Experimental study on dynamic response of an anti-ice hull structurewith square groove longitudinals under ice impact

-

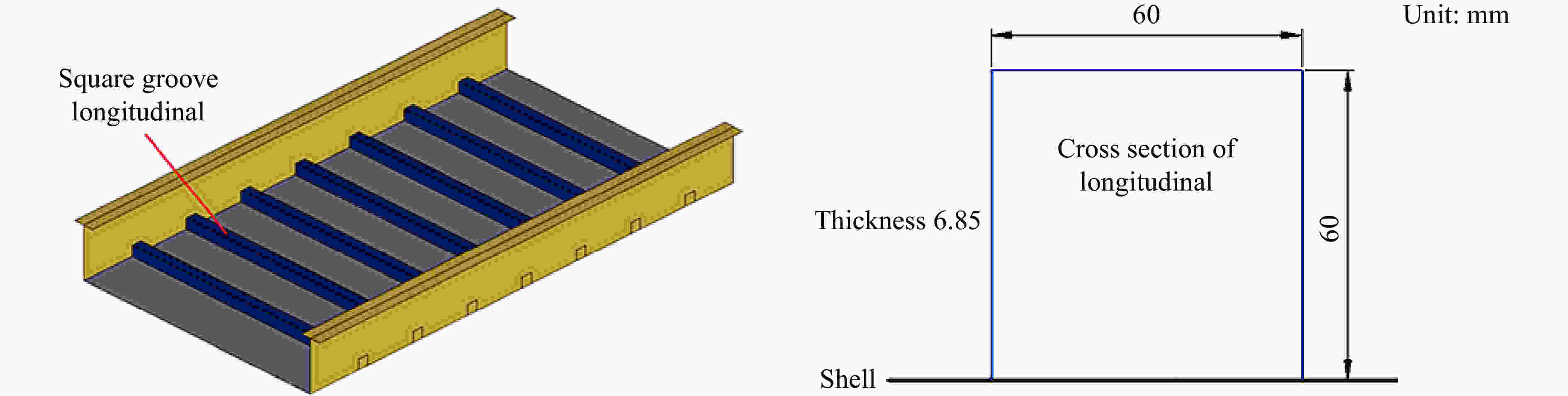

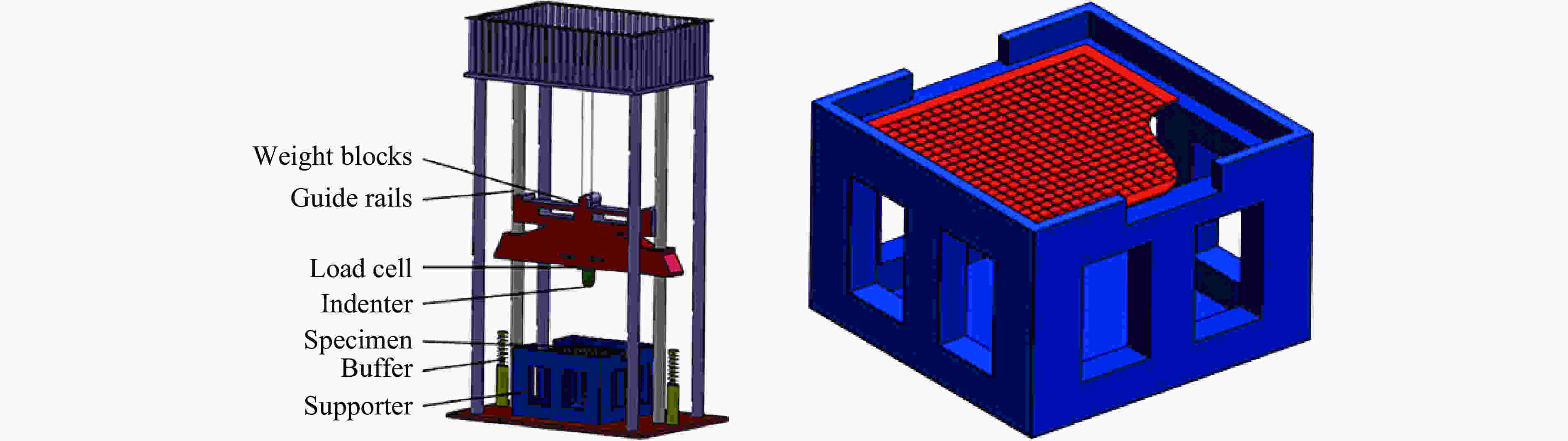

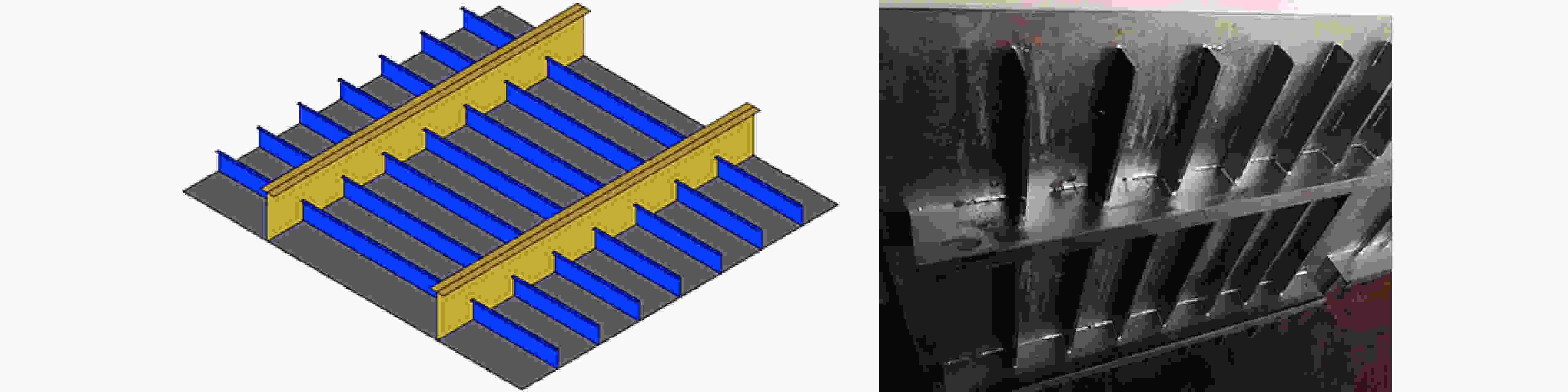

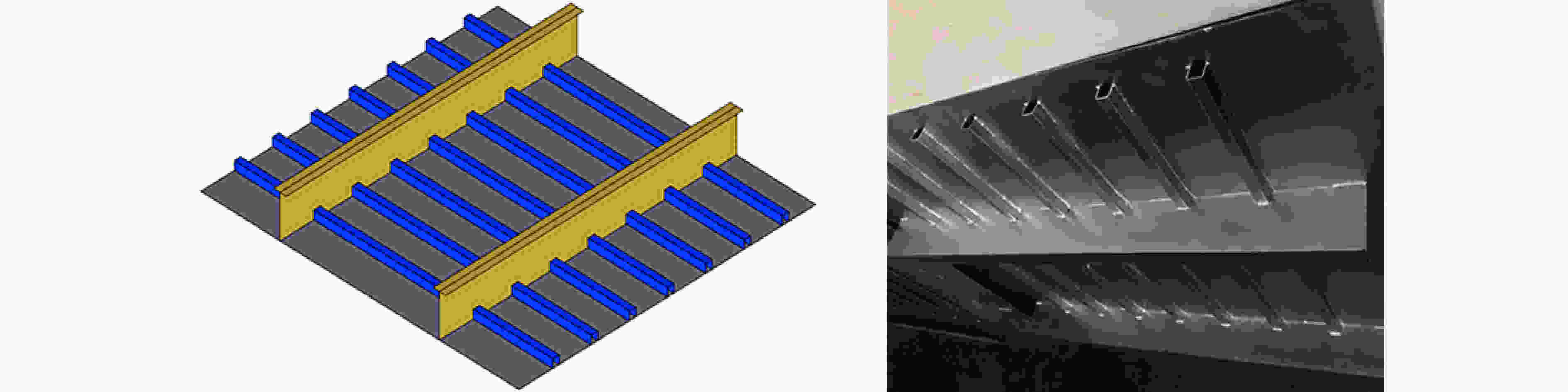

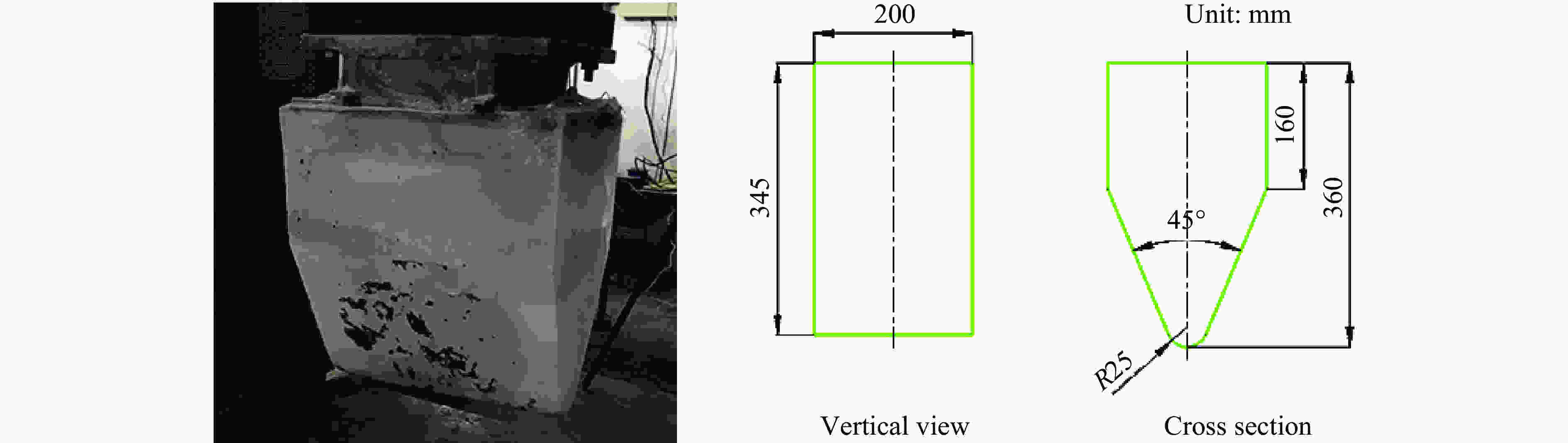

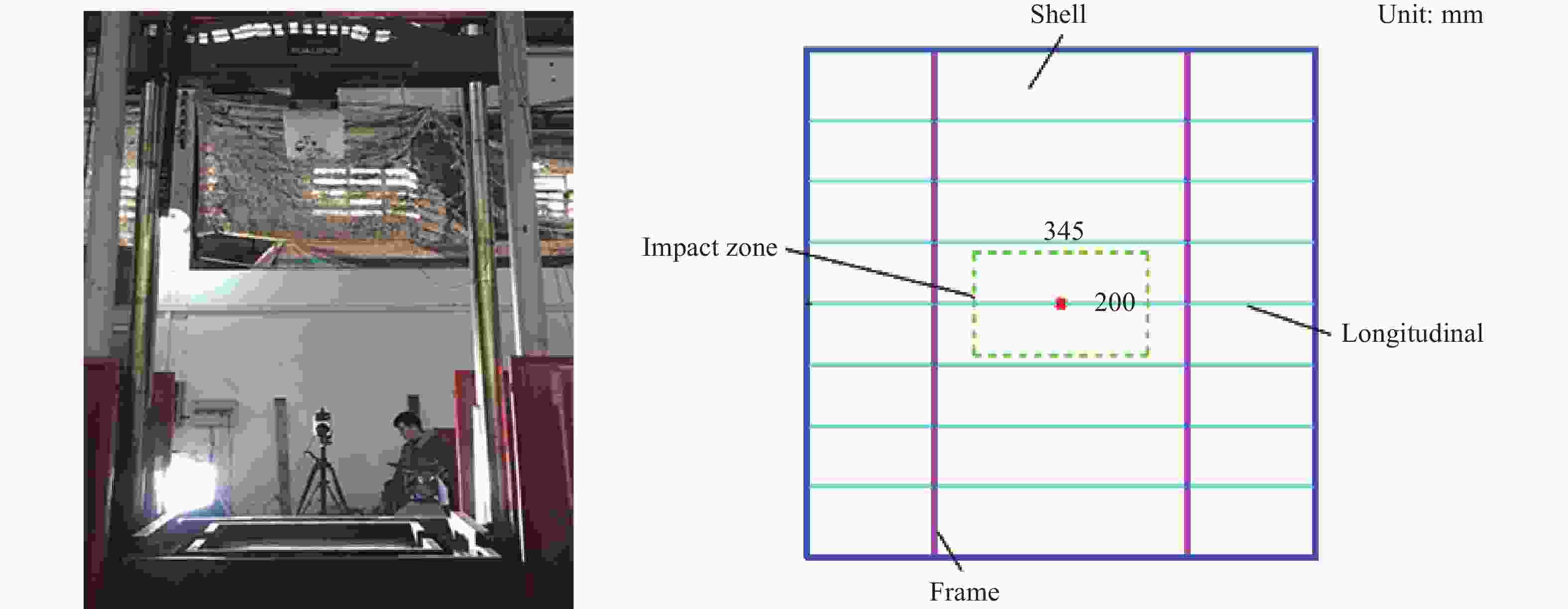

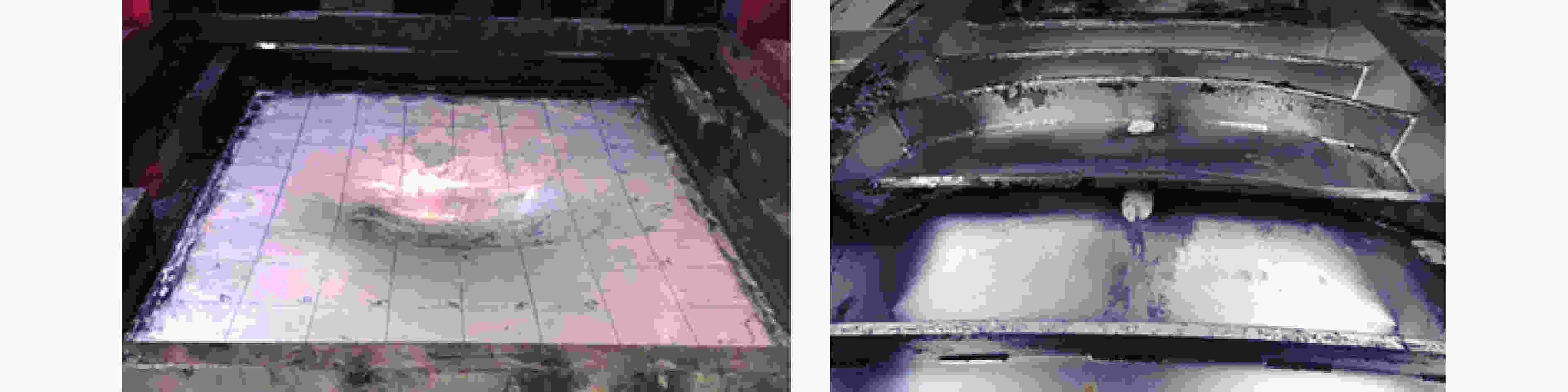

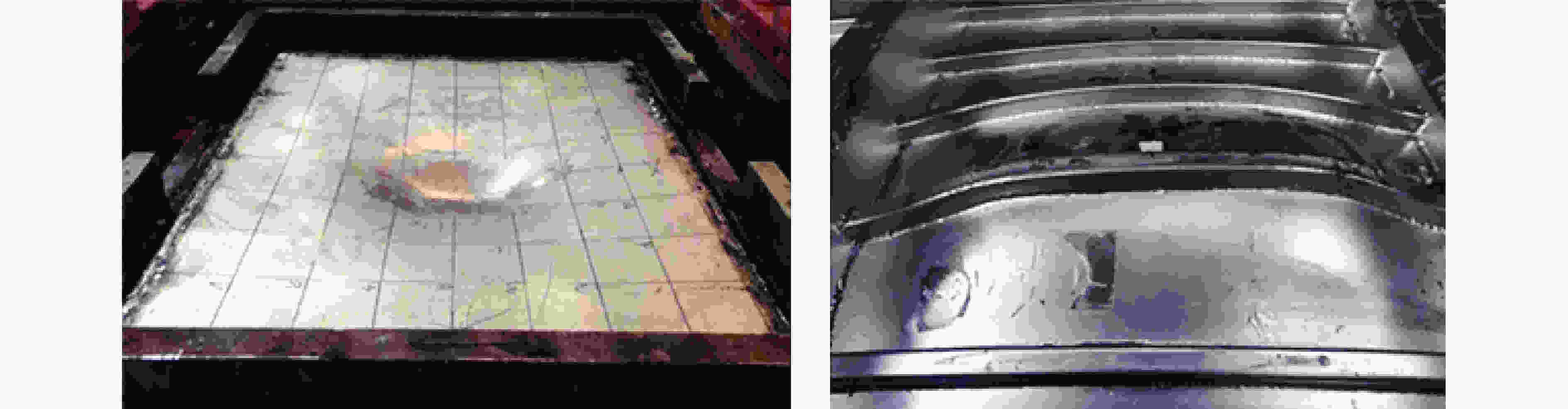

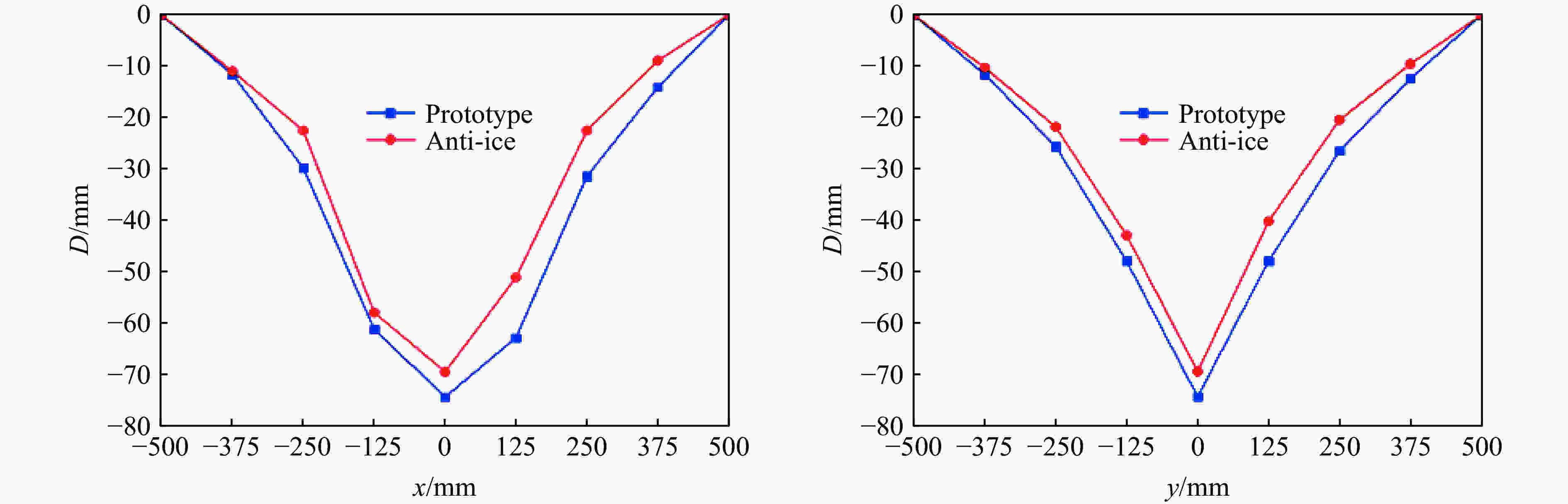

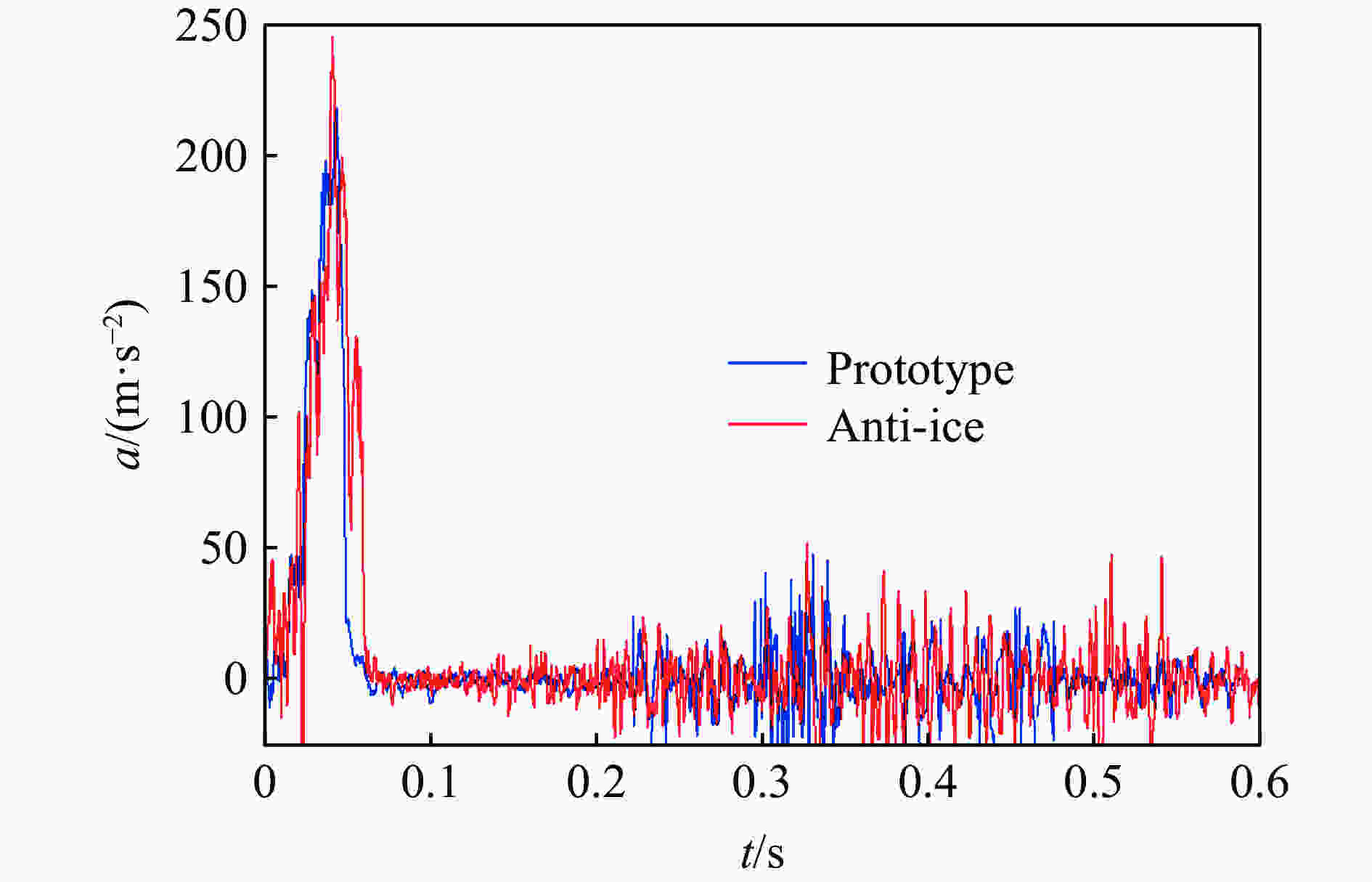

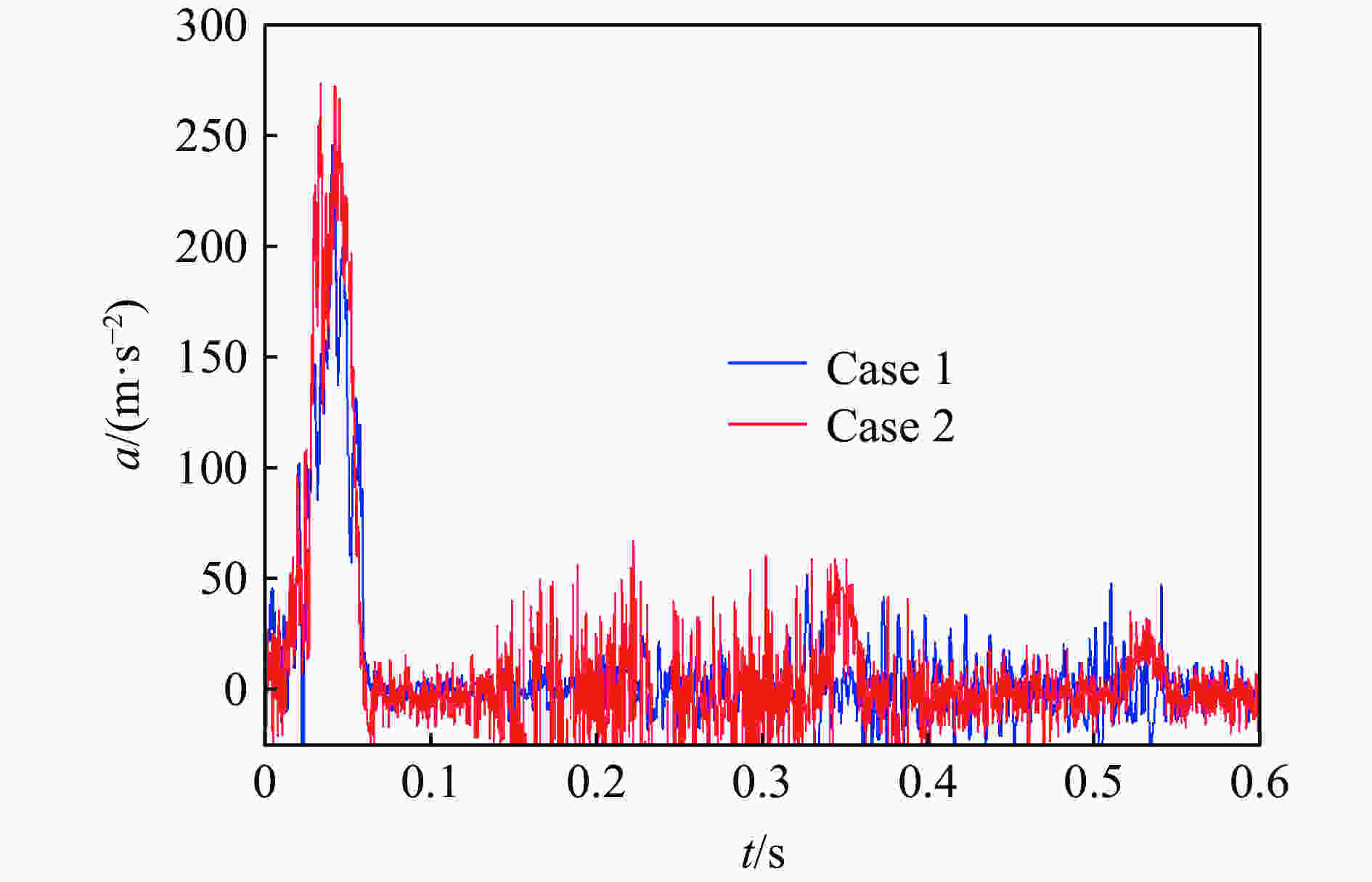

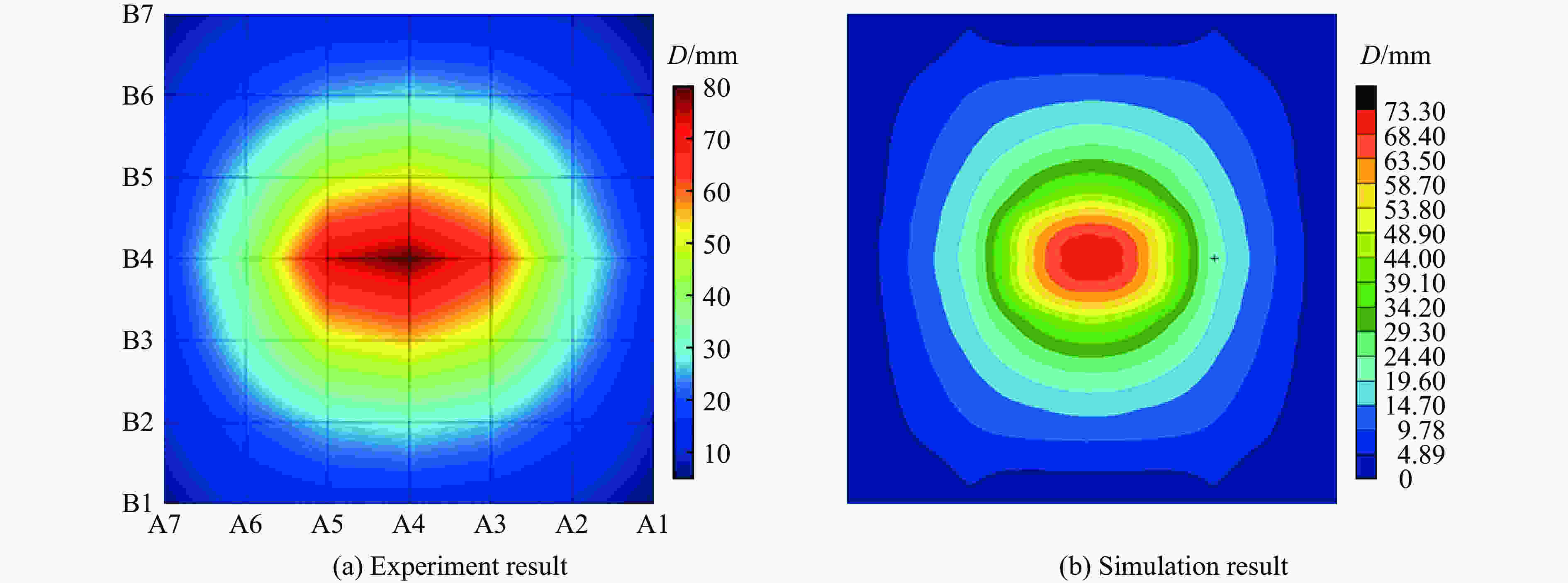

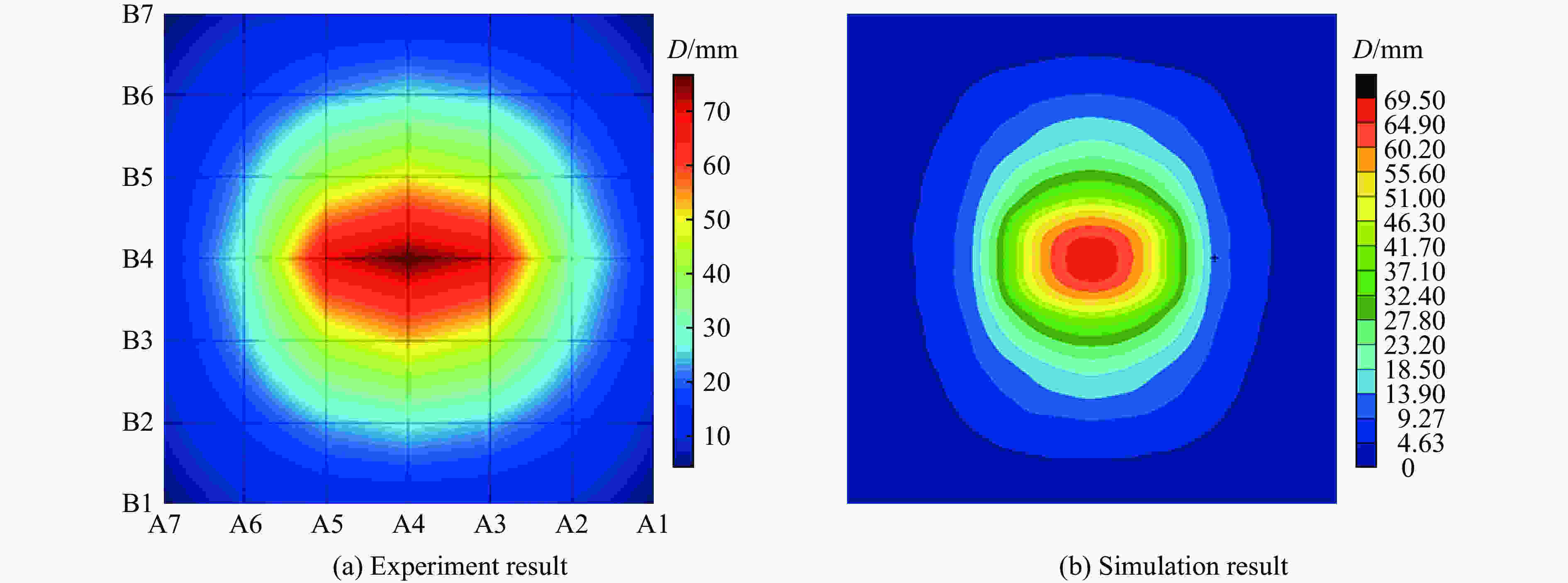

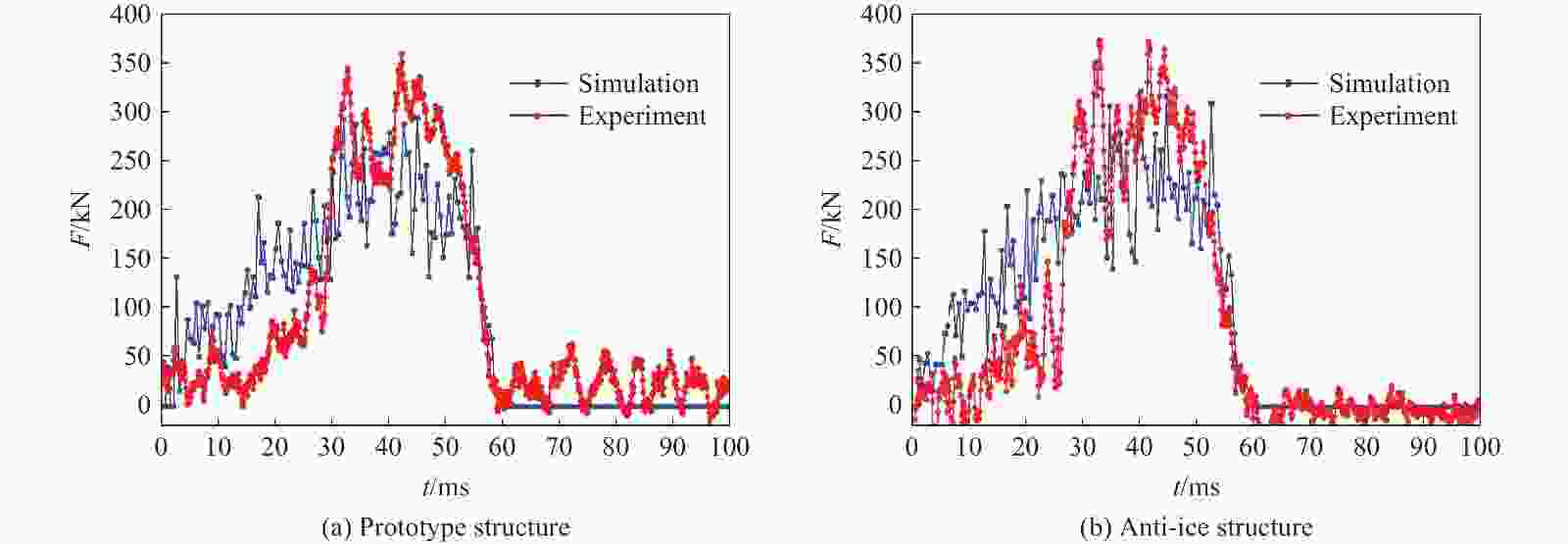

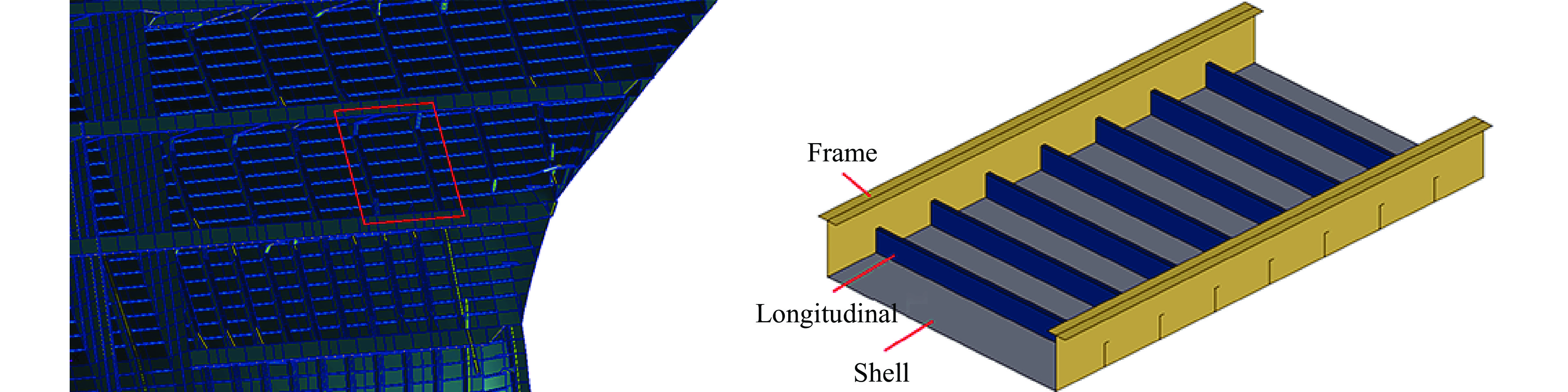

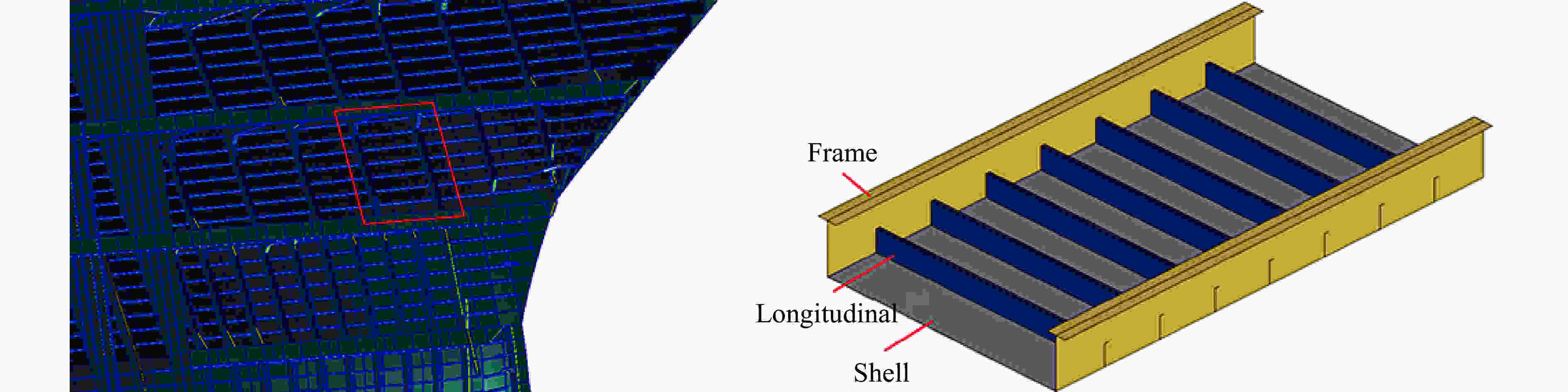

摘要: 针对船舶冰区航行受冰体撞击结构损伤问题,以一种涉冰带船肩处船体板架结构为原型,提出了一种方槽型纵骨船舶抗冰结构型式。利用落锤冲击实验测试系统,对抗冰和原型加筋板架在相同冰体撞击工况下的结构动响应进行了实验研究,采用MSC.Dytran程序对板架受冰体撞击过程开展数值模拟,并与实验结果进行对比。结果表明,相同冰体撞击工况下,抗冰板架结构产生的撞击力比原型板架略大,冰体造成的抗冰板架结构最大凹陷深度小于原型板架。从船体外板结构损伤程度及对船体内部构件、设备防护作用的角度考虑,抗冰结构较原型具有一定的抗冰效果。研究成果可为冰区航行船或破冰船的抗冰结构设计提供参考。Abstract: In this work, in order to reduce hull structural damage caused by ice impact, a new type of square groove longitudinal anti-ice structure is used in the shoulder structure of a hull in ice belt. Using a falling weight impact test system, the structural dynamic responses of anti-ice and prototype stiffened plates under the same ice impact case were tested and the impacting processes were simulated by the MSC.Dytran software. The results show that under the same impact conditions, the impact force produced by the anti-ice structure is slightly higher than that by the prototype one, and the maximum depression depth is smaller than that of the prototype one. According to the structural damage degree of the hull shell plates and their protection function to the hull internal components and equipment, the new structure has a certain anti-ice effect compared with the prototype structure. The results of the present study can provide a reference for the design of the anti-ice structures of ice-going ships or icebreakers.

-

Key words:

- square groove longitudinal /

- anti-ice structure /

- ice impact /

- dynamic response

-

表 1 原型纵骨与方槽型纵骨结构参数对比

Table 1. Comparison of structural parameters between two kinds of longitudinals

纵骨类型 尺寸/mm 板厚/mm 横截面积/mm2 质量差/% 原型纵骨 腹板126 腹板7 1232.2 面板 26 面板13.2 方槽型纵骨 方槽边长60 6.85 1233 0.064 9 -

[1] LIU Z H, AMDAHL J, LØSET S. Integrated numerical analysis of an iceberg collision with a foreship structure [J]. Marine Structures, 2011, 24(4): 377–395. DOI: 10.1016/j.marstruc.2011.05.004. [2] INCE S T, KUMAR A, PARK D K, et al. An advanced technology for structural crashworthiness analysis of a ship colliding with an ice-ridge: numerical modelling and experiments [J]. International Journal of Impact Engineering, 2017, 110: 112–122. DOI: 10.1016/j.ijimpeng.2017.02.014. [3] KIM J H, KIM Y, KIM H S, et al. Numerical simulation of ice impacts on ship hulls in broken ice fields [J]. Ocean Engineering, 2019, 182: 211–221. DOI: 10.1016/j.oceaneng.2019.04.040. [4] 张健, 万正权, 陈聪. 船-冰碰撞载荷下球鼻艏结构动态响应研究 [J]. 船舶力学, 2014, 18(1−2): 106–114. DOI: 10.3969/j.issn.1007-7294.2014.h1.014.ZHANG J, WAN Z Q, CHEN C. Research on structure dynamic response of bulbous bow in ship-ice collision load [J]. Journal of Ship Mechanics, 2014, 18(1−2): 106–114. DOI: 10.3969/j.issn.1007-7294.2014.h1.014. [5] 张健, 王甫超, 刘海东, 等. 水介质中船体板架模型与冰体碰撞试验研究 [J]. 船舶力学, 2020, 24(4): 492–500. DOI: 10.3969/j.issn.1007-7294.2020.04.009.ZHANG J, WANG F C, LIU H D, et al. Experimental study on collision of hull plate model and ice in water medium [J]. Journal of Ship Mechanics, 2020, 24(4): 492–500. DOI: 10.3969/j.issn.1007-7294.2020.04.009. [6] Finnish Maritime Administration. Finnish-Swedish ice class rules: Bulletin No. 13/1.10. 2002 [R]. 2002. [7] American Bureau of Shipping. ABS 2 polar waters guide: 2008 guide for building and classing vessels intended for navigation in polar waters [S]. 2008. [8] IACS. Requirements concerning polar class [S]. 2011. [9] 李丹, 杨春萍, 杜兆阳. LNG船舷侧抗冰撞性结构设计 [J]. 船舶物资与市场, 2019(11): 17–19. DOI: 10.19727/j.cnki.cbwzysc.2019.11.001.LI D, YANG C P, DU Z Y. Anti-ice impact side structure design of LNG ship [J]. Marine Equipment/Materials and Marketing, 2019(11): 17–19. DOI: 10.19727/j.cnki.cbwzysc.2019.11.001. [10] 陈聪. 冰撞载荷作用下船体结构抗冲击设计研究[D]. 镇江: 江苏科技大学, 2015: 61−72. -

下载:

下载: