Explosion hazard in the concentrated ventilation tube for a group of diesel tanks and its suppression technologies

-

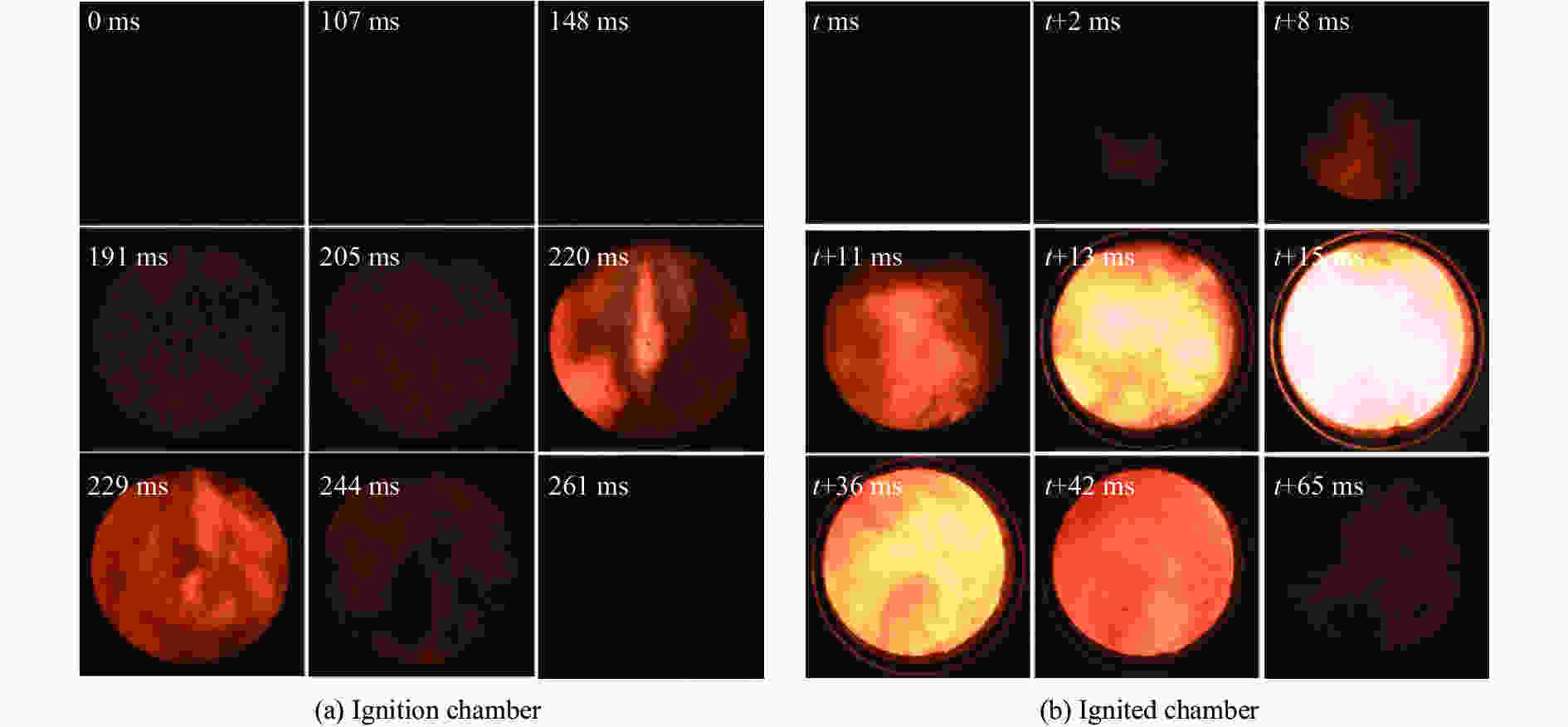

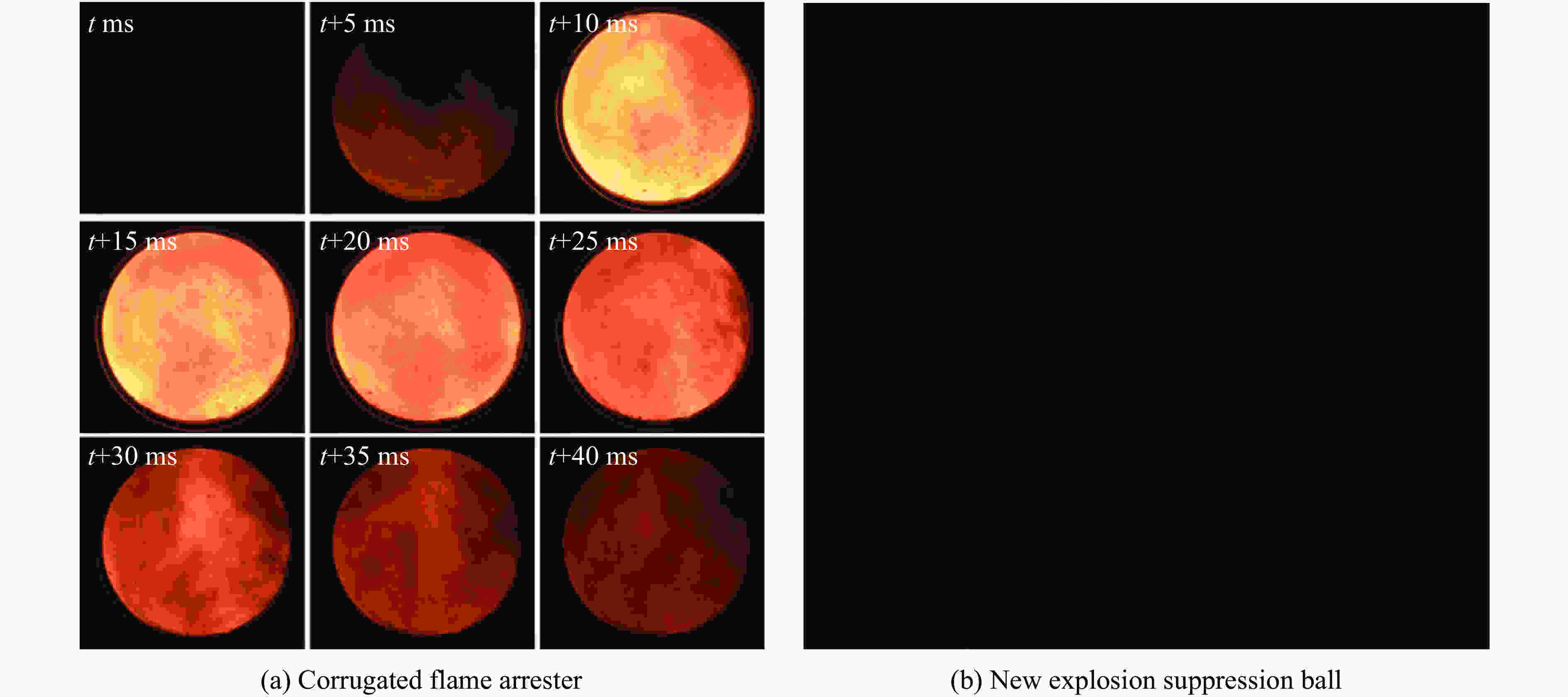

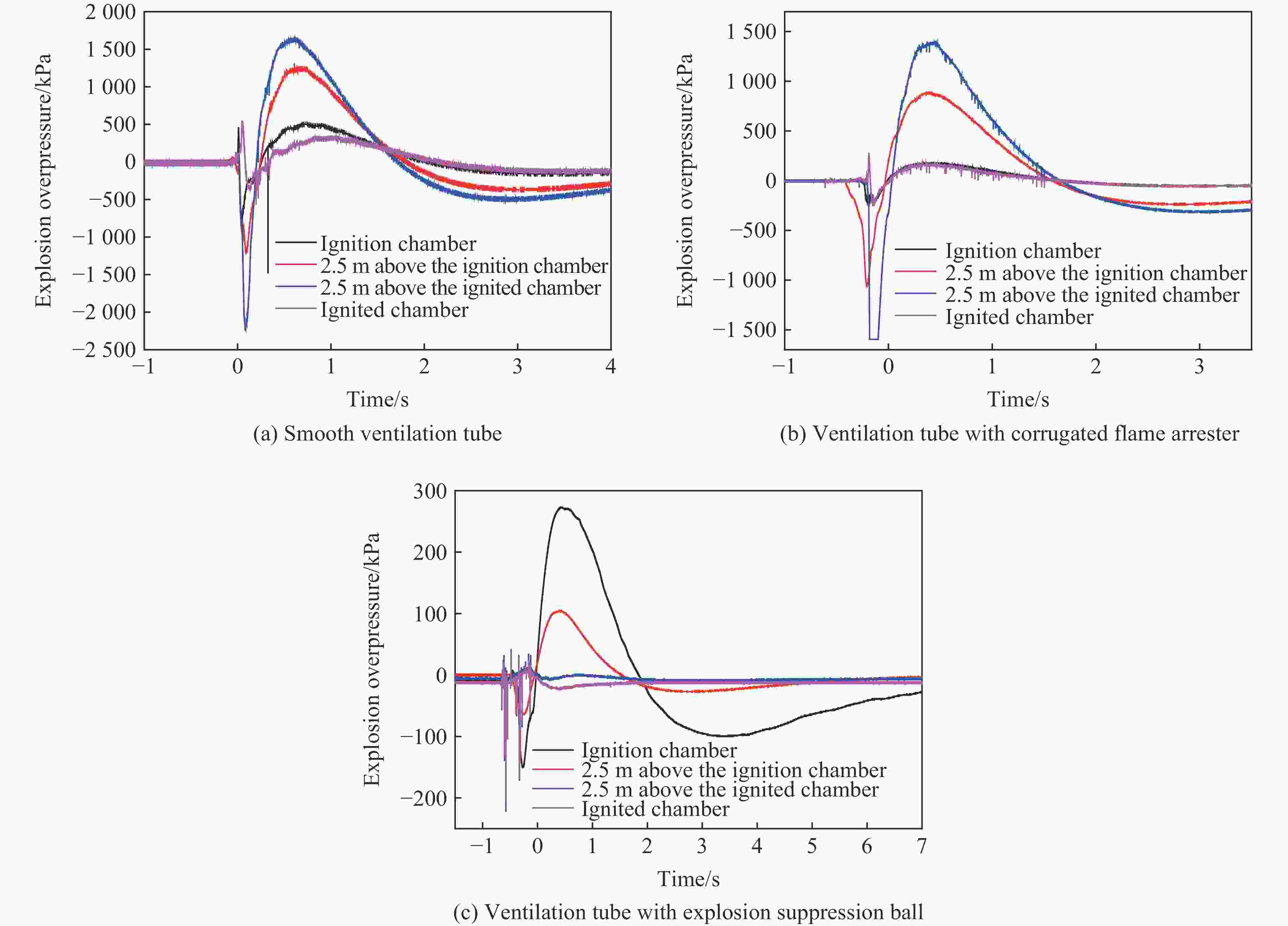

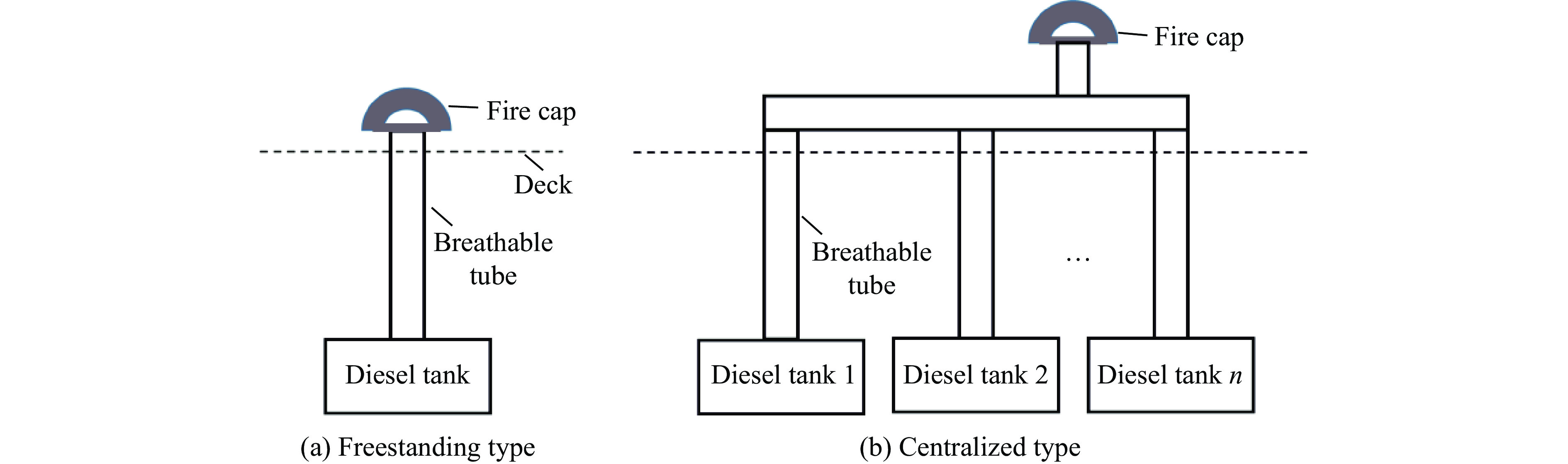

摘要: 对常温常压下柴油舱组集中透气管中柴油蒸汽的燃爆危险性以及阻隔防爆技术的抑爆效能开展了实验研究。利用nac HX-3高速相机和CY-YD-205压力传感器记录燃爆传播过程和爆炸超压,阻隔防爆装置分别采用新型抑爆小球和普通波纹型阻火器。结果表明:常温常压下,一旦柴油油舱发生爆炸,爆炸火球可以通过透气管传播到相邻油舱,并引起二次爆炸,具有较大的危险性;普通波纹型阻火器在爆炸过程中阻火失效,而新型抑爆小球具有较好的抑爆效果;相对于光滑透气管工况,在点火舱上方安装抑爆小球后,被点火舱内的最大爆炸超压可以显著地从552.5 kPa降低到35.0 kPa;抑爆小球的中空多孔结构是其阻隔防爆的关键,多孔结构不仅可以增大比表面积、扩大热损失,而且还可以有效地分割削弱反应面。Abstract: In this study, the explosion hazard and suppression technology were investigated in a concentrated ventilation tube filled with diesel fuel under room temperature and environmental pressure. A high-speed camera (model: nac HX-3) and pressure sensors (model: CY-YD-205) were used to record the flame picture and explosion overpressure. New explosion suppression balls and an ordinary corrugated flame arrester were employed as explosion suppression apparatuses. The results indicate that the explosion flame can propagate into the adjacent fuel tank through the ventilation tube under room temperature and environmental pressure, causing the second explosion. In addition, the ordinary corrugated flame arrester fails to suppress explosion, and the new explosion suppression balls have better anti-explosion effect. Compared to the case of a smooth ventilation tube, the maximum explosion overpressure can be significantly decreased from about 552.5 kPa to 35.0 kPa in the ignited chamber after the new explosion suppression balls are introduced into the tube. The superior explosion suppression effect of the explosion suppression balls can be due to the hollow porous structures. The porous structures not only can significantly increase the specific surface area and heat loss, but also can effectively segment and weaken the reaction surface.

-

Key words:

- diesel /

- ventilation tube /

- deflagration /

- explosion suppression ball

-

表 1 实验工况

Table 1. Experimental conditions

实验工况 测试参数 空白对照实验 高速图像、爆炸超压 普通波纹型阻火器阻火效果测试 新型抑爆小球阻隔防爆效果测试 -

[1] WANG H Z, LU C B, AN G J, et al. Assessment method of liquid fuel field explosion hazardousness [J]. Procedia Engineering, 2014, 84: 394–401. DOI: 10.1016/j.proeng.2014.10.449. [2] LU C B, AN G J, XIONG C H, et al. Progress on fire and explosion suppression technologies for light petroleum fuel [J]. Procedia Engineering, 2014, 84: 384–393. DOI: 10.1016/j.proeng.2014.10.448. [3] 黄勇, 解立峰, 鲁长波, 等. 安全柴油燃爆性能的静爆试验研究 [J]. 爆破器材, 2015, 44(6): 20–24. DOI: 10.3969/j.issn.1001-8352.2015.06.005.HUANG Y, XIE L F, LU C B, et al. Static experimental for combustion and explosion performances of safety diesel fuel [J]. Explosive Materials, 2015, 44(6): 20–24. DOI: 10.3969/j.issn.1001-8352.2015.06.005. [4] 刘健, 姚箭, 宋述忠, 等. 柴油的烤燃燃爆性能实验 [J]. 爆炸与冲击, 2018, 38(3): 534–540. DOI: 10.11883/bzycj-2016-0291.LIU J, YAO J, SONG S Z, et al. Experimental study on cook-off performance of diesel fuel [J]. Explosion and Shock Waves, 2018, 38(3): 534–540. DOI: 10.11883/bzycj-2016-0291. [5] 黄勇, 解立峰, 鲁长波, 等. 柴油云雾最小点火能量的实验研究 [J]. 高压物理学报, 2015, 29(2): 149–154. DOI: 10.11858/gywlxb.2015.02.010.HUANG Y, XIE L F, LU C B, et al. Experimental study on minimum ignition energy of diesel-air cloud [J]. Chinese Journal of High Pressure Physics, 2015, 29(2): 149–154. DOI: 10.11858/gywlxb.2015.02.010. [6] 罗琳, 解立峰, 韩志伟, 等. 柴油的抛撒成雾及燃爆特性研究 [J]. 高压物理学报, 2015, 29(3): 213–218. DOI: 10.11858/gywlxb.2015.03.008.LUO L, XIE L F, HAN Z W, et al. Cloud character in explosion dispersion and combustion feature of diesel [J]. Chinese Journal of High Pressure Physics, 2015, 29(3): 213–218. DOI: 10.11858/gywlxb.2015.03.008. [7] 宋刚, 张文铖, 封晓杰, 等. 油箱内部强起爆条件下安全柴油燃爆性能的试验研究 [J]. 爆破器材, 2018, 47(2): 28–32. DOI: 10.3969/j.issn.1001-8352.2018.02.006.SONG G, ZHANG W C, FENG X J, et al. Experimental study on combustion and explosion performance of safe diesel under strong detonation conditions in fuel tank [J]. Explosive Materials, 2018, 47(2): 28–32. DOI: 10.3969/j.issn.1001-8352.2018.02.006. [8] 贾佳, 吴晓伟, 黎昌海. 舰船柴油舱组及其集中透气管内柴油蒸气燃爆数值模拟 [J]. 船海工程, 2018, 47(6): 21–28. DOI: 10.3963/j.issn.1671-7953.2018.06.006.JIA J, WU X W, LI C H. Numerical simulation of diesel evaporation explosion in diesel oil tank set with its centralized venting tube [J]. Ship and Ocean Engineering, 2018, 47(6): 21–28. DOI: 10.3963/j.issn.1671-7953.2018.06.006. [9] NG H D, RADULESCU M I, HIGGINS A J, et al. Numerical investigation of the instability for one-dimensional Chapman-Jouguet detonations with chain-branching kinetics [J]. Combustion Theory and Modelling, 2005, 9(3): 385–401. DOI: 10.1080/13647830500307758. [10] TORO E F. The equations of fluid dynamics [M] // TORO E F. Riemann Solvers and Numerical Methods for Fluid Dynamics. Berlin, Heidelberg: Springer, 2009: 1–40. [11] KIYANDA C B, MORGAN G H, NIKIFORAKIS N, et al. High resolution GPU-based flow simulation of the gaseous methane-oxygen detonation structure [J]. Journal of Visualization, 2015, 18(2): 273–276. DOI: 10.1007/s12650-014-0247-9. [12] MI X C, HIGGINS A J, NG H D, et al. Propagation of gaseous detonation waves in a spatially inhomogeneous reactive medium [J]. Physical Review Fluids, 2017, 2(5): 053201. DOI: 10.1103/PhysRevFluids.2.053201. -

下载:

下载: