Penetration behaviors of Hf-based amorphous alloy jacketed rods

-

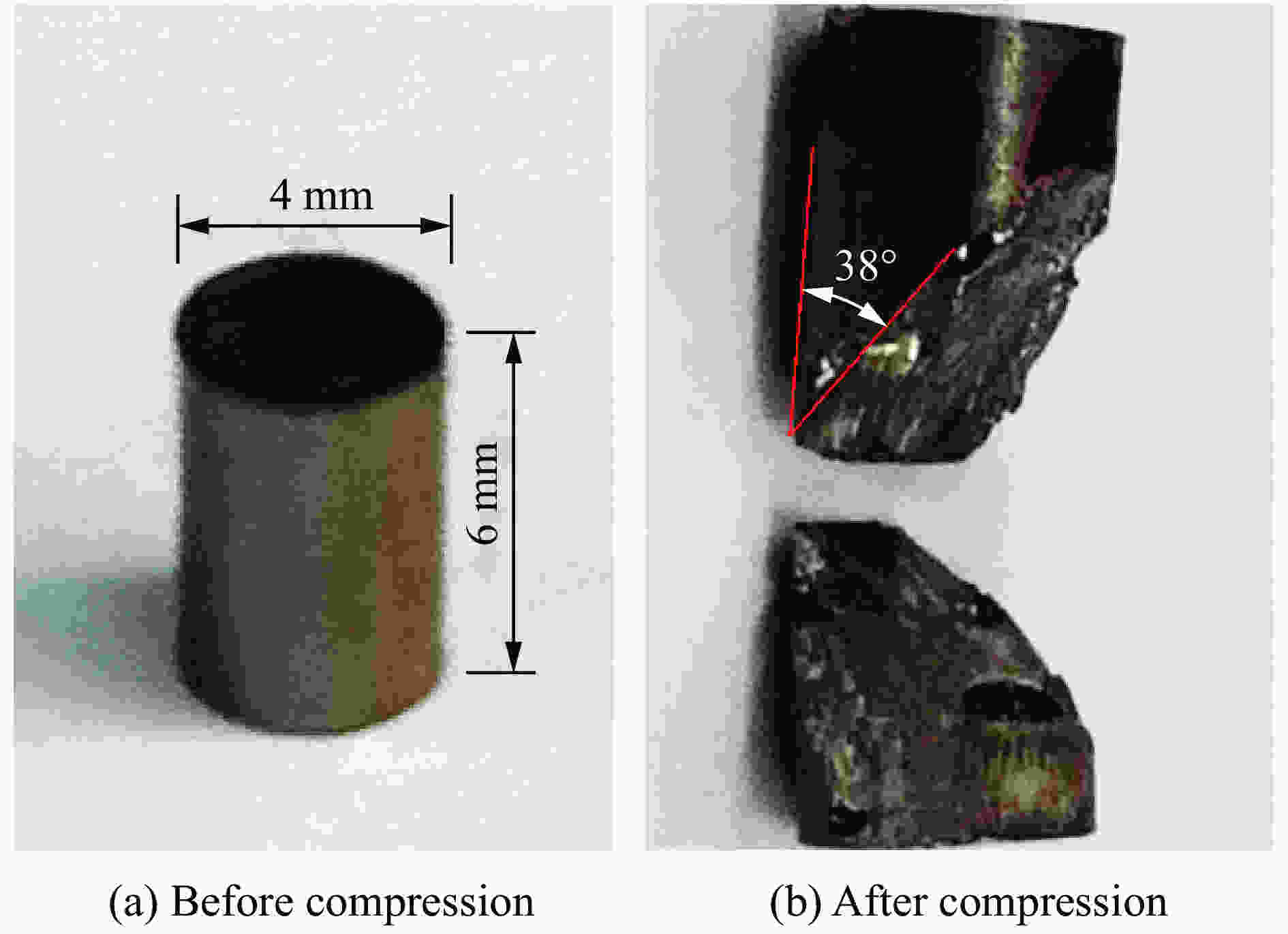

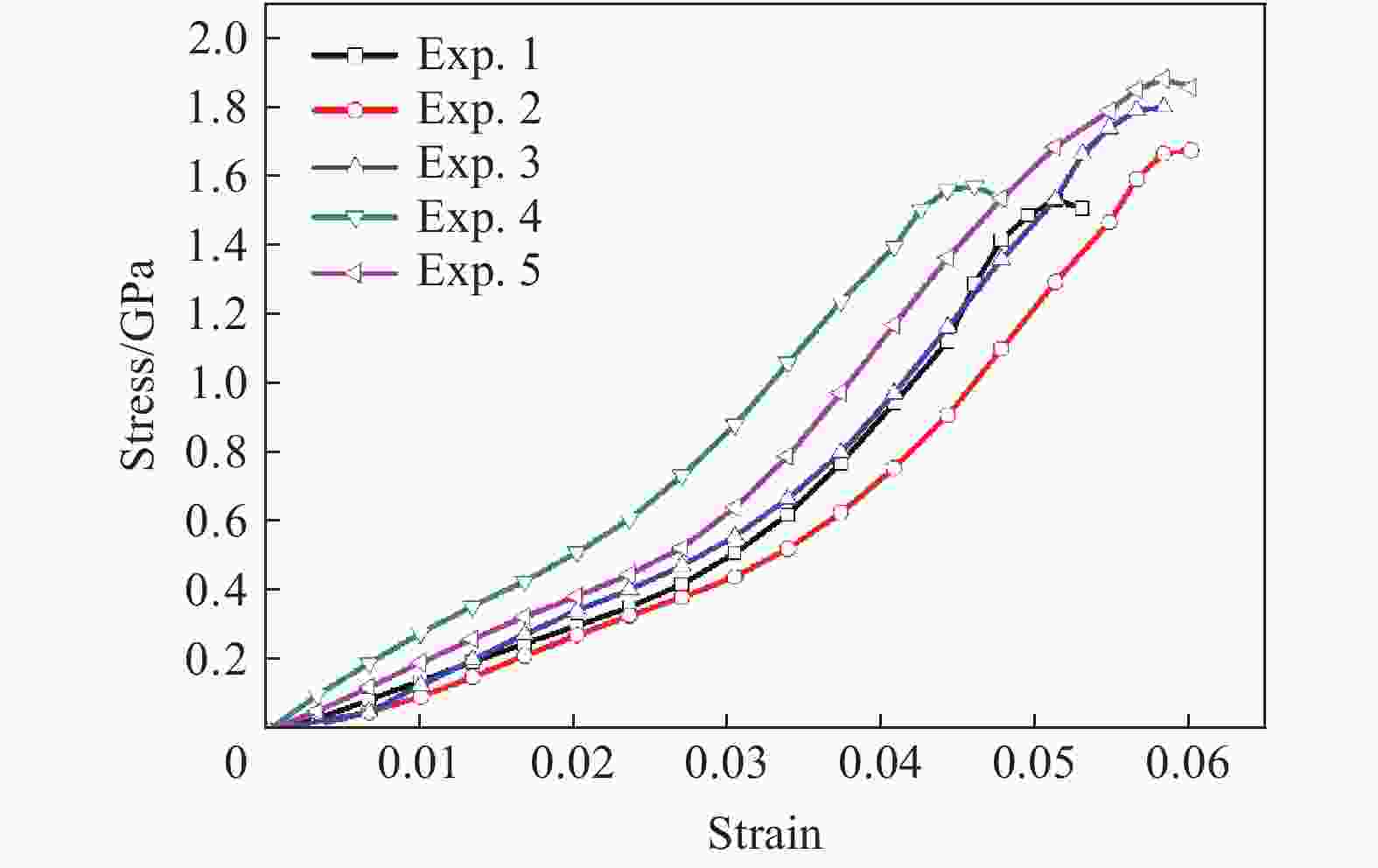

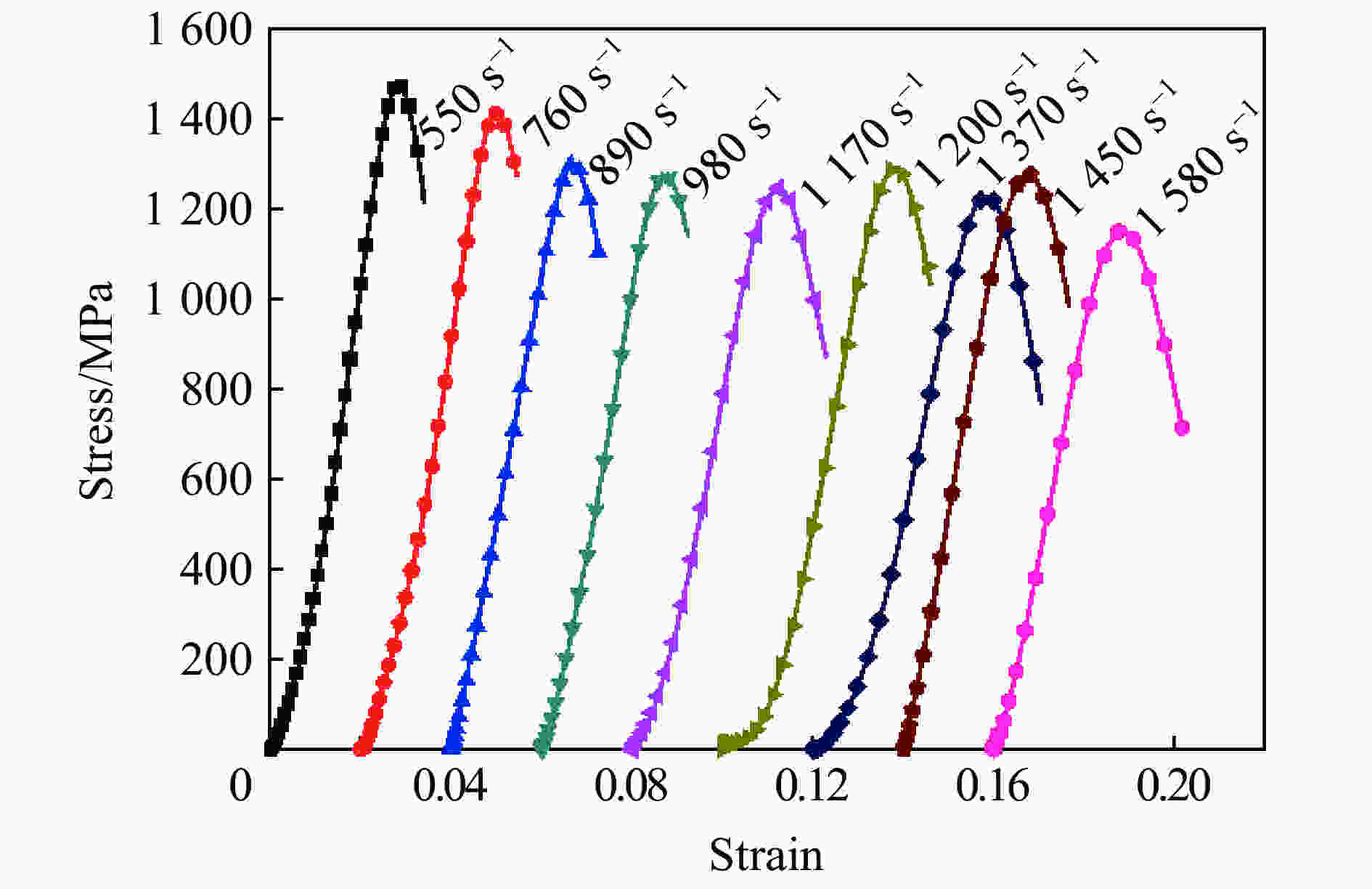

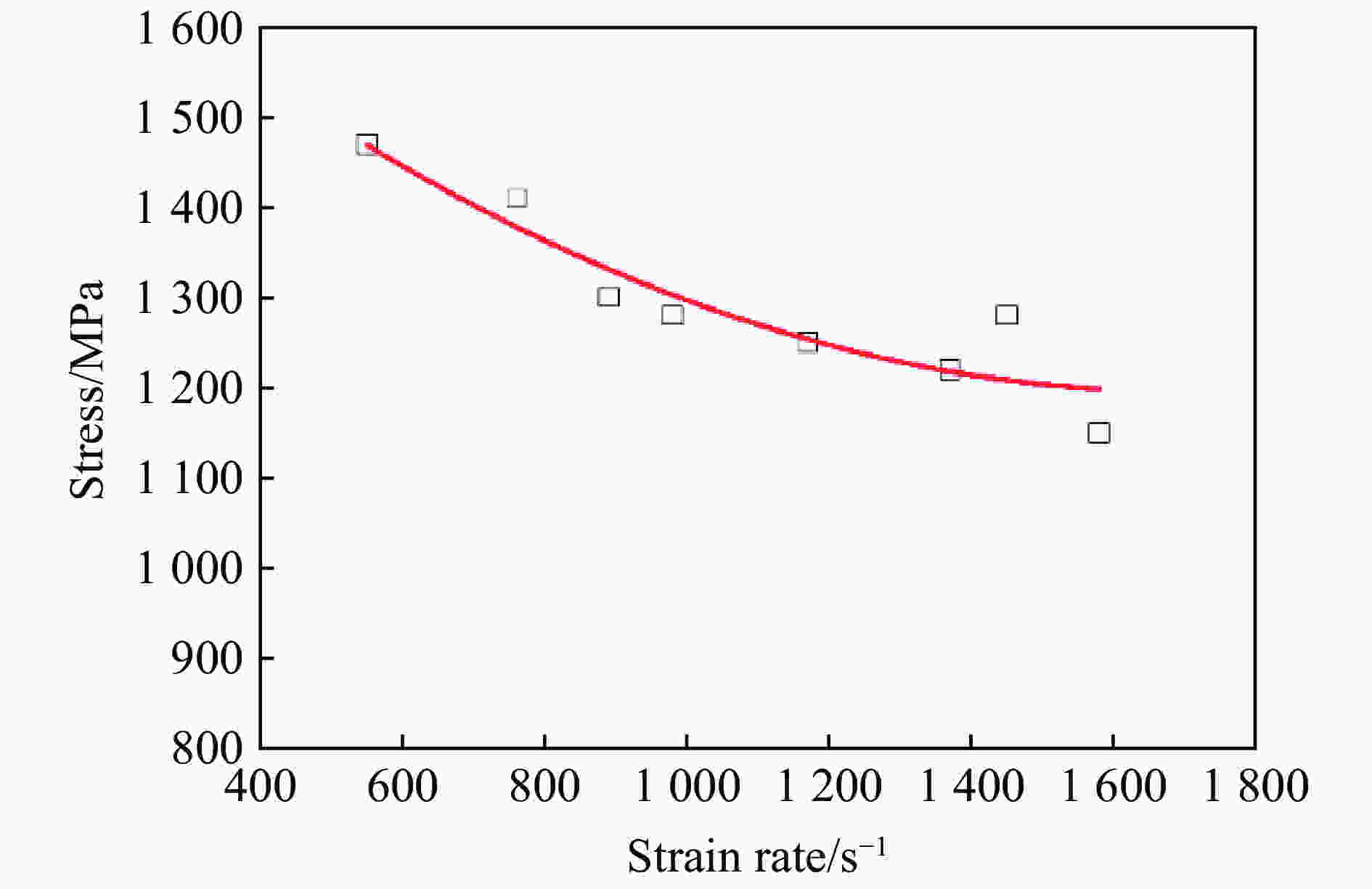

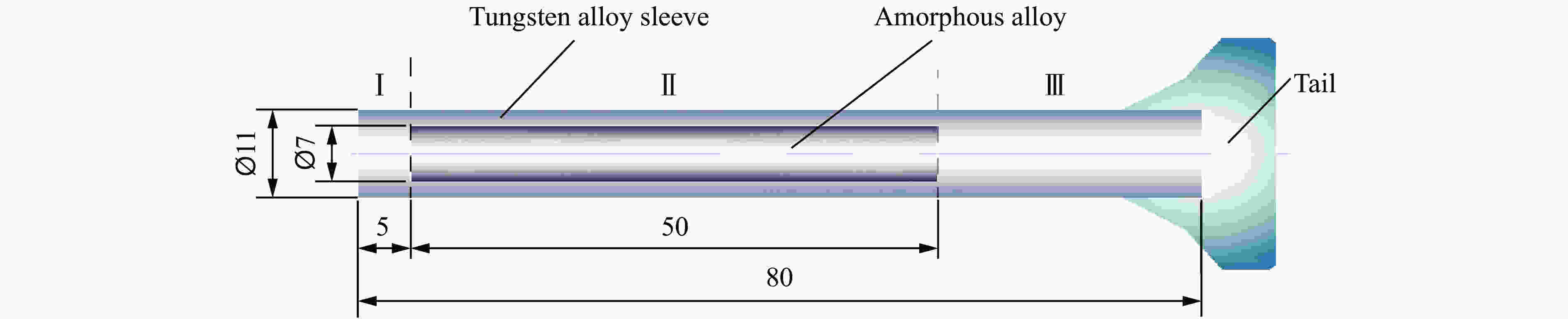

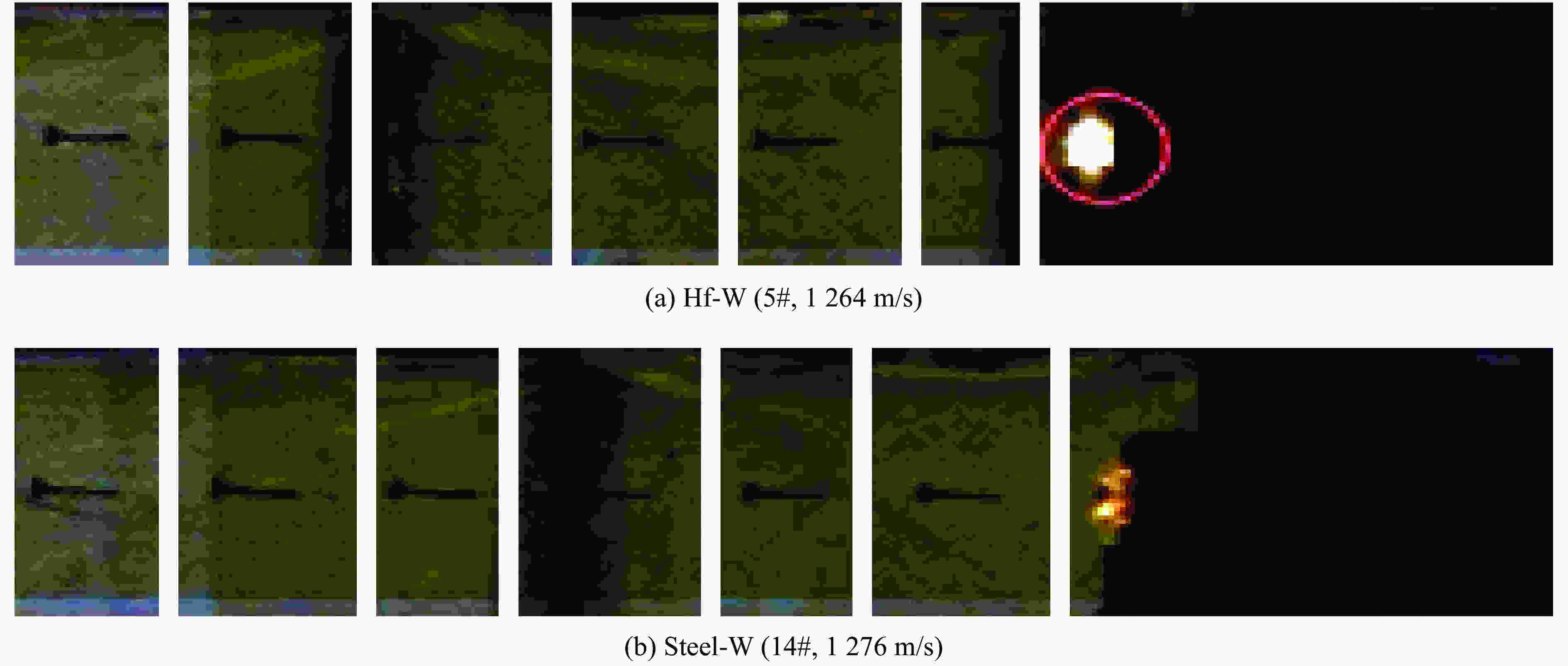

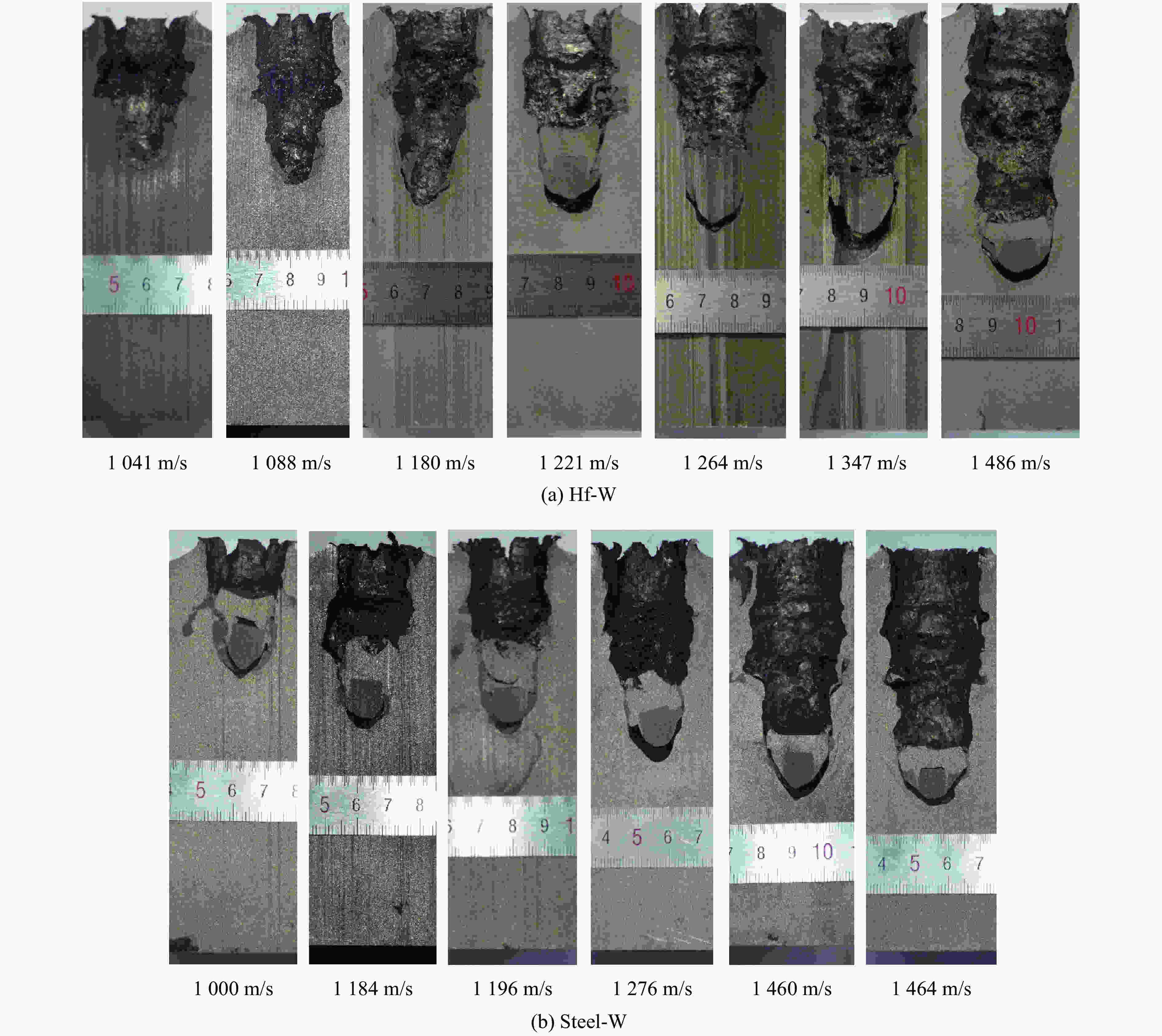

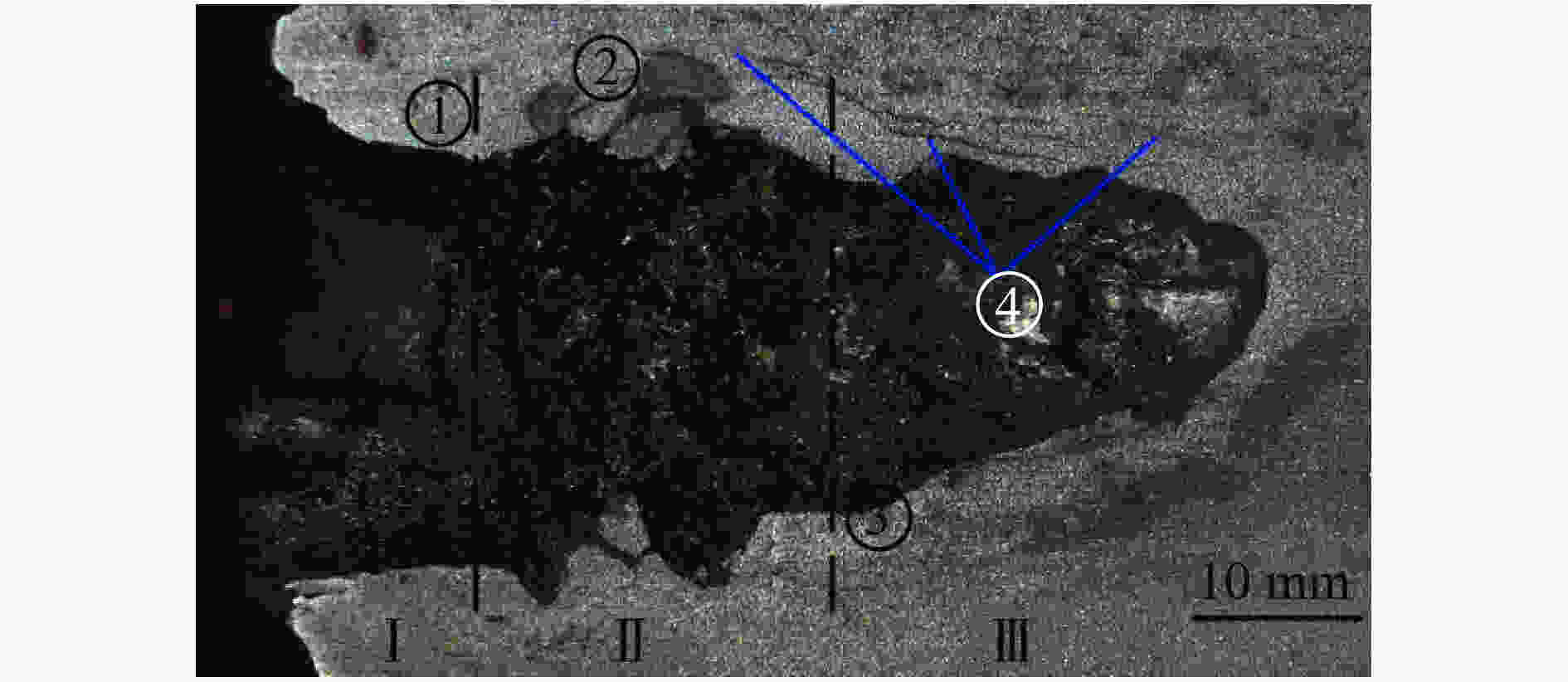

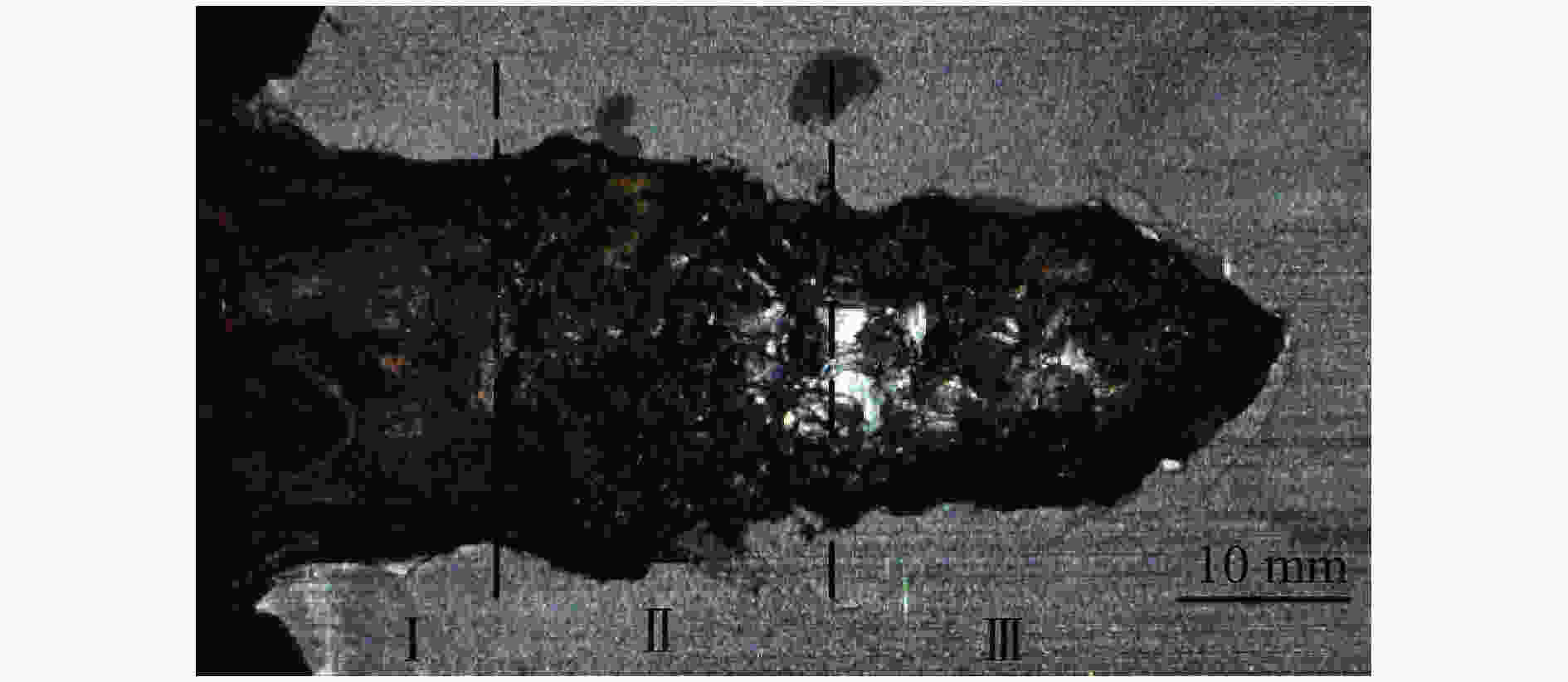

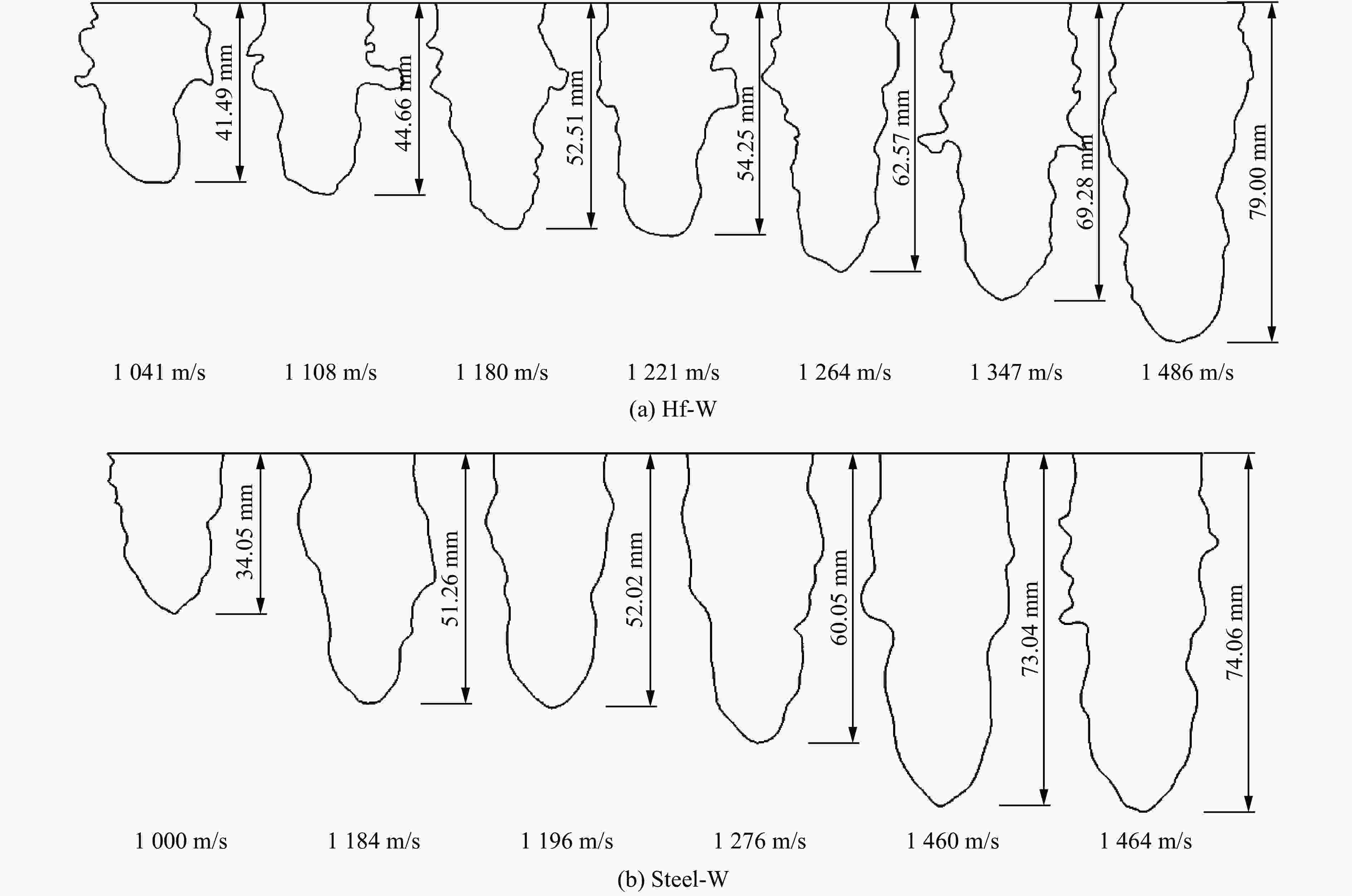

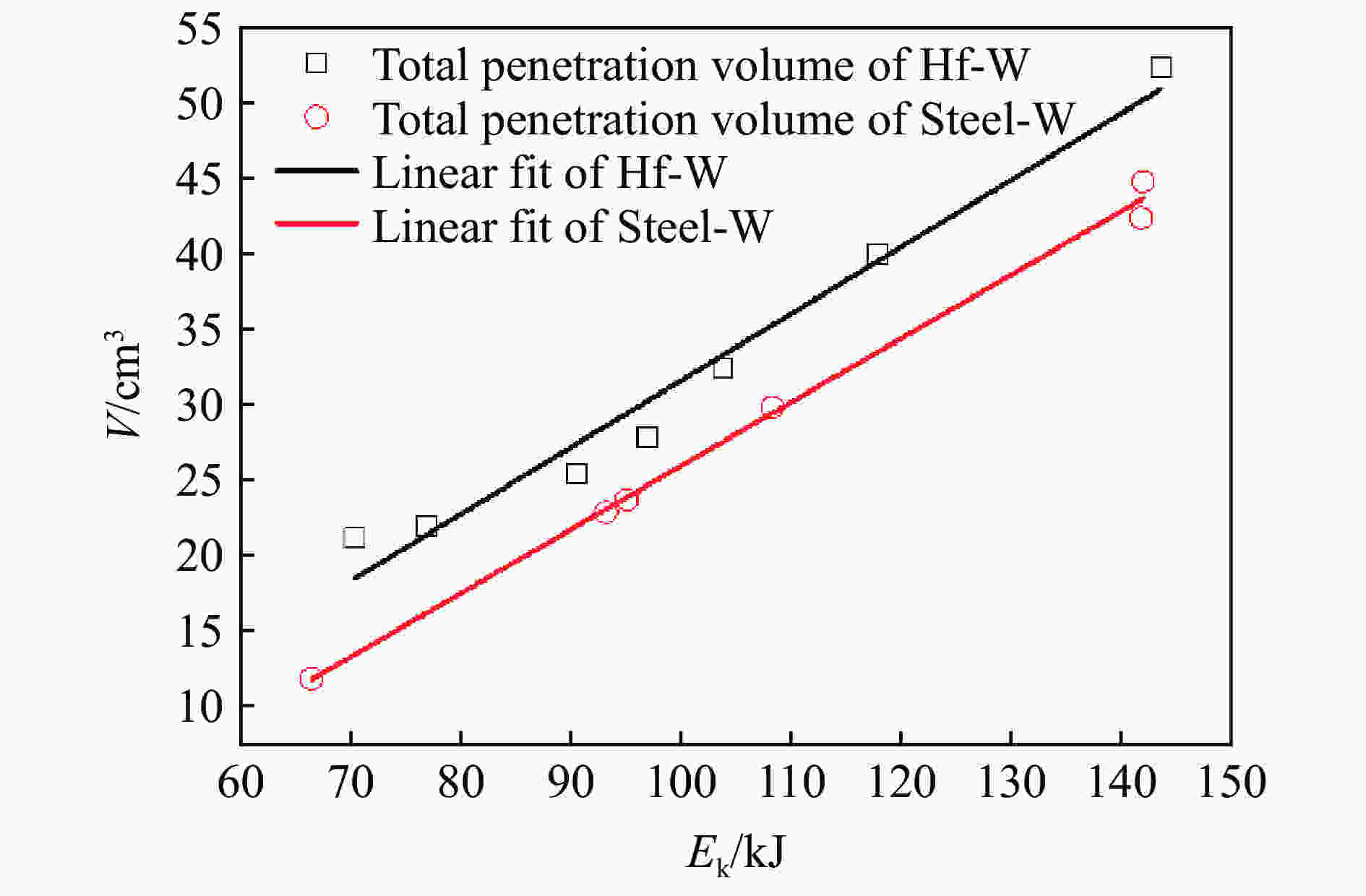

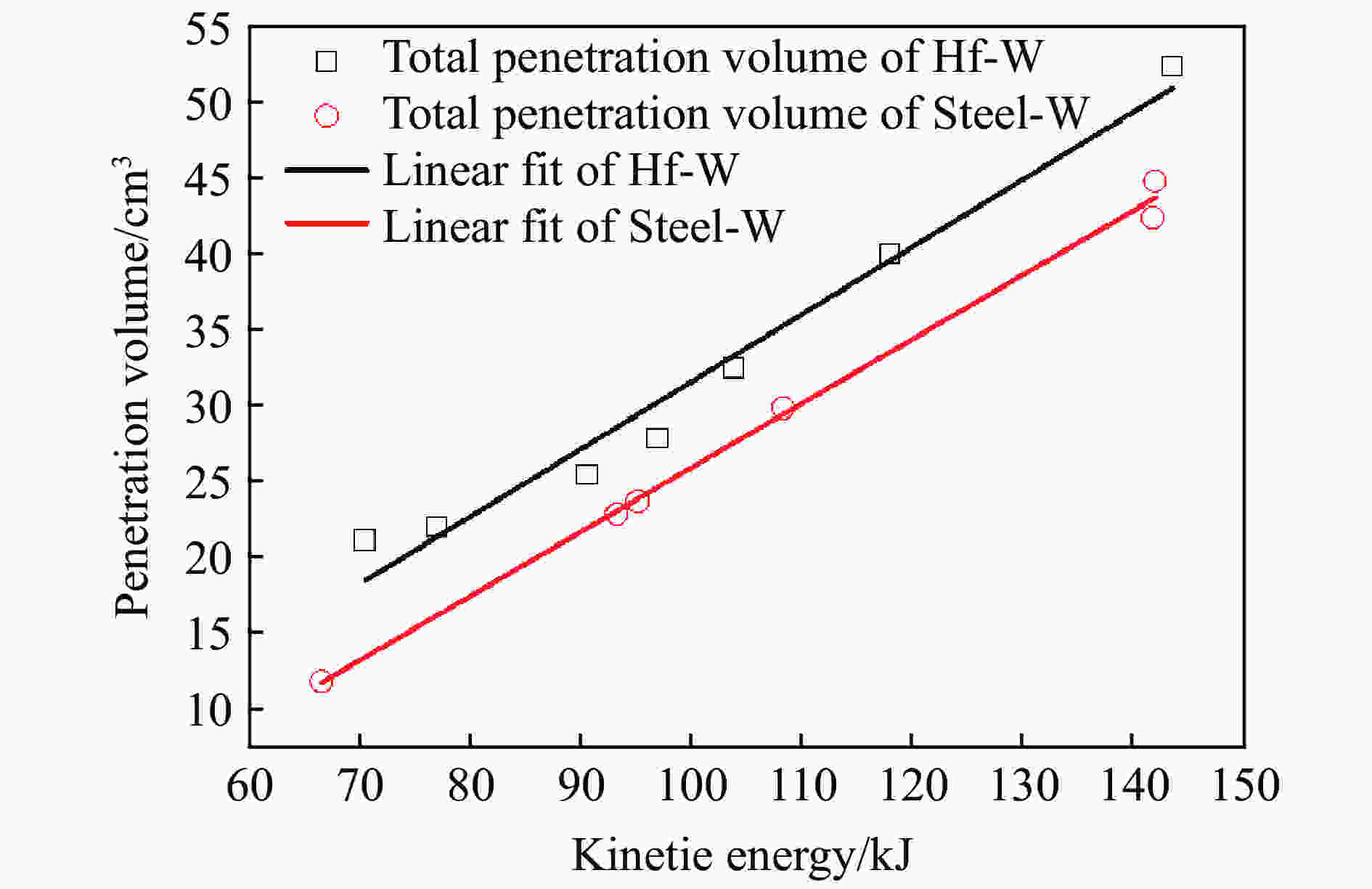

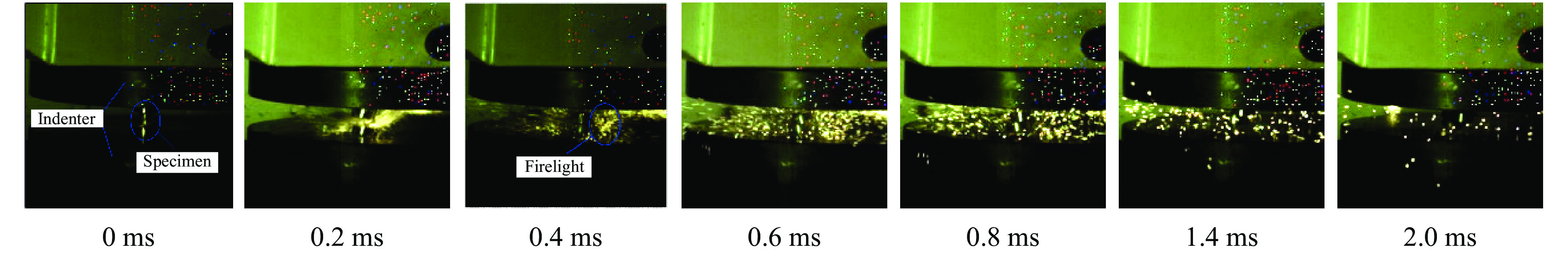

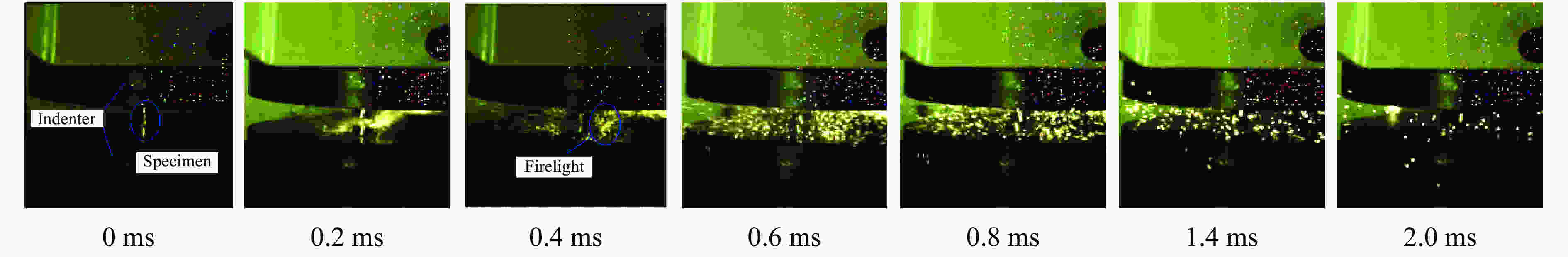

摘要: 为研究Hf基非晶合金的变形行为及高速侵彻性能,分别开展了Hf基非晶合金材料静动态力学性能和Hf基非晶合金夹芯结构长杆弹高速侵彻45钢靶体试验研究,并与45钢夹芯长杆弹侵彻结果进行对比。研究发现:Hf基非晶合金具有较高的断裂强度,断裂时伴随有能量释放现象;Hf基非晶合金夹芯长杆弹侵彻钢靶过程可分为3个阶段:开坑、夹芯结构侵彻和剩余弹体侵彻。Hf非晶合金在侵彻过程中发生了明显的释能反应,显著地增强了弹体毁伤效应,扩大了侵彻弹孔直径,增加了弹体侵彻深度和弹孔体积。在高速冲击下,Hf基非晶合金夹芯长杆弹表现出优异的侵彻性能,可以为非晶合金材料在高效毁伤领域的应用提供新思路。Abstract: Amorphous alloys have attracted wide interest from from domestic and foreign research scholars in recent years. In order to explore the deformation behavior and high-speed penetration performance of Hf-based bulk amorphous alloys, the static (10−3 s−1) and dynamic (102−104 s−1) mechanical properties tests of Hf-based bulk amorphous alloy materials were carried out. Based on the structure of the jacketed rod, penetration experiments were performed as well. Two kinds of jacketed rod projectiles, in Hf-based bulk amorphous alloy and 45 steel, penetrated into the semi-infinite 45 steel targets with velocities in the range of 1000−1500 m/s. The experimental results show that the Hf-based bulk amorphous alloy has a high fracture strength of 1.69 GPa under quasi-static compression (10−3 s−1), and 1.15 GPa under dynamic compression (102−104 s−1). The fracture of Hf-based bulk amorphous alloy is accompanied by a energy release phenomenon. The process of Hf-based bulk amorphous alloy jacketed rod projectiles penetrating the steel target can be divided into three stages: pit opening stage, penetration stage of the jacketed rod structure and remaining projectile penetration. The Hf amorphous alloy has an obvious energy-releasing reaction during the penetration process. The energy-releasing reaction of the Hf-based bulk amorphous alloy enhanced the damage effect of the projectile significantly by enlarging the diameter of the penetration bullet hole, and increasing the penetration depth and bullet hole volume. Compared with the 45 steel jacketed rod within the tested kinetic energy range, the range of increase in the diameter of the penetration single hole, the penetration depth and the volume of penetration bullet holes are 14.4%−23.8%, 5.2%−13.1%, and 12.9%−54.3%, respectively. In conclusion, the Hf-based bulk amorphous alloy jacketed rod projectile exhibits excellent penetration performance, which can provide new ideas for the application of amorphous alloy materials in the field of efficient damage.

-

Key words:

- jacketed rod /

- long rod projectile /

- penetration behavior /

- amorphous alloy /

- energy-releasing reaction /

- Hf

-

表 1 准静态压缩实验数据

Table 1. Quasi-static compression experimental data

编号 压缩速度/(mmmin−1) 尺寸/(mmmm) 最大载荷/kN 应变率/s−1 抗压强度/GPa 1 0.36 $\varnothing $3.98×5.98 20.6 1×10−3 1.53 2 0.36 $\varnothing $3.96×6.00 22.4 1×10−3 1.68 3 0.36 $\varnothing $3.94×6.00 24.0 1×10−3 1.80 4 0.36 $\varnothing $4.00×6.02 21.1 1×10−3 1.58 5 0.36 $\varnothing $4.02×6.02 25.2 1×10−3 1.88 表 2 SHPB实验数据

Table 2. SHPB experimental data

编号 速度/(m∙s−1) 尺寸/(mmmm) 应变率/s−1 断裂强度/MPa 1 10.4 $ \varnothing $4.02×6.00 550 1 470 2 12.3 $ \varnothing $4.00×5.98 760 1 410 3 13.7 $ \varnothing $4.02×5.98 890 1 300 4 14.8 $ \varnothing $4.02×6.02 980 1 280 5 16.2 $ \varnothing $4.02×6.00 1170 1 260 6 16.4 $ \varnothing $4.02×5.98 1200 1 250 7 17.5 $ \varnothing $4.02×6.00 1370 1 220 8 18.5 $ \varnothing $4.02×6.02 1450 1 280 9 18.9 $ \varnothing $4.02×6.02 1580 1 150 表 3 弹体材料参数

Table 3. Material parameters of the projectile

材料 密度/(g∙cm−3) HRC硬度 强度/MPa Hf基非晶合金 8.10 50 1 600 调质处理45钢 7.85 50 562 钨合金[22] 17.6 35.5 1 250 表 4 实验后靶体成坑参数

Table 4. Crater parameters of targets

弹体材料 编号 弹体速度/(m∙s−1) 弹体动能/kJ 侵彻深度/mm 弹孔体积/cm3 弹孔直径/mm Hf-W 9 1 041 70.44 41.49 21.14 30.24 8 1 088 76.94 44.66 21.99 29.51 1 1 180 90.51 52.51 25.42 31.81 4 1 221 96.90 54.25 27.86 32.47 5 1 264 103.85 62.57 32.47 32.82 7 1 347 117.94 69.28 40.00 32.56 6 1 486 143.53 79.00 52.36 34.62 Steel-W 17 1 000 66.50 34.05 11.82 23.33 11 1 184 93.22 51.26 22.86 27.57 13 1 196 95.12 52.02 23.71 26.68 14 1 276 108.27 60.05 29.85 28.10 15 1 460 141.75 73.04 42.39 30.31 16 1 464 141.95 74.06 44.81 30.14 -

[1] 杜忠华, 杜成鑫, 朱正旺, 等. 钨丝/锆基非晶复合材料长杆体弹芯穿甲实验研究 [J]. 稀有金属材料与工程, 2016, 45(5): 1308–1313.DU Z H, DU C X, ZHU Z W, et al. An experimental study on perforation behavior of pole penetrator prepared from WF/Zr-based bulk metallic glass matrix composite [J]. Rare Metal Materials and Engineering, 2016, 45(5): 1308–1313. [2] CULLIS I G, LYNCH N J. Hydrocode and experimental analysis of scale size jacketed KE projectiles [C] // Proceedings of the 14th International Symposium on Ballistics. Quebec, Canada, 1993: 271−280. [3] LEHR H F, WOLLMAN E, KOERBER G. Experiments with jacketed rods of high fineness ratio [J]. International Journal of Impact Engineering, 1995, 17(4−6): 517–526. DOI: 10.1016/0734-743x(95)99876-s. [4] SORENSEN B R, KIMSEY K D, ZUKAS J A, et al. Numerical analysis and modeling of jacketed rod penetration [J]. International Journal of Impact Engineering, 1999, 22(1): 71–91. DOI: 10.1016/S0734-743X(98)00043-8. [5] PEDERSEN B A, BLESS S J, CAZAMIAS J U. Hypervelocity jacketed penetrators [J]. International Journal of Impact Engineering, 2001, 26(1−10): 603–611. DOI: 10.1016/S0734-743X(01)00121-X. [6] LEE M. Analysis of jacketed rod penetration [J]. International Journal of Impact Engineering, 2000, 24(9): 891–905. DOI: 10.1016/S0734-743X(00)00020-8. [7] WEN H M, HE Y, LAN B. A combined numerical and theoretical study on the penetration of a jacketed rod into semi-infinite targets [J]. International Journal of Impact Engineering, 2011, 38(12): 1001–1010. DOI: 10.1016/j.ijimpeng.2011.07.001. [8] TANG K, WANG J, CHEN X, et al. Investigation on the damage mechanisms and penetration performance of jacketed rods with different striking velocities [J]. Journal of Applied Mechanics and Technical Physics, 2019, 60(4): 724–731. DOI: 10.1134/S0021894419040175. [9] 兰彬. 长杆弹侵彻半无限靶的数值模拟和理论研究[D]. 合肥: 中国科学技术大学, 2008: 91−99. [10] 何雨. 长杆弹撞击下金属靶板侵彻与穿透的进一步研究[D]. 合肥: 中国科学技术大学, 2013: 40−46. [11] CHEN X W, WEI L M, LI J C. Experimental research on the long rod penetration of tungsten-fiber/Zr-based metallic glass matrix composite into Q235 steel target [J]. International Journal of Impact Engineering, 2015, 79: 102–116. DOI: 10.1016/j.ijimpeng.2014.11.007. [12] MARTIN M, KECSKES L, THADHANI N N. Dynamic compression of a zirconium-based bulk metallic glass confined by a stainless steel sleeve [J]. Scripta Materialia, 2008, 59(7): 688–691. DOI: 10.1016/j.scriptamat.2008.05.045. [13] 潘念侨. Zr基非晶合金材料动态本构关系及其释能效应研究[D]. 南京: 南京理工大学, 2016: 36−54. [14] 尚春明, 施冬梅, 张云峰, 等. Zr基非晶合金毁伤研究进展 [J]. 兵器装备工程学报, 2020, 41(7): 182–186. DOI: 10.11809/bqzbgcxb2020.07.036.SHANG C M, SHI D M, ZHANG Y F, et al. Research progress on damage of Zr-based amorphous alloys [J]. Journal of Ordnance Equipment Engineering, 2020, 41(7): 182–186. DOI: 10.11809/bqzbgcxb2020.07.036. [15] 汪卫华. 非晶态物质的本质和特性 [J]. 物理学进展, 2013, 33(5): 177–351.WANG W H. The nature and properties of amorphous matter [J]. Progress in Physics, 2013, 33(5): 177–351. [16] 陈曦, 杜成鑫, 程春, 等. Zr基非晶合金材料的冲击释能特性 [J]. 兵器材料科学与工程, 2018, 41(6): 44–49. DOI: 10.14024/j.cnki.1004-244x.20180717.002.CHEN X, DU C X, CHENG C, et al. Impact energy releasing characteristics of Zr-based amorphous alloy [J]. Ordnance Material Science and Engineering, 2018, 41(6): 44–49. DOI: 10.14024/j.cnki.1004-244x.20180717.002. [17] 宋璇, 吴先前, 戴兰宏, 等. 纳秒脉冲激光烧蚀非晶合金的研究进展 [J]. 固体力学学报, 2018, 39(5): 439–452. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2018.032.SONG X, WU X Q, DAI L H, et al. Advances on nanosecond pulse laser ablation of amorphous alloys [J]. Chinese Journal of Solid Mechanics, 2018, 39(5): 439–452. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2018.032. [18] 尚春明, 施冬梅, 张云峰, 等. Zr基非晶合金的燃烧释能特性 [J]. 含能材料, 2020, 28(6): 564–568. DOI: 10.11943/CJEM2019219.SHANG C M, SHI D M, ZHANG Y F, et al. Combustion and energy release characteristics of Zr-based amorphous alloys [J]. Chinese Journal of Energetic Materials, 2020, 28(6): 564–568. DOI: 10.11943/CJEM2019219. [19] HUANG C M, LI S, BAI S X. Quasi-static and impact-initiated response of Zr55Ni5Al10Cu30 alloy [J]. Journal of Non-Crystalline Solids, 2018, 481: 59–64. DOI: 10.1016/j.jnoncrysol.2017.10.011. [20] 石永相, 施冬梅. ZrCuNiAlAg块体非晶合金动静态力学性能研究 [J]. 热加工工艺, 2019, 48(6): 83–86, 90. DOI: 10.14158/j.cnki.1001-3814.2019.06.020.SHI Y X, SHI D M. Study on dynamic and static mechanical properties of ZrCuNiAlAg bulk amorphous alloy [J]. Hot Working Technology, 2019, 48(6): 83–86, 90. DOI: 10.14158/j.cnki.1001-3814.2019.06.020. [21] 石永相. 多元非晶合金含能材料药型罩应用研究[D]. 石家庄: 陆军工程大学, 2017: 44−56. [22] HU K, LI X Q, GUAN M, et al. Dynamic deformation behavior of 93W-5.6Ni-1.4Fe heavy alloy prepared by spark plasma sintering [J]. International Journal of Refractory Metals and Hard Materials, 2016, 58: 117–124. DOI: 10.1016/j.ijrmhm.2016.04.010. [23] 郭俊. 活性分段动能杆对混凝土靶的毁伤效应研究[D]. 北京: 北京理工大学, 2016: 36−64. -

下载:

下载: