On ductile fracture of 30CrMnSiNi2A steel considering effects of stress triaxiality

-

摘要: 30CrMnSiNi2A钢是一种在军工领域应用广泛的低合金高强度钢。针对结构完整性的评估问题,采用试验和数值计算结合的方法研究了30CrMnSiNi2A钢的韧性断裂特性。对光滑圆棒试件在不同温度下进行准静态和动态拉伸试验,并通过有限元迭代方法标定了材料的Johnson-Cook动态本构模型参数,分析了温度和应变率对30CrMnSiNi2A钢断裂行为的影响。开展了缺口圆棒拉伸、缺口平板剪切和圆柱压缩试验,计算了各试件对应的平均应力三轴度和断裂应变,给出了应力三轴度在−1/3~1.5区间内的断裂应变变化曲线,分别确定了Johnson-Cook和Bao-Wierzbicki失效模型参数。研究表明,30CrMnSiNi2A钢的断裂应变与应力状态密切相关,且在不同的应力三轴度区间内曲线单调性差异较大,Bao-Wierzbicki失效模型较好地描述了这种钢在不同应力状态下的断裂特性。

-

关键词:

- 韧性断裂 /

- 动态力学性能 /

- 应力三轴度 /

- 30CrMnSiNi2A钢

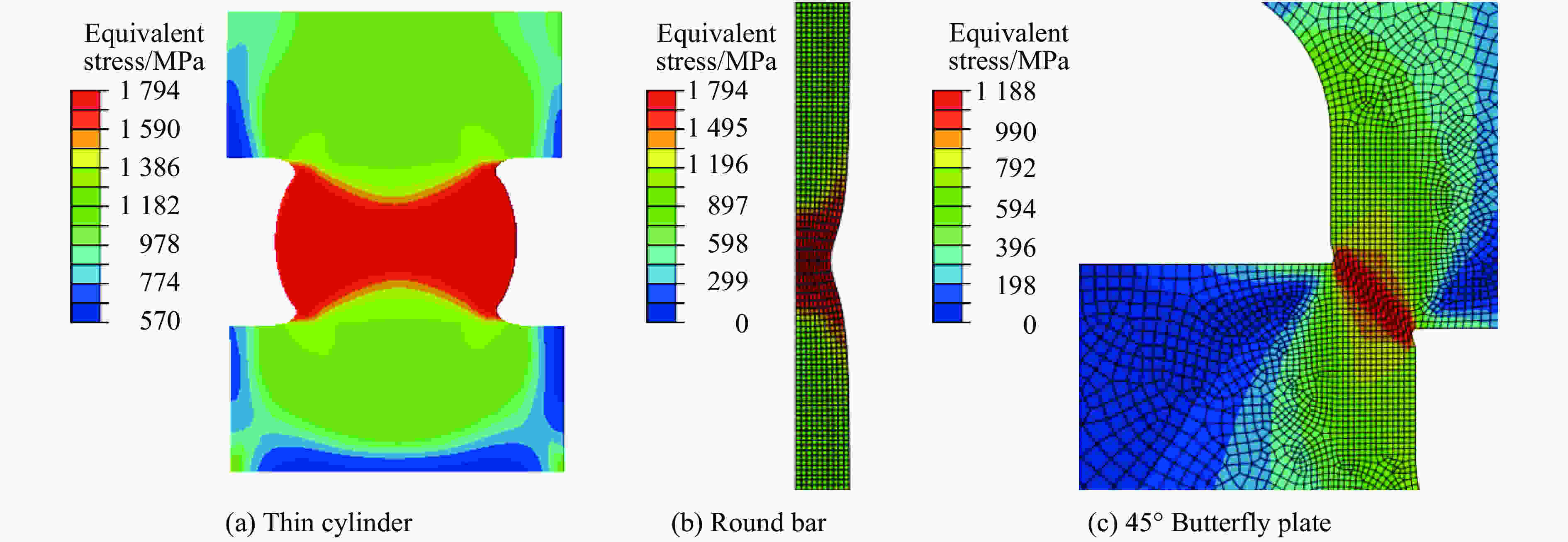

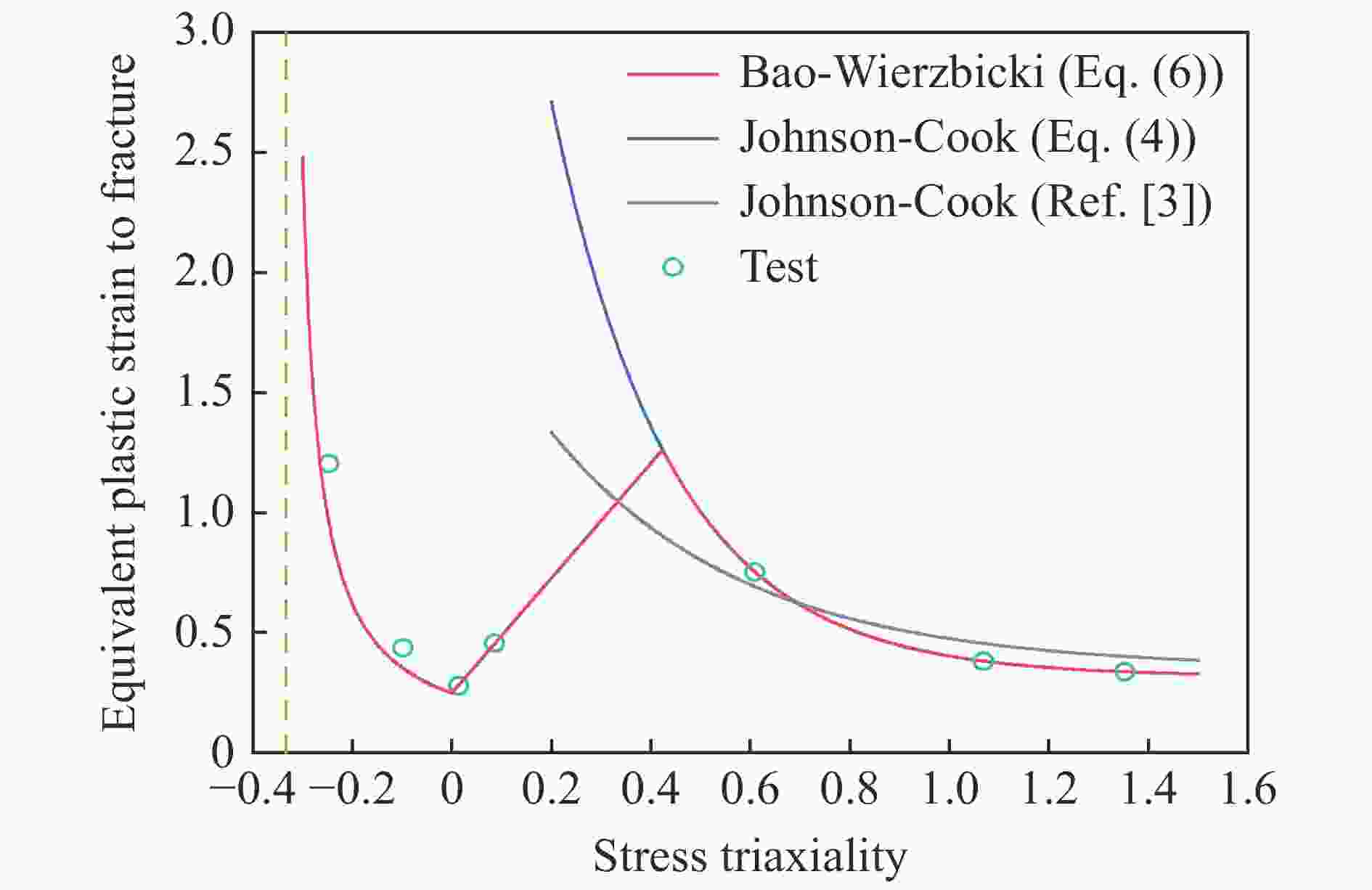

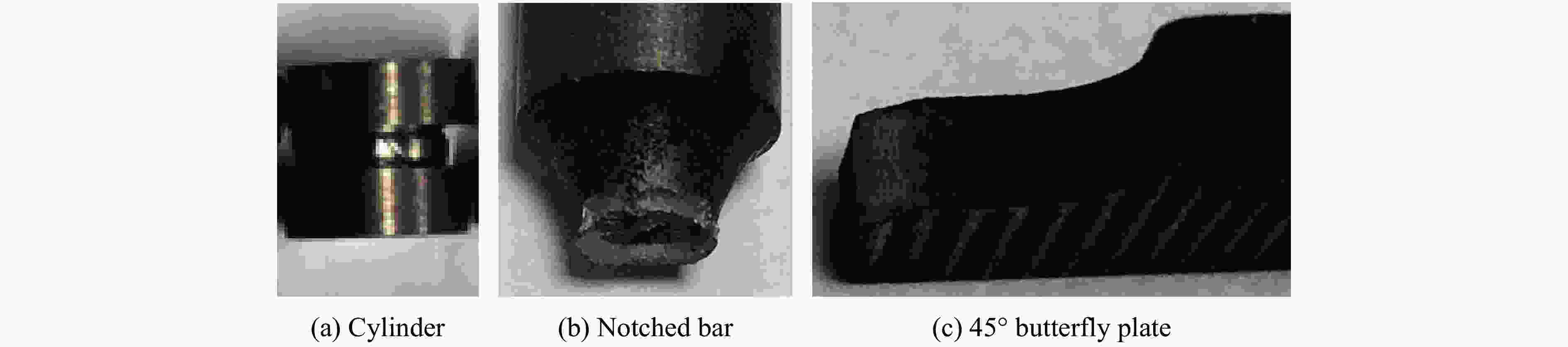

Abstract: 30CrMnSiNi2A steel is a high-strength low-alloy steel and it is widely used in the defense industry. Its ductile fracture properties were investigated by using a combined experimental-numerical approach to address the need for assessment of structural integrity. The parameters of the Johnson-Cook constitutive model were obtained through quasi-static and dynamic tensile tests on round bar specimens at different temperatures and relevant finite element method iterations. The effects of strain rate and temperature on fracture were studied. The tensile tests on notched round bar specimens were performed to calibrate the fracture strain in the range of high positive stress triaxiality. The tensile tests on butterfly plates and compression tests on short cylindrical specimens covered the fracture properties in the range of low and negative stress triaxiality. The finite element models were computed and the fracture loci in the space of the effective plastic strain to fracture and the stress triaxiality in a wide range from −1/3 to 1.5 were constructed. The parameters of the Johnson-Cook fracture model and Bao-Wierzbicki fracture model were calibrated. It is shown that stress triaxiality has a significant effect on the fracture of 30CrMnSiNi2A steel and the monotonicity of the fracture loci varies in different stress triaxiality range. The Bao-Wierzbicki model is capable of predicting the fracture patterns of the 30CrMnSiNi2A steel in different stress states.-

Key words:

- ductile fracture /

- dynamic mechanical behavior /

- stress triaxiality /

- 30CrMnSiNi2A steel

-

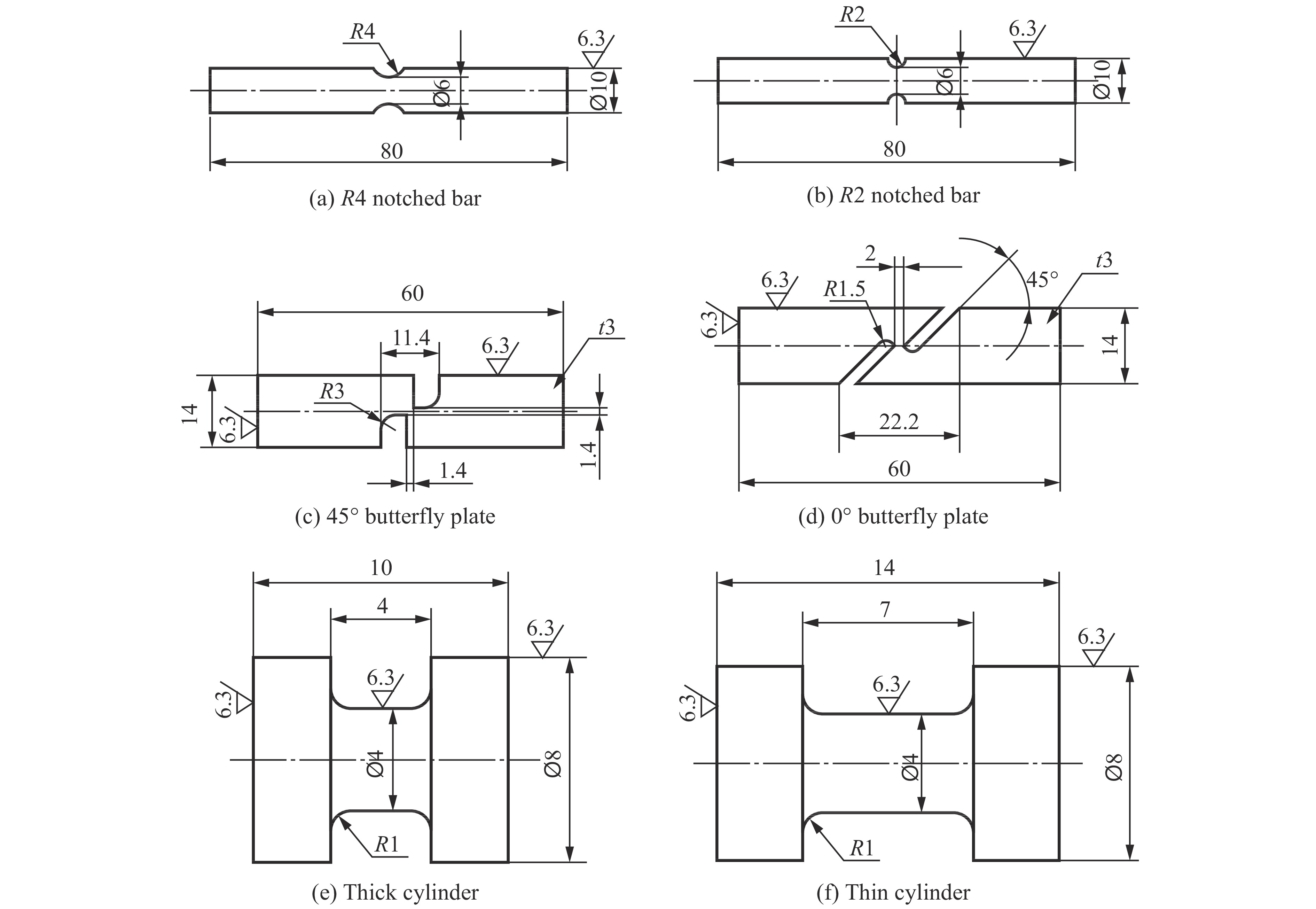

表 1 异形试件

Table 1. Abnormal specimens

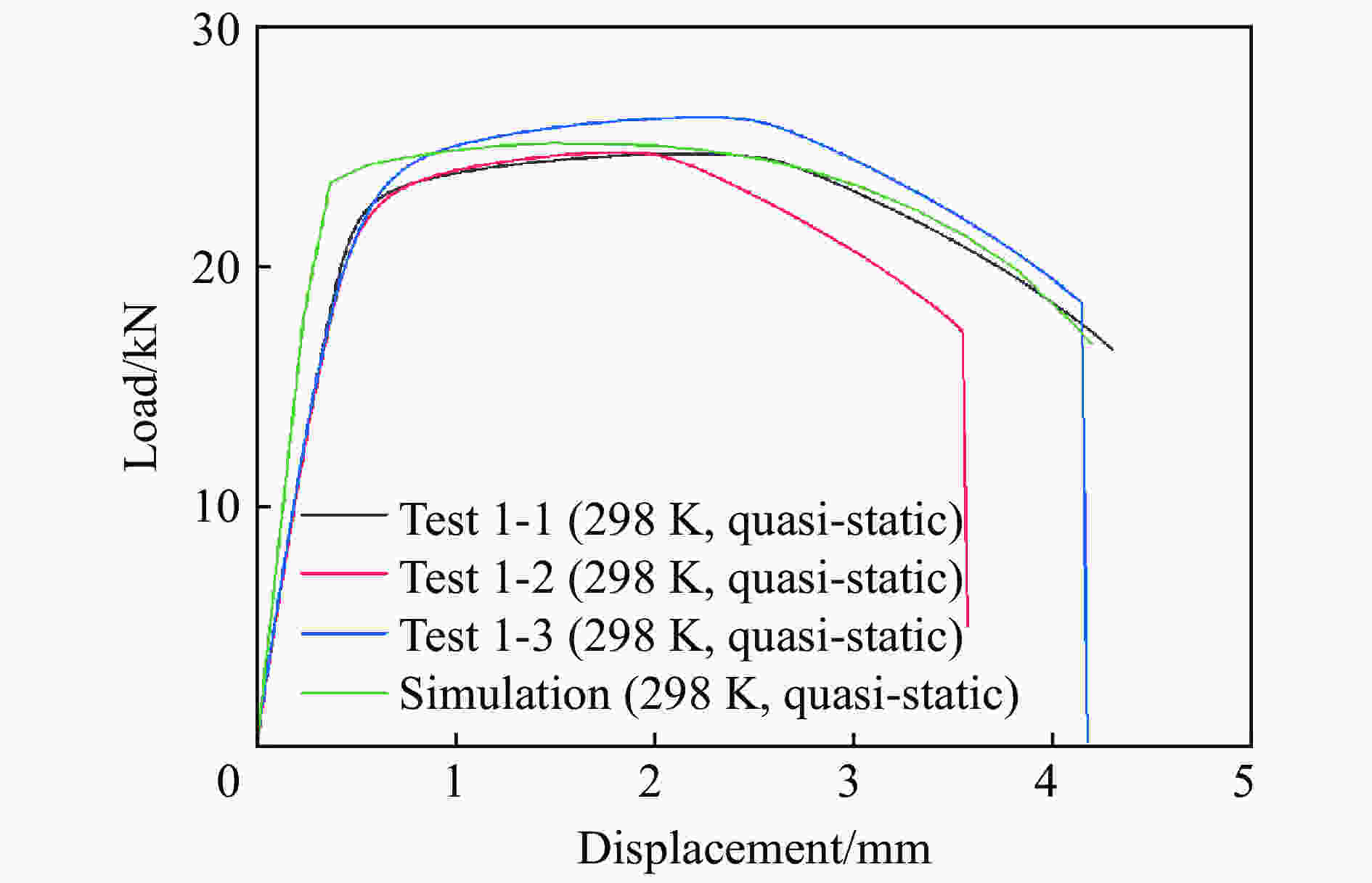

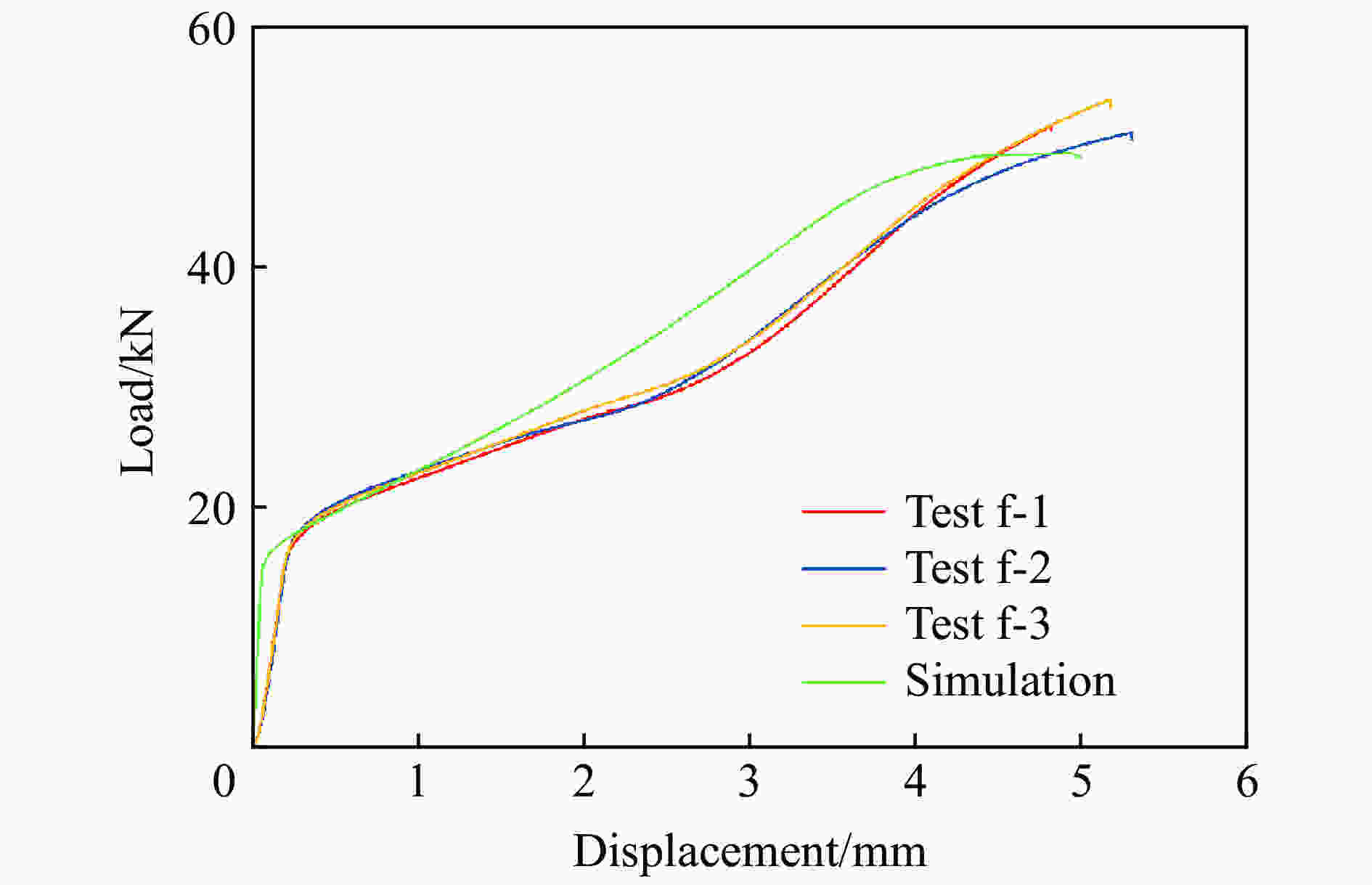

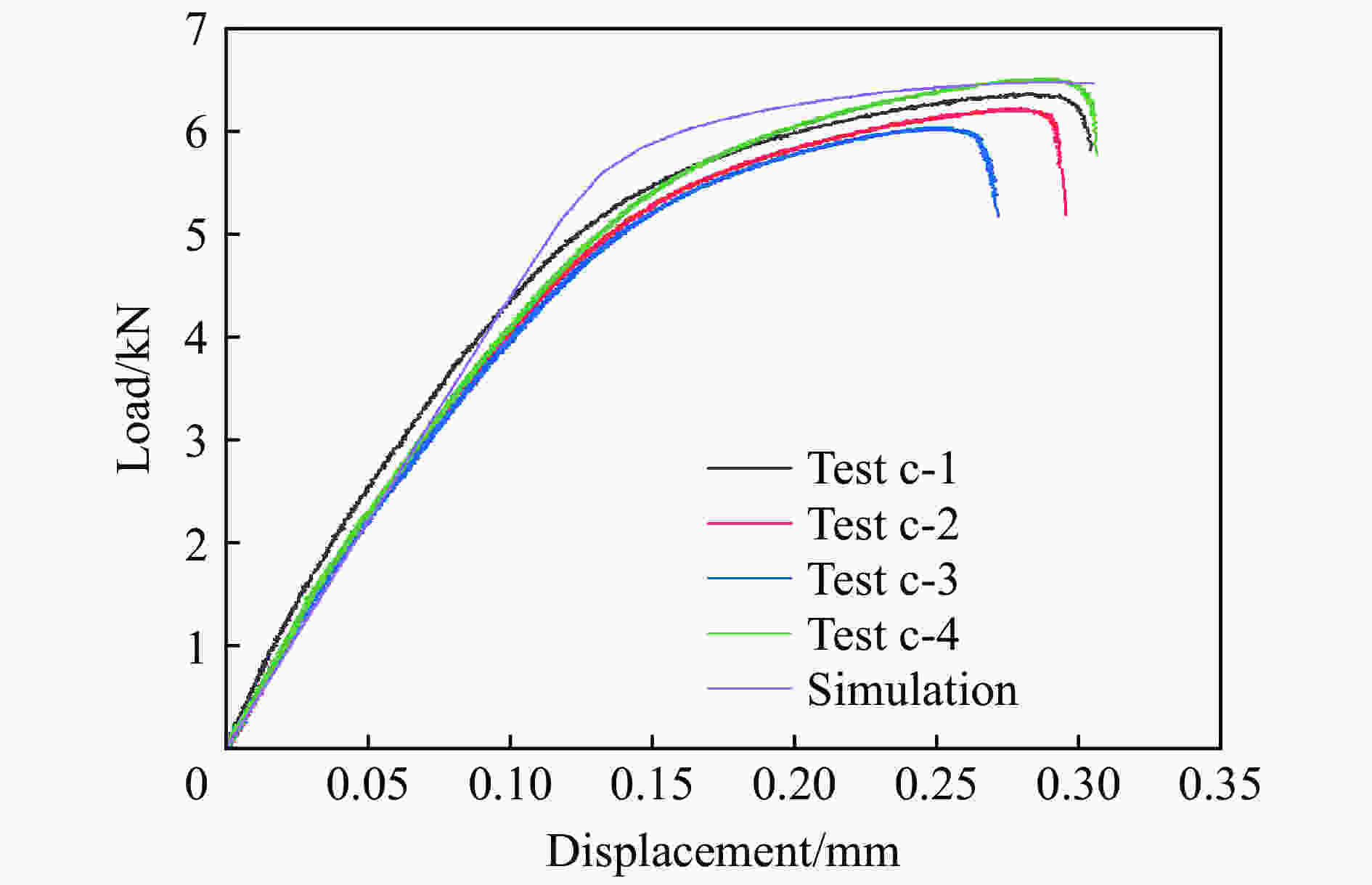

序号 试件 载荷 数量 应力三轴度范围 a R4缺口圆棒 拉伸 3 [1/3,+∞] b R2缺口圆棒 拉伸 3 [1/3,+∞] c 45°缺口平板 拉伸 4 [0,1/3] d 0°缺口平板 拉伸 4 [0,1/3] e 短粗圆柱 压缩 3 [−1/3,0] f 细长圆柱 压缩 3 [−1/3,0] 表 2 30CrMnSiNi2A钢的化学成分(质量分数,%)

Table 2. Composition of 30CrMnSiNi2A steel (mass fraction, %)

C Cr Mn Si Ni Cu P S 0.300 1.030 1.160 1.040 1.680 0.080 0.014 0.020 表 3 光滑圆棒试件的屈服应力和断裂应变

Table 3. Yield strength and fracture strain of round bars

序号 温度/K 应变率/s−1 屈服应力/MPa 断裂应变 1 298 0.001 1 163 0.753 2 298 1 000 1 591 0.775 3 298 2 000 1 716 0.881 4 298 4 000 1 883 0.962 5 473 0.001 1 115 0.827 6 773 0.001 698 1.513 表 4 平均应力三轴度和断裂应变对应表

Table 4. A summary of average stress triaxiality and equivalent plastic fracture strain

序号 应力三轴度理论值 平均应力三轴度 断裂应变 1 −1/3 −0.246 3 1.203 2 −1/3 −0.097 2 0.437 3 0 0.013 6 0.281 4 1/6 0.086 6 0.455 5 1/3 0.609 4 0.753 6 0.652 1.069 0 0.382 7 0.893 1.353 0 0.337 -

[1] 武海军, 姚伟, 黄风雷, 等. 超高强度钢30CrMnSiNi2A动态力学性能实验研究 [J]. 北京理工大学学报, 2010, 30(3): 258–262. DOI: 10.15918/j.tbit1001-0645.2010.03.002.WU H J, YAO W, HUANG F L, et al. Experimental study on dynamic mechanical properties of ultrahigh strength 30CrMnSiNi2A steel [J]. Transactions of Beijing Institute of Technology, 2010, 30(3): 258–262. DOI: 10.15918/j.tbit1001-0645.2010.03.002. [2] 周义清, 张治民. 30CrMnSiNi2A钢在不同应变率下的力学性能研究 [J]. 兵器材料科学与工程, 2010, 33(4): 46–50. DOI: 10.14024/j.cnki.1004-244x.2010.04.021.ZHOU Y Q, ZHANG Z M. Mechanical property of 30CrMnSiNi2A steel under various strain rates [J]. Ordnance Material Science and Engineering, 2010, 33(4): 46–50. DOI: 10.14024/j.cnki.1004-244x.2010.04.021. [3] 李磊, 张先锋, 吴雪, 等. 不同硬度30CrMnSiNi2A钢的动态本构与损伤参数 [J]. 高压物理学报, 2017, 31(3): 239–248. DOI: 10.11858/gywlxb.2017.03.005.LI L, ZHANG X F, WU X, et al. Dynamic constitutive and damage parameters of 30CrMnSiNi2A steel with different hardnesses [J]. Chinese Journal of High Pressure Physics, 2017, 31(3): 239–248. DOI: 10.11858/gywlxb.2017.03.005. [4] HANCOCK J W, MACKENZIE A C. On the mechanisms of ductile failure in high-strength steels subjected to multi-axial stress-states [J]. Journal of the Mechanics and Physics of Solids, 1976, 24(2−3): 147–169. DOI: 10.1016/0022-5096(76)90024-7. [5] MIRZA M S, BARTON D C, CHURCH P. The effect of stress triaxiality and strain-rate on the fracture characteristics of ductile metals [J]. Journal of Materials Science, 1996, 31(2): 453–461. DOI: 10.1007/BF01139164. [6] CLAUSEN A H, BORVIK T, HOPPERSTAD O S, et al. Flow and fracture characteristics of aluminium alloy AA5083-H116 as function of strain rate, temperature and triaxiality [J]. Materials Science and Engineering: A, 2004, 364(1−2): 260–272. DOI: 10.1016/j.msea.2003.08.027. [7] BAO Y B, WIERZBICKI T. On fracture locus in the equivalent strain and stress triaxiality space [J]. International Journal of Mechanical Sciences, 2004, 46(1): 81–98. DOI: 10.1016/j.ijmecsci.2004.02.006. [8] 李营, 吴卫国, 朱海清, 等. 基于大范围应力三轴度的船用低碳钢断裂特性研究 [J]. 中国造船, 2016, 57(3): 54–64. DOI: 10.3969/j.issn.1000-4882.2016.03.007.LI Y, WU W G, ZHU H Q, et al. Fracture properties of ship-build mild steel in wide range of stress triaxiality [J]. Shipbuilding of China, 2016, 57(3): 54–64. DOI: 10.3969/j.issn.1000-4882.2016.03.007. [9] 张朴, 赵明艳, 李营, 等. 复杂应力状态下船用低碳钢断裂应变的“断崖现象” [J]. 船舶力学, 2020, 24(2): 191–196. DOI: 10.3969/j.issn.1007-7294.2020.02.008.ZHANG P, ZHAO M Y, LI Y, et al. Failure strain sharp-down of marine mild steel under complex stress states [J]. Journal of Ship Mechanics, 2020, 24(2): 191–196. DOI: 10.3969/j.issn.1007-7294.2020.02.008. [10] 桂良进, 高付海, 范子杰. 先进高强度钢的断裂失效准则研究 [J]. 固体力学学报, 2012, 33(4): 395–403. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2012.04.007.GUI L J, GAO F H, FAN Z J. Study of failure criterion of advanced high strength steel [J]. Chinese Journal of Solid Mechanics, 2012, 33(4): 395–403. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2012.04.007. [11] MAE H, TENG X, BAI Y, et al. Calibration of ductile fracture properties of a cast aluminum alloy [J]. Materials Science and Engineering: A, 2007, 459(1/2): 156–166. DOI: 10.1016/j.msea.2007.01.047. [12] 朱浩, 朱亮, 陈剑虹. 应力三轴度和应变率对6063铝合金力学性能的影响及材料表征 [J]. 材料科学与工程学报, 2007, 25(3): 358–362. DOI: 10.3969/j.issn.1673-2812.2007.03.009.ZHU H, ZHU L, CHEN J H. Influence of stress triaxiality and strain rate on the mechanics behavior of 6063 aluminum alloy and material characterization [J]. Journal of Materials Science & Engineering, 2007, 25(3): 358–362. DOI: 10.3969/j.issn.1673-2812.2007.03.009. [13] BAO Y B, WIERZBICKI T. A comparative study on various ductile crack formation criteria [J]. Journal of Engineering Materials and Technology, 2004, 126(3): 314–324. DOI: 10.1115/1.1755244. -

下载:

下载: