated through the practical formula were compared with the existing test data, as well as the dynamic finite element (FE) analysis results. The perforation state of the SC walls can be judged by the practical calculation formula concretely, and the residual velocities of the missile given by the formula are in good agreement with the test results. To further verify the application extent of the formula, the FE models about 10 cases of an aircraft engine impacting on the SC walls were established, and the solid FE models and the front closed cylindrical shell FE models of the aircraft engine were described, respectively. The results calculated through the practical formula were compared with the 10 cases of the aircraft engine impacting on the SC wall. It indicates that the deviation value of one case is slightly more than 10%. In other cases, the deviation values are all less than 10%. The accuracy and effectiveness of the proposed method can be verified.

-

Key words:

- steel plate concrete (SC) walls /

- energy method /

- impact /

- perforation /

- finite element (FE) analysis

-

表 1 钢板计算参数

Table 1. Calculation parameters of steel plate

密度${\rho _{\rm{s}}}$/(kg·m−3) 屈服强度$\sigma $ /MPa 弹性模量Es /GPa 厚度Hs/mm 无量纲参数B 应变强化指数n 7.8×103 307 210 6 1.1 0.08[10] 表 2 混凝土计算参数

Table 2. Calculation parameters of concrete

密度${\rho _{\rm{c}}}$/(kg·m−3) 抗压强度fc/MPa 抗拉强度设计值ft1 / MPa 厚度Hc/m 2.37×103 50.075 1.9 0.163或0.238 表 3 公式计算及实验结果

Table 3. Formula calculation and test results

钢板 撞击速度v/(m·s−1) 贯穿速度vp/(m·s−1) 破坏形式 剩余速度vkr/ (m·s−1) 公式计算

(未考虑栓钉)公式计算

(考虑栓钉)公式计算 实验 公式计算

(未考虑栓钉)公式计算

(考虑栓钉)实验 SCS-175-6T 152.4 140.7 143.8 贯穿 贯穿 41.5 34.3 33.9 SCS-250-6T 147.7 155.0 159.7 未贯穿 未贯穿 0 0 0 表 4 有限元模型材料(MAT003)参数

Table 4. Material parameters for FE models

组件 密度/(kg·m−3) 屈服强度/MPa 杨氏模量 /GPa 切线模量 /MPa 泊松比 侵蚀参数 失效应变 C P 钢板(6 mm) 7.8×103 307 210 603 0.3 40 5 0.28 栓钉 7.8×103 345 210 504 0.3 40 5 0.30 弹体 7.8×103 250 210 502 0.3 40 5 0.30 表 5 数值计算和实验结果

Table 5. Numerical analysis and test results

钢板 撞击速度v/(m·s−1) 破坏形式 剩余速度vkr/(m·s−1) 有限元模拟 实验 有限元模拟 实验 SCS-175-6T 152.4 贯穿 贯穿 28.7 33.9 SCS-250-6T 147.7 鼓包 鼓包 0 0 表 6 双钢板混凝土墙贯穿速度对比

Table 6. Comparison of perforation velocities of SC walls

钢板 贯穿速度/(m·s−1) 偏差/% 公式计算(未考虑栓钉) 公式计算(考虑栓钉) 有限元分析 未考虑栓钉 考虑栓钉 SCS-175-6T 140.7 143.8 148 −4.93 −2.84 SCS-250-6T 155.0 159.7 161 −3.73 −0.81 表 7 飞机发动机撞击双钢板混凝土墙的贯穿速度对比

Table 7. Comparison of perforation velocities for SC walls subjected to an aircraft engine

工况 发动机类型 发动机质量/kg 发动机直径/m 发动机总长/m 混凝土墙厚度/m 贯穿速度/(m·s−1) 偏差/% 公式计算 有限元分析 C1 实心 998 0.5 0.650 0.48 128.3 126 1.83 C2 圆柱壳 998 0.5 0.650 0.48 128.3 129 −0.54 C3 实心 2 003 1.0 1.950 0.48 169.9 162 4.88 C4 圆柱壳 2 003 1.0 1.950 0.48 169.9 174 −2.36 C5 实心 4 500 1.5 3.000 0.48 166.9 151 10.53 C6 圆柱壳 4 500 1.5 3.000 0.48 166.9 159 4.97 C7 实心 8 014 2.0 4.225 0.98 178.2 178 0.11 C8 圆柱壳 8 014 2.0 4.225 0.98 178.2 187 −4.71 C9 实心 17 339 2.5 6.000 0.98 147.9 137 7.96 C10 圆柱壳 17 339 2.5 6.000 0.98 147.9 146 1.30 -

United States Nuclear Regulatory Commission. 50.150 aircraft impact assessment [DB/OL]. (2009-06-12)[2019-10-02]. https://www.nrc.gov/reading-rm/doc-collections/cfr/part050/part050-0150.html. Nuclear Energy Institute. NEI 07-13 methodology for performing aircraft impact assessments for new plant designs [S]. Washington: Nuclear Energy Institute, 2011. U.S. Nuclear Regulatory Commission. DG-1176 Guidance for the assessment of beyond-design-basis aircraft impacts [S]. Washington: U.S. Nuclear Regulatory Commission, 2009. 国家核安全局. 核动力厂设计安全规定: HAF 102-2016 [S]. 北京: 国家核安全局, 2016: 24−25. 刘晶波, 韩鹏飞, 林丽, 等. 飞机撞击建(构)筑物研究进展 [J]. 爆炸与冲击, 2016, 36(2): 269–278. DOI: 10.11883/1001-1455(2016)02-0269-10.LIU J B, HAN P F, LIN L, et al. Research progress of buildings and structures subjected to aircraft impact [J]. Explosion and Shock Waves, 2016, 36(2): 269–278. DOI: 10.11883/1001-1455(2016)02-0269-10. 刘晶波, 韩鹏飞, 郑文凯, 等. 商用飞机撞击核电站屏蔽厂房数值模拟 [J]. 爆炸与冲击, 2016, 36(3): 391–399. DOI: 10.11883/1001-1455(2016)03-0391-09.LIU J B, HAN P F, ZHENG W K, et al. Numerical investigation of shield building for nuclear power plant subjected to commercial aircraft impact [J]. Explosion and Shock Waves, 2016, 36(3): 391–399. DOI: 10.11883/1001-1455(2016)03-0391-09. LIU J B, HAN P F. Numerical analyses of a shield building subjected to a large commercial aircraft impact [J]. Shock and Vibration, 2018, 2018(6): 1–17. ARROS J, DOUMBALSKI N. Analysis of aircraft impact to concrete structures [J]. Nuclear Engineering and Design, 2007, 237(12−13): 1241–1249. DOI: 10.1016/j.nucengdes.2006.09.044. THAI D K, KIM S E. Safety assessment of a nuclear power plant building subjected to an aircraft crash [J]. Nuclear Engineering and Design, 2015, 293: 38–52. DOI: 10.1016/j.nucengdes.2015.07.053. BRUHL J C, VARMA A H, JOHNSON W H. Design of composite SC walls to prevent perforation from missile impact [J]. International Journal of Impact Engineering, 2015, 75: 75–87. DOI: 10.1016/j.ijimpeng.2014.07.015. CHEN X Y, HUANG X L, LIANG G J. Comparative analysis of perforation models of metallic plates by rigid sharp-nosed projectiles [J]. International Journal of Impact Engineering, 2011, 38(7): 613–621. DOI: 10.1016/j.ijimpeng.2010.12.005. FORRESTAL M J, WARREN T L. Perforation equations for conical and ogival nose rigid projectiles into aluminum target plates [J]. International Journal of Impact Engineering, 2009, 36(2): 220–225. DOI: 10.1016/j.ijimpeng.2008.04.005. CHEN X Y, LI Q M. Deep penetration of a non-deformable projectile with different geometrical characteristics [J]. International Journal of Impact Engineering, 2002, 27(6): 619–637. DOI: 10.1016/S0734-743X(02)00005-2. LI Q M, CHEN X W. Dimensionless formulae for penetration depth of concrete target impacted by a non-deformable projectile [J]. International Journal of Impact Engineering, 2003, 28(1): 93–116. DOI: 10.1016/S0734-743X(02)00037-4. LI Q M, REID S R, WEN H M, et al. Local impact effects of hard missiles on concrete targets [J]. International Journal of Impact Engineering, 2005, 32(1−4): 224–284. DOI: 10.1016/j.ijimpeng.2005.04.005. KAR A K. Residual velocity for projectiles [J]. Nuclear Engineering and Design, 1979, 53(1): 87–95. DOI: 10.1016/0029-5493(79)90042-6. 中华人民共和国住房和城乡建设部. 混凝土结构设计规范(2015版): GB 50010-2010 [S]. 北京: 中国建筑工业出版社, 2011: 103−106. KIM K S, MOON I H, CHOI H J, et al. A preliminary study on the local impact behavior of steel-plate concrete walls [J]. Annals of Nuclear Energy, 2017, 102: 210–219. DOI: 10.1016/j.anucene.2016.12.006. HALLQUIST J O. LS-DYNA theory manual: Version 971 [M]. Livermore: Livermore Software Technology Corporation, 2007: 15−19. MIZUNO J, KOSHIKA N, MORIKAWA H, et al. Investigation on impact resistance of steel plate reinforced concrete barriers against aircraft impact, part 1: test program and results [C] // Proceedings of the 18th International Conference on Structural Mechanics in Reactor Technology. Beijing: China Nuclear Society, 2005: 2566−2579. 中华人民共和国建设部, 中华人民共和国国家质量监督检验检疫总局. 人民防空地下室设计规范: GB 50038-2005 [S]. 北京: 国标图集出版社, 2006: 52−68. US Department of the Army. TM5-1300 The design of structures to resist the effects of accidental explosions [M]. Washington, DC: US Department of the Army, the Navy and the Air Force, 1990. Westinghouse Electric Company LLC. Passive safety systems and timeline for station blackout [DB/OL]. (2011)[2017-08-01]. https://www.westinghousenuclear.com/Portals/0/New%20Plants/AP1000/AP1000%20Station%20Blackout.pdf?timestamp=1404842353431. The Boeing Company. Boeing commercial airplanes [DB/OL]. (2020-05-18)[2017-09-02]. https://boeing.mediaroom.com. Boeing Commercial Airplanes. 767 Airplane characteristics for airport planning: D6-58328 [R]. Seattle: Boeing Commercial Airplanes, 2005. -

下载:

下载: