Oblique impact resistance of a bionic thin-walled tube based on antles osteon

-

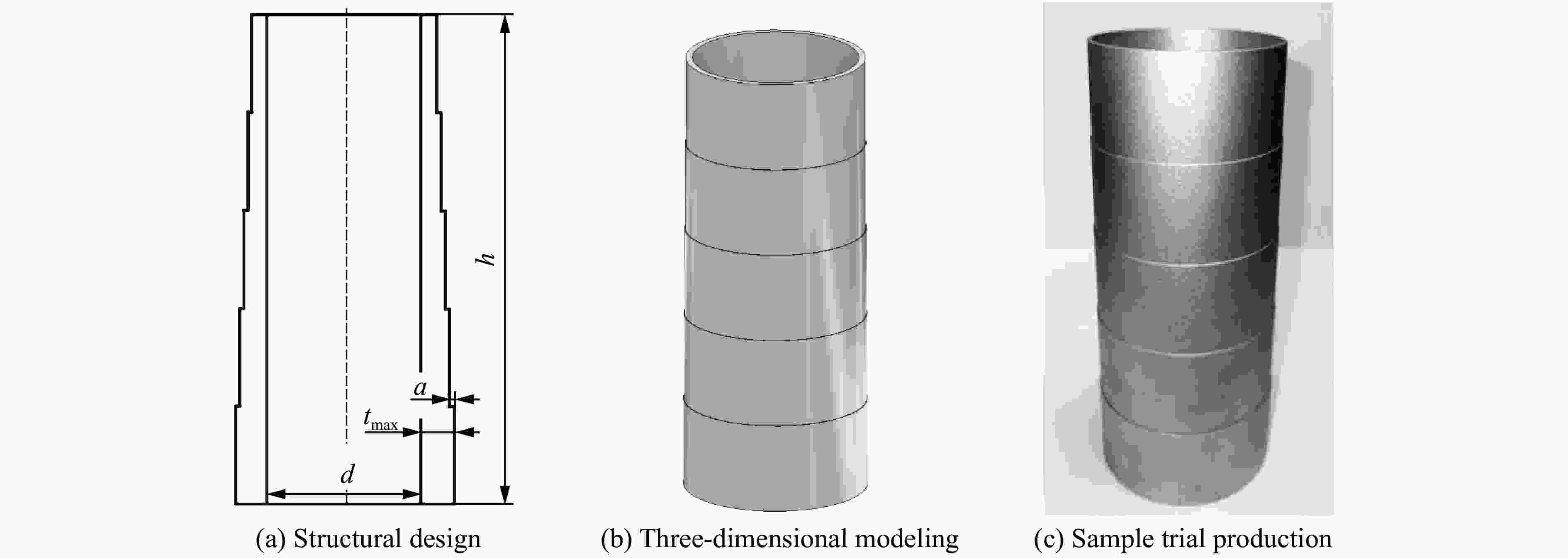

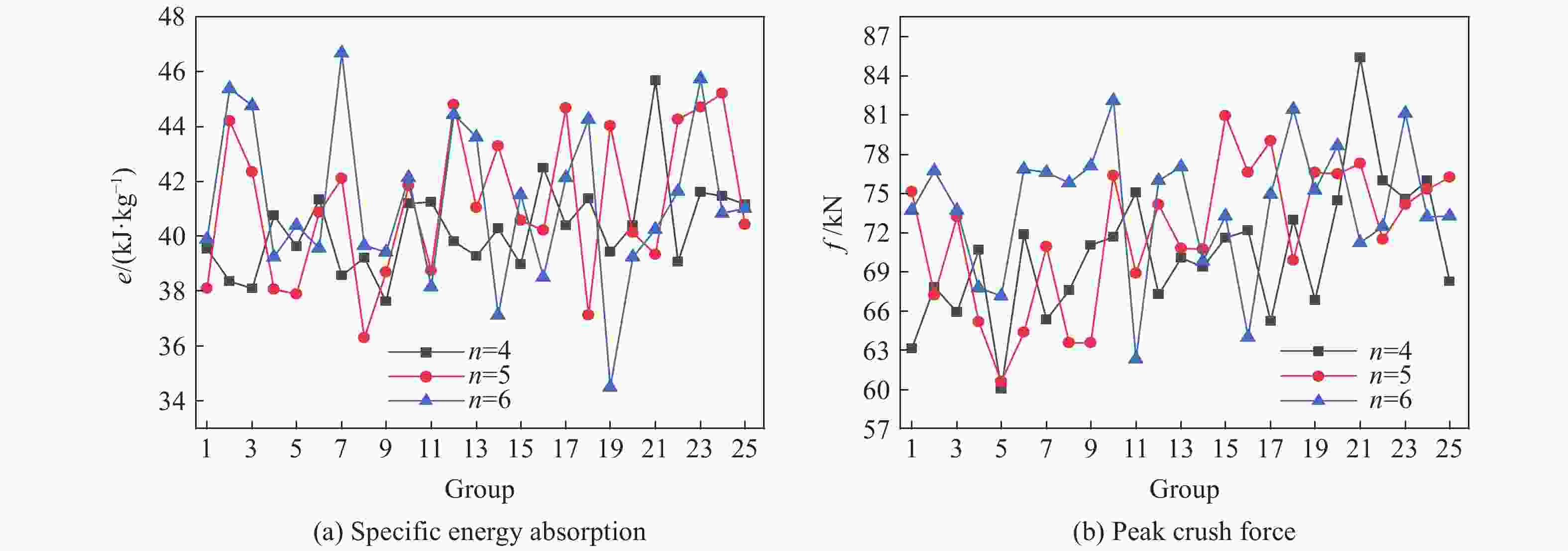

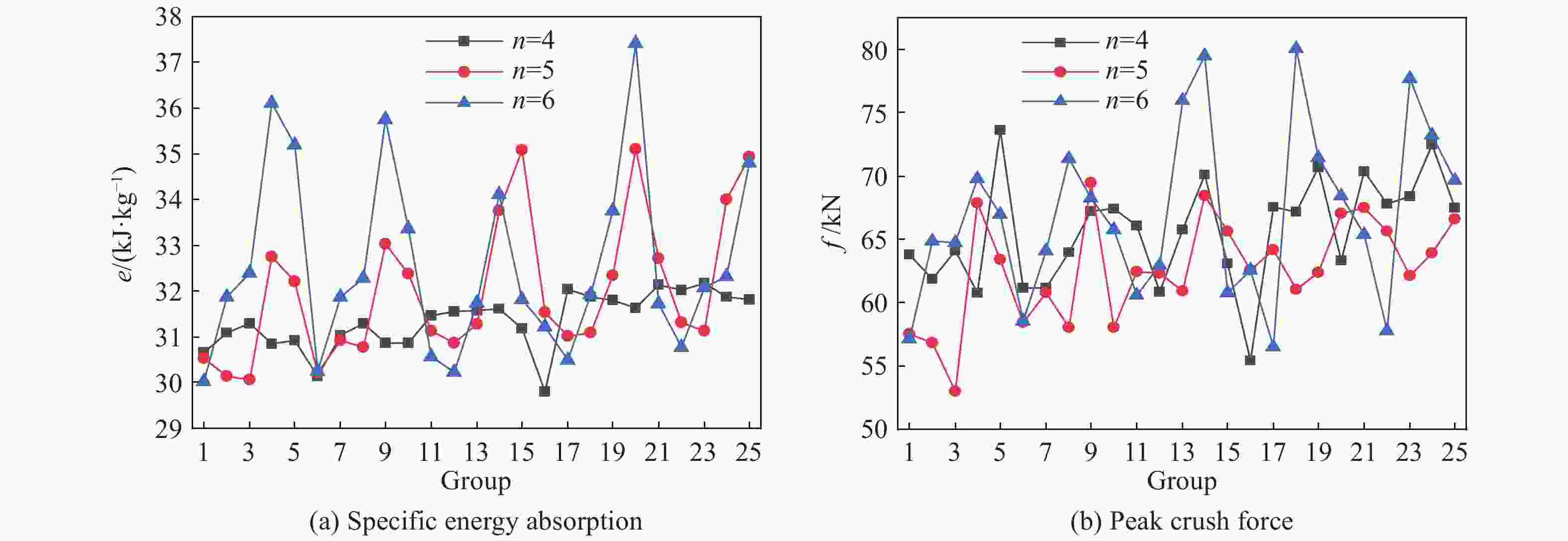

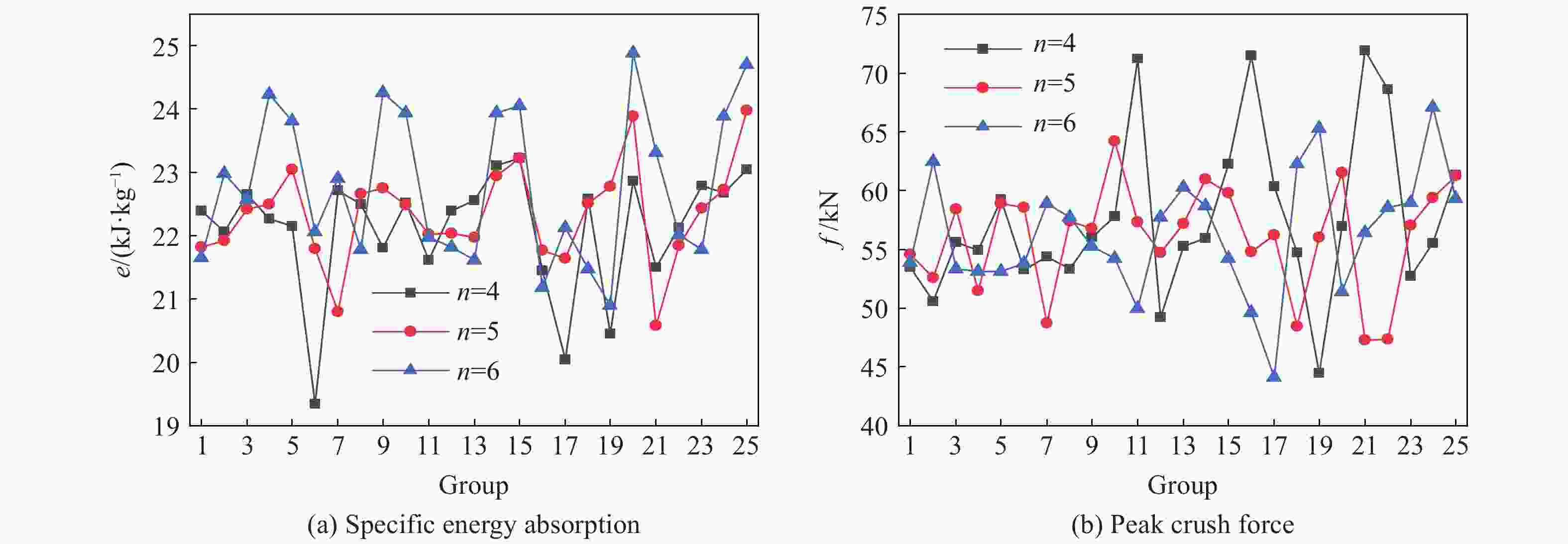

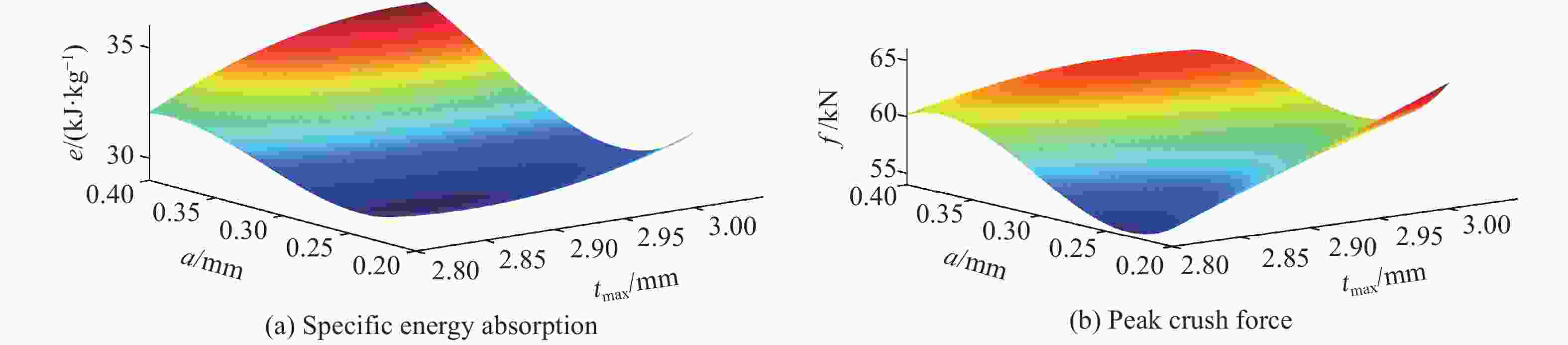

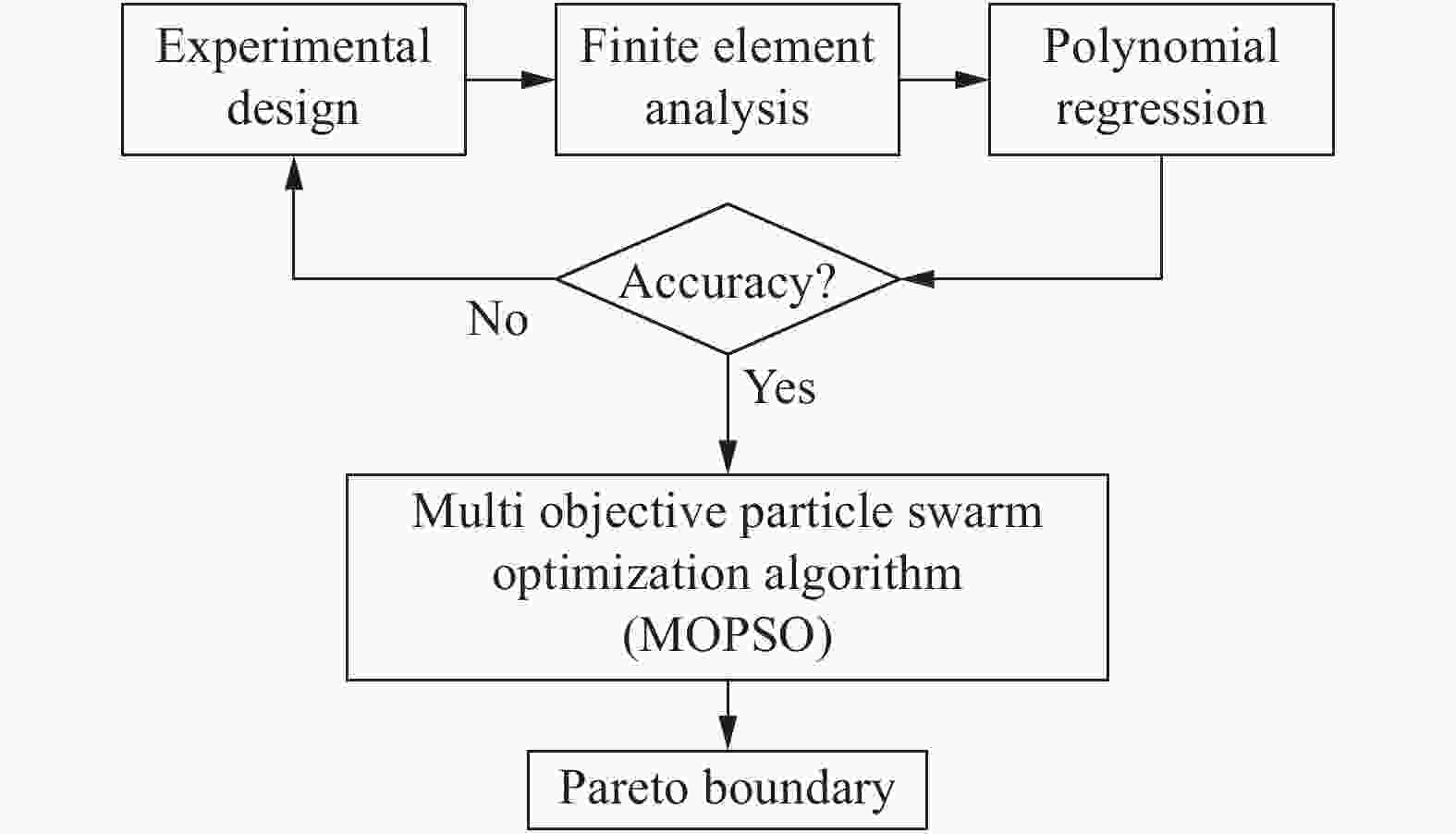

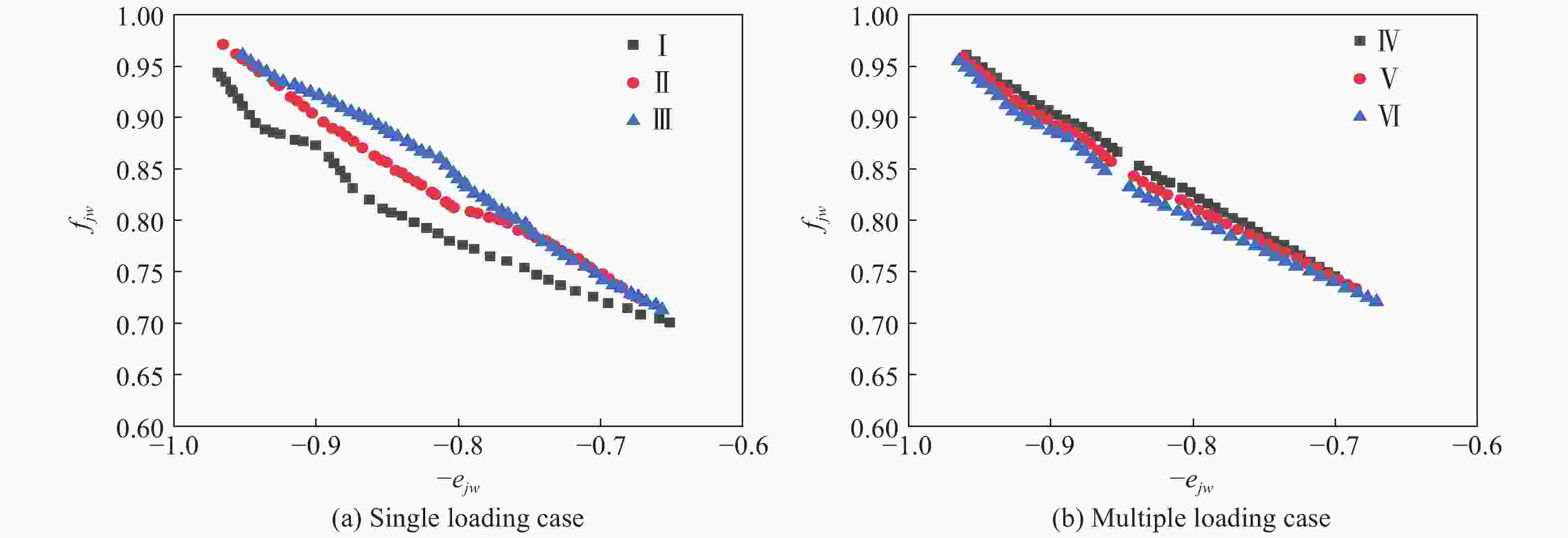

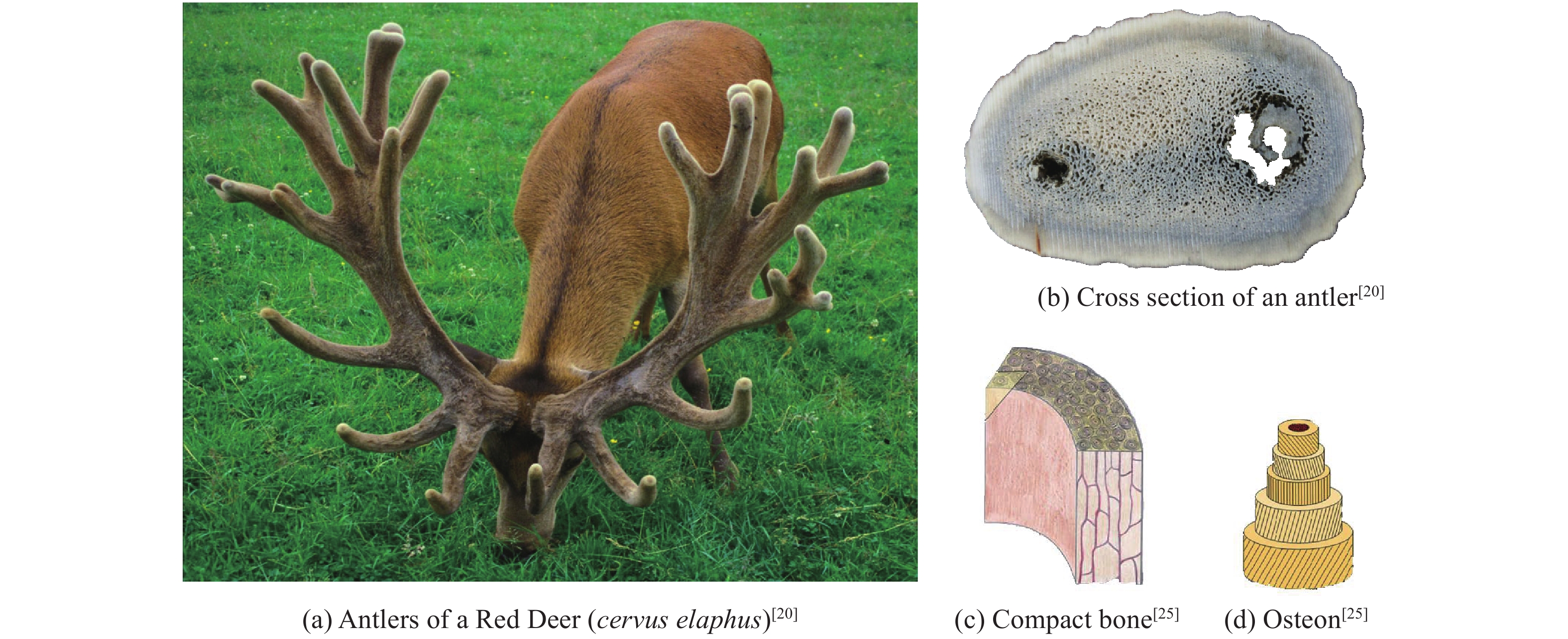

摘要: 为提高薄壁管结构的耐撞性和吸能性,基于鹿角骨单位结构特征,结合结构仿生学原理设计出内径相同、外径等梯度逐层递减的仿生薄壁管。采用有限元法对75种仿生薄壁管结构进行10°、20°、30°等3种斜向冲击角度的吸能特性模拟;通过多项式回归元模型和多目标粒子群优化算法进行优化,以Pareto前沿最优原则得到各目标最优化的配置方案;采用最小距离选择法进行优化分析,得到各配置方案的最优结构设计参数。结果表明:仅考虑单一冲击角度时,在10°、20°、30°冲击角度下的仿生薄壁管耐撞性最优的仿生层数n均为6,最大壁厚与厚度梯度值参数组合tmax-a分别为2.84 mm-0.38 mm、2.89 mm-0.29 mm、2.91 mm-0.34 mm;综合考虑多种冲击角度权重因数不同配置方案时,仿生薄壁管耐撞性最优的仿生层数n均为6,最大壁厚与厚度梯度值参数组合tmax-a分别为2.95 mm-0.28 mm、2.92 mm-0.30 mm、2.85 mm-0.33 mm。Abstract: Some achievements have been made in the study on mechanical properties of antler, but they have not been applied in engineering practice, especially in the study of thin-walled tubes similar to antler crashworthiness. In order to improve the crashworthiness and energy absorption of the thin-walled tube structures, a bionic thin-walled tube with the same inner diameter and equal gradient of outer diameter was designed based on the structural characteristics of antler bone and the principle of structural bionics. The finite element method was used to simulate the energy absorption characteristics of 75 kinds of bionic thin-walled tube structures under the oblique impacts with the impact angles of 10°, 20° and 30°. The polynomial regression element model and multi-objective particle swarm optimization algorithm were used to optimize, and the Pareto front optimization principle was used to obtain the optimal allocation scheme of each target. The minimum distance selection method was used in optimization analysis to obtain the optimal structural design parameters of each scheme. The optimization method used in this study can provide reference for the follow-up research on the crashworthiness of thin-walled tubes, and the optimal structure of bionic thin-walled tubes can provide reference for practical engineering application. The results show that when only considering a single impact angle, the optimal number of biomimetic layers n is 6, and the parameter combination of maximum wall thickness and thickness gradient tmax-a is 2.84 mm-0.38 mm, 2.89 mm-0.29 mm, 2.91 mm-0.34 mm, respectively under 10°, 20° and 30° impact angles. Considering various impact angle weight factors and different configuration schemes, the optimal number of biomimetic layers n is 6, and the parameter combination of maximum wall thickness and thickness gradient tmax-a is 2.95 mm-0.28 mm, 2.92 mm-0.30 mm and 2.85 mm-0.33 mm, respectively.

-

Key words:

- thin-walled tube /

- structural bionics /

- oblique impact /

- crashworthiness /

- multi-objective optimization

-

表 1 试验组别

Table 1. Group of test factors

因素 组别 1 2 3 4 5 6 7 8 9 10 11 12 tmax/mm 2.80 2.80 2.80 2.80 2.80 2.85 2.85 2.85 2.85 2.85 2.9 2.90 a/mm 0.20 0.25 0.30 0.35 0.40 0.20 0.25 0.30 0.35 0.40 0.20 0.25 因素 组别 13 14 15 16 17 18 19 20 21 22 23 24 25 tmax/mm 2.90 2.90 2.90 2.95 2.95 2.95 2.95 2.95 3.00 3.00 3.00 3.00 3.00 a/mm 0.30 0.35 0.40 0.20 0.25 0.30 0.35 0.40 0.20 0.25 0.30 0.35 0.40 表 2 设计样本的拟合系数R2

Table 2. Fitting coefficient R2 of design samples

性能指标 层数 4 5 6 10° 20° 30° 10° 20° 30° 10° 20° 30° e 0.993 8 0.995 3 0.989 9 0.989 1 0.995 2 0.993 5 0.993 3 0.991 2 0.983 3 f 0.993 2 0.994 7 0.996 0 0.992 0 0.993 4 0.991 4 0.991 2 0.993 1 0.995 2 表 3 不同设计方案的权重因数

Table 3. Weighting factors for different design cases

配置方案 w1 w2 w3 Ⅰ 1 0 0 Ⅱ 0 1 0 Ⅲ 0 0 1 Ⅳ 1/6 1/3 1/2 Ⅴ 1/3 1/3 1/3 Ⅵ 1/2 1/3 1/6 表 4 不同设计方案的最优结构设计参数

Table 4. Optimum structural design parameters in different design cases

配置方案 最优指标 结构设计参数 性能指标 fi−ei 组内排名 ejw fjw tmax/mm a/mm α/(°) n e/(kJ·kg−1) f/kN Ⅰ −0.839 0.804 2.84 0.38 10 4 36.55 75.08 0.151 3 5 39.31 76.64 0.047 2 6 38.50 78.65 −0.064 1 Ⅱ −0.819 0.829 2.89 0.29 20 4 32.06 65.77 0.131 2 5 30.72 60.39 0.244 3 6 31.92 68.00 −0.216 1 Ⅲ −0.803 0.846 2.91 0.34 30 4 22.07 59.25 0.266 2 5 22.41 58.58 0.434 3 6 21.82 59.53 −0.447 1 Ⅳ −0.824 0.816 2.95 0.28 10 4 40.72 71.04 0.010 3 5 42.49 74.11 −0.025 2 6 42.44 75.26 0.024 4 20 4 32.40 66.88 0.138 5 5 30.80 60.95 0.242 6 6 32.07 68.79 −0.213 1 30 4 22.50 55.96 0.216 7 5 22.04 57.16 0.443 9 6 22.90 57.19 0.423 8 Ⅴ −0.817 0.826 2.92 0.30 10 4 46.01 65.32 −0.176 2 5 38.87 64.35 0.057 5 6 38.42 67.75 −0.060 4 20 4 31.47 61.47 0.090 6 5 31.00 63.17 0.237 8 6 36.12 58.42 −0.120 3 30 4 23.10 52.70 0.161 7 5 20.98 48.75 0.466 9 6 24.71 53.39 −0.381 1 Ⅵ −0.830 0.848 2.85 0.33 10 4 37.80 71.82 0.083 5 5 39.05 75.32 0.053 4 6 39.81 76.63 −0.036 3 20 4 31.60 72.34 0.224 7 5 32.81 62.38 0.196 6 6 30.23 61.30 −0.255 2 30 4 20.04 68.63 0.429 9 5 22.79 60.95 0.425 8 6 21.18 62.58 −0.462 1 -

[1] BAROUTAJI A, SAJJIA M, OLABI A G. On the crashworthiness performance of thin-walled energy absorbers: recent advances and future developments [J]. Thin-Walled Structures, 2017, 118: 137–163. DOI: 10.1016/j.tws.2017.05.018. [2] 徐峰祥, 张锁, 武昆迎. 厚度幂指数分布管状结构耐撞性设计准则与方法研究 [J]. 爆炸与冲击, 2019, 39(3): 035103. DOI: 10.11883/bzycj-2018-0013.XU F X, ZHANG S, WU K Y. Study on crashworthiness design criteria and method of tubular structures with power exponent distribution of thickness [J]. Explosion and Shock Waves, 2019, 39(3): 035103. DOI: 10.11883/bzycj-2018-0013. [3] 郝文乾, 卢进帅, 黄睿, 等. 轴向冲击载荷下薄壁折纹管的屈曲模态与吸能 [J]. 爆炸与冲击, 2015, 35(3): 380–385. DOI: 10.11883/1001-1455-(2015)03-0380-06.HAO W Q, LU J S, HUANG R, et al. Buckling and energy absorption properties of thin-walled corrugated tubes under axial impacting [J]. Explosion and Shock Waves, 2015, 35(3): 380–385. DOI: 10.11883/1001-1455-(2015)03-0380-06. [4] 谭丽辉, 徐涛, 崔晓梅, 等. 带有圆弧形凹槽金属薄壁圆管抗撞性优化设计 [J]. 爆炸与冲击, 2014, 34(5): 547–553. DOI: 10.11883/1001-1455(2014)05-0547-07.TAN L H, XU T, CUI X M, et al. Design optimization for crashworthiness of metal thin-walled cylinders with circular arc indentations [J]. Explosion and Shock Waves, 2014, 34(5): 547–553. DOI: 10.11883/1001-1455(2014)05-0547-07. [5] 张涛, 刘土光, 肖汉林, 等. 高速冲击下薄壁组合结构吸能特性研究 [J]. 爆炸与冲击, 2006, 26(5): 395–403.ZHANG T, LIU T G, XIAO H L, et al. Energy absorption performance of thin-walled structures with triggering holes subjected to high-speed axial impact [J]. Explosion and Shock Waves, 2006, 26(5): 395–403. [6] 殷之平, 李玉龙, 黄其青. 含诱导缺陷薄壁圆管耐撞性优化设计 [J]. 爆炸与冲击, 2011, 31(4): 418–422. DOI: 10.11883/1001-1455(2011)04-0418-05.YIN Z P, LI Y L, HUANG Q Q. Optimal crashworthiness design of thin-walled circular tubes with triggering holes [J]. Explosion and Shock Waves, 2011, 31(4): 418–422. DOI: 10.11883/1001-1455(2011)04-0418-05. [7] 李松晏, 郑志军, 虞吉林. 高速列车吸能结构设计和耐撞性分析 [J]. 爆炸与冲击, 2015, 35(2): 164–170. DOI: 10.11883/1001-1455(2015)02-0164-07.LI S Y, ZHENG Z J, YU J L. Energy-absorbing structure design and crashworthiness analysis of high-speed trains [J]. Explosion and Shock Waves, 2015, 35(2): 164–170. DOI: 10.11883/1001-1455(2015)02-0164-07. [8] SUN G Y, LIU T Y, FANG J G, et al. Configurational optimization of multi-cell topologies for multiple oblique loads [J]. Structural and Multidisciplinary Optimization, 2018, 57(2): 469–488. DOI: 10.1007/s00158-017-1839-5. [9] ALKHATIB S E, TARLOCHAN F, HASHEM A, et al. Collapse behavior of thin-walled corrugated tapered tubes under oblique impact [J]. Thin-Walled Structures, 2018, 122: 510–528. DOI: 10.1016/j.tws.2017.10.044. [10] ASANJARANI A, DIBAJIAN S H, MAHDIAN A. Multi-objective crashworthiness optimization of tapered thin-walled square tubes with indentations [J]. Thin-Walled Structures, 2017, 116: 26–36. DOI: 10.1016/j.tws.2017.03.015. [11] 亓昌, 董方亮, 杨姝, 等. 锥形多胞薄壁管斜向冲击吸能特性仿真研究 [J]. 振动与冲击, 2012, 31(24): 102–107. DOI: 10.13465/j.cnki.jvs.2012.24.009.QI C, DONG F L, YANG S, et al. Energy-absorbing characteristics of a tapered multi-cell thin-walled tube under oblique impact [J]. Journal of Vibration and Shock, 2012, 31(24): 102–107. DOI: 10.13465/j.cnki.jvs.2012.24.009. [12] 任露泉, 梁云虹. 仿生学导论[M]. 北京: 科学出版社, 2016: 208-210. [13] HUANG H, XU S C. Crashworthiness analysis and bionic design of multi-cell tubes under axial and oblique impact loads [J]. Thin-Walled Structures, 2019, 144: 106333. DOI: 10.1016/j.tws.2019.106333. [14] 许述财, 邹猛, 魏灿刚, 等. 仿竹结构薄壁管的轴向耐撞性分析及优化 [J]. 清华大学学报(自然科学版), 2014, 54(3): 299–304. DOI: 10.16511/J.CNKI.QHDXXB.2014.03.007.XU S C, ZOU M, WEI C G, et al. Axial crashworthiness analysis and optimization of a bionic thin-walled tube based on bamboo structure [J]. Journal of Tsinghua University (Science and Technology), 2014, 54(3): 299–304. DOI: 10.16511/J.CNKI.QHDXXB.2014.03.007. [15] ZOU M, XU S C, WEI C G, et al. A bionic method for the crashworthiness design of thin-walled structures inspired by bamboo [J]. Thin-Walled Structures, 2016, 101: 222–230. DOI: 10.1016/j.tws.2015.12.023. [16] SONG J F, XU S C, WANG H X, et al. Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures [J]. Thin-Walled Structures, 2018, 125: 76–88. DOI: 10.1016/j.tws.2018.01.010. [17] LI Z, DUAN L B, CHEN T, et al. Crashworthiness analysis and multi-objective design optimization of a novel lotus root filled tube (LFT) [J]. Structural and Multidisciplinary Optimization, 2018, 57(2): 865–875. DOI: 10.1007/s00158-017-1782-5. [18] YIN H F, XIAO Y Y, WEN G L, et al. Multi-objective robust optimization of foam-filled bionic thin-walled structures [J]. Thin-Walled Structures, 2016, 109: 332–343. DOI: 10.1016/j.tws.2016.10.011. [19] CURREY J D. Bones: structure and mechanics [M]. New Jersey: Princeton University Press, 2006. [20] PICAVET P P, BALLIGAND M. Organic and mechanical properties of Cervidae antlers: a review [J]. Veterinary Research Communications, 2016, 40(3-4): 141–147. DOI: 10.1007/s11259-016-9663-8. [21] FANG Z Q, CHEN B, LIN S Y, et al. Investigation of inner mechanism of anisotropic mechanical property of antler bone [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2018, 88: 1–10. DOI: 10.1016/j.jmbbm.2018.07.043. [22] CURREY J D, LANDETE-CASTILLEJOS T, ESTEVEZ J, et al. The mechanical properties of red deer antler bone when used in fighting [J]. Journal of Experimental Biology, 2009, 212(24): 3985–3993. DOI: 10.1242/jeb.032292. [23] DAVISON K S, SIMINOSKI K, ADACHI J D, et al. Bone strength: the whole is greater than the sum of its parts [J]. Seminars in Arthritis and Rheumatism, 2006, 36(1): 22–31. DOI: 10.1016/j.semarthrit.2006.04.002. [24] HENSHAW J. Antlers: the unbrittle bones of contention [J]. Nature, 1971, 231(5303): 469. DOI: 10.1038/231469a0. [25] CHEN P Y, STOKES A G, MCKITTRICK J. Comparison of the structure and mechanical properties of bovine femur bone and antler of the North American elk (cervus elaphus canadensis) [J]. Acta Biomaterialia, 2009, 5(2): 693–706. DOI: 10.1016/j.actbio.2008.09.011. [26] 杨欣, 范晓文, 许述财, 等. 仿虾螯结构薄壁管设计及耐撞性分析 [J]. 爆炸与冲击, 2020, 40(4): 043301. DOI: 10.11883/bzycj-2019-0280.YANG X, FAN X W, XU S C, et al. Design and crashworthiness analysis of thin-walled tubes based on a shrimp chela structure [J]. Explosion and Shock Waves, 2020, 40(4): 043301. DOI: 10.11883/bzycj-2019-0280. -

下载:

下载: