Dynamic mechanical properties and constitutive relations of CoCrFeNiAlx high entropy alloys

-

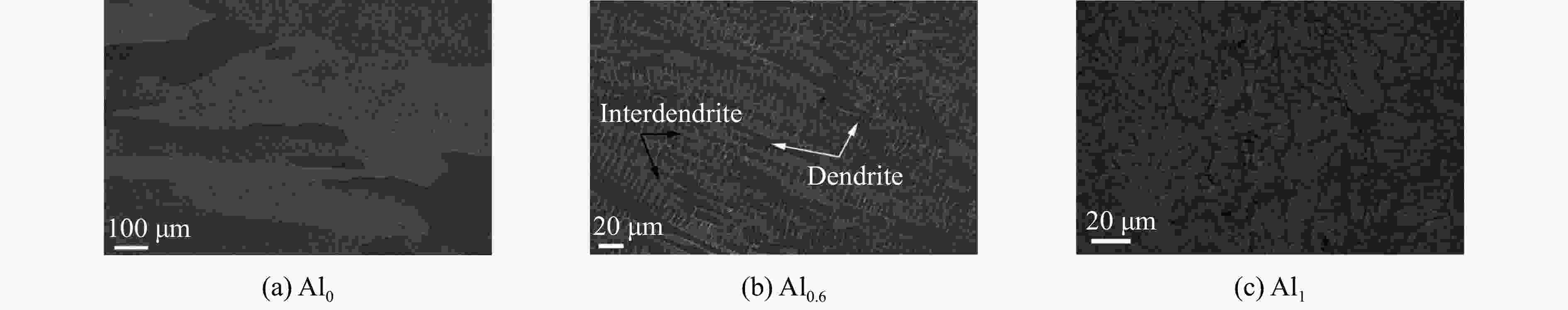

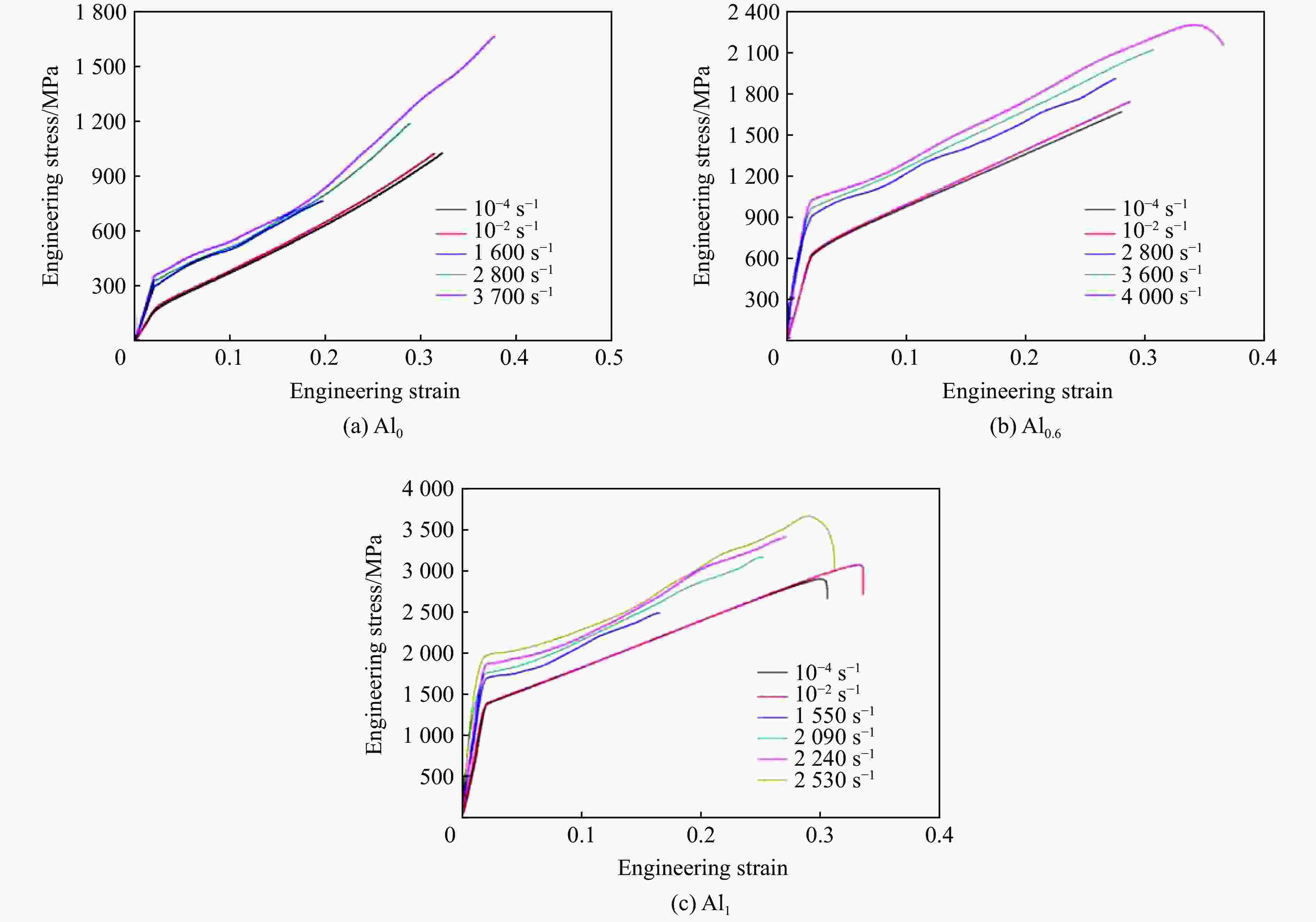

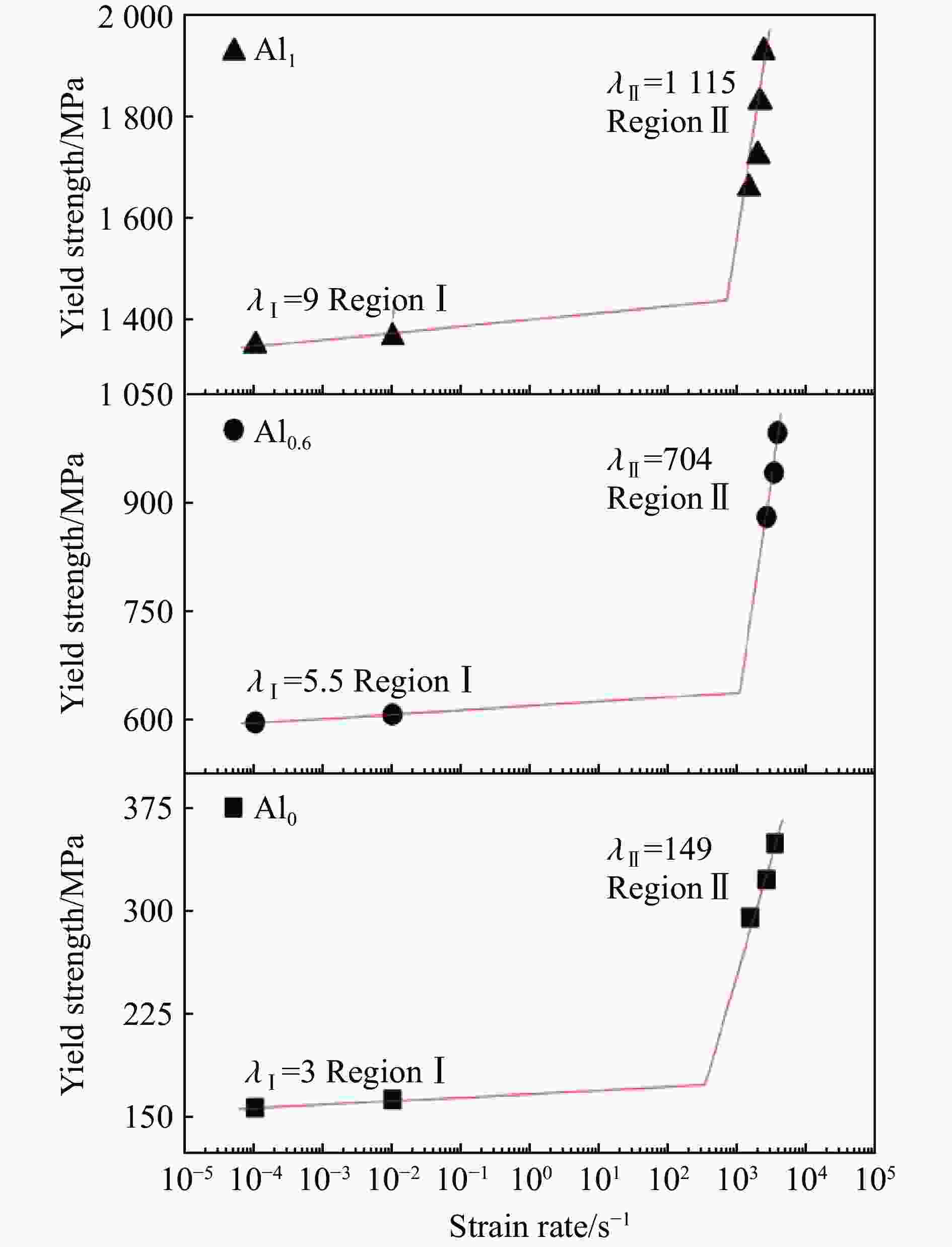

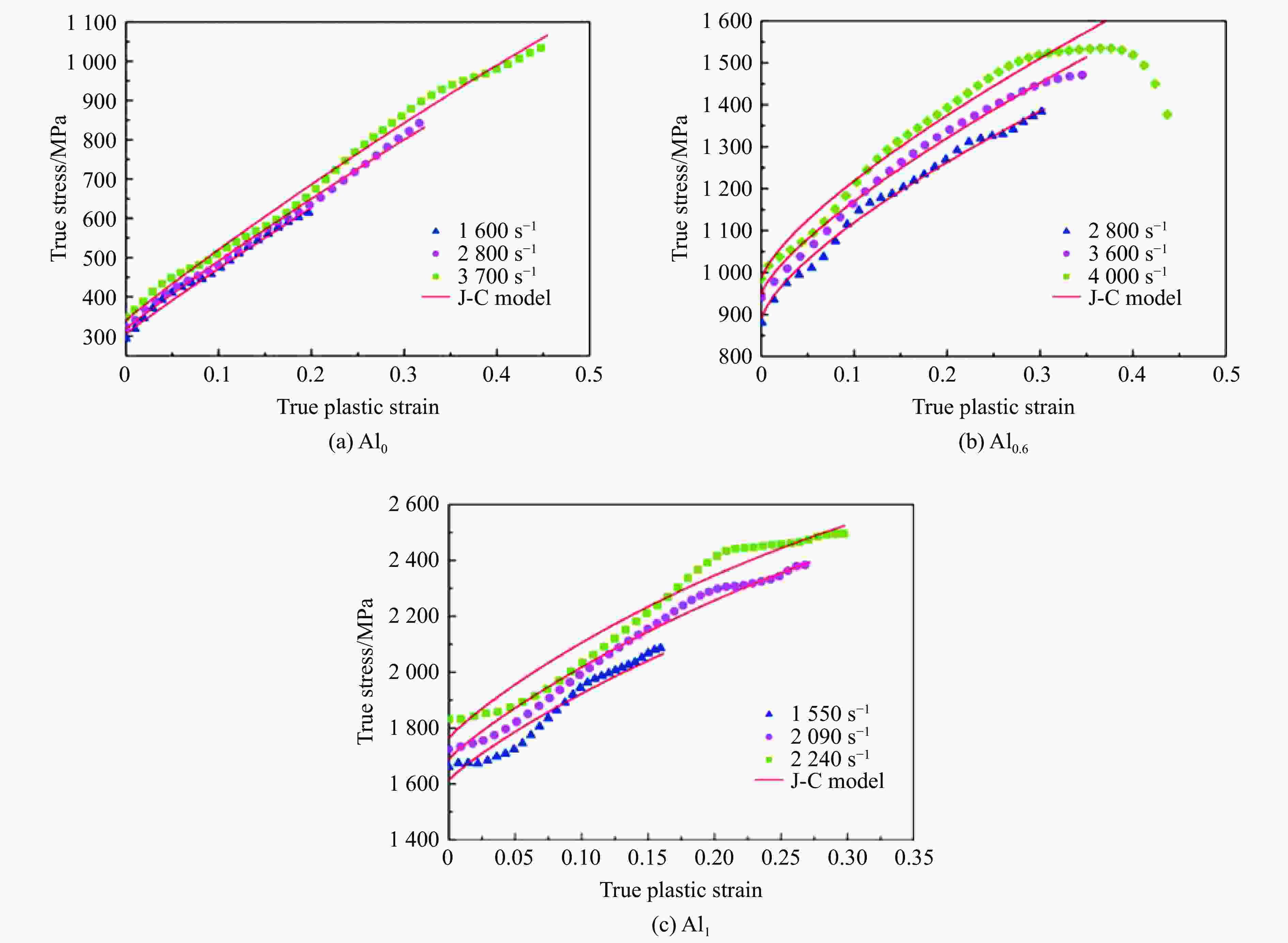

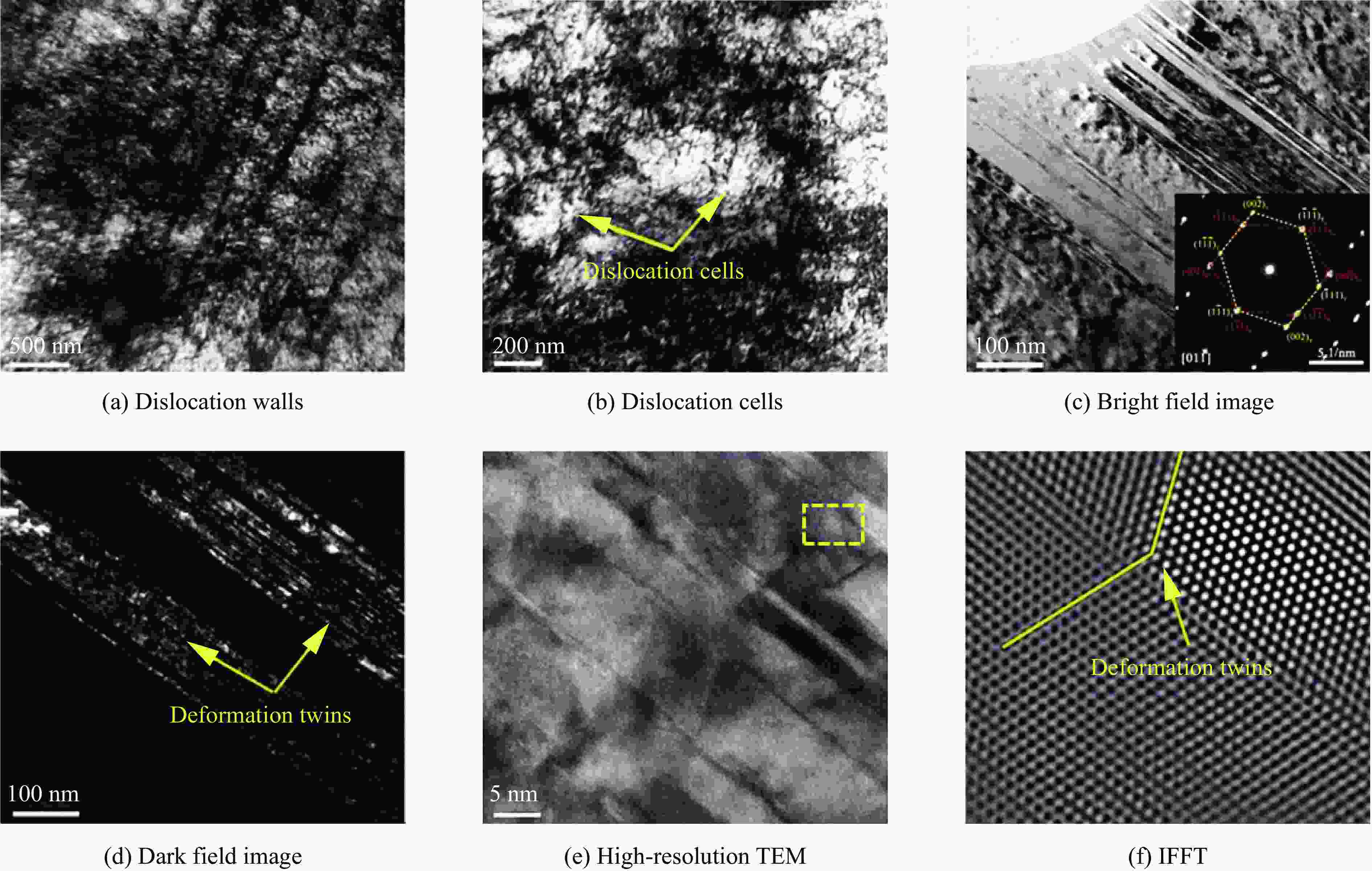

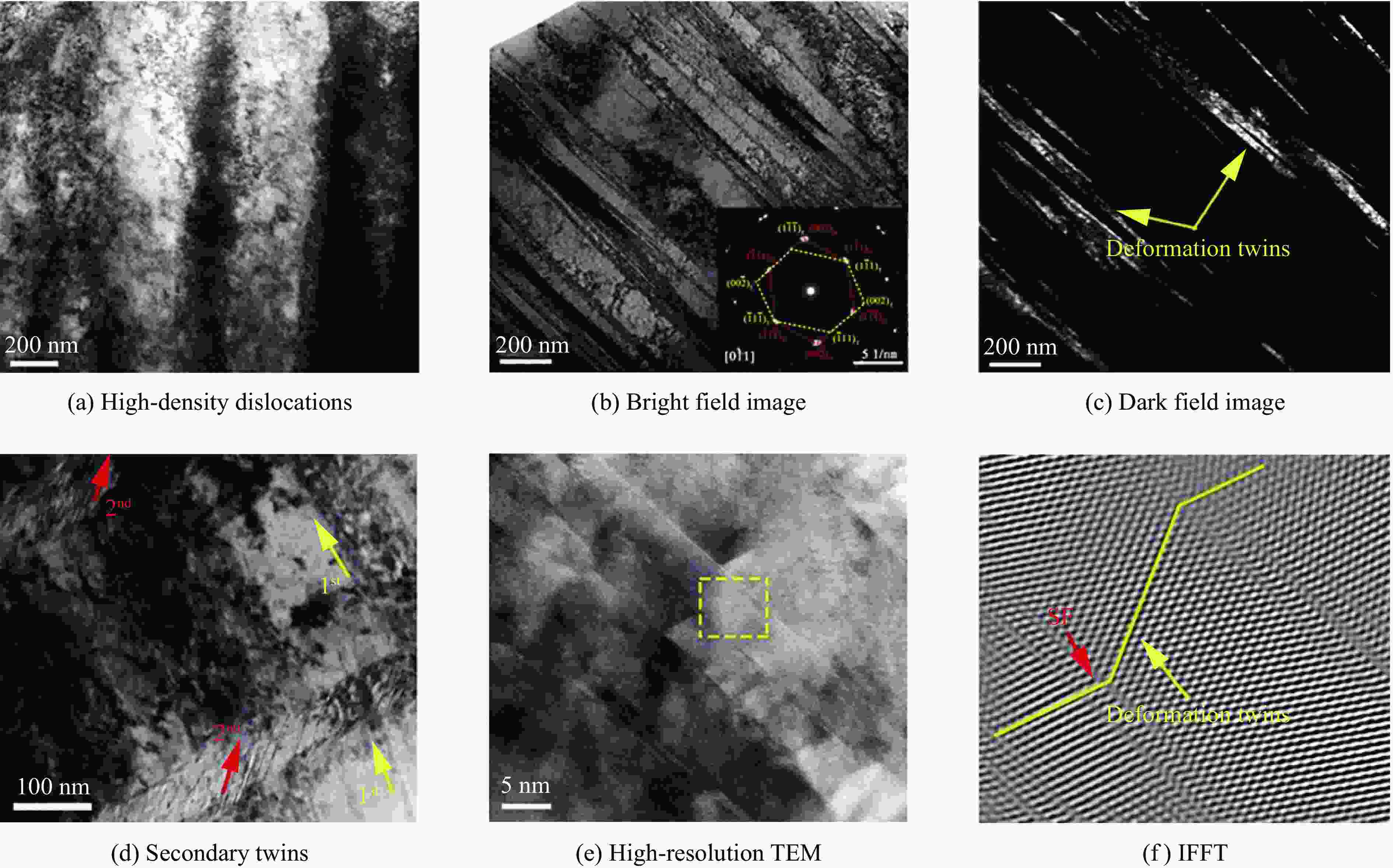

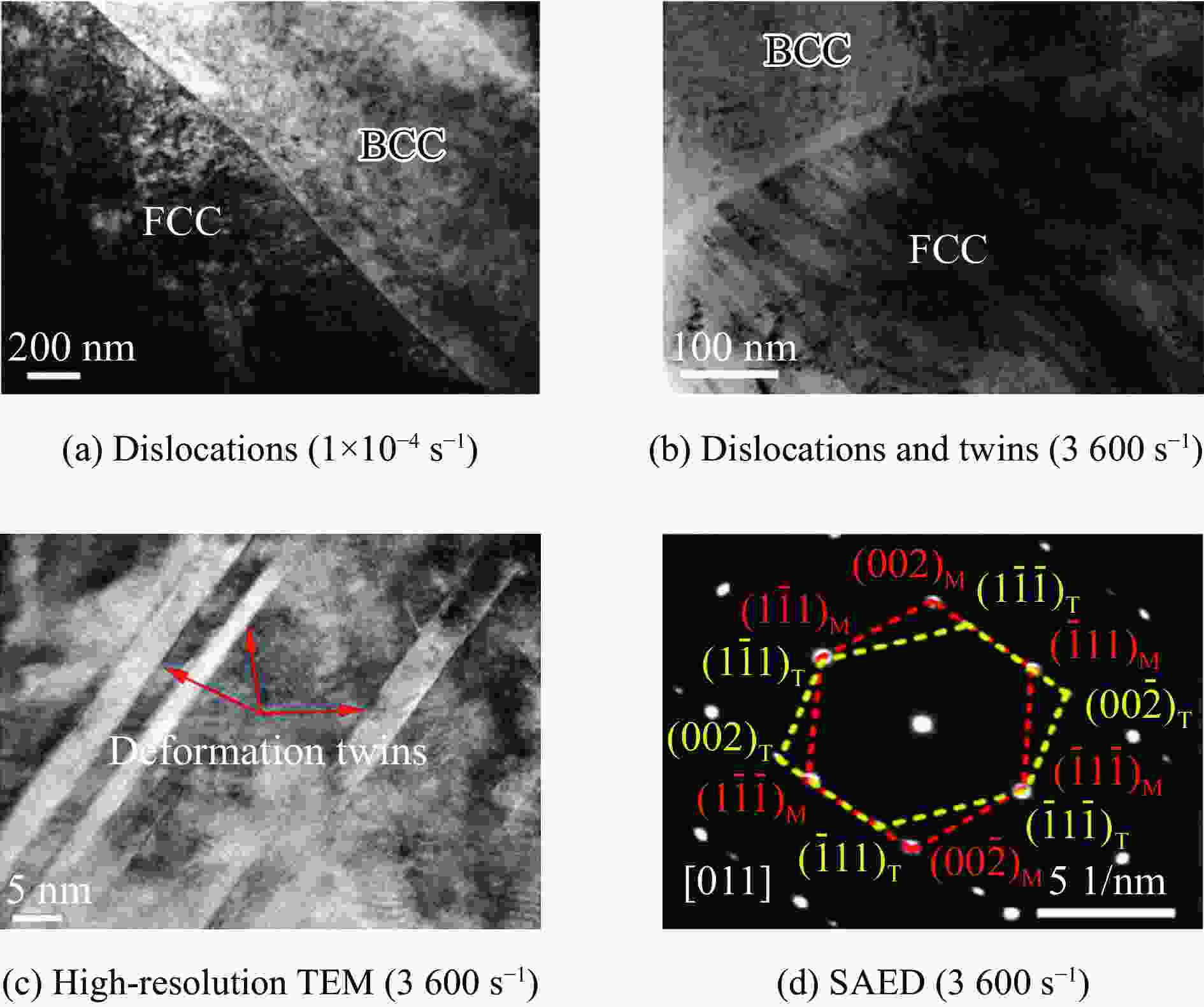

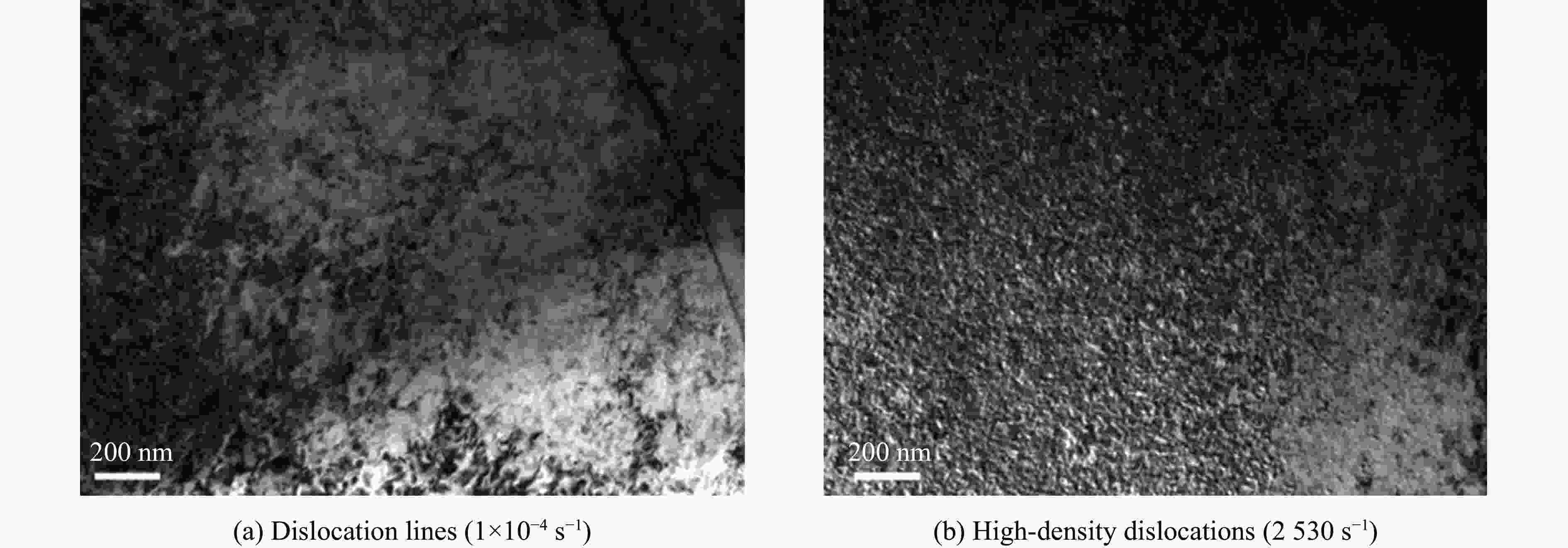

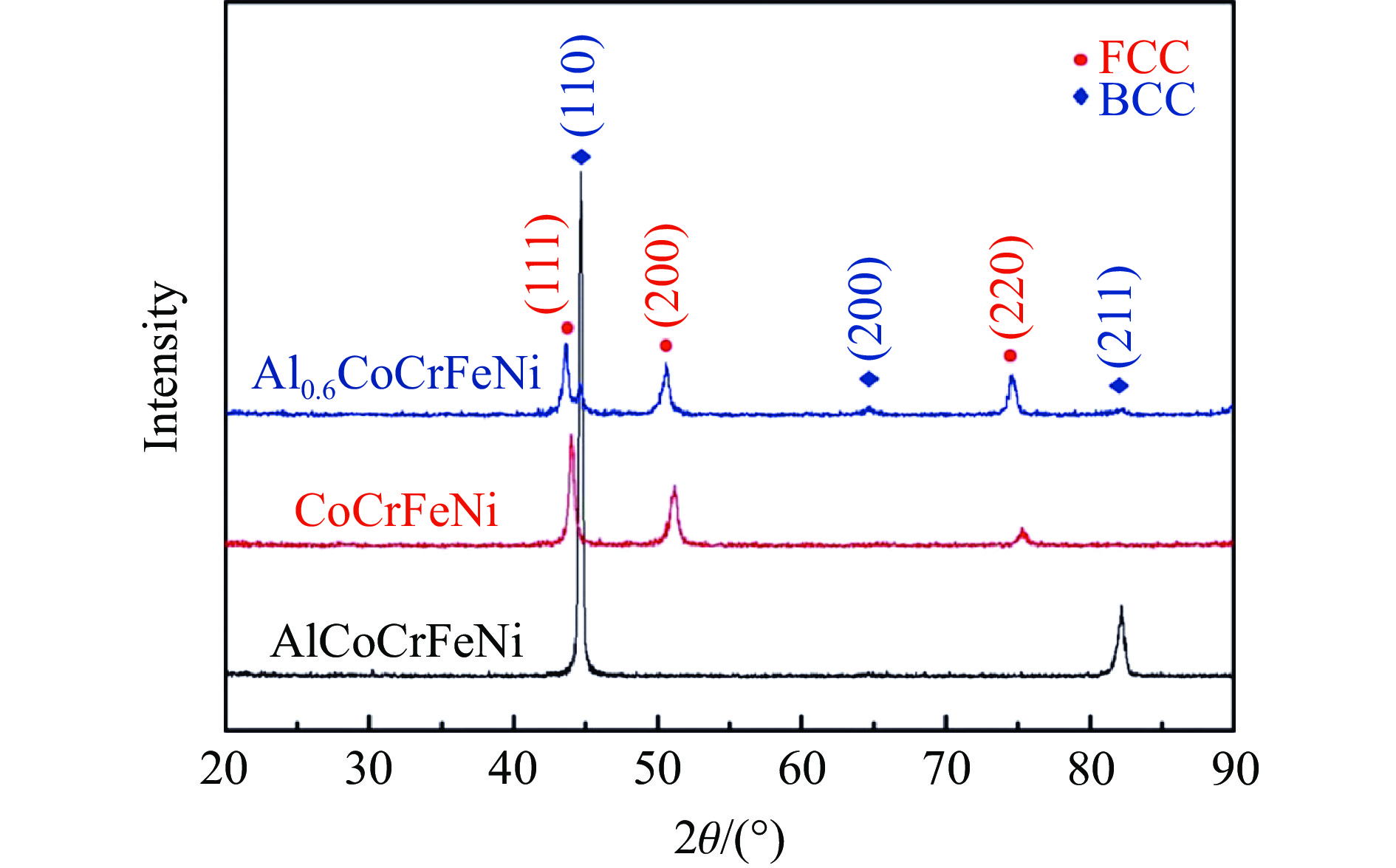

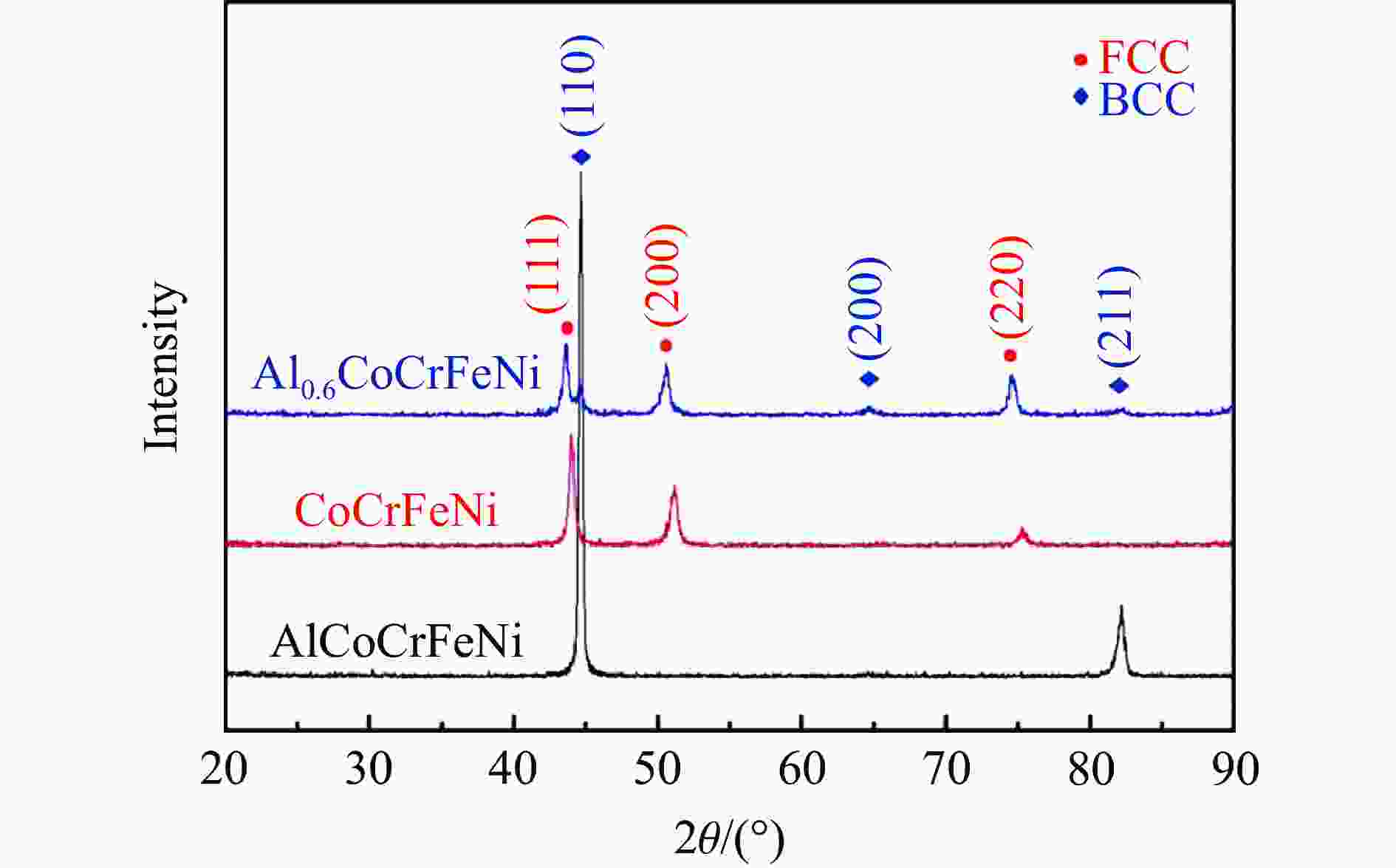

摘要: 高熵合金,以其独特的合金设计和优异的综合性能,成为当下材料研究的热点。本文利用高真空电弧熔炼法成功制备出了CoCrFeNiAlx(x=0, 0.6, 1)系高熵合金,并通过分离式霍普金森压杆对其进行一系列不同应变速率下的动态压缩试验。通过X射线、扫描电镜和透射电镜分析,深入探索了该合金系的晶体结构、微观组织和变形特征。最后,利用修正后的Johnson-Cook (J-C)本构模型,获得了该体系高熵合金的动态本构关系。Abstract: High-entropy alloys (HEAs), due to their unique alloy-design concepts and excellent comprehensive properties, are becoming a research hotspot nowadays. However, previous reports were scarcely focused on the dynamic mechanical loading of the HEAs, that is the applied strain rates often were limited in the quasi-static regime. In this research, CoCrFeNiAlx HEAs were successfully prepared by vacuum arc melting pure elements in a high-purity argon atmosphere on a water-cooled Cu hearth. Each ingot was remelted at least five times to ensure its chemical homogeneity. Cylindrical samples with a diameter of three millimeters were then synthesized by copper-mould suction casting. Quasi-static compressive tests at room temperature were conducted by using an Instron 5969 testing machine, wherein the test specimens with an aspect ratio of 1∶1 were cut from the cylindrical samples along the longitudinal direction by electrical discharge machining. As a comparison, dynamic compression experiments with various strain rates were carried out at room temperature by the split Hopkinson pressure bar (SHPB). For characterization, crystal structure, microstructure and deformation characteristics were investigated in detail by a combination of X-ray diffraction (XRD), scanning-electron microscopy (SEM), and transmission-electron microscopy (TEM) analyses. The XRD results reveal that simple solid solution structures, in forms of face-centered cube (FCC) and/or body-centered cube (BCC), were obtained in the current alloys. All the alloys exhibit positive strain-rate sensitivity and excellent work-hardening ability. Interestingly, three isolated deformation mechanisms were detected by TEM analysis, that is combined dislocation slip plus deformation twinning dominats the plastic deformation in the CoCrFeNi alloy (with FCC structure) for both quasi-static and dynamic loading conditions, however, such phenomenon was only observed in the CoCrFeNiAl0.6 alloy (with FCC plus BCC structure) under dynamic loading. As for the CoCrFeNiAl alloy (with BCC structure), single dislocation slip accounts for the plastic deformation in both quasi-static and dynamic loading conditions. Moreover, the dynamic constitutive relations of CoCrFeNiAlx HEAs were obtained by the modified John-Cook (J-C) constitutive model.

-

Key words:

- high-entropy alloy /

- dynamic loading /

- constitutive relation /

- deformation mechanism

-

图 8 CoCrFeNiAl0.6高熵合金在应变速率为1×10−4 s−1和3 600 s−1下的TEM图[19]

Figure 8. TEM images of the CoCrFeNiAl0.6 high-entropy alloy at the strain rates of 1×10−4 s−1 and 3 600 s−1

表 1 3种高熵合金在2种加载方式下的强化机制比较

Table 1. Comparison of strengthening mechanisms for the three HEAs under two loading conditions

合金 相组成 强化机制(低应变速率) 强化方式(高应变速率) Al0 FCC 位错+孪晶,具有TWIP效应 位错+孪晶,具有TWIP效应 Al0.6 FCC 位错 位错+孪晶,具有TWIP效应 BCC 位错 位错 Al1 BCC 位错 位错 -

[1] YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes [J]. Advanced Engineering Materials, 2004, 6(5): 299–303. DOI: 10.1002/adem.200300567. [2] CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys [J]. Materials Science and Engineering A, 2004, 375−377: 213–218. DOI: 10.1016/j.msea.2003.10.257. [3] ZHANG Y, ZUO T T, TANG Z, et al. Microstructures and properties of high-entropy alloys [J]. Progress in Materials Science, 2014, 61(8): 1–93. DOI: 10.1016/j.pmatsci.2013.10.001. [4] LI Z Z, ZHAO S T, RITCHIE R O, et al. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys [J]. Progress in Materials Science, 2019, 102: 296–345. DOI: 10.1016/j.pmatsci.2018.12.003. [5] 张勇, 陈明彪, 杨潇. 先进高熵合金技术 [M]. 北京: 化学工业出版社, 2019. [6] SHAHMIR H, HE J Y, LU Z P, KAWASAKI M, et al. Evidence for superplasticity in a CoCrFeNiMn high-entropy alloy processed by high-pressure torsion [J]. Materials Science and Engineering A, 2017, 685: 342–348. DOI: 10.1016/j.msea.2017.01.016. [7] SONI V, SENKOV O N, GWALANI B, et al. Microstructural design for improving ductility of an initially brittle refractory high entropy alloy [J]. Scientific Reports, 2018, 8: 8816. DOI: 10.1038/s41598-018-27144-3. [8] LIU J P, GUO X X, LIN Q Y, et al. Excellent ductility and serration feature of metastable CoCrFeNi high-entropy alloy at extremely low temperatures [J]. Science China Materials, 2019, 62: 853–863. DOI: 10.1007/s40843-018-9373-y. [9] ZHAO D, FANG H Q, JIN T, et al. Constitutive modeling and strain hardening of CoCrFeNiAl x high-entropy alloys [J]. Materials Research Express, 2019, 6: 1065h3. DOI: 10.1088/2053-1591/ab42e8. [10] CHEN C L, SUPRIANTO. Microstructure and mechanical properties of AlCuNiFeCr high entropy alloy coatings by mechanical alloying [J]. Surface and Coating Technology, 2020, 386: 125443. DOI: 10.1016/j.surfcoat.2020.125443. [11] VARVENNE C, CURTIN W A. Strengthening of high entropy alloys by dilute solute additions: CoCrFeNiAl x and CoCrFeNiMnAl x alloys [J]. Scripta Materialia, 2017, 138: 92–95. DOI: 10.1016/j.scriptamat.2017.05.035. [12] LI D Y, ZHANG Y. The ultrahigh charpy impact toughness of forged AlxCoCrFeNi high entropy alloys at room and cryogenic temperatures [J]. Intermetallics, 2016, 70: 24–28. DOI: 10.1016/j.intermet.2015.11.002. [13] LI Z, ZHAO S, DIAO H, et al. High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: remarkable resistance to shear failure [J]. Scientific Reports, 2017, 7: 42742. DOI: 10.1038/srep42742. [14] ZHANG T W, JIAO Z M, WANG Z H, et al. Dynamic deformation behaviors and constitutive relations of an AlCoCr1.5Fe1.5NiTi0.5 high-entropy alloy [J]. Scripta Materialia, 2017, 136: 15–19. DOI: 10.1016/j.scriptamat.2017.03.039. [15] 郭子涛, 高斌, 郭钊, 等. 基于J-C模型的Q235钢的动态本构关系 [J]. 爆炸与冲击, 2018, 38(4): 804–810. DOI: 10.11883/bzycj-2016-0333.GUO Z T, GAO B, GUO Z, et al. Dynamic constitutive relation based on J-C model of Q235 steel [J]. Explosion and Shock Waves, 2018, 38(4): 804–810. DOI: 10.11883/bzycj-2016-0333. [16] 郭鹏程, 李键, 曹淑芬, 等. 大应变率范围内AM80镁合金的变形行为及组织演变 [J]. 爆炸与冲击, 2018, 38(3): 586–595. DOI: 10.11883/bzycj-2016-0266.GUO P C, Li J, CAO S F, et al. Deformation behavior and microstructure evolution of an AM80 magnesium alloy at large strain rate range [J]. Explosion and Shock Waves, 2018, 38(3): 586–595. DOI: 10.11883/bzycj-2016-0266. [17] TAKEUCHI A, INOUE A. Classification of Bulk Metallic Glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element [J]. Materials Transactions, 2005, 46(12): 2817–2829. DOI: 10.2320/matertrans.46.2817. [18] 唐长国, 朱金华, 周惠久. 金属材料屈服强度的应变率效应和热激活理论 [J]. 金属学报, 1995, 31(6): 248–253.TANG C G, ZHU J H, ZHOU H J. Correlation between yield stress and strain rate for metallic materials and thermal activation approach [J]. Acta Metallurgica Sinica, 1995, 31(6): 248–253. [19] WANG L, QIAO J W, MA S G, et al. Mechanical response and deformation behavior of Al0.6CoCrFeNi high-entropy alloys upon dynamic loading [J]. Materials Science and Engineering A, 2018, 727: 208–213. DOI: 10.1016/j.msea.2018.05.001. [20] DODD B, BAI Y. Adiabatic shear localization: frontiers and advances [M]. Amsterdam: Elsevier, 2012. [21] ZENER C, HOLLOMN J H. Effect of Strain Rate upon Plastic Flow of Steel [J]. Journal of Applied Physics, 1944, 15(1): 22–32. DOI: 10.1063/1.1707363. [22] 王璐. CoCrFeNiAlx系高熵合金的动态力学特性 [D]. 太原, 太原理工大学, 2018. [23] ZHU L, KOU H, LU J. On the role of hierarchical twins for achieving maximum yield strength in nanotwinned metals [J]. Applied Physics Letters, 2012, 101(8): 081906–081910. DOI: 10.1063/1.4747333. [24] CAO T, SHANG J, ZHAO J, et al. The influence of Al elements on the structure and the creep behavior of AlxCoCrFeNi high entropy alloys [J]. Materials Letters, 2016, 164: 344–347. DOI: 10.1016/j.matlet.2015.11.016. [25] 王璐, 马胜国, 赵聃, 等. AlCoCrFeNi高熵合金在冲击载荷下的动态力学性能 [J]. 热加工工艺, 2018, 47(24): 86–89. DOI: 10.14158/j.cnki.1001-3814.2018.24.021.WANG L, MA S G, ZHAO D, et al. Dynamic mechanical properties of AlCoCrFeNi high-entropy alloys under impact load [J]. Hot Working Technology, 2018, 47(24): 86–89. DOI: 10.14158/j.cnki.1001-3814.2018.24.021. -

下载:

下载: