Lateral impact resistance of Q420 steel tubes after atmospheric corrosion

-

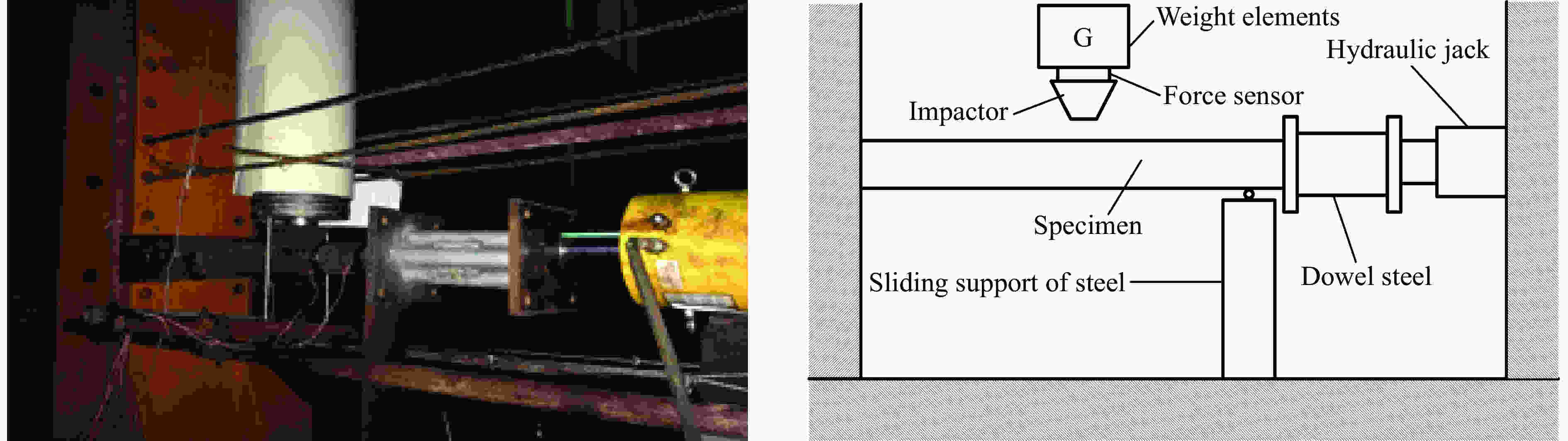

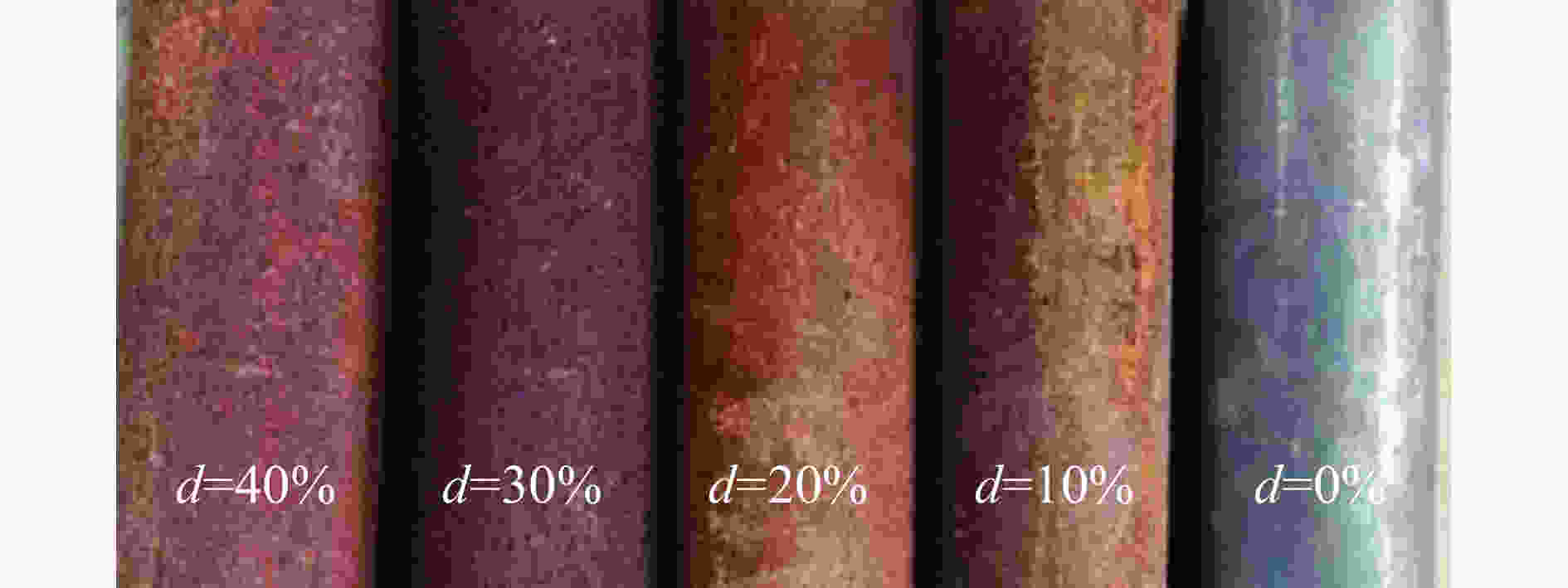

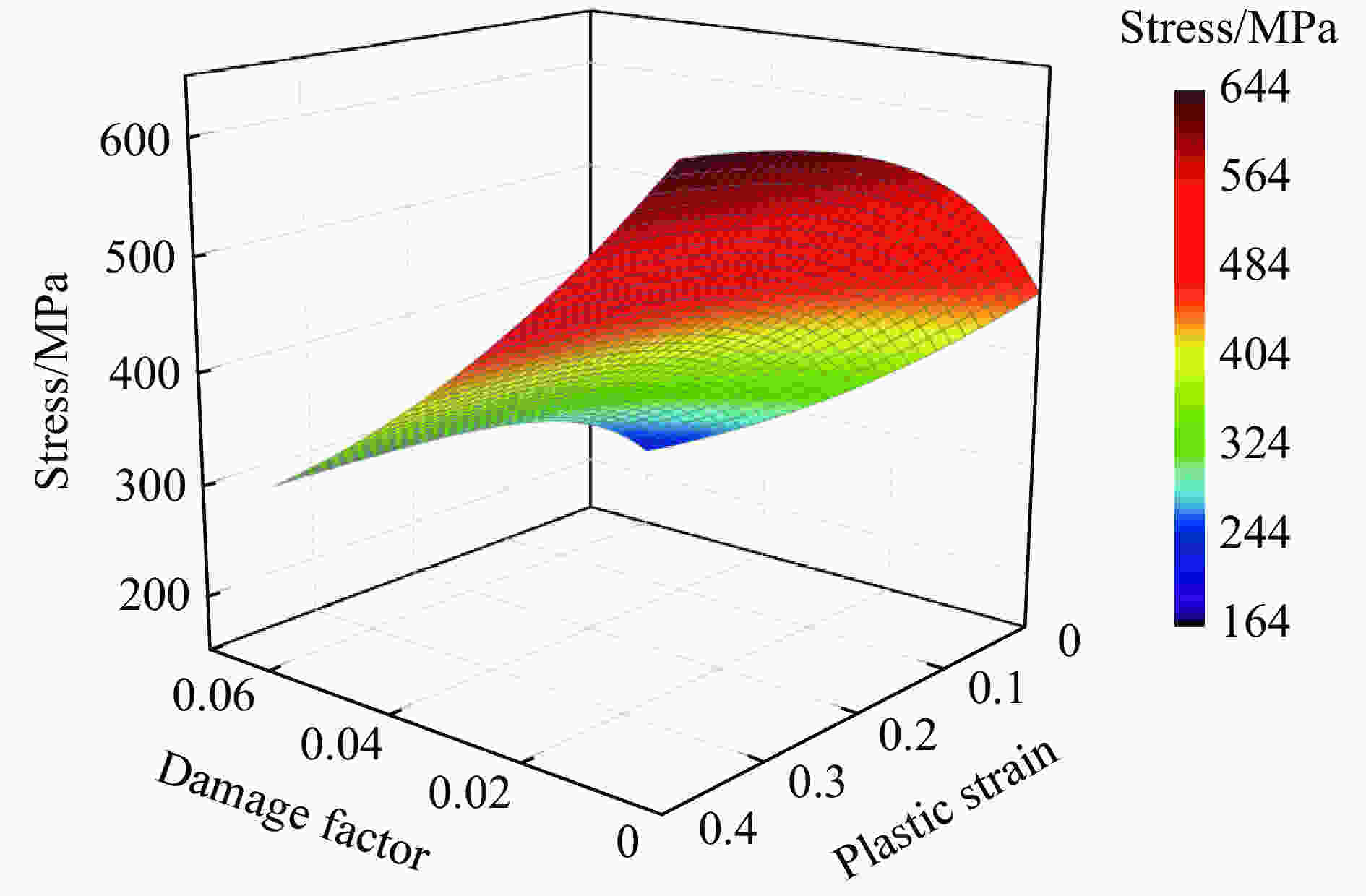

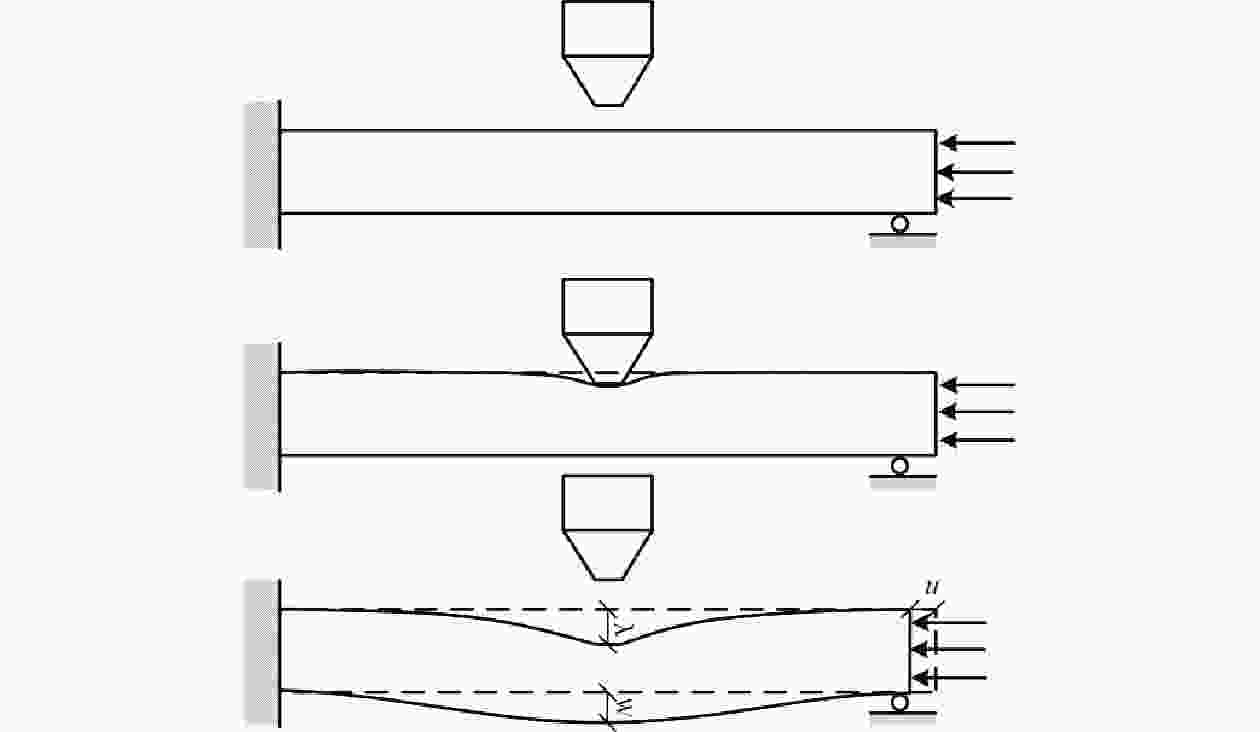

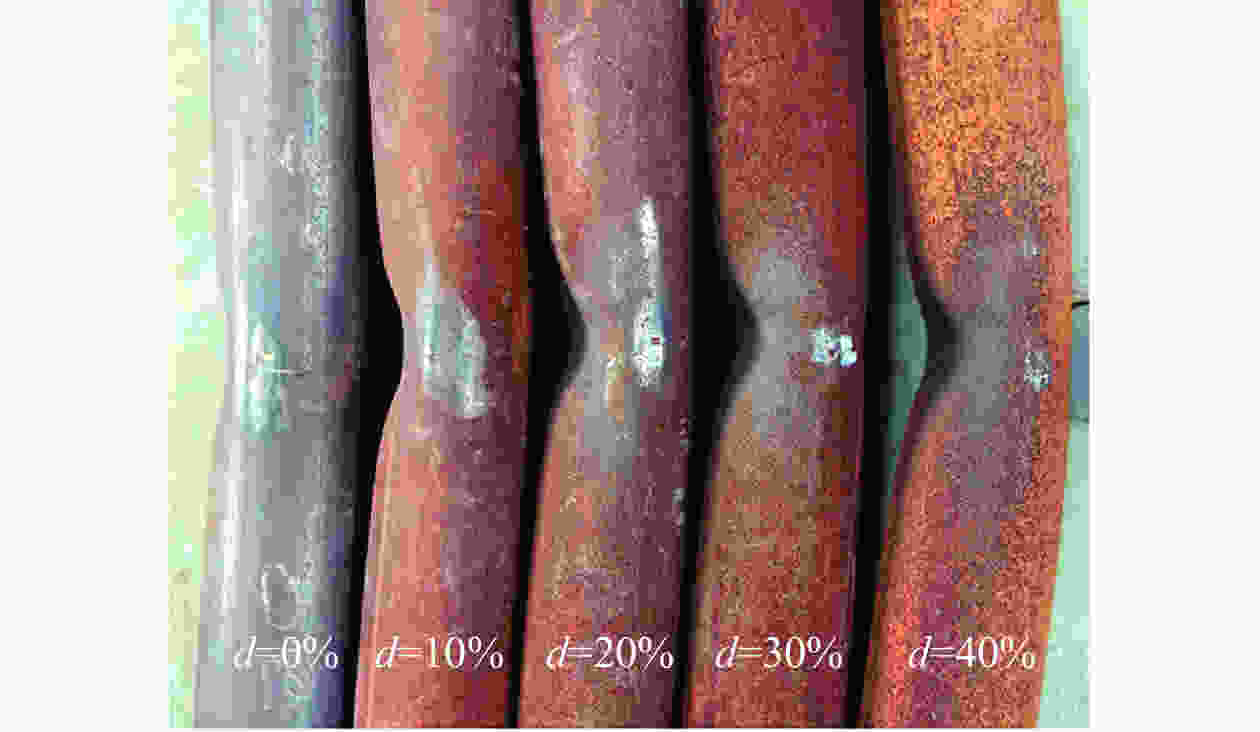

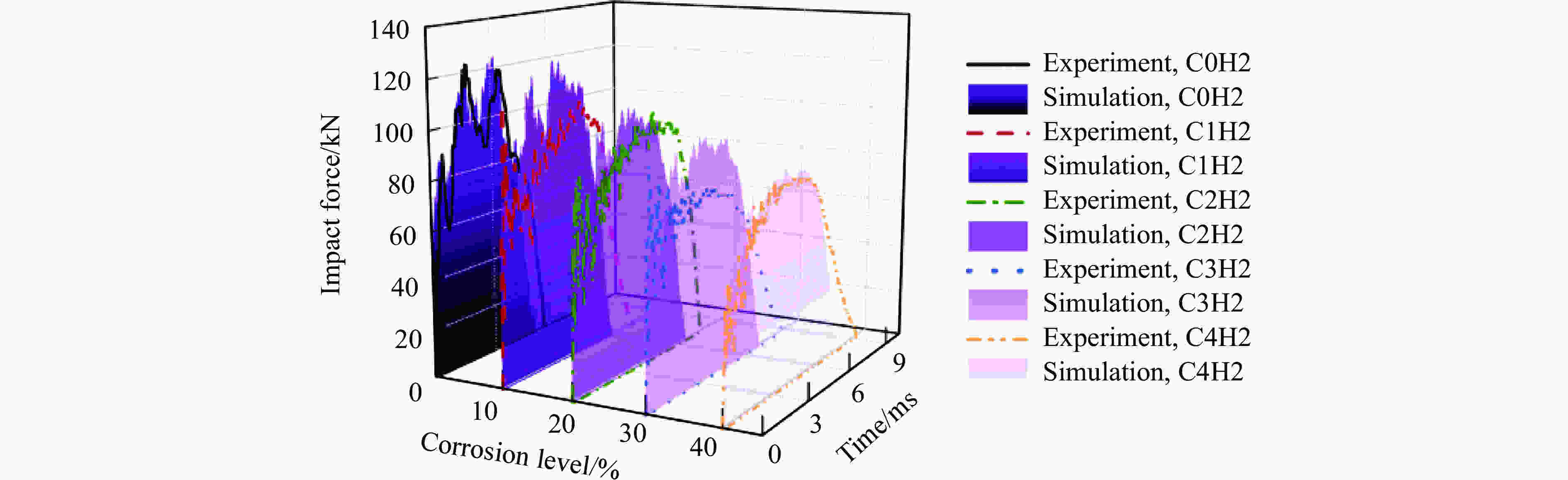

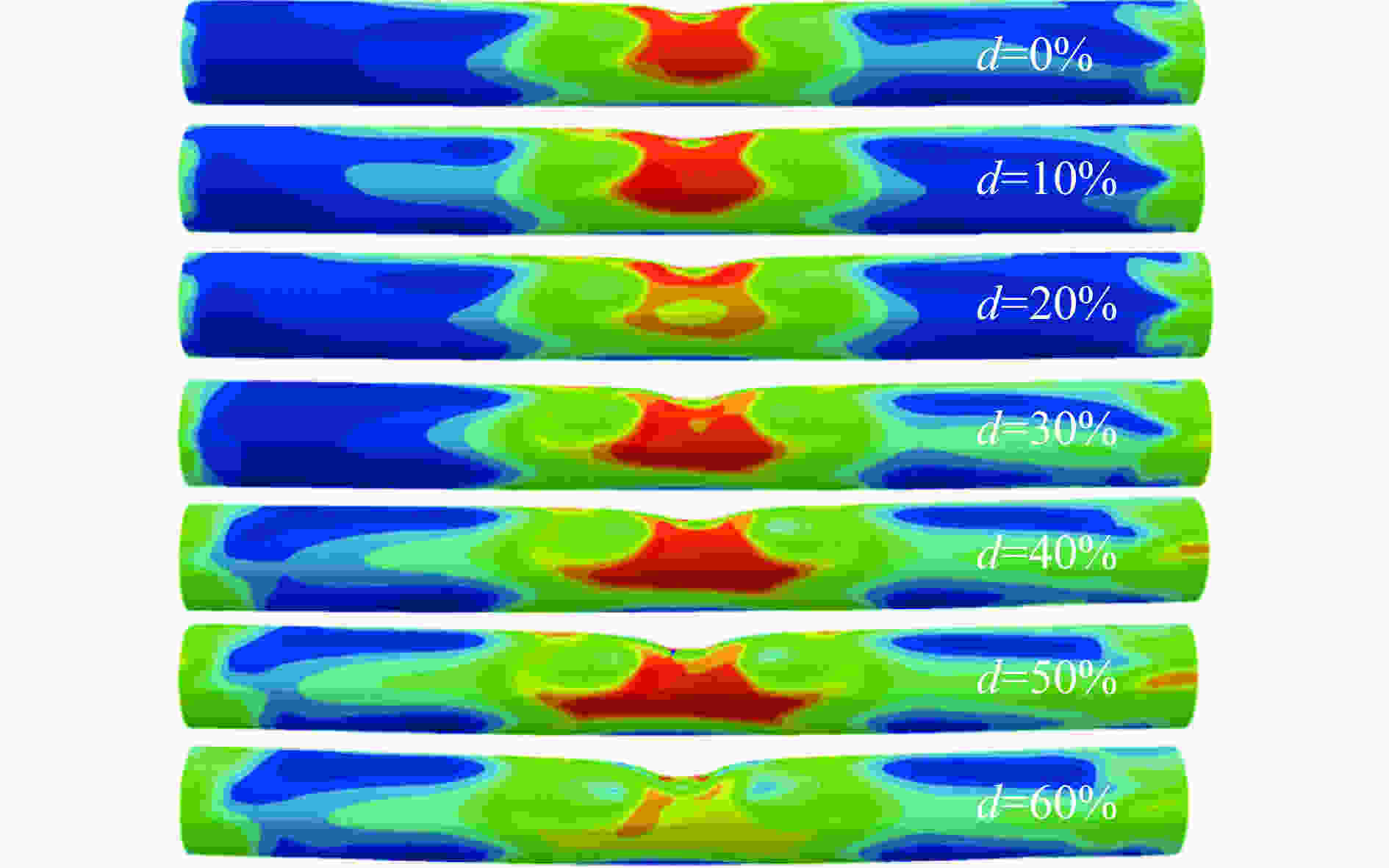

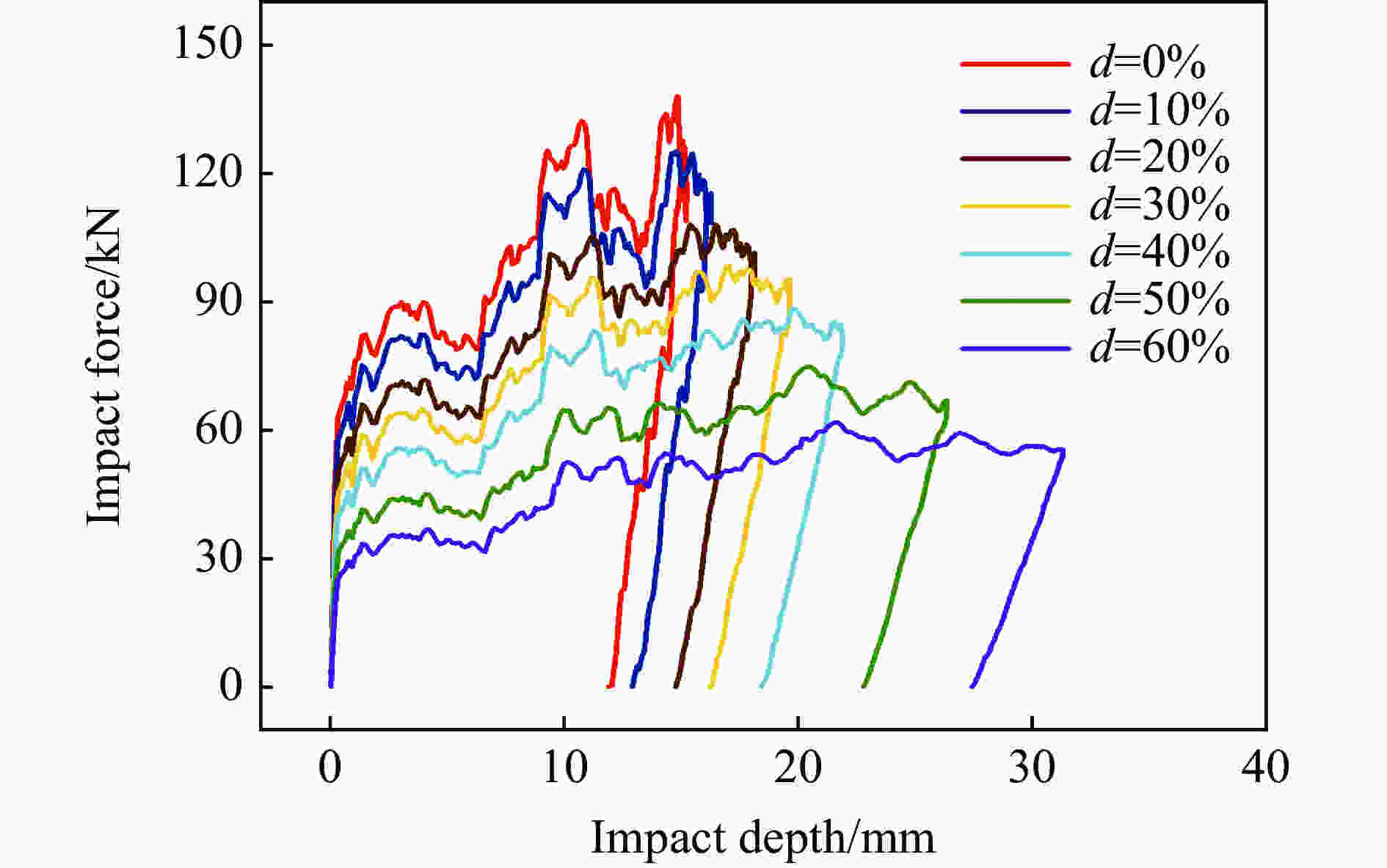

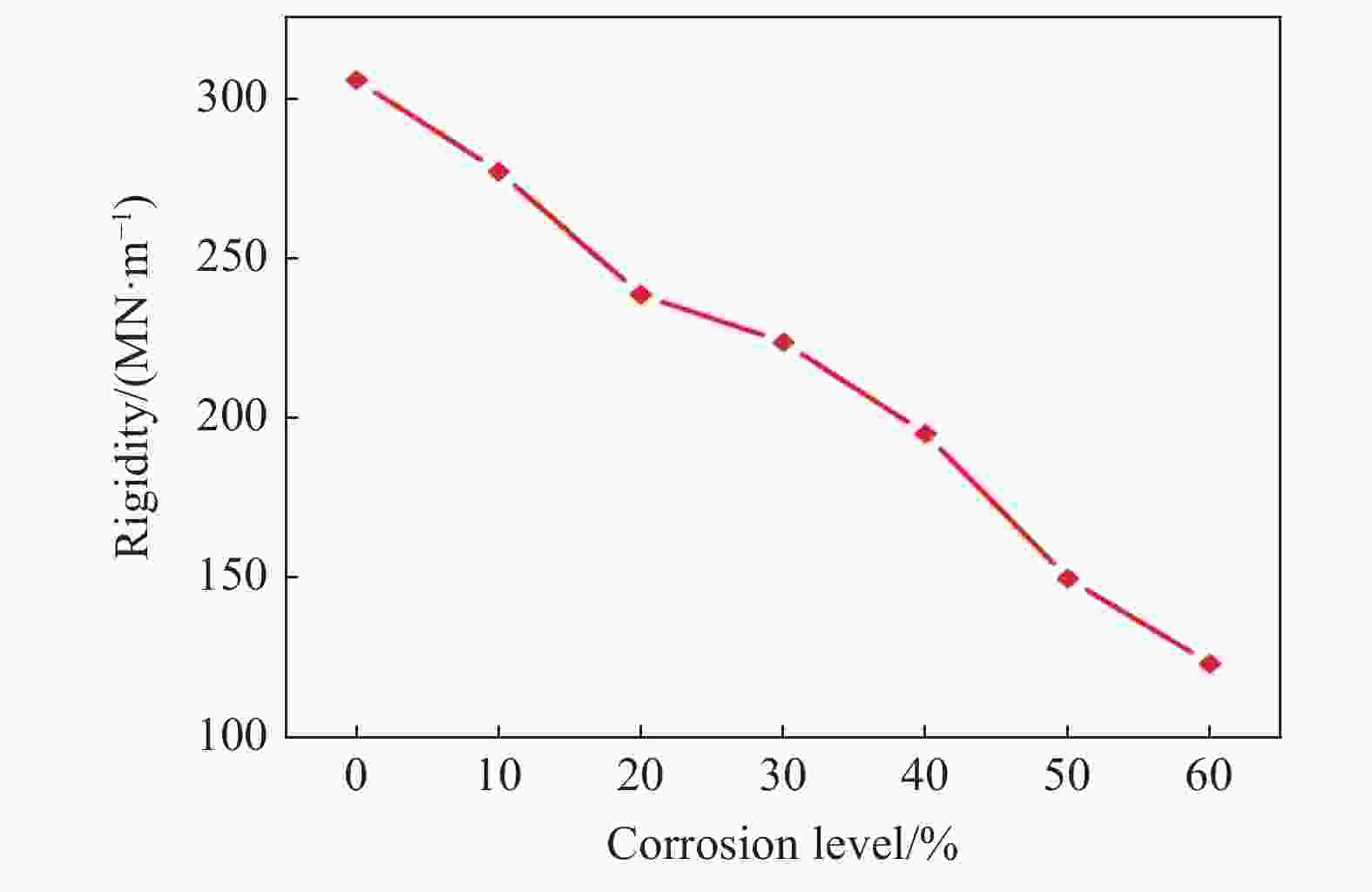

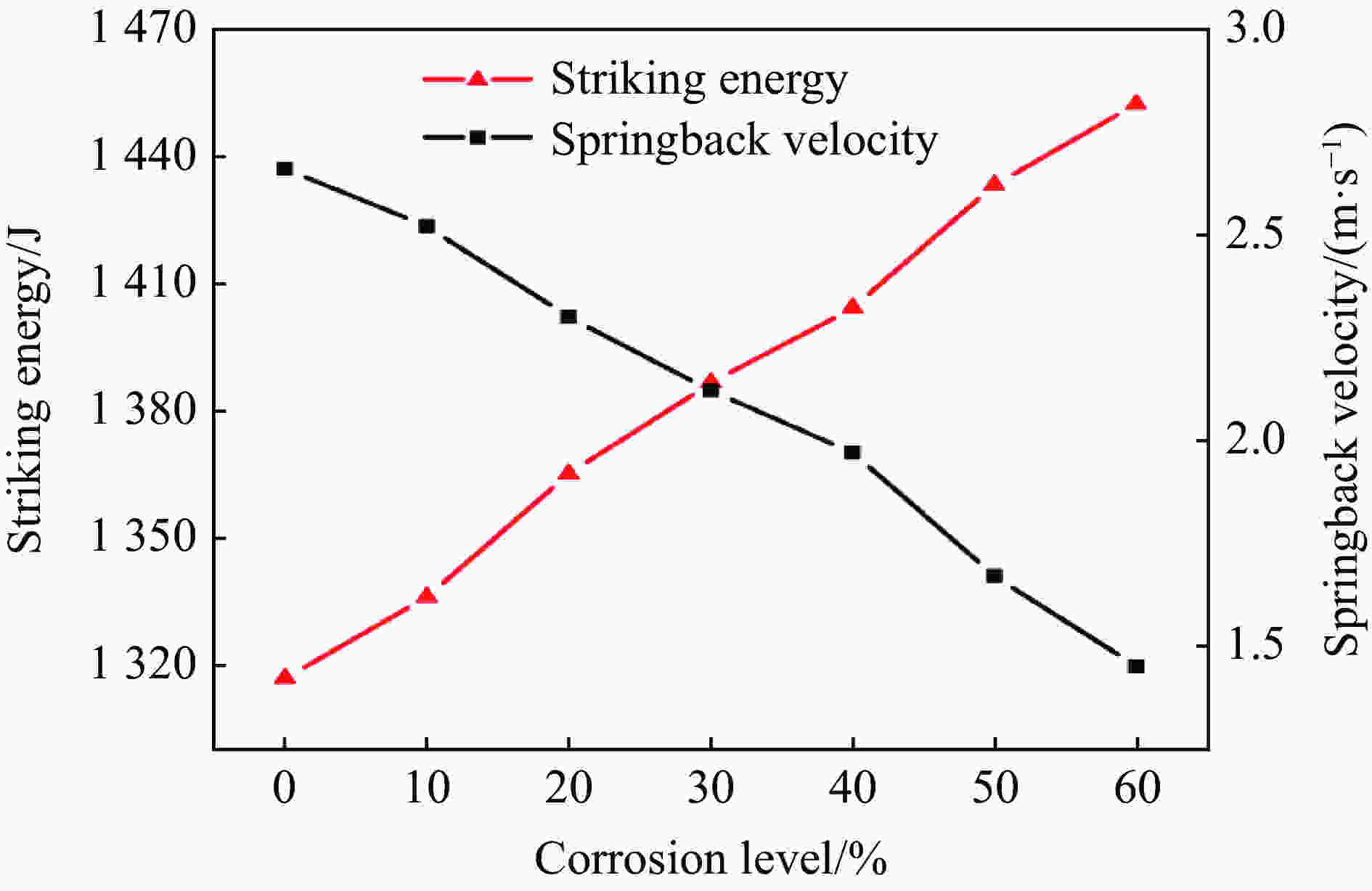

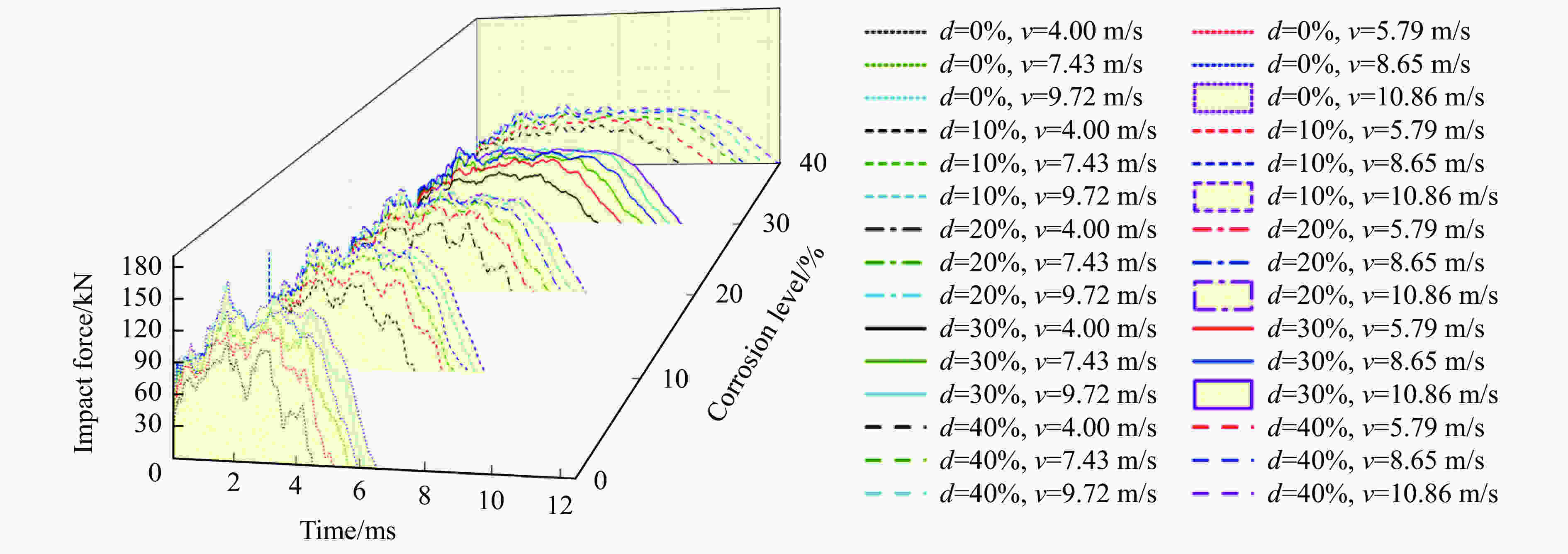

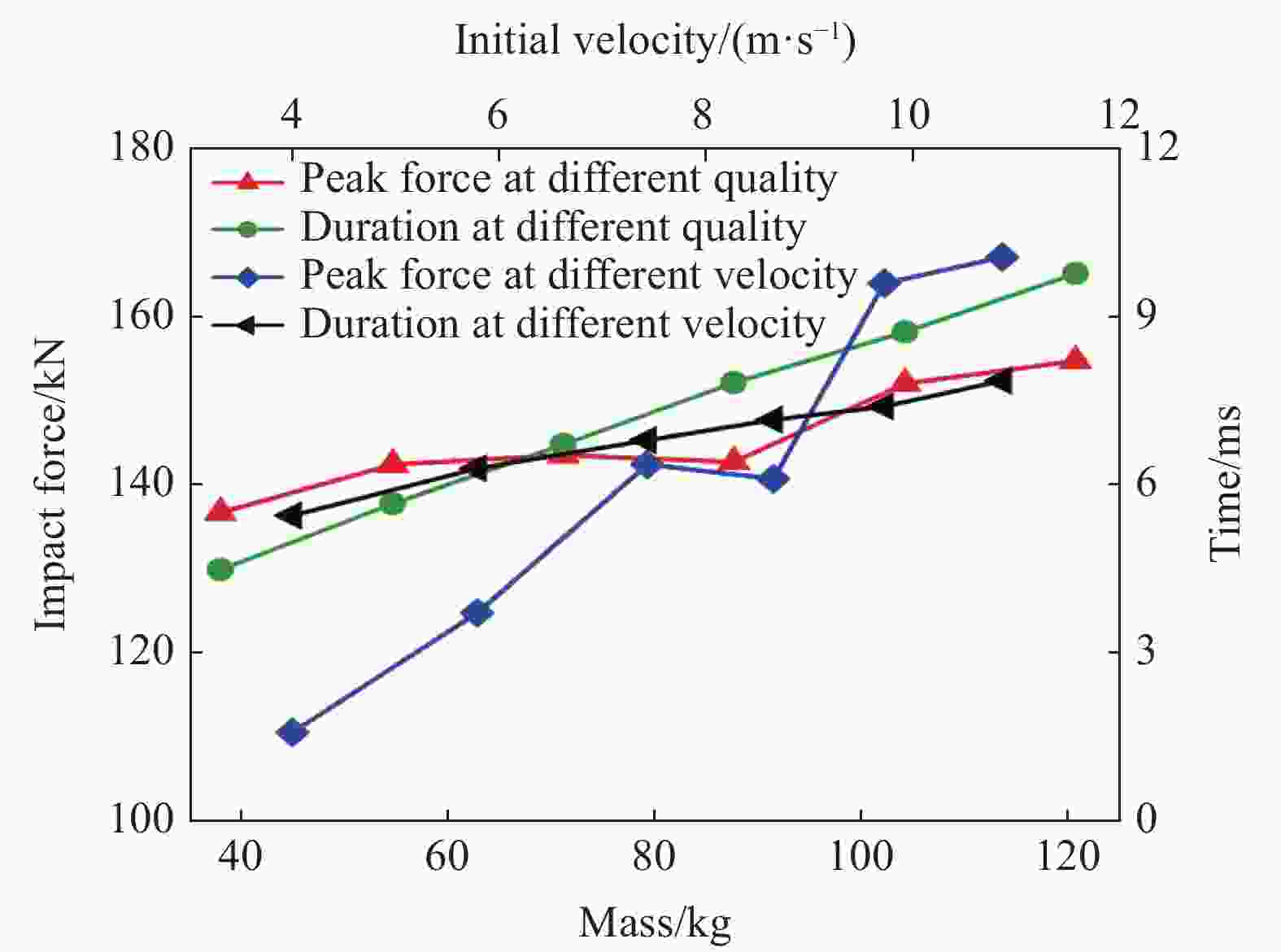

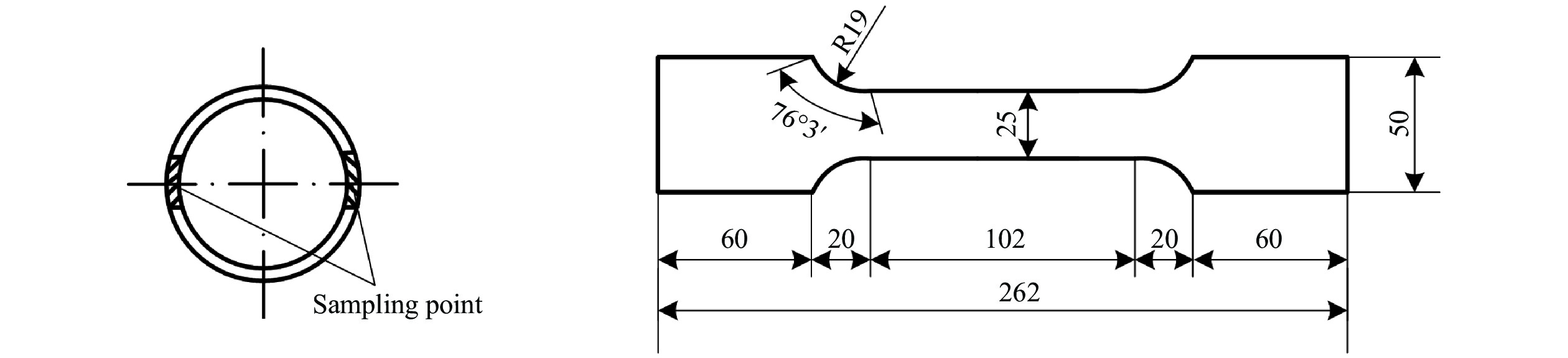

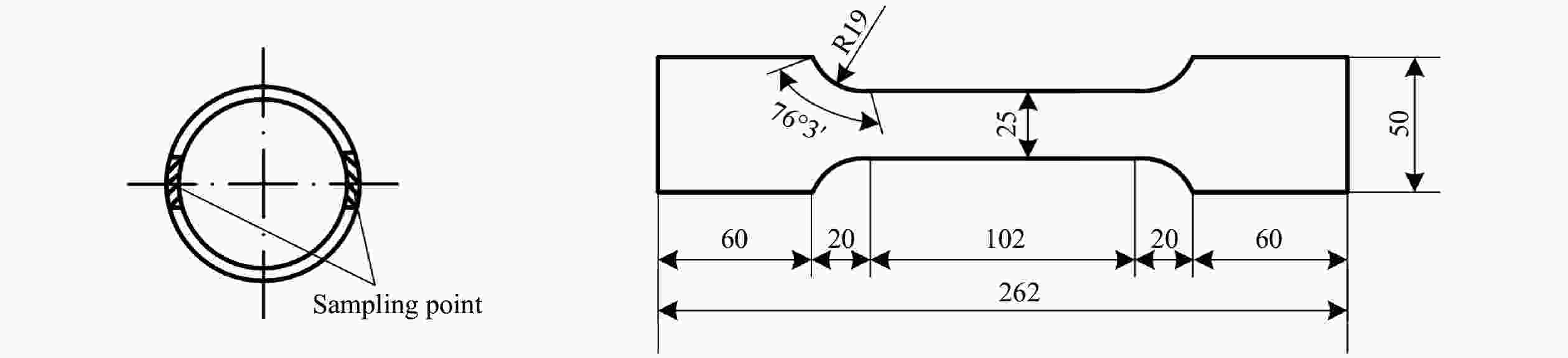

摘要: 为研究大气腐蚀对Q420钢管构件服役期内耐撞性的影响,提出了计及腐蚀损伤的材料模型。引入损伤因子(ω)修正Voce模型,推导随腐蚀程度变化的低合金钢材本构方程,并通过加速腐蚀试验结果回归相应参数。利用ABAQUS软件定义构件材料特性,建立起受腐蚀的Q420钢管仿真模型,采用显式动力算法分析多种初始状态下,撞击体与不同腐蚀程度钢管的冲击响应规律。开展预腐蚀Q420钢管的落锤试验,将试验结果与数值计算结果进行对比,验证所建模型的合理性。结果表明:大气腐蚀导致材料名义强度降低,对Q420钢管抗撞击能力影响显著;随着腐蚀程度增加,冲击力峰值减小,撞击时间和深度增加;Q420钢管受腐蚀后抗冲击刚度减小,构件整体变形耗能增加,表明大气腐蚀使其抗冲击性能下降;同等动能增量下,增大撞击体初速度比增加初始质量获得的冲击力峰值增幅更大,而所得到的接触时间增幅更小。Abstract: Q420 circular steel tubes are widely used to build large-scale steel structures. Such buildings serving in mountain areas are subject to atmospheric corrosion and impact load. In order to study the effect of atmospheric corrosion on the crashworthiness of Q420 steel tube members during service, a material model considering corrosion damage was proposed which treated corrosion damage as a change in material parameters. Specifically, a damage factor ω was introduced to modify the Voce constitutive equation based on the one-dimensional damage theory. A constitutive equation for low alloy steel varied with the degree of corrosion was deduced, these model parameters were determined through accelerated corrosion test that used acidic solution to accelerate steel corrosion and used static force to stretch the specimens. Based on the proposed constitutive method, relevant material properties were defined by utilizing the ABAQUS software to establish the finite element model of the Q420 steel tubes. A number of 0.84 meters long Q420 steel tube member models within different degrees of corrosion were developed, and these pipes were impacted at their mid-span by a flat-headed impactor with a certain mass and initial velocity. An explicit dynamic algorithm has been used for the simulation to analyze impact response law of rigid impactor and corroded steel pipes under various initial conditions. In addition, a series of impact tests were conducted to compare the behaviour of pre-corroded Q420 steel tubes subjected to lateral impact by drop hammers falling through changing initial height. The weight loss of pipes respectively was 0%, 10%, 20%, 30% and 40%, and the speed of moving hammers was 4.00, 5.79 and 7.43 m/s. Steel tube specimens were subjected to a constant axial pressure, without considering the effect of the axial force on test results. Numerical results were compared with test results to verify the rationality of the established models. According to numerical and experimental results, it demonstrates that atmospheric corrosion leads to a decrease in the nominal strength of the materials, which has a significant effect on the impact resistance of Q420 steel tubes and causes variation in the time history curve of impact force. With increase of corrosion degree of specimens, the yield strength and ultimate tensile strength of Q420 steel materials show a downward trend. As weight loss of Q420 steel tube increases, peak value of impact force decreases and duration and depth of impact increases. It indicates the decline of lateral impact resistance of Q420 steel tubes affected by atmospheric corrosion that impact stiffness of Q420 steel tubes decreases and overall deformation energy consumption of these components increases after corroded. The initial conditions of impactor have different effects on collision process under same kinetic energy increment. Compared with the increase of the initial mass, increase in the peak value of impact force obtained by increasing the initial velocity of impactor is greater, while the increase of duration is smaller.

-

Key words:

- Q420 steel tube /

- atmospheric corrosion /

- crashworthiness /

- constitutive model /

- impact test

-

表 1 落锤试验工况

Table 1. Drop hammer test conditions

腐蚀程度/% 试件编号 初始高度/m 冲击能量/J 腐蚀程度/% 试件编号 初始高度/m 冲击能量/J 0 C0H1 0.82 439.57 30 C3H1 0.82 439.57 C0H2 1.82 975.63 C3H2 1.82 975.63 C0H3 2.82 1 511.69 C3H3 2.82 1 511.69 10 C1H1 0.82 439.57 40 C4H1 0.82 439.57 C1H2 1.82 975.63 C4H2 1.82 975.63 C1H3 2.82 1 511.69 C4H3 2.82 1 511.69 20 C2H1 0.82 439.57 C2H2 1.82 975.63 C2H3 2.82 1 511.69 表 2 静力拉伸材料力学性能

Table 2. Static tensile properties of mechanical properties

腐蚀程度/% 名义屈服强度/MPa 名义极限抗拉强度/MPa 极限应变/% 弹性模量/GPa 伸长率/% 0 446.43 650.90 39.97 206.85 33.37 10 410.80 545.22 37.37 189.78 27.53 20 354.33 488.49 32.00 166.44 23.08 30 319.40 454.46 28.97 151.14 22.43 40 276.39 358.53 20.21 133.74 18.31 表 3 材性参数预测模型计算结果与试验结果对比

Table 3. Comparison of calculation results and test results of material parameters prediction model

腐蚀程度/% 试验屈服强度/MPa 预测屈服强度/MPa 误差/% 试验极限抗拉强度/MPa 预测极限抗拉强度/MPa 误差/% 0 446.43 454.79 1.87 650.90 645.44 −0.84 10 410.80 404.31 −1.58 545.22 572.23 4.95 20 354.33 359.39 1.43 488.49 506.99 3.79 30 319.40 319.41 0 454.46 448.91 −1.22 40 276.39 283.84 2.70 358.53 397.27 8.02 表 4 落锤试验工况

Table 4. Drop hammer test conditions

试件编号 冲击力峰值/kN 作用时间/ms 撞击深度/mm 底部挠曲/mm 试件编号 冲击力峰值/kN 作用时间/ms 撞击深度/mm 底部挠曲/mm C0H1 110.13 5.20 2.32 0.87 C2H3 103.56 7.65 13.91 4.20 C0H2 123.41 5.25 6.30 1.67 C3H1 59.77 7.68 5.94 1.67 C0H3 136.28 6.56 8.33 2.97 C3H2 82.03 7.41 11.74 2.75 C1H1 87.23 5.74 2.97 1.09 C3H3 96.83 8.86 16.81 4.57 C1H2 107.35 6.40 7.10 2.03 C4H1 47.99 8.60 7.39 1.96 C1H3 112.93 7.40 11.52 3.41 C4H2 72.09 8.69 15.43 2.97 C2H1 69.49 6.42 5.00 1.38 C4H3 84.33 9.38 21.52 5.00 C2H2 95.01 6.85 9.64 2.46 -

[1] JONES N, BIRCH R S. Low-velocity impact of pressurized pipelines [J]. International Journal of Impact Engineering, 2010, 37(2): 207–219. DOI: 10.1016/j.ijimpeng.2009.05.006. [2] 茹重庆, 王仁. 关于冲击载荷下圆柱壳塑性屈曲的两个问题 [J]. 固体力学学报, 1988(1): 64–68.RU C Q, WANG R. On two problems of plastic buckling of cylindrical shell under impulsive loading [J]. Acta Mechanica Solida Sinica, 1988(1): 64–68. [3] 程国强, 雷建平, 张善元. 经受侧向撞击圆管的大变形分析 [J]. 固体力学学报, 2000, 21(1): 57–60. DOI: 10.3969/j.issn.0254-7805.2000.01.008.CHENG G Q, LEI J P, ZHANG S Y. Large deformation analysis of circular tubes under lateral impact [J]. Acta Mechanica Solida Sinica, 2000, 21(1): 57–60. DOI: 10.3969/j.issn.0254-7805.2000.01.008. [4] ZHANG R, ZHI X D, FAN F. Plastic behavior of circular steel tubes subjected to low-velocity transverse impact [J]. International Journal of Impact Engineering, 2018, 114: 1–19. DOI: 10.1016/j.ijimpeng.2017.12.003. [5] 朱翔, 刘宏, 陆新征, 等. 钢骨混凝土构件抗冲击性能试验研究 [J]. 爆炸与冲击, 2019, 39(11): 115102. DOI: 10.11883/bzycj-2018-0500.ZHU X, LIU H, LU X Z, et al. Experimental study on impact resistance of steel reinforced concrete members [J]. Explosion and Shock Waves, 2019, 39(11): 115102. DOI: 10.11883/bzycj-2018-0500. [6] 郝志明, 陈裕泽, 陈刚, 等. 横向撞击下短梁的剪切破坏研究 [J]. 爆炸与冲击, 2002, 22(1): 52–55.HAO Z M, CHEN Y Z, CHEN G, et al. Shear failure of beams under transverse impact [J]. Explosion and Shock Waves, 2002, 22(1): 52–55. [7] YOUSUF M, UY B, TAO Z, et al. Transverse impact resistance of hollow and concrete filled stainless steel columns [J]. Journal of Constructional Steel Research, 2013, 82: 177–189. DOI: 10.1016/j.jcsr.2013.01.005. [8] RYU D M, WANG L, KIM S K, et al. Comparative study on deformation and mechanical behavior of corroded pipe: Part Ⅰ–numerical simulation and experimental investigation under impact load [J]. International Journal of Naval Architecture and Ocean Engineering, 2017, 9(5): 509–524. DOI: 10.1016/j.ijnaoe.2017.01.005. [9] JIANG X L, SOARES C G. Nonlinear FEM analysis of pitted mild steel square plate subjected to in-plane compression [J]. Journal of Ship Mechanics, 2009, 13(3): 398–405. DOI: 10.3969/j.issn.1007-7294.2009.03.009. [10] 张健, 沈中祥, 王自力, 等. 腐蚀损伤对深海半潜式平台结构极限强度的影响研究 [J]. 船舶力学, 2012, 16(11): 1283–1290. DOI: CNKI:SUN:CBLX.0.2012-11-008.ZHANG J, SHEN Z X, WANG Z L, et al. Influence research ultimate strength to deepwater semi-submersible platforms structure under corrosion damage [J]. Journal of Ship Mechanics, 2012, 16(11): 1283–1290. DOI: CNKI:SUN:CBLX.0.2012-11-008. [11] KHEDMATI M R, ROSHANALI M M, NOURI Z H M E. Strength of steel plates with both-sides randomly distributed with corrosion wastage under uniaxial compression [J]. Thin-Walled Structures, 2011, 49(2): 325–342. DOI: 10.1016/j.tws.2010.10.002. [12] 陈梦成, 林博洋, 黄宏. 酸雨腐蚀后圆钢管混凝土柱抗震性能研究 [J]. 铁道科学与工程学报, 2017, 14(1): 142–148. DOI: 10.3969/j.issn.1672-7029.2017.01.021.CHEN M C, LIN B Y, HUANG H. A study of seismic performance for circular concrete filled steel tubular column under acid rain attack [J]. Journal of Railway Science and Engineering, 2017, 14(1): 142–148. DOI: 10.3969/j.issn.1672-7029.2017.01.021. [13] 黄宏, 胡志慧, 杨超, 等. 模拟酸雨环境下圆钢管再生混凝土纯弯试验研究 [J]. 应用力学学报, 2019, 36(1): 97–103, viii. DOI: 10.11776/cjam.36.01.B114.HUANG H, HU Z H, YANG C, et al. Experimental study of recycled concrete-filled circle steel tubes subjected to pure bending under the environment of acid rain [J]. Chinese Journal of Applied Mechanics, 2019, 36(1): 97–103, viii. DOI: 10.11776/cjam.36.01.B114. [14] KACHANOV M. On the time to failure under creep conditions [J]. AN SSSR, Otd. Tekhn. Nauk, 1958, 8(26–31): 8. [15] RABOTNOV Y N. On the equation of state of creep [C] // Proceedings of the Institution of Mechanical Engineers. London, England: SAGE Publications, 1963, 178(31): 117–122. DOI: 10.1243/PIME_CONF1963_178_030_02. [16] 史炜洲, 童乐为, 陈以一, 等. 腐蚀对钢材和钢梁受力性能影响的试验研究 [J]. 建筑结构学报, 2012, 33(7): 53–60. DOI: CNKI:SUN:JZJB.0.2012-07-007.SHI Y Z, TONG L W, CHEN Y Y, et al. Experimental study on influence of corrosion on behavior of steel material and steel beams [J]. Journal of Building Structures, 2012, 33(7): 53–60. DOI: CNKI:SUN:JZJB.0.2012-07-007. [17] 郑山锁, 左英, 张晓辉, 等. 酸性大气环境下多龄期平面钢框架结构抗震性能试验研究 [J]. 工程力学, 2017, 34(9): 73–82. DOI: CNKI:SUN:GCLX.0.2017-09-010.ZHENG S S, ZUO Y, ZHANG X H, et al. Experimental research on the seismic behavior of multi-aged plane steel frames under acidic atmospheric environment [J]. Engineering Mechanics, 2017, 34(9): 73–82. DOI: CNKI:SUN:GCLX.0.2017-09-010. [18] VOCE E. The relationship between stress and strain for homogeneous deformation [J]. Journal of the Institute of Metals, 1947, 73: 537–562. [19] 金属材料—拉伸试验 第1部分: 室温试验方法: GB/T 228.1—2010 [S]. 北京: 中国标准出版社, 2012. [20] 陈俊岭, 李金威, 李哲旭. Q420钢材应变硬化与应变率效应的试验 [J]. 同济大学学报(自然科学版), 2017, 45(2): 180–187. DOI: 10.11908/j.issn.0253-374x.2017.02.004.CHEN J L, LI J W, LI Z X. Experimental study on strain hardening and strain rate effect of Q420 steel [J]. Journal of Tongji University (Natural Science), 2017, 45(2): 180–187. DOI: 10.11908/j.issn.0253-374x.2017.02.004. -

下载:

下载: