| [1] |

DODD B, BAI Y L. Adiabatic shear localization [M]. 2nd ed. London: Elsevier, 2012: 4−5.

|

| [2] |

杨扬, 程信林. 绝热剪切的研究现状及发展趋势 [J]. 中国有色金属学报, 2002, 12(3): 401–408. DOI: 1004-0609(2002)03-0401-08.YANG Y, CHENG X L. Current status and trends in researches on adiabatic shearing [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 401–408. DOI: 1004-0609(2002)03-0401-08.

|

| [3] |

WALLEY S M. Shear localization: a historical overview [J]. Metallurgical and Materials Transactions A, 2007, 38(11): 2629–2654. DOI: 10.1007/s11661-007-9271-x.

|

| [4] |

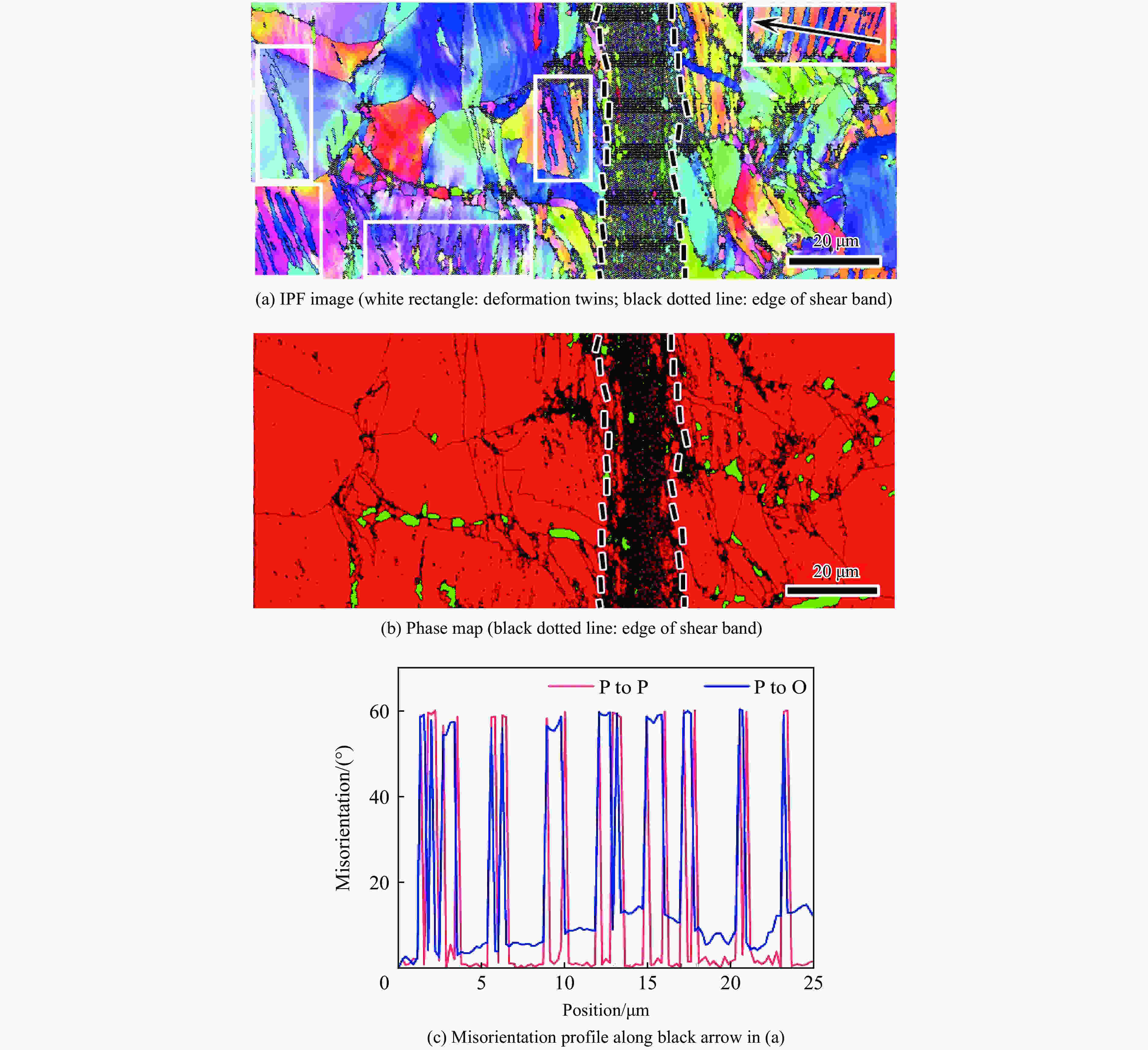

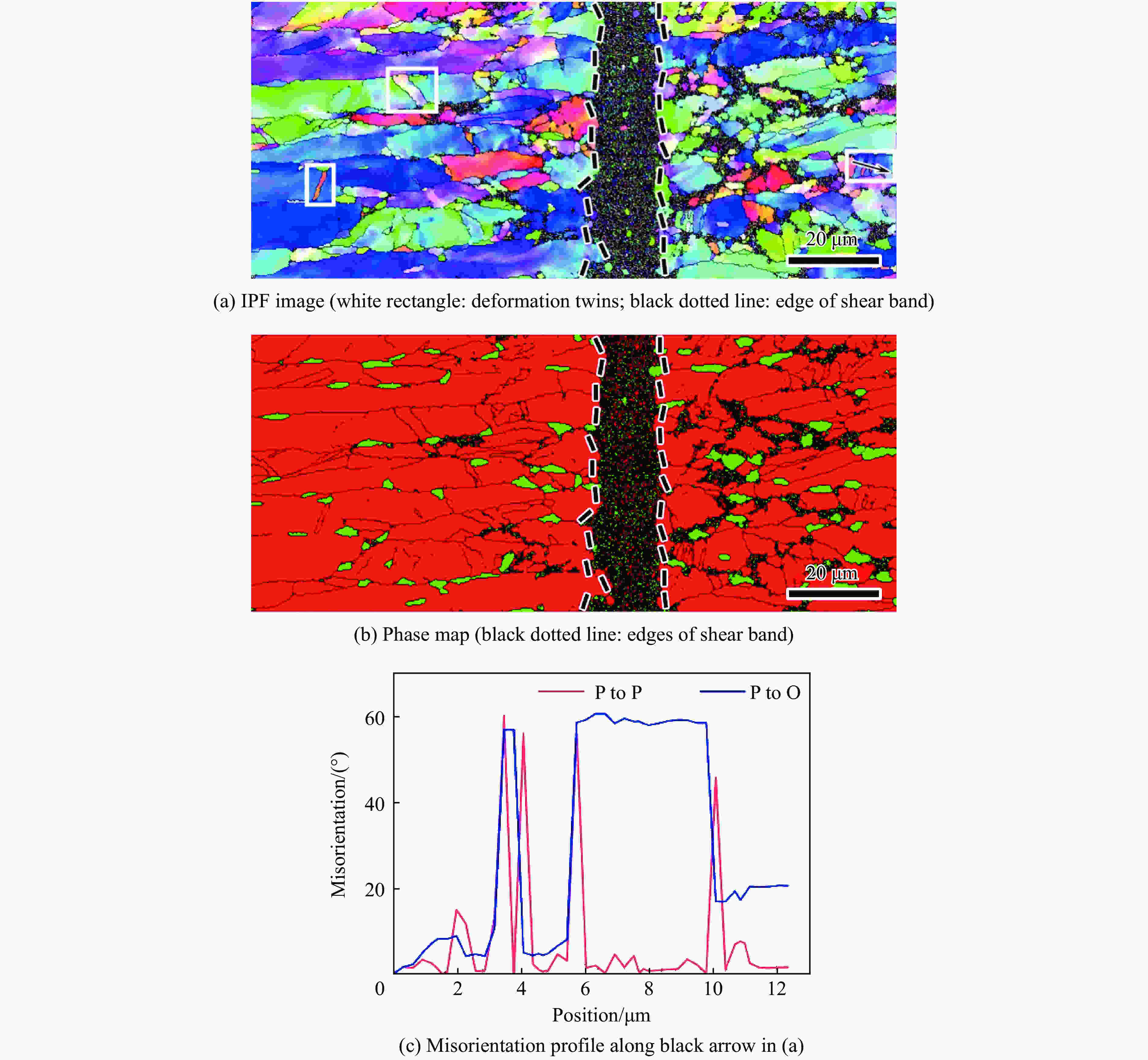

MEYERS M A, XU Y B, XUE Q, et al. Microstructural evolution in adiabatic shear localization in stainless steel [J]. Acta Materialia, 2003, 51(5): 1307–1325. DOI: 10.1016/s1359-6454(02)00526-8.

|

| [5] |

YANG Y, LIAN X L, WANG J L. Effect of the grain boundary character distribution on the self-organization of adiabatic shear bands in 1Cr18Ni9Ti austenitic stainless steel [J]. Journal of Materials Science, 2019, 54(9): 7256–7270. DOI: 10.1007/s10853-019-03377-z.

|

| [6] |

LI N, WANG Y D, PENG R L, et al. Localized amorphism after high-strain-rate deformation in TWIP steel [J]. Acta Materialia, 2011, 59(16): 6369–6377. DOI: 10.1016/j.actamat.2011.06.048.

|

| [7] |

WEI Q, KECSKES L, JIAO T, et al. Adiabatic shear banding in ultrafine-grained Fe processed by severe plastic deformation [J]. Acta Materialia, 2004, 52(7): 1859–1869. DOI: 10.1016/j.actamat.2003.12.025.

|

| [8] |

WEI Q, SCHUSTER B E, MATHAUDHU S N, et al. Dynamic behaviors of body-centered cubic metals with ultrafine grained and nanocrystalline microstructures [J]. Materials Science and Engineering: A, 2008, 493(1/2): 58–64. DOI: 10.1016/j.msea.2007.05.126.

|

| [9] |

ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel [J]. Journal of Applied Physics, 1944, 15(1): 22–32. DOI: 10.1063/1.1707363.

|

| [10] |

BATRA R C, KIM C H. Adiabatic shear banding in elastic-viscoplastic nonpolar and dipolar materials [J]. International Journal of Plasticity, 1990, 6(2): 127–141. DOI: 10.1016/0749-6419(90)90018-a.

|

| [11] |

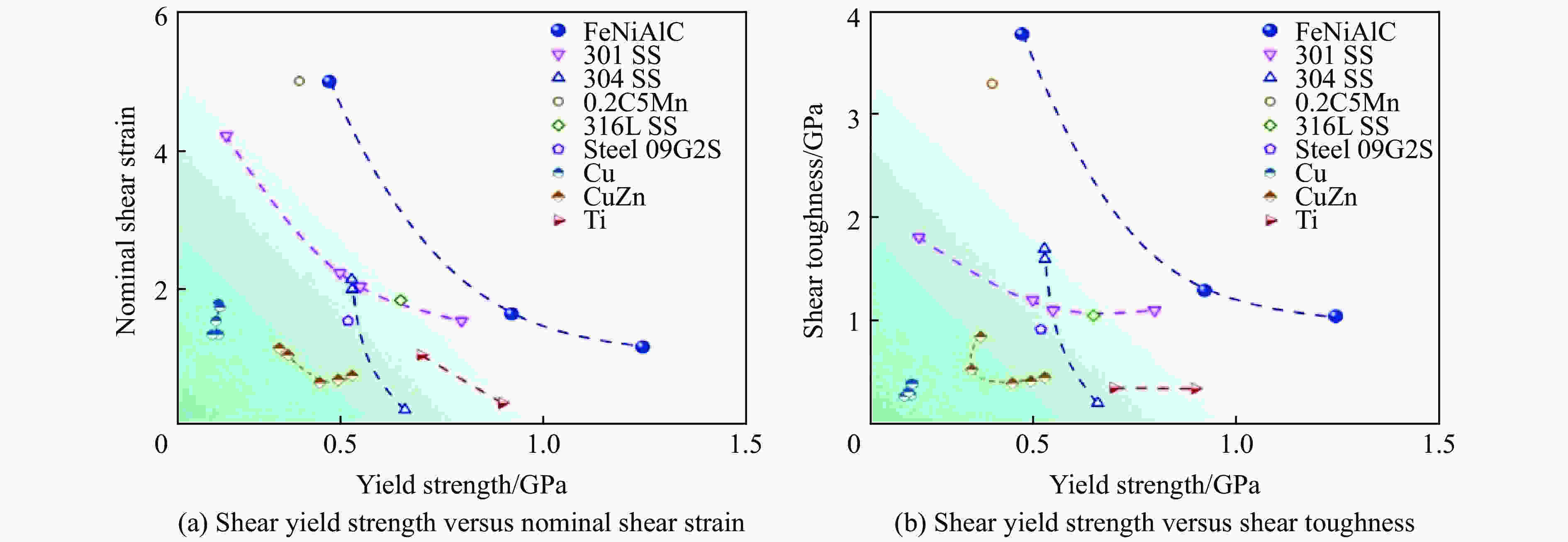

BIAN X D, YUAN F P, ZHU Y T, et al. Gradient structure produces superior dynamic shear properties [J]. Materials Research Letters, 2017, 5(7): 501–507. DOI: 10.1080/21663831.2017.1334715.

|

| [12] |

HE J Y, YUAN F P, YANG M X, et al. Superior mechanical properties and deformation mechanisms of heterogeneous laminates under dynamic shear loading [J]. Materials Science and Engineering: A, 2019, 756: 492–501. DOI: 10.1016/j.msea.2019.04.082.

|

| [13] |

XUE Q, GRAY III G T, HENRIE B L, et al. Influence of shock prestraining on the formation of shear localization in 304 stainless steel [J]. Metallurgical and Materials Transactions A, 2005, 36(6): 1471–1486. DOI: 10.1007/s11661-005-0239-4.

|

| [14] |

YUAN F P, BIAN X D, JIANG P, et al. Dynamic shear response and evolution mechanisms of adiabatic shear band in an ultrafine-grained austenite-ferrite duplex steel [J]. Mechanics of Materials, 2015, 89: 47–58. DOI: 10.1016/j.mechmat.2015.06.004.

|

| [15] |

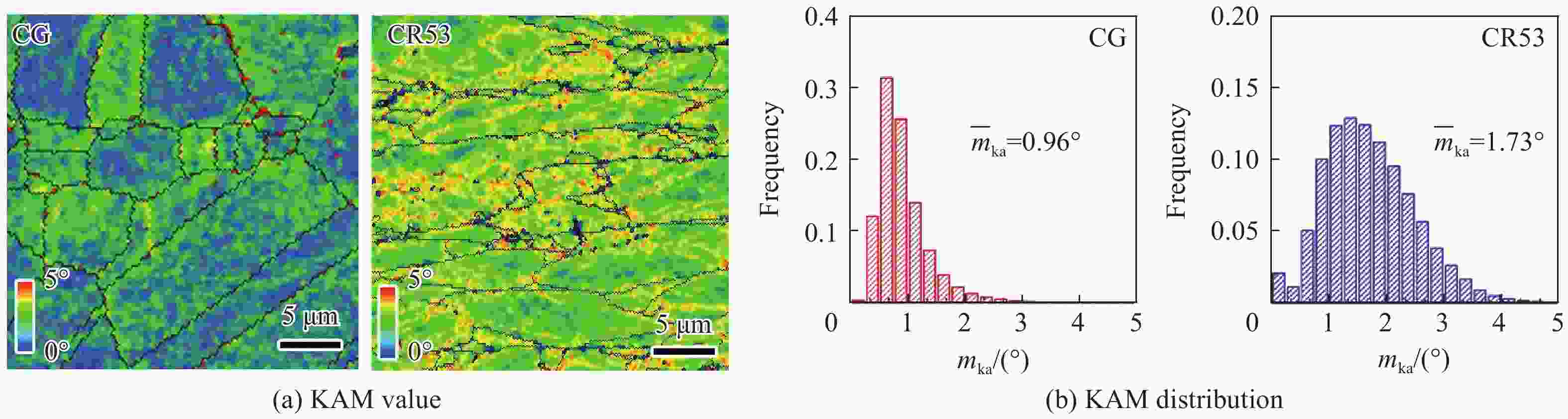

MA Y, YANG M X, JIANG P, et al. Plastic deformation mechanisms in a severely deformed Fe-Ni-Al-C alloy with superior tensile properties [J]. Scientific Reports, 2017, 7(1): 15619. DOI: 10.1038/s41598-017-15905-5.

|

| [16] |

WU X L, YANG M X, YUAN F P, et al. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility [J]. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(47): 14501–14505. DOI: 10.1073/pnas.1517193112.

|

| [17] |

VERCAMMEN S, BLANPAIN B, DE COOMAN B C, et al. Cold rolling behaviour of an austenitic Fe-30Mn-3Al-3Si TWIP-steel: the importance of deformation twinning [J]. Acta Materialia, 2004, 52(7): 2005–2012. DOI: 10.1016/j.actamat.2003.12.040.

|

| [18] |

XING J X, YUAN F P, WU X L. Enhanced quasi-static and dynamic shear properties by heterogeneous gradient and lamella structures in 301 stainless steels [J]. Materials Science and Engineering A, 2017, 680: 305–316. DOI: 10.1016/j.msea.2016.10.111.

|

| [19] |

XUE Q, GRAY III G T. Development of adiabatic shear bands in annealed 316l stainless steel: Part Ⅰ. correlation between evolving microstructure and mechanical behavior [J]. Metallurgical and Materials Transactions A, 2006, 37(8): 2435–2446. DOI: 10.1007/bf02586217.

|

| [20] |

PUSHKOV V, YURLOV A, BOL’SHAKOV A, et al. Study of adiabatic localized shear in metals by split Hopkinson pressure bar method [C] ∥ Conference on New Models and Hydrocodes for Shock Wave Processes in Condensed Matter. Paris: EPJ, 2010, 10: 00029.DOI: 10.1051/epjconf/20101000029.

|

| [21] |

PUSHKOV V A, YURLOV A V, PODURETS A M, et al. Effect of preloading on the formation of adiabatic localized shear in copper [J]. Combustion, Explosion, and Shock Waves, 2013, 49(5): 620–624. DOI: 10.1134/s0010508213050146.

|

| [22] |

HOFMANN U, EL-MAGD E. Behaviour of Cu-Zn alloys in high speed shear tests and in chip formation processes [J]. Materials Science and Engineering: A, 2005, 395(1/2): 129–140. DOI: 10.1016/j.msea.2004.12.030.

|

| [23] |

GU Y B, NESTERENKO V F. Dynamic behavior of HIPed Ti-6Al-4V [J]. International Journal of Impact Engineering, 2007, 34(4): 771–783. DOI: 10.1016/j.ijimpeng.2006.01.006.

|

| [24] |

YANG Y, JIANG F, ZHOU B M, et al. Microstructural characterization and evolution mechanism of adiabatic shear band in a near beta-Ti alloy [J]. Materials Science and Engineering: A, 2011, 528(6): 2787–2794. DOI: 10.1016/j.msea.2010.12.053.

|

| [25] |

MA Y, YUAN F P, YANG M X, et al. Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures [J]. Acta Materialia, 2018, 148: 407–418. DOI: 10.1016/j.actamat.2018.02.016.

|

| [26] |

HE J Y, MA Y, YAN D S, et al. Improving ductility by increasing fraction of interfacial zone in low C steel/304 SS laminates [J]. Materials Science and Engineering: A, 2018, 726: 288–297. DOI: 10.1016/j.msea.2018.04.102.

|

| [27] |

GUO Y Z, RUAN Q C, ZHU S X, et al. Temperature rise associated with adiabatic shear band: causality clarified [J]. Physical Review Letters, 2019, 122: 015503. DOI: 10.1103/PhysRevLett.122.015503.

|

| [28] |

GUO Y Z, RUAN Q C, ZHU S X, et al. Dynamic failure of titanium: temperature rise and adiabatic shear band formation [J]. Journal of the Mechanics and Physics of Solids, 2020, 135: 103811. DOI: 10.1016/j.jmps.2019.103811.

|

| [29] |

SUO T, LI Y L, ZHAO F, et al. Compressive behavior and rate-controlling mechanisms of ultrafine grained copper over wide temperature and strain rate ranges [J]. Mechanics of Materials, 2013, 61: 1–10. DOI: 10.1016/j.mechmat.2013.02.003.

|

| [30] |

WEI Q M. Strain rate effects in the ultrafine grain and nanocrystalline regimes-influence on some constitutive responses [J]. Journal of Materials Science, 2007, 42(5): 1709–1727. DOI: 10.1007/s10853-006-0700-9.

|

| [31] |

TALONEN J, HÄNNINEN H, NENONEN P, et al. Effect of strain rate on the strain-induced γ→α'-martensite transformation and mechanical properties of austenitic stainless steels [J]. Metallurgical and Materials Transactions A, 2005, 36(2): 421–432. DOI: 10.1007/s11661-005-0313-y.

|

下载:

下载: