Continuous resistance test method in determining the attitude of flyer plate driven by sliding detonation

-

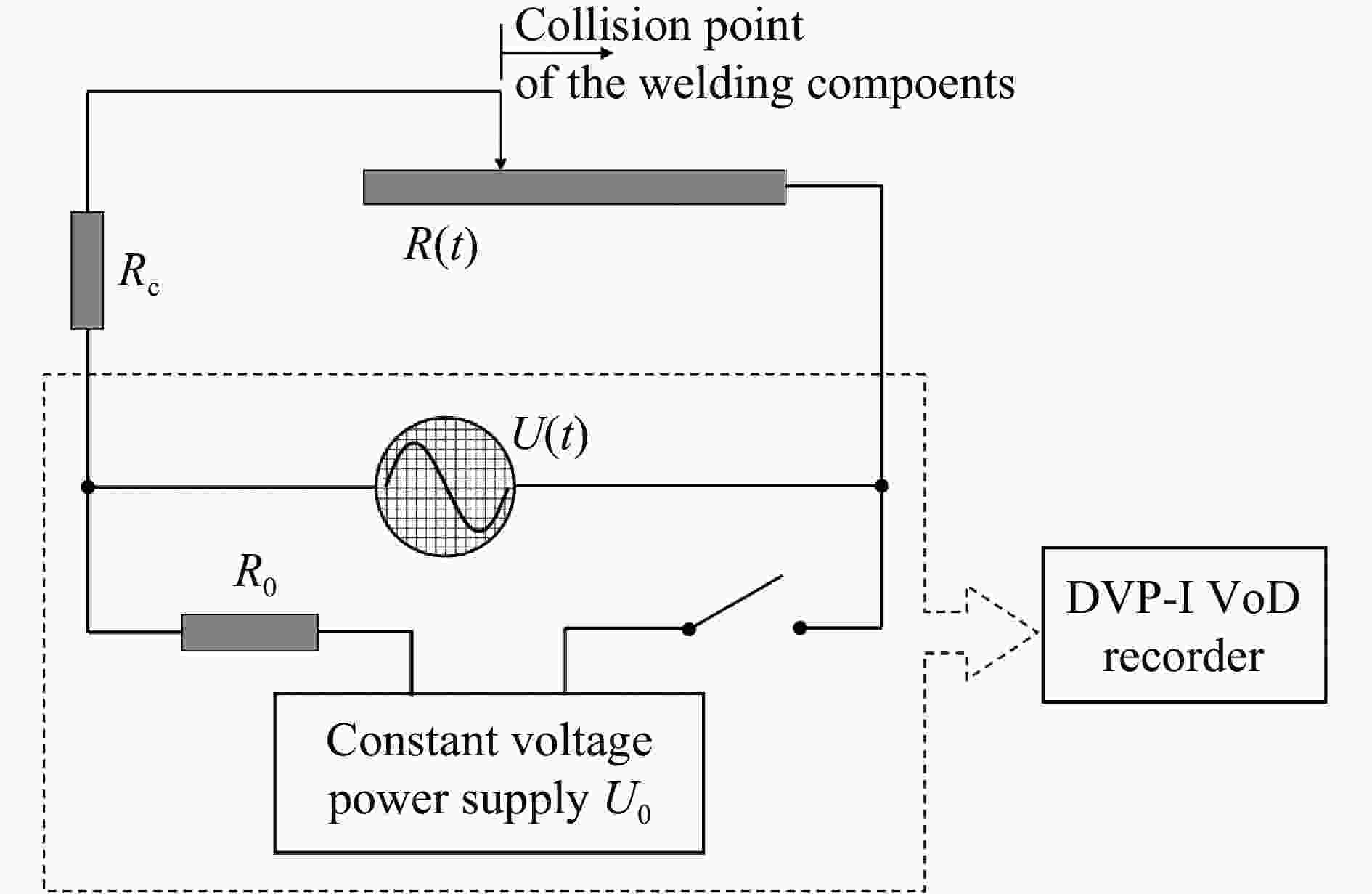

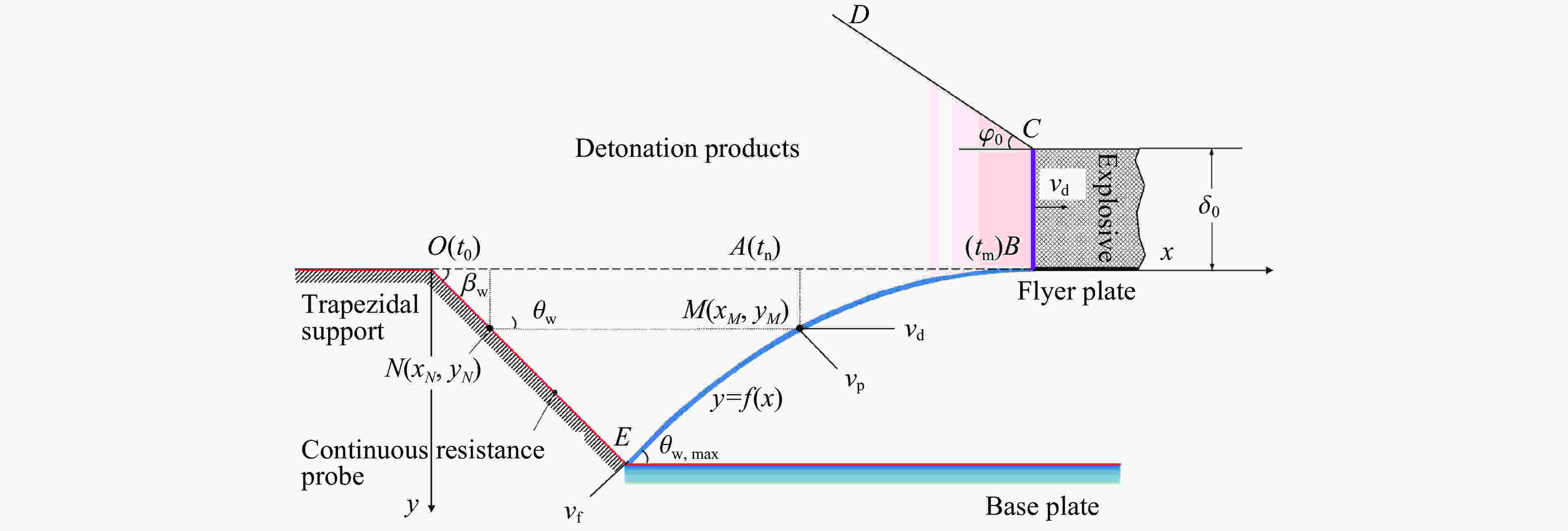

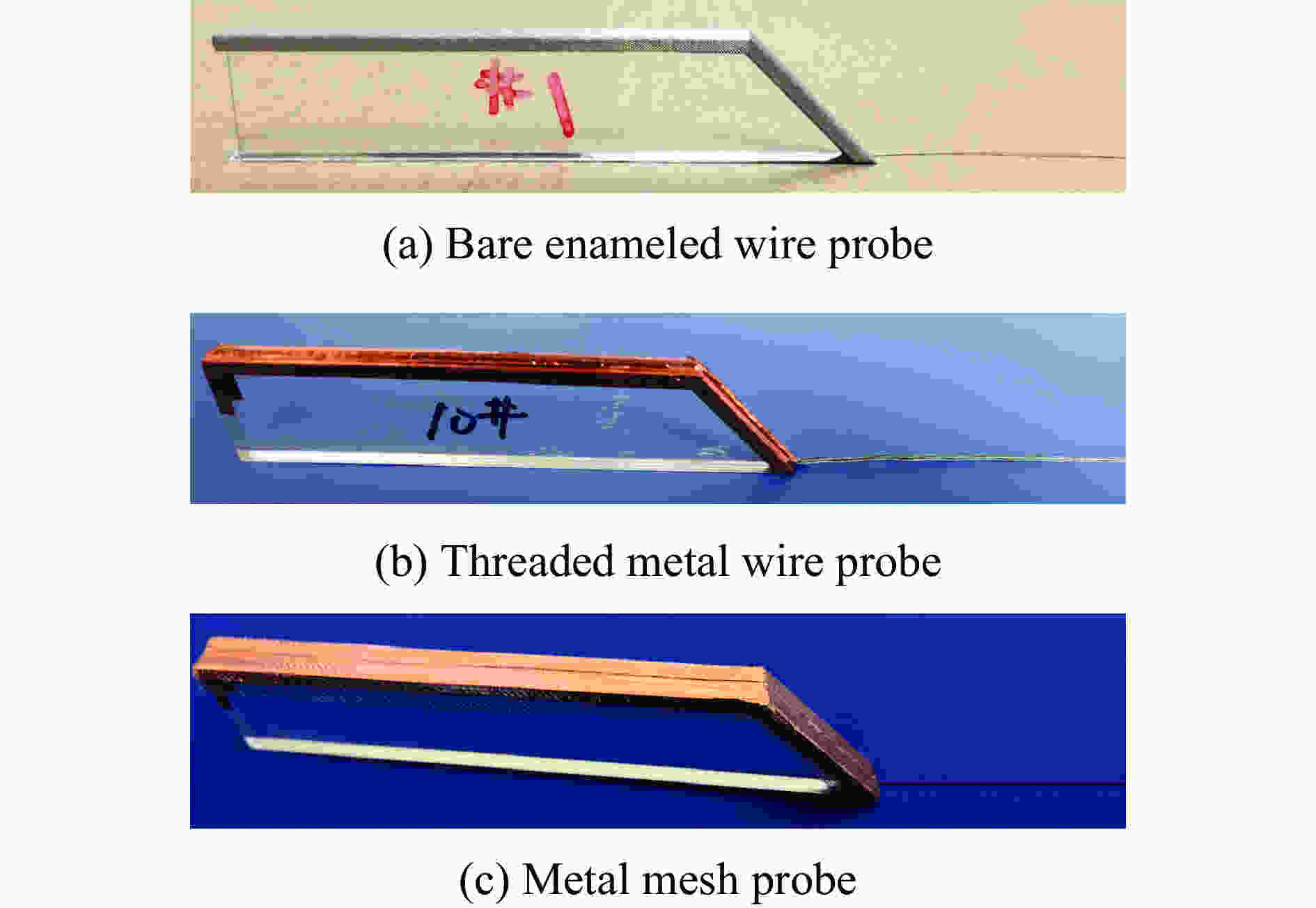

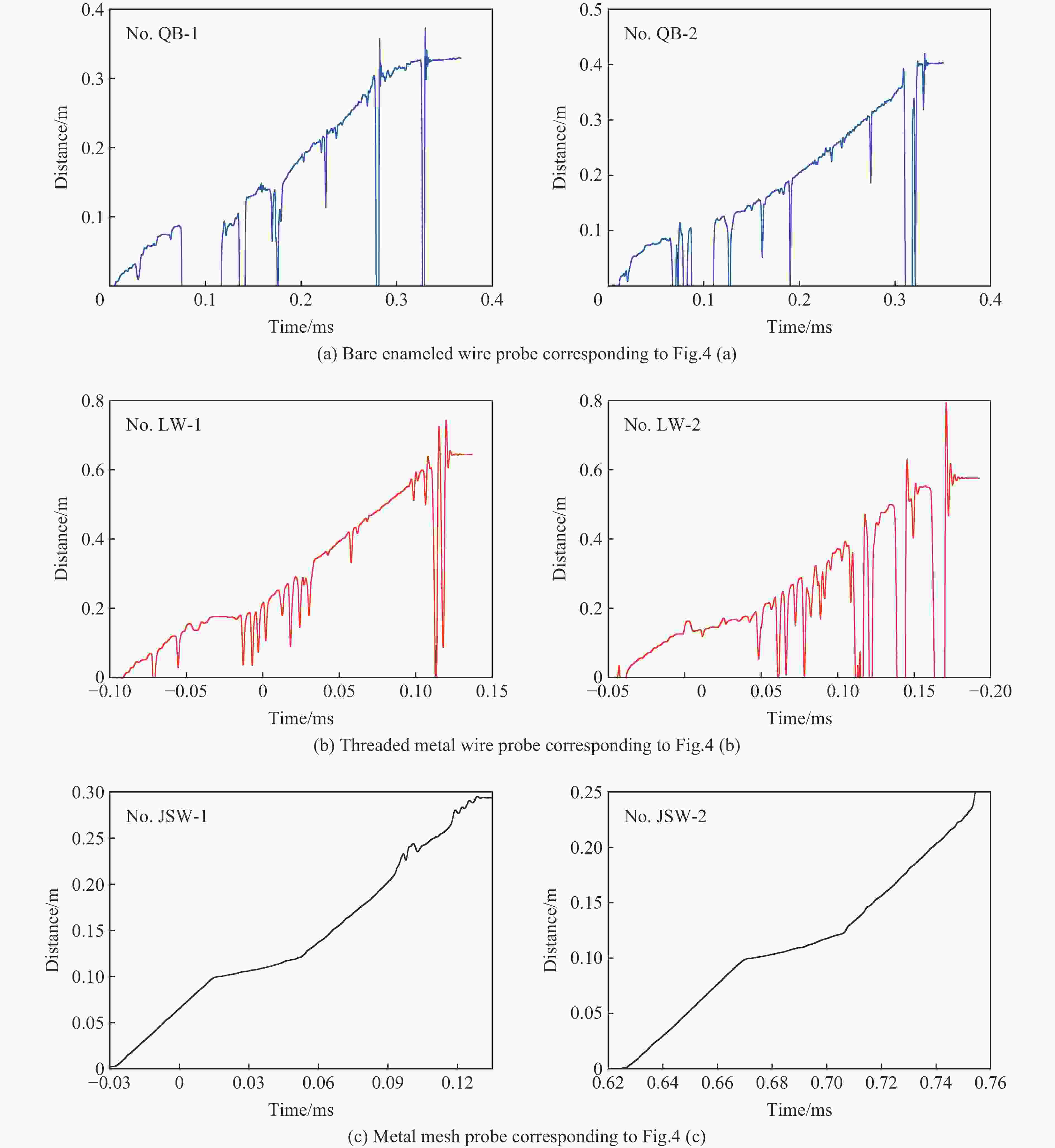

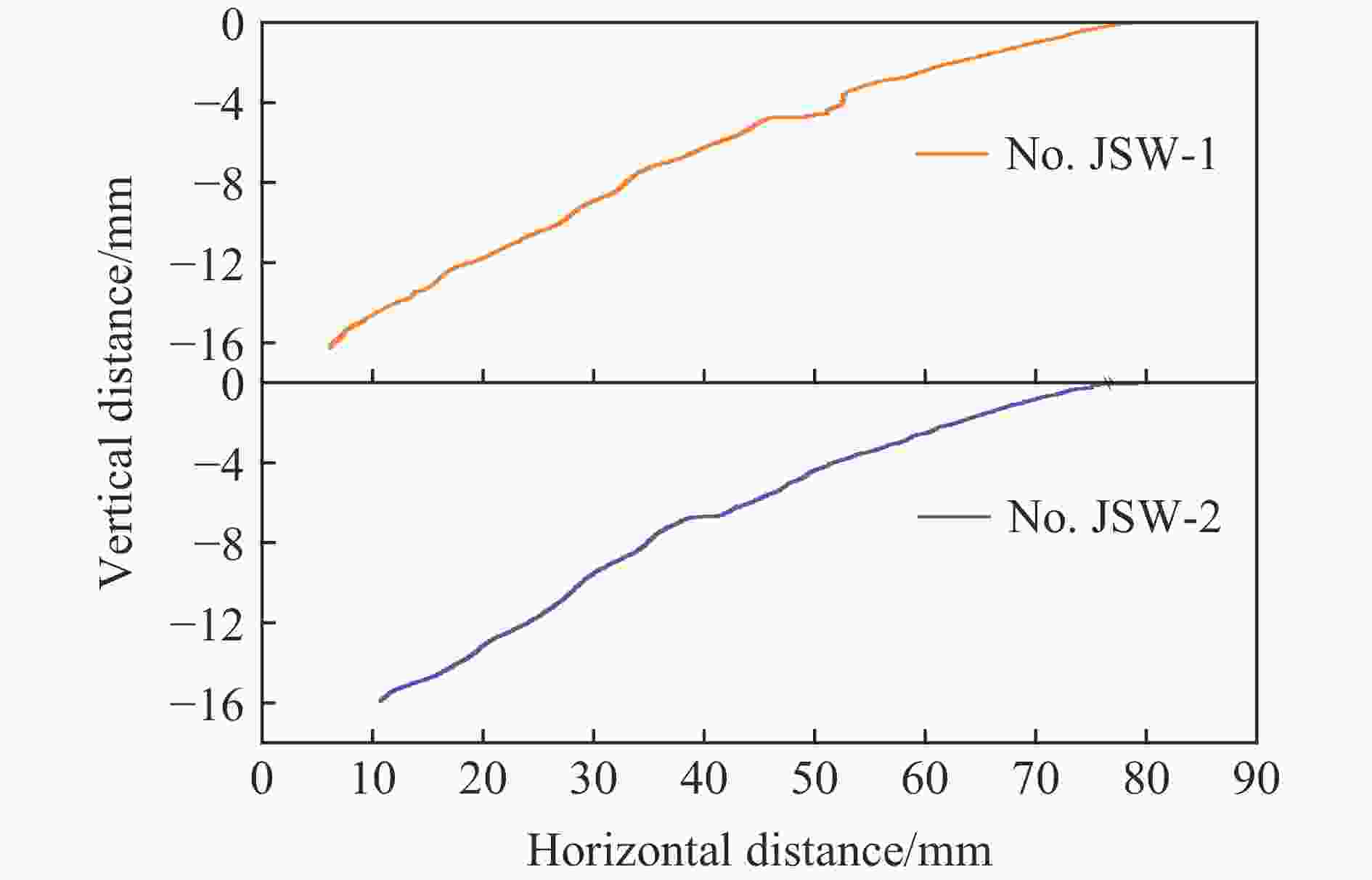

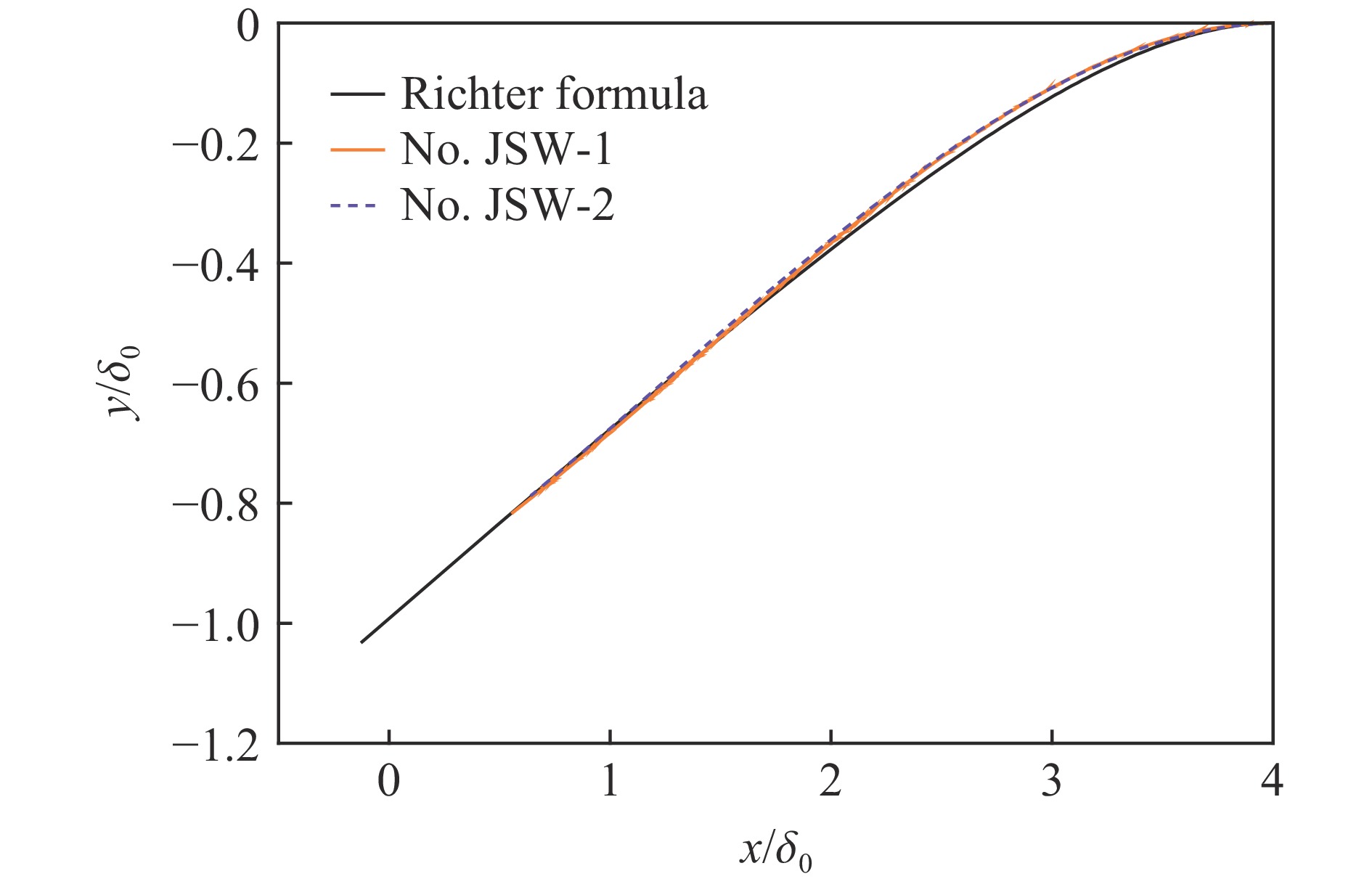

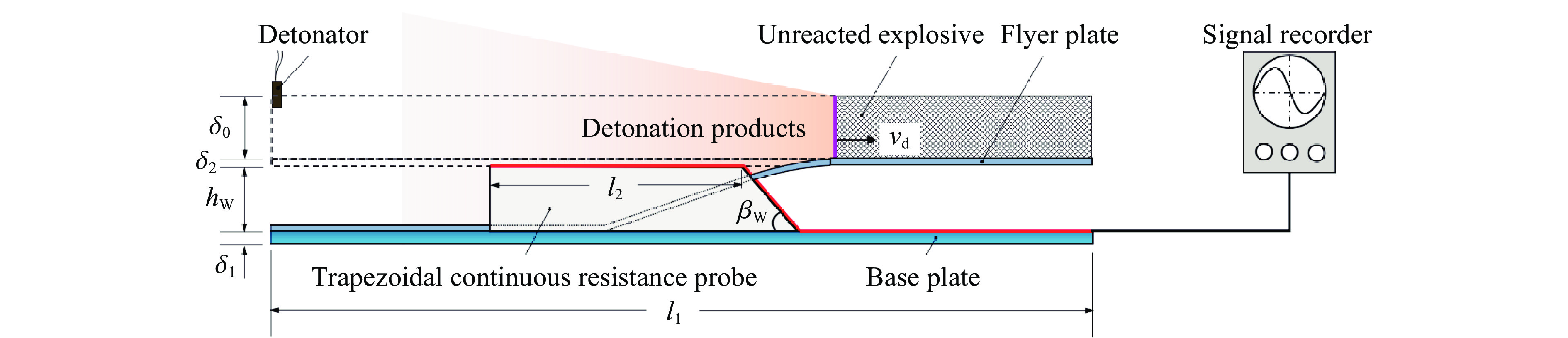

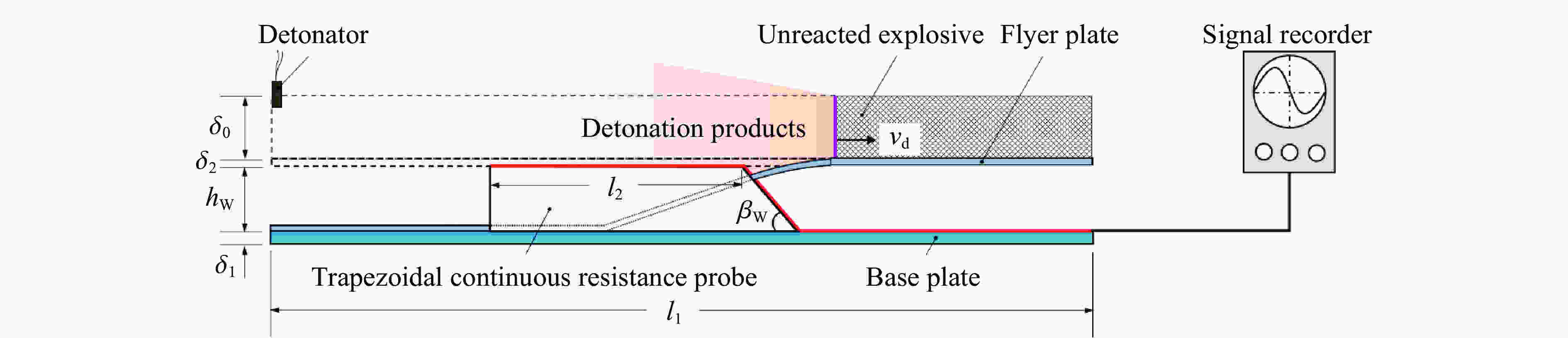

摘要: 飞板运动姿态的测定是爆炸焊接机理研究的基础,针对传统电测方法存在干扰因素多、易产生弯曲波等缺陷,设计了一种适用于野外大当量下爆炸焊接飞板姿态实验的连续电阻测试方法。研制了3种不同结构的梯形支架型连续电阻探针元件,利用有限元程序分析了探针的导通压力和响应时间,在此基础上,对3种探针实施了爆炸焊接实验,实验结果表明:金属丝网型探针元件具有最优的导通效果,各段测试曲线光滑无毛刺。以该探针数据计算获得了待测飞板的运动姿态曲线,并与Richter简化模型下的近似计算公式结果进行了对比,两者基本一致。所述测试方法实现了炸药爆速和飞板变形曲线的连续、可靠和快速测量,为滑移爆轰驱动问题、爆轰产物状态方程等的研究提供了测试方法补充。Abstract: The attitude measurement of a flyer plate is the basis for explosive welding mechanism study. Besides, the key parameters affecting the quality of explosive welding products in the actual explosive processing, including the collision point velocity, the dynamic angle of collision and the impact velocity of the flyer plate, must be determined on the premise by measuring the deformation curve of the flyer plate. Despite the readily available device and convenient operation, the measuring process of the traditional electrical method is easily disturbed by external uncertain factors, and susceptible to bending waves generated by the resistance wire itself. In view of the above shortcomings, a velocity probe-based method was innovatively developed for determining the flyer plate motion of explosive welding in the field. First of all, a velocity probe-based test device, which can effectively suppress the generation and influence of electromagnetic radiation, metal jet and bending wave, was designed and the geometric relationship between the probe data and the flyer plate motion curve was established. After that, three types of trapezoidal velocity probes with different structures were developed, whose conducting pressure and response time were analyzed by the finite element program. Based on the analysis results, two sets of explosive welding experiments were carried out for the three types of probes. The experimental results show that the test performance of the first type (without conducting medium) and the second type (threaded wire type) are not ideal, and there are a lot of data oscillation in the test curves, while the third type of probes (metal mesh type) overcomes the shortcomings of the above two types of probes, whose test curves are smooth without oscillation. The motion attitude curve of the flyer plate was then obtained based on the results of the metal mesh probe, which was in good agreement with the calculation results by Richter's simplified model. The present test method makes it possible to determine detonation velocity and flyer plate attitude continuously, reliably and rapidly, which provides a supplement for the study of the driving problem of sliding detonation and the equation of state of detonation products.

-

表 1 爆炸焊接实验装置尺寸

Table 1. Device parameters of the explosive welding test

长l1/mm 宽b/mm 基板厚δ1/mm 复板厚δ2/mm 架高hw/mm 炸药厚δ0/mm 支架上边长l2/mm 支架厚δ3/mm 斜边倾角βw/(°) 800 200 2 2 20 20 100 6 45 表 2 导通模拟中的主要材料参数

Table 2. Material parameters used in the conduction simulation

部件(材料) 密度ρ/(g·cm−3) 剪切模量G/GPa Johnson-Cook参数 A/GPa B/GPa n C m 螺齿(4340钢) 7.83 77 0.792 0.510 0.26 0.014 1.03 电阻丝/铜管(OFHC铜) 8.96 46 0.090 0.292 0.31 0 1.09 漆包层(聚氨酯) 1.25 3.0 表 3 导通模拟中的主要Grüneisen参数

Table 3. Main Grüneisen parameters in the conduction simulation

部件(材料) 声速c/(km·s−1) 系数γ0 S1 S2 S3 a 螺齿(4340钢) 4.578 1.67 1.330 0 0 0.46 电阻丝/铜管(OFHC铜) 3.940 2.02 1.489 0 0 0.47 漆包层(聚氨酯) 1.933 0.61 3.490 0 0 0 表 4 金属网型连续电阻探针的导通响应时间

Table 4. Response time of the metal mesh velocity probe

外界作用压力pm /GPa 最大螺齿速度vT/(m∙s−1) 导通响应时间Δt/μs 外界作用压力pm /GPa 最大螺齿速度vT/(m∙s−1) 导通响应时间Δt/μs 0.05 12.9 1.140 1 187.3 0.200 0.1 49.8 0.680 2 253.6 0.160 0.2 60.4 0.460 5 311.0 0.104 0.5 138.2 0.280 10 475.0 0.076 表 5 飞板与梯形支架平行段、基板表面的碰撞点速度

Table 5. Collision point velocity between flyer plate and parallel section of trapezoidal support and surface of base plate

实验编号 位置 碰撞点速度vc/(km·s-1) 拟合度 No.JSW-1 支架平行段 2.294 1 0.999 9 基板表面 2.265 8 0.996 4 No.JSW-2 支架平行段 2.312 9 0.999 7 基板表面 2.325 4 0.999 6 -

[1] 邵丙璜, 张凯. 爆炸焊接原理及其工程应用[M]. 大连: 大连工学院出版社, 1987: 1−6. [2] SMITH E G J, LABER D, LINSE V D. Explosive metal acceleration studies using flash X-ray techniques [C] // Proceedings of the 3rd International Conference of the Center for High Energy Forming. Vail, Colorado, 1971. [3] TAKIZAWA Y U, IZUMA T, ONZAWA T, et al. Experimental study of the acceleration zone and the terminal velocity of flyer plate driven by explosives [J]. High Energy Rate Fabrication, 1975, 4(18): 1–42. [4] 黄风雷, 段卫东, 恽寿榕. 爆炸驱动下飞板运动速度的实验研究 [J]. 爆炸与冲击, 2002, 22(1): 26–29.HUANG F L, DUAN W D, YUN S R. Experimental investigation on flying-plate velocity under blasting driving [J]. Explosion and Shock Waves, 2002, 22(1): 26–29. [5] 陈军. 滑移爆轰驱动金属圆管及对碰区的研究[D]. 绵阳: 中国工程物理研究院, 2001. [6] 孙明, 张建臣, 杨文彬, 等. 滑移爆轰作用下复板飞行姿态的测试[C]//第二届全国爆炸力学实验技术交流会论文集. 合肥: 安徽省力学学会, 2002: 74−78. [7] ESEN S, NYBERG U, ARAI H, et al. Determination of the energetic characteristics of commercial explosives using the cylinder expansion test technique [R]. Stockholm och Luleå: Swedish Blasting Research Centre och Luleå Tekniska Universitet, 2005. [8] PRÜMMER R. A new and simple method of determination of the parameters of explosive welding and latest results [J]. Journal of the Industrial Explosives Society, Japan, 1974, 35(3): 121–126. [9] SMITH E G J, LINSE V D. The acceleration characteristics of explosively driven flyer plates [C] // Proceedings of the 6th International Conference on High Energy Rate Fabrication. Essen, Germany, 1977. [10] HELD M, 裴大荣. 爆炸焊接的理论及爆炸焊接参数的测量 [J]. 稀有金属材料与工程, 1982(3): 77–85.HELD M, PEI D R. Theory of explosive welding and measurement of parameters of explosive welding [J]. Rare Metal Materials and Engineering, 1982(3): 77–85. [11] 杨文彬. 滑移爆轰下飞板飞行速度测量的实验方法 [J]. 爆炸与冲击, 1986, 6(1): 39–47.YANG W B. Experimental method of measuring the velocity of a flyer on sliping detonation [J]. Explosion and Shock Waves, 1986, 6(1): 39–47. [12] 赵国民, 张若棋, 王诚洪. 金属圆管在炸药滑移爆轰作用下的运动姿态 [J]. 爆炸与冲击, 1996, 16(1): 80–85.ZHAO G M, ZHANG R Q, WANG C H. Motion of matel tube under action of explosive slide detonation [J]. Explosion and Shock Waves, 1996, 16(1): 80–85. [13] 王诚洪, 张学书. 管-板焊接参数和结合区压力场测量 [J]. 国防科技大学学报, 1987(1): 31–36.WANG C H, ZHANG X S. The measurement of the dynamic welding parameters and the pressure field in bonding region [J]. Journal of National University of Defense Technology, 1987(1): 31–36. [14] 李科斌, 李晓杰, 闫鸿浩, 等. 炸药爆速连续测量的杂波分析及新型探针的研制 [J]. 工程爆破, 2017, 23(5): 85–90. DOI: 10.3969/j.issn.1006-7051.2017.05.017.LI K B, LI X J, YAN H H, et al. The mechanism analysis of noise wave in detonation velocity continuous measurement [J]. Engineering Blasting, 2017, 23(5): 85–90. DOI: 10.3969/j.issn.1006-7051.2017.05.017. [15] 张凯, 奚进一, 杨文彬. 连续斜电阻丝测量飞板速度时弯曲波影响的理论分析 [J]. 爆炸与冲击, 1986, 6(1): 30–38.ZHANG K, XI J Y, YANG W B. A theoretical analysis for the influence of bending wave on the flyer velocity determination measured by slanted resistance wire technique [J]. Explosion and Shock Waves, 1986, 6(1): 30–38. [16] LI K B, LI X J, YAN H H, et al. New approaches for evaluating detonation properties of commercial explosives using a novel continuous velocity probe [J]. Measurement Science and Technology, 2018, 29(11): 115901. DOI: 10.1088/1361-6501/aadc41. [17] LI K B, LI X J, WANG X H, et al. A simple electrometric method for parametric determination of Jones-Wilkins-Lee equation of state from underwater explosion test [J]. Journal of Applied Physics, 2018, 124(21): 215906. DOI: 10.1063/1.5049497. [18] 李科斌, 李晓杰, 王小红, 等. 球形装药水下爆炸近场测量的连续探针法研究 [J]. 兵工学报, 2019, 40(1): 1–7. DOI: 10.3969/j.issn.1000-1093.2019.01.001.LI K B, LI X J, WANG X H, et al. Study of continuous velocity probe method for near-field underwater explosion measurement of spherical charge [J]. Acta Armamentarii, 2019, 40(1): 1–7. DOI: 10.3969/j.issn.1000-1093.2019.01.001. [19] 李科斌, 李晓杰, 王小红, 等. 基于连续压导探针的水箱法测量爆压 [J]. 高压物理学报, 2019, 33(2): 023201. DOI: 10.11858/gywlxb.20180652.LI K B, LI X J, WANG X H, et al. A modified aquarium test using a continuous pressure-conducted velocity probe for measurement of detonation pressure [J]. Chinese Journal of High Pressure Physics, 2019, 33(2): 023201. DOI: 10.11858/gywlxb.20180652. -

下载:

下载: