Design and evaluation of new honeycomb configurations with high in-plane /out-of-plane loading-carrying capacity under impact

-

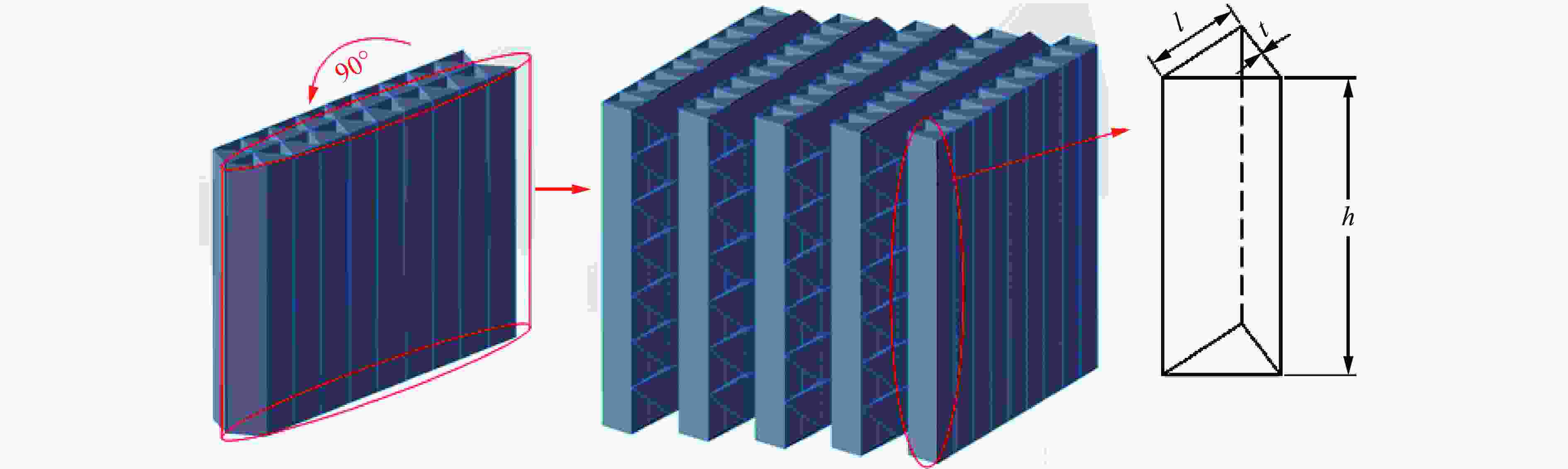

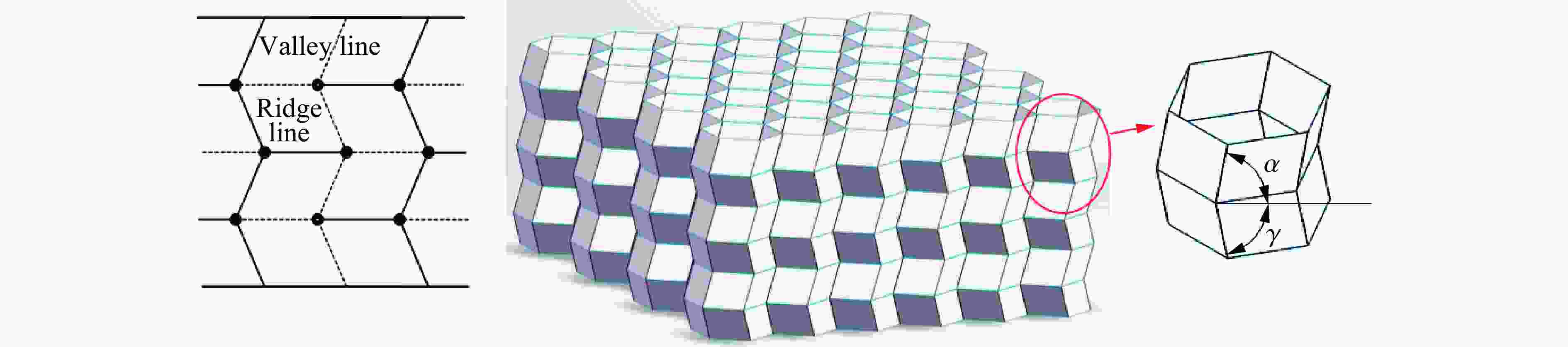

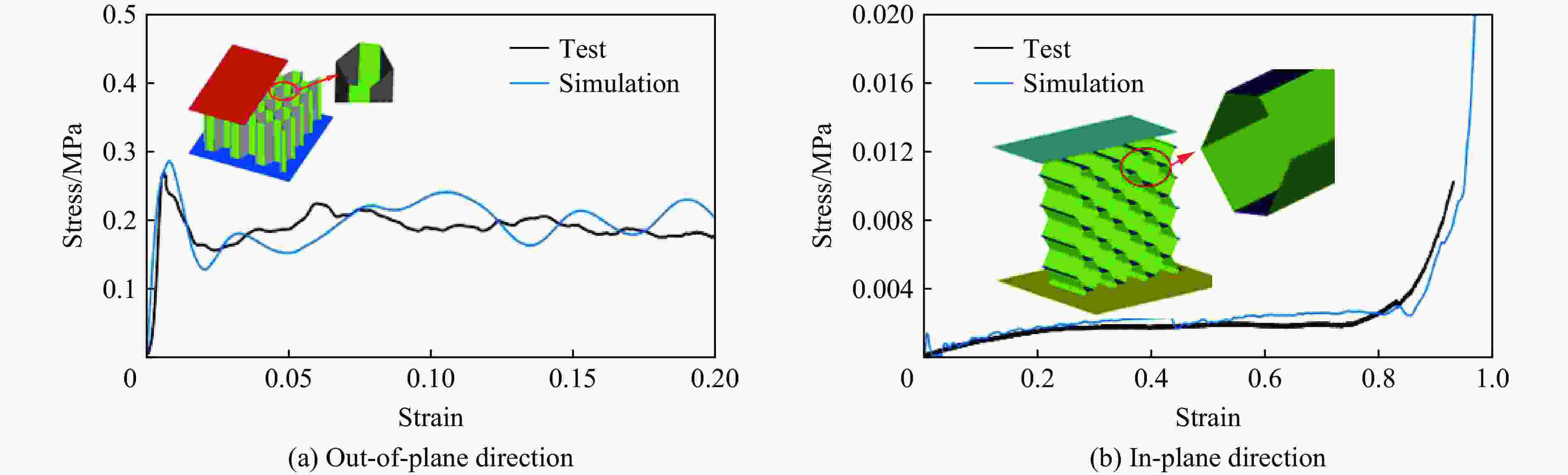

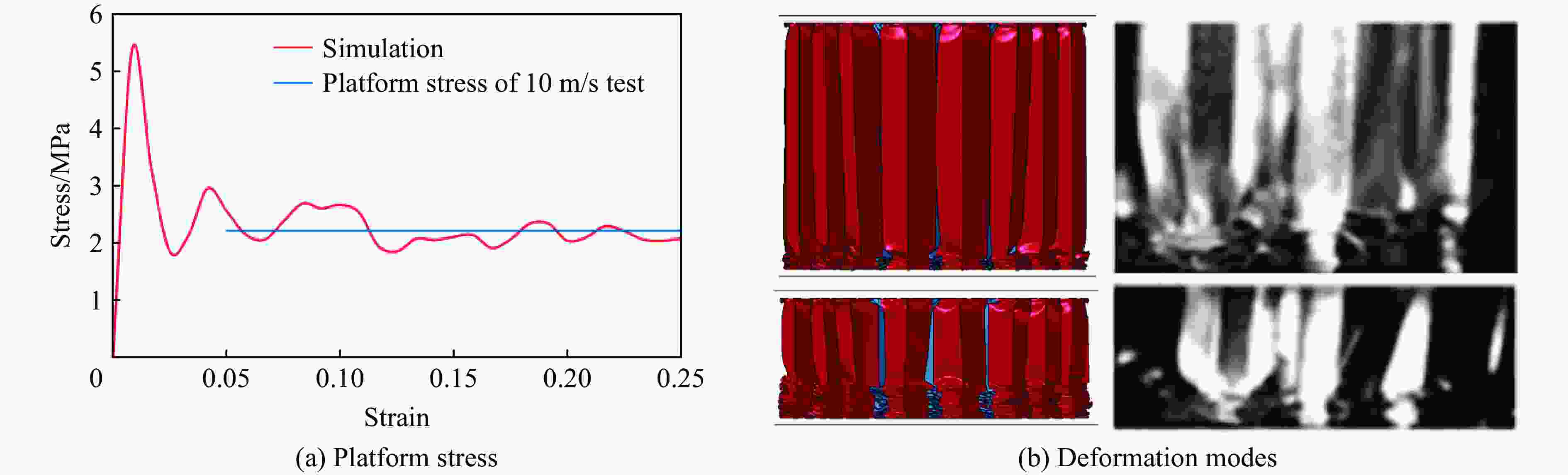

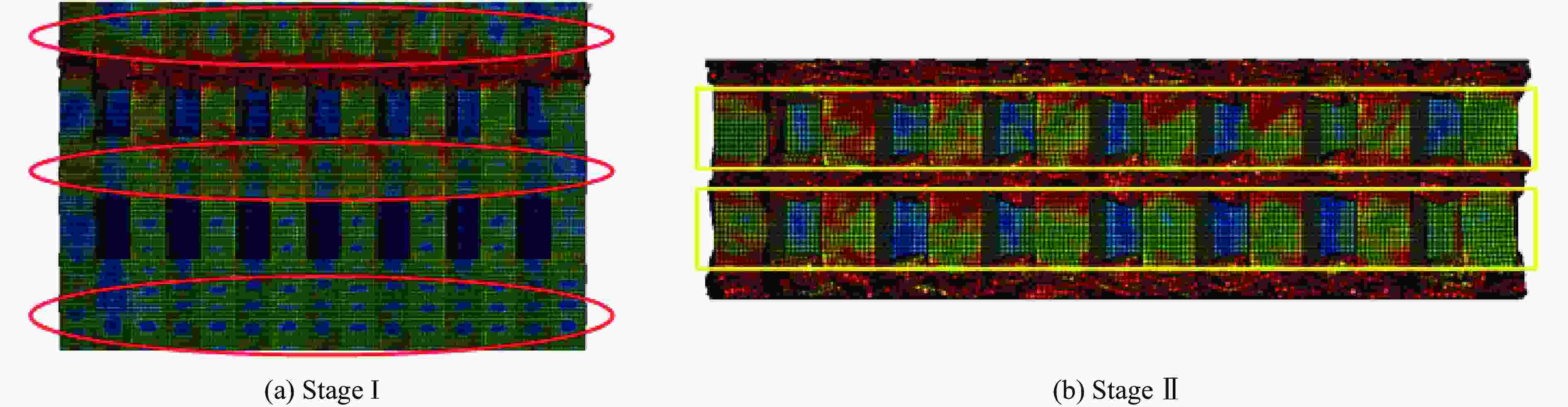

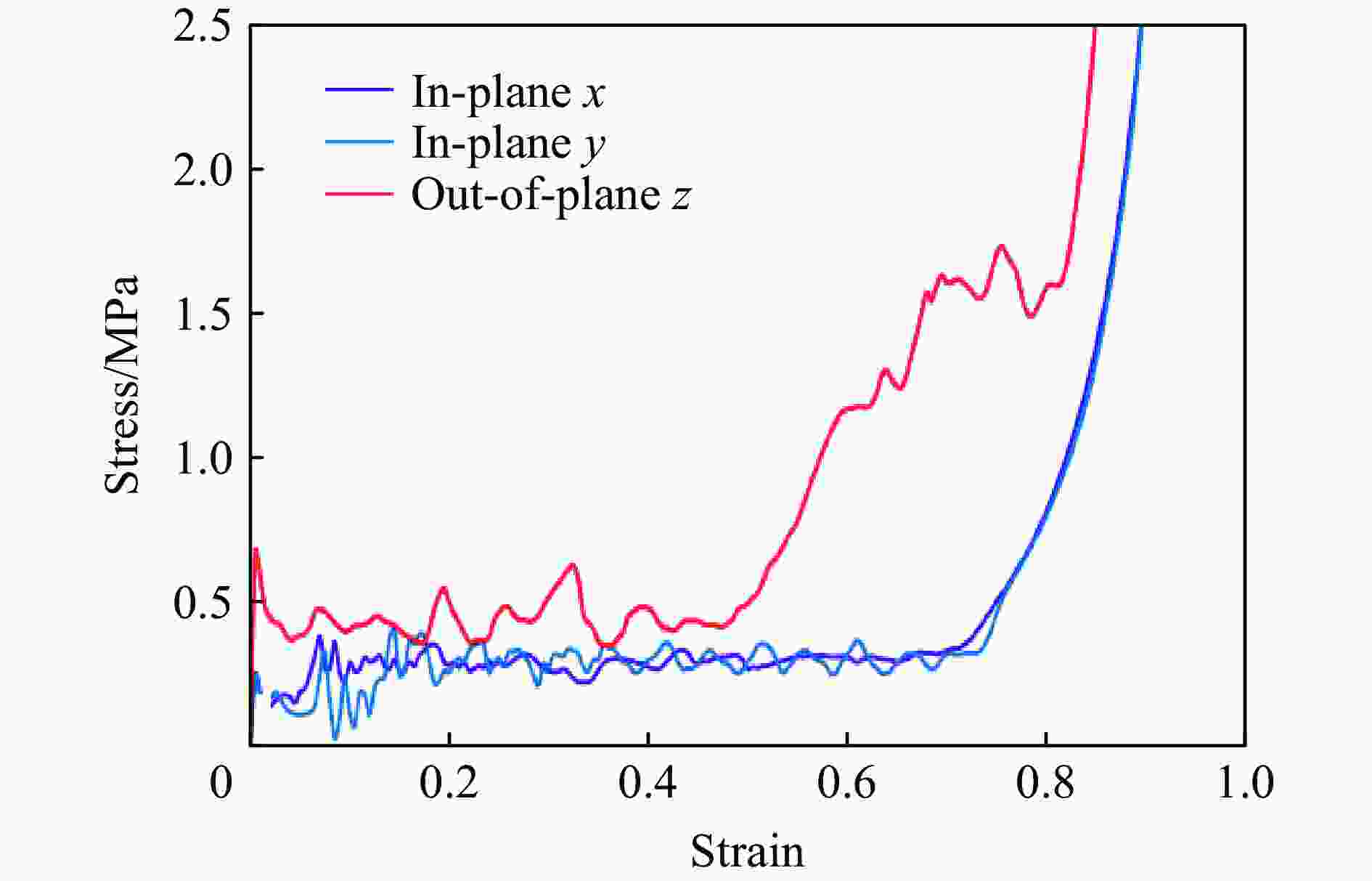

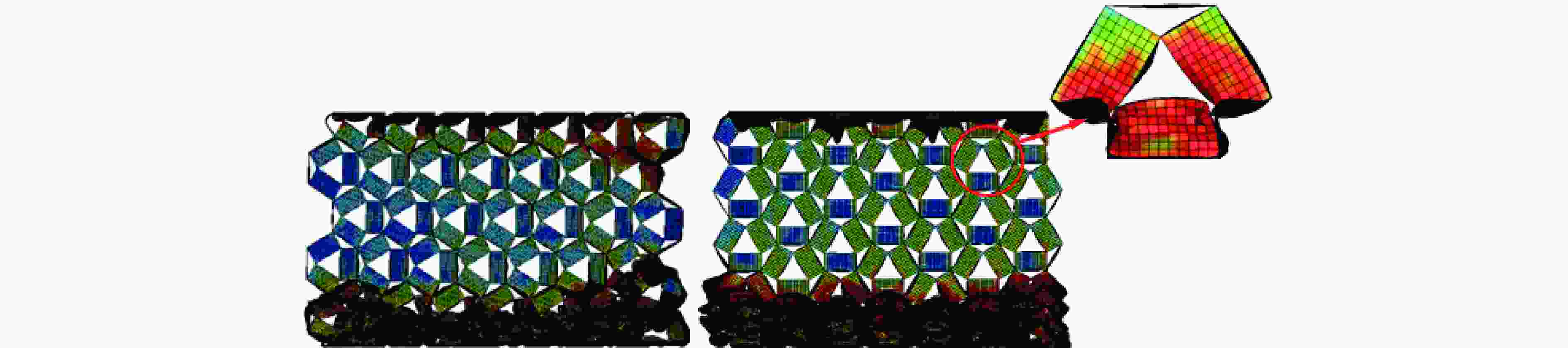

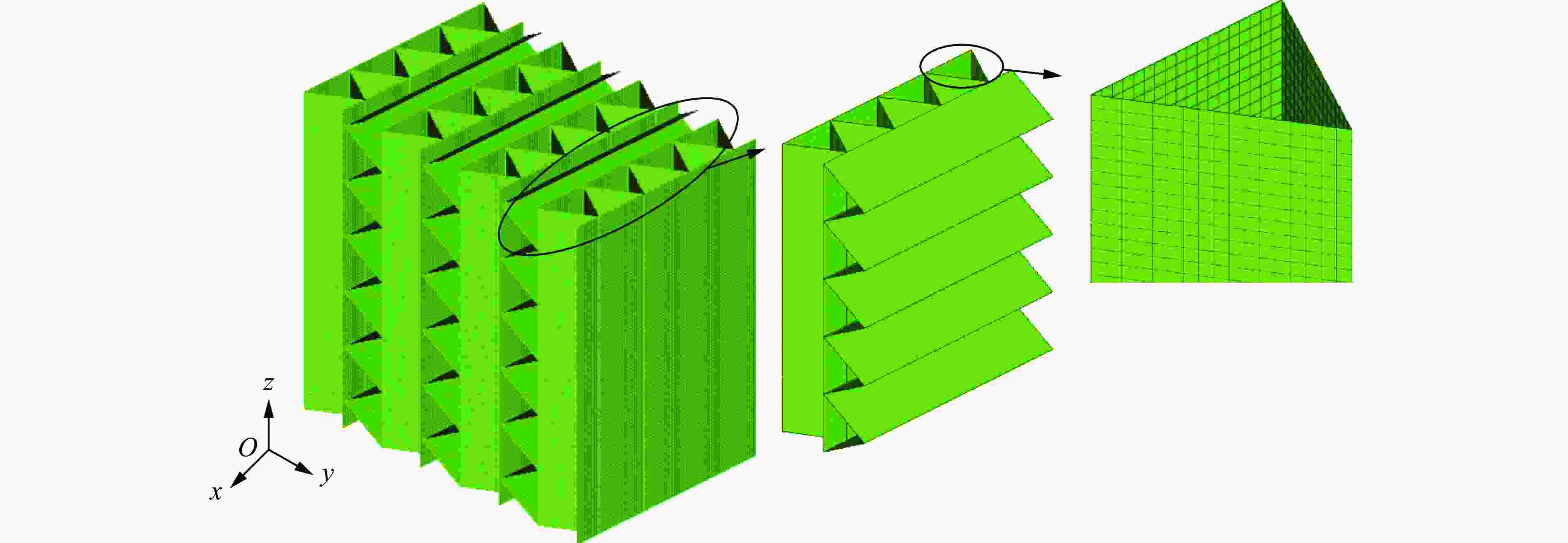

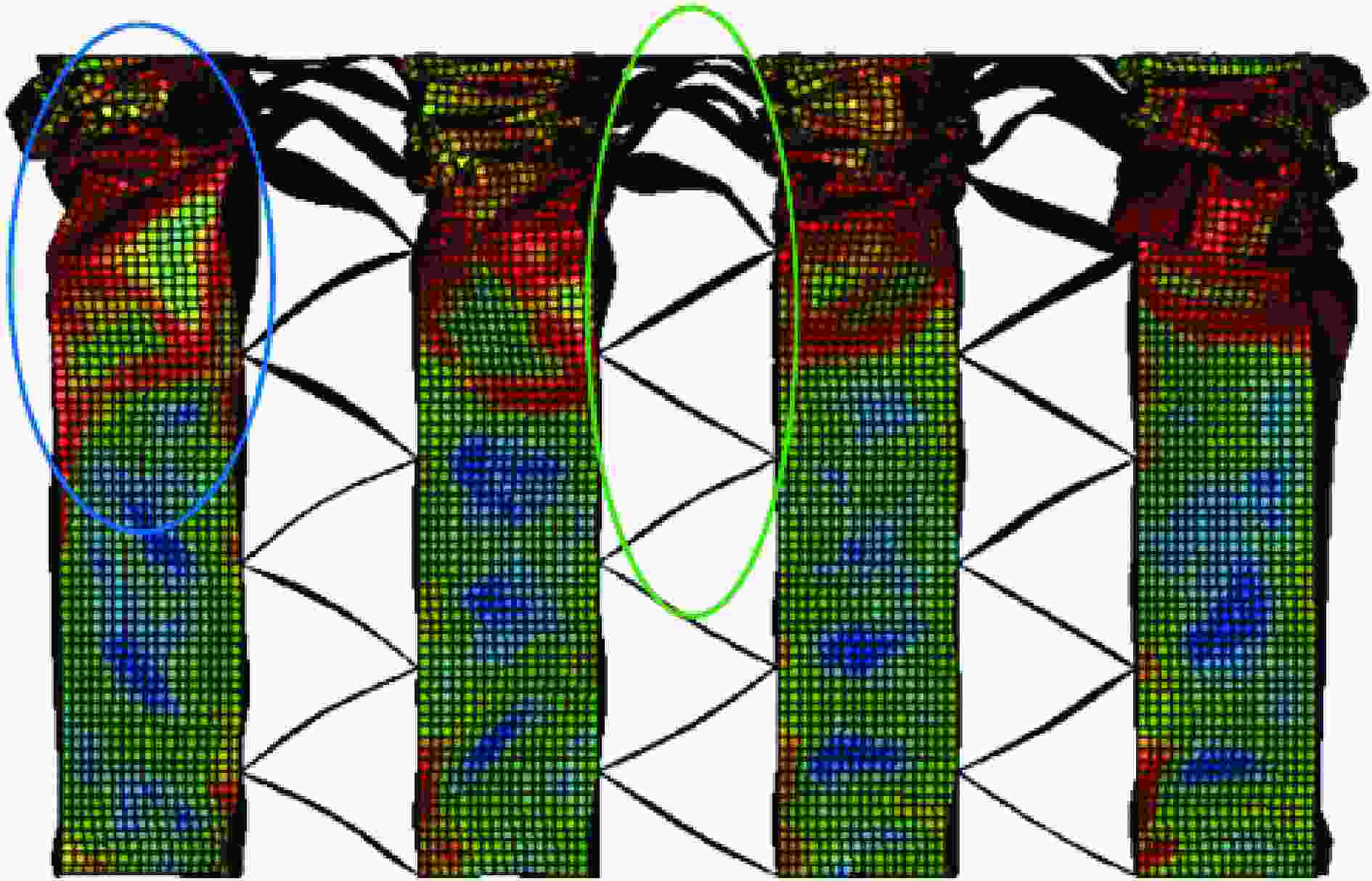

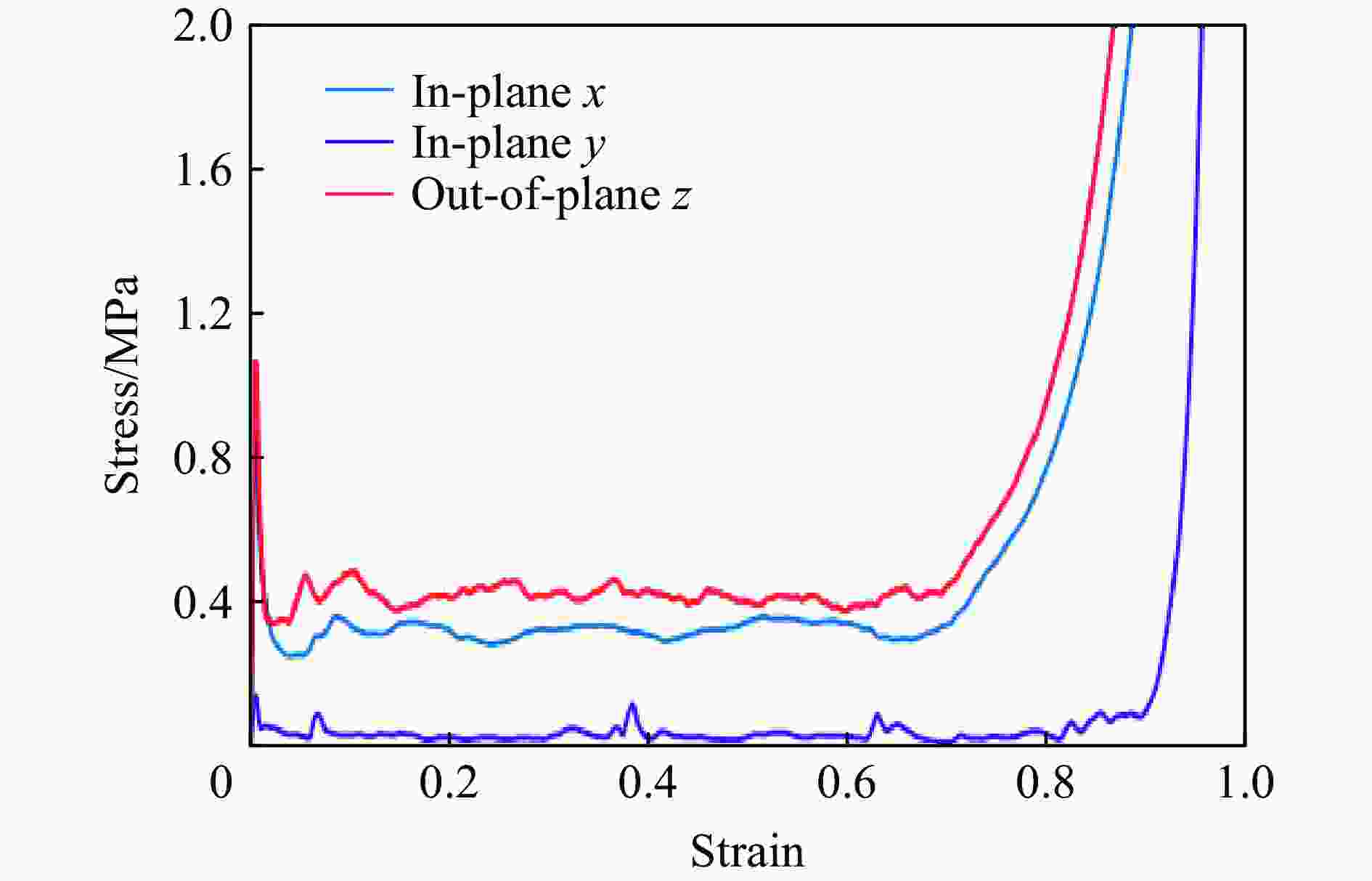

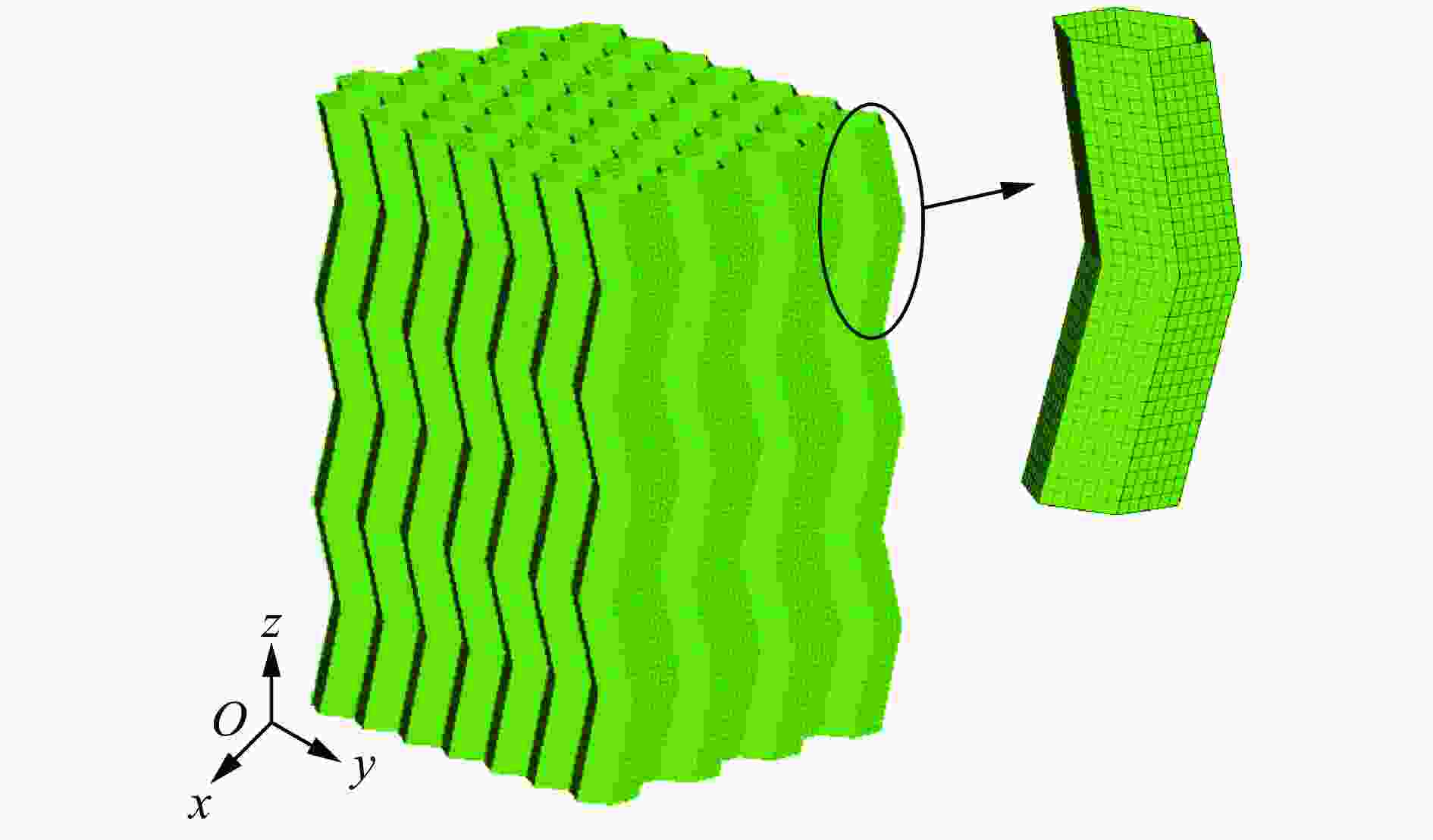

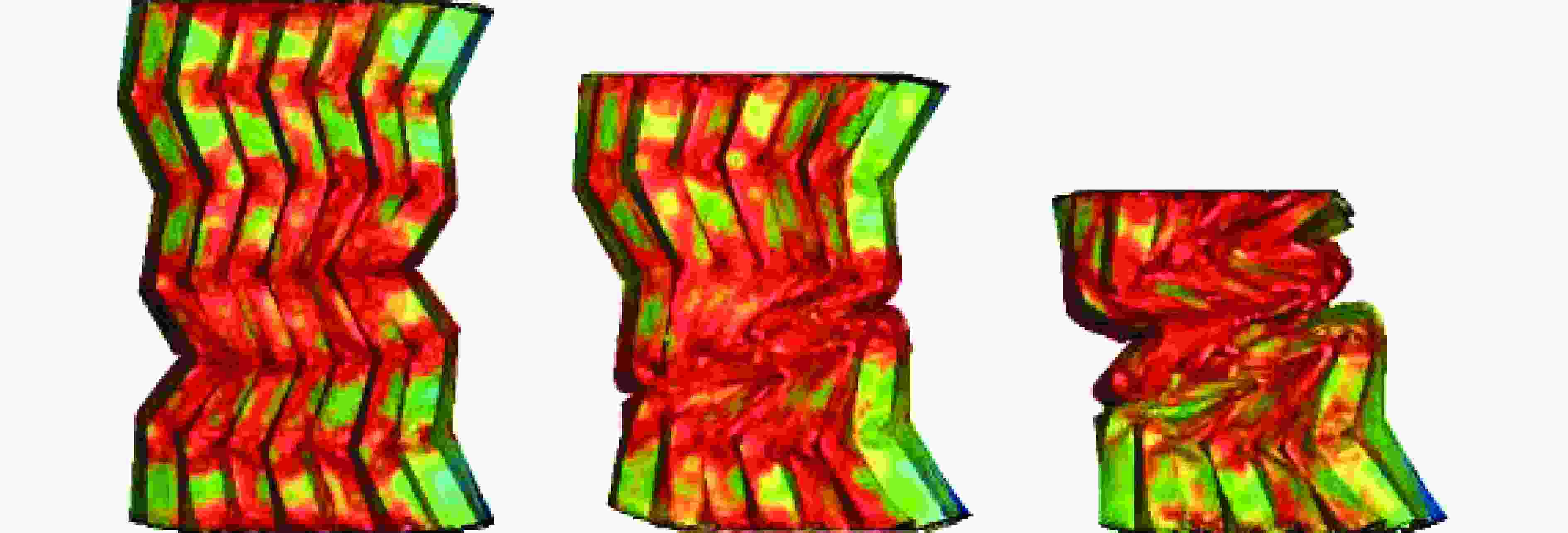

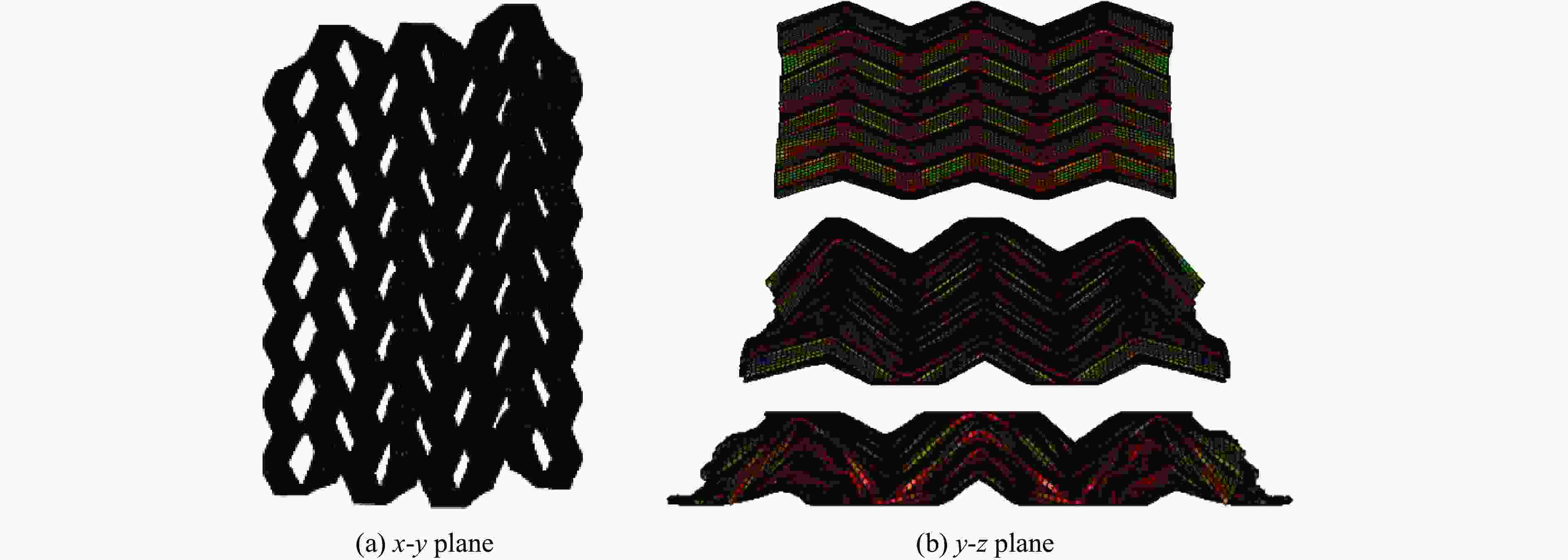

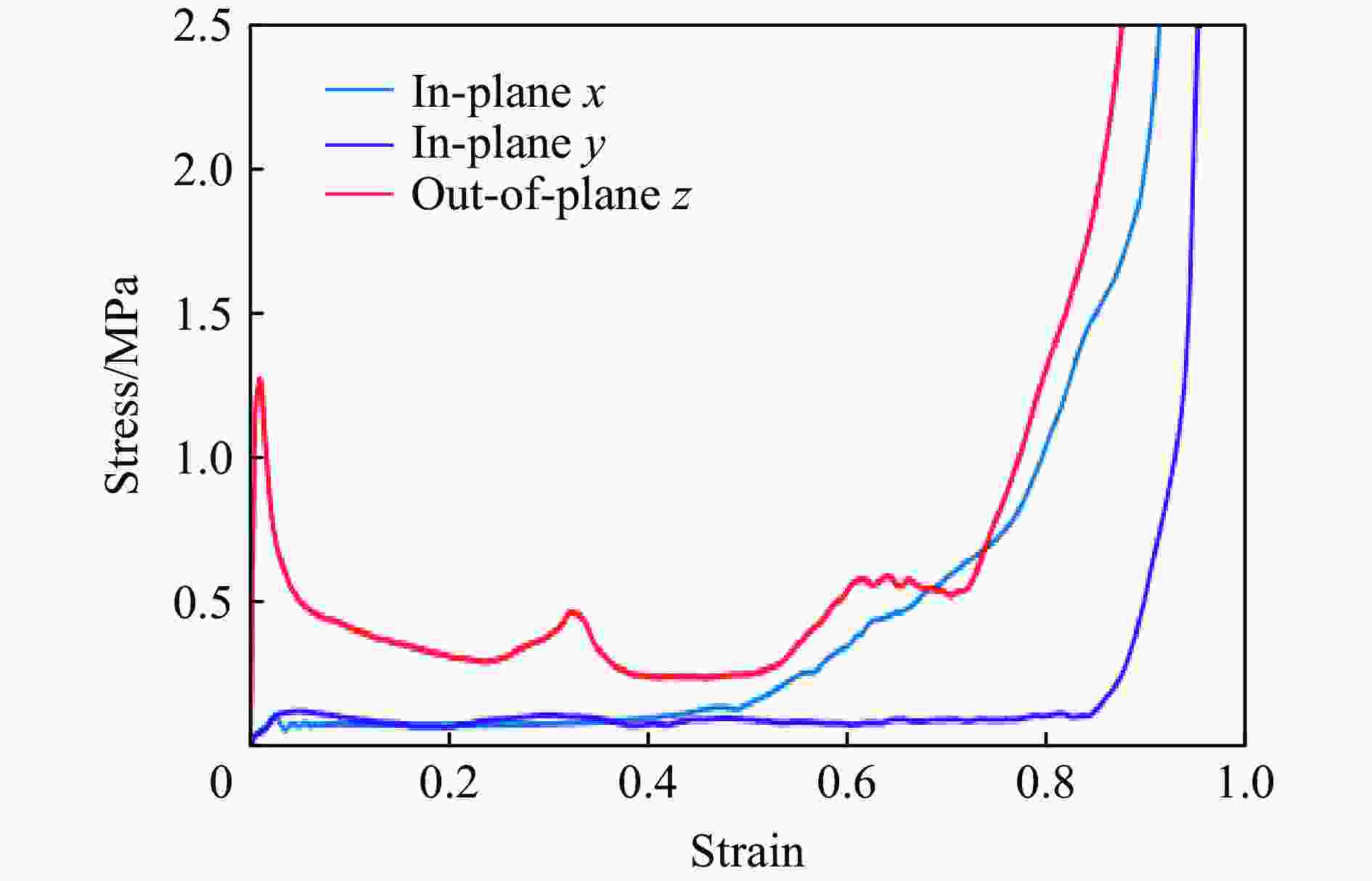

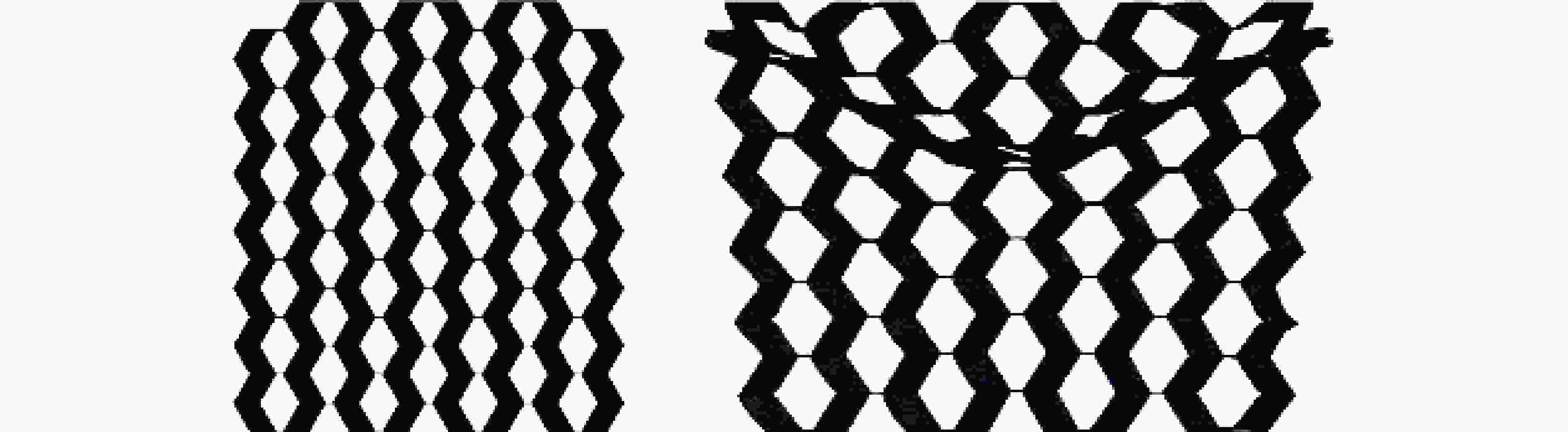

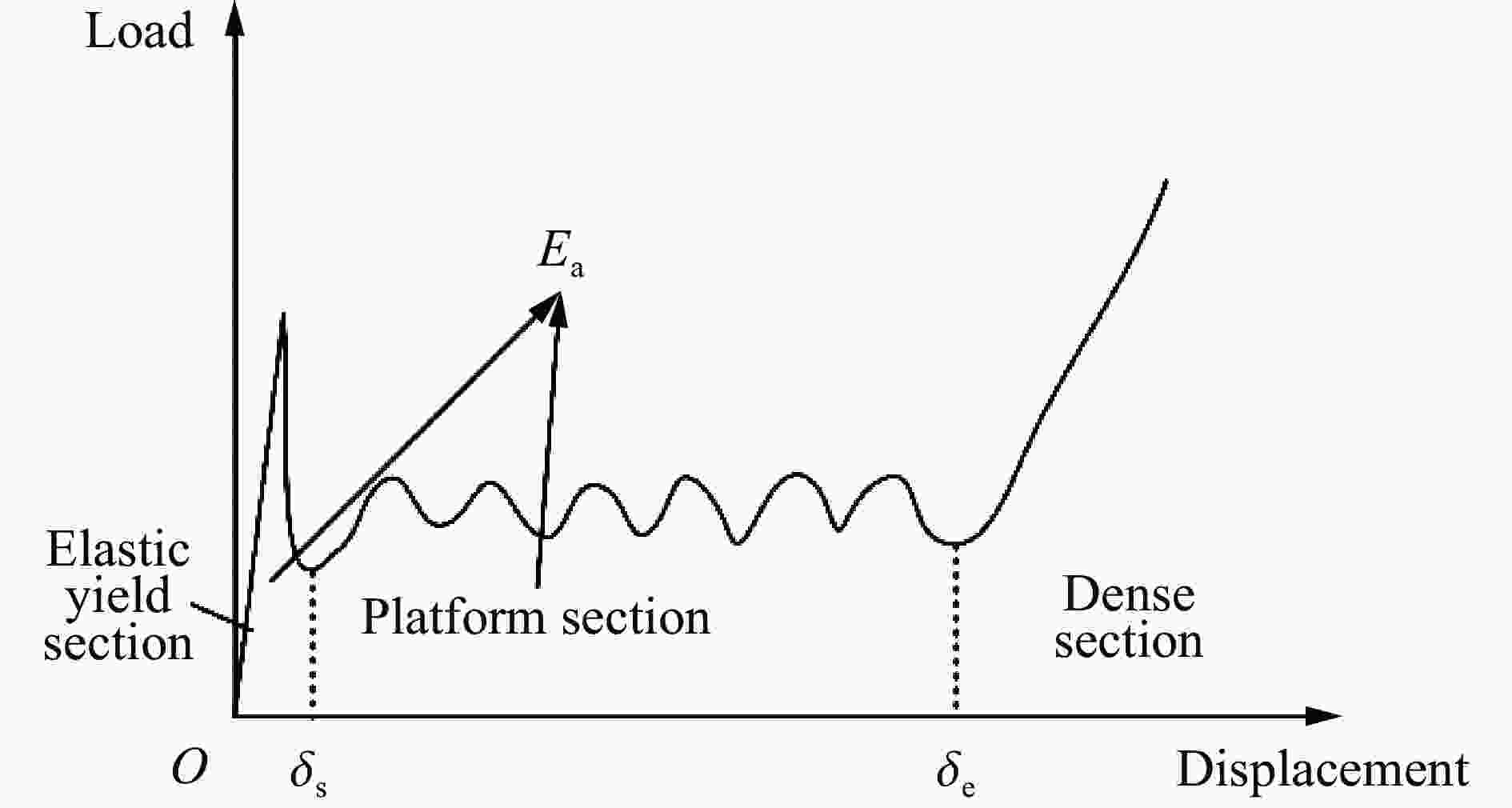

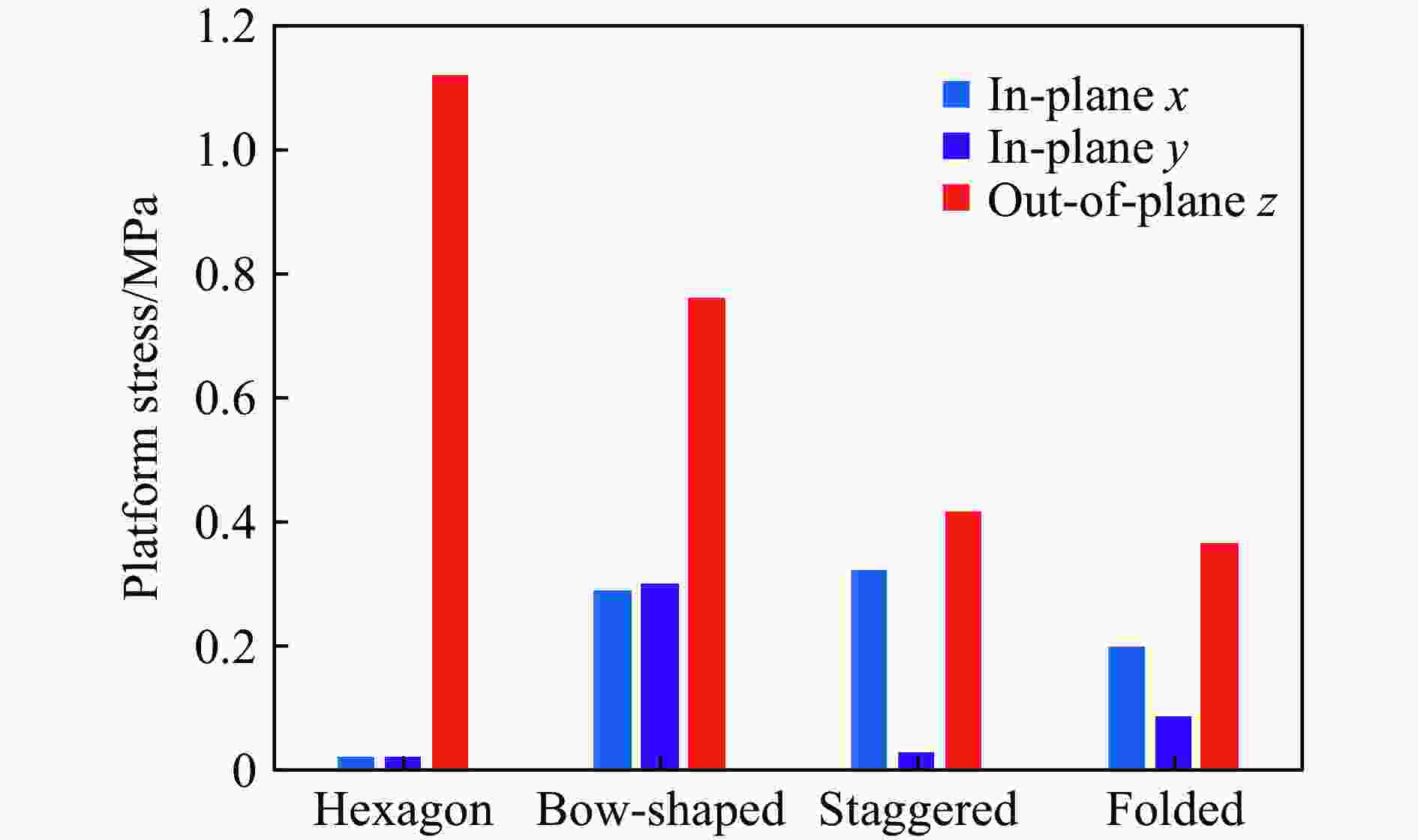

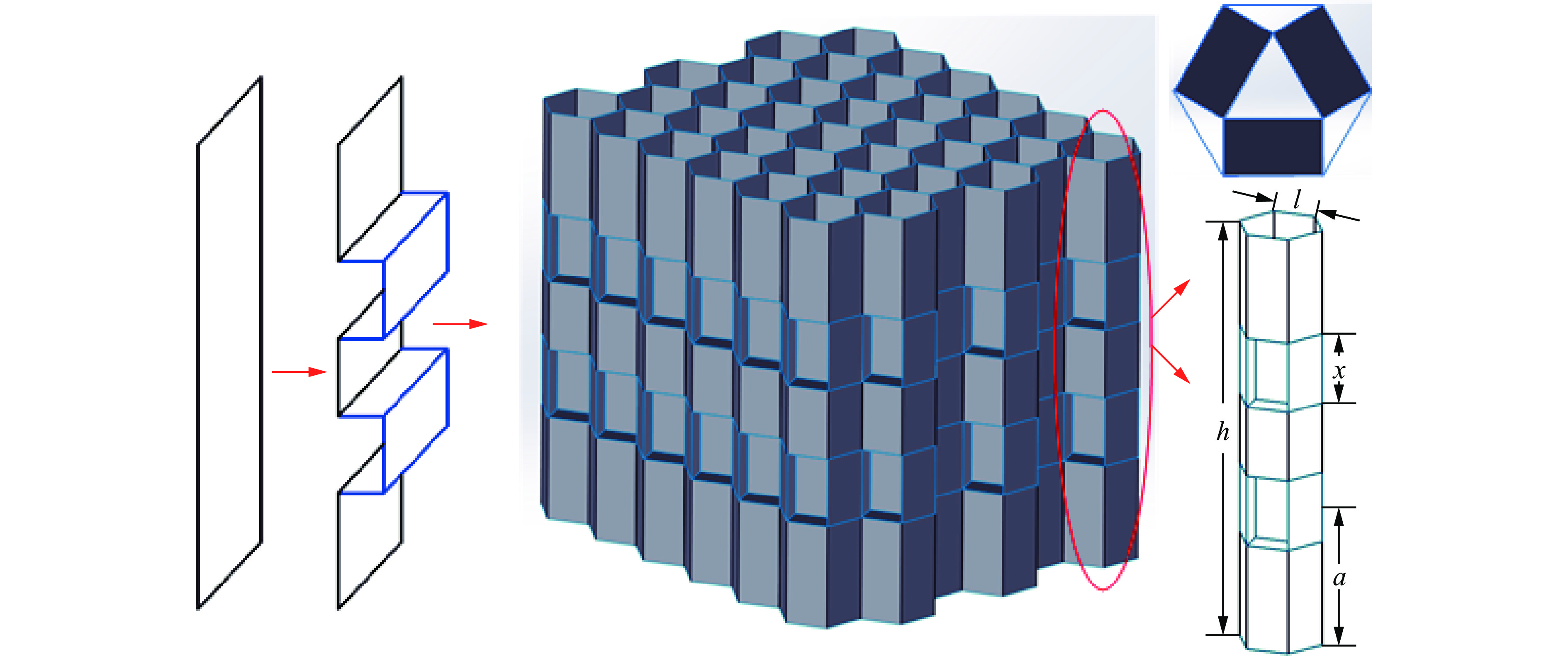

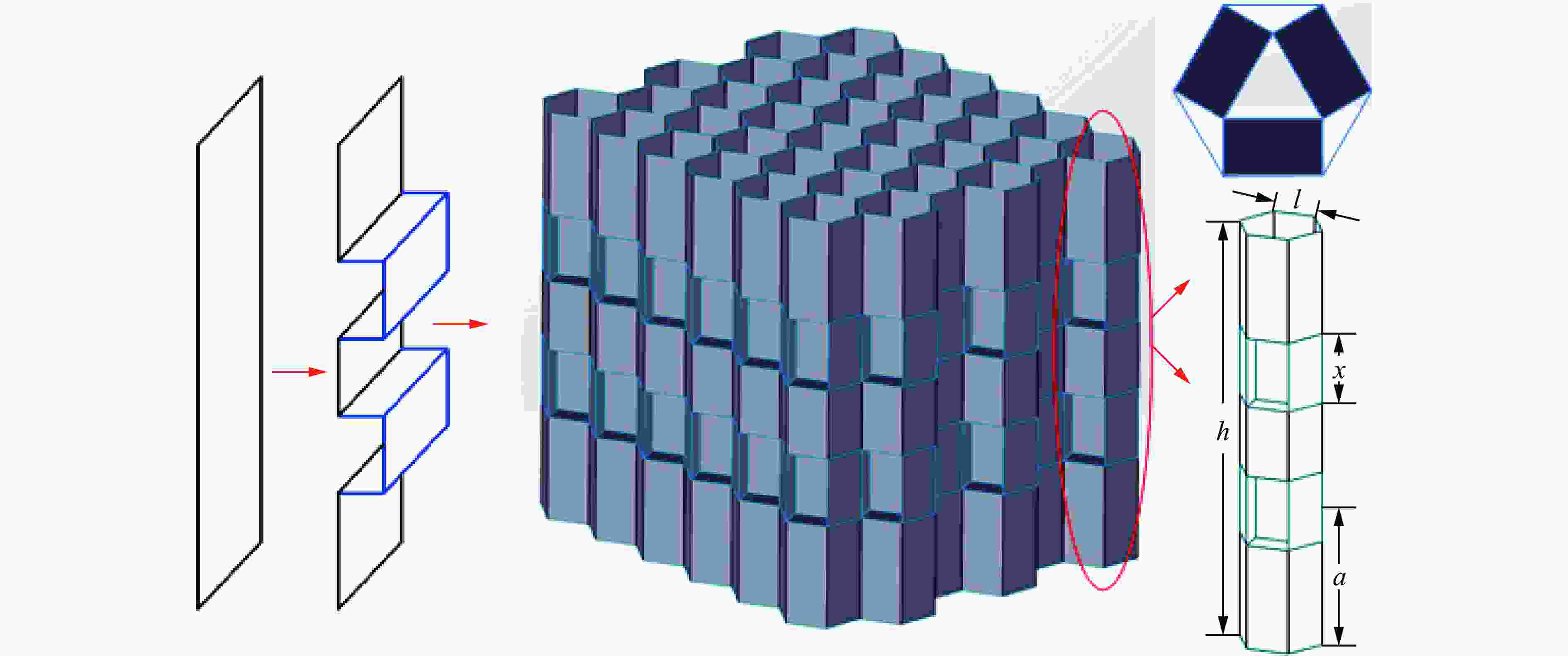

摘要: 针对传统蜂窝共面和异面承载能力差距太大的问题,提出了胞壁弓字形弯折蜂窝、层间组合蜂窝和折叠蜂窝等3种新型蜂窝,建立了新型蜂窝的有限元模型并分析了其变形模式和承载能力。结果表明,在相对密度一致的前提下,与传统正六边形蜂窝相比,这3种新构型蜂窝均缩小了共面和异面方向承载能力的差距。其中胞壁弓字形弯折蜂窝的共面/异面承载比提高了21.3倍;层间组合蜂窝两个共面方向承载能力悬殊,承载能力更强的共面方向与异面的承载比值提高了42倍;折叠蜂窝则提高了21.3倍。研究结果可以为抗多向冲击载荷作用下的蜂窝结构设计提供新思路和参考。Abstract: An aluminum honeycomb is widely used in the field of impact cushioning because of its excellent performance. In order to solve the problem of large difference between the in-plane and out-of-plane load-carrying capacities of traditional honeycombs, three new configurations of honeycombs were proposed as follows: bow-shaped, staggered and folded configurations. The finite element models for these new honeycombs were established, and their deformation modes and load-carrying capacities were analyzed. The results show that under the same relative density, compared with the traditional hexagonal honeycombs, the three new configurations can reduce the difference of load-carrying capacity in in-plane and out-of-plane directions. The average in-plane/out-of-plane (I/O) ratio of loading-carrying capacity of the bow-shaped honeycombs in two coplanar directions increased by 21.3 times. For the staggered honeycomb, the load-carrying capacity of each in-plane direction is of great difference, in which the I/O ratio of the excellent direction is increased by 42 times due to its special structure. For the folded honeycomb, the I/O ratio is increased by 21.3 times on average. The research results can provide a new idea and reference for the design of honeycomb structure under multi-directional impact load.

-

Key words:

- honeycomb /

- cell configuration /

- energy absorption /

- in-plane /

- out-of-plane

-

表 1 不同构型蜂窝的尺寸

Table 1. The sizes of different honeycombs

蜂窝类型 h/mm l/mm t/mm a/mm x/mm α/(°) γ/(°) 相对密度 质量/g 体积/mm3 胞壁弓字形弯折蜂窝 30 3.43 0.03 10 5 0.02 2.607 50 434 层间组合蜂窝 30 5.2 0.03 0.02 1.112 19 670 折叠蜂窝篇 30 1.73 0.03 75 75 0.02 0.745 13 733 表 2 不同构型蜂窝结构的平台应力

Table 2. Platform stresses for different honeycombs

蜂窝类型 平台应力/MPa Kx Ky 异面 共面x 共面y 六边形蜂窝 1.120 0.020 0.0205 0.018 0.018 弓字形弯折蜂窝 0.760 0.290 0.300 0.381 0.395 层间组合蜂窝 0.419 0.322 0.029 0.768 0.069 折叠蜂窝 0.366 0.200 0.087 0.540 0.240 表 3 不同构型蜂窝结构的质量比吸能

Table 3. Specific mass energy absorptionfor different honeycombs

蜂窝类型 质量比吸能/(J·g−1) Rx Ry 异面 共面x 共面y 六边形蜂窝 15.546 0.273 0.324 0.018 0.021 弓字形弯折蜂窝 12.000 3.920 3.951 0.327 0.329 层间组合蜂窝 5.337 4.071 0.544 0.763 0.102 折叠蜂窝 5.391 2.800 1.371 0.520 0.254 -

[1] KHAN M K, BAIG T, MIRZA S. Experimental investigation of in-plane and out-of-plane crushing of aluminum honeycomb [J]. Materials Science and Engineering: A, 2012, 539: 135–142. DOI: 10.1016/j.msea.2012.01.070. [2] 荣吉利, 朱宇博, 宋乾强, 等. 异面压缩下六边形铝蜂窝平均塑性坍塌应力研究 [J]. 宇航学报, 2018, 39(3): 257–263. DOI: 10.3873/j.issn.1000-1328.2018.03.003.RONG J L, ZHU Y B, SONG Q Q, et al. Research on the mean plastic crushing stress of hexagonal aluminum honeycombs under out-of-plane compression [J]. Journal of Astronautics, 2018, 39(3): 257–263. DOI: 10.3873/j.issn.1000-1328.2018.03.003. [3] 罗昌杰, 周安亮, 刘荣强, 等. 金属蜂窝异面压缩下平均压缩应力的理论模型 [J]. 机械工程学报, 2010, 46(18): 52–59. DOI: 10.3901/JME.2010.18.052.LUO C J, ZHOU A L, LIU R Q, et al. Average compressive stress constitutive equation of honeycomb metal under out-of-plane compression [J]. Journal of Mechanical Engineering, 2010, 46(18): 52–59. DOI: 10.3901/JME.2010.18.052. [4] 赵国伟, 白俊青, 祁玉峰, 等. 异面冲击下金属蜂窝结构平均塑性坍塌应力模型 [J]. 振动与冲击, 2016, 35(12): 50–54. DOI: 10.13465/j.cnki.jvs.2016.12.008.ZHAO G W, BAI J Q, QI Y F, et al. Average plastic collapse stress model of metallic honeycomb structure under out-of-plan impact load [J]. Journal of Vibration and Shock, 2016, 35(12): 50–54. DOI: 10.13465/j.cnki.jvs.2016.12.008. [5] 何彬, 李响. 一种新型组合蜂窝的抗冲击性能研究 [J]. 机械设计与制造, 2015(6): 49–51, 54. DOI: 10.19356/j.cnki.1001-3997.2015.06.013.HE B, LI X. Research on the impact resistance of a new type of honeycomb structure [J]. Machinery Design and Manufacture, 2015(6): 49–51, 54. DOI: 10.19356/j.cnki.1001-3997.2015.06.013. [6] 杜义贤, 李涵钊, 谢黄海, 等. 具有创新拓扑构型的周期性点阵结构抗剪切性能分析 [J]. 机械设计与研究, 2016, 32(5): 83–87. DOI: 10.13952/j.cnki.jofmdr.2016.0192.DU Y X, LI H Z, XIE H H, et al. Shear resistance of periodic lattice structure with innovative topology configuration [J]. Machine Design and Research, 2016, 32(5): 83–87. DOI: 10.13952/j.cnki.jofmdr.2016.0192. [7] YANG X F, SUN Y X, YANG J L, et al. Out-of-plane crashworthiness analysis of bio-inspired aluminum honeycomb patterned with horseshoe mesostructure [J]. Thin-Walled Structures, 2018, 125: 1–11. DOI: 10.1016/j.tws.2018.01.014. [8] 王中钢, 姚松. 加筋正六角铝蜂窝异面力学特性与筋胞厚度匹配优化 [J]. 航空材料学报, 2013, 33(3): 86–91. DOI: 10.3969/j.issn.1005-5053.2013.3.016.WANG Z G, YAO S. Out-of-plane mechanical properties and thickness matching optimization between rib and cell thin-wall of reinforced regular hexagon aluminum honeycomb [J]. Journal of Aeronautical Materials, 2013, 33(3): 86–91. DOI: 10.3969/j.issn.1005-5053.2013.3.016. [9] WANG Z G, SHI C, DING S S, et al. Crashworthiness of innovative hexagonal honeycomb-like structures subjected to out-of-plane compression [J]. Journal of Central South University, 2020, 27(2): 621–628. DOI: 10.1007/s11771-020-4321-2. [10] 胡玲玲, 蒋玲. 胞孔构型对金属蜂窝动态力学性能的影响机理 [J]. 爆炸与冲击, 2014, 34(1): 41–46. DOI: 10.11883/1001-1455(2014)01-0041-06.HU L L, JIANG L. Mechanism of cell configuration affecting dynamic mechanical properties of metal honeycombs [J]. Explosion and Shock Waves, 2014, 34(1): 41–46. DOI: 10.11883/1001-1455(2014)01-0041-06. [11] 胡玲玲, 陈依骊. 三角形蜂窝在面内冲击荷载下的力学性能 [J]. 振动与冲击, 2011, 30(5): 226–229, 235. DOI: 10.3969/j.issn.1000-3835.2011.05.047.HU L L, CHEN Y L. Mechanical properties of triangular honeycombs under in-plane impact loading [J]. Journal of Vibration and Shock, 2011, 30(5): 226–229, 235. DOI: 10.3969/j.issn.1000-3835.2011.05.047. [12] LIU Y, ZHANG X C. The influence of cell micro-topology on the in-plane dynamic crushing of honeycombs [J]. International Journal of Impact Engineering, 2009, 36(1): 98–109. DOI: 10.1016/j.ijimpeng.2008.03.001. [13] 何强, 马大为, 张震东. 分层屈服强度梯度蜂窝材料的动力学性能研究 [J]. 工程力学, 2015, 32(4): 191–196. DOI: 10.6052/j.issn.1000-4750.2013.10.0986.HE Q, MA D W, ZHANG Z D. Research on dynamic crushing of layered yielding stress-gradient circular honeycombs [J]. Engineering Mechanics, 2015, 32(4): 191–196. DOI: 10.6052/j.issn.1000-4750.2013.10.0986. [14] HEDAYATI R, SADIGHI M, MOHAMMADI-AGHDAM M, et al. Mechanical properties of additively manufactured octagonal honeycombs [J]. Materials Science and Engineering: C, 2016, 69: 1307–1317. DOI: 10.1016/j.msec.2016.08.020. [15] THOMAS T, TIWARI G. Energy absorption and in-plane crushing behavior of aluminium reinforced honeycomb [J]. Vacuum, 2019, 166: 364–369. DOI: 10.1016/j.vacuum.2018.10.057. [16] 卢子兴, 李康. 负泊松比蜂窝动态压溃行为的有限元模拟 [J]. 机械强度, 2016, 38(6): 1237–1242. DOI: 10.16579/j.issn.1001.9669.2016.06.018.LU Z X, LI K. Dynamic crushing of honeycombs with a negative Poisson’s ratio-a finite element study [J]. Journal of Mechanical Strength, 2016, 38(6): 1237–1242. DOI: 10.16579/j.issn.1001.9669.2016.06.018. [17] HU L L, ZHOU M Z, DENG H. Dynamic indentation of auxetic and non-auxetic honeycombs under large deformation [J]. Composite Structures, 2019, 207: 323–330. DOI: 10.1016/j.compstruct.2018.09.066. [18] 马瑞君, 王玉涛, 李萌, 等. 基于Miura折纸的蜂窝材料共面缓冲性能研究 [J]. 载人航天, 2020, 26(1): 48–55. DOI: 10.16329/j.cnki.zrht.2020.01.007.MA R J, WANG Y T, LI M, et al. Research on in-plane buffer performance of honeycomb material based on Miura pattern [J]. Manned Spaceflight, 2020, 26(1): 48–55. DOI: 10.16329/j.cnki.zrht.2020.01.007. [19] ZHAI J Y, LIU Y F, GENG X Y, et al. Energy absorption of pre-folded honeycomb under in-plane dynamic loading [J]. Thin-Walled Structures, 2019, 145: 106356. DOI: 10.1016/j.tws.2019.106356. [20] 谭思博, 侯兵, 李玉龙, 等. 基体材料对铝蜂窝动态强化特性的影响 [J]. 爆炸与冲击, 2015, 35(1): 16–21. DOI: 10.11883/1001-1455(2015)01-0016-06.TAN S B, HOU B, LI Y L, et al. Effect of base materials on the dynamic enhancement of aluminium honeycombs [J]. Explosion and Shock Waves, 2015, 35(1): 16–21. DOI: 10.11883/1001-1455(2015)01-0016-06. [21] 李萌, 刘荣强, 郭宏伟, 等. 腿式着陆器用不同拓扑结构金属蜂窝吸能特性优化设计 [J]. 振动与冲击, 2013, 32(21): 7–14. DOI: 10.3969/j.issn.1000-3835.2013.21.002.LI M, LIU R Q, GUO H W, et al. Crashworthiness optimization of different topological structures of metal honeycomb used in a legged-typed lander [J]. Journal of Vibration and Shock, 2013, 32(21): 7–14. DOI: 10.3969/j.issn.1000-3835.2013.21.002. -

下载:

下载: