Mechanism study of preventing crack propagation of fractured rockunder dynamic loads

-

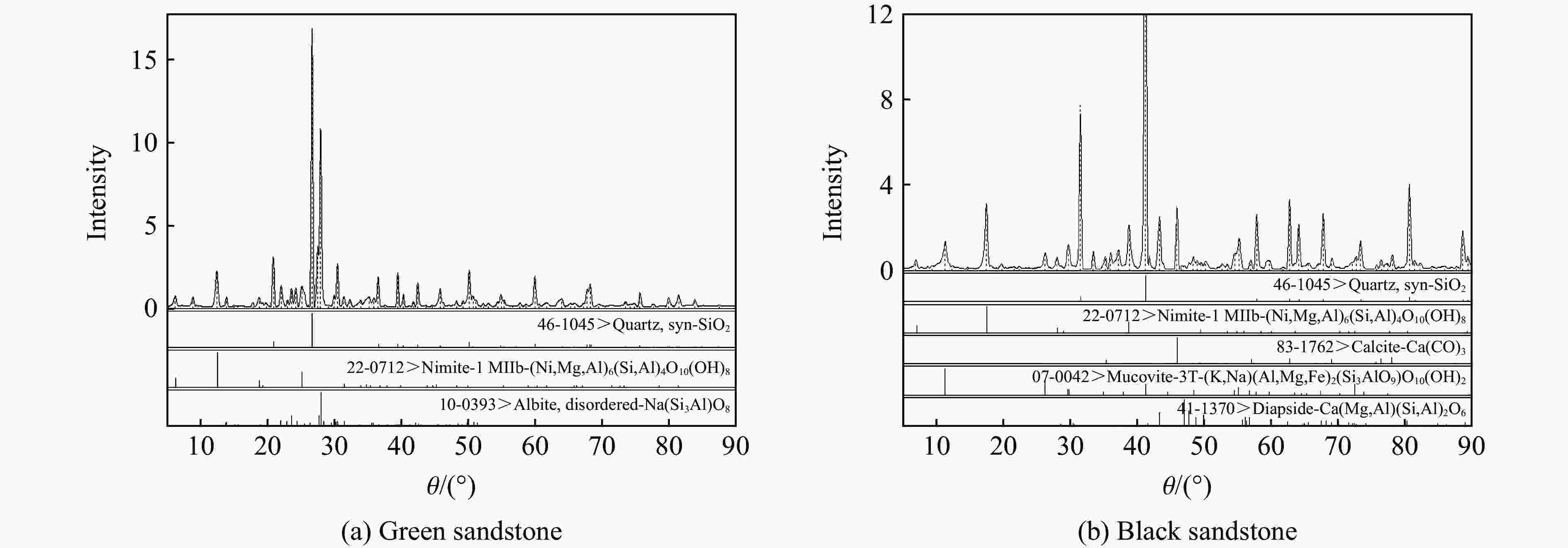

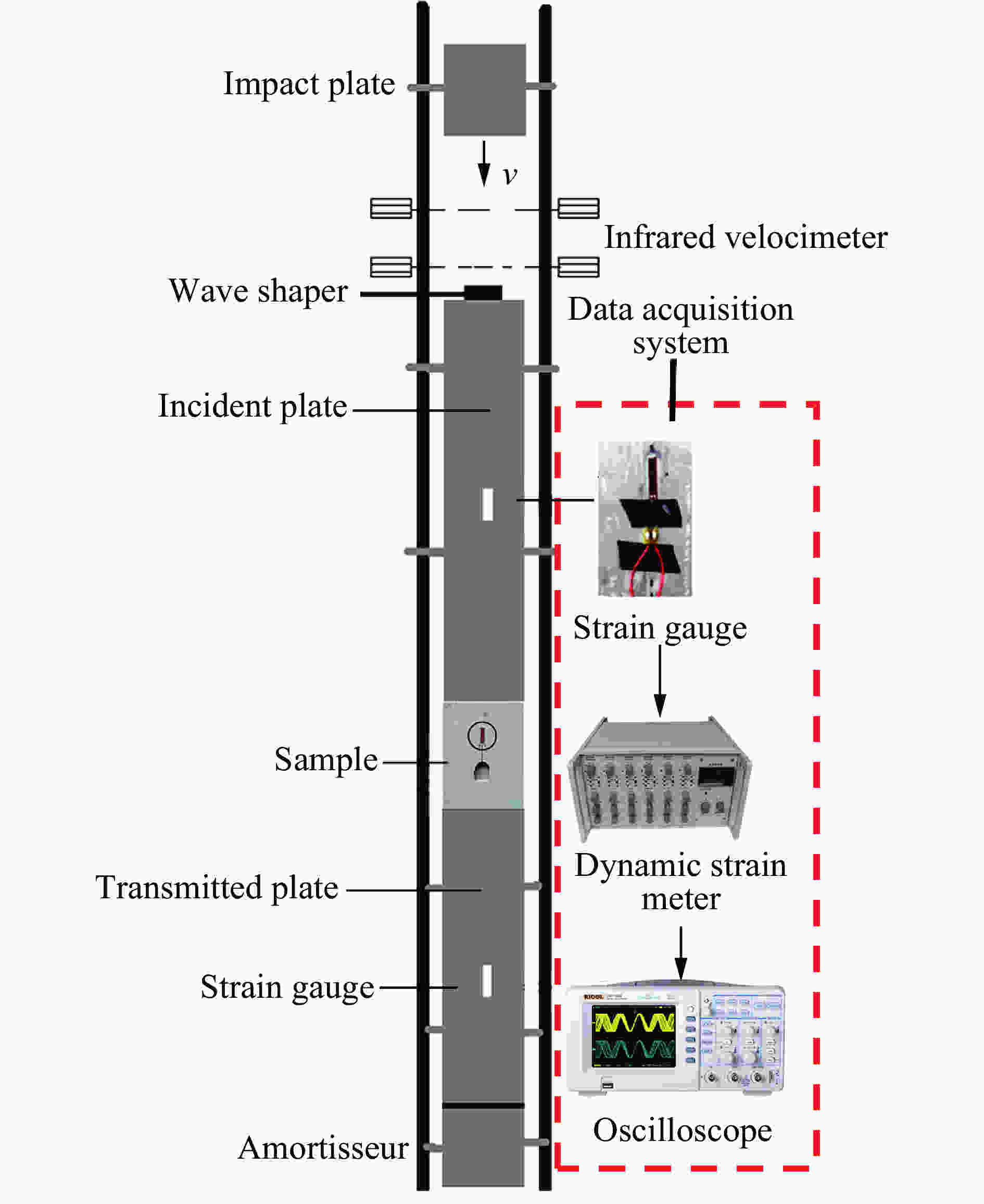

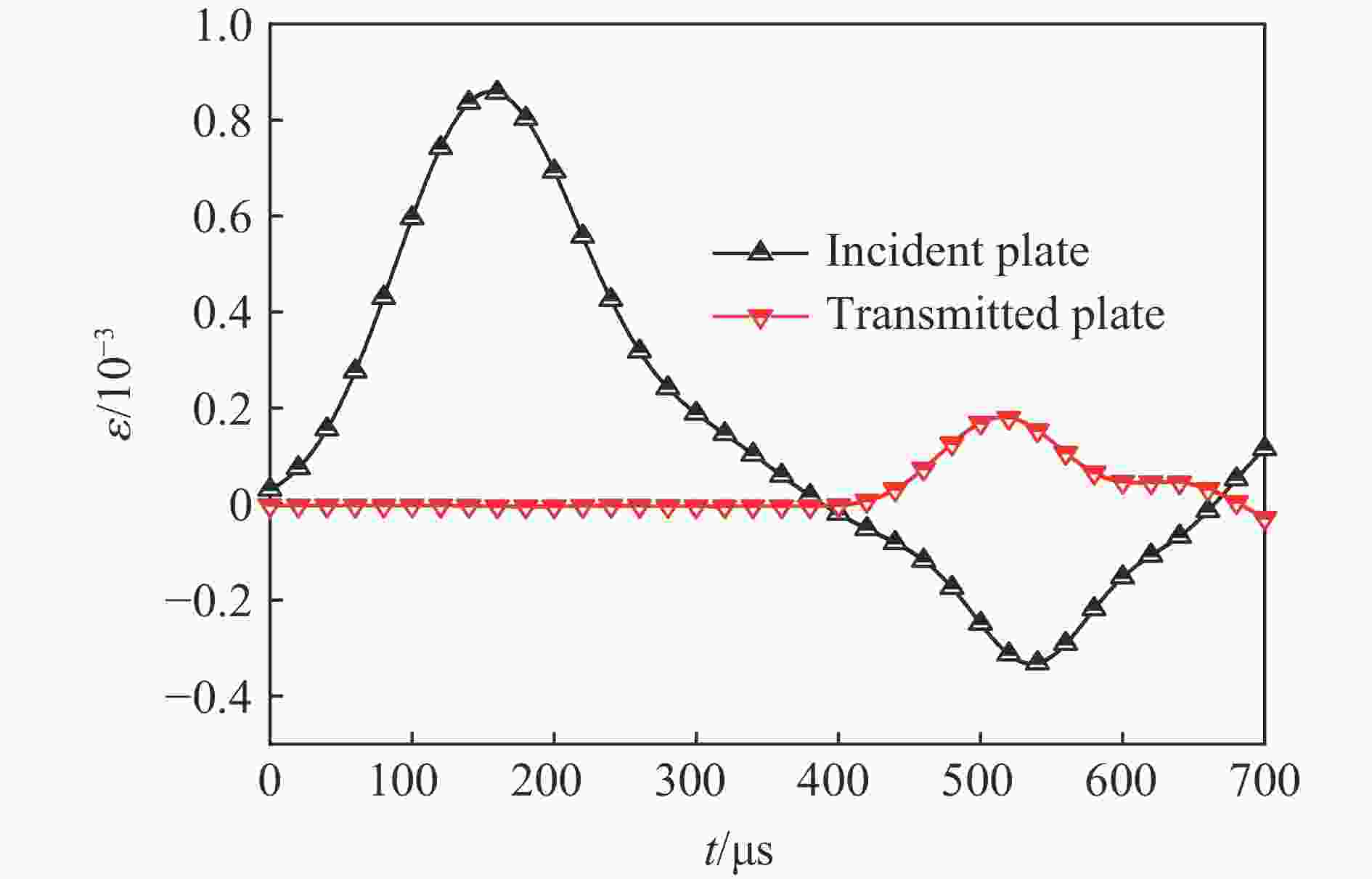

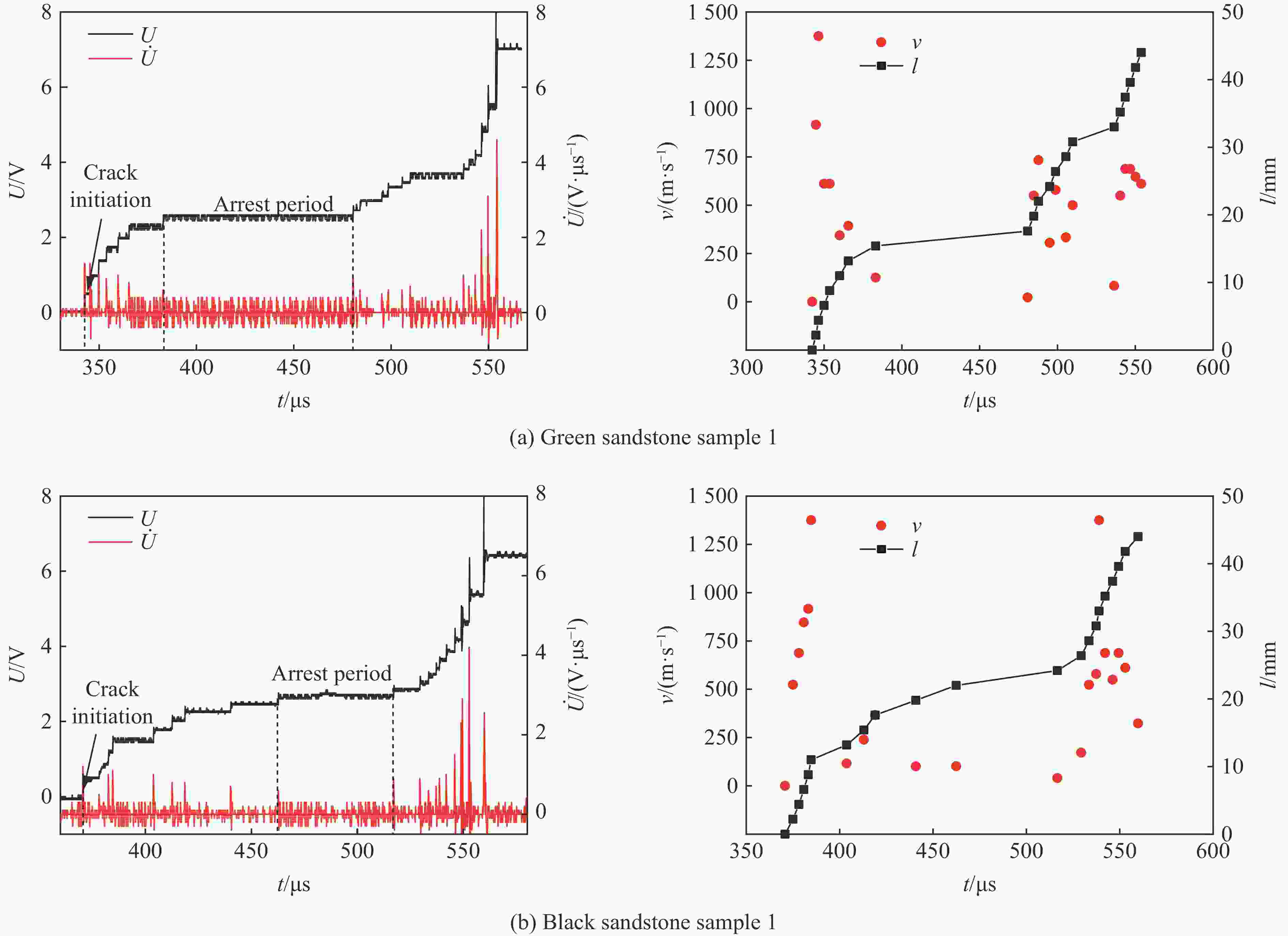

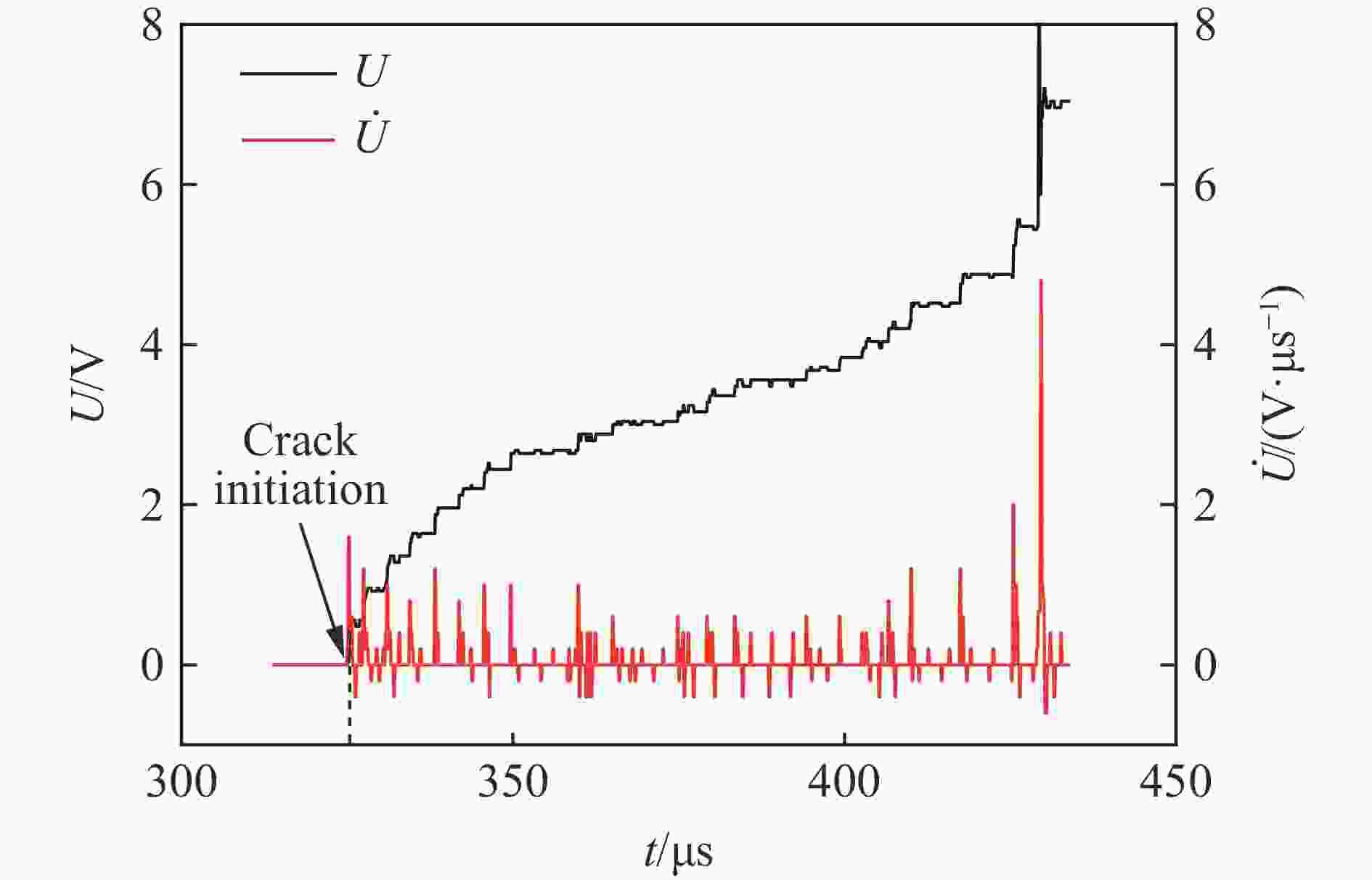

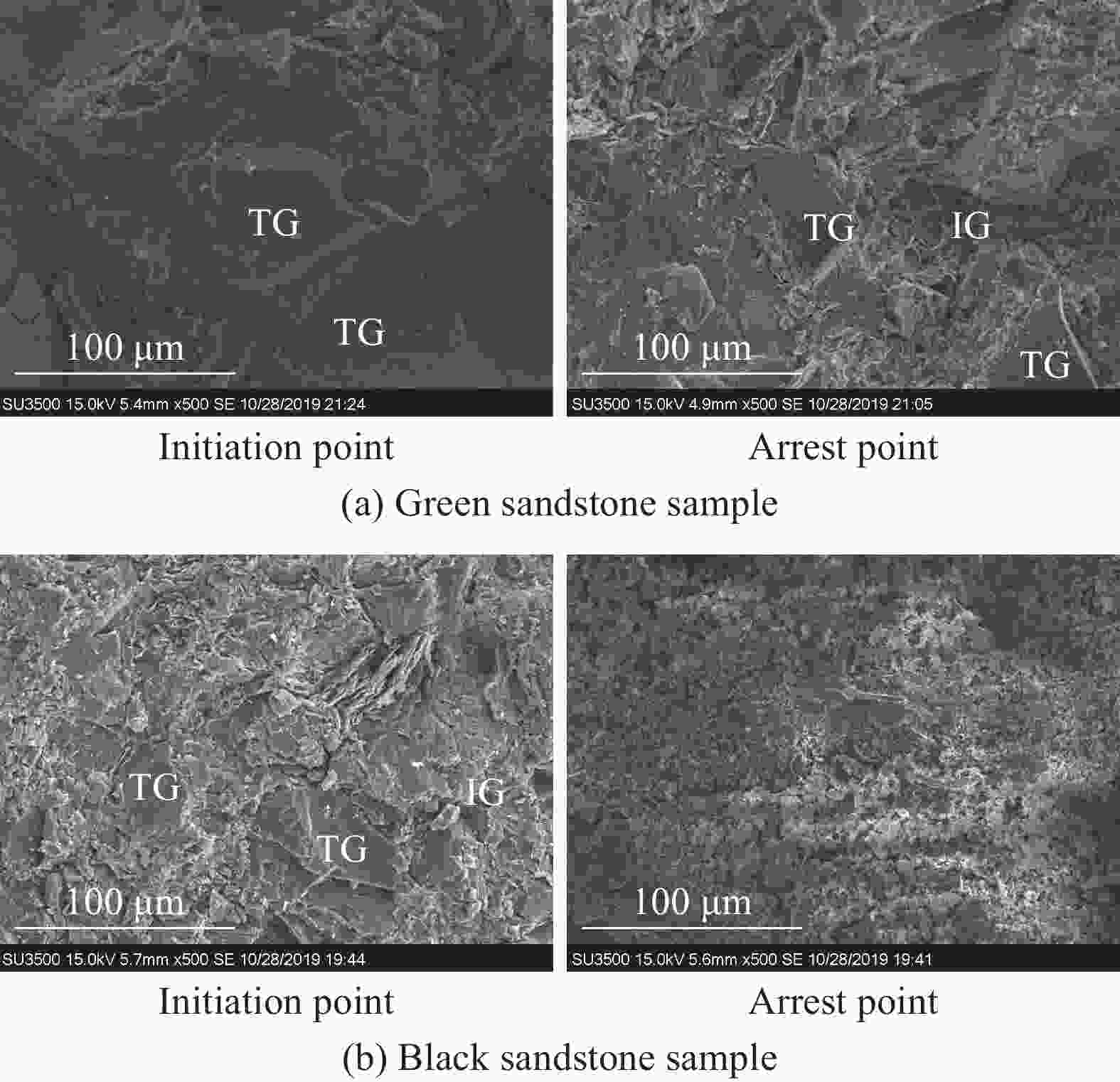

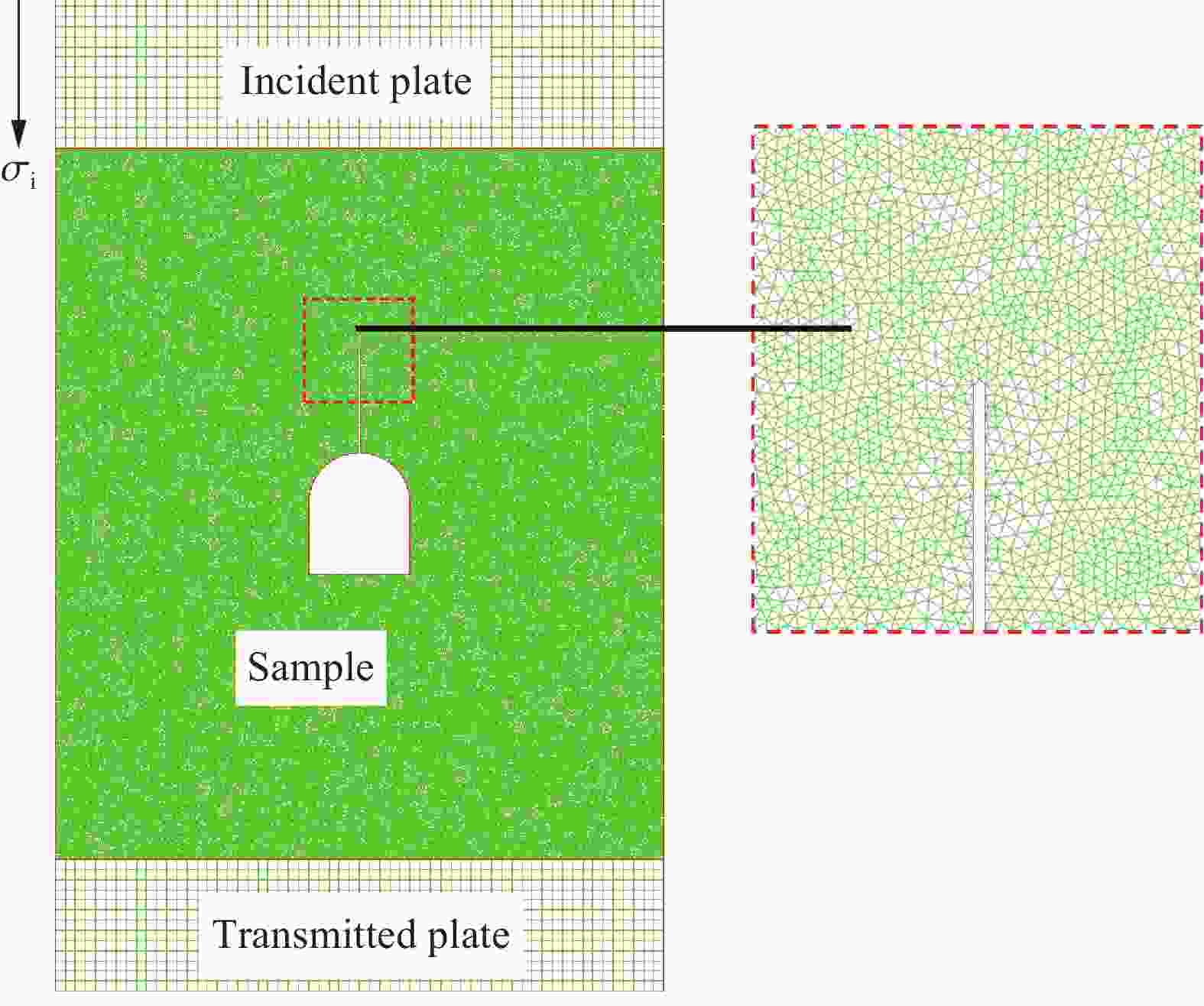

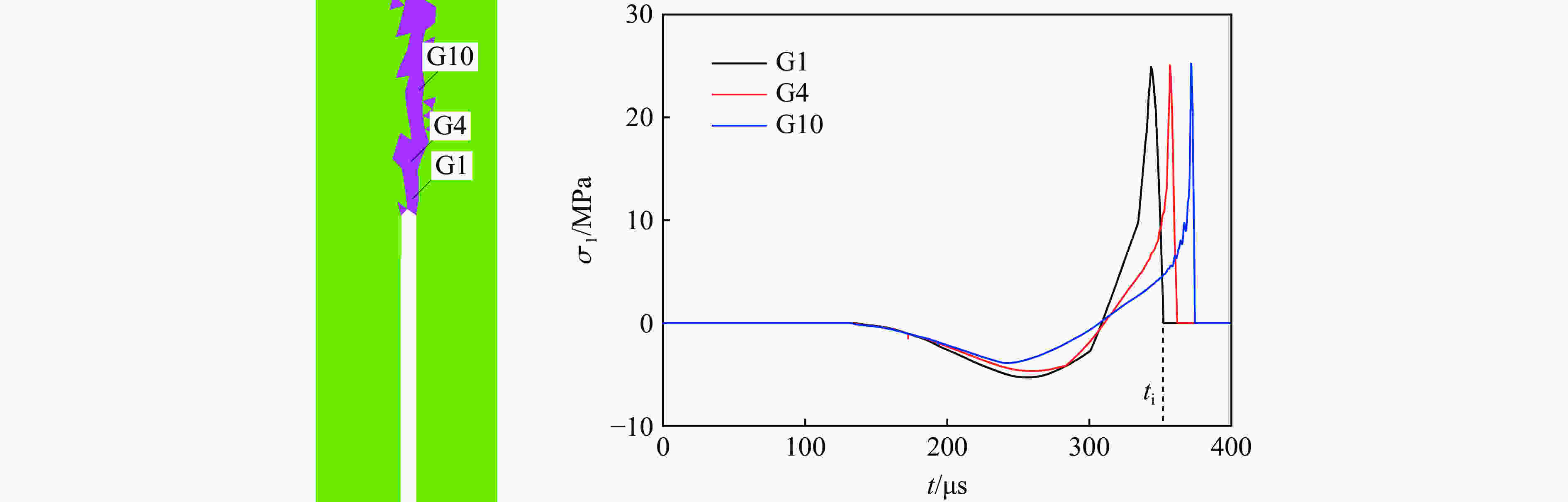

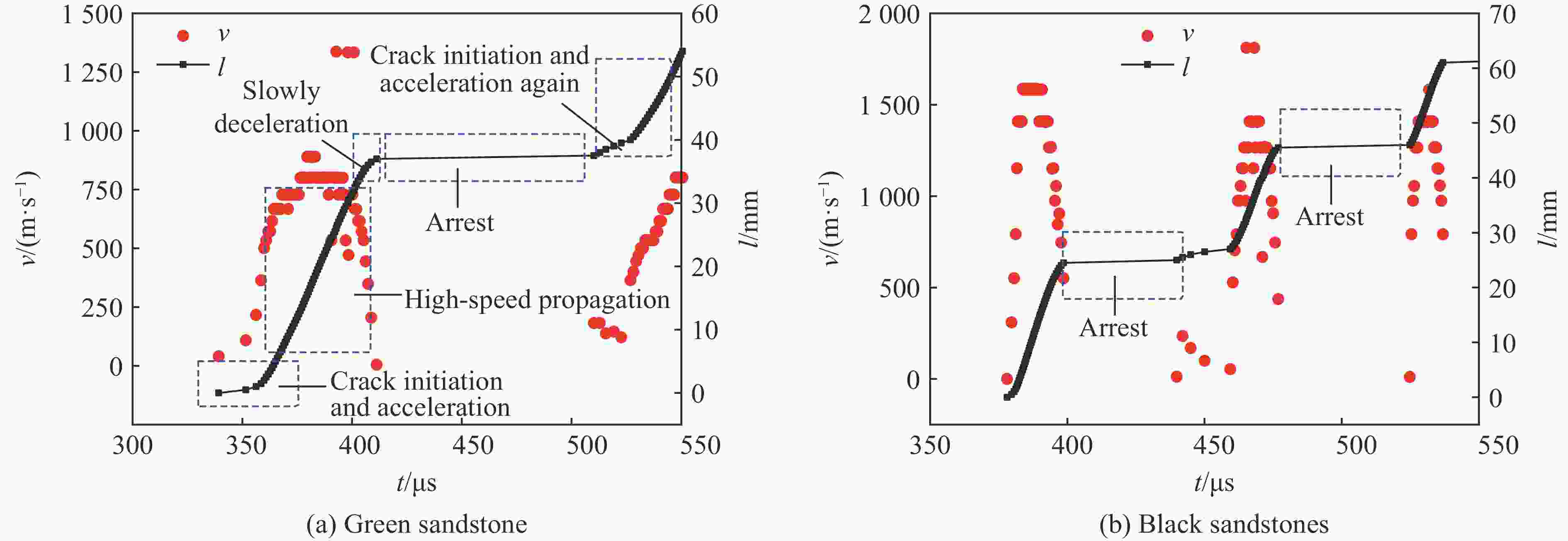

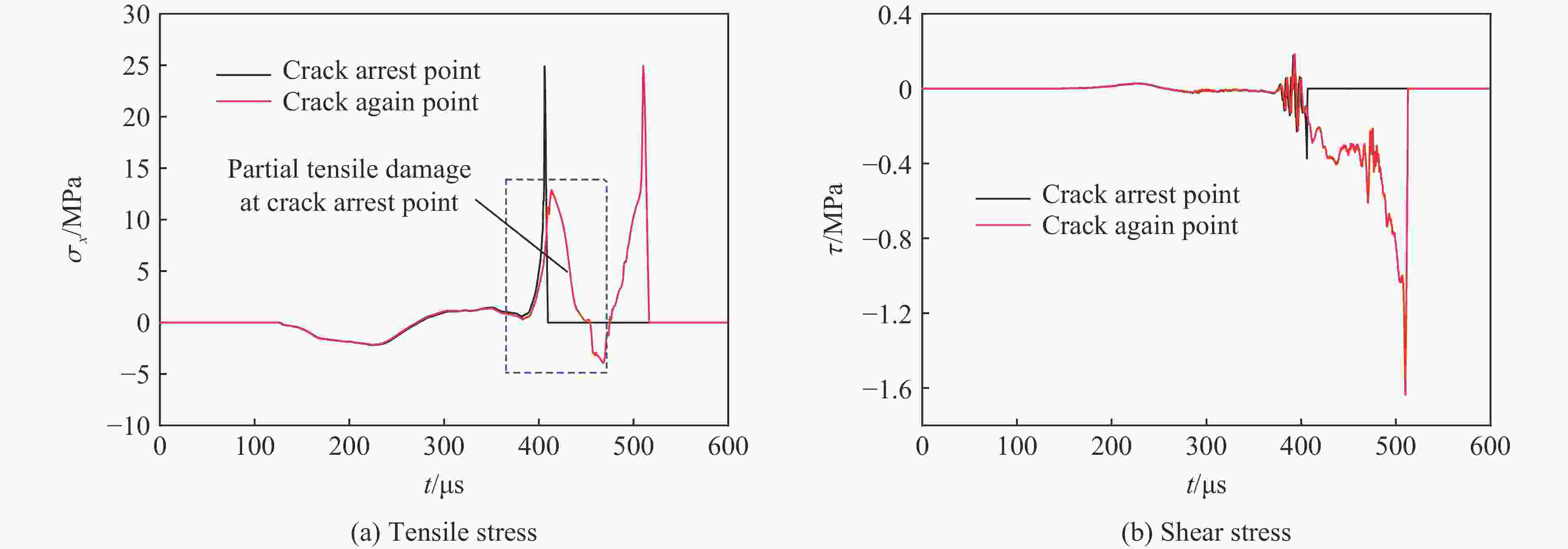

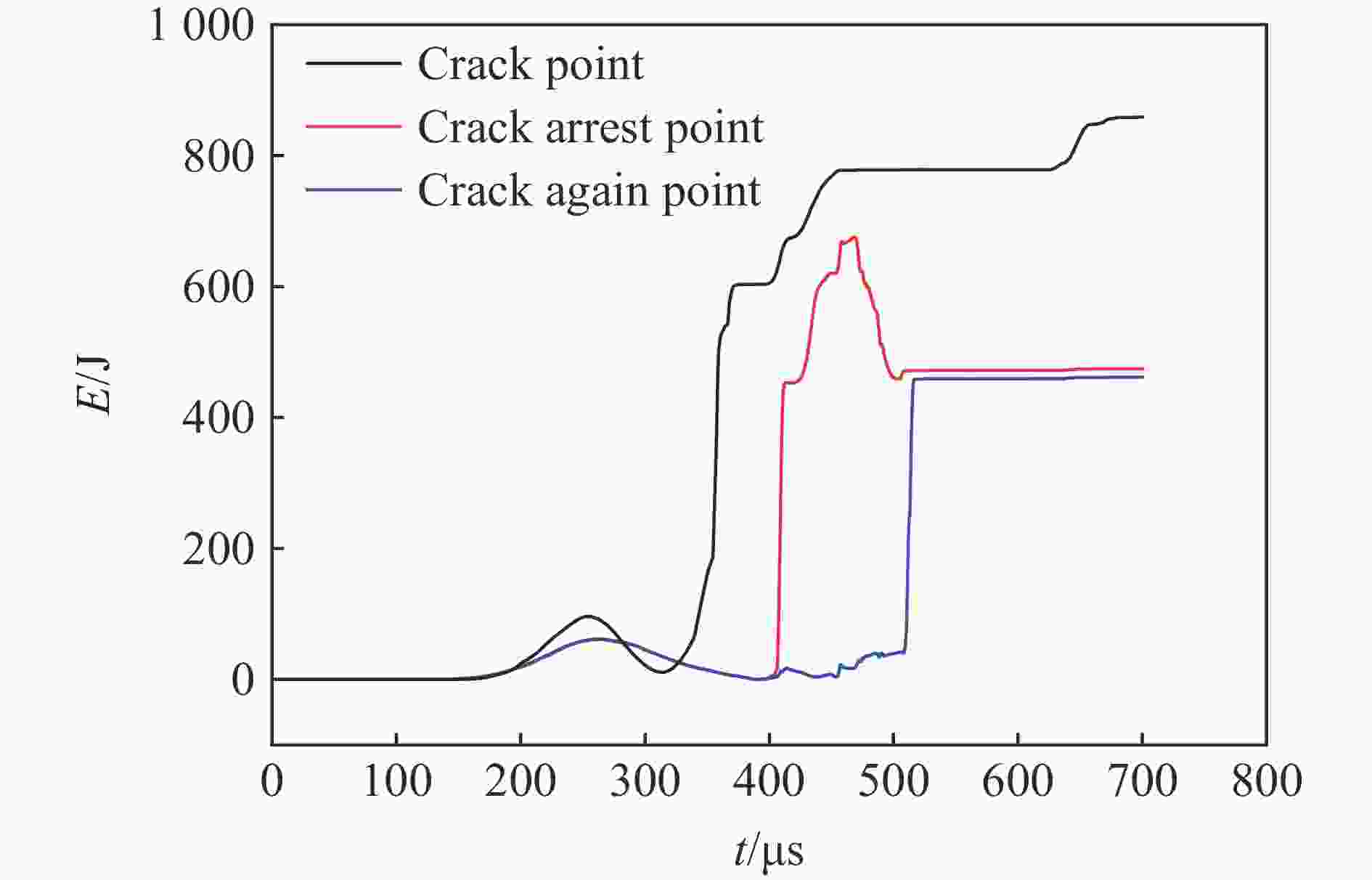

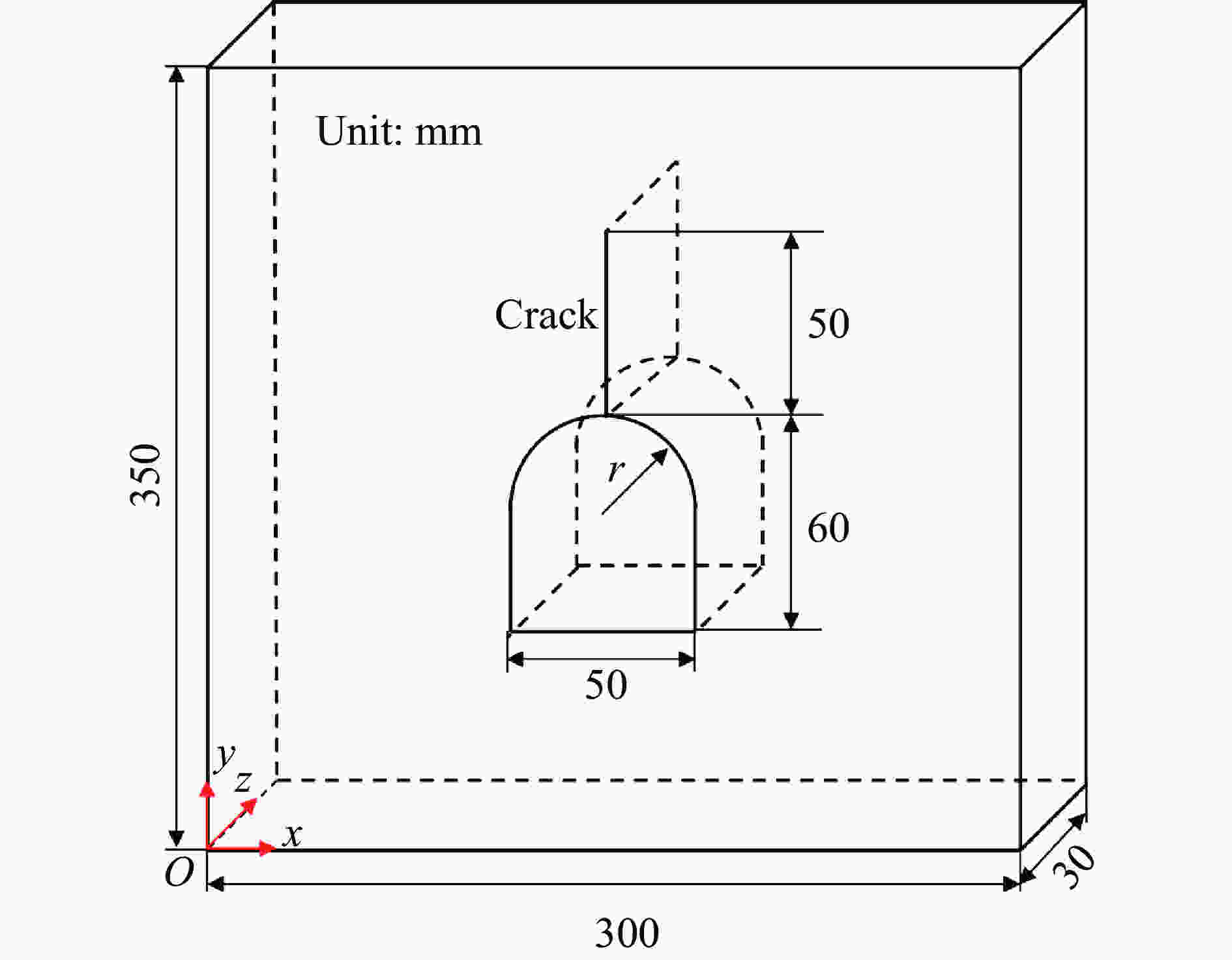

摘要: 为深层次了解裂隙岩体在动载荷作用下的动态断裂特性及止裂机理,采用TWSRC(tunnel with single radial crack)构型进行中低速冲击实验,选择砂岩作为原材料制作裂隙岩体试样,以落锤冲击试验装置与裂纹扩展计实验系统对裂纹的动态起裂、扩展及止裂过程进行全过程监测,重点研究动态破裂过程的破裂行为及止裂现象。使用有限差分法程序进行数值模拟,验证冲击实验结果的科学性与准确性。研究发现:裂隙岩体的动态断裂过程是由起裂加速-高速扩展-缓慢减速-止裂-再次起裂加速-再次高速扩展等多次循环的过程构成,且止裂区间尺寸为微秒量级;裂隙岩体止裂位置的穿晶断裂比例远小于初始起裂点,青砂岩动态断裂过程的穿晶断裂比例稍大于黑砂岩;裂隙岩体中止裂点再次起裂所需的能量,远小于预制裂纹初始起裂所需要的能量。Abstract: To deeply understanding dynamic fracture properties and preventing crack propagation of fractured rock mass under dynamic loads, impact experiments were conducted using TWSRC (tunnel with single radial crack) samples, and sandstone were selected as the raw material to manufacture fractured rock samples. The crack initiation, propagation and obstructing behavior were measured by using a drop hammer impact test device and crack propagation gauge measuring system. The mechanism of preventing crack propagation and failure behavior during dynamic fracturing process was focused, and then the corresponding numerical simulation was conducted by using the finite difference code, which can be used to accurately estimate the experiment result. The results indicate that the whole dynamic fracturing process of fractured rock under dynamic loads is composed of the cyclic process of crack initiation, high-speed crack propagation, slowly deceleration, preventing crack propagation. In addition, the period of crack obstruction was approximate the microsecond level. The ratio of transgranular (TG) fracture at the crack obstruction point of fractured rock was smaller than that of the crack initiation point, and the ratio of TG fracture of green sandstone during the dynamic fracturing process was larger than that of black sandstone. The fracture energy for crack initiation again after crack obstruction was much less than the fracture energy required for the initial initiation of pre-existing crack.

-

Key words:

- fractured rock mass /

- dynamic load /

- crack propagation velocity /

- crack arrest /

- energy evolution

-

表 1 砂岩的力学性能

Table 1. Mechanical properties of sandstone materials

材料 ρ/(kg·m−3) E/GPa μ fd/MPa cl/(m·s−1) ct /(m·s−1) 青砂岩 2 265 13.58 0.165 24.84 2 563 1 607 黑砂岩 2 650 33.67 0.205 52.96 3 678 2 239 表 2 实验结果

Table 2. Experimental results

试件 vs/(m·s−1) ti/μs ta/μs va/(m·s−1) la/mm 青砂岩1 8.43 342.4 97.6 368.6 15.4 青砂岩2 8.40 356.1 79.6 363.7 24.2 青砂岩3 8.38 367.4 57.2 302.7 15.4 黑砂岩1 8.47 370.8 54.2 310.1 19.8 黑砂岩2 8.41 350.0 81.7 372.9 15.4 黑砂岩3 8.39 387.0 85.9 396.1 8.8 -

[1] 曹富, 杨丽萍, 李炼, 等. 压缩单裂纹圆孔板(SCDC)岩石动态断裂全过程研究 [J]. 岩土力学, 2017, 38(6): 1573–1582, 1588. DOI: 10.16285/j.rsm.2017.06.005.CAO F, YANG L P, LI L, et al. Research on whole dynamical fracture process of rock using single cleavage drilled compression (SCDC) specimen [J]. Rock and Soil Mechanics, 2017, 38(6): 1573–1582, 1588. DOI: 10.16285/j.rsm.2017.06.005. [2] 张盛, 鲁义强, 王启智. 用P-CCNBD试样测定岩石动态扩展韧度和观察动态止裂现象 [J]. 岩土力学, 2017, 38(11): 3095–3105. DOI: 10.16285/j.rsm.2017.11.003.ZHANG S, LU Y Q, WANG Q Z. Measurement of dynamic fracture propagation toughness of rock and observation of dynamic arrest phenomenon using P-CCNBD specimens [J]. Rock and Soil Mechanics, 2017, 38(11): 3095–3105. DOI: 10.16285/j.rsm.2017.11.003. [3] 周辉, 徐荣超, 张传庆, 等. 预应力锚杆锚固止裂效应的试验研究 [J]. 岩石力学与工程学报, 2015, 34(10): 2027–2037. DOI: 10.13722/j.cnki.jrme.2015.0983.ZHOU H, XU R C, ZHANG C Q, et al. Experimental study of crack prevention effect of pre-stressed bolt anchoring [J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(10): 2027–2037. DOI: 10.13722/j.cnki.jrme.2015.0983. [4] FENG P, DAI F, LIU Y, et al. Coupled effects of static-dynamic strain rates on the mechanical and fracturing behaviors of rock-like specimens containing two unparallel fissures [J]. Engineering Fracture Mechanics, 2019, 207: 237–253. DOI: 10.1016/j.engfracmech.2018.12.033. [5] ZHANG Q B, ZHAO J. Determination of mechanical properties and full-field strain measurements of rock material under dynamic loads [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 60: 423–439. DOI: 10.1016/j.ijrmms.2013.01.005. [6] 郭东明, 刘康, 胡久羡, 等. 爆生气体对邻近硐室背爆侧预制裂纹影响机理 [J]. 煤炭学报, 2016, 41(1): 265–270. DOI: 10.13225/j.cnki.jccs.2015.1249.GUO D M, LIU K, HU J X, et al. Experimental study on the effect mechanism of the explosion gas on the precrack in the back-blasting of adjacent tunnel [J]. Journal of China Coal Society, 2016, 41(1): 265–270. DOI: 10.13225/j.cnki.jccs.2015.1249. [7] XU Y, YAO W, ZHAO G L, et al. Evaluation of the short core in compression (SCC) method for measuring mode Ⅱ fracture toughness of rocks [J]. Engineering Fracture Mechanics, 2020, 224: 106747. DOI: 10.1016/j.engfracmech.2019.106747. [8] LI D Y, HAN Z Y, SUN X L, et al. Dynamic mechanical properties and fracturing behavior of marble specimens containing single and double flaws in SHPB tests [J]. Rock Mechanics and Rock Engineering, 2019, 52(6): 1623–1643. DOI: 10.1007/s00603-018-1652-5. [9] 李地元, 韩震宇, 孙小磊, 等. 含预制裂隙大理岩SHPB动态力学破坏特性试验研究 [J]. 岩石力学与工程学报, 2017, 36(12): 2872–2883. DOI: 10.13722/j.cnki.jrme.2017.0488.LI D Y, HAN Z Y, SUN X L, et al. Characteristics of dynamic failure of marble with artificial flaws under split Hopkinson pressure bar tests [J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(12): 2872–2883. DOI: 10.13722/j.cnki.jrme.2017.0488. [10] HUANG Y H, YANG S Q, TIAN W L. Crack coalescence behavior of sandstone specimen containing two pre-existing flaws under different confining pressures [J]. Theoretical and Applied Fracture Mechanics, 2019, 99: 118–130. DOI: 10.1016/j.tafmec.2018.11.013. [11] WANG M, WANG F, ZHU Z M, et al. Modelling of crack propagation in rocks under SHPB impacts using a damage method [J]. Fatigue & Fracture of Engineering Materials & Structures, 2019, 42(8): 1699–1710. DOI: 10.1111/ffe.13012. [12] 杨仁树, 苏洪, 龚悦, 等. 爆炸荷载下不对称Y型裂纹扩展规律的试验研究 [J]. 岩土力学, 2017, 38(8): 2175–2181. DOI: 10.16285/j.rsm.2017.08.003.YANG R S, SU H, GONG Y, et al. Study on the regularity of asymmetric Y-shaped cracks propagation under blast loading [J]. Rock and Soil Mechanics, 2017, 38(8): 2175–2181. DOI: 10.16285/j.rsm.2017.08.003. [13] ZHOU L, ZHU Z M, LIU R F, et al. Investigation on fracture properties of single-flawed tunnel model under medium-to-low-speed impacts [J]. Acta Mechanica Solida Sinica, 2020, 33(2): 205–225. DOI: 10.1007/s10338-019-00124-4. [14] ZHOU Q, ZHU Z M, WANG X, et al. The effect of a pre‐existing crack on a running crack in brittle material under dynamic loads [J]. Fatigue & Fracture of Engineering Materials & Structures, 2019, 42(11): 2544–2557. DOI: 10.1111/ffe.13105. [15] 岳中文, 宋耀, 陈彪, 等. 冲击载荷下层状岩体动态断裂行为的模拟试验研究 [J]. 振动与冲击, 2017, 36(12): 223–229. DOI: 10.13465/j.cnki.jvs.2017.12.036.YUE Z W, SONG Y, CHEN B, et al. Study on behaviors of dynamic fracture in layered rock under impact loading [J]. Journal of Vibration and Shock, 2017, 36(12): 223–229. DOI: 10.13465/j.cnki.jvs.2017.12.036. [16] WANG Q Z, YANG J R, ZHANG C G, et al. Sequential determination of dynamic initiation and propagation toughness of rock using an experimental-numerical-analytical method [J]. Engineering Fracture Mechanics, 2015, 141: 78–94. DOI: 10.1016/j.engfracmech.2015.04.025. [17] GAO G, HUANG S, XIA K, et al. Application of digital image correlation (DIC) in dynamic notched semi-circular bend (NSCB) tests [J]. Experimental Mechanics, 2015, 55(1): 95–104. DOI: 10.1007/s11340-014-9863-5. [18] 李地元, 成腾蛟, 周韬, 等. 冲击载荷作用下含孔洞大理岩动态力学破坏特性试验研究 [J]. 岩石力学与工程学报, 2015, 34(2): 249–260. DOI: 10.13722/j.cnki.jrme.2015.02.004.LI D Y, CHENG T J, ZHOU T, et al. Experimental study of the dynamic strength and fracturing characteristics of marble specimens with a single hole under impact loading [J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(2): 249–260. DOI: 10.13722/j.cnki.jrme.2015.02.004. [19] 郭东明, 刘康, 杨仁树, 等. 动静荷载对邻近巷道裂纹缺陷扰动的模拟实验 [J]. 爆炸与冲击, 2016, 36(3): 297–304. DOI: 10.11883/1001-1455(2016)03-0297-08.GUO D M, LIU K, YANG R S, et al. Simulated experiment of disturbance effect on crack defects of adjacent tunnel under dynamic and static load [J]. Explosion and Shock Waves, 2016, 36(3): 297–304. DOI: 10.11883/1001-1455(2016)03-0297-08. [20] 王蒙, 朱哲明, 王雄. 冲击荷载作用下的Ⅰ/Ⅱ复合型裂纹扩展规律研究 [J]. 岩石力学与工程学报, 2016, 35(7): 1323–1332. DOI: 10.13722/j.cnki.jrme.2015.1260.WANG M, ZHU Z M, WANG X. The growth of mixed-mode Ⅰ/Ⅱ crack under impacting loads [J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(7): 1323–1332. DOI: 10.13722/j.cnki.jrme.2015.1260. [21] 邓帅, 朱哲明, 王磊, 等. 原岩应力对裂纹动态断裂行为的影响规律研究 [J]. 岩石力学与工程学报, 2019, 38(10): 1989–1999. DOI: 10.13722/j.cnki.jrme.2019.0347.DENG S, ZHU Z M, WANG L, et al. Study on the influence of in-situ stresses on dynamic fracture behaviors of cracks [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(10): 1989–1999. DOI: 10.13722/j.cnki.jrme.2019.0347. [22] 万端莹, 朱哲明, 刘瑞峰, 等. 基于RPC试件的爆炸应力波作用下Ⅰ型裂纹扩展行为的研究 [J]. 岩石力学与工程学报, 2019, 38(12): 2478–2490. DOI: 10.13722/j.cnki.jrme.2019.0573.WAN D Y, ZHU Z M, LIU R F, et al. Study of propagation behaviors of mode Ⅰ cracks under blasting stress wave based on RPC specimens [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(12): 2478–2490. DOI: 10.13722/j.cnki.jrme.2019.0573. [23] ZHANG Q B, ZHAO J. Quasi-static and dynamic fracture behaviour of rock materials: phenomena and mechanisms [J]. International Journal of Fracture, 2014, 189(1): 1–32. DOI: 10.1007/s10704-014-9959-z. [24] ZHOU L, ZHU Z M, DONG Y Q, et al. Study of the fracture behavior of mode I and mixed mode Ⅰ/Ⅱ cracks in tunnel under impact loads [J]. Tunnelling and Underground Space Technology, 2019, 84: 11–21. DOI: 10.1016/j.tust.2018.10.018. [25] 李夕兵. 岩石动力学基础与应用[M]. 北京: 科学出版社, 2014: 1-66. [26] JU M H, LI J C, YAO Q L, et al. Rate effect on crack propagation measurement results with crack propagation gauge, digital image correlation, and visual methods [J]. Engineering Fracture Mechanics, 2019, 219: 106537. DOI: 10.1016/j.engfracmech.2019.106537. [27] WU Q H, WENG L, ZHAO Y L, et al. On the tensile mechanical characteristics of fine-grained granite after heating/cooling treatments with different cooling rates [J]. Engineering Geology, 2019, 253: 94–110. DOI: 10.1016/j.enggeo.2019.03.014. [28] 谢和平. 分形-岩石力学导论[M]. 北京: 科学出版社, 1996: 168-261. [29] WONG L N Y, LI H Q. Numerical study on coalescence of two pre-existing coplanar flaws in rock [J]. International Journal of Solids and Structures, 2013, 50(22–23): 3685–3706. DOI: 10.1016/j.ijsolstr.2013.07.010. [30] HE C L, YANG J. Experimental and numerical investigations of dynamic failure process in rock under blast loading [J]. Tunnelling and Underground Space Technology, 2019, 83: 552–564. DOI: 10.1016/j.tust.2018.08.047. [31] JIANG H X, DU C L, LIU Z H. Theoretical and numerical investigation on rock fragmentation under high-pressure water-jet impact [J]. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 2017, 41(3): 305–315. DOI: 10.1007/s40996-017-0065-0. [32] JIANG H X, DU C L, LIU S Y, et al. Numerical simulation of rock fragmentation under the impact load of water jet [J]. Shock and Vibration, 2014, 2014: 219489. DOI: 10.1155/2014/219489. -

下载:

下载: