| [1] |

ANZ-MEADOR P D, OPIELA J N, SHOOTS D, et al. History of on-orbit satellite fragmentations: NASA/TM-2018-220037 [R]. Houston, Texas: Lyndon B. Johnson Space Center, NASA, 2018.

|

| [2] |

龚自正, 徐坤博, 牟永强, 等. 空间碎片环境现状与主动移除技术 [J]. 航天器环境工程, 2014, 31(2): 129–135. DOI: 10.12126/see.2014.02.003.GONG Z Z, XU K B, MU Y Q, et al. The space debris environment and the active debris removal techniques [J]. Spacecraft Environment Engineering, 2014, 31(2): 129–135. DOI: 10.12126/see.2014.02.003.

|

| [3] |

郑世贵, 闫军. 空间碎片防护需求与防护材料进展 [J]. 国际太空, 2014(6): 49–53.ZHENG S G, YAN J. A review on the space debris protection and protective materials [J]. Space International, 2014(6): 49–53.

|

| [4] |

龚自正, 杨继运, 张文兵, 等. 航天器空间碎片超高速撞击防护的若干问题 [J]. 航天器环境工程, 2007, 24(3): 125–130. DOI: 10.3969/j.issn.1673-1379.2007.03.001.GONG Z Z, YANG J Y, ZHANG W B, et al. Spacecraft protection from the hypervelocity impact of space meteoroid and orbital debris [J]. Spacecraft Environment Engineering, 2007, 24(3): 125–130. DOI: 10.3969/j.issn.1673-1379.2007.03.001.

|

| [5] |

WHIPPLE F L. Meteorites and space travel [J]. The Astronomical Journal, 1947, 52: 131. DOI: 10.1086/106009.

|

| [6] |

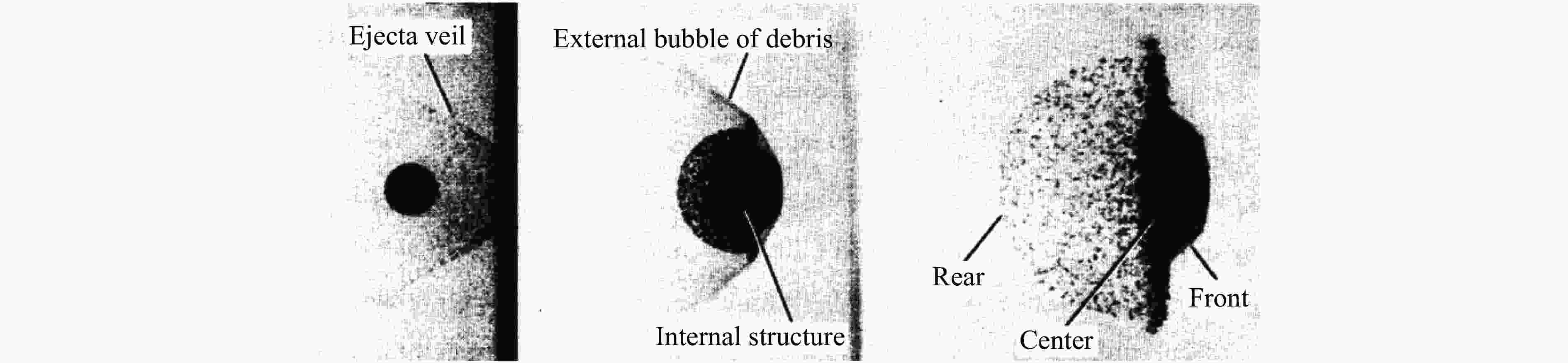

PIEKUTOWSKI A J. Formation and description of debris clouds produced by hypervelocity impact [R]. Huntsville, Alabama: Marshall Space Flight Center, NASA, 1996.

|

| [7] |

ANDERSON JR C E, TRUCANO T G, MULLIN SA. Debris cloud dynamics [J]. International Journal of Impact Engineering, 1990, 9(1): 89–113. DOI: 10.1016/0734-743X(90)90024-P.

|

| [8] |

PIEKUTOWSKI A J. Debris clouds generated by hypervelocity impact of cylindrical projectiles with thin aluminum plates [J]. International Journal of Impact Engineering, 1987, 5(1–4): 509–518. DOI: 10.1016/0734-743X(87)90066-2.

|

| [9] |

MORRISON R H. A preliminary investigation of projectile shape effects in hypervelocity impact of a double-sheet structure: TN-D-6944 [R]. Washington: National Aeronautics and Space Administration, 1972.

|

| [10] |

MACLAY T D, CULP R D, BAREISS L, et al. Topographically modified bumper concepts for spacecraft shielding [J]. International Journal of Impact Engineering, 1993, 14(1–4): 479–489. DOI: 10.1016/0734-743X(93)90044-8.

|

| [11] |

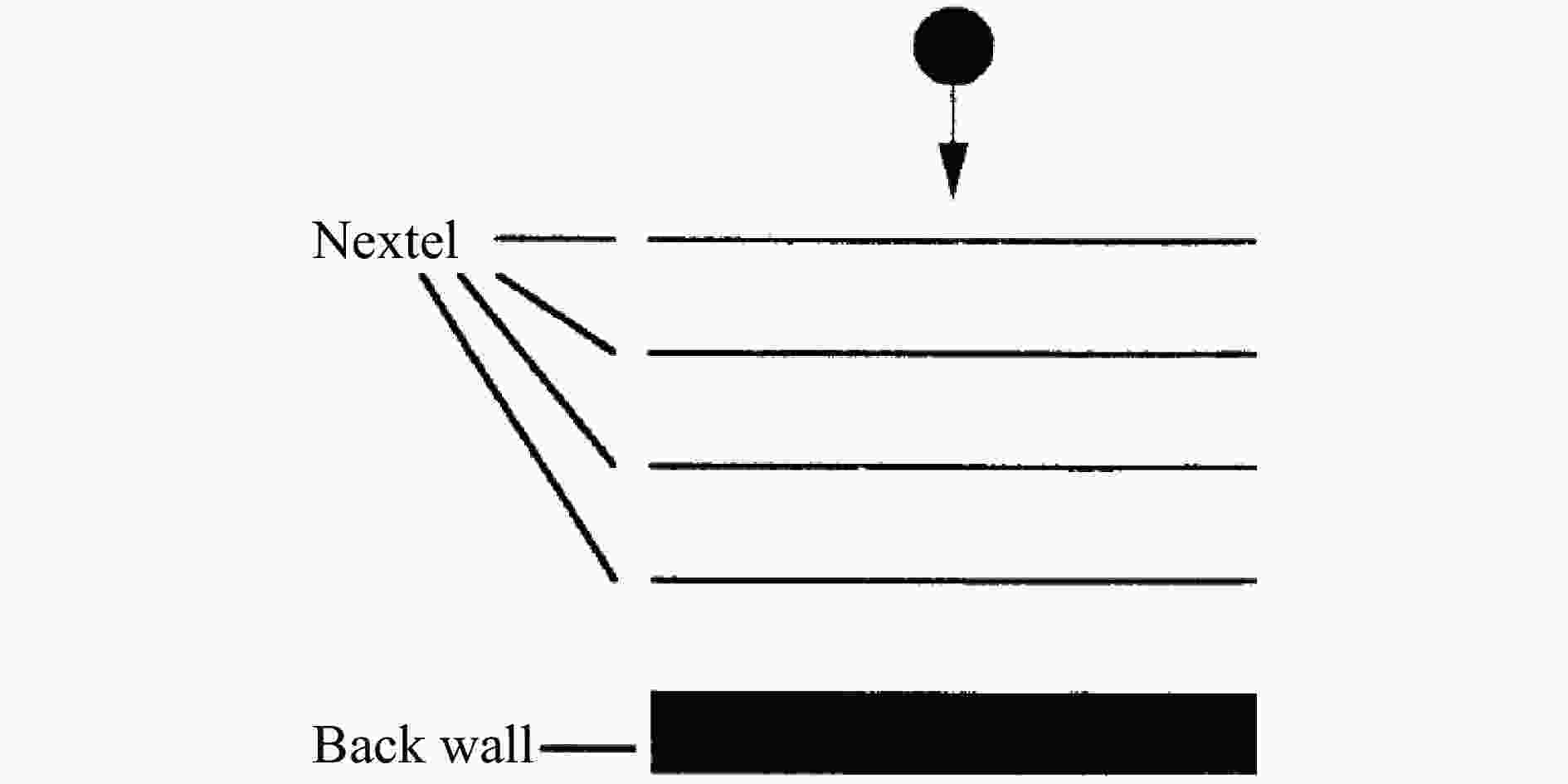

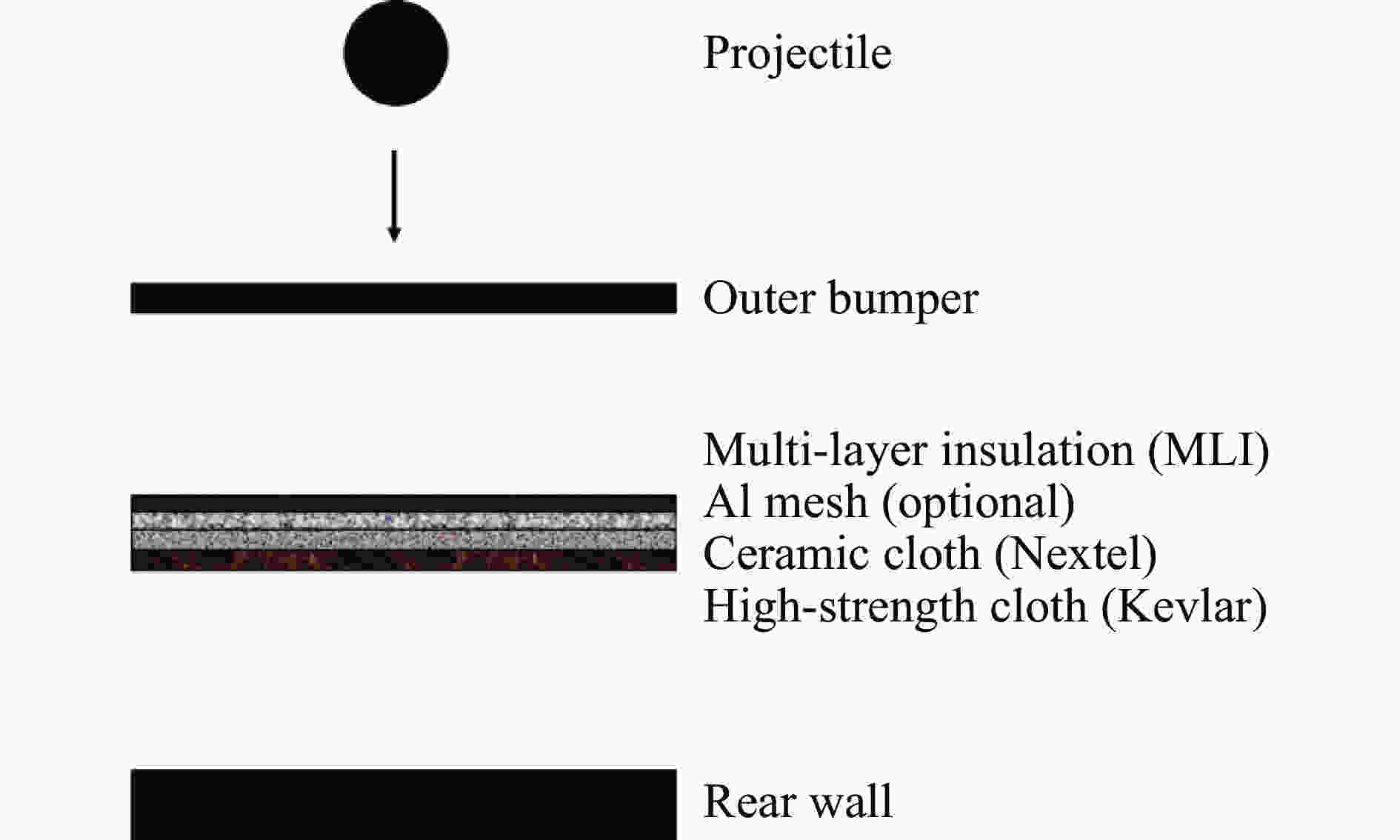

COUR-PALAIS B G, CREWS J L. A multi-shock concept for spacecraft shielding [J]. International Journal of Impact Engineering, 1990, 10(1–4): 135–146. DOI: 10.1016/0734-743X(90)90054-Y.

|

| [12] |

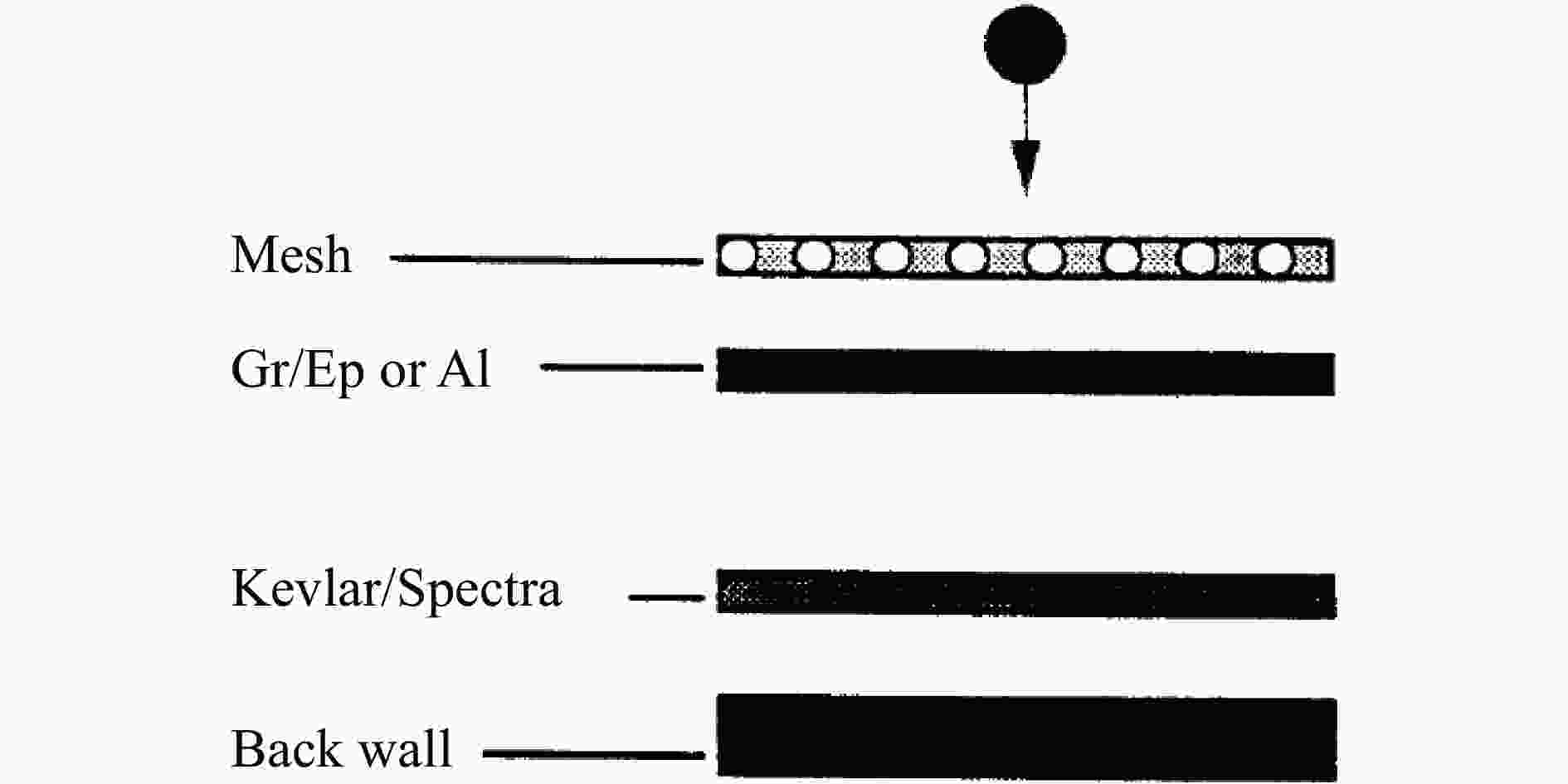

CHRISTIANSEN E L. Performance equations for advanced orbital debris shields [C]// Space Programs and Technologies Conference. Huntsivolle: AIAA, 1992.

|

| [13] |

CREWS J L, CHRISTIANSEN E L. The NASA JSC hypervelocity impact test facility (HIT-F) [C]// Space Programs and Technologies Conference. Huntsivolle: AIAA, 1992. DOI: 10.2514/6.1992-1640.

|

| [14] |

CHRISTIANSEN E L, CREWS J L, WILLIAMSEN J E, et al. Enhanced meteoroid and orbital debris shielding [J]. International Journal of Impact Engineering, 1995, 17(1–3): 217–228. DOI: 10.1016/0734-743X(95)99848-L.

|

| [15] |

DESTEFANIS R, SCHÄFER F, LAMBERT M, et al. Enhanced space debris shields for manned spacecraft [J]. International Journal of Impact Engineering, 2003, 29(1–10): 215–226. DOI: 10.1016/j.ijimpeng.2003.09.019.

|

| [16] |

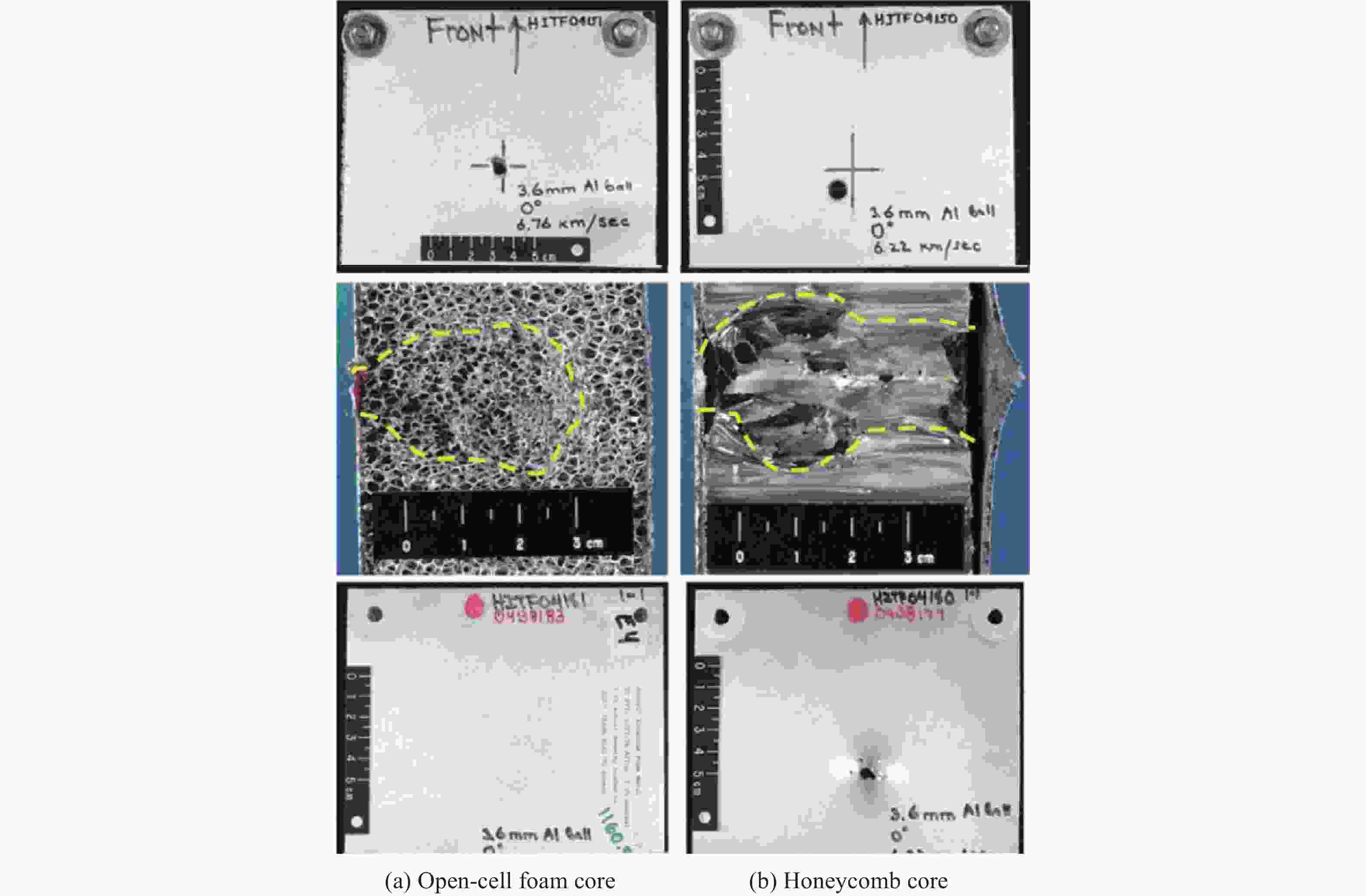

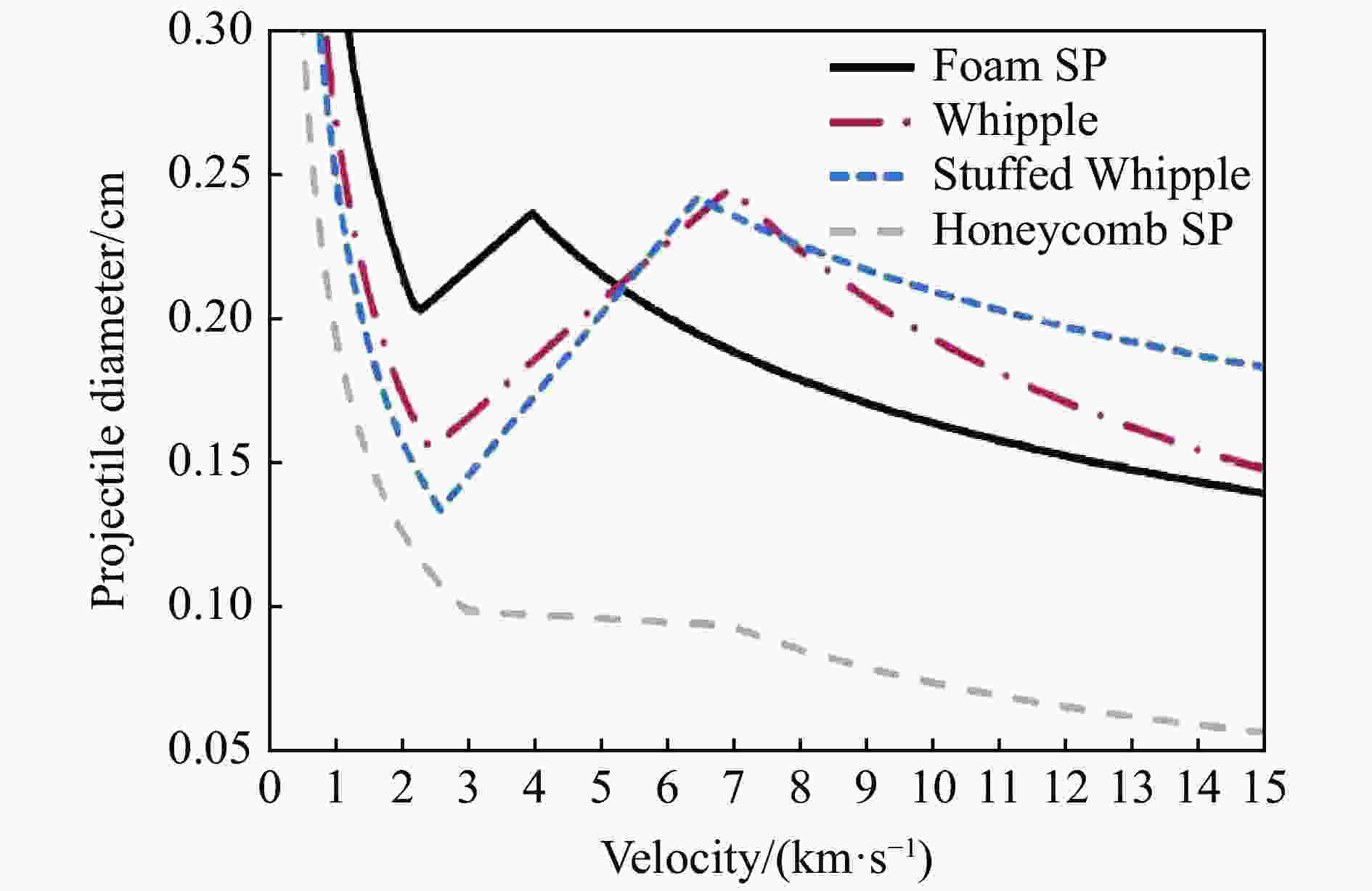

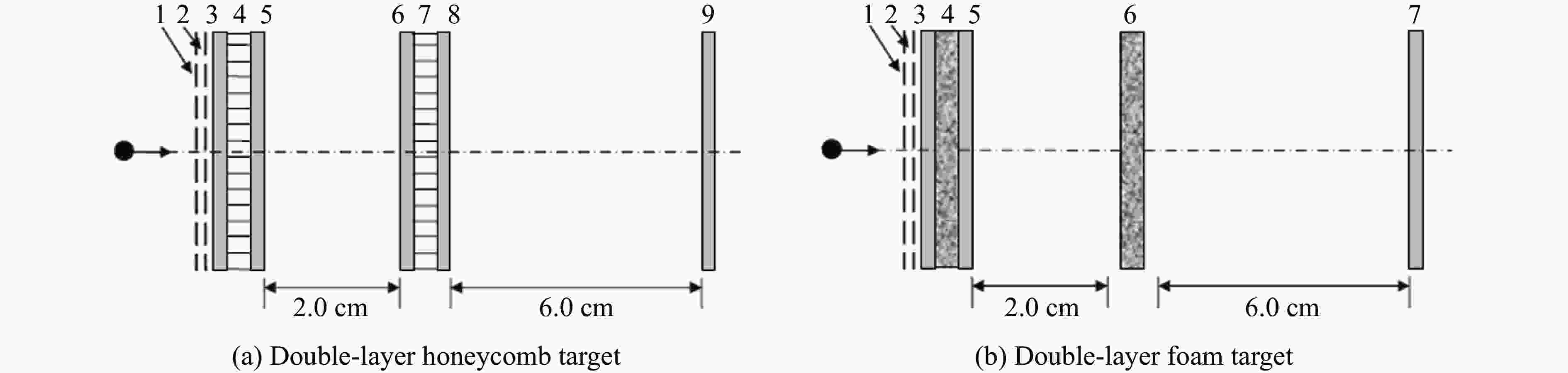

RYAN S, HEDMAN T, CHRISTIANSEN E L. Honeycomb vs. foam: evaluating potential upgrades to ISS module shielding [J]. Acta Astronautica, 2010, 67: 818–825. DOI: 10.1016/j.actaastro.2010.05.021.

|

| [17] |

周昊, 郭锐, 南博华, 等. 填充式波纹夹层结构超高速撞击特性仿真 [J]. 国防科技大学学报, 2017, 39(2): 57–63. DOI: 10.11887/j.cn.201702008.ZHOU H, GUO R, NAN B H, et al. Simulation on hypervelocity impact characteristics of stuffed corrugation-cored sandwiches [J]. Journal of National University of Defense Technology, 2017, 39(2): 57–63. DOI: 10.11887/j.cn.201702008.

|

| [18] |

SCHONBERG W P, TULLOS R J. Spacecraft wall design for increased protection against penetration by orbital debris impacts [J]. AIAA Journal, 1991, 29(12): 2207–2214. DOI: 10.2514/6.1990-3663.

|

| [19] |

KAWAI N, KURODA Y, NAGANO M, et al. Stress-wave propagation and damage formation associated with hypervelocity penetration into polycarbonate [J]. Procedia Engineering, 2017, 204: 255–261. DOI: 10.1016/j.proeng.2017.09.733.

|

| [20] |

KUMAR S K S, JURADO-MANRIQUEZ E A, KIM Y H, et al. Polybenzimidazole (PBI) film coating for improved hypervelocity impact energy absorption for space applications [J]. Composite Structures, 2018, 188: 72–77. DOI: 10.1016/j.compstruct.2017.12.052.

|

| [21] |

LI T, YU X, LIU H F, et al. Tensile behavior of C/SiC composites plate after hypervelocity penetration: residual strength and fracture mechanism [J]. Composite Structures, 2018, 189: 378–385. DOI: 10.1016/j.compstruct.2018.01.058.

|

| [22] |

WU Q, ZHANG Q M, LONG R R, et al. Potential space debris shield structure using impact-initiated energetic materials composed of polytetrafluoroethylene and aluminum [J]. Applied Physics Letters, 2016, 108: 135–183. DOI: 10.1063/1.4943584.

|

| [23] |

COUR-PALAIS B G. Meteorid environment model: NASA/SP-8013 [R]. Washington: National Aeronautics and Space Administration, 1969. DOI: CDSTIC.GRA.00159492.

|

| [24] |

CHRISTIANSEN E L. Meteoroid/debris shielding: NASA/TP-2003-210788 [R]. Houston, Texas: NASA Johnson Space Center, 2003.

|

| [25] |

HAYASHIDA K B, ROBINSON J H. Double-plate penetration equations: NASA/TM-2000-209907 [R]. Alabama: Marshall Space Flight Center, NASA, 2000.

|

| [26] |

郑建东, 龚自正, 童靖宇, 等. 一种新的Whipple防护结构弹道极限方程准确率分析 [J]. 航天器环境工程, 2012, 29(2): 134–138. DOI: 10.3969/j.issn.1673-1379.2012.02.004.ZHENG J D, GONG Z Z, TONG J Y, et al. Accuracy analysis of a new Whipple shield ballistic limit equations [J]. Spacecraft Environment Engineering, 2012, 29(2): 134–138. DOI: 10.3969/j.issn.1673-1379.2012.02.004.

|

| [27] |

CHRISTIANSEN E L, KERR J H. Mesh double-bumper shield: a low-weight alternative for spacecraft meteoroid and orbital debris protection [J]. International Journal of Impact Engineering, 1993, 14(1 –4): 169–180. DOI: 10.1016/0734-743X(93)90018-3.

|

| [28] |

CHRISTIANSEN E L. Advanced meteoroid and debris shielding concepts [C]// Orbital Debris Conference: Technical Issues and Future Directions, AIAA. 1990. DOI: 10.2514/6.1990-1336.

|

| [29] |

CHRISTIANSEN E L, KERR J H, DE LA FUENTE H M, et al. Flexible and deployable meteoroid/debris shielding for spacecraft [J]. International Journal of Impact Engineering, 1999, 23: 125–136. DOI: 10.1016/S0734-743X(99)00068-8.

|

| [30] |

RYAN S, CHRISTIANSEN E L. Hypervelocity impact testing of advanced materials and structures for micrometeoroid and orbital debris shielding [J]. Acta Astronautica, 2013, 83: 216–231. DOI: 10.1016/j.actaastro.2012.09.012.

|

| [31] |

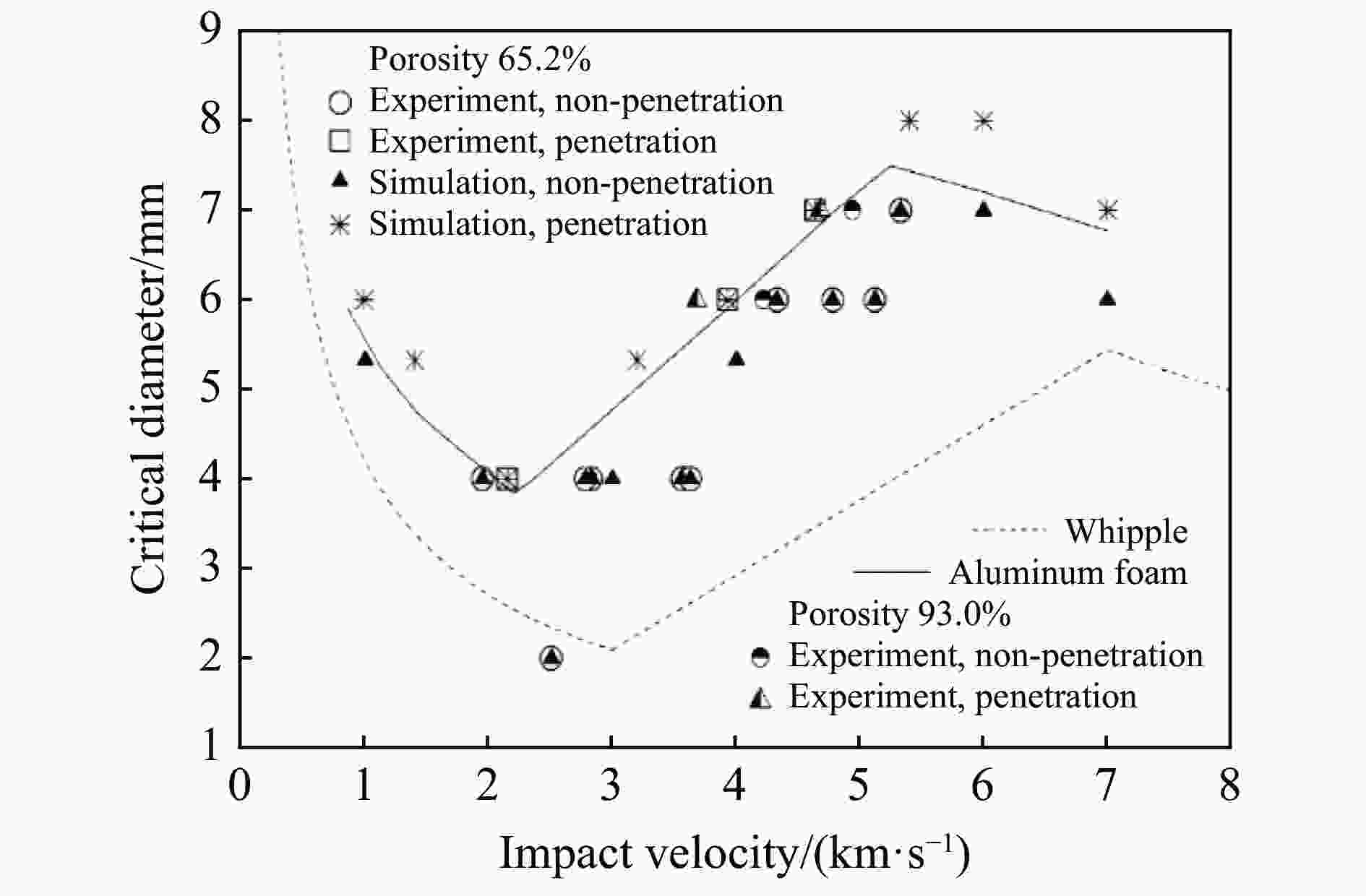

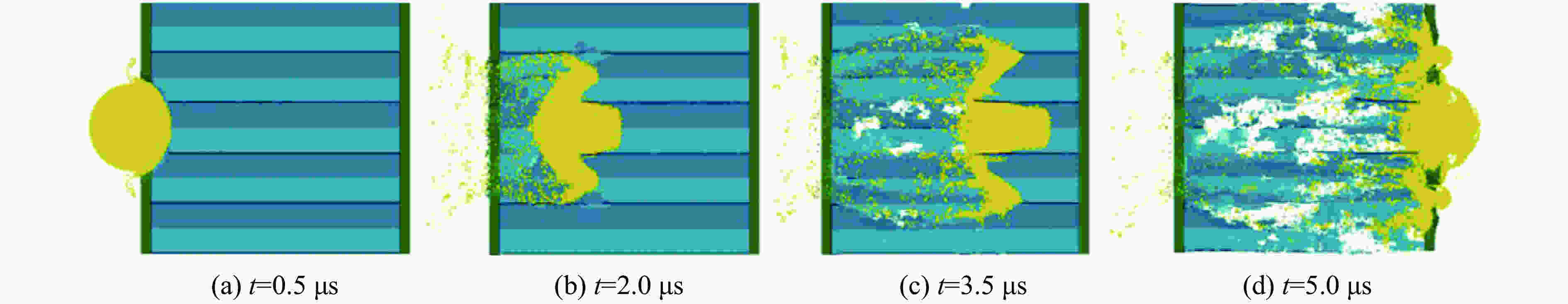

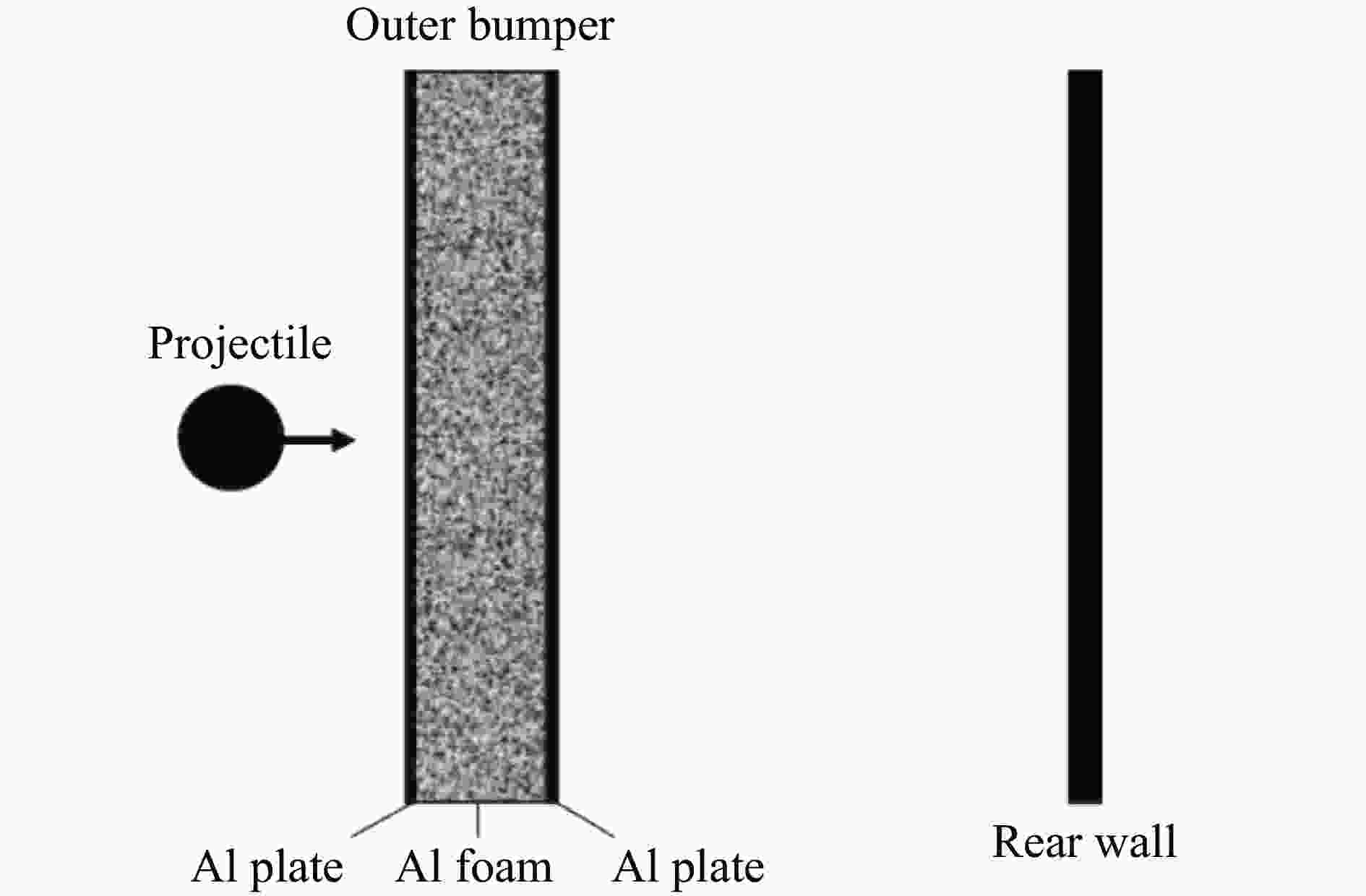

贾斌, 马志涛, 庞宝君. 填充泡沫铝防护结构的超高速撞击数值模拟 [J]. 哈尔滨工业大学学报, 2011, 43(1): 16–20. DOI: 10.11918/j.issn.0367-6234.2011.01.004.JIA B, MA Z T, PANG B J. Numerical simulation investigation in hypervelocity impact on Al-foam stuffed shields [J]. Journal of Harbin Institute of Technology, 2011, 43(1): 16–20. DOI: 10.11918/j.issn.0367-6234.2011.01.004.

|

| [32] |

贾斌, 马志涛, 庞宝君. 含泡沫铝防护结构的超高速撞击数值模拟研究 [J]. 高压物理学报, 2009, 23(6): 453–459. DOI: 10.11858/gywlxb.2009.06.009.JIA B, MA Z T, PANG B J. Numerical simulation investigation in hypervelocity impact on shield structure containing aluminum foam [J]. Chinese Journal of High Pressure Physics, 2009, 23(6): 453–459. DOI: 10.11858/gywlxb.2009.06.009.

|

| [33] |

刘文祥, 张德志, 张向荣, 等. 填充式泡沫铝防护结构的弹道极限 [J]. 爆炸与冲击, 2012, 32(1): 43–46. DOI: 10.11883/1001-1455(2012)01-0043-04.LIU W X, ZHANG D Z, ZHANG X R, et al. Ballistic limit of an aluminum foam-filledshield [J]. Explosion and Shock Waves, 2012, 32(1): 43–46. DOI: 10.11883/1001-1455(2012)01-0043-04.

|

| [34] |

DESTEFANIS R, SCHÄFER F, LAMBERT M, et al. Selecting enhanced space debris shields for manned spacecraft [J]. International Journal of Impact Engineering, 2006, 33(1–12): 219–230. DOI: 10.1016/j.ijimpeng.2006.09.065.

|

| [35] |

TAYLOR E A, GLANVILLE J P, CLEGG R A, et al. Hypervelocity impact on spacecraft honeycomb: hydrocode simulation and damage laws [J]. International Journal of Impact Engineering, 2003, 29: 691–702. DOI: 10.1016/j.ijimpeng.2003.10.016.

|

| [36] |

TAYLOR E A. Computational study of hypervelocity impact onto Whipple bumpers and sandwich plates with honeycomb core [R]. European Space Agency/European Space Research and Technology Centre, 1999.

|

| [37] |

RYAN S, SCHÄFER F, DESTEFANIS R, et al. A ballistic limit equation for hypervelocity impacts on composite honeycomb sandwich panel satellite structures [J]. Advances in Space Research, 2008, 41(7): 1152–1166. DOI: 10.1016/j.asr.2007.02.032.

|

| [38] |

SIBEAUD J-M, PRIEUR C, PUILLET C. Hypervelocity impact on honeycomb target structures: experimental part [C]// The 4th European Conference on Space Debris. Darmstadt, Germany: The European Space Agency, 2005.

|

| [39] |

SIBEAUD J-M, THAMIE L, PUILLET C. Hypervelocity impact on honeycomb target structures: experiments and modeling [J]. International Journal of Impact Engineering, 2008, 35(12): 1799–1807. DOI: 10.1016/j.ijimpeng.2008.07.037.

|

| [40] |

JEX D W, MAC KAY C, MILLER A. The characteristics of penetration for a double-sheet structure with honeycomb: NASA/TM-X-53974 [R]. Huntsville: Marshall Space Flight Center, NASA, 1970.

|

| [41] |

DECONINCK P, ABDULHAMID H, HÉREIL P L, et al. Experimental and numerical study of submillimeter-sized hypervelocity impacts on honeycomb sandwich structures [J]. Procedia engineering, 2017, 204: 452–459. DOI: 10.1016/j.proeng.2017.09.740.

|

| [42] |

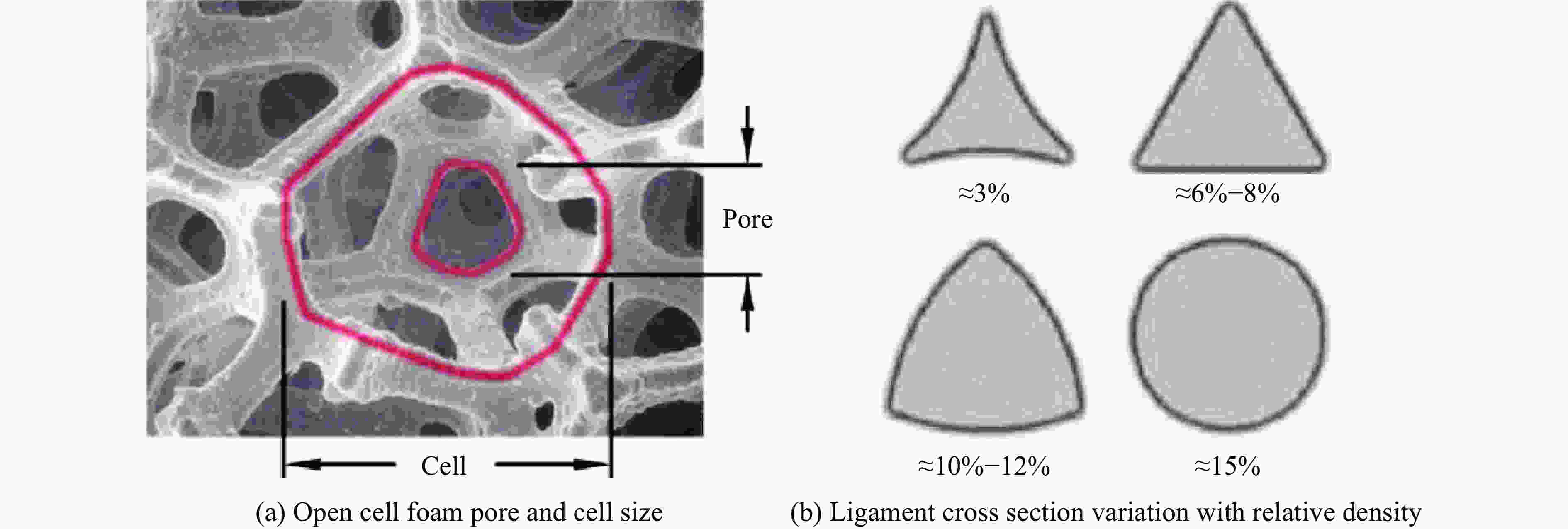

NITTA K, HIGASHIDE M, KITAZAWA Y, et al. Response of a aluminum honeycomb subjected to hypervelocity impacts [J]. Procedia Engineering, 2013, 58: 709–714. DOI: 10.1016/j.proeng.2013.05.082.

|

| [43] |

SCHONBERG W, SCHÄFER F, PUTZAR R. Hypervelocity impact response of honeycomb sandwich panels [J]. Acta Astronautica, 2010, 66(3–4): 455–466. DOI: 10.1016/j.actaastro.2009.06.018.

|

| [44] |

ANON. Effectiveness of aluminum honeycomb shields in preventing meteoroid damage to liquid-filled spacecraft tanks: NASA/CR-65261 [R]. Salt Lake City: Utah Research and Development Co. Inc., NASA, 1964.

|

| [45] |

LATHROP B L, SENNETT R E. Effects of hypervelocity impact on honeycomb structures [J]. Journal of Spacecraft and Rockets, 1968, 5(12): 1496–1497. DOI: 10.2514/3.29514.

|

| [46] |

LAMBERT M, SCHÄFER F K, GEYER T. Impact damage on sandwich panels and multi-layer insulation [J]. International Journal of Impact Engineering, 2001, 26(1–10): 369–380. DOI: 10.1016/S0734-743X(01)00108-7.

|

| [47] |

KANG P, YOUN S K, LIM J H. Modification of the critical projectile diameter of honeycomb sandwich panel considering the channeling effect in hypervelocity impact [J]. Aerospace Science and Technology, 2013, 29: 413–425. DOI: 10.1016/j.ast.2013.04.011.

|

| [48] |

RYAN S, ORDONEZ E, CHRISTIANSEN E L, et al. Hypervelocity impact performance of open cell foam core sandwich panel structures [C]// The 11th Hypervelocity Impact Symposium. Freiburg, Germany, 2010.

|

| [49] |

YASENSKY J, CHRISTIANSEN E L. Hypervelocity impact evaluation of metal foam core sandwich structures: NASA/JSC63945 [R]. NASA, 2007.

|

| [50] |

RYAN S, HEDMAN T, CHRISTIANSEN E L. Honeycomb vs. foam: evaluating a potential upgrade to international space station module shielding for micrometeoroids and orbital debris: NASA/TM-2009-214793 [R]. Arizona: USRA Lunar and Planetary Institute, NASA, 2009.

|

| [51] |

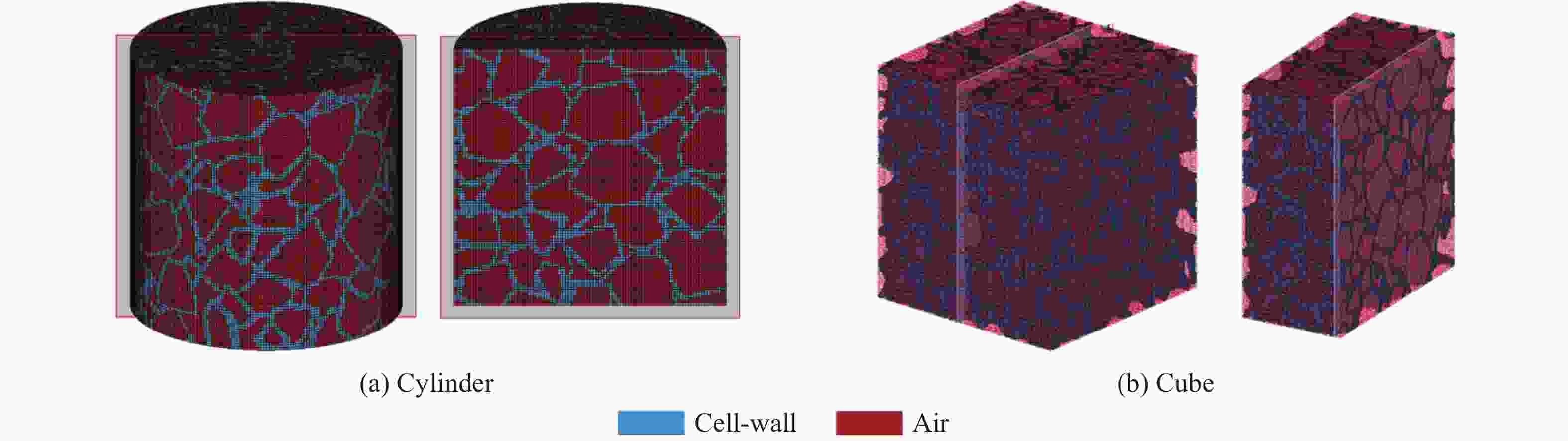

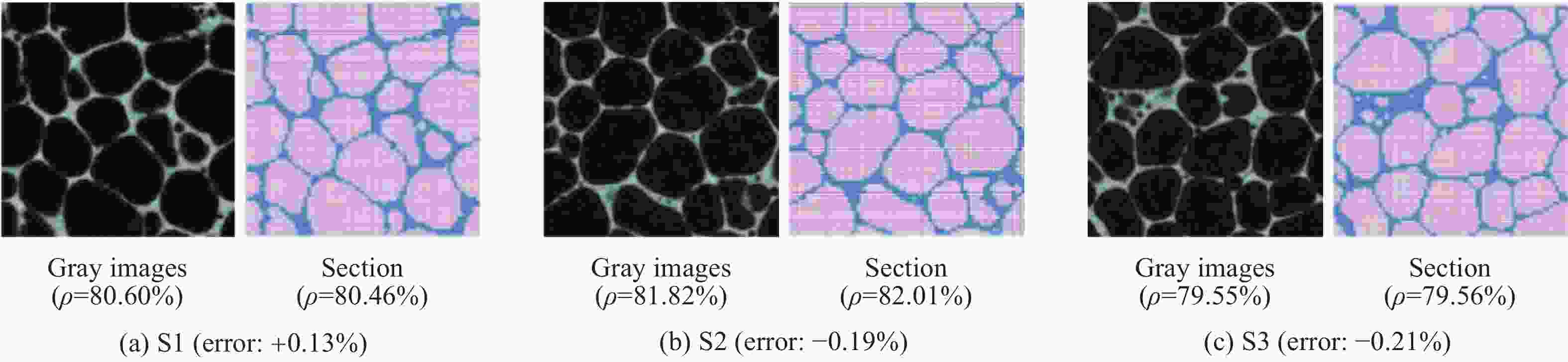

VOILLAT R, GALLIEN F, MORTENSEN A, et al. Hypervelocity impact testing on stochastic and structured open porosity cast Al-Si cellular structures for space applications [J]. International Journal of Impact Engineering, 2018, 120: 126–137. DOI: 10.1016/j.ijimpeng.2018.05.002.

|

| [52] |

GAITANAROS S, KYRIAKIDES S. On the effect of relative density on the crushing and energy absorption of open-cell foams under impact [J]. International Journal of Impact Engineering, 2015, 82: 3–13. DOI: 10.1016/j.ijimpeng.2015.03.011.

|

| [53] |

SHI X P, LIU S Y, NIE H L, et al. Study of cell irregularity effects on the compression of closed-cell foams [J]. International Journal of Mechanical Sciences, 2018, 135: 215–225. DOI: 10.1016/j.ijmecsci.2017.11.026.

|

| [54] |

SANCHEZ G A, CHRISTIANSEN E L. FGB energy block meteoroid and orbital (M/OD) debris shield test report: NASA/JSC-27460 [R]. Washington: National Aeronautics and Space Administration, 1996.

|

| [55] |

THOMA K, SCHÄFER F, HIERMAIER S, et al. An approach to achieve progress in spacecraft shielding [J]. Advances in Space research, 2004, 34(5): 1063–1075. DOI: 10.1016/j.asr.2003.03.034.

|

| [56] |

张雄, 刘岩, 马上. 无网格法的理论及应用 [J]. 力学进展, 2009, 39(1): 1–36. DOI: 10.3321/j.issn:1000-0992.2009.01.001.ZHANG X, LIU Y, MA S. Meshfree methods and their applications [J]. Advances in Mechanics, 2009, 39(1): 1–36. DOI: 10.3321/j.issn:1000-0992.2009.01.001.

|

| [57] |

张雄, 宋康祖, 陆明万. 无网格法研究进展及其应用 [J]. 计算力学学报, 2003, 20(6): 730–742. DOI: 10.7511/jslx20036138.ZHANG X, SONG K Z, LU M W. Research progress and application of meshless method [J]. Chinese Journal of Computational Mechanics, 2003, 20(6): 730–742. DOI: 10.7511/jslx20036138.

|

| [58] |

胡德安, 韩旭, 肖毅华, 等. 光滑粒子法及其与有限元耦合算法的研究进展 [J]. 力学学报, 2013, 45(5): 639–652. DOI: 10.6052/0459-1879-13-092.HU D A, HAN X, XIAO Y H, et al. Research developments of smoothed particle hydrodynamicsmethod and its coupling with finite element method [J]. Chinese Journal of Theoretical and Applied Mechanics, 2013, 45(5): 639–652. DOI: 10.6052/0459-1879-13-092.

|

| [59] |

GINGOLD R A, MONAGHAN J J. Smoothed particle hydrodynamics: theory and application to non-spherical stars [J]. Monthly Notices of the Royal Astronomical Society, 1977, 181(3): 375–389. DOI: 10.1093/mnras/181.3.375.

|

| [60] |

LUCY L B. A numerical approach to the testing of the fission hypothesis [J]. The Astronomical Journal, 1977, 82(12): 1013–1024. DOI: 10.1086/112164.

|

| [61] |

LIBERSKY L D, PETSCHEK A G. Smooth particle hydrodynamics with strength of materials [J]. Advances in the Free Lagrange Method, 1990, 248: 248–257. DOI: 10.1007/3-540-54960-9_58.

|

| [62] |

LIBERSKY L D, RANDLES P W, CARNEY T C, et al. Recent improvements in SPH modeling of hypervelocity impact [J]. International Journal of Impact Engineering, 1997, 20(6–10): 525–532. DOI: 10.1016/S0734-743X(97)87441-6.

|

| [63] |

LIBERSKY L D, PETSCHEK A G, CARNEY T C, et al. High strain Lagrangian hydrodynamics: a three-dimensional SPH code for dynamic material response [J]. Journal of Computational Physics, 1993, 109(1): 67–75. DOI: 10.1006/jcph.1993.1199.

|

| [64] |

RANDLES P W, LIBERSKY L D. Smoothed particle hydrodynamics: some recent improvements and applications [J]. Computer Methods in Applied Mechanics and Engineering, 1996, 139(1–4): 375–408. DOI: 10.1016/S0045-7825(96)01090-0.

|

| [65] |

HAYHURST C J, CLEGG R A. Cylindrically symmetric SPH simulations of hypervelocity impacts on thin plates [J]. International Journal of Impact Engineering, 1997, 20(1–5): 337–348. DOI: 10.1016/S0734-743X(97)87505-7.

|

| [66] |

崔伟峰, 曾新吾. SPH算法在超高速碰撞数值模拟中的应用 [J]. 国防科技大学学报, 2007, 29(2): 43–46. DOI: 10.3969/j.issn.1001-2486.2007.02.010.CUI W F, ZENG X W. Smoothed particle hydrodynamics algorithm applied in numerical simulation of hypervelocity impact [J]. Journal of National University of Defense Technology, 2007, 29(2): 43–46. DOI: 10.3969/j.issn.1001-2486.2007.02.010.

|

| [67] |

徐志宏, 汤文辉, 罗永. SPH 算法在高速侵彻问题中的应用 [J]. 国防科技大学学报, 2005, 27(4): 41–44. DOI: 10.3969/j.issn.1001-2486.2005.04.010.XU Z H, TANG W H, LUO Y. Smoothed particle hydrodynamics algorithm applied in penetration problem [J]. Journal of National University of Defense Technology, 2005, 27(4): 41–44. DOI: 10.3969/j.issn.1001-2486.2005.04.010.

|

| [68] |

LIU G R, LIU M B, LI S F. Smoothed particle hydrodynamics: a meshfree method [J]. Computational Mechanics, 2004, 33: 491–491. DOI: 10.1007/s00466-004-0573-1.

|

| [69] |

DYKA C T, INGEL R P, FLIPPEN L D. A new approach to dynamic condensation for FEM [J]. Computers & Structures, 1995, 61(4): 763–773. DOI: 10.1016/0045-7949(96)00017-X.

|

| [70] |

SWEGLE J W, HICKS D L, ATTAWAY S W. Smoothed particle hydrodynamics stability analysis [J]. Journal of Computational Physics, 1995, 116(1): 123–134. DOI: 10.1006/jcph.1995.1010.

|

| [71] |

傅学金, 强洪夫, 杨月诚. 固体介质中SPH方法的拉伸不稳定性问题研究进展 [J]. 力学进展, 2007, 37(3): 375–388. DOI: 10.3321/j.issn:1000-0992.2007.03.005.FU X J, QIANG H F, YANG Y C. Advances in the tensile instability of smoothed particle hydrodynamics applied to solid dynamics [J]. Advances in Mechanics, 2007, 37(3): 375–388. DOI: 10.3321/j.issn:1000-0992.2007.03.005.

|

| [72] |

MORRIS J P. A study of the stability properties of smooth particle hydrodynamics [J]. Publications of the Astronomical Society of Australia, 1996, 13(1): 97–102. DOI: 10.1017/S1323358000020610.

|

| [73] |

刘谋斌, 常建忠. 光滑粒子动力学方法中粒子分布与数值稳定性分析 [J]. 物理学报, 2010, 59(6): 3654–3662. DOI: 10.7498/aps.59.3654.LIU M B, CHANG J Z. Particle distribution and numerical stability in smoothed particle hydrodynamics method [J]. Acta Physica Sinica, 2010, 59(6): 3654–3662. DOI: 10.7498/aps.59.3654.

|

| [74] |

卞梁, 王肖钧, 章杰, 等. 高速碰撞数值计算中的 SPH 分区算法 [J]. 计算物理, 2011, 28(2): 207–212. DOI: 10.3969/j.issn.1001-246X.2011.02.007.BIAN L, WANG X J, ZHANG J, et al. Numerical simulation of hypervelocity impact with subdomains in SPH computation [J]. Chinese Journal of Computational Physics, 2011, 28(2): 207–212. DOI: 10.3969/j.issn.1001-246X.2011.02.007.

|

| [75] |

倪国喜, 王瑞利, 林忠, 等. 任意区域上的粒子均匀分布方法 [J]. 计算力学学报, 2007, 24(4): 408–413. DOI: 10.3969/j.issn.1007-4708.2007.04.005.NI G X, WANG R L, LIN Z, et al. Equi-distribution of particles in arbitrary domain [J]. Chinese Journal of Computational Mechanics, 2007, 24(4): 408–413. DOI: 10.3969/j.issn.1007-4708.2007.04.005.

|

| [76] |

董晃晃. SPH 的粒子生成方法及其在弹体侵彻金属靶中的应用[D]. 南昌: 华东交通大学, 2017.DONG H H. Particle generation method for SPH and the application of SPH to penetration of metal targets by projectiles [D]. Nanchang: East China Jiaotong University, 2017.

|

| [77] |

DYKA C T, RANDLES P W, INGEL R P. Stress point for tension instability in SPH [J]. International Journal for Numerical Methods in Engineering, 1997, 40(13): 2325–2341. DOI: 10.1002/(SICI)1097-0207(19970715)40:13<2325::AID-NME161>3.0.CO,2.

|

| [78] |

MONAGHAN J J. SPH without a tensile instability [J]. Journal of Computational Physics, 2000, 159(2): 290–311. DOI: 10.1006/jcph.2000.6439.

|

| [79] |

LIU M B, LIU G R, ZONG Z. An overview on smoothed particle hydrodynamics [J]. International Journal of Computational Methods, 2008, 5(1): 135–188. DOI: 10.1142/S021987620800142X.

|

| [80] |

LIU M B, XIE W P, LIU G R. Modeling incompressible flows using a finite particle method [J]. Applied Mathematical Modelling, 2005, 29(12): 1252–1270. DOI: 10.1016/j.apm.2005.05.003.

|

| [81] |

LIU M B, LIU G R. Restoring particle consistency in smoothed particle hydrodynamics [J]. Applied Numerical Mathematics, 2006, 56(1): 19–36. DOI: 10.1016/j.apnum.2005.02.012.

|

| [82] |

杨秀峰, 刘谋斌. 光滑粒子动力学 SPH 方法应力不稳定性的一种改进方案 [J]. 物理学报, 2012, 61(22): 224701. DOI: 10.7498/aps.61.224701.YANG X F, LIU M B. Improvement on stress instability in smoothed particle hydrodynamics [J]. Acta Physica Sinica, 2012, 61(22): 224701. DOI: 10.7498/aps.61.224701.

|

| [83] |

GRADY D E, WINFREE N A. Impact fragmentation of high-velocity compact projectiles on thin plates: a physical and statistical characterization of fragment debris [J]. International Journal of Impact Engineering, 2001, 26(1 –10): 249–262. DOI: 10.1016/S0734-743X(01)00085-9.

|

| [84] |

NAKAMURA A, FUJIWARA A. Velocity distribution of fragments formed in a simulated collisional disruption [J]. Icarus, 1991, 92(1): 132–146. DOI: 10.1016/0019-1035(91)90040-Z.

|

| [85] |

HOCKNEY R W, EASTWOOD J W. Computer simulation using particles [M]. New York: McGraw-Hill, 1981.

|

| [86] |

HOCKNEY R W, EASTWOOD J W. Computer simulation using particles [M]. Boca Raton: CRC Press, 1988.

|

| [87] |

BENZ W. Smooth particle hydrodynamics: a review [C] // The Numerical Modelling of Nonlinear Stellar Pulsations. Dordrecht: NATO ASI Series, 1990: 269–288. DOI: 10.1007/978-94-009-0519-1_16.

|

| [88] |

BENZ W, ASPHAUG E. Impact simulations with fracture: I: method and tests [J]. Icarus, 1994, 107(1): 98–116. DOI: 10.1006/icar.1994.1009.

|

| [89] |

BENZ W, ASPHAUG E. Simulations of brittle solids using smooth particle hydrodynamics [J]. Computer Physics Communications, 1995, 87(1–2): 253–265. DOI: 10.1016/0010-4655(94)00176-3.

|

| [90] |

徐金中, 汤文辉, 徐志宏. 超高速碰撞碎片云特征的SPH方法数值分析 [J]. 高压物理学报, 2008, 22(4): 377–383. DOI: 10.11858/gywlxb.2008.04.007.XU J Z, TANG W H, XU Z H. Numerical analysis of the characteristics of debris clouds produced by hypervelocity impacts using SPH method [J]. Chinese Journal of High Pressure Physics, 2008, 22(4): 377–383. DOI: 10.11858/gywlxb.2008.04.007.

|

| [91] |

LIANG S C, LI Y, CHEN H, et al. Research on the technique of identifying debris and obtaining characteristic parameters of large-scale 3D point set [J]. International Journal of Impact Engineering, 2013, 56: 27–31. DOI: 10.1016/j.ijimpeng.2012.07.004.

|

| [92] |

SAKONG J, WOO S C, KIM T W. Determination of impact fragments from particle analysis via smoothed particle hydrodynamics and k-means clustering [J]. International Journal of Impact Engineering, 2019, 134: 103387. DOI: 10.1016/j.ijimpeng.2019.103387.

|

| [93] |

ZHANG X T, JIA G H, HUANG H. Fragment identification and statistics method of hypervelocity impact SPH simulation [J]. Chinese Journal of Aeronautics, 2011, 24: 18–24. DOI: 10.1016/S1000-9361(11)60003-4.

|

| [94] |

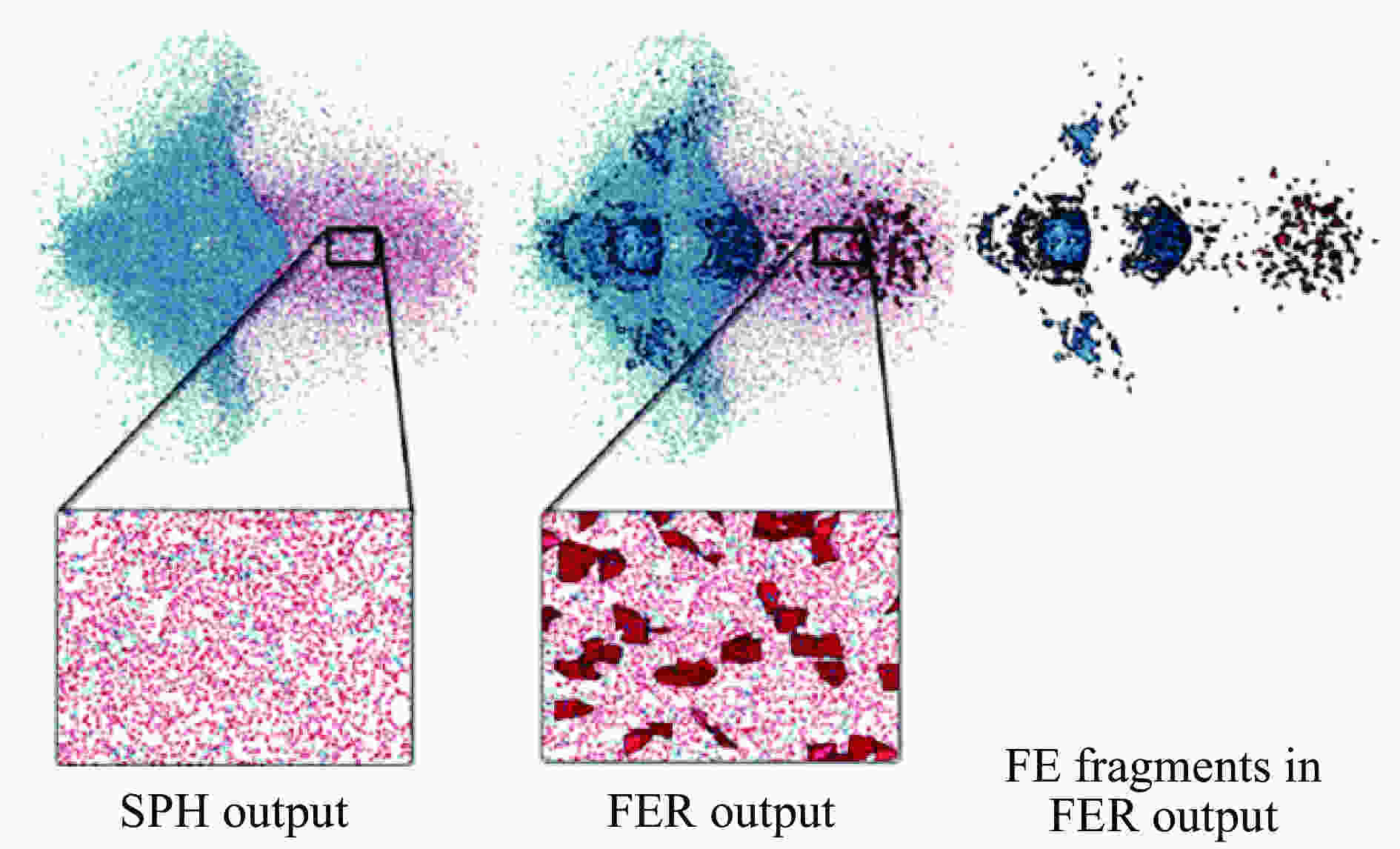

张晓天, 贾光辉, 黄海. 基于 FE 重构方法的冲击破碎仿真 [J]. 计算力学学报, 2011, 28(5): 792–797. DOI: 10.7511/jslx201105024.ZHANG X T, JIA G H, HUANG H. Combination of FE and SPH method for impact fragmentation [J]. Chinese Journal of Computational Mechanics, 2011, 28(5): 792–797. DOI: 10.7511/jslx201105024.

|

| [95] |

ZHANG X T, JIA G H, HUANG H. Finite element reconstruction approach for on-orbit spacecraft breakup dynamics simulation and fragment analysis [J]. Advances in Space Research, 2013, 51(3): 423–433. DOI: 10.1016/j.asr.2012.09.023.

|

| [96] |

张晓天, 贾光辉, 黄海. 基于超高速碰撞仿真的卫星碰撞解体碎片分析 [J]. 航空学报, 2011, 32(7): 1224–1230. DOI: CNKI:11-1929/V.20110330.1305.004.ZHANG X T, JIA G H, HUANG H. Debris analysis of on-orbit satellite collision based on hypervelocity impact simulation [J]. Acta Aeronautica Astronautica Sinica, 2011, 32(7): 1224–1230. DOI: CNKI:11-1929/V.20110330.1305.004.

|

| [97] |

ATTAAWAY S W, HEINSTEIN M W, SWEGLE J W. Coupling of smooth particle hydrodynamics with the finite element method [J]. Nuclear Engineering and Design, 1994, 150(2–3): 199–205. DOI: 10.1016/0029-5493(94)90136-8.

|

| [98] |

VUYST TD, VIGNJEVIC R, CAMPBELL J C. Coupling between meshless and finite element methods [J]. International Journal of Impact Engineering, 2005, 31(8): 1054–1064. DOI: 10.1016/j.ijimpeng.2004.04.017.

|

| [99] |

JOHNSON G R. Linking of Lagrangian particle methods to standard finite element methods for high velocity impact computations [J]. Nuclear Engineering and Design, 1994, 150(2–3): 265–274. DOI: 10.1016/0029-5493(94)90143-0.

|

| [100] |

冷冰林, 许金余, 邵宁, 等. 刚性弹丸侵彻金属靶体的 FEM-SPH 耦合计算 [J]. 弹箭与制导学报, 2008, 28(5): 105–108. DOI: 10.3969/j.issn.1673-9728.2008.05.032.LENG B L, XU J Y, SHAO N, et al. Computation of steel penetrated by rigid projectile with coupled FEM-SPH methods [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2008, 28(5): 105–108. DOI: 10.3969/j.issn.1673-9728.2008.05.032.

|

| [101] |

肖毅华, 胡德安, 韩旭, 等. 一种自适应轴对称FEM-SPH耦合算法及其在高速冲击模拟中的应用 [J]. 爆炸与冲击, 2012, 32(4): 51–59. DOI: 10.11883/1001-1455(2012)04-0384-09.XIAO Y H, HU D A, HAN X, et al. An adaptive axisymmetric FEM-SPH coupling algorithm and its application to high velocity impact simulation [J]. Explosion and Shock Waves, 2012, 32(4): 51–59. DOI: 10.11883/1001-1455(2012)04-0384-09.

|

| [102] |

纪冲, 龙源, 方向. 基于FEM-SPH耦合法的弹丸侵彻钢纤维混凝土数值模拟 [J]. 振动与冲击, 2010, 29(7): 69–74. DOI: 10.3969/j.issn.1000-3835.2010.07.015.JI C, LONG Y, FANG X. Numerical simulation for projectile penetrating steel fiber reinforced concrete with FEM-SPH coupling algorithm [J]. Journal of Vibration and Shock, 2010, 29(7): 69–74. DOI: 10.3969/j.issn.1000-3835.2010.07.015.

|

| [103] |

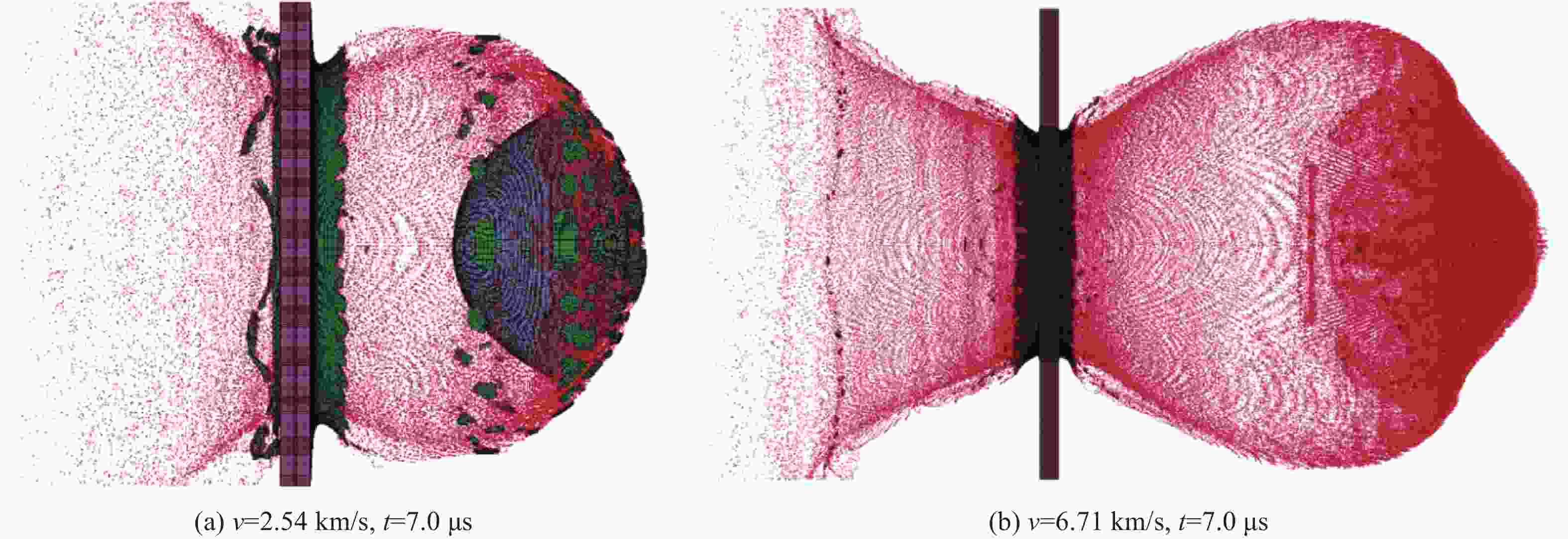

武玉玉, 何远航, 李金柱. 耦合方法在超高速碰撞数值模拟中的应用 [J]. 高压物理学报, 2005, 19(4): 385–389. DOI: 10.11858/gywlxb.2005.04.019.WU Y Y, HE Y H, LI J Z. Application of the coupling method in simulating the hypervelocity impact [J]. Chinese Journal of High Pressure Physics, 2005, 19(4): 385–389. DOI: 10.11858/gywlxb.2005.04.019.

|

| [104] |

何远航, 武玉玉, 张庆明. 碰撞倾角对碎片云分布影响的数值模拟 [J]. 北京理工大学学报, 2007, 27(10): 851–854. DOI: 10.3969/j.issn.1001-0645.2007.10.002.HE Y H, WU Y Y, ZHANG Q M. Numerical simulation for the influence of impact angle on debris clouds distribution [J]. Transactions of Beijing Institute of Technology, 2007, 27(10): 851–854. DOI: 10.3969/j.issn.1001-0645.2007.10.002.

|

| [105] |

SAKONG J, WOO S C, KIM J Y, et al. Study on material fracture and debris dispersion behavior via high velocity impact [J]. Transactions of the Korean Society of Mechanical Engineers A, 2017, 41(11): 1065–1075. DOI: 10.3795/KSME-A.2017.41.11.1065.

|

| [106] |

BECKER M, SEIDL M, MEHL M, et al. Numerical and experimental investigation of SPH, SPG, and FEM for high-velocity impact applications [C]// The 12th European LS-DYNA Conference. Koblenz: DYNAmore GmbH, 2019.

|

| [107] |

JOHNSON G R, BEISSEL S R, STRYK R A. An improved generalized particle algorithm that includes boundaries and interfaces [J]. International Journal for Numerical Methods in Engineering, 2002, 53(4): 875–904. DOI: 10.1002/nme.316.

|

| [108] |

JOHNSON G R, STRYK R A. Conversion of 3D distorted elements into meshless particles during dynamic deformation [J]. International Journal of Impact Engineering, 2003, 28(9): 947–966. DOI: 10.1016/S0734-743X(03)00012-5.

|

| [109] |

JOHNSON G R. Numerical algorithms and material models for high-velocity impact computations [J]. International Journal of Impact Engineering, 2011, 38(6): 456–472. DOI: 10.1016/j.ijimpeng.2010.10.017.

|

| [110] |

JOHNSON G R, STRYK R A, BEISSEL S R, et al. An algorithm to automatically convert distorted finite elements into meshless particles during dynamic deformation [J]. International Journal of Impact Engineering, 2002, 27(10): 997–1013. DOI: 10.1016/S0734-743X(02)00030-1.

|

| [111] |

BEISSEL S R, GERLACH C A, JOHNSON G R. Hypervelocity impact computations with finite elements and meshfree particles [J]. International Journal of Impact Engineering, 2006, 33(1–12): 80–90. DOI: 10.1016/j.ijimpeng.2006.09.047.

|

| [112] |

BEISSEL S R, GERLACH C A, JOHNSON G R. A quantitative analysis of computed hypervelocity debris clouds [J]. Cement Technology, 2008, 35(12): 1410–1418. DOI: 10.1016/j.ijimpeng.2008.07.059.

|

| [113] |

JOHNSON G R, BEISSEL S R, GERLACH C A. A 3D combined particle-element method for intense impulsive loading computations involving severe distortions [J]. International Journal of Impact Engineering, 2015, 84: 171–180. DOI: 10.1016/j.ijimpeng.2015.06.006.

|

| [114] |

JOHNSON G R, BEISSEL S R, STRYK R A. A generalized particle algorithm for high velocity impact computations [J]. Computational Mechanics, 2000, 25: 245–256. DOI: 10.1007/s004660050473.

|

| [115] |

GERLACH C A, JOHNSON G R. A contact and sliding interface algorithm for the combined particle-element method [J]. International Journal of Impact Engineering, 2018, 113: 21–28. DOI: 10.1016/j.ijimpeng.2017.11.003.

|

| [116] |

SAUER M. Adaptive kopplung des netzfreien SPH-verfahrens mit finiten elementen zur berechnung von impaktvorgängen [D]. Munich: Universität der Bundeswehr München, 2000.

|

| [117] |

王吉, 王肖钧, 卞梁. 光滑粒子法与有限元的耦合算法及其在冲击动力学中的应用 [J]. 爆炸与冲击, 2007, 27(6): 44–50. DOI: 10.11883/1001-1455(2007)06-0522-07.WANG J, WANG X J, BIAN L. Linking of smoothed particle hydronamics method to standard finite element method and its application in impact dynamics [J]. Explosion and Shock Waves, 2007, 27(6): 44–50. DOI: 10.11883/1001-1455(2007)06-0522-07.

|

| [118] |

张志春, 强洪夫, 高巍然. 一种新型SPH-FEM耦合算法及其在冲击动力学问题中的应用 [J]. 爆炸与冲击, 2011, 31(3): 243–249. DOI: 10.11883/1001-1455(2011)03-0243-07.ZHANG Z C, QIANG H F, GAO W R. A new coupled SPH-FEM algorithm and its application to impact dynamics [J]. Explosion and Shock Waves, 2011, 31(3): 243–249. DOI: 10.11883/1001-1455(2011)03-0243-07.

|

| [119] |

HE Q G, CHEN X W, CHEN J F. Finite element-smoothed particle hydrodynamics adaptive method in simulating debris cloud [J]. Acta Astronautica, 2020, 175: 99–117. DOI: 10.1016/j.actaastro.2020.05.056.

|

| [120] |

PIEKUTOWSKI A J. Characteristics of debris clouds produced by hypervelocity impact of aluminum spheres with thin aluminum plates [J]. International Journal of Impact Engineering, 1993, 14(1–4): 573–586. DOI: 10.1016/0734-743X(93)90053-A.

|

| [121] |

PIEKUTOWSKI A J. Fragmentation initiation threshold for spheres impacting at hypervelocity [J]. International Journal of Impact Engineering, 2003, 29(1–10): 563–574. DOI: 10.1016/j.ijimpeng.2003.10.005.

|

| [122] |

HE Y, BAYLY A E, HASSANPOUR A, et al. A GPU-based coupled SPH-DEM method for particle-fluid flow with free surfaces [J]. Powder Technology, 2018, 338: 548–562. DOI: 10.1016/j.powtec.2018.07.043.

|

| [123] |

ZAITSEV Y B, WITTMANN F H. Simulation of crack propagation and failure of concrete [J]. Matériaux et Construction, 1981, 14: 357–365. DOI: 10.1007/BF02478729.

|

| [124] |

GIBSON L J, ASHBY M F. Cellular solids: structure and properties [M]. Cambridge: Cambridge University Press, 1997.

|

| [125] |

SANTOSA S, WIERZBICKI T. On the modeling of crush behavior of a closed-cell aluminum foam structure [J]. Journal of the Mechanics and Physics of Solids, 1998, 46(4): 645–669. DOI: 10.1016/S0022-5096(97)00082-3.

|

| [126] |

LI K, GAO X L, ROY A K. Micromechanics model for three-dimensional open-cell foams using a tetrakaidecahedral unit cell and Castigliano’s second theorem [J]. Composites Science and Technology, 2003, 63(12): 1769–1781. DOI: 10.1016/S0266-3538(03)00117-9.

|

| [127] |

CHEON S S, MEGUID S A. Crush behavior of metallic foams for passenger car design [J]. International Journal of Automotive Technology, 2004, 5(1): 17–22. DOI: 10.1109/TVT.2004.823505.

|

| [128] |

TUNVIR K, KIM A, CHEON S. Analytical solution for crushing behavior of closed cell al-alloy foam [J]. Mechanics of Advanced Materials and Structures, 2007, 14: 321–327. DOI: 10.1080/15376490600845660.

|

| [129] |

冯阳, 梁增友, 吴鸿超, 等. 基于渗流法的泡沫铝细观结构模型研究 [J]. 中北大学学报(自然科学版), 2016, 37(1): 90–96. DOI: 10.3969/j.issn.1673-3193.2016.01.017.FENG Y, LIANG Z Y, WU H C, et al. Research on micro structural model of open-cell aluminum foam based on infiltration casting methods [J]. Journal of North University of China (Natural Science Edition), 2016, 37(1): 90–96. DOI: 10.3969/j.issn.1673-3193.2016.01.017.

|

| [130] |

LI L, XUE P, CHEN Y, et al. Insight into cell size effects on quasi-static and dynamic compressive properties of 3D foams [J]. Materials Science & Engineering A, 2015, 636: 60–69. DOI: 10.1016/j.msea.2015.03.052.

|

| [131] |

TEKOĞLU C, GIBSON L, PARDOEN T, et al. Size effects in foams: experiments and modeling [J]. Progress in Materials Science, 2011, 56(2): 109–138. DOI: 10.1016/j.pmatsci.2010.06.001.

|

| [132] |

王长峰, 郑志军, 虞吉林. 泡沫杆撞击刚性壁的动态压溃模型 [J]. 爆炸与冲击, 2013, 33(6): 587–593. DOI: 10.11883/1001-1455(2013)06-0587-07.WANG C F, ZHENG Z J, YU J L. Dynamic crushing models for a foam rod striking a rigid wall [J]. Explosion and Shock Waves, 2013, 33(6): 587–593. DOI: 10.11883/1001-1455(2013)06-0587-07.

|

| [133] |

LI Z Q, ZHANG J J, FAN J H, et al. On crushing response of the three-dimensional closed-cell foam based on Voronoi model [J]. Mechanics of Materials, 2014, 68: 85–94. DOI: 10.1016/j.mechmat.2013.08.009.

|

| [134] |

TANG L Q, SHI X P, ZHANG L, et al. Effects of statistics of cell’s size and shape irregularity on mechanical properties of 2D and 3D Voronoi foams [J]. Acta Mechanica, 2014, 225: 1361–1372. DOI: 10.1007/s00707-013-1054-4.

|

| [135] |

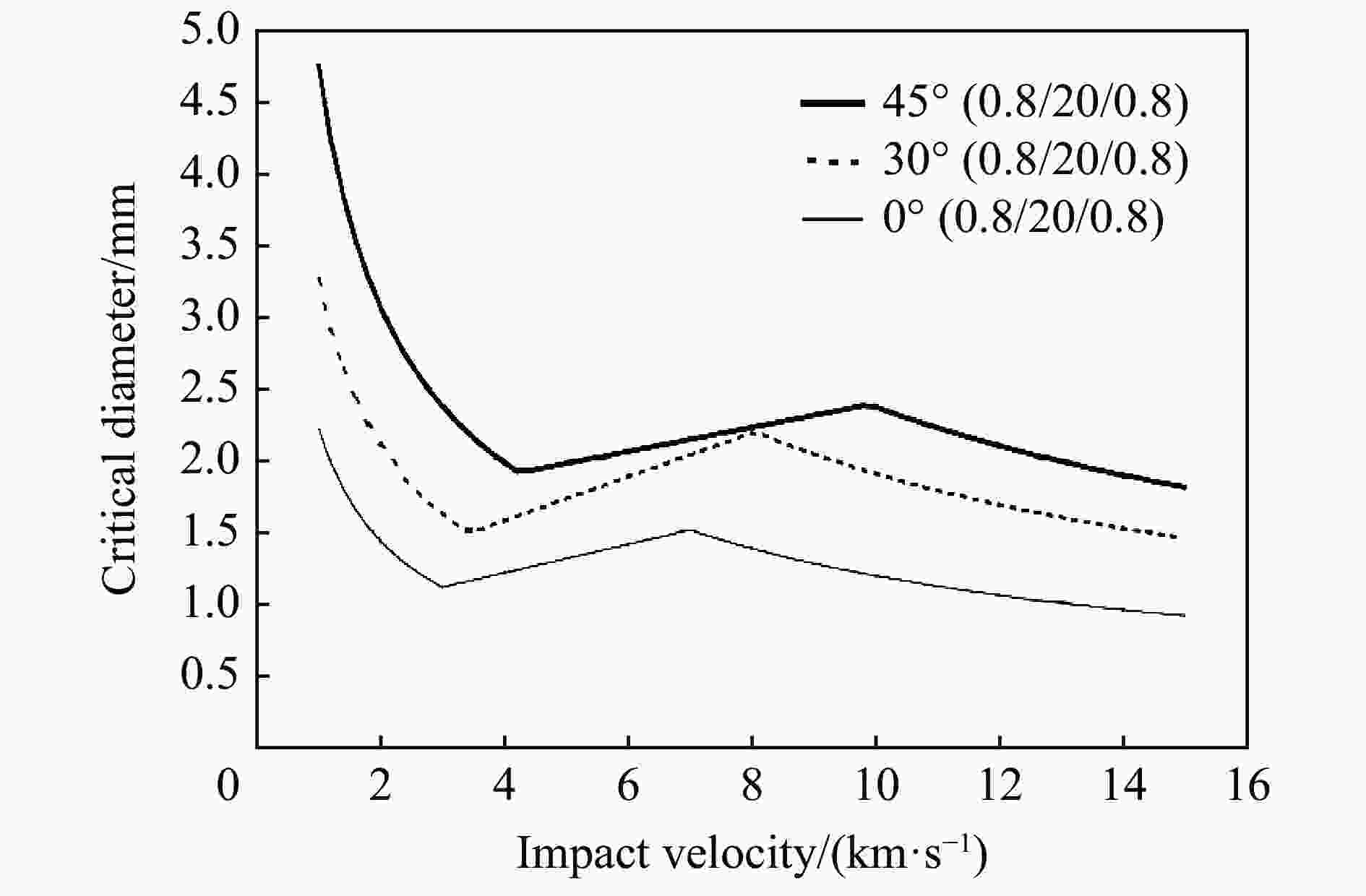

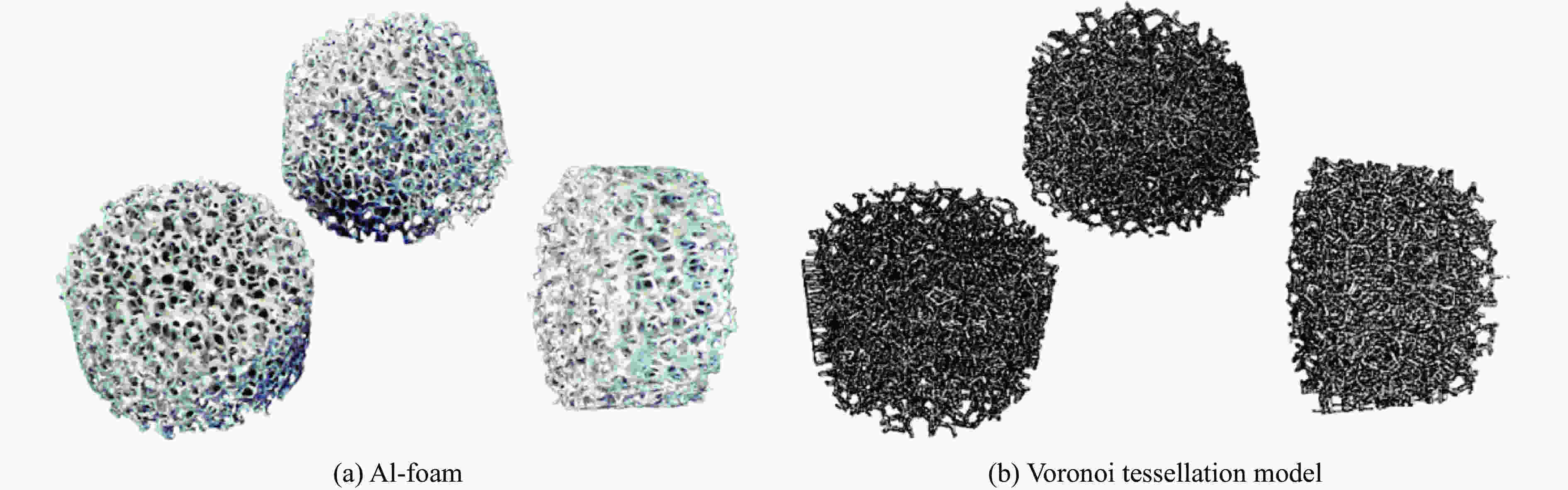

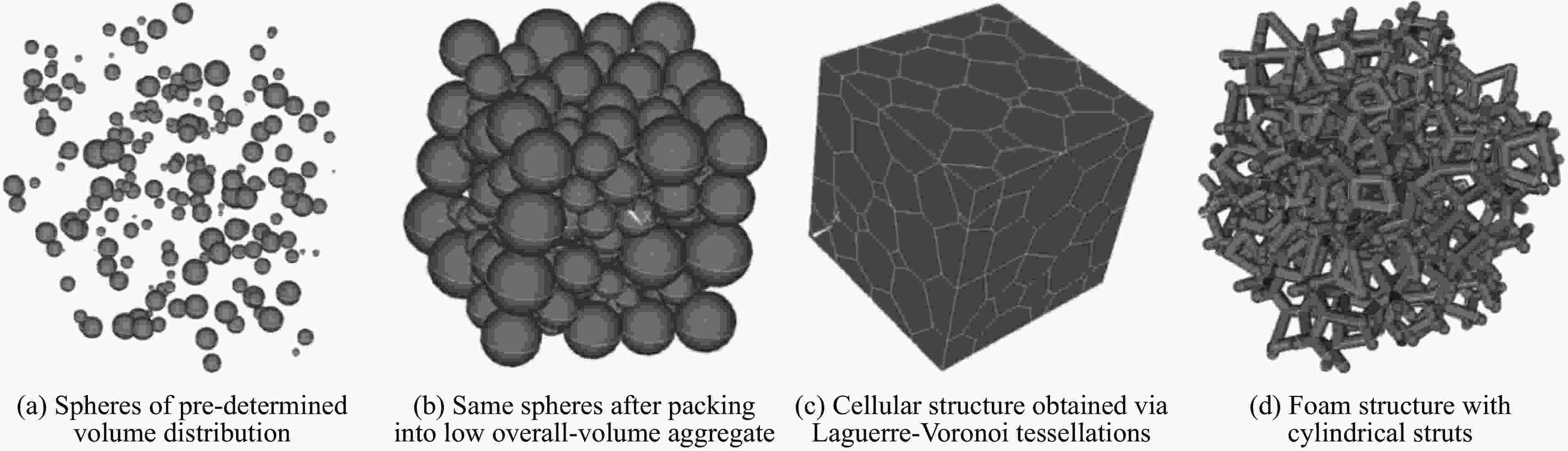

ZHANG X T, WANG R Q, LIU J X, et al. A numerical method for the ballistic performance prediction of the sandwiched open cell aluminum foam under hypervelocity impact [J]. Aerospace Science and Technology, 2018, 75: 254–260. DOI: 10.1016/j.ast.2017.12.034.

|

| [136] |

WEJRZANOWSKI T, SKIBINSKI J, SZUMBARSKI J, et al. Structure of foams modeled by Laguerre–Voronoi tessellations [J]. Computational Materials Science, 2013, 67: 216–221. DOI: 10.1016/j.commatsci.2012.08.046.

|

| [137] |

FAN Z G, WU Y G, ZHAO X H, et al. Simulation of polycrystalline structure with Voronoi diagram in Laguerre geometry based on random closed packing of spheres [J]. Computational materials science, 2004, 29(3): 301–308. DOI: 10.1016/j.commatsci.2003.10.006.

|

| [138] |

REDENBACH C. Microstructure models for cellular materials [J]. Computational Materials Science, 2009, 44(4): 1397–1407. DOI: 10.1016/j.commatsci.2008.09.018.

|

| [139] |

FANG Q, ZHANG J H, ZHANG Y D, et al. A 3D mesoscopic model for the closed-cell metallic foams subjected to static and dynamic loadings [J]. International Journal of Impact Engineering, 2015, 82: 103–112. DOI: 10.1016/j.ijimpeng.2014.10.009.

|

| [140] |

FANG Q, ZHANG J H, ZHANG Y D, et al. Mesoscopic investigation of closed-cell aluminum foams on energy absorption capability under impact [J]. Composite Structures, 2015, 124: 409–420. DOI: 10.1016/j.compstruct.2015.01.001.

|

| [141] |

ZHENG Z J, WANG C F, YU J L, et al. Dynamic stress-strain states for metal foams using a 3D cellular model [J]. Journal of the Mechanics and Physics of Solids, 2014, 72: 93–114. DOI: 10.1016/j.jmps.2014.07.013.

|

| [142] |

ZHANG C Y, TANG L Q, YANG B, et al. Meso-mechanical study of collapse and fracture behaviors of closed-cell metallic foams [J]. Computational Materials Science, 2013, 79: 45–51. DOI: 10.1016/j.commatsci.2013.05.046.

|

| [143] |

GREENBERGER M. An a priori determination of serial correlation in computer generated random numbers [J]. Mathematics of Computation, 1961, 15(76): 383–389. DOI: 10.1090/S0025-5718-1961-0144489-8.

|

| [144] |

FANG Q, ZHANG J H, CHEN L, et al. An algorithm for the grain-level modelling of a dry sand particulate system [J]. Modelling and Simulation in Materials Science and Engineering, 2014, 22(5): 055021. DOI: 10.1088/0965-0393/22/5/055021.

|

| [145] |

MAIRE E, FAZEKAS A, SALVO L, et al. X-ray tomography applied to the characterization of cellular materials. Related finite element modeling problems [J]. Composites Science and Technology, 2003, 63(16): 2431–2443. DOI: 10.1016/S0266-3538(03)00276-8.

|

| [146] |

MCDONALD S A, MUMMERY P M, JOHNSON G, et al. Characterization of the three-dimensional structure of a metallic foam during compressive deformation [J]. Journal of Microscopy, 2006, 223(2): 150–158. DOI: 10.1111/j.1365-2818.2006.01607.x.

|

| [147] |

JEON I, ASAHINA T, KANG K-J, et al. Finite element simulation of the plastic collapse of closed-cell aluminum foams with X-ray computed tomography [J]. Mechanics of Materials, 2010, 42(3): 227–236. DOI: 10.1016/j.mechmat.2010.01.003.

|

| [148] |

SAENGER E H, URIBE D, JÄNICKE R, et al. Digital material laboratory: wave propagation effects in open-cell aluminium foams [J]. International Journal of Engineering Science, 2012, 58: 115–123. DOI: 10.1016/j.ijengsci.2012.03.030.

|

| [149] |

陈鹏. 泡沫铝夹芯结构力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.CHEN P. Research on mechanical properties of aluminum foam sandwich structure [D]. Harbin: Harbin Institute of Technology, 2013.

|

| [150] |

SUN Y L, LI Q M, LOWE T, et al. Investigation of strain-rate effect on the compressive behaviour of closed-cell aluminium foam by 3D image-based modelling [J]. Materials and Design, 2016, 89: 215–224. DOI: 10.1016/j.matdes.2015.09.109.

|

| [151] |

程振, 方秦, 张锦华, 等. 闭孔泡沫金属三维细观模型建模方法 [J]. 工程力学, 2017, 34(8): 212–221. DOI: 10.6052/j.issn.1000-4750.2016.02.0098.CHENG Z, FANG Q, ZHANG J H, et al. Mesoscopic methodology for the three-dimensional modelling of closed-cell metallic foam [J]. Engineering Mechanics, 2017, 34(8): 212–221. DOI: 10.6052/j.issn.1000-4750.2016.02.0098.

|

| [152] |

李侯贞强, 张亚栋, 张锦华, 等. 基于CT的泡沫铝三维细观模型重建及应用 [J]. 北京航空航天大学学报, 2018, 44(1): 160–168. DOI: 10.13700/j.bh.1001-5965.2016.0959.LI H Z Q, ZHANG Y D, ZHANG J H, et al. Reconstruction and application of three-dimensional mesoscopic model of aluminum foam based on CT [J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(1): 160–168. DOI: 10.13700/j.bh.1001-5965.2016.0959.

|

下载:

下载: