On the parameters of dynamic deformation and damage models of aluminum alloy 6008-T4 used for high-speed railway vehicles

-

摘要: 高速列车在实际服役过程中会经受复杂的应力状态和环境条件,铝合金型材以其优良的力学和加工性能被广泛应用于新型高速列车的吸能结构,其防撞性能对高速列车的安全运行至关重要。本文针对一种新型轨道车辆用材料6008-T4铝合金型材进行了多种力学性能测试,包括动静态拉压实验、准静态高低温实验、不同应力路径的断裂实验等,提出了一种计算局部断裂应变的新方法,进而标定和获取了Johnson-Cook本构和损伤模型参数。最后利用平板侵彻实验来对所获取的参数进行检验,发现模拟和实验结果吻合良好,说明本文所获取的参数和参数标定方法都是有效的。

-

关键词:

- 车用铝合金 /

- Johnson-Cook本构和损伤模型 /

- 力学性能 /

- 参数标定 /

- 高速列车

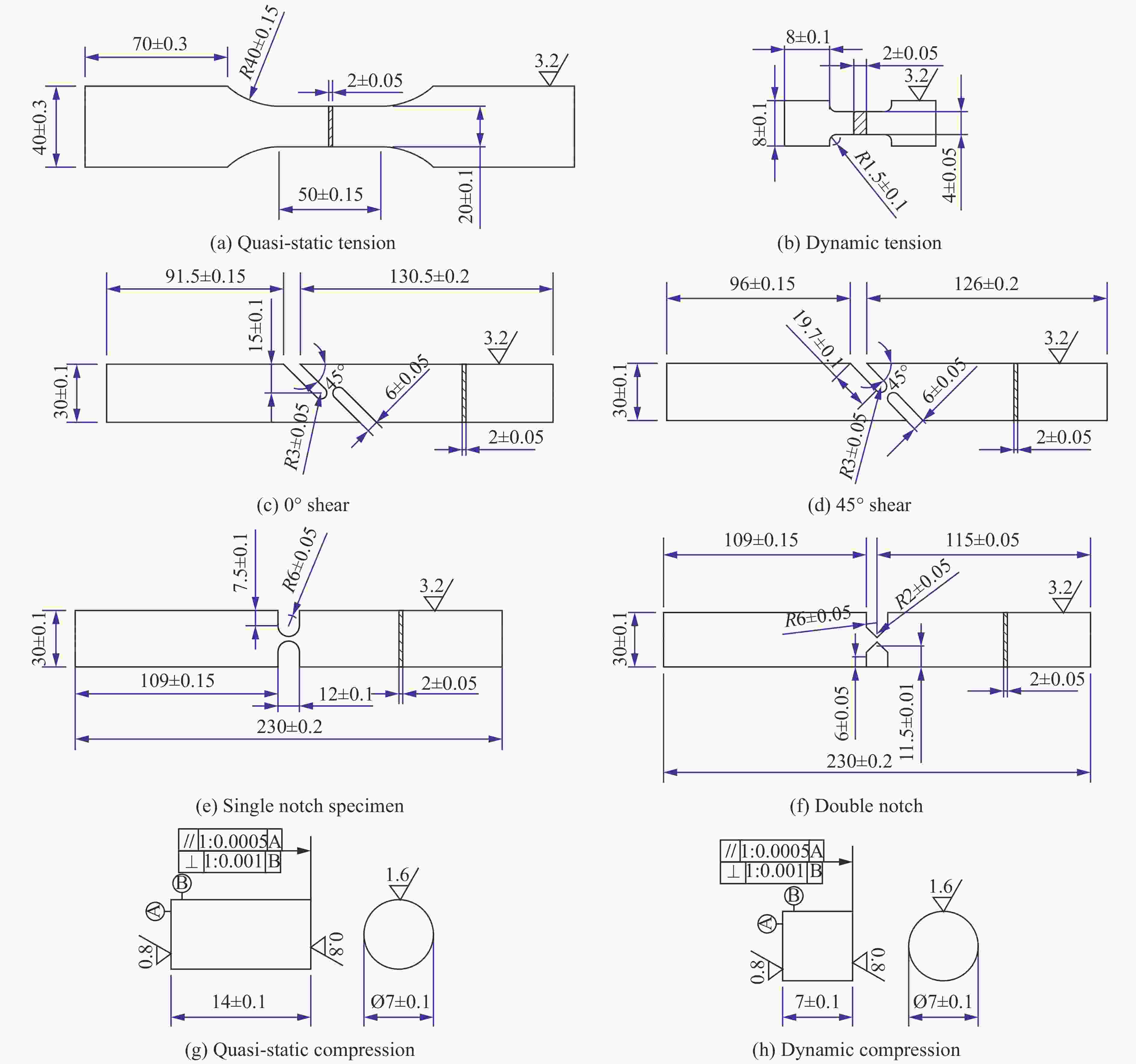

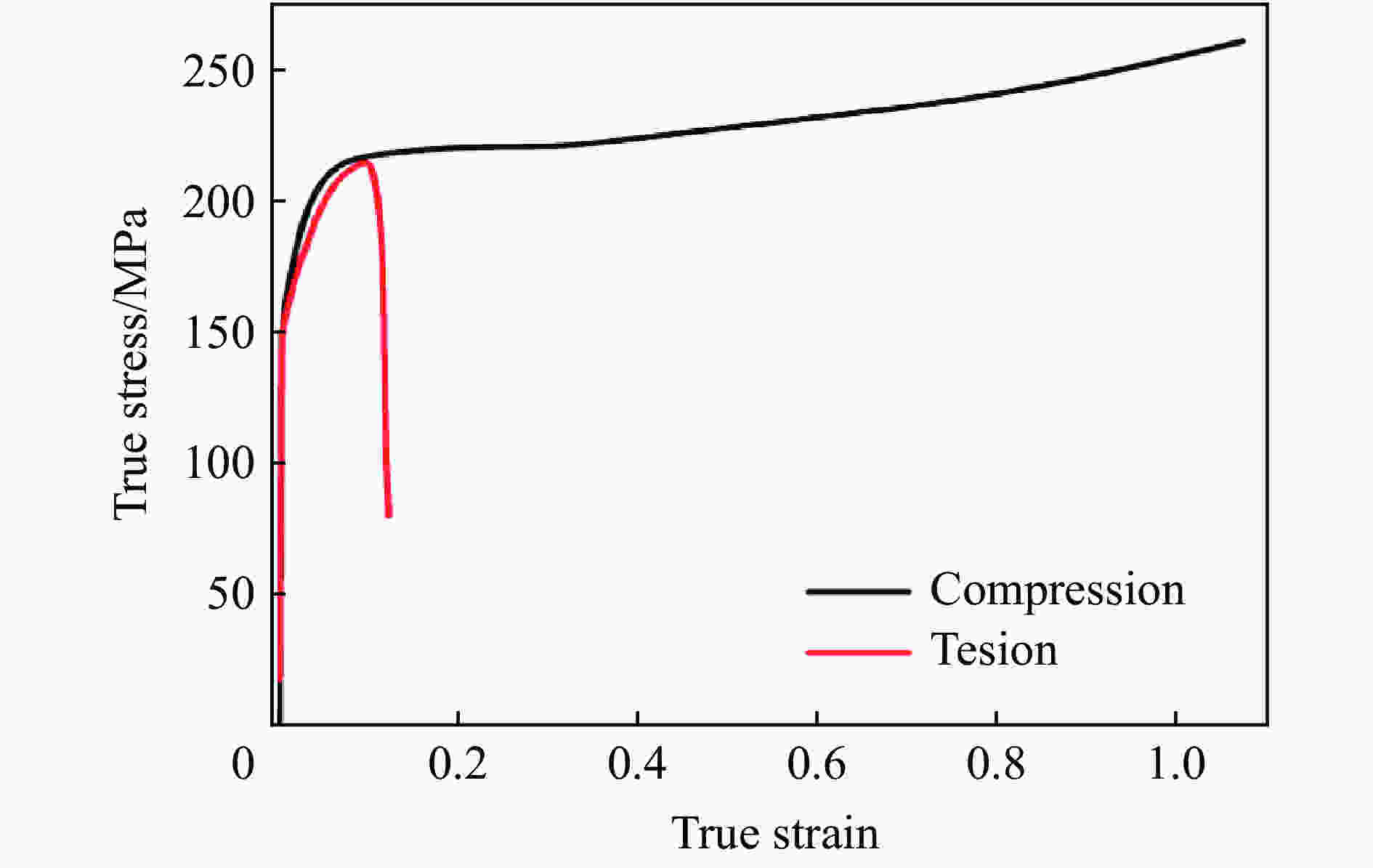

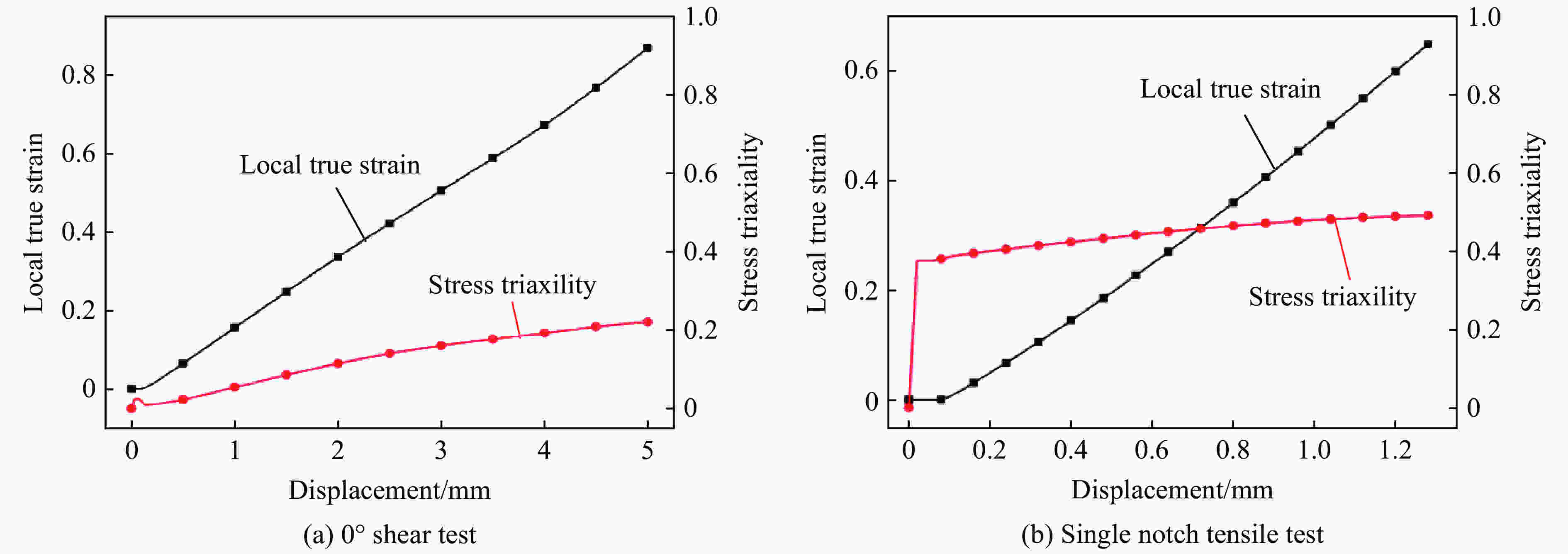

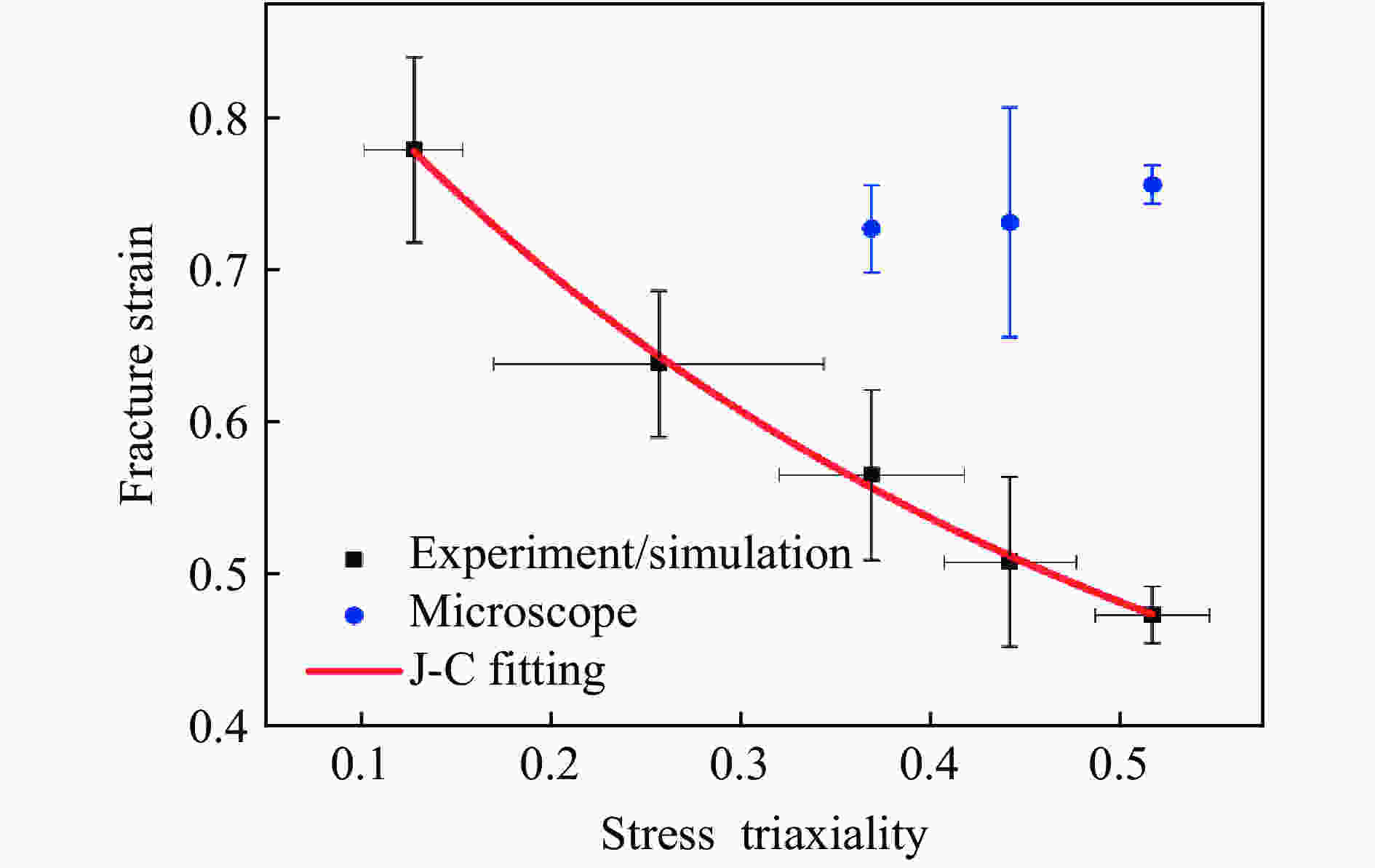

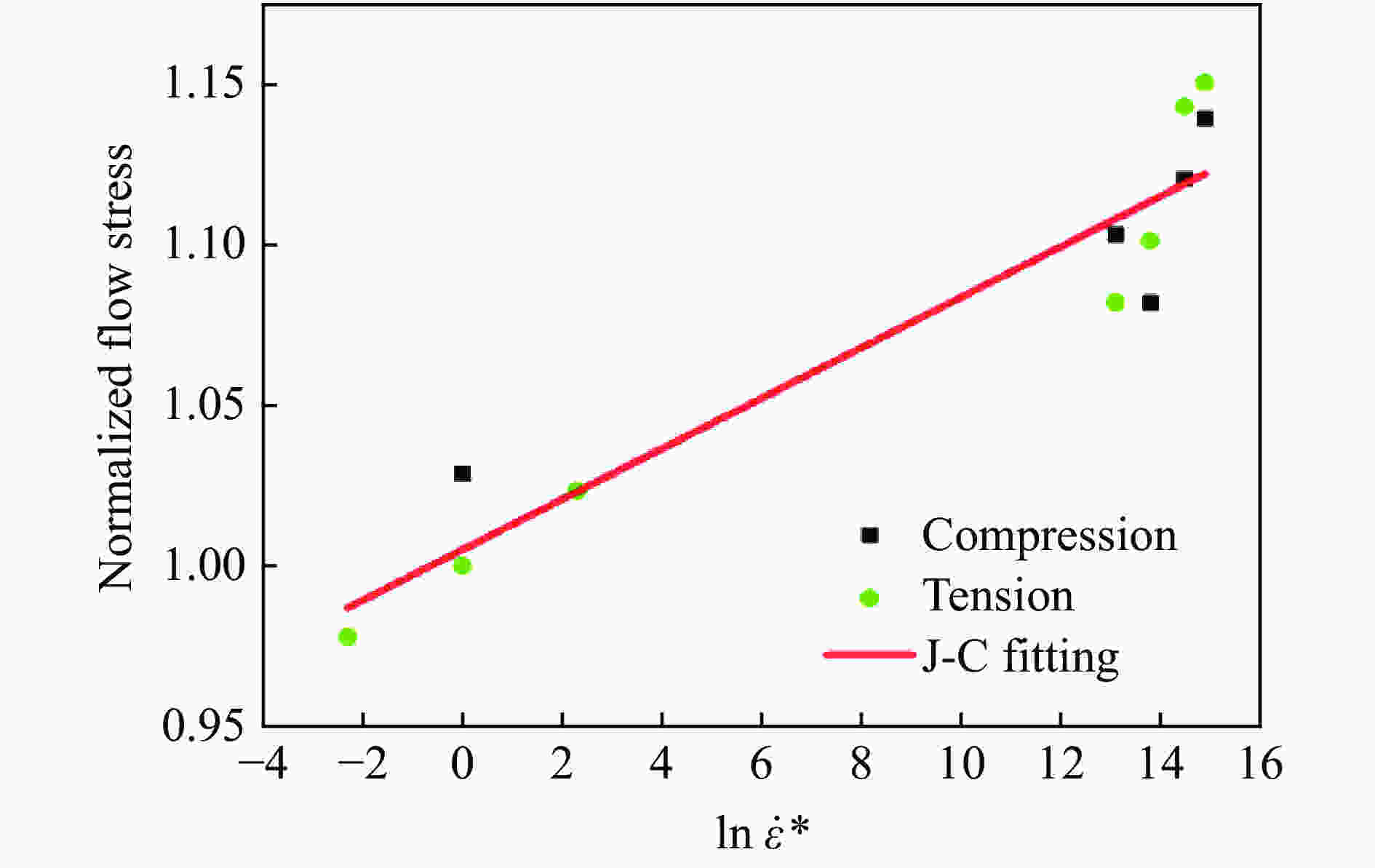

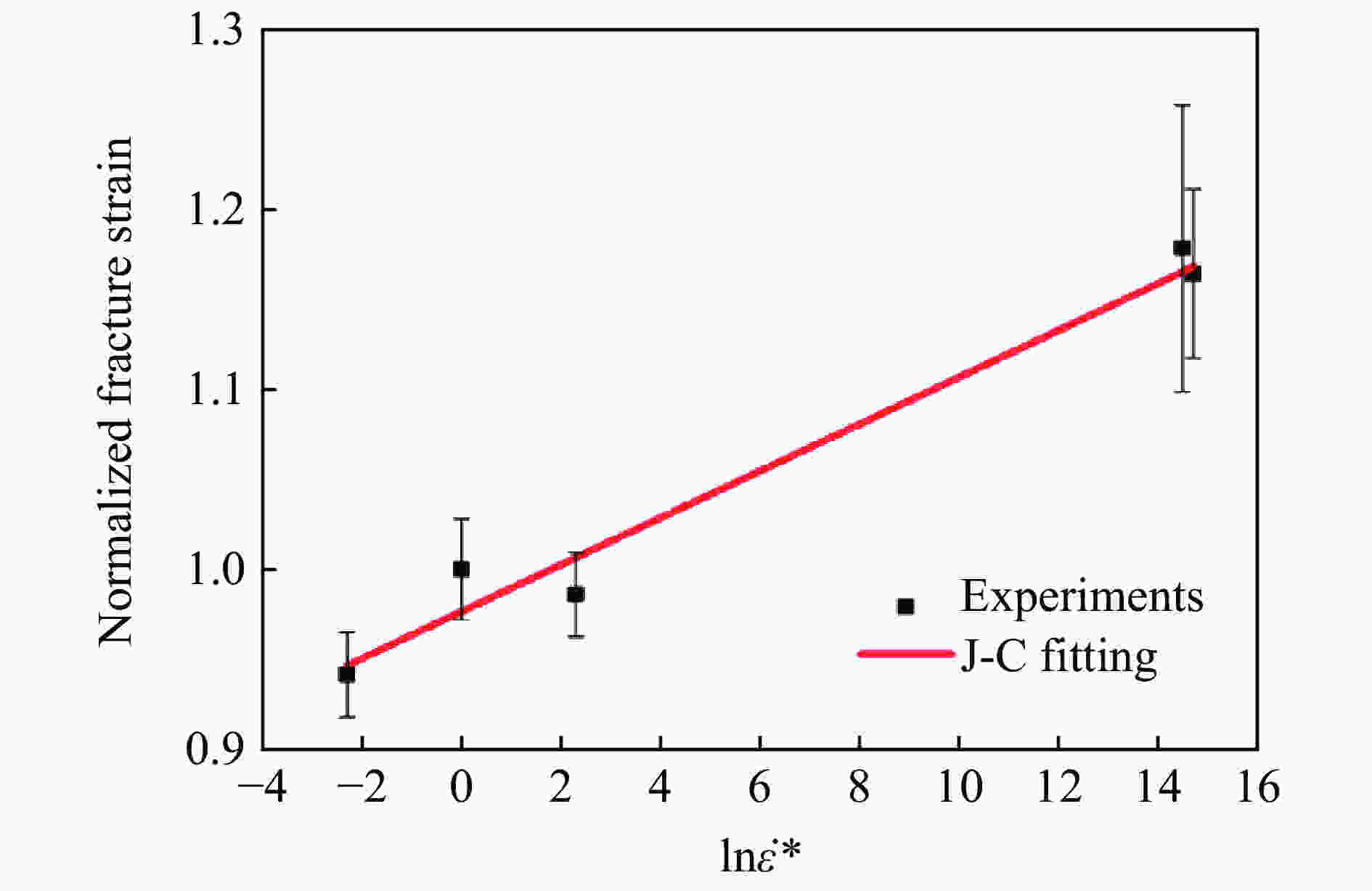

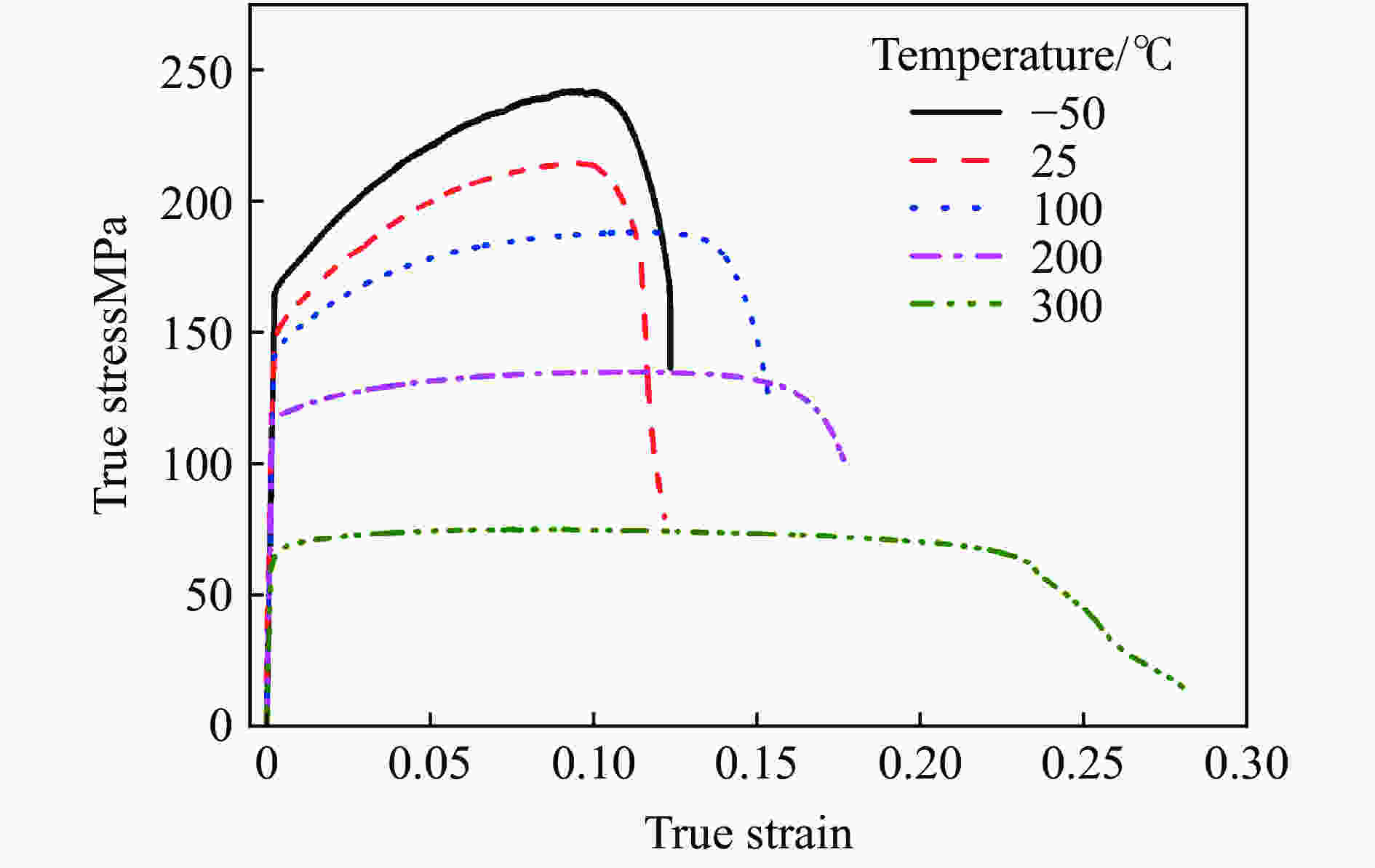

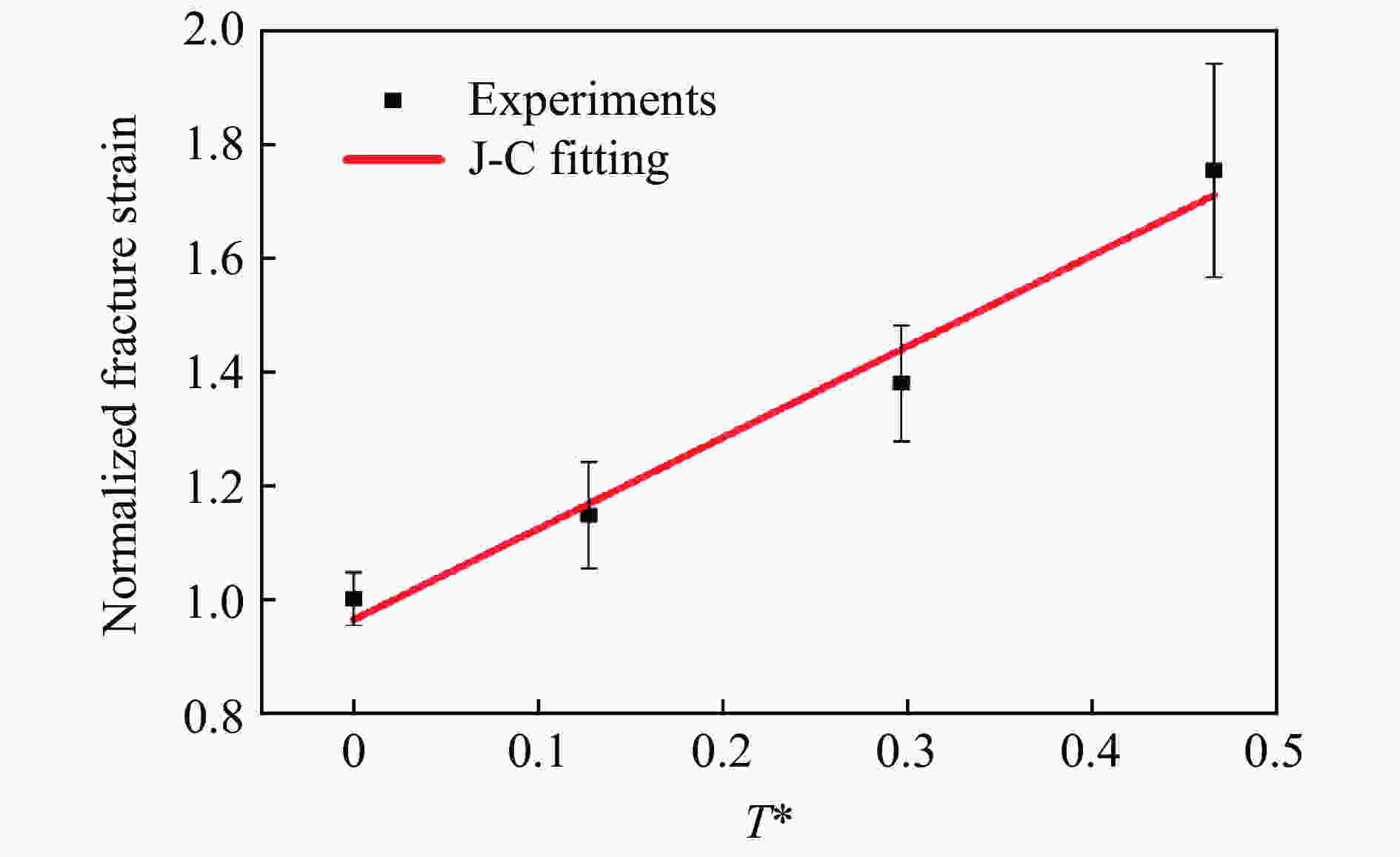

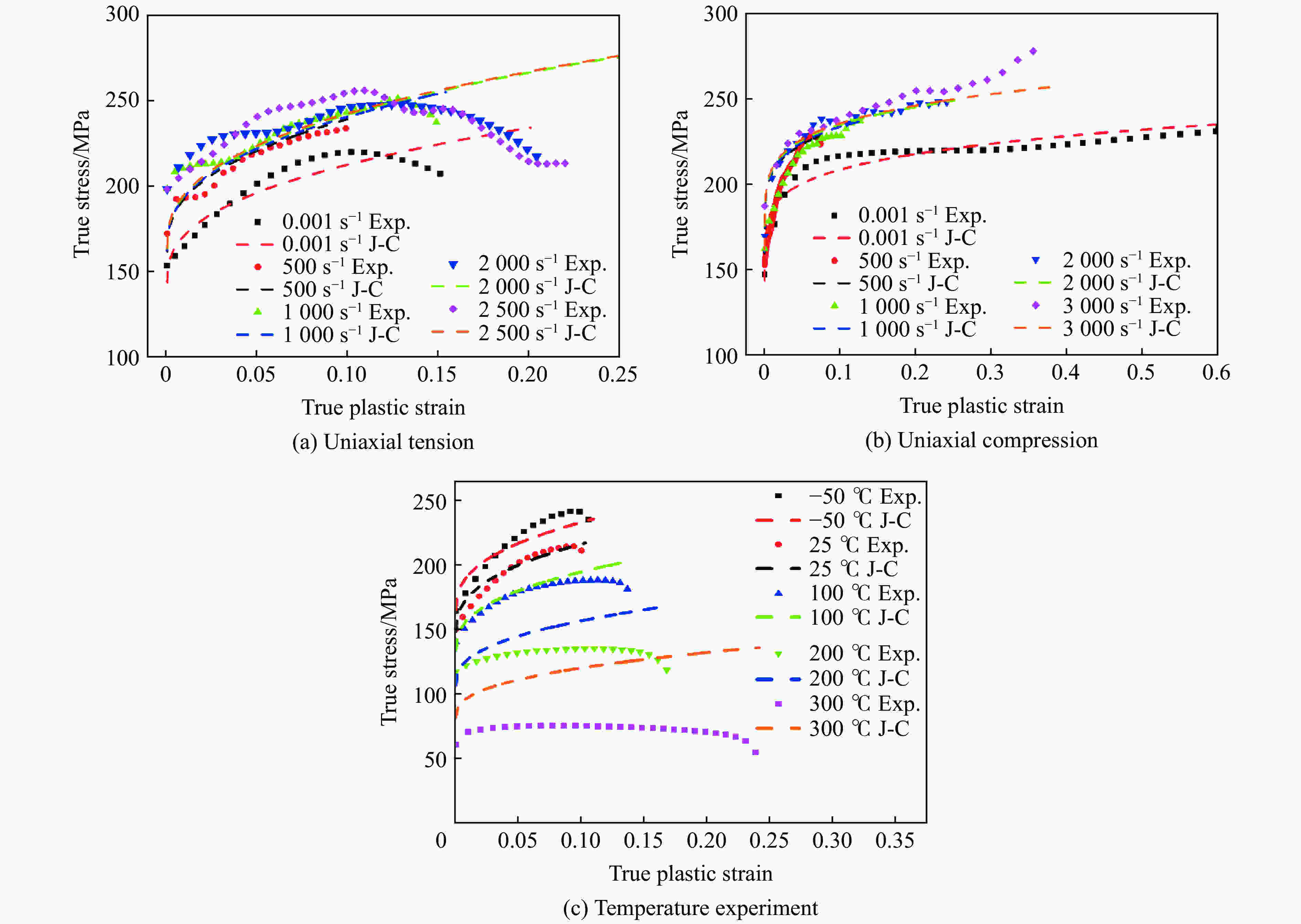

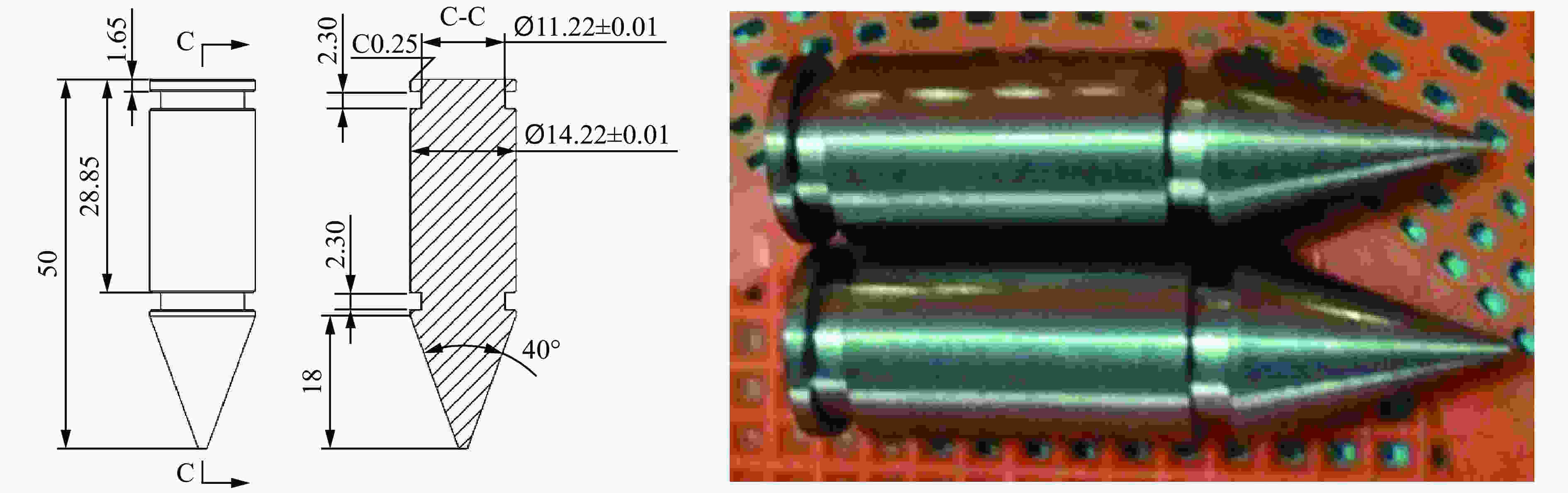

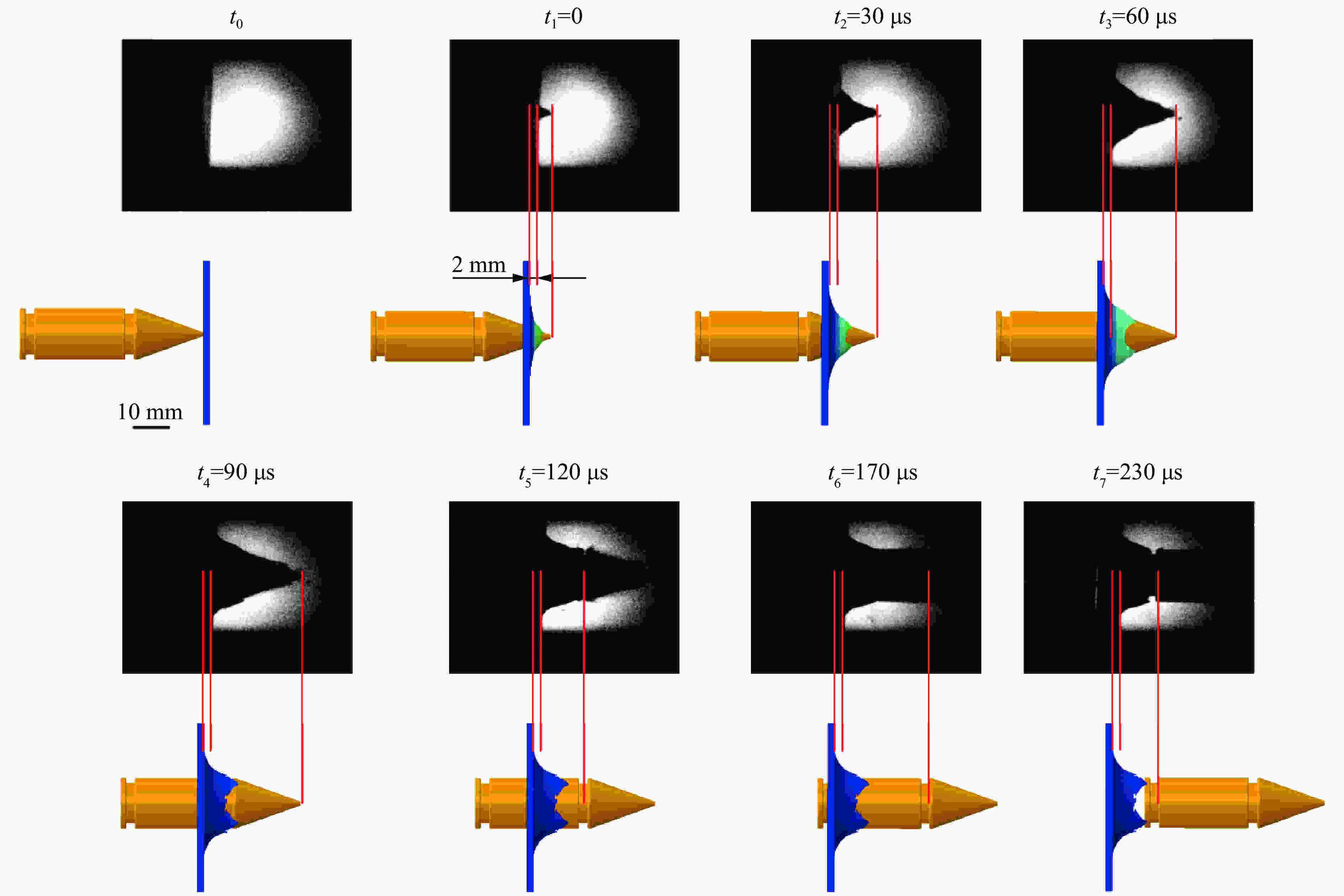

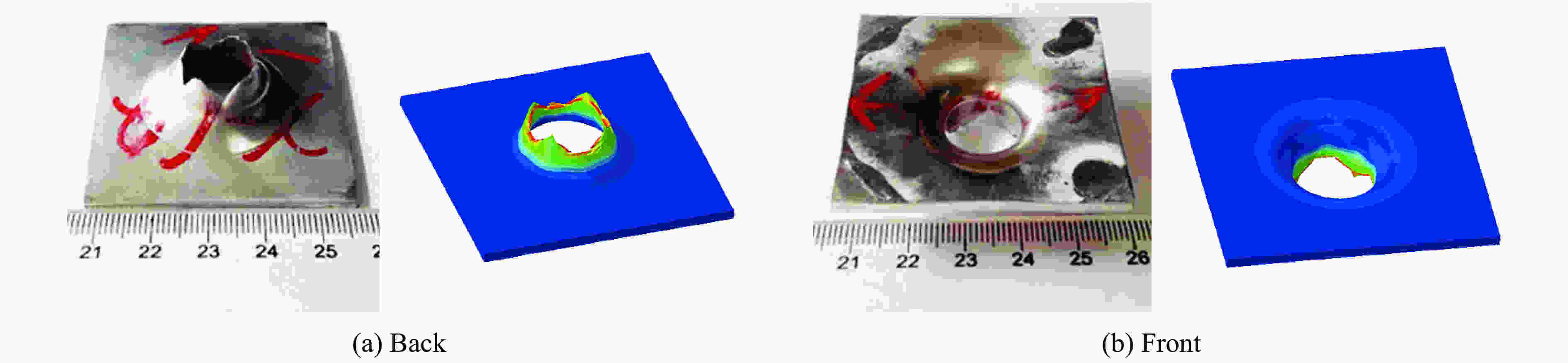

Abstract: High-speed railway vehicles are subjected to complex stress and environmental conditions in service. Aluminum alloy extrusions are widely used in energy absorption structures of high-speed trains, due to their excellent mechanical and processing properties. The crashworthiness of the aluminum alloy extrusions is critical to the safe and steady operations of the railway vehicles. In this study, a variety of mechanical tests were conducted on a novel aluminum alloy used for vehicles, i.e., aluminum alloy 6008-T4, including quasi-static and dynamic tension/compression tests, quasi-static tension tests at a wide range of temperatures, fracture tests along different stress paths, etc. The results show that the yield stress of the 6008-T4 aluminum alloy increases by about 15% while the fracture strain increases by about 25% when the strain rate varies from 0.001 s−1 to 2500 s−1. The aluminum alloy 6008-T4 exhibits significant temperature softening in strength: the yield stress decreases by about 60% when the temperature rises from 25 ℃ to 300 ℃. However, the fracture strain at 300 ℃ shows an 80% increase compared to the ambient (25 ℃) result. With the increase of stress triaxiality from 0.1 to 0.6, the fracture strain of the aluminum alloy 6008-T4 decreases by about 40%, and the decreasing trend conforms well to the theoretical prediction by the Johnson-Cook (J-C) model. Then the parameters of the J-C constitutive and damage models were calibrated according to the experimental results. In particular, the local fracture strains are critical for deriving the parameters of the damage model parameters. Therefore, the finite element simulations were combined with the force-displacement curves obtained in the tests to calculate the local fracture strains of the specimens. Compared to the direct measurements, the combined method of the experiments and simulation is more simple and accurate. The experimental curves at different strain rates and temperatures were compared with those predicted by the J-C model. The compariosn shows that they agree well at high temperatures. Finally, the impact penetration test was adopted to verify the acquired parameters. The simulation and experimental results, regarding the projectile positions and the fracture patterns of the target, are consistent, indicating that the parameters and calibration methods presented in this paper are reliable and effective. -

表 1 6008-T4铝合金J-C本构和损伤断裂参数

Table 1. J-C constitutive and damage parameters of the 6008-T4 aluminum alloy

A/MPa B/MPa n C m D1 D2 D3 D4 D5 150 101 0.19 0.0079 1.060 0.284 0.677 −2.461 0.013 1.60 -

[1] 田红旗. 中国列车空气动力学研究进展 [J]. 交通运输工程学报, 2006, 6(1): 1–9. DOI: 10.3321/j.issn:1671-1637.2006.01.001.TIAN H Q. Study evolvement of train aerodynamics in China [J]. Journal of Traffic and Transportation Engineering, 2006, 6(1): 1–9. DOI: 10.3321/j.issn:1671-1637.2006.01.001. [2] 关庆华. 列车脱轨机理及运行安全性研究 [D]. 成都: 西南交通大学, 2010. DOI: 10.7666/d.y1957673.GUAN Q H. Study on the derailment mechanism and running safety of trains [D]. Chengdu: Southwest Jiaotong University, 2010. DOI: 10.7666/d.y1957673. [3] LIAO X T, LI Q, YANG X J, et al. A two-stage multi-objective optimisation of vehicle crashworthiness under frontal impact [J]. International Journal of Crashworthiness, 2008, 13(3): 279–288. DOI: 10.1080/13588260801933659. [4] 单其雨. 高速列车车体耐碰撞结构研究 [D]. 成都: 西南交通大学, 2010. DOI: 10.7666/d.y1687195.SHAN Q Y. The study of crash-resistant structure for high-speed trains [D]. Chengdu: Southwest Jiaotong University, 2010. DOI: 10.7666/d.y1687195. [5] 王文斌, 康康, 赵洪伦. 列车耐碰撞系统有限元和多体动力学联合仿真 [J]. 同济大学学报(自然科学版), 2011, 39(10): 1552–1556. DOI: 10.3969/j.issn.0253-374x.2011.10.026.WANG W B, KANG K, ZHAO H L. Joint simulation of crashworthy train set based on finite element and multibody dynamic [J]. Journal of Tongji University (Natural Science), 2011, 39(10): 1552–1556. DOI: 10.3969/j.issn.0253-374x.2011.10.026. [6] 刘金朝, 房加志, 王成国, 等. 铁道客车大变形碰撞仿真研究 [J]. 中国铁道科学, 2004, 25(6): 1–8. DOI: 10.3321/j.issn:1001-4632.2004.06.001.LIU J Z, FANG J Z, WANG C G, et al. Simulation research on finite deformation crashworthiness of railway passenger car [J]. China Railway Science, 2004, 25(6): 1–8. DOI: 10.3321/j.issn:1001-4632.2004.06.001. [7] 杜志岐, 邵朋礼. 铝合金车体抗冲击能力的动态有限元仿真 [J]. 兵工学报, 2009, 30(1): 1–4. DOI: 10.3321/j.issn:1000-1093.2009.01.001.DU Z Q, SHAO P L. Dynamic finite element simulation of the aluminum alloy hull at landing [J]. Acta Armamentarii, 2009, 30(1): 1–4. DOI: 10.3321/j.issn:1000-1093.2009.01.001. [8] ESKANDARIAN A, MARZOUGUI D, BEDEWI N E. Finite element model and validation of a surrogate crash test vehicle for impacts with roadside objects [J]. International Journal of Crashworthiness, 1997, 2(3): 239–258. DOI: 10.1533/cras.1997.0048. [9] MIZUNO K, KAJZER J. Head injuries in vehicle-pedestrian impact: 2000-01-0157 [R]. Warrendale, PA: Society for Automotive Engineers, 2000. DOI: 10.4271/2000-01-0157. [10] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates, and high temperatures [C] // Proceedings of the 7th International Symposium on Ballistics. Hague: International Ballistics Committee, 1983: 541−547. [11] UMBRELLO D, M’SAOUBI R, OUTEIRO J C. The influence of Johnson-Cook material constants on finite element simulation of machining of AISI 316L steel [J]. International Journal of Machine Tools and Manufacture, 2007, 47(3-4): 462–470. DOI: 10.1016/j.ijmachtools.2006.06.006. [12] WANG X Y, HUANG C Z, ZOU B, et al. Dynamic behavior and a modified Johnson-Cook constitutive model of Inconel 718 at high strain rate and elevated temperature [J]. Materials Science and Engineering: A, 2013, 580: 385–390. DOI: 10.1016/j.msea.2013.05.062. [13] 刘再德, 王冠, 冯银成, 等. 6061铝合金高应变速率本构参数研究 [J]. 矿冶工程, 2011, 31(6): 120–123. DOI: 10.3969/j.issn.0253-6099.2011.06.032.LIU Z D, WANG G, FENG Y C, et al. High-strain-rate constitutive parameters of 6061 aluminum alloys [J]. Mining and Metallurgical Engineering, 2011, 31(6): 120–123. DOI: 10.3969/j.issn.0253-6099.2011.06.032. [14] 胡昌明, 贺红亮, 胡时胜. 45号钢的动态力学性能研究 [J]. 爆炸与冲击, 2003, 23(2): 188–192.HU C M, HE H L, HU S S. A study on dynamic mechanical behaviors of 45 steel [J]. Explosion and Shock Waves, 2003, 23(2): 188–192. [15] 林莉, 支旭东, 范锋, 等. Q235B钢Johnson-Cook模型参数的确定 [J]. 振动与冲击, 2014, 33(9): 153–158, 172. DOI: 10.13465/j.cnki.jvs.2014.09.028.LIN L, ZHI X D, FAN F, et al. Determination of parameters of Johnson-Cook models of Q235B steel [J]. Journal of Vibration and Shock, 2014, 33(9): 153–158, 172. DOI: 10.13465/j.cnki.jvs.2014.09.028. [16] 吴璐, 刘廷玉, 董万鹏, 等. 6008铝合金在不同挤压方向上的力学性能和断裂行为的研究 [J]. 热加工工艺, 2016, 45(2): 53–55, 59. DOI: 10.14158/j.cnki.1001-3814.2016.02.014.WU L, LIU T Y, DONG W P, et al. Study on tensile behavior and fractography of 6008 Al alloy at different extruded direction [J]. Hot Working Technology, 2016, 45(2): 53–55, 59. DOI: 10.14158/j.cnki.1001-3814.2016.02.014. [17] HӦRLING D. Parameter identification of GISSMO damage model for DOCOL 1200M: a study on crash simulation for high strength steel sheet components [D]. Karlstad: Karlstad University, 2015. [18] 姚宗勇, 刘庆, GODFREY A, 等. 大应变量冷轧AA1050铝合金微观组织与织构的演变 [J]. 金属学报, 2009, 45(6): 647–651. DOI: 10.3321/j.issn:0412-1961.2009.06.002.YAO Z Y, LIU Q, GODFREY A, et al. Micro structure and texture evolutions of AA1050 aluminum alloy cold rolled to high strains [J]. Acta Metallurgica Sinica, 2009, 45(6): 647–651. DOI: 10.3321/j.issn:0412-1961.2009.06.002. [19] 赵磊, 李玉龙, 陈煊. 一种绸布的冲击拉伸性能实验 [J]. 爆炸与冲击, 2014, 34(4): 476–482. DOI: 10.11883/1001-1455(2014)04-0476-07.ZHAO L, LI Y L, CHEN X. Experimental study on dynamic tensile behaviour of a kind of fiber silk [J]. Explosion and Shock Waves, 2014, 34(4): 476–482. DOI: 10.11883/1001-1455(2014)04-0476-07. [20] 胡时胜, 王礼立, 宋力, 等. Hopkinson压杆技术在中国的发展回顾 [J]. 爆炸与冲击, 2014, 34(6): 641–657. DOI: 10.11883/1001-1455(2014)06-0641-17.HU S S, WANG L L, SONG L, et al. Review of the development of Hopkinson pressure bar technique in China [J]. Explosion and Shock Waves, 2014, 34(6): 641–657. DOI: 10.11883/1001-1455(2014)06-0641-17. [21] GAMBIRASIO L, RIZZI E. On the calibration strategies of the Johnson-Cook strength model: discussion and applications to experimental data [J]. Materials Science and Engineering: A, 2014, 610: 370–413. DOI: 10.1016/j.msea.2014.05.006. [22] 李言荣, 恽正中. 材料物理学概论[M]. 北京: 清华大学出版社, 2001. [23] ZHANG W H, SUN D Q, HAN L J, et al. Characterization of intermetallic compounds in dissimilar material resistance spot welded joint of high strength steel and aluminum alloy [J]. ISIJ International, 2011, 51(11): 1870–1877. DOI: 10.2355/isijinternational.51.1870. -

下载:

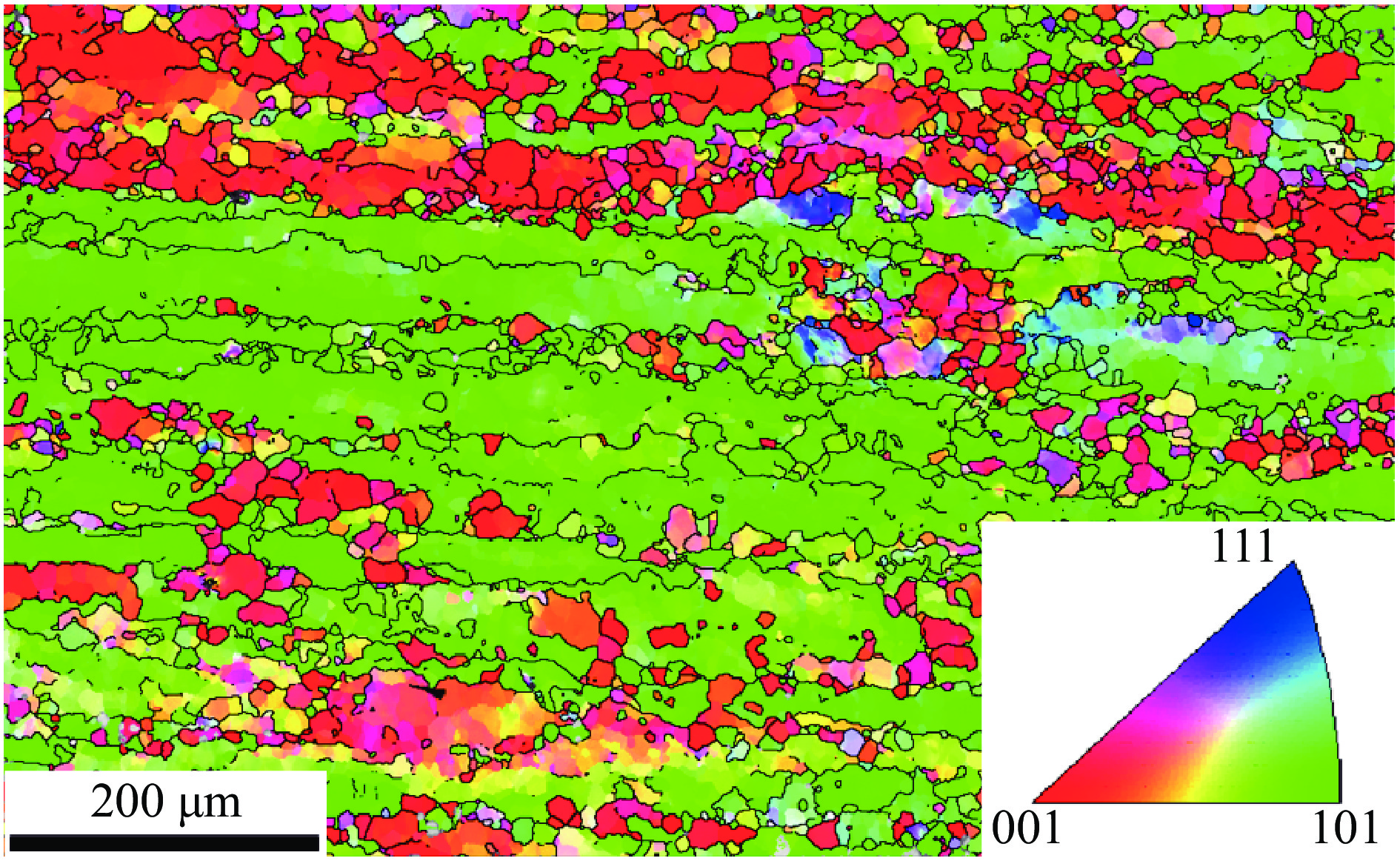

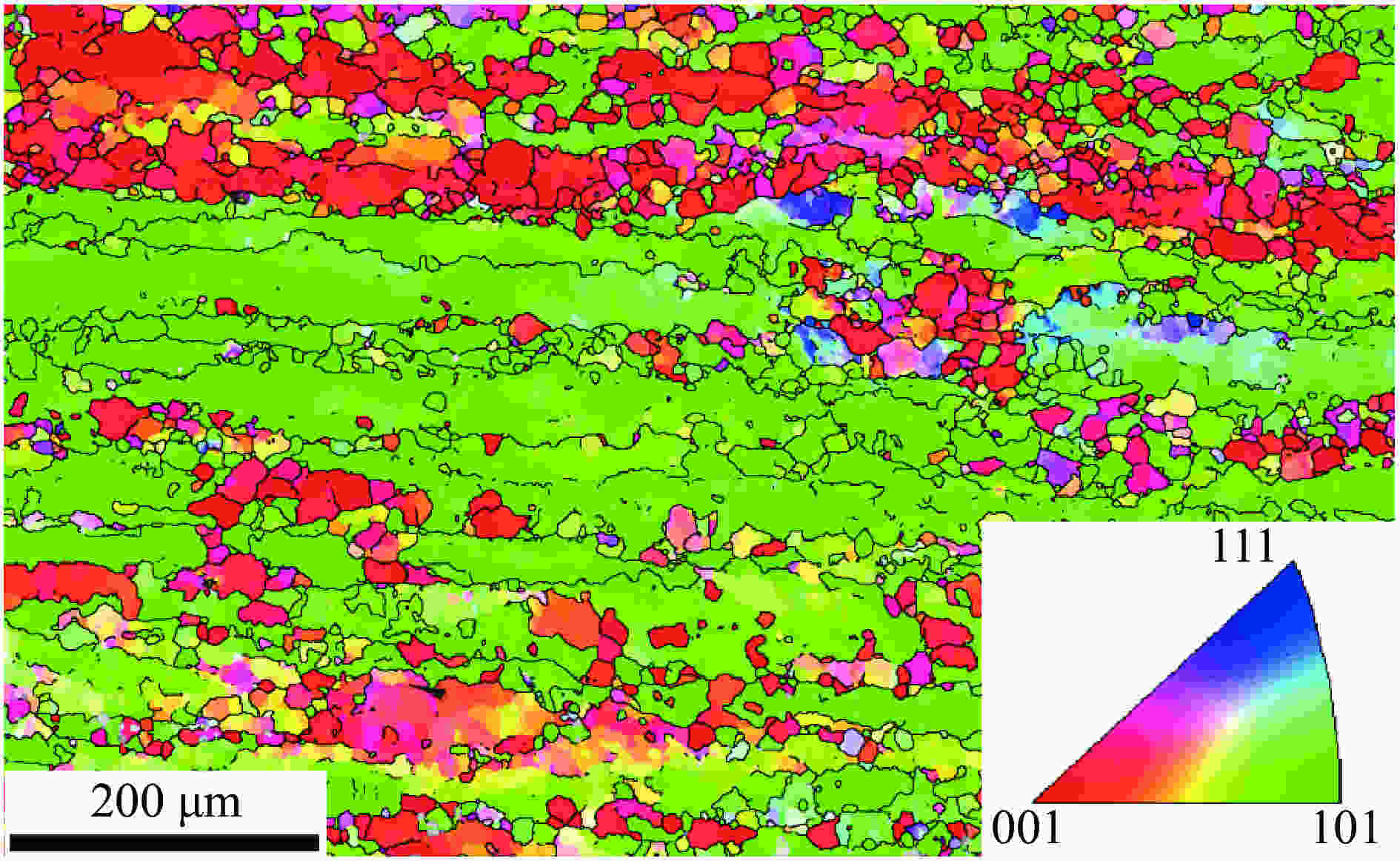

下载: