Impact resistance of concrete-filled steel tubular members under long-term loading

-

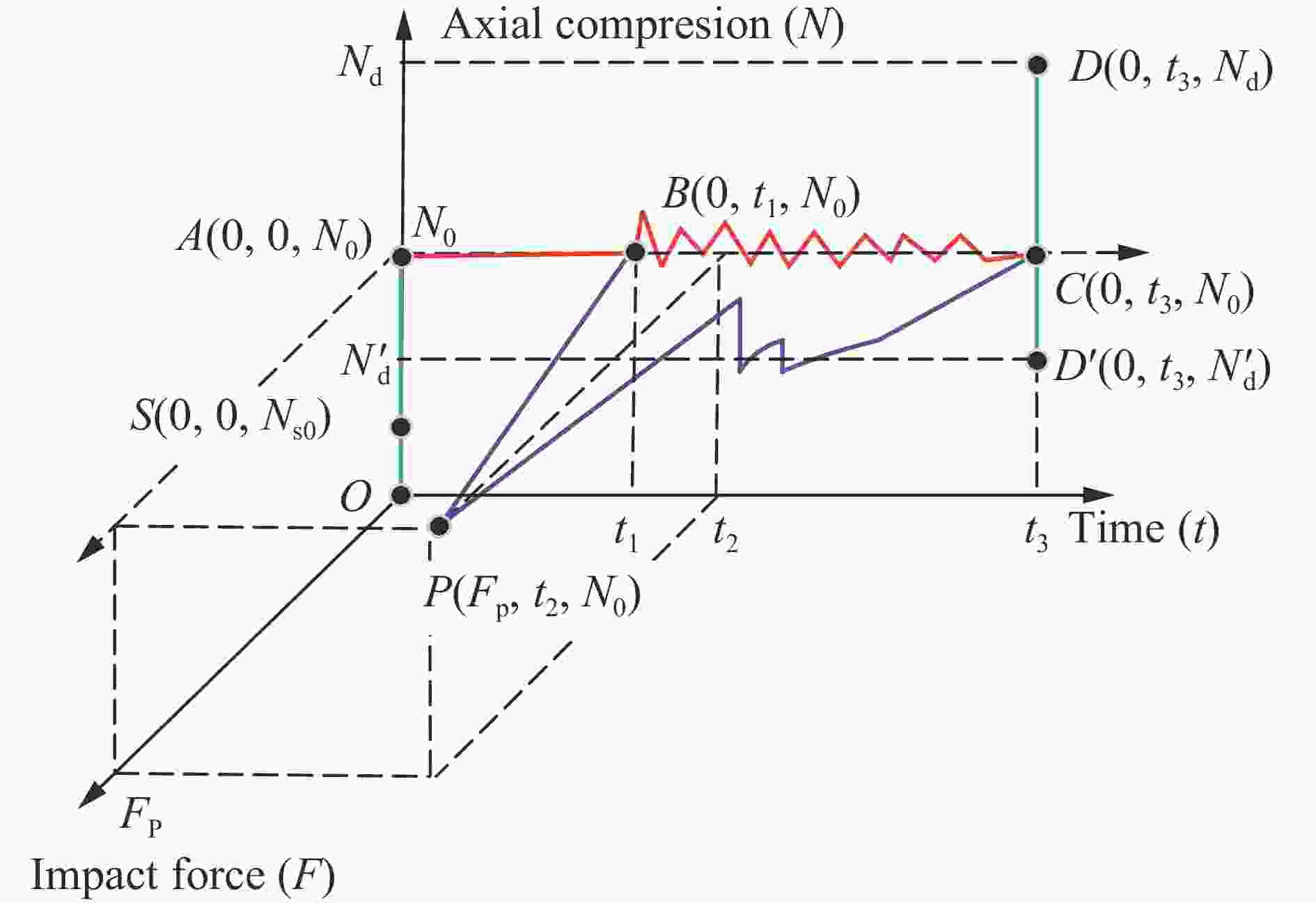

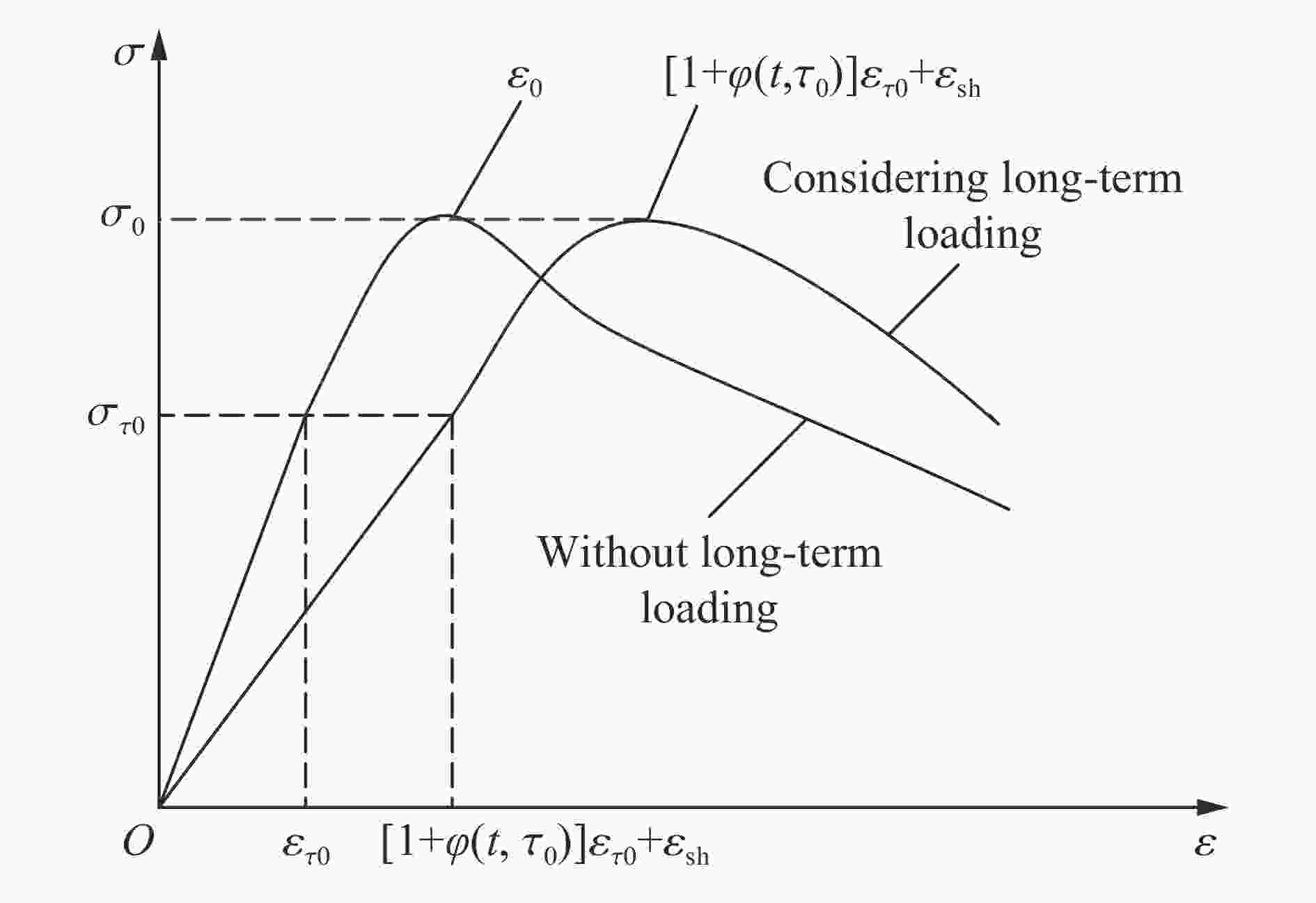

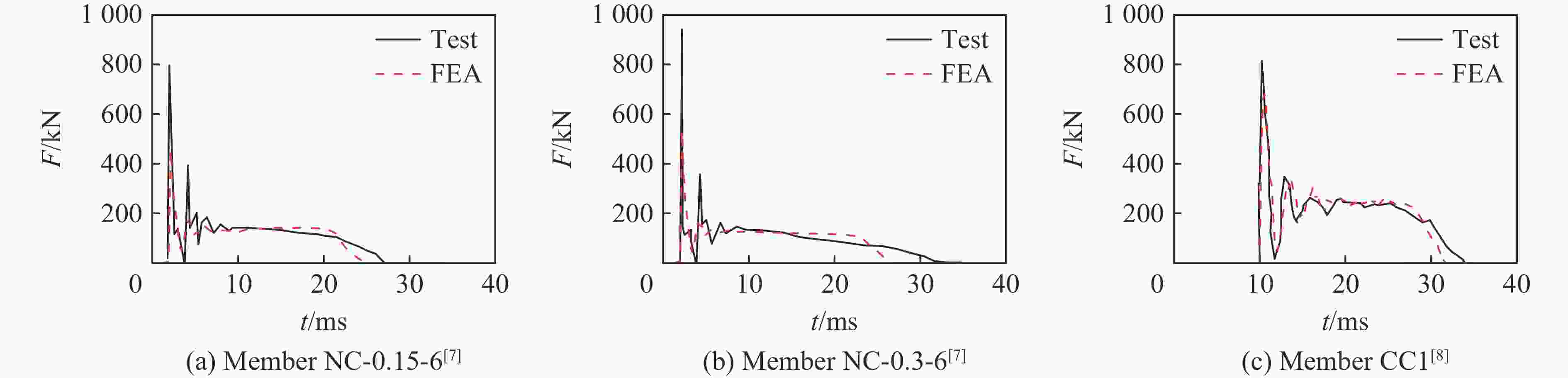

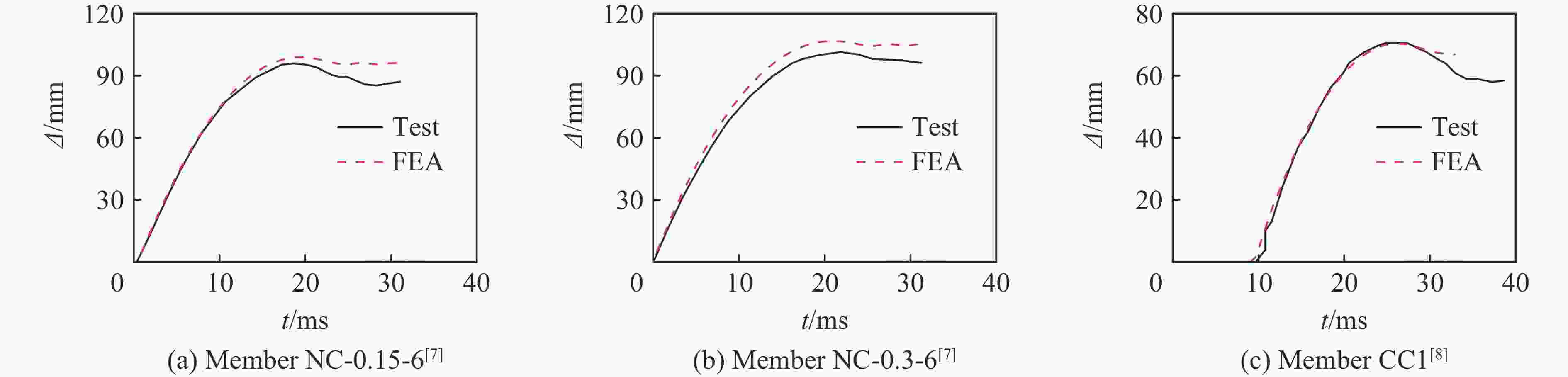

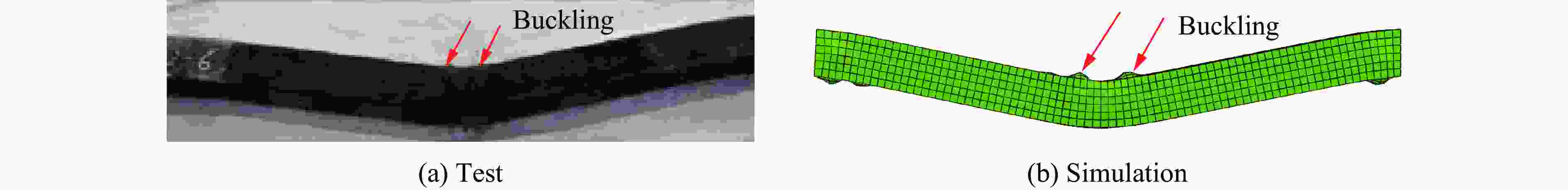

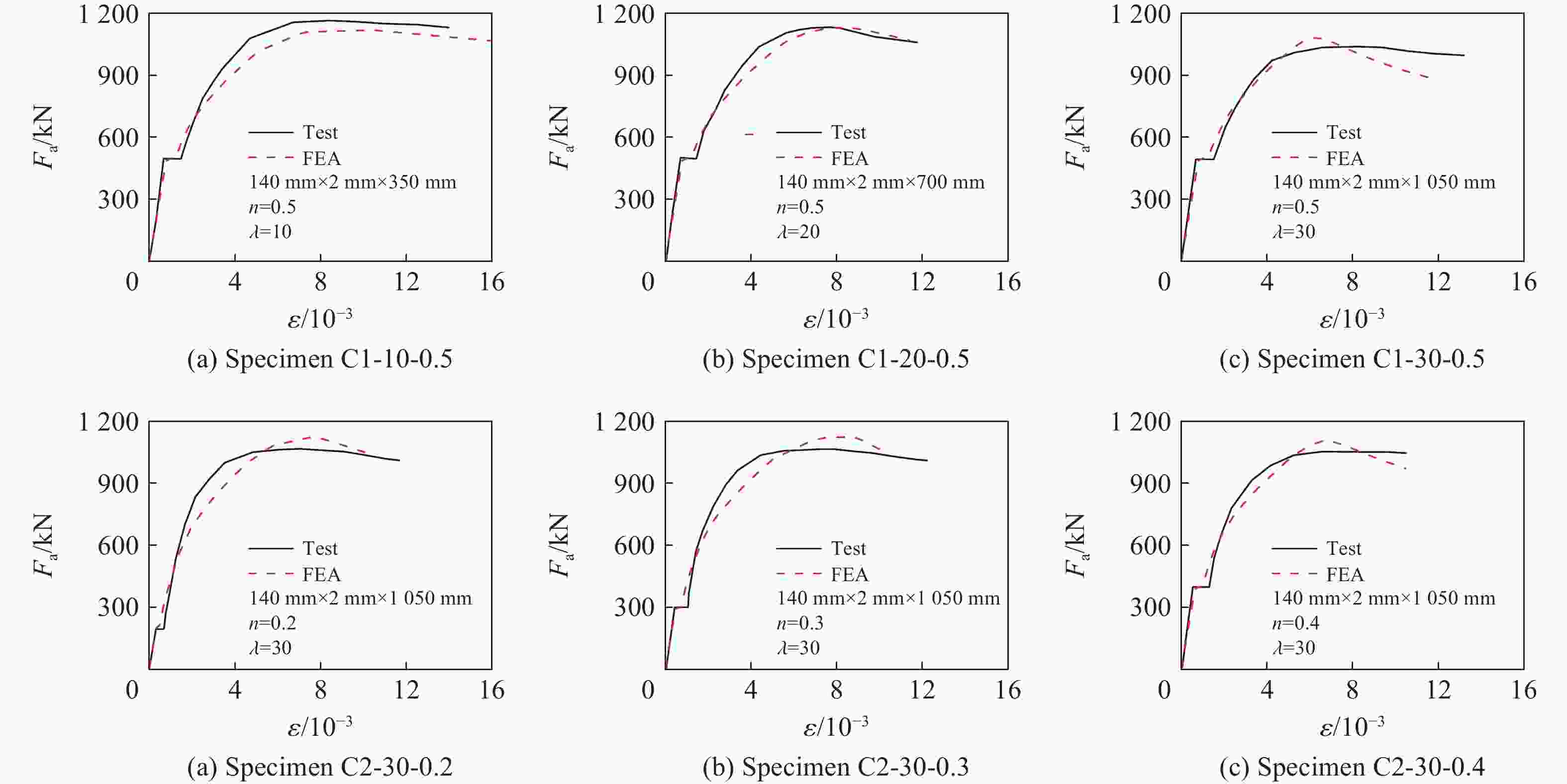

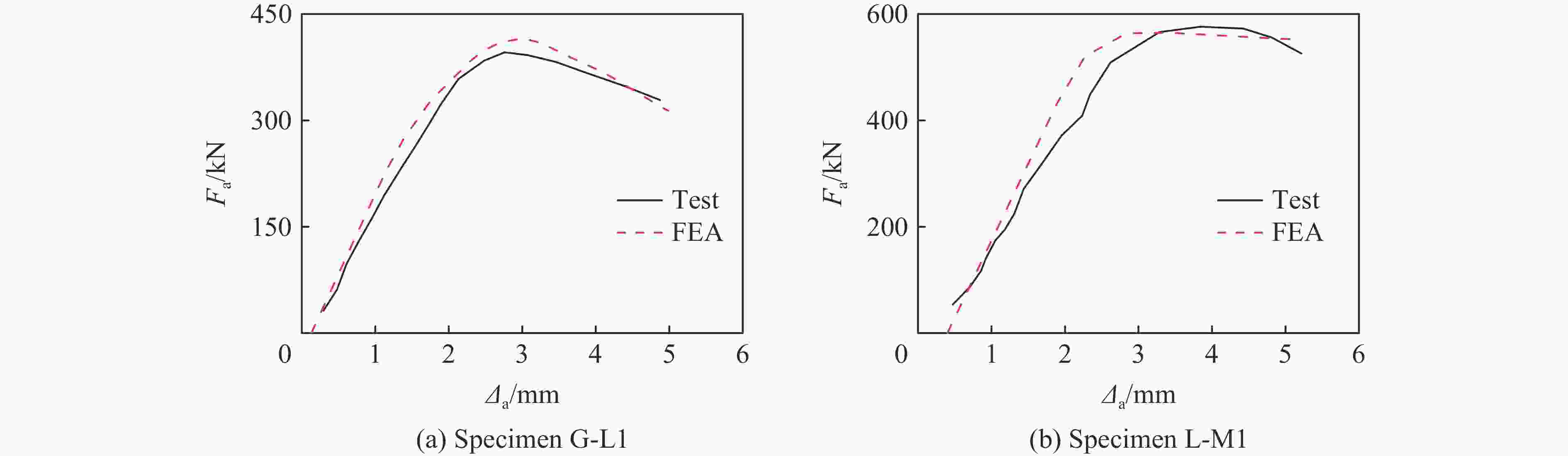

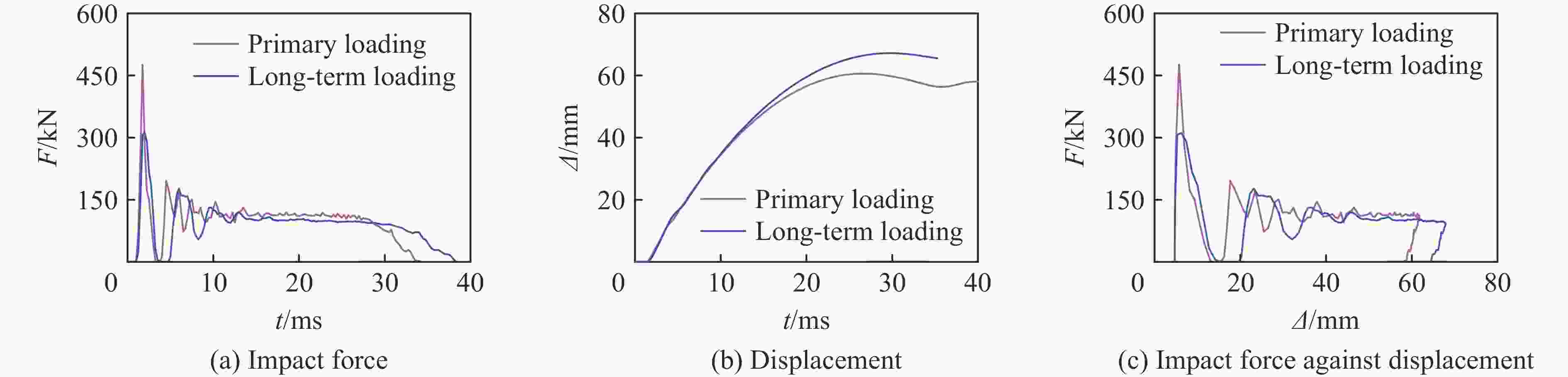

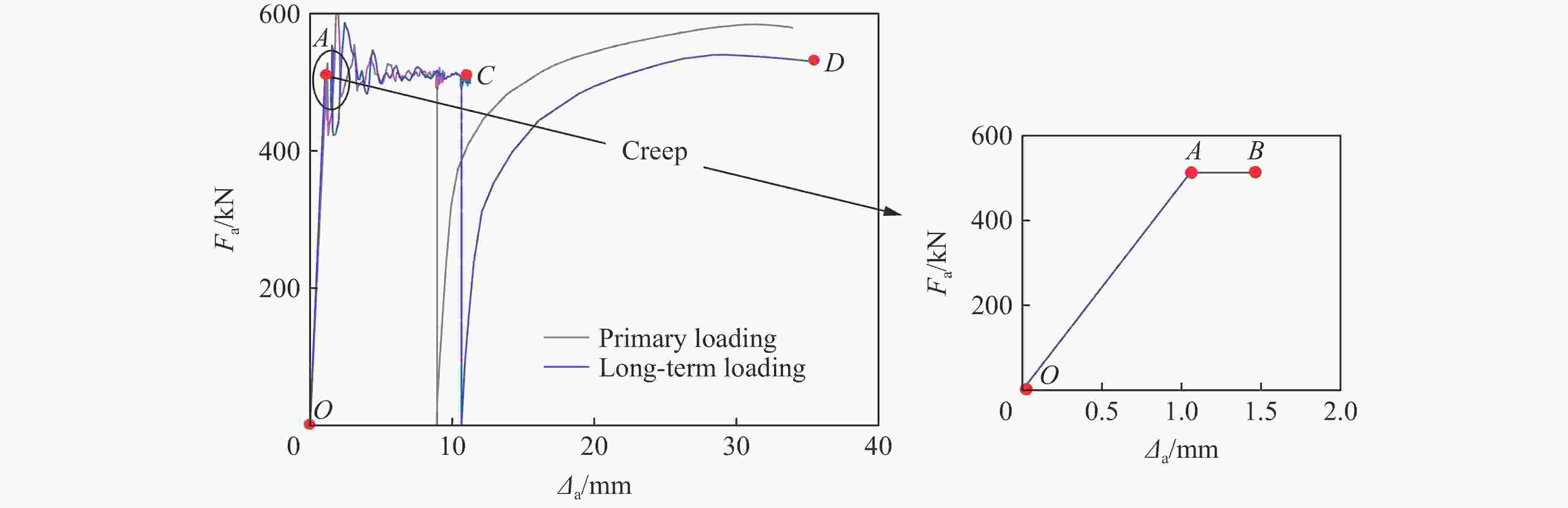

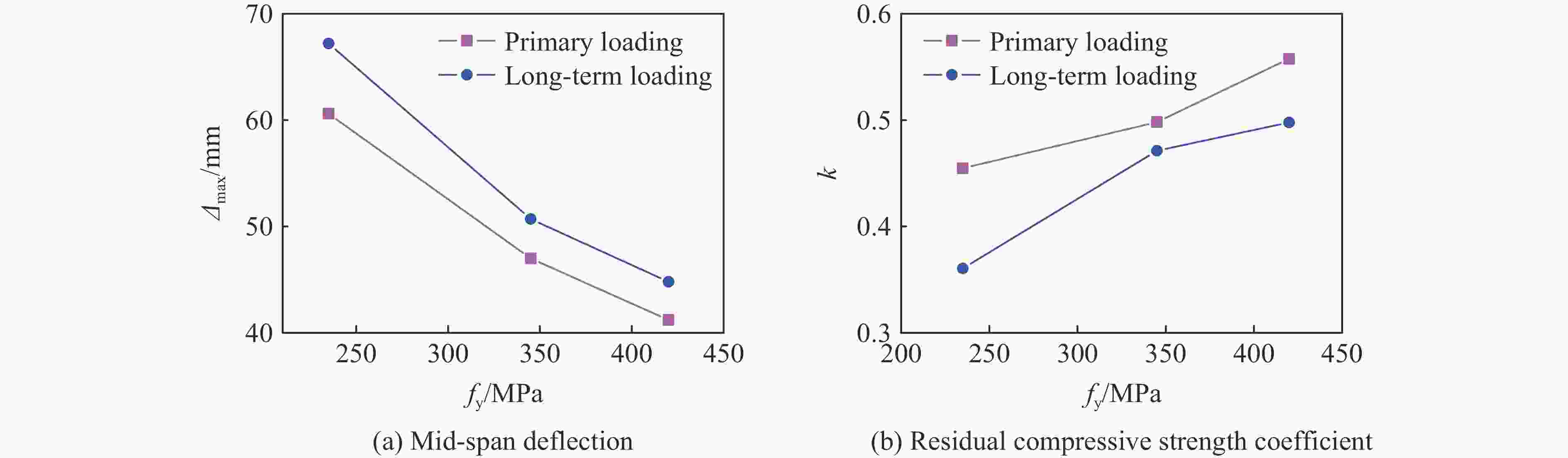

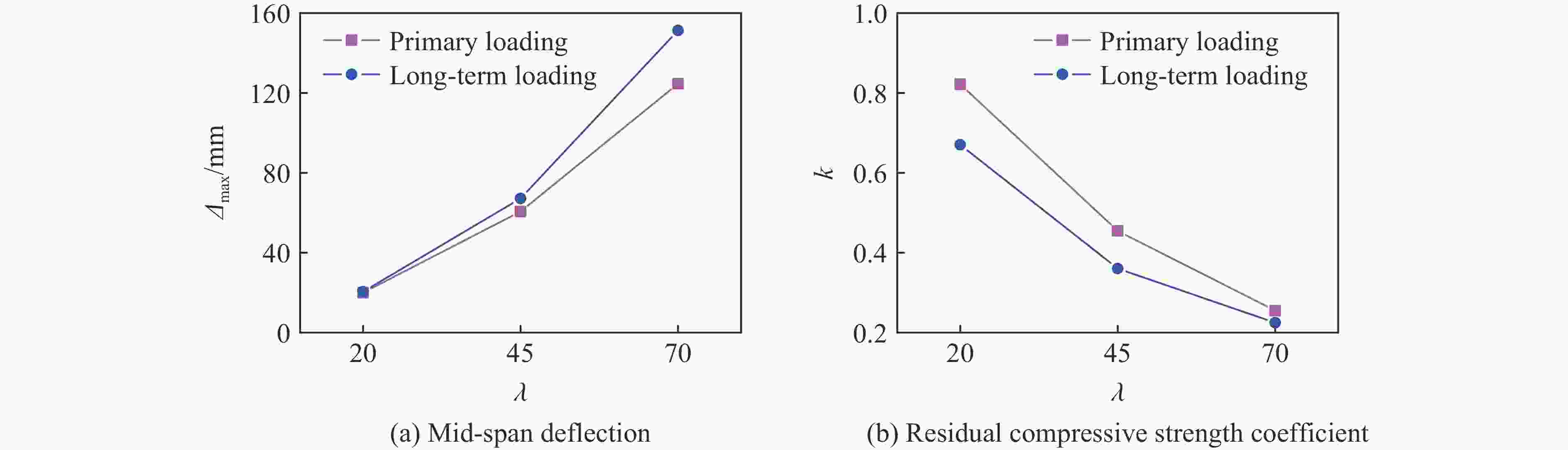

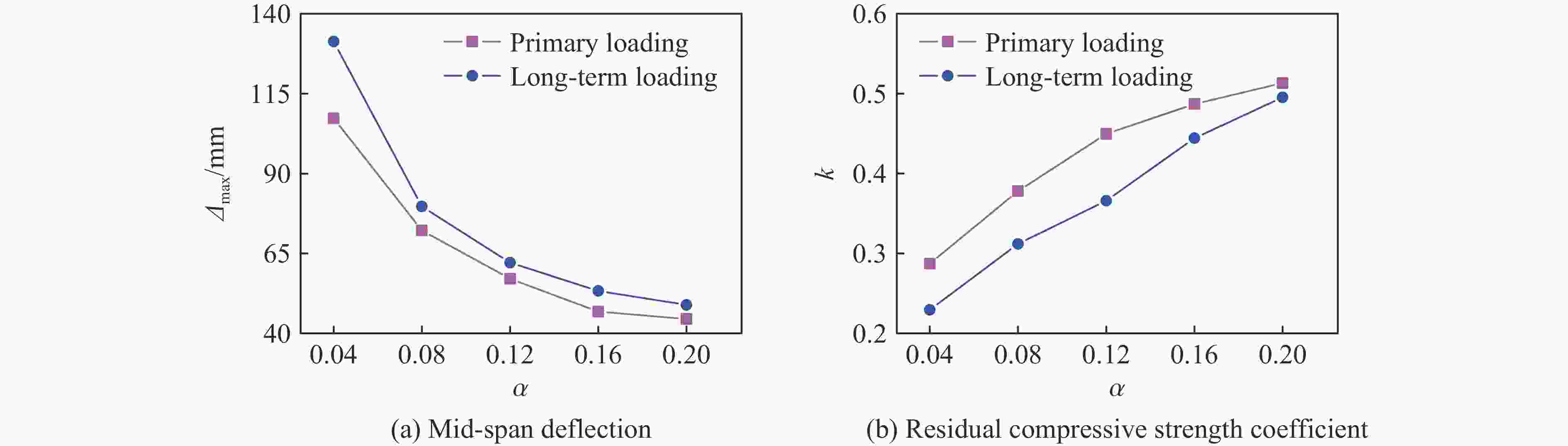

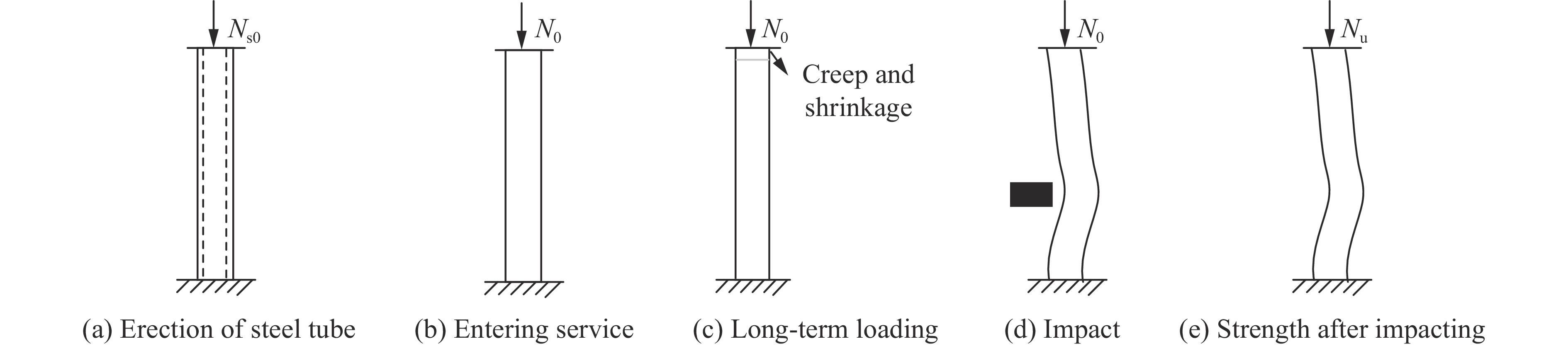

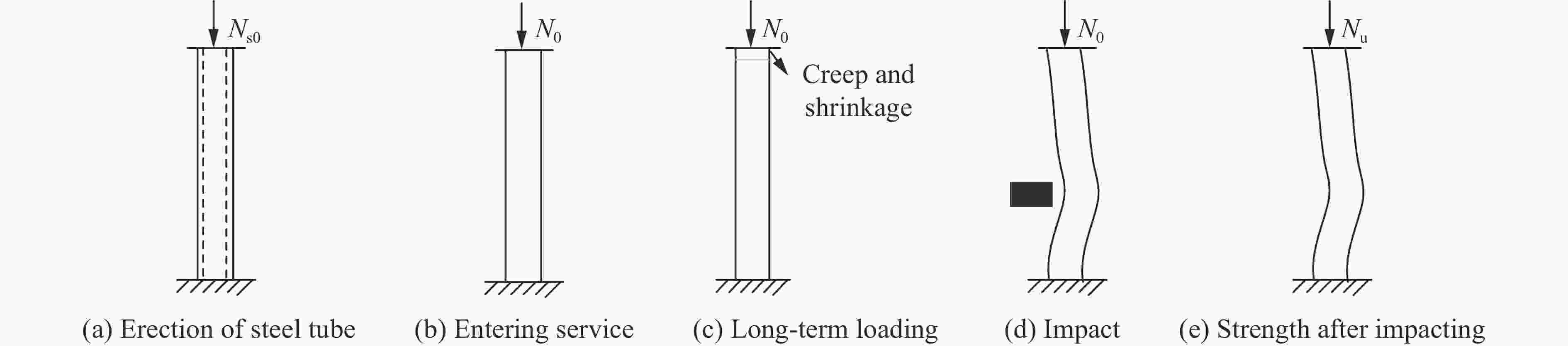

摘要: 为研究长期荷载作用对钢管混凝土构件抗撞击性能的影响,利用有限元软件ABAQUS建立了长期荷载与侧向撞击荷载作用的耦合分析模型以及撞击后剩余受压承载力计算模型。对比了一次加载模式下和长期荷载作用下构件遭受撞击的动力响应,采用剩余受压承载力系数量化分析了两种加载模式下构件的剩余受压承载力。典型的有限元模型分析表明:相较于一次加载模式,考虑长期荷载作用时撞击力峰值和平台值下降,撞击时间延长,构件跨中挠度增大,但撞击力对构件做功基本保持不变;考虑长期荷载作用的撞击过程轴向荷载做功比一次加载模式增大,增加的功主要通过外钢管的塑性变形耗散,核心混凝土贡献较小;长期荷载作用下构件的剩余受压承载力系数均低于一次加载模式,撞击条件相同时,一次加载模式下撞击后可以继续承载的构件在考虑长期荷载作用时可能会丧失承载能力;提高含钢率和钢材屈服强度、降低长期荷载比可有效减小长期荷载对构件抗撞击性能的不利影响。Abstract: In order to study the influence of long-term loading on the impact resistance of concrete-filled steel tubular (CFST) members, a finite element analysis (FEA) model was developed by using the software ABAQUS, which embeds the coupling analysis of long-term loading and lateral impact loading, along with the calculation of the residual compressive strength after impacting. The developed FEA models were verified by three tests. Based on the proposed method, the dynamic response of the CFST members under long-term loading was compared with that under primary loading. The residual compressive strength coefficient was used to quantitatively compare the residual compressive strength of the CFST members under those two loading modes and the influences of the steel ratio, steel yield strength, concrete strength, long-term loading ratio, slenderness ratio on the residual compressive strength coefficient were investigated as well. The results from the FEA show that compared with the primary loading mode, when considering the long-term loading, the peak and plateau values of the impact force decrease, the mid-span displacement increases, but the works done by the impact forces under two circumstances are equal. The work done by the axial load is more than that of the primary loading mode when the long-term loading is included, the excess work is mainly dissipated due to plastic deformation of the steel and the concrete has little contribution to the energy dissipation. At the same condition, the members that can continue to bear loads under the primary loading may lose their bearing capacity when considering the long-term loading. According to the parametric analysis, increasing the steel ratio and steel yield strength, and reducing the long-term loading ratio can effectively reduce the adverse effects of the long-term loading on the anti-impact performance of the members, with the increase of the slenderness ratio, the long-term loading will bring more adverse effects on the anti-impact performance of the members, the concrete strength has little effects on the impact resistance of the CFST members.

-

表 1 撞击试验构件基本参数

Table 1. Basic parameters of impact test members

编号 d(b) /mm δa/mm l/mm F/kN n m/kg v/(m·s−1) tc/te Δc/Δe 来源 NC-0.15-6 100 2.45 1 800 100 0.15 238.16 10.844 1.02 0.97 文献[7] NC-0.3-6 200 0.30 1.12 0.95 TSC5 114 2.00 1 800 355 0.50 206.65 9.391 1.09 0.95 文献[13] SRC5 315 0.50 206.65 1.18 1.06 CC1 180 3.65 1 940 0 0 465.00 9.210 1.06 1.00 文献[8] CC2 180 3.65 1 940 0 0 920.00 6.400 1.07 0.96 CS3 180 3.65 2 400 0 0 465.00 7.970 0.98 1.05 -

[1] 新浪新闻. 阿根廷首都城铁出轨至少49死600伤 [EB/OL]. (2012-2-23)[2020-06-18]. http://news.sina.com.cn/w/p/2012-02-23/033523976508.shtml. [2] 王文达, 邹爱华, 张鹏鹏. 长期荷载作用下矩形钢管混凝土轴压短柱力学性能 [J]. 公路交通科技, 2011, 28(7): 73–78. DOI: 10.3969/j.issn.1002-0268.2011.07.013.WANG W D, ZOU A H, ZHANG P P. Behavior of rectangular CFST axial compressive stub column under long-term loading [J]. Journal of Highway and Transportation Research and Development, 2011, 28(7): 73–78. DOI: 10.3969/j.issn.1002-0268.2011.07.013. [3] 韩林海, 刘威. 长期荷载作用对圆钢管混凝土压弯构件力学性能影响的研究 [J]. 土木工程学报, 2002, 35(2): 8–19. DOI: 10.3321/j.issn:1000-131X.2002.02.002.HAN L H, LIU W. The effects of long-time loading on the behavior of concrete-filled steel tubular member [J]. China Civil Engineering Journal, 2002, 35(2): 8–19. DOI: 10.3321/j.issn:1000-131X.2002.02.002. [4] WANG R, HAN L H, HOU C C. Behavior of Concrete Filled Steel Tubular (CFST) members under lateral impact: experiment and FEA model [J]. Journal of Constructional Steel Research, 2013, 80: 188–201. DOI: 10.1016/j.jcsr.2012.09.003. [5] 王潇宇, DEMARTINO C, 徐金俊, 等. 侧向冲击作用下钢管混凝土柱动力响应试验研究及计算方法 [J]. 土木工程学报, 2017, 50(12): 28–36. DOI: 10.15951/j.tmgcxb.2017.12.004.WANG X Y, DEMARTINO C, XU J J, et al. Dynamic response of concrete filled steel tube column under lateral impact load: experimental study and calculation method [J]. China Civil Engineering Journal, 2017, 50(12): 28–36. DOI: 10.15951/j.tmgcxb.2017.12.004. [6] BAMBACH M R. Validation of a general design procedure for the transverse impact capacity of steel columns [J]. Journal of Constructional Steel Research, 2018, 150: 153–161. DOI: 10.1016/j.jcsr.2018.08.021. [7] YANG Y F, ZHANG Z C, FU F. Experimental and numerical study on square RACFST members under lateral impact loading [J]. Journal of Constructional Steel Research, 2015, 111: 43–56. DOI: 10.1016/j.jcsr.2015.04.004. [8] HAN L H, HOU C C, ZHAO X L, et al. Behaviour of high-strength concrete filled steel tubes under transverse impact loading [J]. Journal of Constructional Steel Research, 2014, 92: 25–39. DOI: 10.1016/j.jcsr.2013.09.003. [9] 史艳莉, 纪孙航, 王文达, 等. 高温作用下钢管混凝土构件侧向撞击性能 [J]. 爆炸与冲击, 2020, 40(4): 043303. DOI: 10.11883/bzycj-2019-0293.SHI Y L, JI S H, WANG W D, et al. The lateral impact performance of concrete-filled steel tubular (CFST) members at high temperatures [J]. Explosion and Shock Waves, 2020, 40(4): 043303. DOI: 10.11883/bzycj-2019-0293. [10] XIAN W, WANG W D, WANG R, et al. Dynamic response of steel-reinforced concrete-filled circular steel tubular members under lateral impact loads [J]. Thin-Walled Structures, 2020, 151: 106736. DOI: 10.1016/j.tws.2020.106736. [11] 史艳莉, 鲜威, 王蕊, 等. 方套圆中空夹层钢管混凝土组合构件横向撞击试验研究 [J]. 土木工程学报, 2019, 52(12): 11–21, 35. DOI: 10.15951/j.tmgcxb.2019.12.002.SHI Y L, XIAN W, WANG R, et al. Experimental study on circular-in-square concrete filled double-skin steel tubular (CFDST) composite components under lateral impact [J]. China Civil Engineering Journal, 2019, 52(12): 11–21, 35. DOI: 10.15951/j.tmgcxb.2019.12.002. [12] 史艳莉, 何佳星, 王文达, 等. 内配圆钢管的圆钢管混凝土构件耐撞性能分析 [J]. 振动与冲击, 2019, 38(9): 123–132. DOI: 10.13465/j.cnki.jvs.2019.09.017.SHI Y L, HE J X, WANG W D, et al. Anti-impact performance analysis for circular CFST members with inner circular steel tube [J]. Journal of Vibration and Shock, 2019, 38(9): 123–132. DOI: 10.13465/j.cnki.jvs.2019.09.017. [13] 朱翔, 陆新征, 杜永峰, 等. 新型复合柱抗冲击试验研究及有限元分析 [J]. 工程力学, 2016, 33(8): 158–166, 220. DOI: 10.6052/j.issn.1000-4750.2015.03.0153.ZHU X, LU X Z, DU Y F, et al. Experimental study and finite element analysis of impact resistance of novel composite columns [J]. Engineering Mechanics, 2016, 33(8): 158–166, 220. DOI: 10.6052/j.issn.1000-4750.2015.03.0153. [14] WANG R, HAN L H, ZHAO X L, et al. Experimental behavior of concrete filled double steel tubular (CFDST) members under low velocity drop weight impact [J]. Thin-Walled Structures, 2015, 97: 279–295. DOI: 10.1016/j.tws.2015.09.009. [15] WANG R, HAN L H, ZHAO X L, et al. Analytical behavior of concrete filled double steel tubular (CFDST) members under lateral impact [J]. Thin-Walled Structures, 2016, 101: 129–140. DOI: 10.1016/j.tws.2015.12.006. [16] 章琪, 蒋庆, 陆新征. 侧向冲击对钢管混凝土受压承载力影响研究 [J]. 结构工程师, 2013, 29(3): 59–64. DOI: 10.3969/j.issn.1005-0159.2013.03.011.ZHANG Q, JIANG Q, LU X Z. Lateral impact effects on the compressive strength of concrete filled steel tubes [J]. Structural Engineers, 2013, 29(3): 59–64. DOI: 10.3969/j.issn.1005-0159.2013.03.011. [17] HOU C C, HAN L H. Life-cycle performance of deteriorated concrete-filled steel tubular (CFST) structures subject to lateral impact [J]. Thin-Walled Structures, 2018, 132: 362–374. DOI: 10.1016/j.tws.2018.08.025. [18] ZHANG X Y, CHEN Y, WAN J, et al. Tests on residual ultimate bearing capacity of square CFST columns after impact [J]. Journal of Constructional Steel Research, 2018, 147: 27–42. DOI: 10.1016/j.jcsr.2018.03.039. [19] 韩林海. 钢管混凝土结构-理论与实践[M]. 3版. 北京: 科学出版社, 2016. [20] 陈俊岭, 舒文雅, 李金威. Q235钢材在不同应变率下力学性能的试验研究 [J]. 同济大学学报(自然科学版), 2016, 44(7): 1071–1075. DOI: 10.11908/j.issn.0253-374x.2016.07.014.CHEN J L, SHU W Y, LI J W. Experimental study on dynamic mechanical property of Q235 steel at different strain rates [J]. Journal of Tongji University (Natural Science), 2016, 44(7): 1071–1075. DOI: 10.11908/j.issn.0253-374x.2016.07.014. [21] ACI Committee. Prediction of creep, shrinkage, and temperature effects in concrete structures: 209R-1992[S]. Detroit: ACI Committee, 1992. [22] 赖秀英. 钢管混凝土拱桥收缩、徐变效应研究[D]. 福州: 福州大学, 2016: 72−77. [23] 崔娟玲, 郭昭胜, 王蕊, 等. 热轧H型钢柱侧向冲击试验研究 [J]. 振动与冲击, 2014, 33(18): 133–139. DOI: 10.13465/j.cnki.jvs.2014.18.022.CUI J L, GUO Z S, WANG R, et al. Tests for behavior of a hot rolled H-shaped steel column under lateral impact [J]. Journal of Vibration and Shock, 2014, 33(18): 133–139. DOI: 10.13465/j.cnki.jvs.2014.18.022. -

下载:

下载: