Numerical simulation of methane-air explosion in a connected device with volume fraction gradient

-

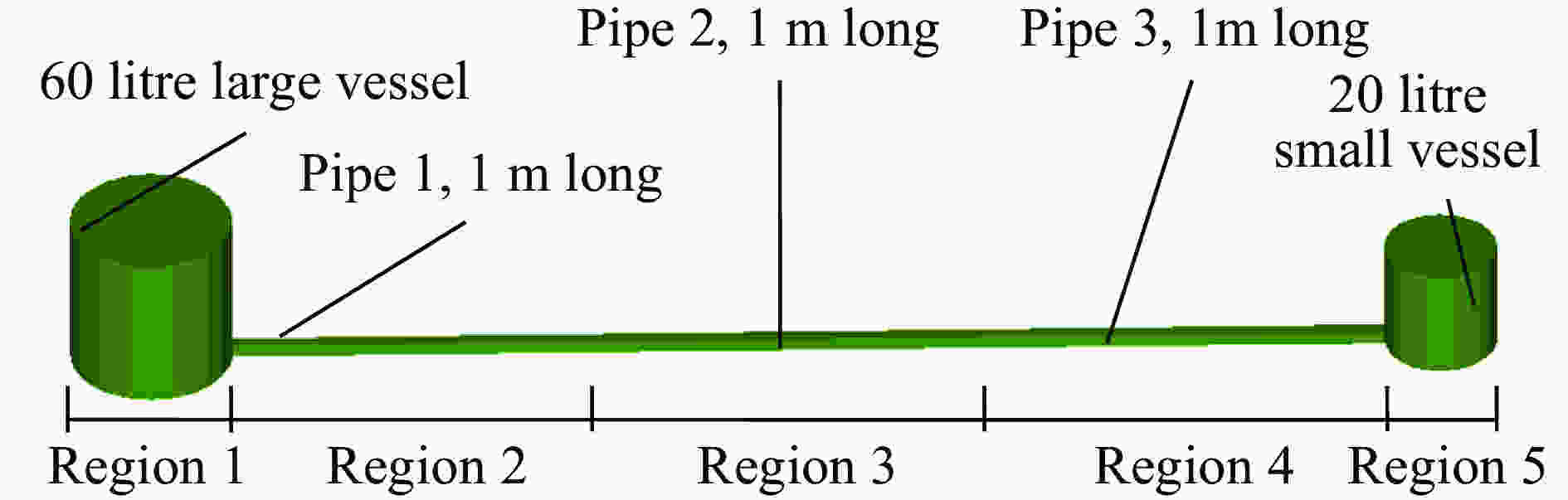

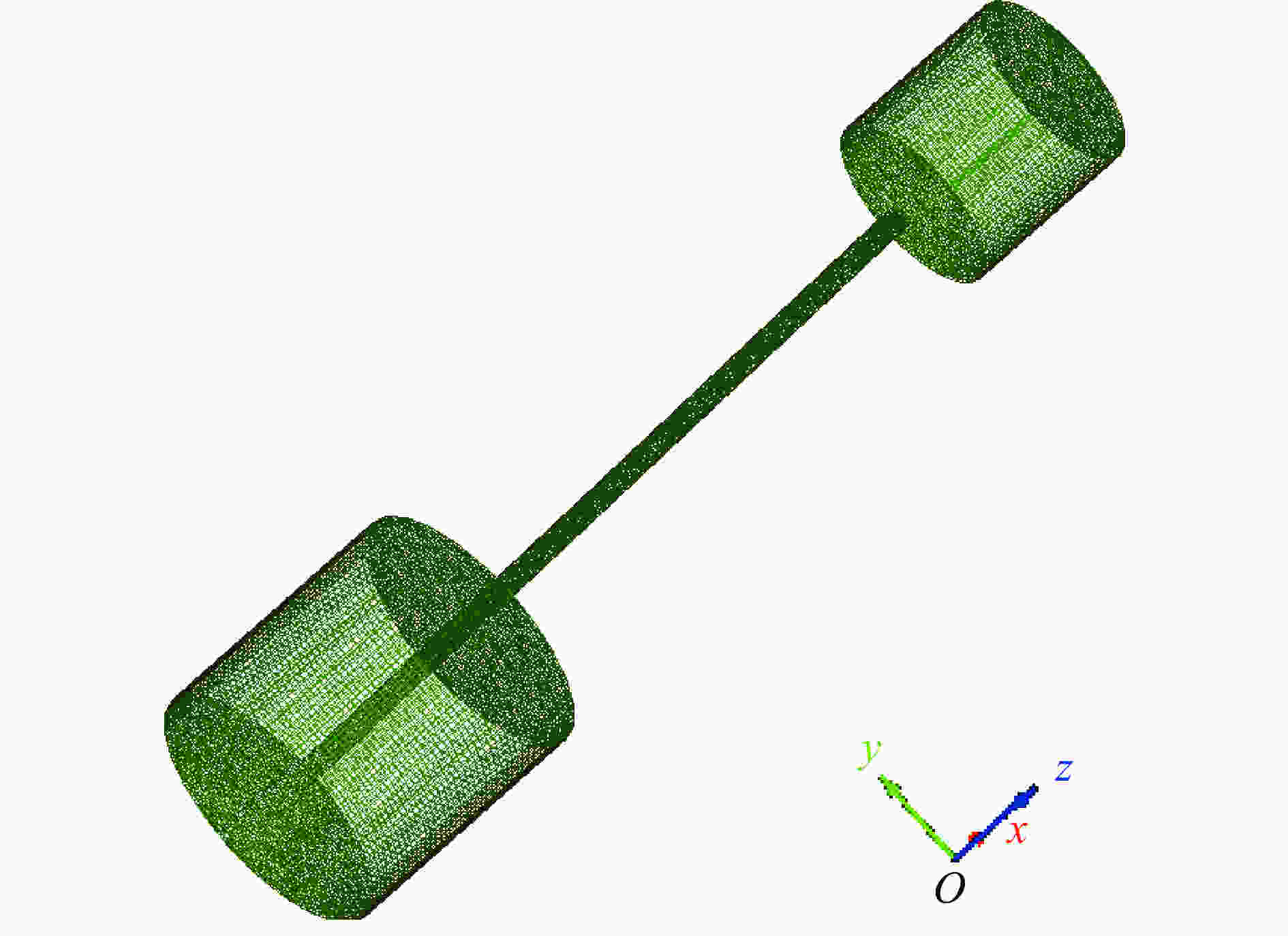

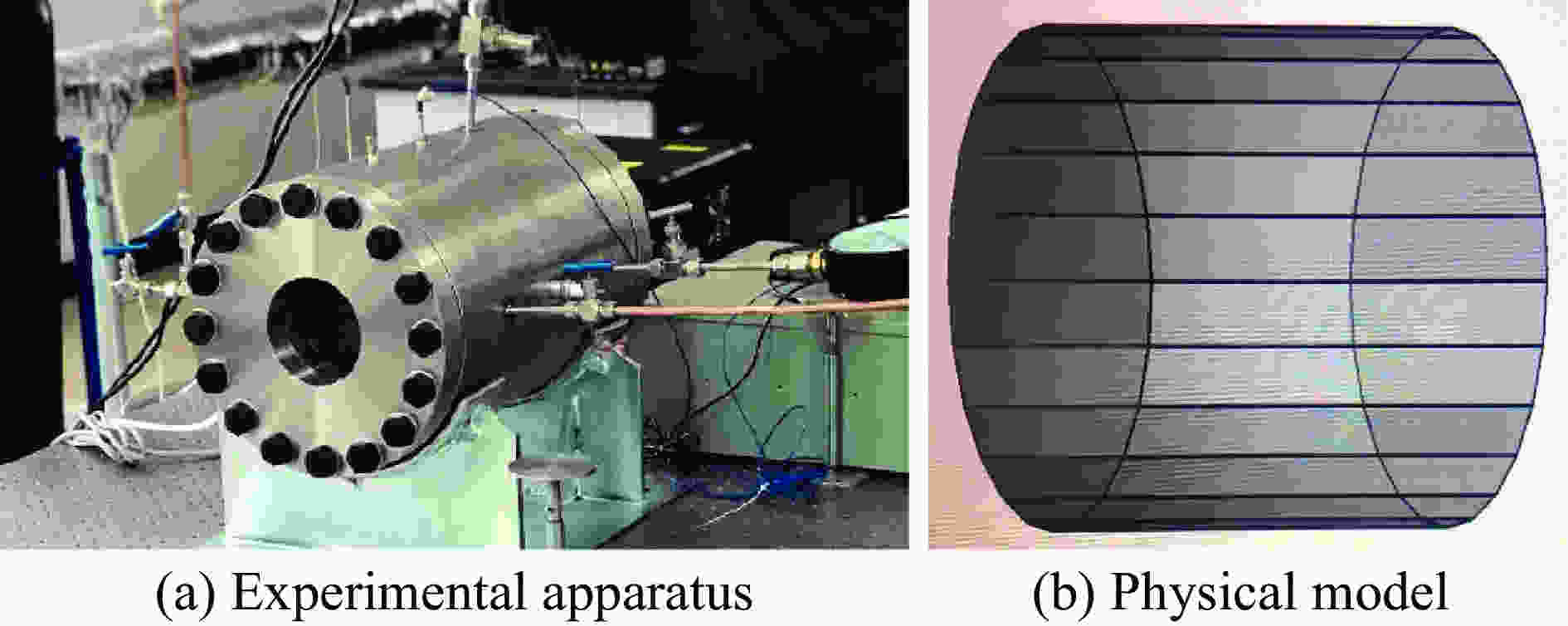

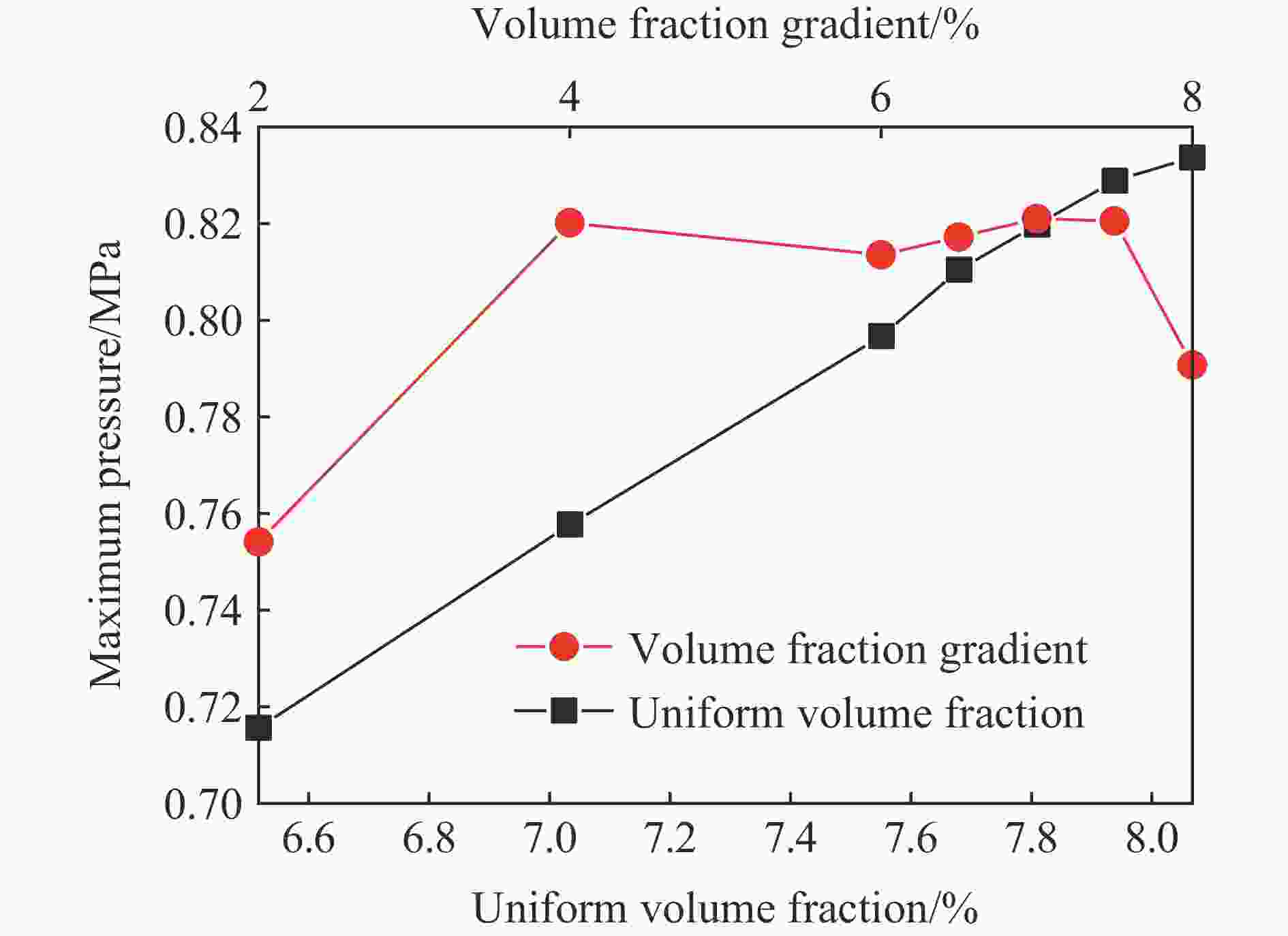

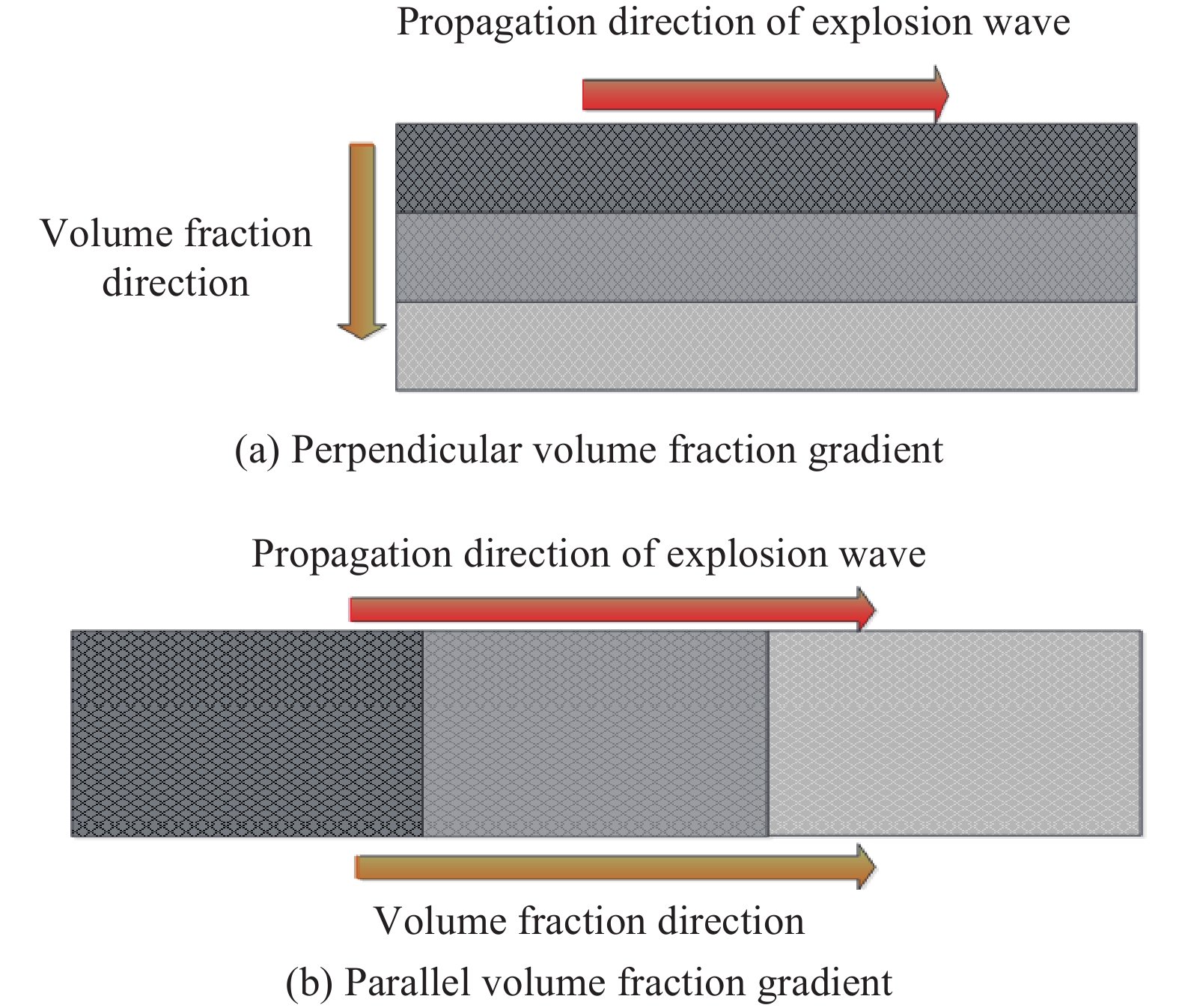

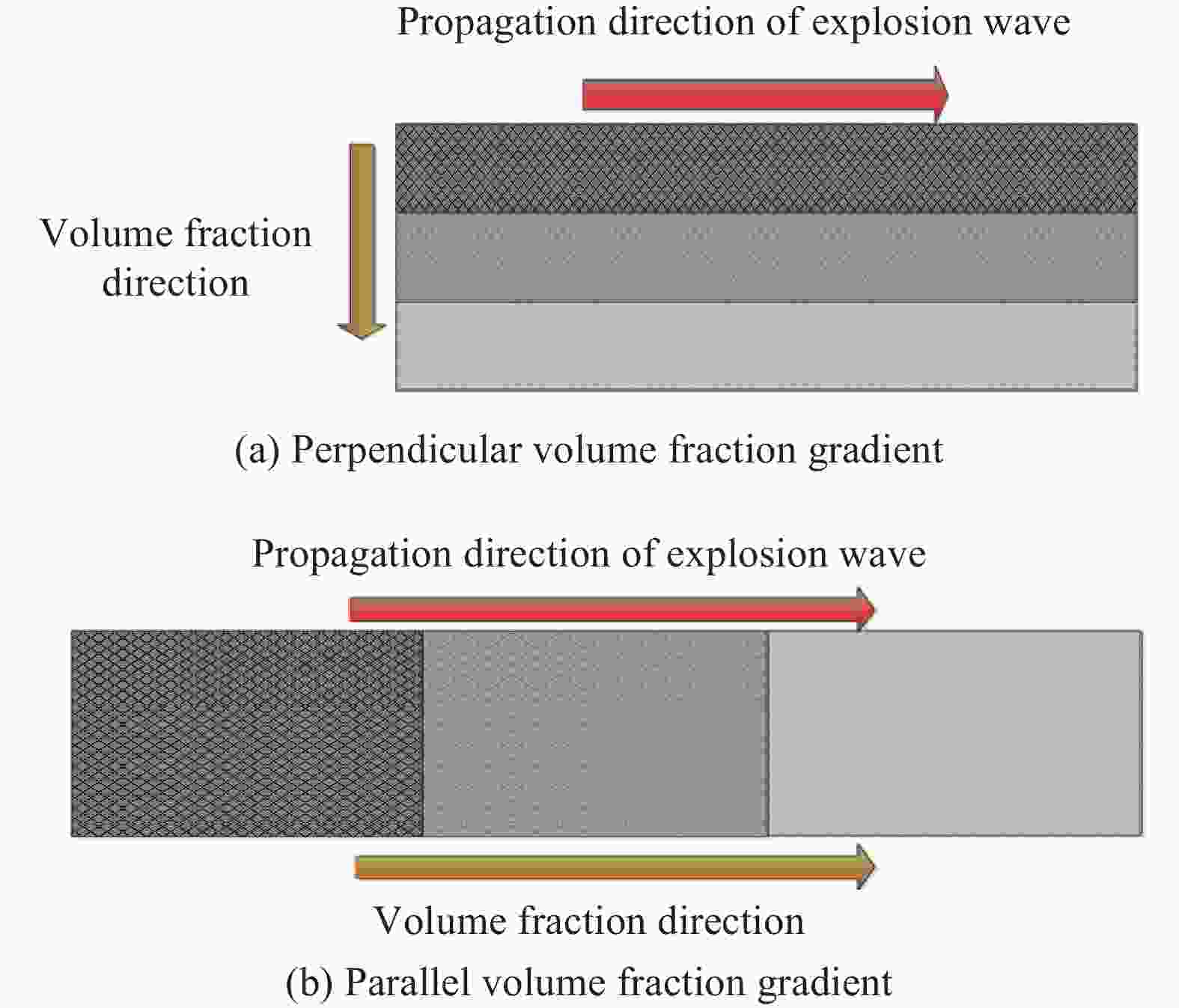

摘要: 为了研究具有体积分数梯度的连通装置内甲烷-空气爆炸特性,以60 L圆柱体容器和20 L圆柱体容器通过3 m长,截面为0.035 m×0.035 m的方形管道而连接形成的容器管道连通装置作为研究对象,利用Fluidyn软件对均一体积分数的连通装置以及具有体积分数梯度的连通装置中甲烷-空气爆炸的特性进行了数值模拟。结果表明:连通装置中甲烷的均一体积分数为6.517%~8.067%时,并由大容器中心点火工况时,最大爆炸压力、最大爆炸压力上升速率、最高温度和最大速度,以及这些爆炸参数达到最大值时的时刻值随体积分数的变化约呈线性关系;连通装置大容器甲烷体积分数6.0%体积分数梯度为2.0%~8.0%且大容器中心点火时,最大爆炸压力、最大爆炸压力上升速率、最高温度和最大速度随体积分数梯度总体上呈现先增大后减小趋势;大容器中心点火时,最大爆炸压力位于小容器,最大压力上升速率位于管道1或管道2,最大速度位于管道3,速度值可达400~600m/s。本研究可为连通装置内可燃气体爆炸事故防控提供理论指导。Abstract: A connected vessel is a common typical chemical plant, and its explosion hazard is much higher than that of an independent vessel. In an actual explosion accident, the combustible gas volume fraction in the connected device presents a non-uniform state, and there is a volume fraction gradient. A connected device was chosen as the research object. The device was formed by connecting two cylindrical vessels with the volumes of 60 litres and 20 litres, respectively, through a square pipe as long as 3 meters, with a cross section of 35 mm×35 mm. To explore the methane-air explosion characteristics in the connected device with combustible gas volume fraction gradient, the Fluidyn software was applied to numerically simulate the methane-air explosions in the connected devices with uniform and non-uniform combustible gas volume fractions, respectively. The results show as follows. When the volume fraction of the methane in the connected device is uniform and ranges from 6.517% to 8.067% and the ignition is located in the center of the large vessel, the maximum explosion pressure, the maximum explosion pressure rise rate, the maximum temperature and the maximum velocity as well as their arrival times change linearily with the volume fraction of the methane. When the volume fraction of the methane in the large vessel of the connected device is 6.0%, the volume fraction gradient of the methane is 2.0% to 8.0%, and the ignition is located in the center of the large vessel, the maximum values of the parameters, including explosion pressure, explosion pressure rise rate, flame temperature and velocity, increase firstly and then decrease with increasing volume fraction gradient. When the ignition is located in the center of the large vessel, the maximum explosion pressure is in the small vessel, the maximum pressure rising rate is in the pipe connected to the large vessel, and the maximum flame velocity is in the pipe connected to the small vessel, and the flame velocity can reach 400-600 m/s. The research results can provide a theoretical guidance for preventing and controling combustible gas explosion accident in connected devices.

-

Key words:

- connected device /

- volume fraction gradient /

- methane explosion /

- pressure rise rate

-

表 1 模拟工况

Table 1. Simulated working conditions

工况 体积分数梯度/% 体积分数分布/% 区域1 区域2 区域3 区域4 区域5 1 0 6.517 2 2 6 6.5 7 7.5 8 3 0 7.034 4 4 6 7 8 9 10 5 0 7.551 6 6 6 7.5 9 10.5 12 7 0 7.697 8 6.5 6 7.625 9.25 10.875 12.5 9 0 7.827 10 7 6 7.75 9.5 11.25 13 11 0 7.958 12 7.5 6 7.875 9.75 11.625 13.5 13 0 8.067 14 8 6 8 10 12 14 表 2 连通装置不同体积分数时最大爆炸压力相关参数

Table 2. Related parameters of the maximum explosion pressures for different volume fractions of connected devices

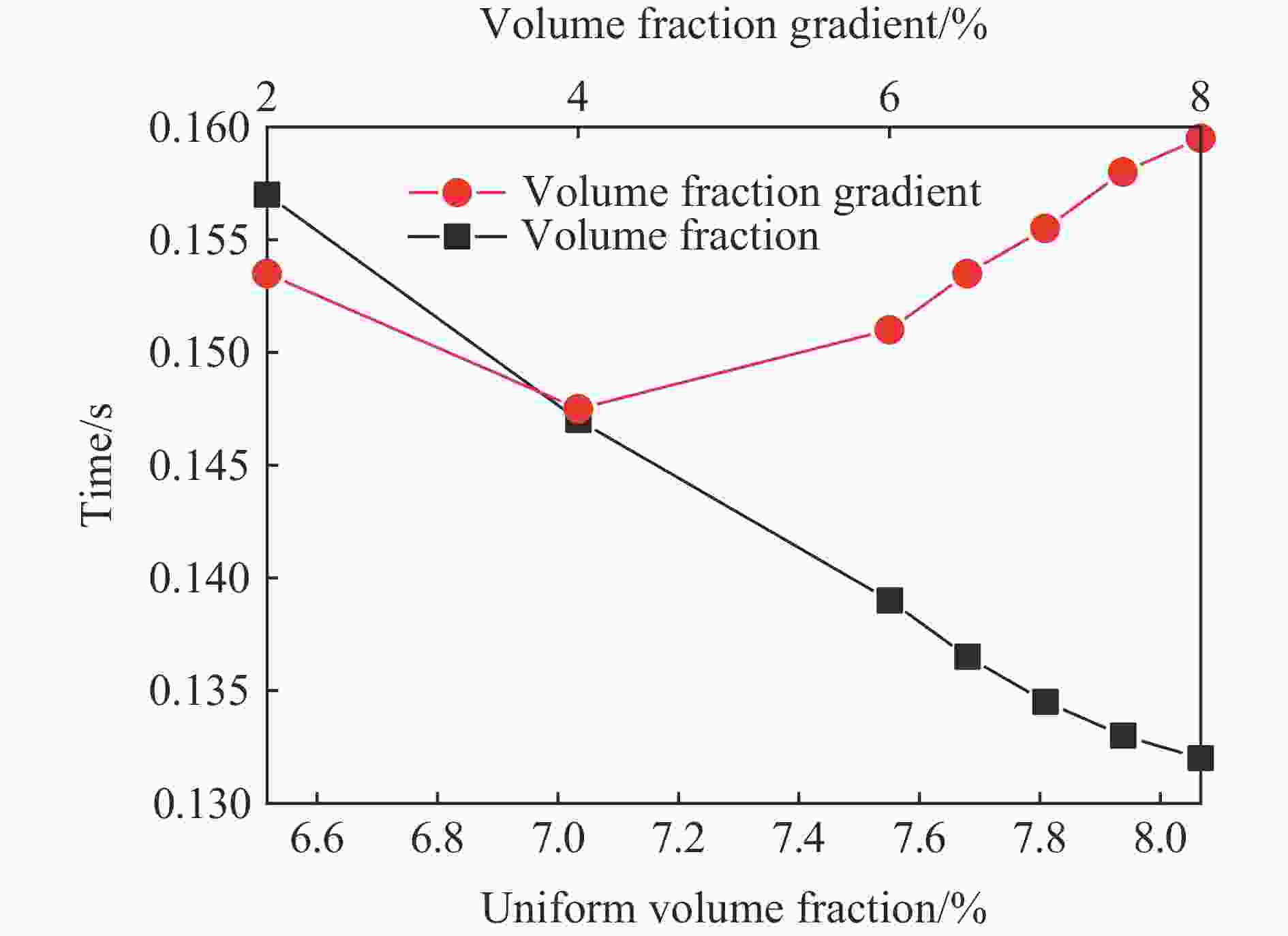

工况 体积分数/% 最大爆炸压力 位置 时刻/s 数值/MPa 1 6.517 区域5 0.157 0.716 3 7.034 区域5 0.147 0.758 5 7.551 区域5 0.139 0.797 7 7.696 区域5 0.137 0.810 9 7.827 区域5 0.135 0.820 11 7.958 区域5 0.133 0.829 13 8.067 区域5 0.132 0.834 表 3 连通装置不同体积分数梯度时最大爆炸压力相关参数

Table 3. Related parameters of the maximum explosion pressures for different volume fraction gradients of connected devices

工况 体积分数梯度/% 最大爆炸压力 位置 时刻/s 数值/MPa 2 2.0 区域5 0.154 0.754 4 4.0 区域5 0.147 0.820 6 6.0 区域5 0.151 0.814 8 6.5 区域5 0.154 0.817 10 7.0 区域5 0.156 0.821 12 7.5 区域5 0.158 0.821 14 8.0 区域5 0.160 0.791 表 4 连通装置不同体积分数时最大压力上升速率相关参数

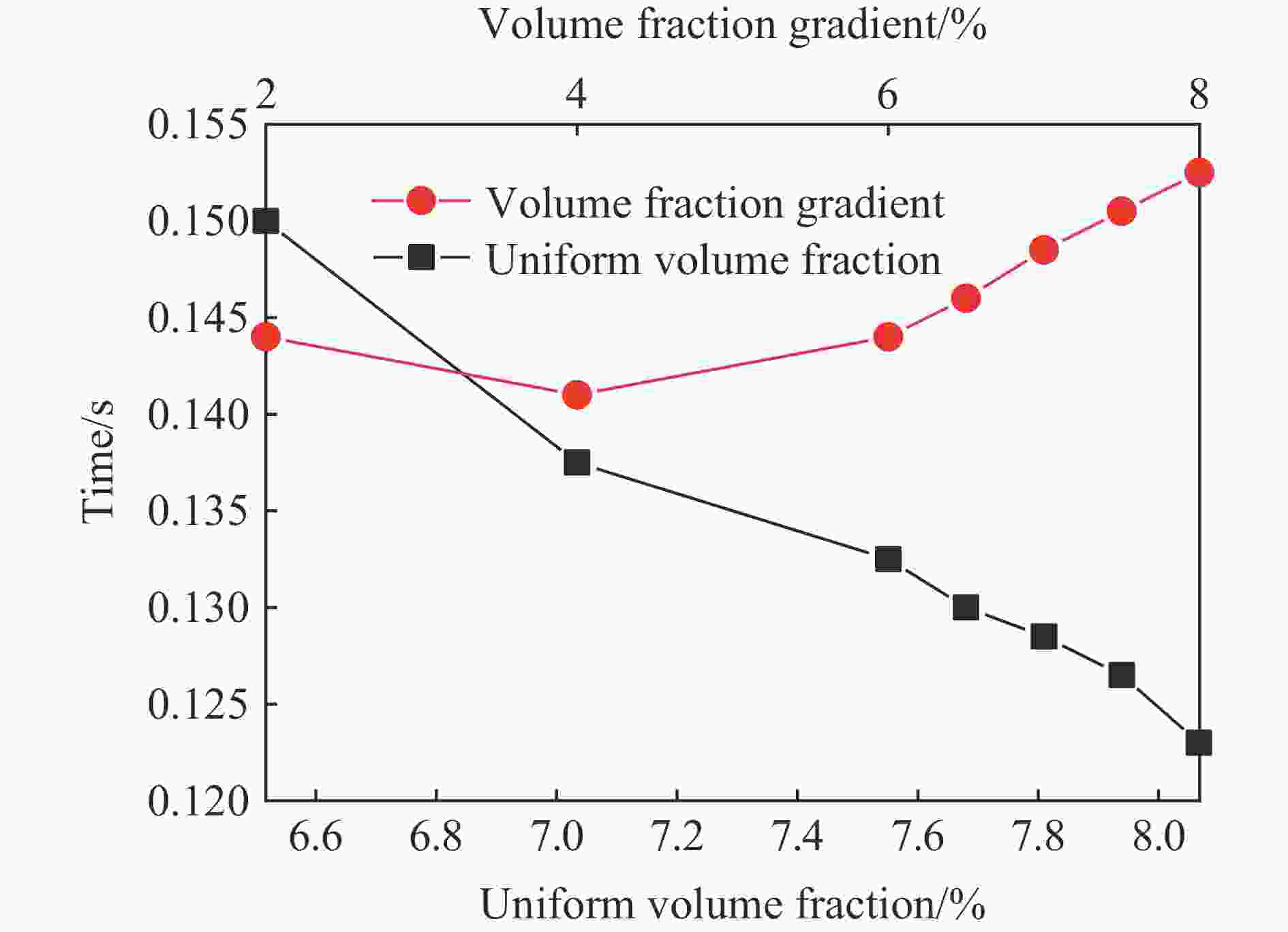

Table 4. Related parameters of the maximum pressure rise rates for different volume fractions of connected devices

工况 体积分数/% 最大压力上升速率 位置 时刻/s 数值/(GPa·s−1) 1 6.517 区域2 0.150 0.194 3 7.034 区域3 0.138 0.220 5 7.551 区域2 0.132 0.247 7 7.697 区域2 0.130 0.255 9 7.830 区域2 0.129 0.260 11 7.958 区域2 0.127 0.265 13 8.067 区域3 0.123 0.267 表 5 连通装置不同体积分数梯度时最大压力上升速率相关参数

Table 5. Parameters related to the maximum pressure rise rates in the connected devices with different volume fraction gradients

工况 体积分数梯度/% 最大压力上升速率 位置 时刻/s 数值/(GPa·s−1) 2 2.0 区域3 0.144 0.220 4 4.0 区域2 0.141 0.263 6 6.0 区域2 0.144 0.240 8 6.5 区域2 0.146 0.231 10 7.0 区域2 0.148 0.234 12 7.5 区域2 0.151 0.250 14 8.0 区域2 0.153 0.247 表 6 连通装置不同均一体积分数下最高温度相关参数

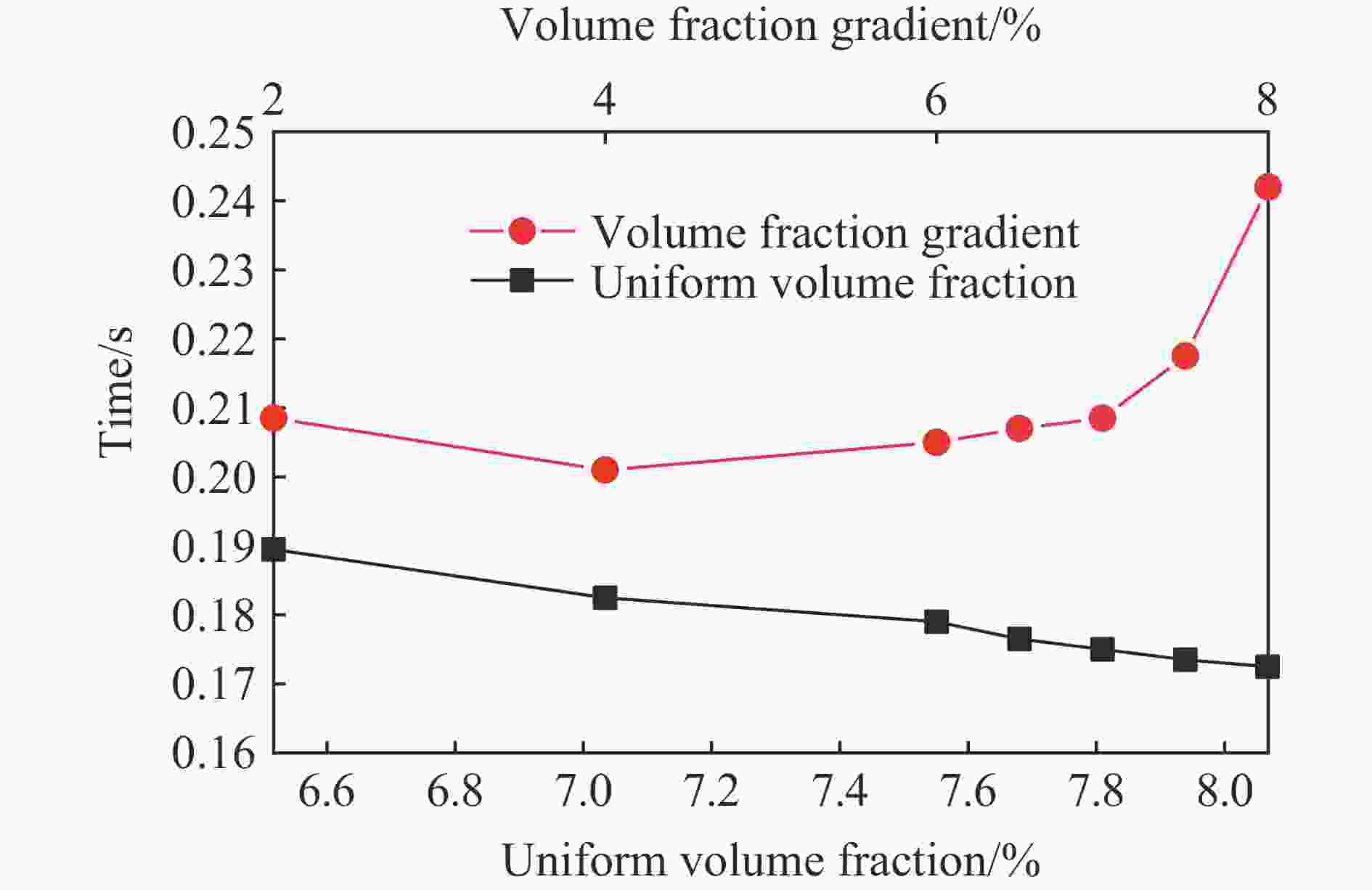

Table 6. Related parameters of the maximum temperatures in connected devices with different volume fractions

工况 体积分数/% 最高温度 位置 时刻/s 数值/℃ 1 6.517 区域1 0.189 1 917.58 3 7.034 区域1 0.182 2 023.45 5 7.551 区域1 0.179 2 121.45 7 7.697 区域1 0.176 2 156.08 9 7.827 区域1 0.175 2 181.71 11 7.958 区域1 0.173 2 209.39 13 8.067 区域1 0.172 2 223.58 表 7 连通装置不同体积分数梯度时最高温度相关参数

Table 7. Rrelated parameters of the maximum temperatures in connected devices with different volume fraction gradients

工况 体积分数梯度/% 最高温度 位置 时刻/s 数值/℃ 2 2.0 区域5 0.208 1 946.72 4 4.0 区域5 0.201 2 250.03 6 6.0 区域5 0.205 2 248.07 8 6.5 区域5 0.207 2 247.44 10 7.0 区域5 0.208 2 291.28 12 7.5 区域5 0.217 2 302.43 14 8.0 区域5 0.242 2 251.81 表 8 连通装置不同体积分数时最大速度相关参数

Table 8. Related parameters of the maximum velocities in connected devices with different volume fractions

工况 体积分数/% 最大速度 位置 时刻/s 数值/(m·s−1) 1 6.517 区域4 0.141 450.01 3 7.034 区域4 0.133 486.93 5 7.551 区域4 0.125 517.60 7 7.696 区域4 0.122 527.40 9 7.827 区域4 0.121 533.92 11 7.957 区域4 0.119 540.47 13 8.067 区域4 0.118 543.77 表 9 连通装置存在不同体积分数梯度时最大速度相关参数

Table 9. Related parameters of the maximum velocities in connected devices with different volume fraction gradients

工况 体积分数梯度/% 最大速度 位置 时刻/s 数值/(m·s−1) 2 2.0 区域4 0.138 445.20 4 4.0 区域4 0.133 456.60 6 6.0 区域4 0.136 448.40 8 6.5 区域4 0.138 443.01 10 7.0 区域4 0.141 437.55 12 7.5 区域4 0.143 431.70 14 8.0 区域4 0.145 427.08 -

[1] BARTKNECHT W. Explosion course prevention protection [M]. Berlin: Springer-Verlag, 1981. [2] PHYLAKTON H, ANDREWS G E. Gas explosions in linked vessels [J]. Journal of Loss Prevention in the Process Industries, 1993, 6(1): 15–19. DOI: 10.1016/0950-4230(93)80015-E. [3] LUNN G A, HOLBROW P, ANDRES S, et al. Dust explosions in totally enelosed interconnected vessel systems [J]. Journal of Loss Prevention in the Proeess Industries, 1995, 9(1): 45–58. [4] HOLBROW P, ANDRES S, LUNN G A. Dust explosions in interconnected vented vessels [J]. Journal of Loss Prevention in the Process Industries, 1996, 9(1): 91–103. DOI: 10.1016/0950-4230(95)00055-0. [5] HOLBROW P, LUNN G A. Dust explosion protection in linked vessels: guidance for containment and venting [J]. Journal of Loss Prevention in the Process Industries, 1999, 12: 227–234. DOI: 10.1016/S0950-4230(98)00050-3. [6] 严建骏, 蒋军成, 王志荣, 等. 连通容器内预混气体爆炸过程的实验研究 [J]. 中国安全生产科学技术, 2009, 4(6): 10–14.YAN J J, JIANG J C, WANG Z R, et al. Experimental investigation into explosion of premixed gases in linked vessels [J]. Safety Production Science and Technology in China, 2009, 4(6): 10–14. [7] 尤明伟, 蒋军成, 王志荣, 等. 连通容器中不同连通管径爆炸数值模拟分析 [J]. 工业安全与环保, 2010, 36(12): 25–26.YOU M W, JIANG J C, WANG Z R, et al. Numerical simulation of gas explosion in linked vessels with different pipe diameters [J]. Industrial Safety and Environmental Protection, 2010, 36(12): 25–26. [8] 王志荣, 蒋军成, 郑杨艳. 连通容器内气体爆炸过程的数值分析 [J]. 化学工程, 2006, 34(10): 13–16. DOI: 10.3969/j.issn.1005-9954.2006.10.004.WANG Z R, JIANG J C, ZHENG Y Y. Numerical analysis of gas explosion process in linked vessels [J]. Chemical Engineering, 2006, 34(10): 13–16. DOI: 10.3969/j.issn.1005-9954.2006.10.004. [9] 尤明伟, 喻源, 蒋军成, 等. 不同管长条件下连通容器预混气体的爆炸 [J]. 燃烧科学与技术, 2012, 18(3): 256–259.YOU M W, YU Y, JIANG J C, et al. Premixed flammable gas explosion in containers connected by pipes with different lengths [J]. Journal of Combustion Science and Technology, 2012, 18(3): 256–259. [10] 王志荣, 周超, 师喜林, 等. 连通容器内预混气体泄爆过程 [J]. 化工学报, 2011, 62(1): 287–291.WANG Z R, ZHOU C, SHI X L, et al. Gas explosion venting of premixed gases in linked vessels [J]. CIESC Journal, 2011, 62(1): 287–291. [11] THOMAS G O, SUTTON P, EDWARDS D H. The behavior of detonation waves at concentration gradients [J]. Combustion Flame, 1991(84): 312–322. [12] KUZNETSOV M S, ALEKSEEV V I, DOROFEEV S B, et al, Detonation propagation, decay, and reinitiation in nonuniform gaseous mixtures [C]// Twenty-Seventh International Symposium on Combustion/The Combustion Institute, 1998:2241–2247. [13] VOLLMER, K G, ETTNER F, SATTELMAYER T. Influence of concentration gradients on flame acceleration in tubes [J]. Energetic Matter Science Technology, 2011, 72: 74–77. [14] VOLLMER K G, ETTNER F, SATTELMAYER T. Deflagration-to-detonation transition in hydrogen-air mixtures with a concentration gradient [J]. Combust Science & Technology, 2012, 184(10-11): 1903–1915. DOI: 10.1080/00102202.2012.690652. [15] KESSLER D A, GAMEZO V N, ORAN E S. Wave structures and irregular detonation cells in methane-air mixtures with concentration gradients[C]//49th AIAA Aerospace Science Meeting. Orlando,Florida, 2011. [16] ISHII K, KOJIMA M. Behavior of detonation propagation in mixtures with concentration gradients [J]. Shock Waves, 2007, 17(1): 95–102. [17] WANG C J, WEN J X. Numerical simulations of hydrogen-air detonation wave propagation in a non-uniform semi-confined flat layer [C]//The Sixteenth International Colloquium on Dust Explosions and the Eleventh Colloquium on Gas, Vapour, Liquid and Hybrid Explosions. Bergen, Norway, 2014. [18] HAN W H, WANG C, CHUNG K. Role of transversal concentration gradient in detonation propagation [J]. Journal of Fluid Mechanics, 2019, 865: 602–649. DOI: 10.1017/jfm.2019.37. [19] 陈昊驰. 柱状空间内不同浓度甲烷爆炸传播特性的实验研究[D]. 石家庄: 华北科技学院, 2018: 38−44. [20] 王信群, 王婷, 徐海顺, 等. BC粉体抑爆剂改性及抑制甲烷/空气混合物爆炸 [J]. 化工学报, 2015, 66(12): 5171–5178.WANG X Q, WANG T, XU H S, et al. Modification of commercial BC dry chemical powder suppressant and experiments on suppression of methane-air explosion [J]. CIESC Journal, 2015, 66(12): 5171–5178. [21] XIAO H H, HE X C, DUAN Q L, et al. An investigation of premixed flame propagation in a closed combustion duct with a 90° blend [J]. Applied Energy, 2014, 134: 248–256. DOI: 10.1016/j.apenergy.2014.07.071. [22] 尤明伟. 连通容器气体爆炸及泄爆动力学过程研究[D]. 南京: 南京工业大学,2011. [23] 王志荣. 受限空间气体爆炸传播及其动力学过程研究[D]. 南京: 南京工业大学, 2005. -

下载:

下载: