| [1] |

WILLIS M J, JASON T D. Effect of aluminum particle size on the impact initiation of pressed rods [J]. Shock Compression of Condensed Matter, 2007, CP955: 971–974.

|

| [2] |

HAMBLING D. Behind the reactive materials revolution [N/OL]. [2008–05–07] [2020–09–22] https://www.wired.com/2008/05/reactive-revolu-3/.

|

| [3] |

张先锋, 赵晓宁. 多功能含能结构材料研究进展 [J]. 含能材料, 2009, 17(6): 731–739. DOI: 10.3969/j.issn.1006-9941.2009.06.021.ZHANG X F, ZHAO X N. Review on multifunctional energetic structural materials [J]. Chinese Journal of Energetic Materials, 2009, 17(6): 731–739. DOI: 10.3969/j.issn.1006-9941.2009.06.021.

|

| [4] |

XIONG W, ZHANG X F, ZHENG L, et al. The shock-induced chemical reaction behaviour of Al/Ni composites by cold rolling and powder compaction [J]. Journal of Materials Science, 2019, 54(1): 6651–6667. DOI: 10.1007/s10853-019-03357-3.

|

| [5] |

CHENG J L, HNG H H, LEE Y W, et al. Kinetic study of thermal- and impact-initiated reactions in Al-Fe2O3 nanothermite [J]. Combustion and Flame, 2010, 157(12): 2241–2249. DOI: 10.1016/j.combustflame.2010.07.012.

|

| [6] |

PERRY W L, TAPPAN B C, REARDON B L, et al. Energy release characteristics of the nanoscale aluminum-tungsten oxide hydrate metastable intermolecular composite [J]. Journal of Applied Physics, 2007, 101(6): 064313. DOI: 10.1063/1.2435797.

|

| [7] |

WANG L, LIU J X, LI S K, et al. Insensitive high-energy energetic structural material of tungsten-polytetrafluoroethylene-aluminum composites [J]. AIP Advances, 2015, 5(11): 117142. DOI: 10.1063/1.4936557.

|

| [8] |

FENG B, FANG X, LI Y C, et al. Influence of processing techniques on mechanical properties and impact initiation of an Al-PTFE reactive material [J]. Central European Journal of Energetic Materials, 2016, 13(4): 989–1004. DOI: 10.22211/cejem/61496.

|

| [9] |

HERBOLD E B, JORDAN J L, THADHANI N N. Effects of processing and powder size on microstructure and reactivity in arrested reactive milled Al+Ni [J]. Acta Materialia, 2011, 59(17): 6717–6728. DOI: 10.1016/j.actamat.2011.07.029.

|

| [10] |

XIONG W, ZHANG X F, WU Y, et al. Influence of additives on microstructures, mechanical properties and shock-induced reaction characteristics of Al/Ni composites [J]. Journal of Alloys and Compounds, 2015, 648: 540–549. DOI: 10.1016/j.jallcom.2015.07.004.

|

| [11] |

WEI H Y, YOO C S. Dynamic responses of reactive metallic structures under thermal and mechanical ignitions [J]. Journal of Materials Research, 2012, 27(21): 2705–2717. DOI: 10.1557/jmr.2012.302.

|

| [12] |

刘晓俊, 任会兰, 宁建国. Zr-W多功能含能结构材料的制备及动态压缩特性 [J]. 复合材料学报, 2016, 33(10): 2297–2303. DOI: 10.13801/j.cnki.fhclxb.20160315.001.LIU X J, REN H L, NING J G. Preparation and dynamic compression properties of Zr-W multifunctional energetic structural material [J]. Journal of Composite Materials, 2016, 33(10): 2297–2303. DOI: 10.13801/j.cnki.fhclxb.20160315.001.

|

| [13] |

REN K R, CHEN R. LIN Y L, et al Probing the impact energy release behavior of Al/Ni-based reactive metals with experimental and numerical methods [J]. Metals, 2019, 9(5): 499. DOI: 10.3390/met9050499.

|

| [14] |

Committee on Advanced Energetic Materials and Manufacturing Technologies, National Research Council. Advanced energetic materials [M]. Washington D C: The National Academies Press, 2004. DOI: 10.17226/10918.

|

| [15] |

丁亮亮. PELE弹活性内芯配方与弹体结构设计及毁伤机理研究 [D]. 长沙: 国防科技大学, 2019.

|

| [16] |

WADDELL J T, BOOTES T H, BUDY G D, et al. Reactive shaped charge, reactive liner, and method for target penetration using a reactive shaped charge: US8037829B1 [P]. 2011-08-18.

|

| [17] |

BATSANOV S S, DORONIN G S, KLOCHKOV S V, et al. Synthesis reactions behind shock fronts [J]. Combustion, Explosion, and Shock Waves, 1986, 22(6): 765–768. DOI: 10.1007/BF00751890.

|

| [18] |

BAUER F. Ferroelectric properties and shock response of a poled PVF2 polymer and of VF2/C2F3H copolymers [C] // Shock Waves in Condensed Matter. Boston, MA: Springer, 1986: 483–496. DOI: 10.1007/978-1-4613-2207-8_69.

|

| [19] |

GRAHAM R A, ANDERSON M U, BAUER F, et al. Piezoelectric polarization of the ferroelectric polymer PVDF from 10 MPato 10 GPa: studies of loading-path dependence [C]// SCHMIDT S C, DICK R D, FORBES J W, et al. Shock Compression of Condensed Matter. Amsterdam: Elsevier, 1992: 883–886. DOI: 10.1016/B978-0-444-89732-9.50203-X.

|

| [20] |

NELLIS W J, MITCHELL A C, MCCANDLESS P C, et al. Electronic energy gap of molecular hydrogen from electrical conductivity measurements at high shock pressures [J]. Physical Review Letters, 1992, 68(19): 2937–2940. DOI: 10.1103/PhysRevLett.68.2937.

|

| [21] |

BOSLOUGH M B. Shock-induced chemical reactions in nickel-aluminum powder mixtures: radiation pyrometer measurements [J]. Chemical Physics Letters, 1989, 160(5–6): 618–622. DOI: 10.1016/0009-2614(89)80074-0.

|

| [22] |

BARKER L M, HOLLENBACH R E. Laser interferometer for measuring high velocities of any reflecting surface [J]. Journal of Applied Physics, 1972, 43(11): 4669–4675. DOI: 10.1063/1.1660986.

|

| [23] |

BARKER L M, HOLLENBACH R E. Interferometer technique for measuring the dynamic mechanical properties of materials [J]. Review of Scientific Instruments, 1965, 36(11): 1617–1620. DOI: 10.1063/1.1719405.

|

| [24] |

MOORE D S, SCHMIDT S C. Experimental molecular spectroscopy in shock-compressed materials [C] // Proceedings the 5th APS Topical Conference on ‘Shock Waves in Condensed Matter’. Monterey, CA, USA: APS, 1987.

|

| [25] |

GUPTA Y M. Time-resolved optical spectroscopy under shock loading: electronic and chemical changes in liquid carbon disulfide [J]. High Pressure Research, 1992, 10(5–6): 717–732. DOI: 10.1080/08957959208225324.

|

| [26] |

DLOTT D D. Ultrafast spectroscopy of shock waves in molecular materials [J]. Annual Review of Physical Chemistry, 1999, 50(1): 251–278. DOI: 10.1146/annurev.physchem.50.1.251.

|

| [27] |

TROTT W M, KNUDSON M D, CHHABILDAS L C, et al. Measurements of spatially resolved velocity variations in shock compressed heterogeneous materials using a line-imaging velocity interferometer [J]. AIP Conference Proceedings, 2000, 505(1): 993–998. DOI: 10.1063/1.1303635.

|

| [28] |

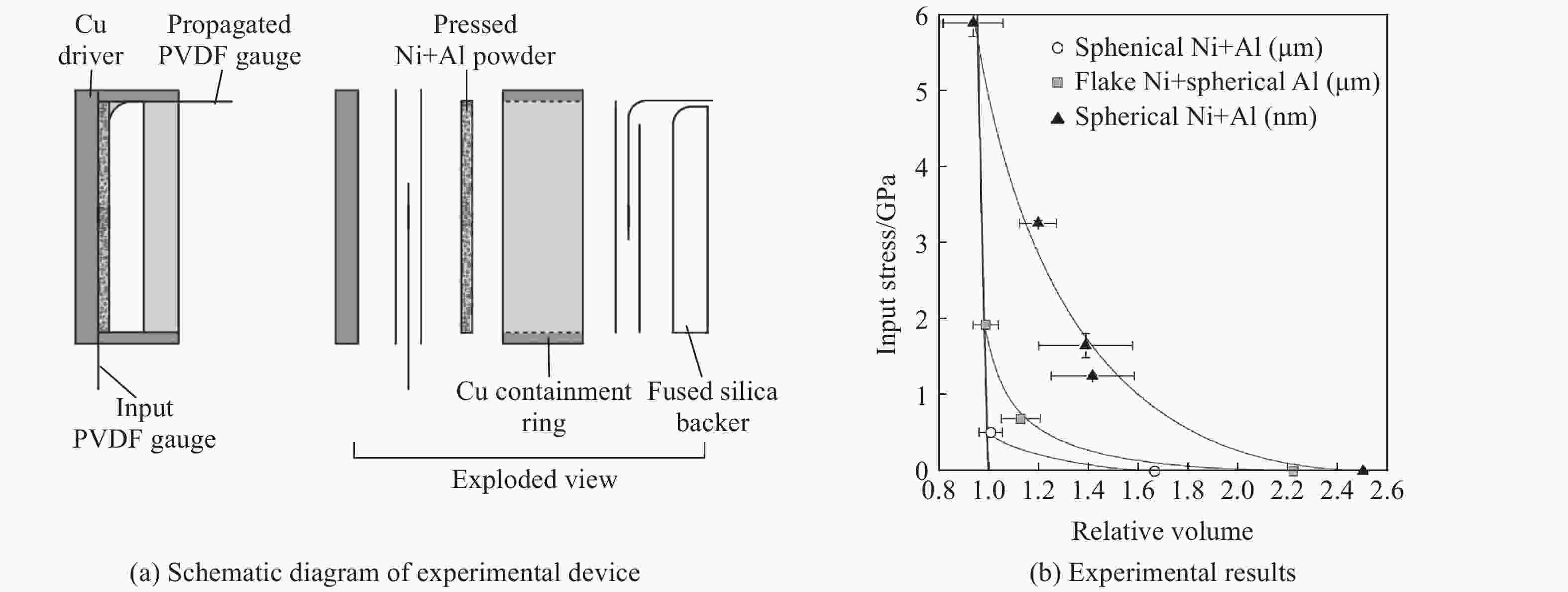

EAKINS D E, THADHANI N N. The shock-densification behavior of three distinct Ni+Al powder mixtures [J]. Applied Physics Letters, 2008, 92(11): 111903. DOI: 10.1063/1.2896653.

|

| [29] |

BENNETT L S, SORRELL F Y, SIMONSEN I K, et al. Ultrafast chemical reactions between nickel and aluminum powders during shock loading [J]. Applied Physics Letters, 1992, 61(5): 520–521. DOI: 10.1063/1.107874.

|

| [30] |

IYER K R, BENNETT L S, SORRELL F Y, et al. Solid state chemical reactions at the shock front [J]. AIP Conference Proceedings, 1994, 309(1): 1337–1340. DOI: 10.1063/1.46457.

|

| [31] |

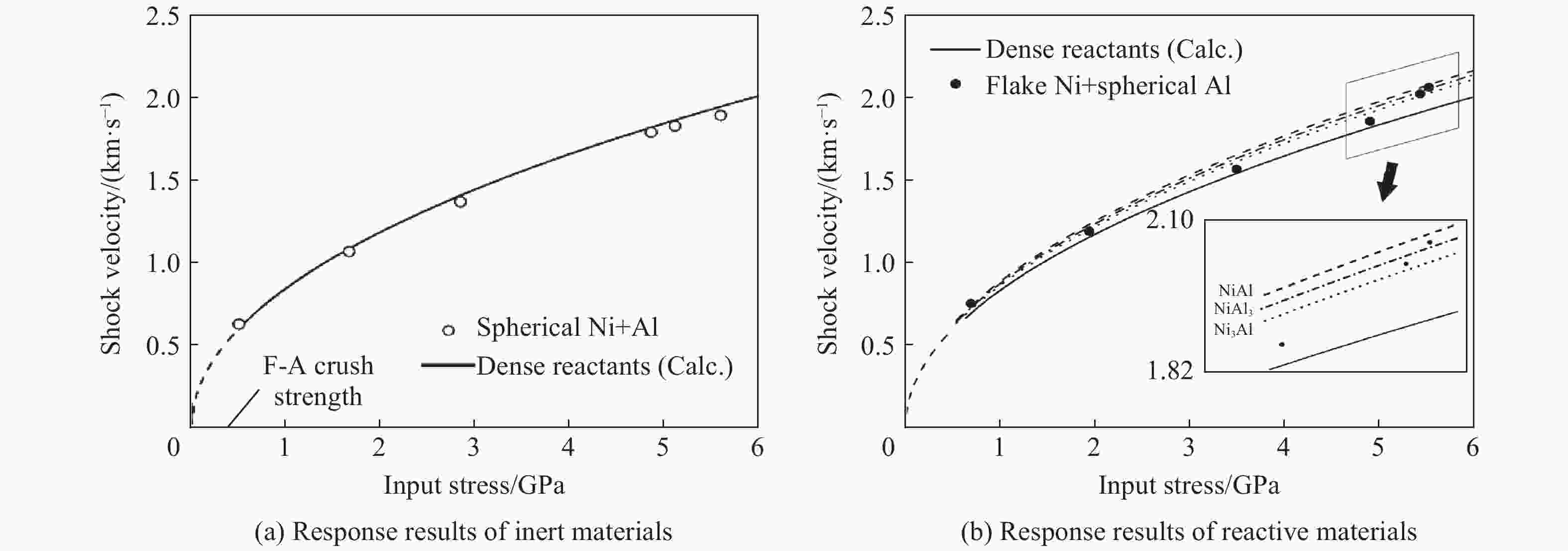

EAKINS D, THADHANI N N. Shock-induced reaction in a flake nickel+spherical aluminum powder mixture [J]. Journal of Applied Physics, 2006, 100(11): 113521. DOI: 10.1063/1.2396797.

|

| [32] |

GRAHAM R A, ANDERSON M U, HORIE Y, et al. Pressure measurements in chemically reacting powder mixtures with the Bauer piezoelectric polymer gauge [J]. Shock Waves, 1993, 3(2): 79–82. DOI: 10.1007/BF02115887.

|

| [33] |

XU X, THADHANI N N. Investigation of shock-induced reaction behavior of as-blended and ball-milled Ni+Ti powder mixtures using time-resolved stress measurements [J]. Journal of Applied Physics, 2004, 96(4): 2000–2009. DOI: 10.1063/1.1773380.

|

| [34] |

MCQUEEN R G, MARSH S P, TAYLOR J W, et al. The equation of state of solids from shock wave studies [M]// KINSLOW R. High Velocity Impact Phenomena. New York: Academic Press, 1970.

|

| [35] |

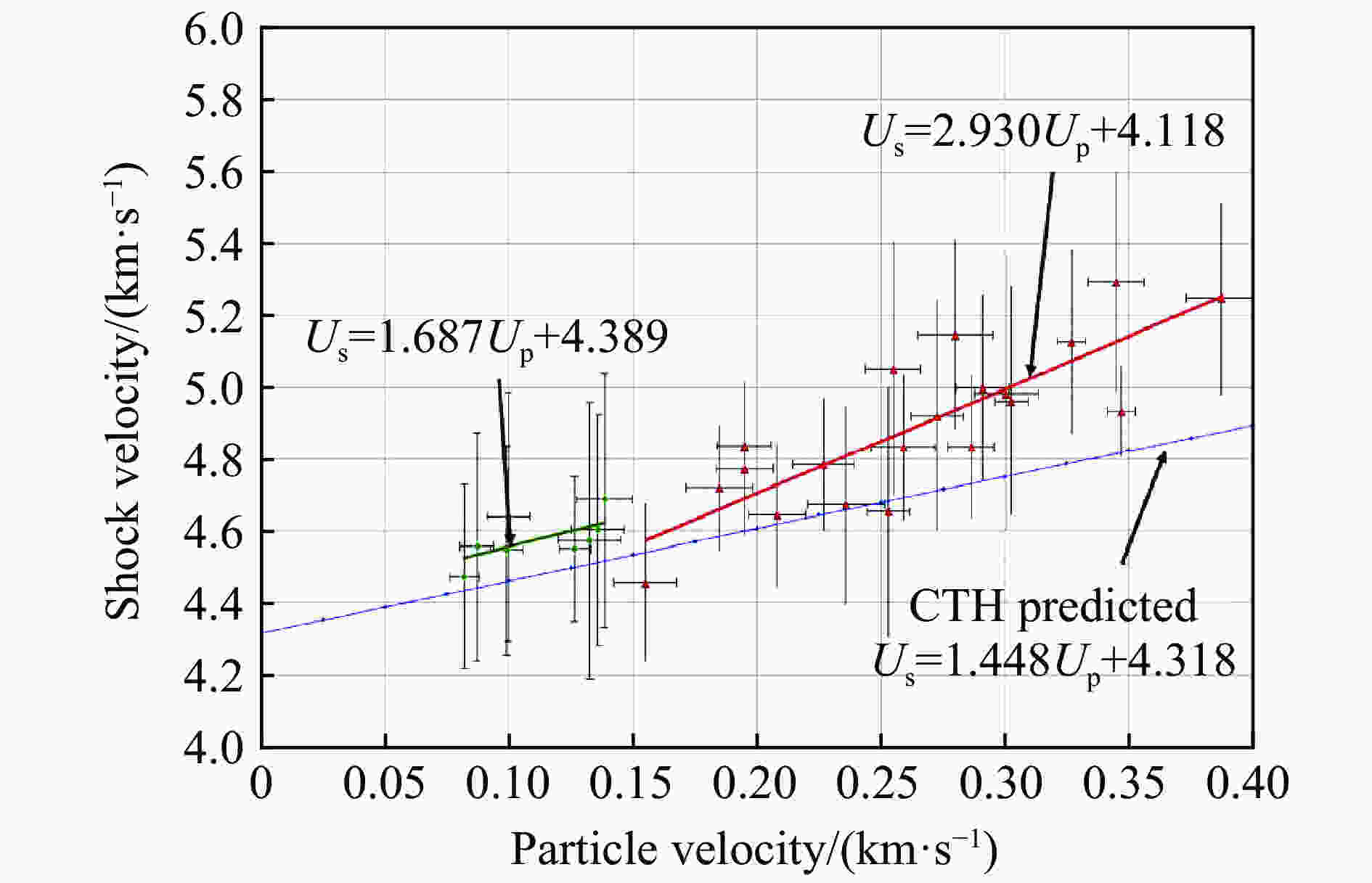

KELLY S C, THADHANI N N. Shock compression response of highly reactive Ni+Al multilayered thin foils [J]. Journal of Applied Physics, 2016, 119(9): 095903. DOI: 10.1063/1.4942931.

|

| [36] |

AMES R G. Vented chamber calorimetry for impact-initiated energetic materials [C] // Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit. Reno, USA: AIAA, 2005: 1013. DOI: 10.2514/6.2005-279.

|

| [37] |

AMES R G. Energy release characteristics of impact-initiated energetic materials [C] // MRS Online Proceeding Library. UK: Cambridge University Press, 2005: 0896-H03-08. DOI: 10.1557/PROC-0896-H03-08.

|

| [38] |

王海福, 刘宗伟, 俞为民, 等. 活性破片能量输出特性实验研究 [J]. 北京理工大学学报, 2009, 29(8): 663–666. DOI: 1001-0645(2009)08-0663-04.WANG H F, LIU Z W, YU W M, et al. Experimental investigation of energy release characteristics of reactive fragments [J]. Transactions of Beijing Institute of Technology, 2009, 29(8): 663–666. DOI: 1001-0645(2009)08-0663-04.

|

| [39] |

ZHANG X F, SHI A S, QIAO L, et al. Experimental study on impact-initiated characters of multifunctional energetic structural materials [J]. Journal of Applied Physics, 2013, 113(8): 083508. DOI: 10.1063/1.4793281.

|

| [40] |

LUO P G, WANG Z C, JIANG C L, et al. Experimental study on impact-initiated characters of W/Zr energetic fragments [J]. Materials and Design, 2015, 84: 72–78. DOI: 10.1016/j.matdes.2015.06.107.

|

| [41] |

XIONG W, ZHANG X F, TAN M T, et al. The energy release characteristics of shock-induced chemical reaction of Al/Ni composites [J]. The Journal of Physical Chemistry C, 2016, 120(43): 24551–24559. DOI: 10.1021/acs.jpcc.6b06530.

|

| [42] |

ZHANG S, LIU J X, YANG M, et al. Effects of multi-component co-addition on reaction characteristics and impact damage properties of reactive material [J]. Materials and Design, 2018, 153: 1–8. DOI: 10.1016/j.matdes.2018.04.077.

|

| [43] |

MASON B A, GROVEN L J, SON S F. The role of microstructure refinement on the impact ignition and combustion behavior of mechanically activated Ni/Al reactive composites [J]. Journal of Applied Physics, 2013, 114(11): 113501. DOI: 10.1063/1.4821236.

|

| [44] |

FENG S S, WANG C L, HUANG G Y. Experimental study on the reaction zone distribution of impact-induced reactive materials [J]. Propellants, Explosives, Pyrotechnics, 2017, 42(8): 896–905. DOI: 10.1002/prep.201600274.

|

| [45] |

EAKINS D E, THADHANI N N. Investigation of shock-induced reactions in a Ni+Al powder mixture [J]. AIP Conference Proceedings, 2006, 845(1): 1153–1156. DOI: 10.1063/1.2263528.

|

| [46] |

THADHAN N N. Shock-induced and shock-assisted solid-state chemical reactions in powder mixtures [J]. Journal of Applied Physics, 1994, 76(4): 2129–2138. DOI: 10.1063/1.357624.

|

| [47] |

NESTERENKO V F, MEYERS M A, CHEN H C, et al. Controlled high-rate localized shear in porous reactive media [J]. Applied Physics Letters, 1994, 65(24): 3069–3071. DOI: 10.1063/1.112509.

|

| [48] |

VANDERSALL K S, THADHANI N N. Investigation of“shock-induced”and“shock-assisted”chemical reactions in Mo+2Si powder mixtures [J]. Metallurgical and Materials Transactions A, 2003, 34(1): 15–23. DOI: 10.1007/s11661-003-0204-z.

|

| [49] |

YU L H, MEYERS M A. Shock synthesis and synthesis-assisted shock consolidation of suicides [J]. Journal of Materials Science, 1991, 26(3): 601–611. DOI: 10.1007/BF00588294.

|

| [50] |

DUNBAR E, THADHANI N N, GRAHAM R A. High-pressure shock activation and mixing of nickel-aluminium powder mixtures [J]. Journal of Materials Science, 1993, 28(11): 2903–2914. DOI: 10.1007/BF00354693.

|

| [51] |

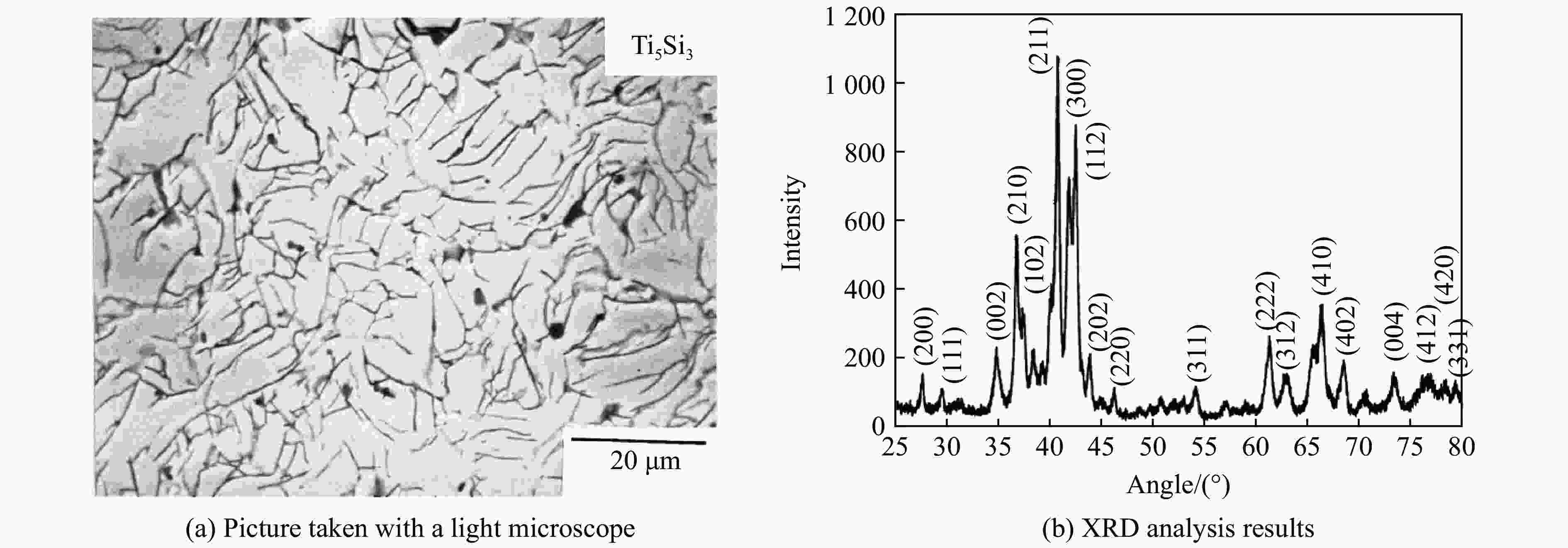

THADHANI N N, GRAHAM R A, ROYAL T, et al. Shock-induced chemical reactions in titanium-silicon powder mixtures of different morphologies: time-resolved pressure measurements and materials analysis [J]. Journal of Applied Physics, 1997, 82(3): 1113–1128. DOI: 10.1063/1.365878.

|

| [52] |

ROYAL T E, NAMJOSHI S, THADHANI N N. Mechanistic processes influencing shock chemistry in powder mixtures of the Ti-Si, Ti-Al, and Ti-B systems [J]. Metallurgical and Materials Transactions A, 1996, 27(7): 1761–1771. DOI: 10.1007/BF02651925.

|

| [53] |

HORIE Y, GRAHAM R A, SIMONSEN I K. Synthesis of nickel aluminides under high-pressure shock loading [J]. Materials Letters, 1985, 3(9–10): 354–359. DOI: 10.1016/0167-577X(85)90075-8.

|

| [54] |

AKASHI T, SAWAOKA A, SAITO S, et al. Structural changes of boron nitride caused by multiple shock-compressions [J]. Japanese Journal of Applied Physics, 1976, 15(5): 891. DOI: 10.1143/JJAP.15.891.

|

| [55] |

BOSLOUGH M B. A thermochemical model for shock-induced reactions (heat detonations) in solids [J]. The Journal of Chemical Physics, 1990, 92(3): 1839–1848. DOI: 10.1063/1.458066.

|

| [56] |

MEYERS M A. Dynamic behaviour of materials [M]. New York: John Wiley & Sons, 1994. DOI: 10.1002/9780470172278.

|

| [57] |

BOLME C A, MCGRANE S D, MOORE D S, et al. Single shot measurements of laser driven shock waves using ultrafast dynamic ellipsometry [J]. Journal of Applied Physics, 2007, 102(3): 033513. DOI: 10.1063/1.2767376.

|

| [58] |

VANDERSALL K S, THADHANI N N. Time-resolved measurements of the shock-compression response of Mo+2Si elemental powder mixtures [J]. Journal of Applied Physics, 2003, 94(3): 1575–1583. DOI: 10.1063/1.1586968.

|

| [59] |

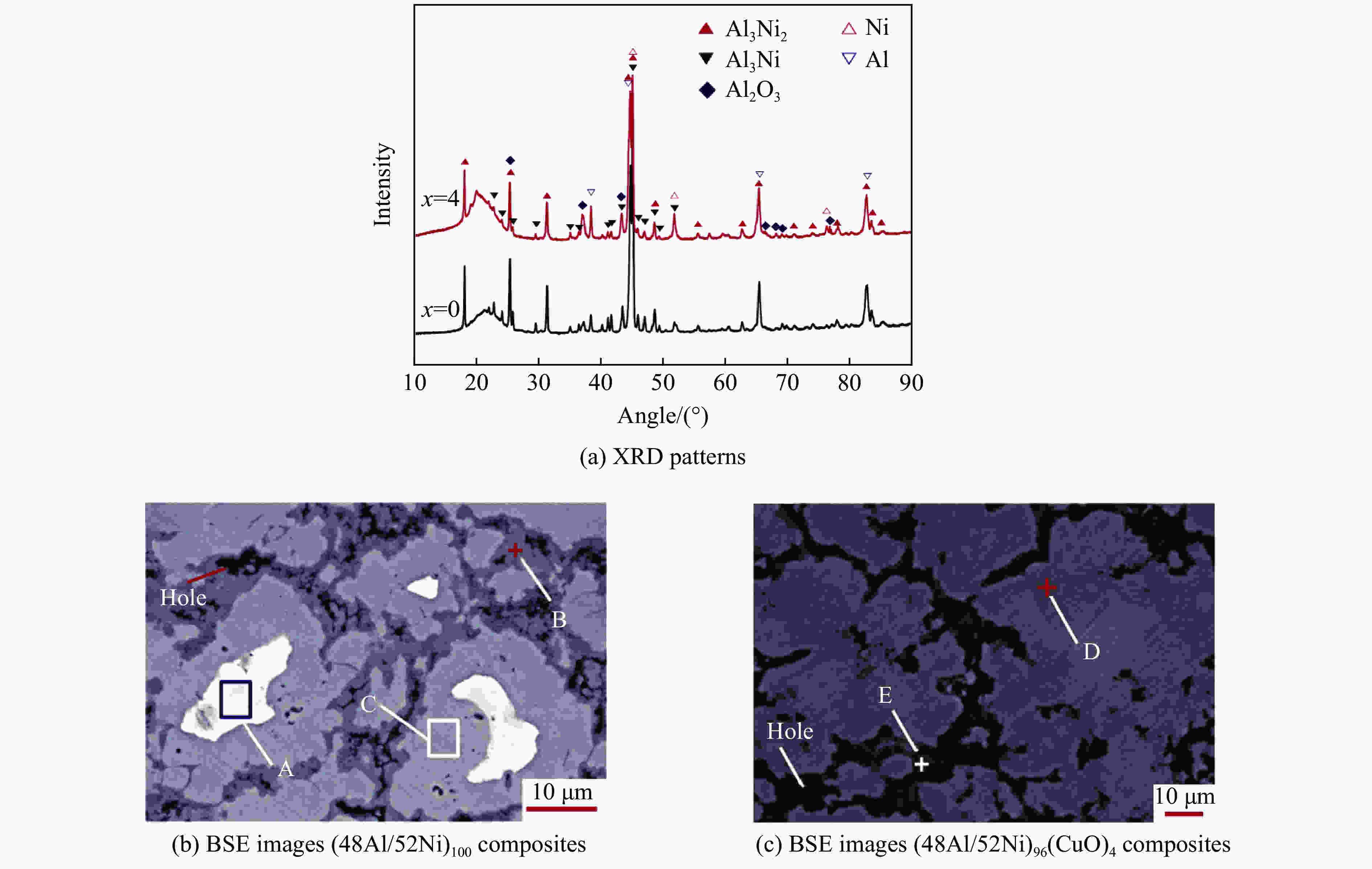

HUANG C M, CHEN J, BAI S X, et al. Enhancement of energy release performance of Al-Ni composites by adding CuO [J]. Journal of Alloys and Compounds, 2020, 835: 155271. DOI: 10.1016/j.jallcom.2020.155271.

|

| [60] |

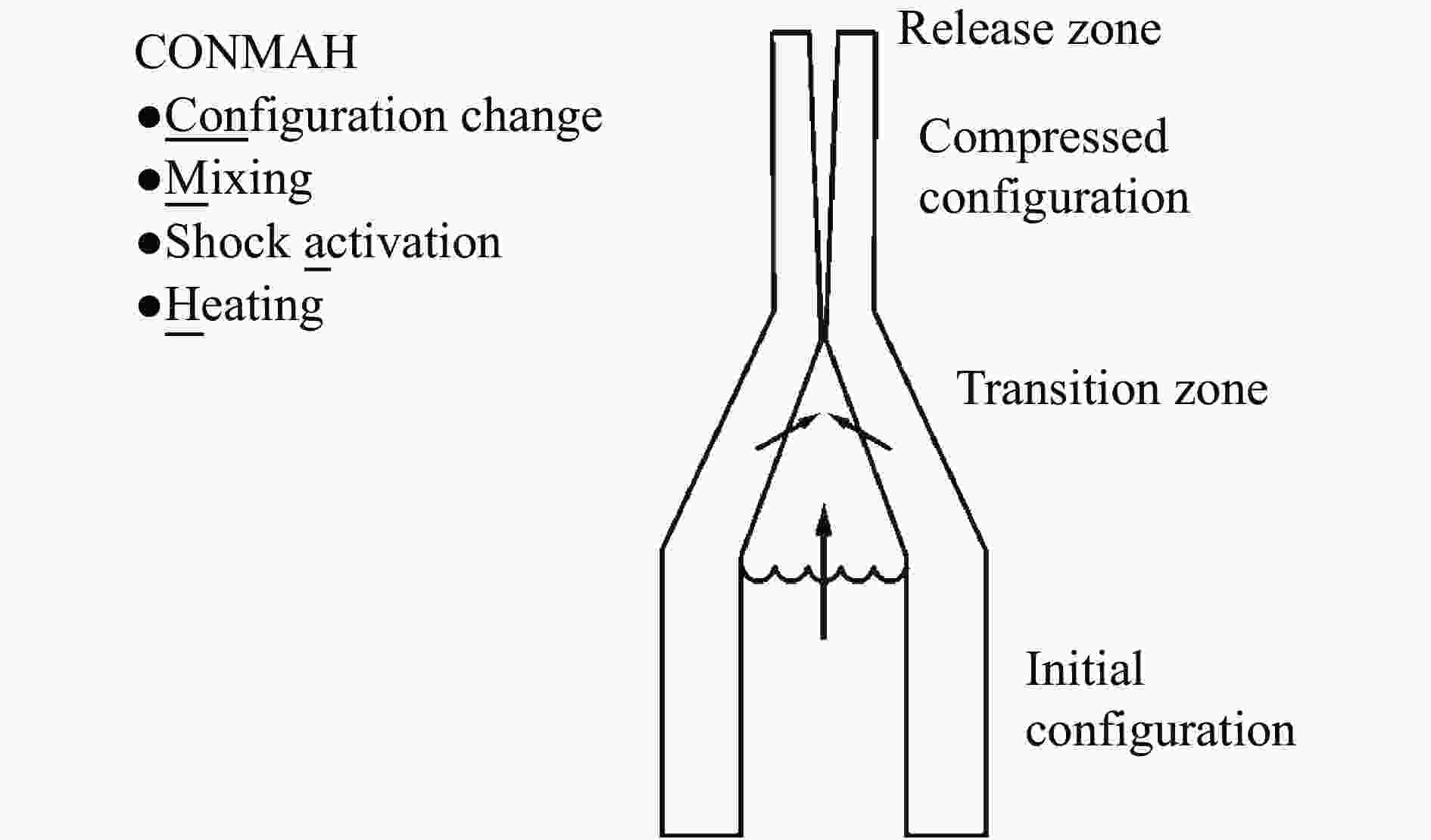

EAKINS D E, THADHANI N N. Shock compression of reactive powder mixtures [J]. International Materials Reviews, 2009, 54(4): 181–213. DOI: 10.1179/174328009X461050.

|

| [61] |

GRAHAM R A. Issues in shock-induced solid state chemistry [R]. Albuquerque: Sandia National Lab, 1989.

|

| [62] |

YANO K, HORIE Y. A numerical study of shock-induced particle velocity dispersion in solid mixtures [J]. Journal of Applied Physics, 1998, 84(3): 1292–1298. DOI: 10.1063/1.368197.

|

| [63] |

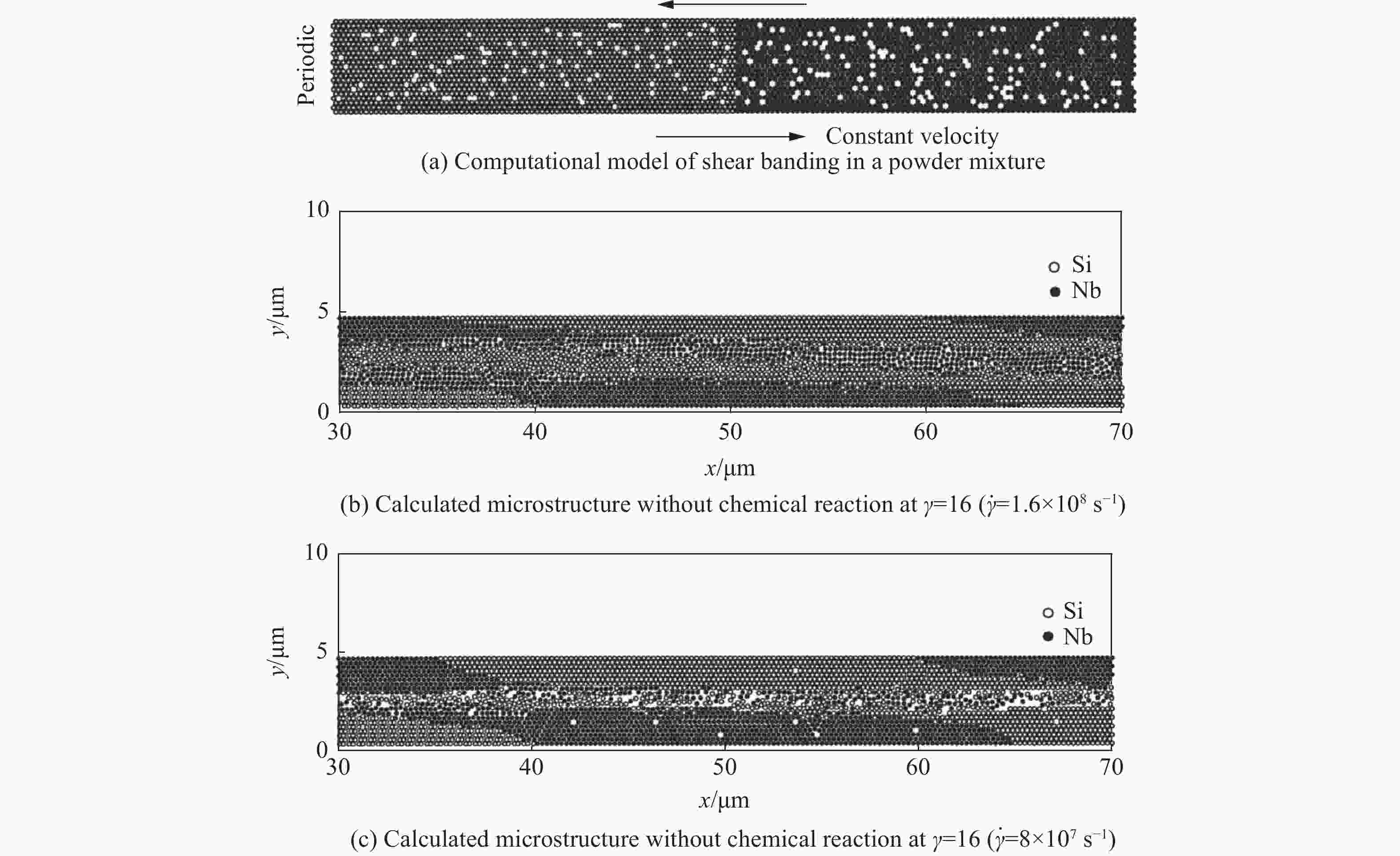

TAMURA S, HORIE Y. Discrete meso-dynamic simulation of thermal explosion in shear bands [J]. Journal of Applied Physics, 1998, 84(7): 3574–3580. DOI: 10.1063/1.368532.

|

| [64] |

AUSTIN R A. Numerical simulation of the shock compression of microscale reactive particle systems [D]. Atlanta: Georgia Institute of Technology, 2005.

|

| [65] |

BOLKHOVITINOV L G, BATSANOV S S. Theory of solid-state detonation [J]. Combustion, Explosion, and Shock Waves, 2007, 43(2): 219–221. DOI: 10.1007/s10573-007-0030-5.

|

| [66] |

ZHANG X F, QIAO L, SHI A S, et al. A cold energy mixture theory for the equation of state in solid and porous metal mixtures [J]. Journal of Applied Physics, 2011, 110(1): 013506. DOI: 10.1063/1.3603018.

|

| [67] |

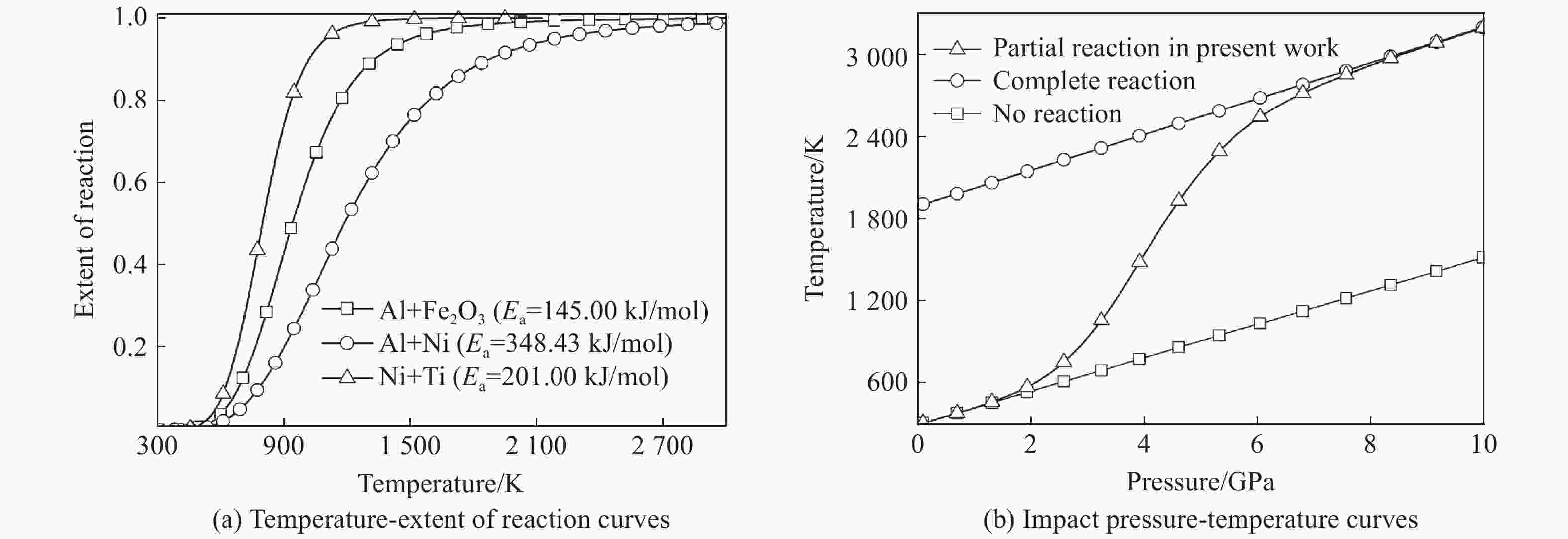

张先锋, 赵晓宁, 乔良. 反应金属冲击反应过程的理论分析 [J]. 爆炸与冲击, 2010, 30(2): 145–151. DOI: 10.11883/1001-1455(2010)02-0145-07.ZHANG X F, ZHAO X N, QIAO L. Theory analysis on shock-induced chemical reaction of reactive metal [J]. Explosion and Shock Waves, 2010, 30(2): 145–151. DOI: 10.11883/1001-1455(2010)02-0145-07.

|

| [68] |

HORIE Y, KIPP M E. Modeling of shock-induced chemical reactions in powder mixtures [J]. Journal of Applied Physics, 1988, 63(12): 5718–5727. DOI: 10.1063/1.340309.

|

| [69] |

DO I P H, BENSON D J. Micromechanical modeling of shock-induced chemical reactions in heterogeneous multi-material powder mixtures [J]. International Journal of Plasticity, 2001, 17(4): 641–668. DOI: 10.1016/S0749-6419(00)00065-6.

|

| [70] |

BENSON D J. The calculation of the shock velocity-particle velocity relationship for a copper powder by direct numerical simulation [J]. Wave Motion, 1995, 21(1): 85–99. DOI: 10.1016/0165-2125(94)00044-6.

|

| [71] |

NIEH T G, LUO P, NELLIS W, et al. Dynamic compaction of aluminum nanocrystals [J]. Acta Materialia, 1996, 44(9): 3781–3788. DOI: 10.1016/1359-6454(96)83816-X.

|

| [72] |

AUSTIN R A, MCDOWELL D L, BENSON D J. Numerical simulation of shock wave propagation in spatially-resolved particle systems [J]. Modelling and Simulation in Materials Science and Engineering, 2006, 14(4): 537–561. DOI: 10.1088/ 0965-0393/14/4/001.

|

| [73] |

BENSON D J. An analysis by direct numerical simulation of the effects of particle morphology on the shock compaction of copper powder [J]. Modelling and Simulation in Materials Science and Engineering, 1994, 2(3A): 535–550. DOI: 10.1088/0965-0393/2/3A/008.

|

| [74] |

BAER M R, TROTT W M. Mesoscale studies of shock loaded tin sphere lattices [J]. AIP Conference Proceedings, 2004, 706(1): 517–520. DOI: 10.1063/1.1780290.

|

| [75] |

BAER M R. Modeling heterogeneous energetic materials at the mesoscale [J]. Thermochimica Acta, 2002, 384(1–2): 351–367. DOI: 10.1016/S0040-6031(01)00794-8.

|

| [76] |

BENSON D J, CONLEY P. Eulerian finite-element simulations of experimentally acquired HMX microstructures [J]. Modelling and Simulation in Materials Science and Engineering, 1999, 7(3): 333–354. DOI: 10.1088/0965-0393/7/3/304.

|

| [77] |

EAKINS D E, THADHANI N N. Discrete particle simulation of shock wave propagation in a Ni+Al powder mixture [J]. Journal of Applied Physics, 2007, 101(4): 043508. DOI: 10.1063/1.2431682.

|

| [78] |

EAKINS D E, THADHANI N N. Mesoscale simulation of the configuration-dependent shock-compression response of Ni+Al powder mixtures [J]. Acta Materialia, 2008, 56(7): 1496–1510. DOI: 10.1016/j.actamat.2007.12.009.

|

| [79] |

CHAWLA N, SIDHU R S, GANESH V V. Three-dimensional visualization and microstructure-based modeling of deformation in particle-reinforced composites [J]. Acta Materialia, 2006, 54(6): 1541–1548. DOI: 10.1016/j.actamat.2005.11.027.

|

| [80] |

SIDHU R S, CHAWLA N. Three-dimensional (3D) visualization and microstructure-based modeling of deformation in a Sn-rich solder [J]. Scripta Materialia, 2006, 54(9): 1627–1631. DOI: 10.1016/j.scriptamat.2006.01.013.

|

| [81] |

AYYAR A, CHAWLA N. Microstructure-based modeling of the influence of particle spatial distribution and fracture on crack growth in particle-reinforced composites [J]. Acta Materialia, 2007, 55(18): 6064–6073. DOI: 10.1016/j.actamat.2007.06.044.

|

| [82] |

ZHAI J, TOMAR V, ZHOU M. Micromechanical simulation of dynamic fracture using the cohesive finite element method [J]. Journal of Engineering Materials and Technology, 2004, 126(2): 179–191. DOI: 10.1115/1.1647127.

|

| [83] |

YANG Y, GOULD R D, HORIE Y, et al. Shock-induced chemical reactions in a Ni/Al powder mixture [J]. Applied Physics Letters, 1997, 70(25): 3365–3367. DOI: 10.1063/1.119172.

|

| [84] |

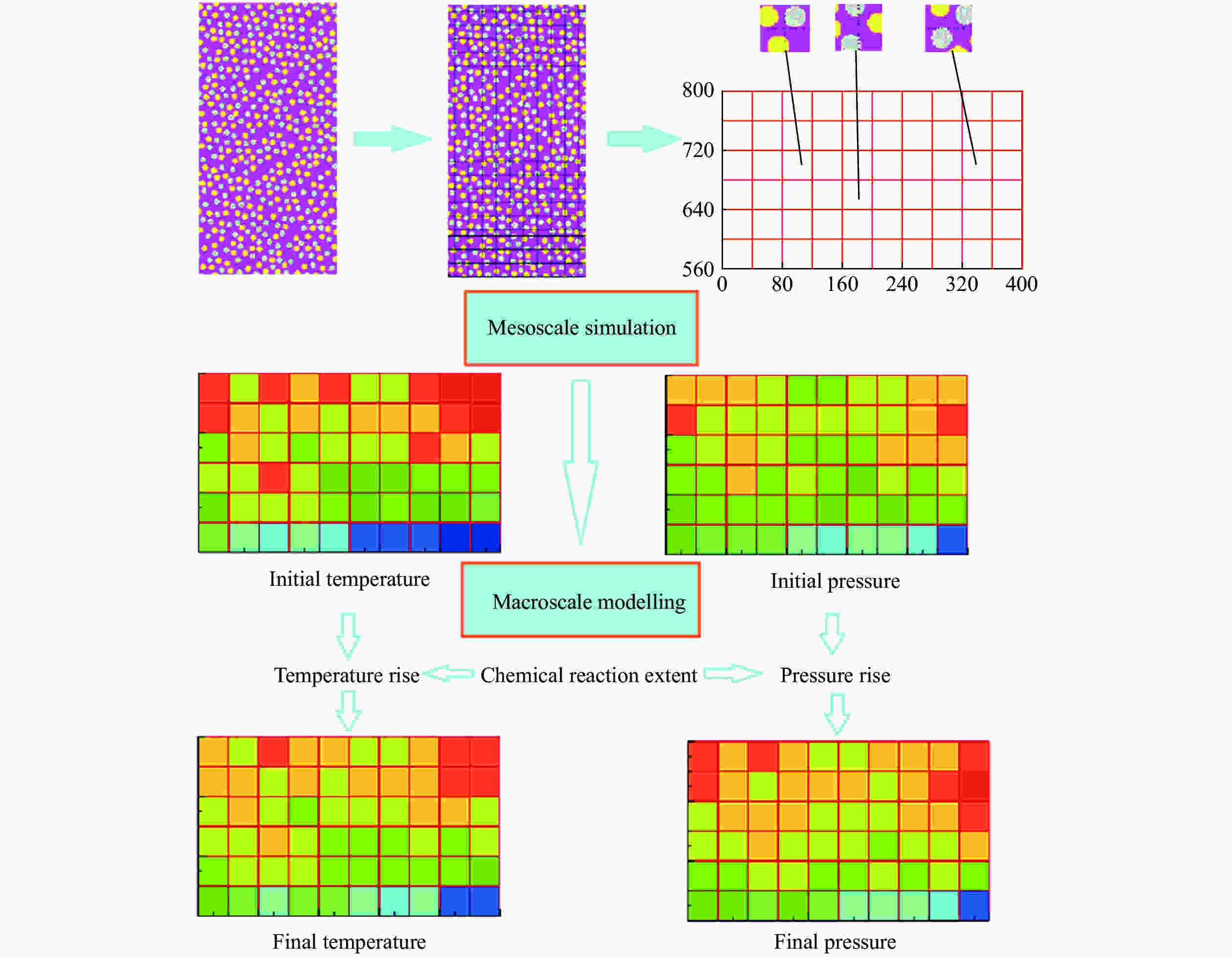

QIAO L, ZHANG X F, HE Y, et al. Multiscale modelling on the shock-induced chemical reactions of multifunctional energetic structural materials [J]. Journal of Applied Physics, 2013, 113(17): 173513. DOI: 10.1063/1.4803712.

|

| [85] |

乔良. 多功能含能结构材料冲击反应与细观特性关联机制研究[D]. 南京: 南京理工大学, 2013.

|

| [86] |

REDING D J, HANAGUD S. Multiscale chemical reactions in reactive powder metal mixtures during shock compression [J]. Journal of Applied Physics, 2010, 105(2): 024912. DOI: 10.1063/1.2976313.

|

| [87] |

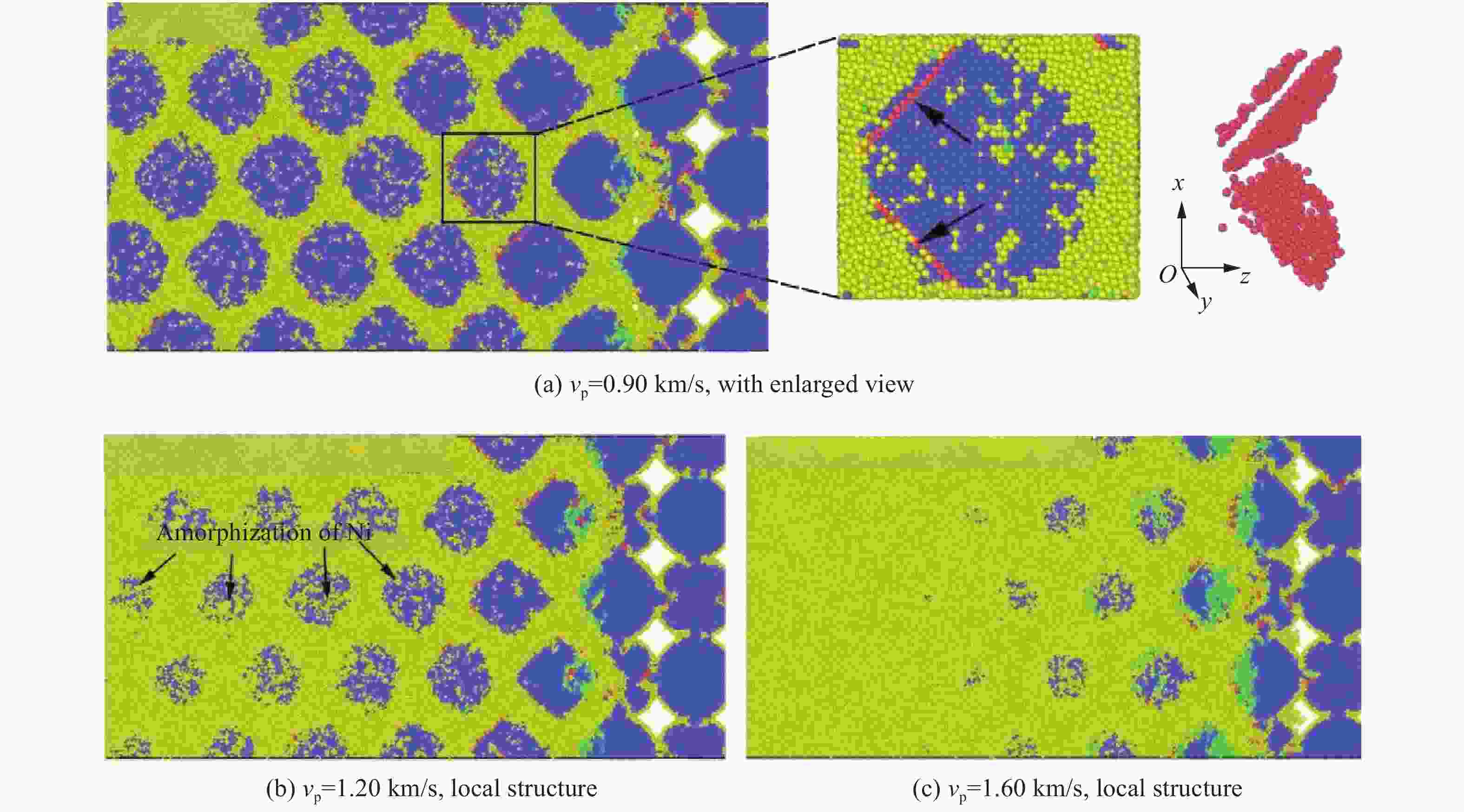

XIONG Y N, XIAO S F, DENG H Q, et al. Investigation of the shock-induced chemical reaction (SICR) in Ni+Al nanoparticle mixtures [J]. Physical Chemistry Chemical Physics, 2017, 27(19): 17607–17617. DOI: 10.1039/C7CP03176A.

|

下载:

下载: