Experimental study on a cabin filled with shear-thickening fluid penetrated by projectiles

-

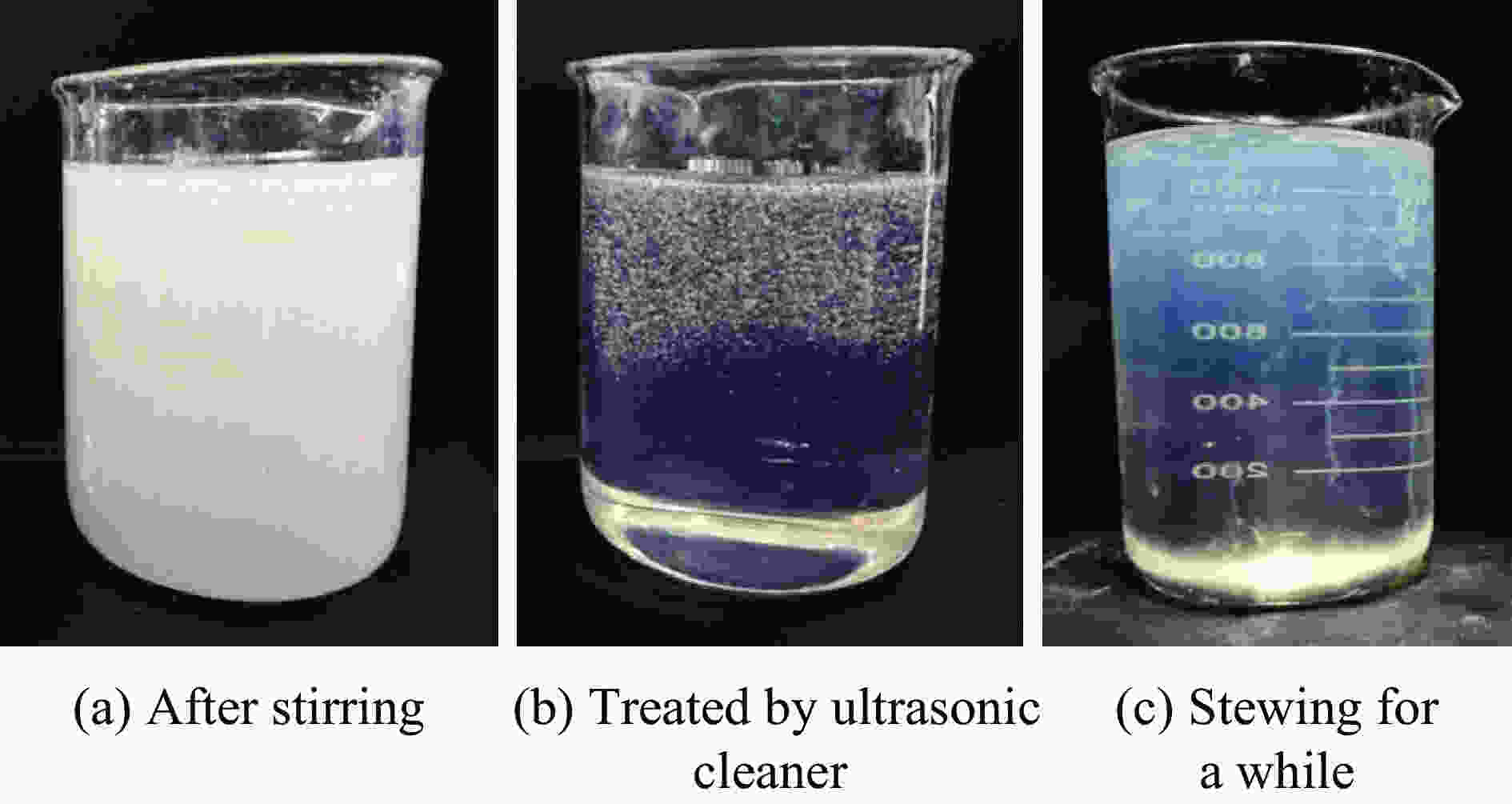

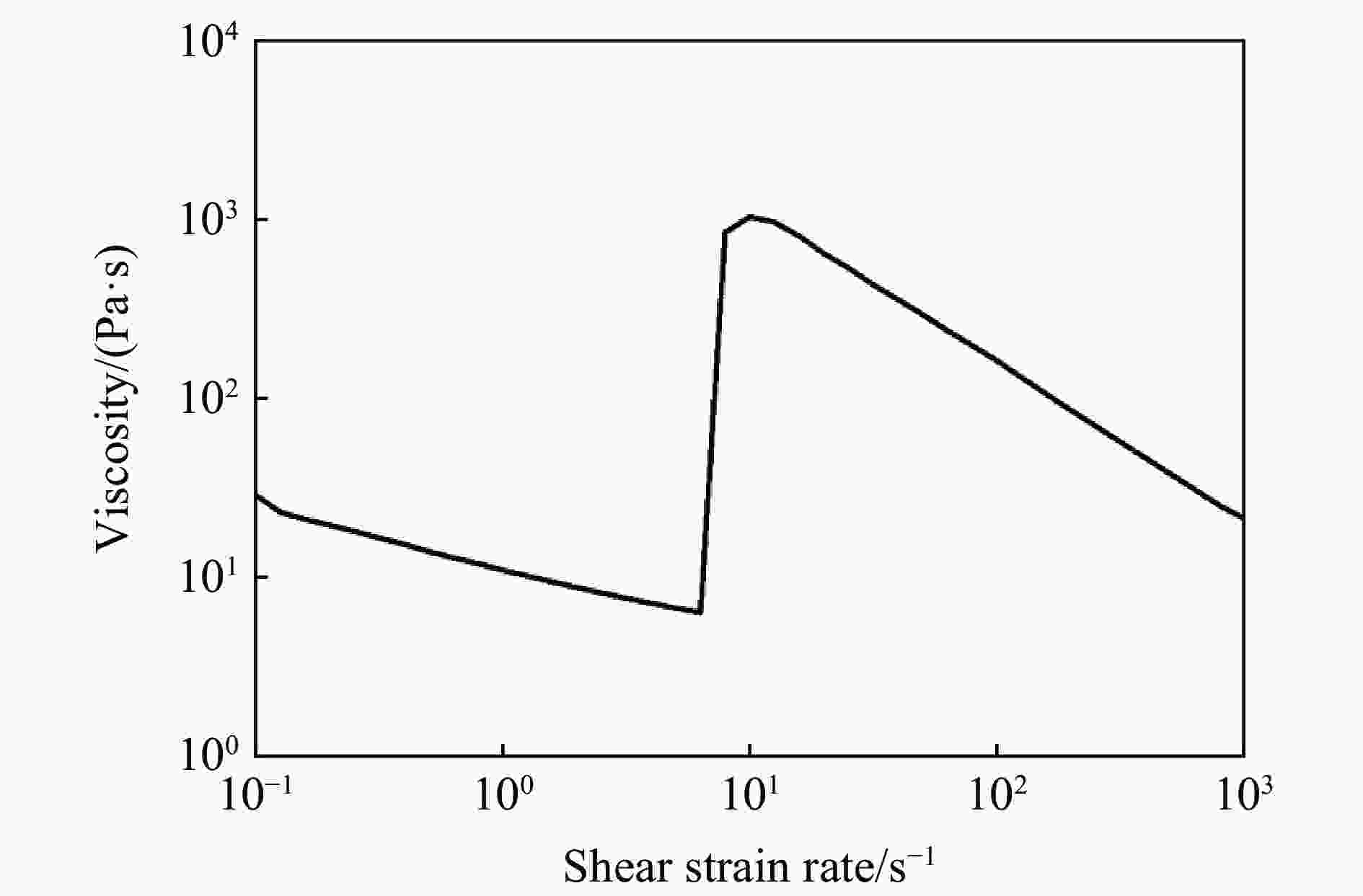

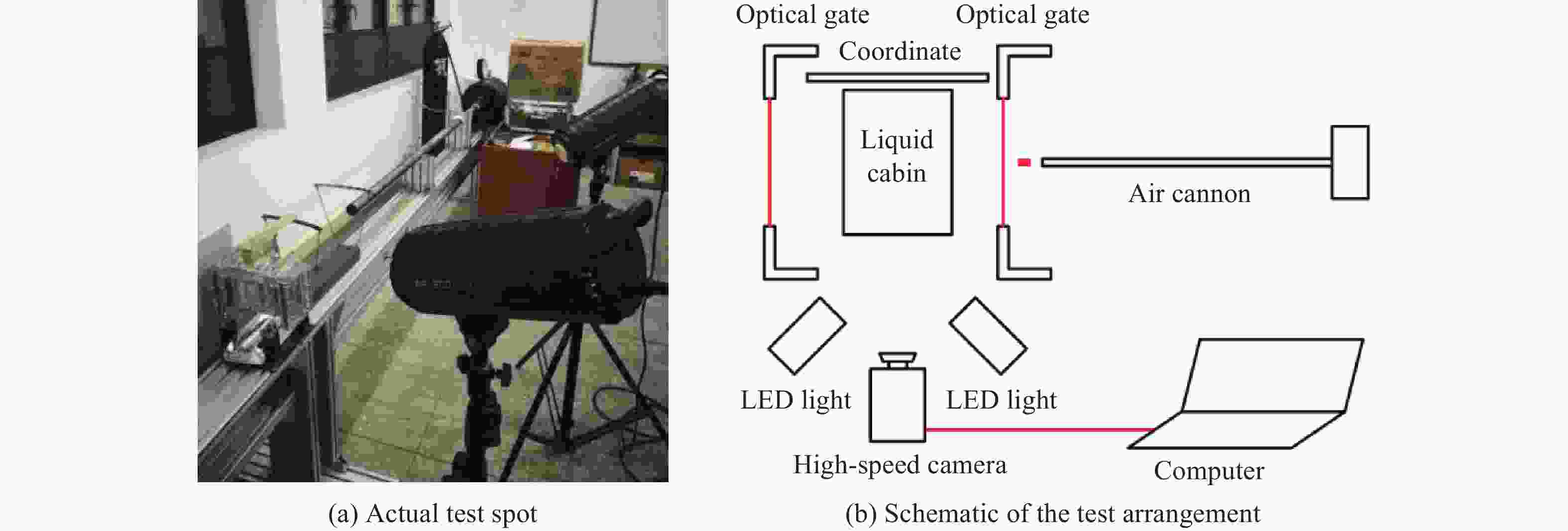

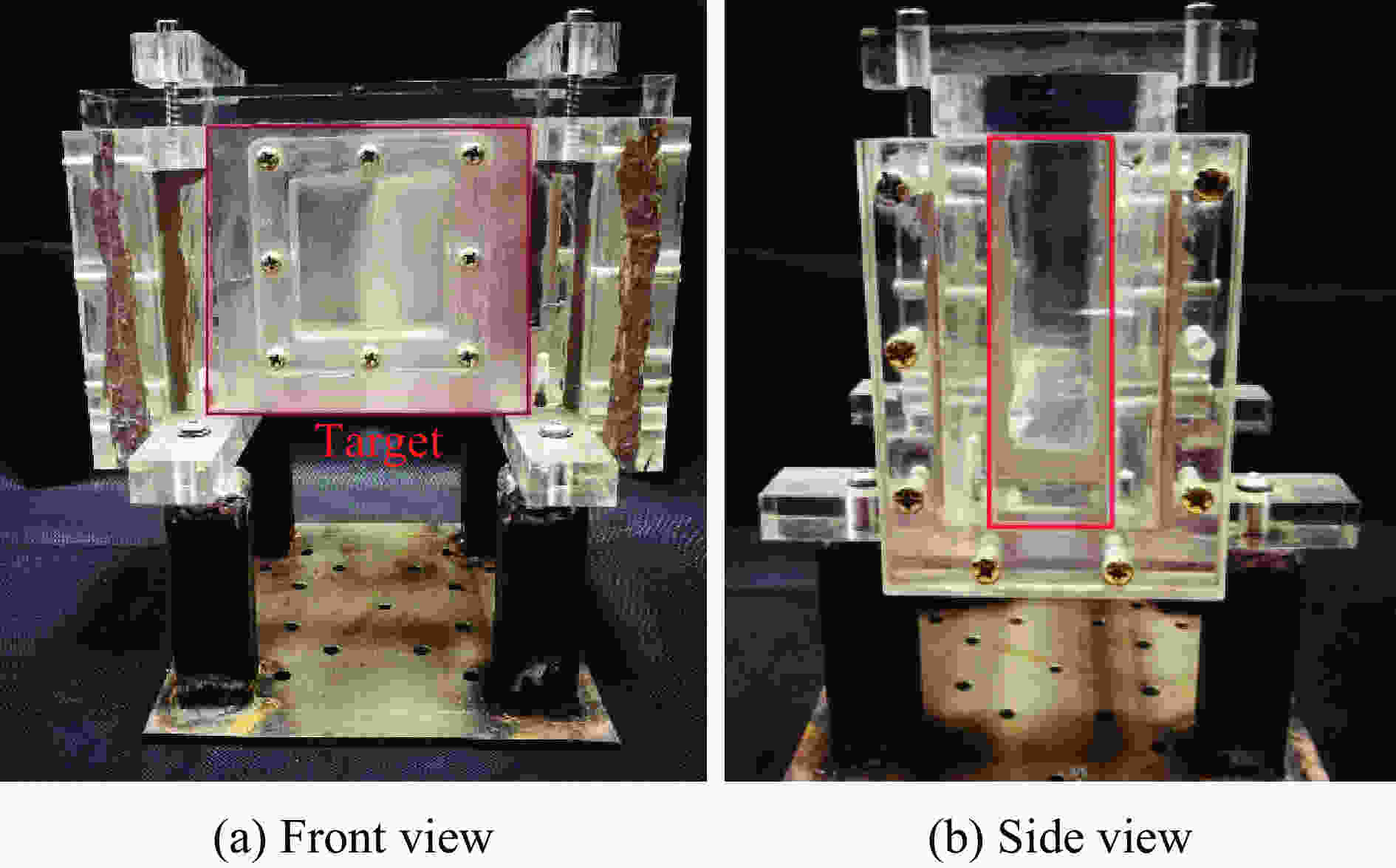

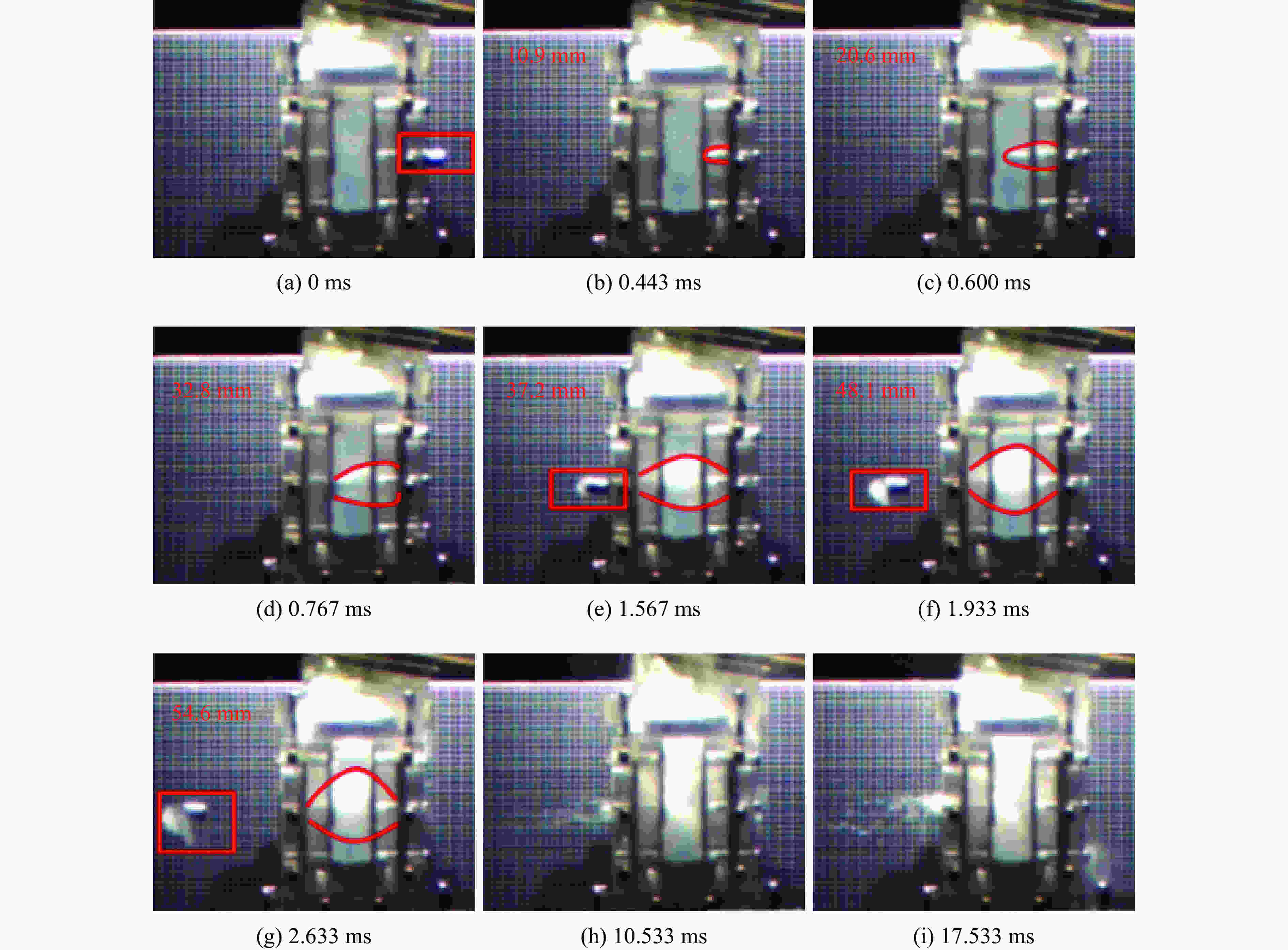

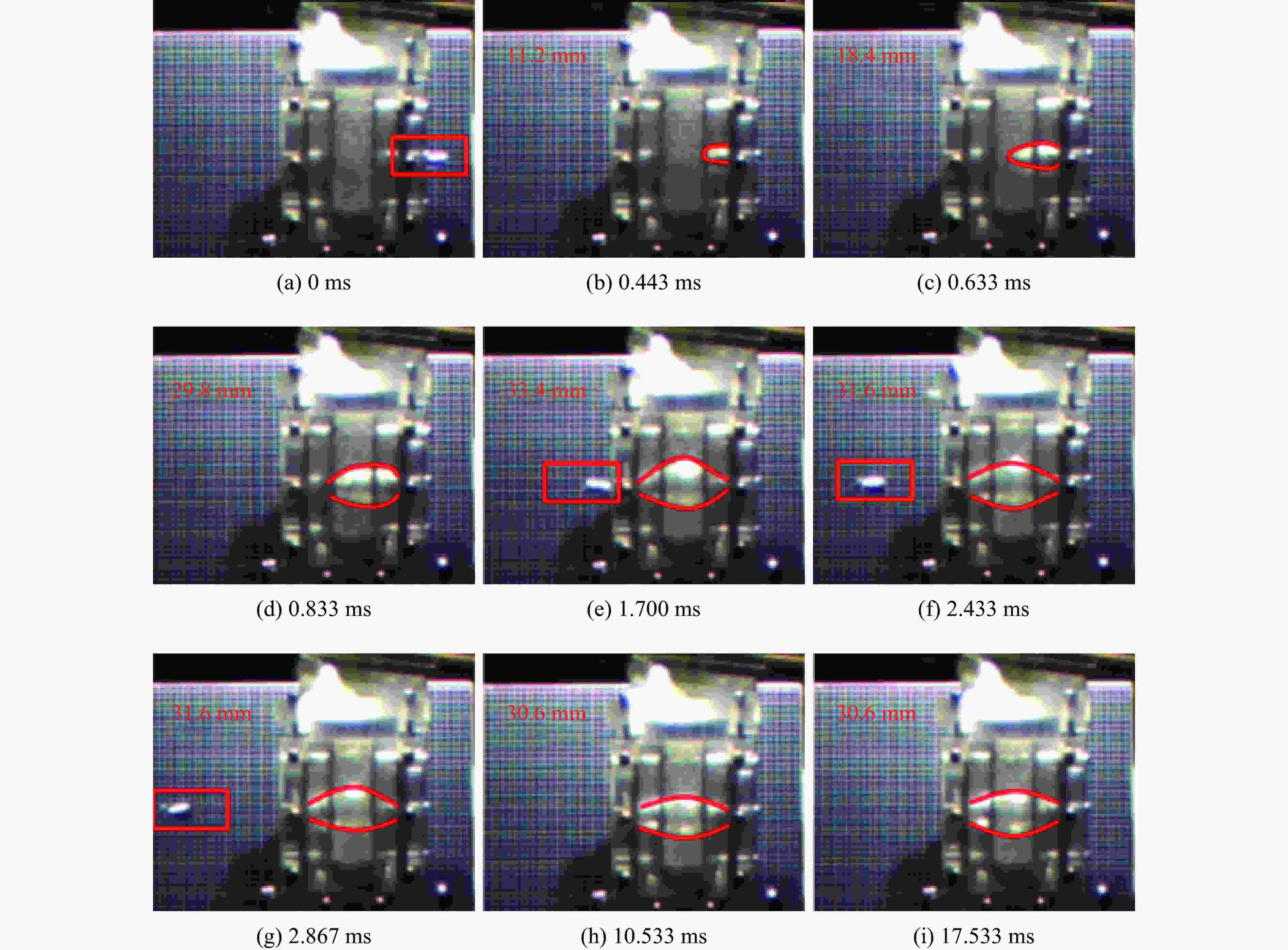

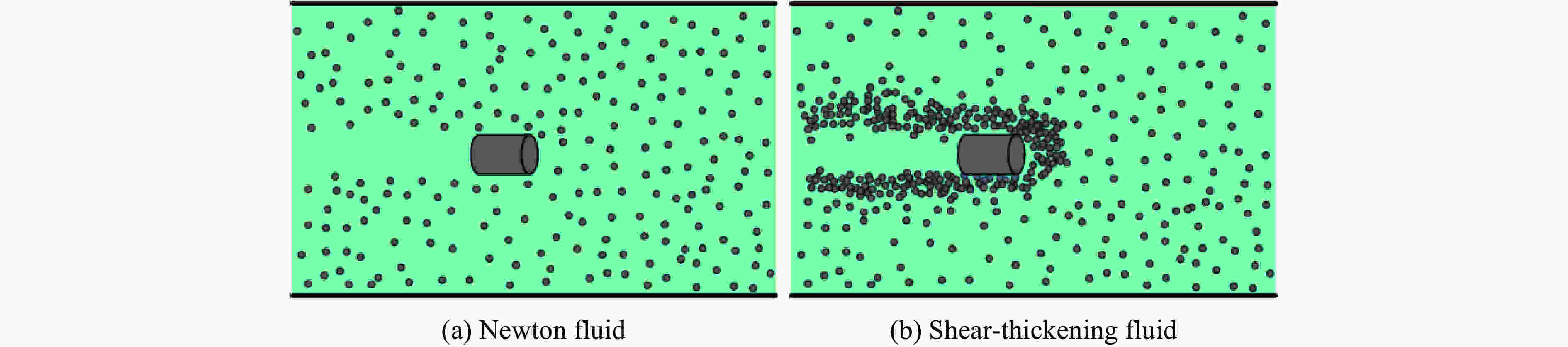

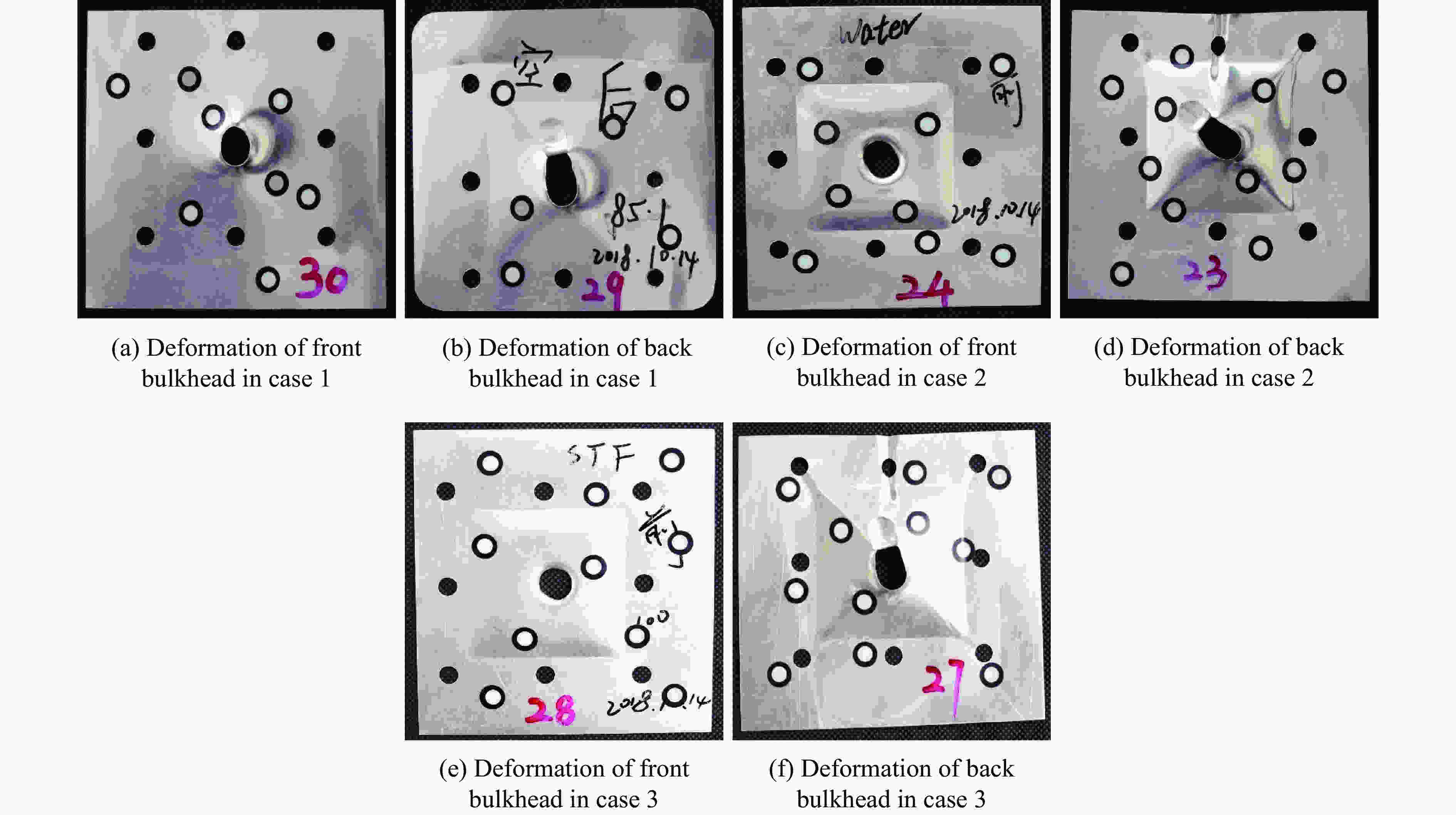

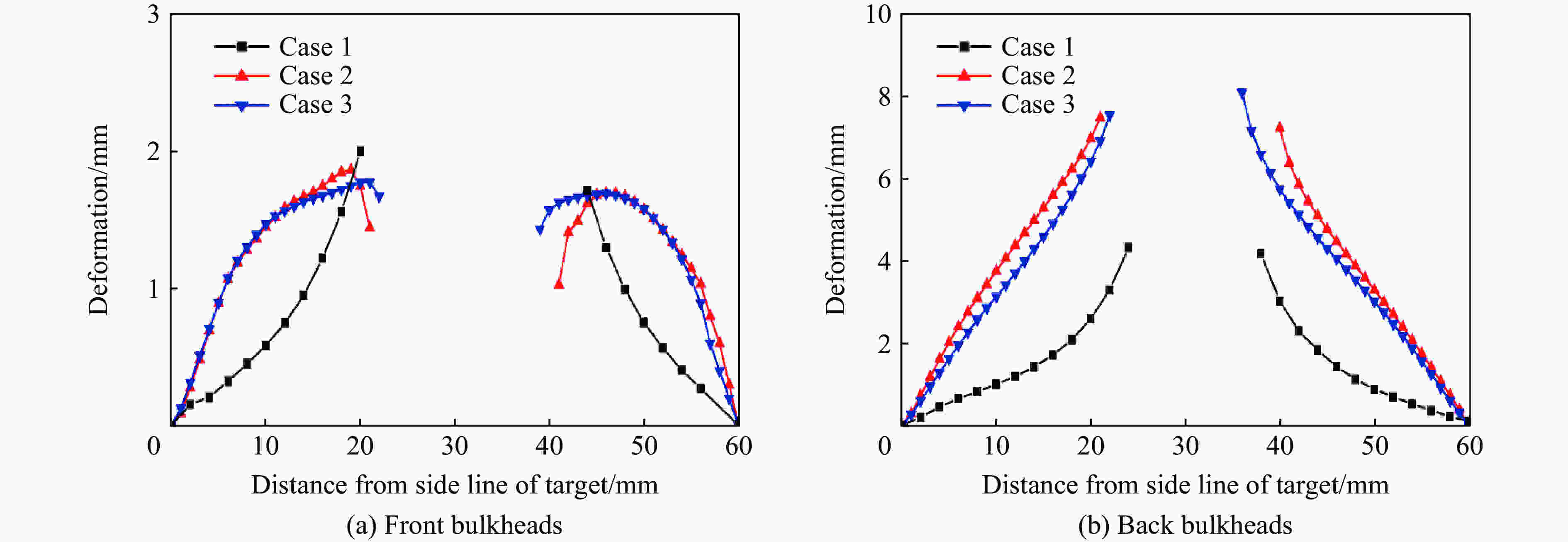

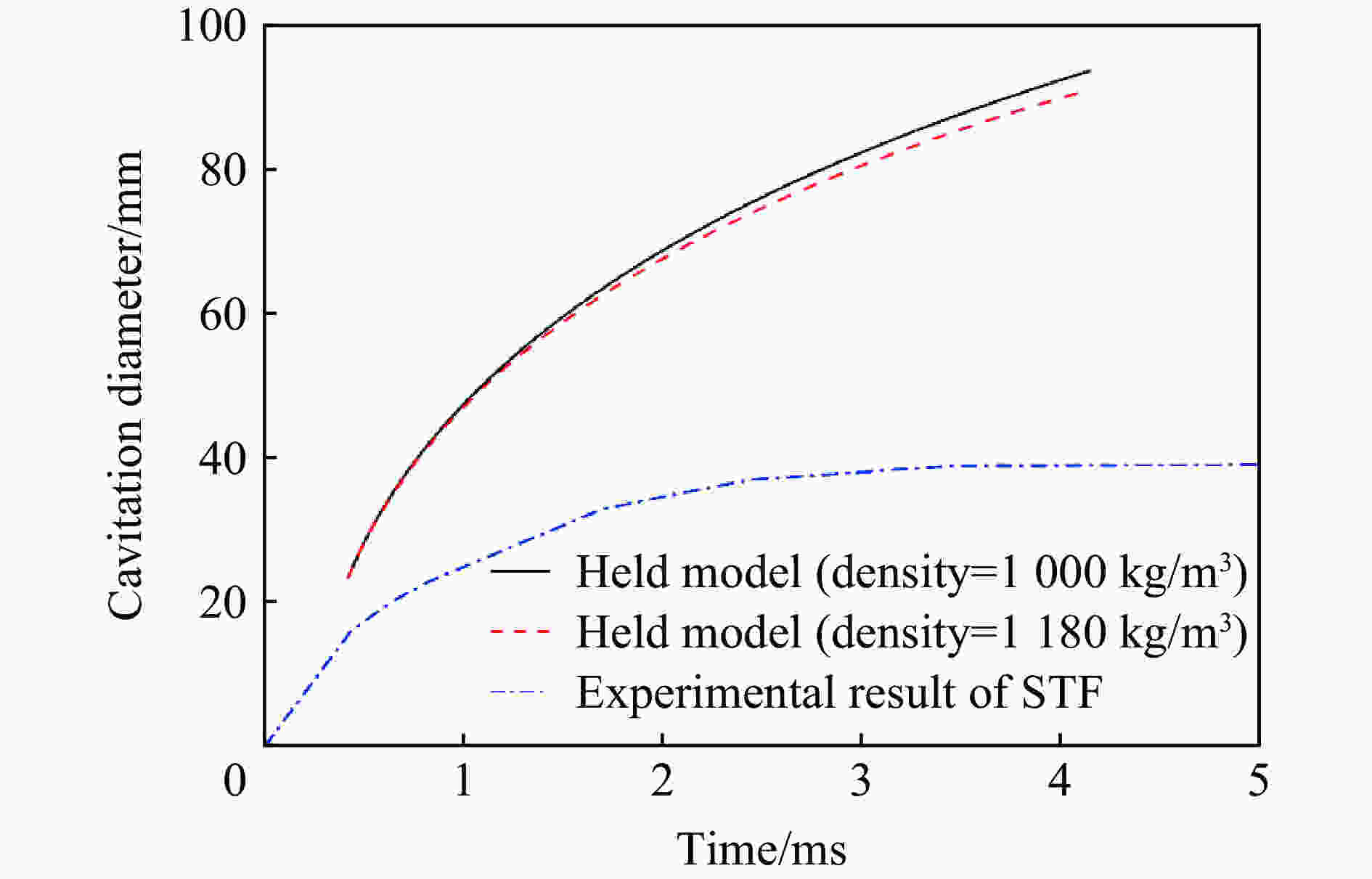

摘要: 为研究剪切增稠液体(shear-thickening fluid, STF)液舱对弹体的防护性能,制备特定规格剪切增稠液体,并开展弹体侵彻剪切增稠液舱实验研究。实验中采用高速相机记录液舱侵彻过程中空泡的演化情况,并测试得到了弹体的剩余弹速以及前后靶板变形数据。实验结果显示,剪切增稠液体可有效抑制液舱侵彻过程中空泡的增长,从而降低液舱结构的损伤程度。结合空泡扩展理论模型,并考虑液体密度以及黏度变化对空泡增长的影响,验证了剪切增稠液体在高速冲击下产生的局部密度增大以及固化现象是抑制空泡扩展的主要原因。此外,剪切增稠液体对弹体速度的衰减作用明显,且相同初始弹速下,剪切增稠液体液舱前后靶板变形明显小于水体液舱。将剪切增稠液体填充于舰船液舱防护结构,可显著提高液舱结构的防护性能。Abstract: Experimental tests were designed to study the protection performance of the shear-thickening fluid (STF) cabin penetrated by projectiles. The penetration process and the development of cavitation in fluid cabins during the tests were captured by a high-speed camera. The residual velocities of the projectiles and the deformation of the front and rear targets of the fluid cabins were obtained as well. According to the cavitation images taken by the camera, the cavitation diameter of the STF was obviously smaller than that of water. Furthermore, cavitation collapse phenomenon was not found in the STF which shows that the STF has a significant effect in suppressing the evolution of cavitation during the penetration, and therefore decreasing the damage of the structure. A theoretical model for liquid cavitation evolution was used to find out the main factor in the cavitation suppression effect of the STF. On the one hand, the calculated cavitation diameters based on the theoretical model at two different densities were compared with the experimental results. The two densities are the densities of the STF and water, respectively, and the experimental cavitation diameters are much smaller than the calculated diameters, thus excluding the effect of density of liquid. On the other hand, the calculated cavitation diameter was also compared with the experimental data of common Newton liquid in the literature, and the effect of viscosity of liquid was excluded as well. Since both the density and viscosity may not be the main factor of the cavitation suppression effect of the STF, the assumption that the local density increase and curing effect of the STF particles attribute to the cavitation suppression was made. Besides, the STF also has a significant effect in the velocity attenuation of the projectiles and the deformation reduction of the targets. Hence, filling the STF into broadside liquid cabins of ships can significantly improve the protective performance of the structure.

-

Key words:

- shear-thickening fluid /

- fluid cabin /

- penetration /

- projectile /

- residual velocities of projectiles /

- cavitation

-

表 1 剪切增稠液体密度测试结果

Table 1. Tested density of shear-thickening fluid

序号 剪切增稠液体样本质量/g 流体密度/(g·cm−3) 1 5.8 1.16 2 5.9 1.18 3 6.0 1.20 表 2 剪切增稠液体液舱侵彻实验测试结果

Table 2. Results of the penetration experiments on shear-thickening fluid cabins

工况 液舱液体

种类前靶板厚度/

mm后靶板厚度/

mm初始弹速/

(m·s−1)1 空舱 0.5 0.5 96.2 2 水 0.5 0.5 105.0 3 STF 0.5 0.5 105.0 表 3 剪切增稠液舱侵彻实验测试结果

Table 3. Results of the penetration experiments of shear-thickening fluid cabin

工况 液体种类 前靶板厚度/mm 后靶板厚度/mm 初始弹速/(m·s−1) 剩余弹速/(m·s−1) 弹速衰减/% 1 空舱 0.5 0.5 96.2 85.1 11.5 2 水 0.5 0.5 105.0 53.8 48.8 3 STF 0.5 0.5 105.0 38.2 63.6 -

[1] VARAS D, LÓPEZ-PUENTE J, ZAERA R. Experimental analysis of fluid-filled aluminum tubes subjected to high-velocity impact [J]. International Journal of Impact Engineering, 2009, 36(1): 81–91. DOI: 10.1016/j.ijimpeng.2008.04.006. [2] 孔祥韶, 吴卫国, 刘芳, 等. 舰船舷侧防护液舱对爆炸破片的防御作用研究 [J]. 船舶力学, 2014, 18(8): 996–1004. DOI: 10.3969/j.issn.1007-7294.2014.08.015.KONG X S, WU W G, LIU F, et al. Research on protective effect of guarding fluid cabin under attacking by explosion fragments [J]. Journal of Ship Mechanics, 2014, 18(8): 996–1004. DOI: 10.3969/j.issn.1007-7294.2014.08.015. [3] 徐双喜, 吴卫国, 李晓彬, 等. 舰船舷侧防护液舱舱壁对爆炸破片的防御作用 [J]. 爆炸与冲击, 2010, 30(4): 395–400. DOI: 10.11883/1001-1455(2010)04-0395-06.XU S X, WU W G, LI X B, et al. Protective effect of guarding fluid cabin bulkhead under attacking by explosion fragments [J]. Explosion and Shock Waves, 2010, 30(4): 395–400. DOI: 10.11883/1001-1455(2010)04-0395-06. [4] DISIMILE P J, DAVIS J, TOY N. Mitigation of shock waves within a liquid filled tank [J]. International Journal of Impact Engineering, 2011, 38(2−3): 61–72. DOI: 10.1016/j.ijimpeng.2010.10.006. [5] 孔祥韶, 王旭阳, 徐敬博, 等. 复合防护液舱抗爆效能对比试验研究 [J]. 兵工学报, 2018, 39(12): 2438–2449. DOI: 10.3969/j.issn.1000-1093.2018.12.018.KONG X S, WANG X Y, XU J B, et al. Comparative experimental study of anti-explosion performance of compound protective liquid cabin [J]. Acta Armamentarii, 2018, 39(12): 2438–2449. DOI: 10.3969/j.issn.1000-1093.2018.12.018. [6] HARIS A, LEE H P, TAY T E, et al. Shear thickening fluid impregnated ballistic fabric composites for shock wave mitigation [J]. International Journal of Impact Engineering, 2015, 80: 143–151. DOI: 10.1016/j.ijimpeng.2015.02.008. [7] GUILLOU S, MAKHLOUFI R. Effect of a shear-thickening rheological behaviour on the friction coefficient in a plane channel flow: a study by direct numerical simulation [J]. Journal of Non-Newtonian Fluid Mechanics, 2007, 144(2−3): 73–86. DOI: 10.1016/j.jnnfm.2007.03.008. [8] HOFFMAN R L. Discontinuous and dilatant viscosity behavior in concentrated suspensions: Ⅱ: theory and experimental tests [J]. Journal of Colloid and Interface Science, 1974, 46(3): 491–506. DOI: 10.1016/0021-9797(74)90059-9. [9] HOFFMAN R L. Discontinuous and dilatant viscosity behavior in concentrated suspensions:Ⅰ: observation of a flow instability [J]. Transactions of the Society of Rheology, 1972, 16(1): 155–173. DOI: 10.1122/1.549250. [10] HOFFMAN R L. Explanations for the cause of shear thickening in concentrated colloidal suspensions [J]. Journal of Rheology, 1998, 42(1): 111–123. DOI: 10.1122/1.550884. [11] BARNES H A. Shear-thickening (dilatancy) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids [J]. Journal of Rheology, 1989, 33(2): 329–366. DOI: 10.1122/1.550017. [12] MARANZANO B J, WAGNER N J. The effects of particle size on reversible shear thickening of concentrated colloidal dispersions [J]. The Journal of chemical physics, 2001, 114(23): 10514–10527. DOI: 10.1063/1.1373687. [13] LEE Y S, WETZEL E D, WAGNER N J. The ballistic impact characteristics of Kevlar woven fabrics impregnated with a colloidal shear thickening fluid [J]. Journal of materials science, 2003, 38(13): 2825–2833. DOI: 10.1023/A: 1024424200221. [14] XU Y, CHEN X, WANG Y, et al. Stabbing resistance of body armour panels impregnated with shear thickening fluid [J]. Composite Structures, 2017, 163: 465–473. DOI: 10.1016/j.compstruct.2016.12.056. [15] ASIJA N, CHOUHAN H, GEBREMESKEL S A, et al. Impact response of shear thickening fluid (STF) treated high strength polymer composites: effect of STF intercalation method [J]. Procedia Engineering, 2017, 173: 655–662. DOI: 10.1016/j.proeng.2016.12.133. [16] ZHAO S, ZHANG M Y, REN Y N, et al. Impact resistance of shear thickening fluid (STF)/Kevlar composites for body armor application [J]. Advanced Materials Research, 2014, 834−836: 241–245. DOI: 10.4028/www.scientific.net/AMR.834-836.241. [17] DECKER M J, HALBACH C J, NAM C H, et al. Stab resistance of shear thickening fluid (STF)-treated fabrics [J]. Composites Science and Technology, 2007, 67(3−4): 565–578. DOI: 10.1016/j.compscitech.2006.08.007. [18] LU Z Q, WU L W, GU B H et al. Numerical simulation of the impact behaviors of shear thickening fluid impregnated warp-knitted spacer fabric [J]. Composites Part B: Engineering, 2015, 69: 191–200. DOI: 10.1016/j.compositesb.2014.10.003. [19] PARK Y, KIM Y H, BALUCH A H, et al. Empirical study of the high velocity impact energy absorption characteristics of shear thickening fluid (STF) impregnated Kevlar fabric [J]. International Journal of Impact Engineering, 2014, 72: 67–74. DOI: 10.1016/j.ijimpeng.2014.05.007. [20] PARK Y, KIM Y H, BALUCH A H, et al. Numerical simulation and empirical comparison of the high velocity impact of STF impregnated Kevlar fabric using friction effects [J]. Composite Structures, 2015, 125: 520–529. DOI: 10.1016/j.compstruct.2015.02.041. [21] ZHANG X Z, LI W H, GONG X L. The rheology of shear thickening fluid (STF) and the dynamic performance of an STF-filled damper [J]. Smart Materials and Structures, 2008, 17(3): 035027. DOI: 10.1088/0964-1726/17/3/035027. [22] ZHOU H, YAN L X, JIANG W Q, et al. Shear thickening fluid-based energy-free damper: design and dynamic characteristics [J]. Journal of Intelligent Material Systems and Structures, 2016, 27(2): 208–220. DOI: 10.1177/1045389X14563869. [23] YEH F Y, CHANG K C, CHEN T W, et al. The dynamic performance of a shear thickening fluid viscous damper [J]. Journal of the Chinese Institute of Engineers, 2014, 37(8): 983–994. DOI: 10.1080/02533839.2014.912775. [24] WAITUKAITIS S R, JAEGER H M. Impact-activated solidification of dense suspensions via dynamic jamming fronts [J]. Nature, 2012, 487(7406): 205–209. DOI: 10.1038/nature11187. [25] JIANG W F, GONG X L, XUAN S H, et al. Stress pulse attenuation in shear thickening fluid [J]. Applied Physics Letters, 2013, 102(10): 101901. DOI: 10.1063/1.4795303. [26] CAO S S, CHEN Q, WANG Y P, et al. High strain-rate dynamic mechanical properties of Kevlar fabrics impregnated with shear thickening fluid [J]. Composites Part A: Applied Science and Manufacturing, 2017, 100: 161–169. DOI: 10.1016/j.compositesa.2017.04.015. [27] PETEL O E, HOGAN J D. An investigation of shear thickening fluids using ejecta analysis techniques [J]. International Journal of Impact Engineering, 2016, 93: 39–48. DOI: 10.1016/j.ijimpeng.2016.02.001. [28] PETEL O E, OUELLET S, LOISEAU J, et al. The effect of particle strength on the ballistic resistance of shear thickening fluids [J]. Applied Physics Letters, 2013, 102(6): 064103. DOI: 10.1063/1.4791785. [29] 冯新娅. 剪切增稠流体的动态响应及其在防护结构中的应用[D]. 北京: 北京理工大学, 2014: 45−57.FENG X Y. Dynamic response of shear thickening fluid and its application in protective structures [D]. Beijing: Beijing Institute of Technology, 2014: 45−57. [30] HELD M. Verification of the equation for radial crater growth by shaped charge jet penetration [J]. International Journal of Impact Engineering, 1995, 17(1−3): 387–398. DOI: 10.1016/0734-743X(95)99864-N. [31] SZENDREI T. Analytical model of crater formation by jet impact and its application to calculation of penetration curves and hole profiles [C] // Proceedings of the 7th International Symposium on Ballistics. The Hague, 1983: 575−583. [32] LECYSYN N, BONY-DANDRIEUX A, APRIN L, et al. Experimental study of hydraulic ram effects on a liquid storage tank: analysis of overpressure and cavitation induced by a high-speed projectile [J]. Journal of Hazardous Materials, 2010, 178: 635–643. DOI: 10.1016/j.jhazmat.2010.01.132. [33] 沈晓乐, 朱锡, 侯海量, 等. 高速破片侵彻防护液舱试验研究 [J]. 中国舰船研究, 2011, 6(3): 12–15. DOI: 10.3969/j.issn.1673-3185.2011.03.003.SHEN X L, ZHU X, HOU H L, et al. Experimental study on penetration properties of high velocity fragment into safety liquid cabin [J]. Chinese Journal of Ship Research, 2011, 6(3): 12–15. DOI: 10.3969/j.issn.1673-3185.2011.03.003. -

下载:

下载: