Fracture characteristics of YAG transparent ceramic composite targets subjected to impact of sphere fragments

-

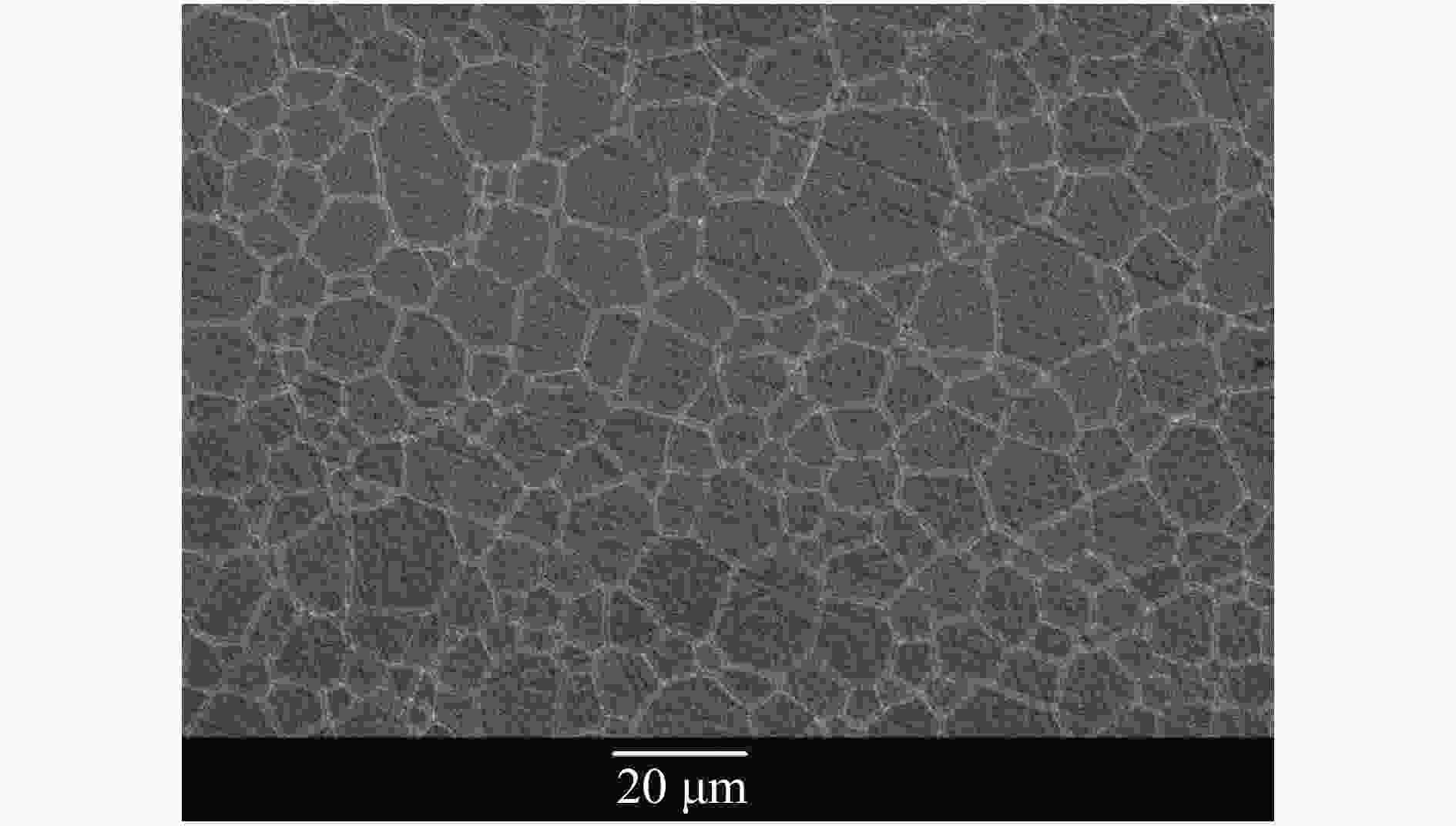

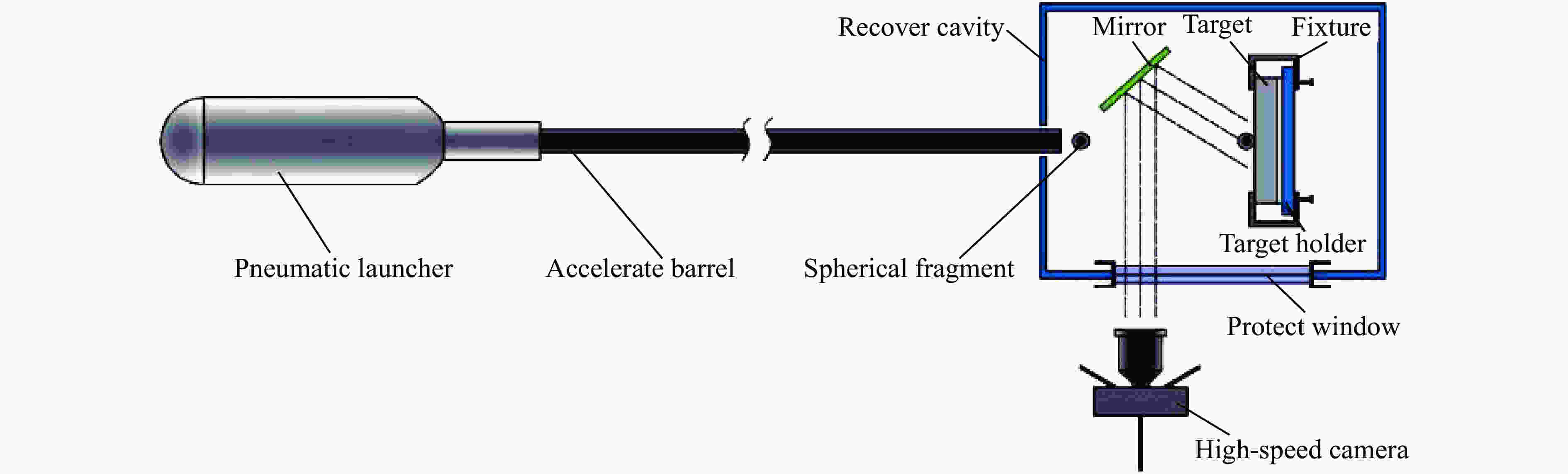

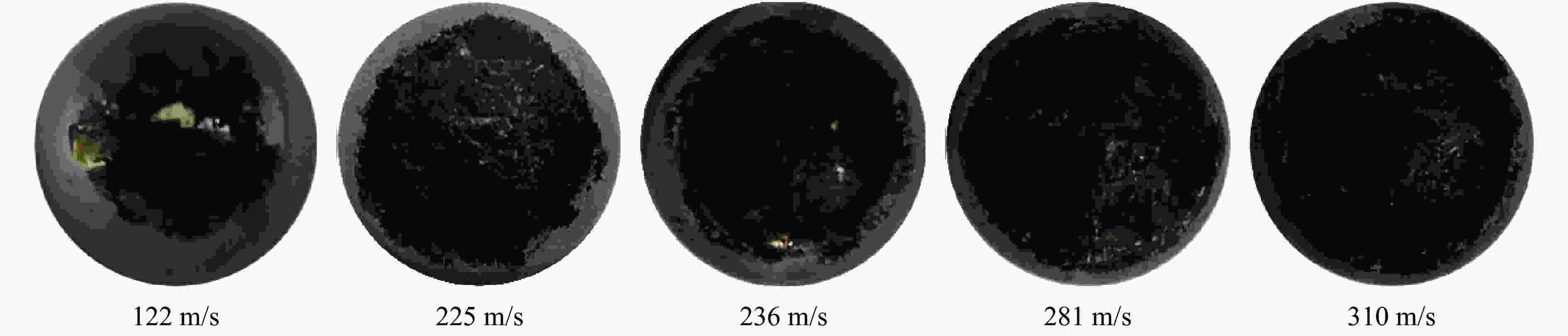

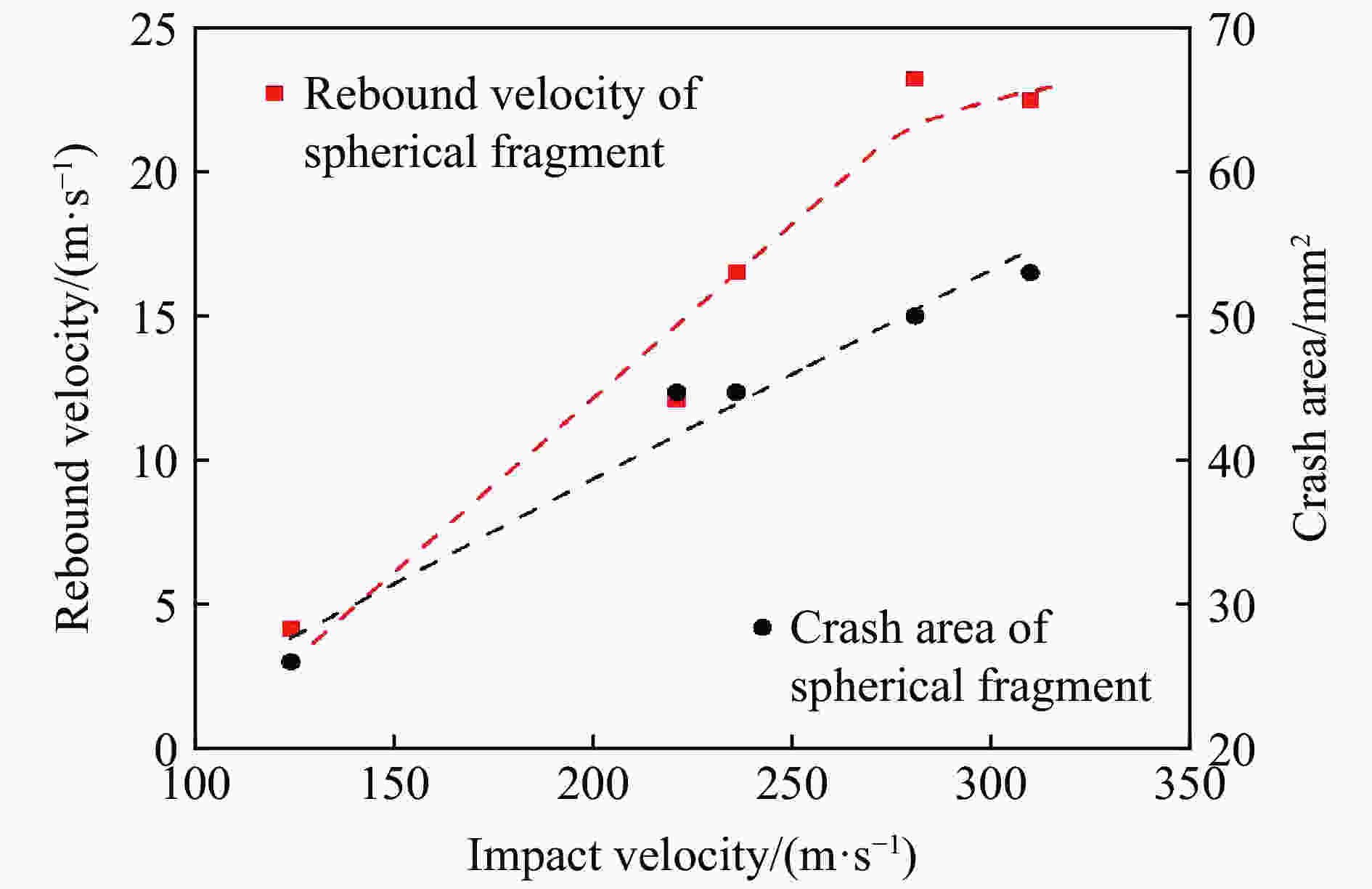

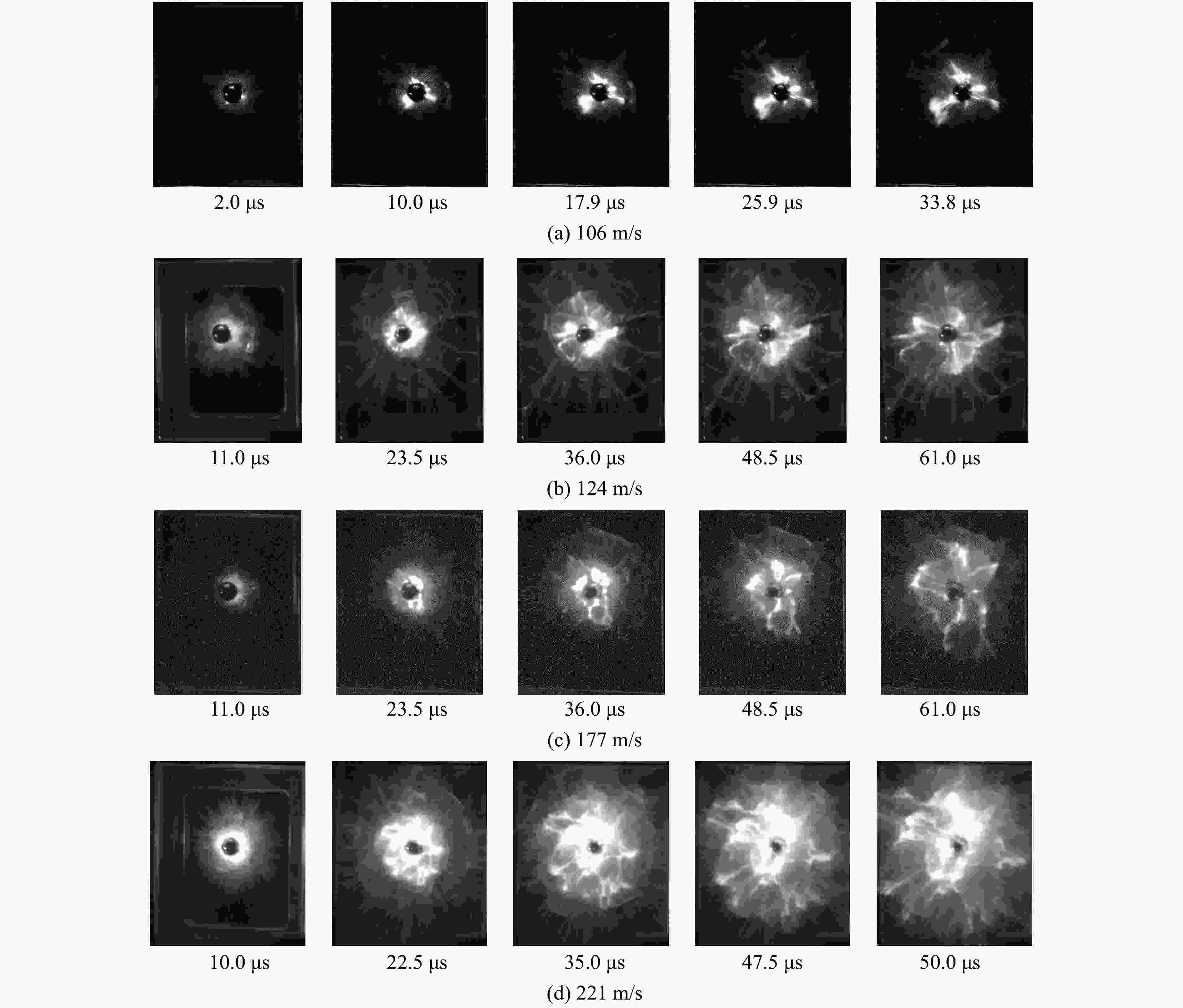

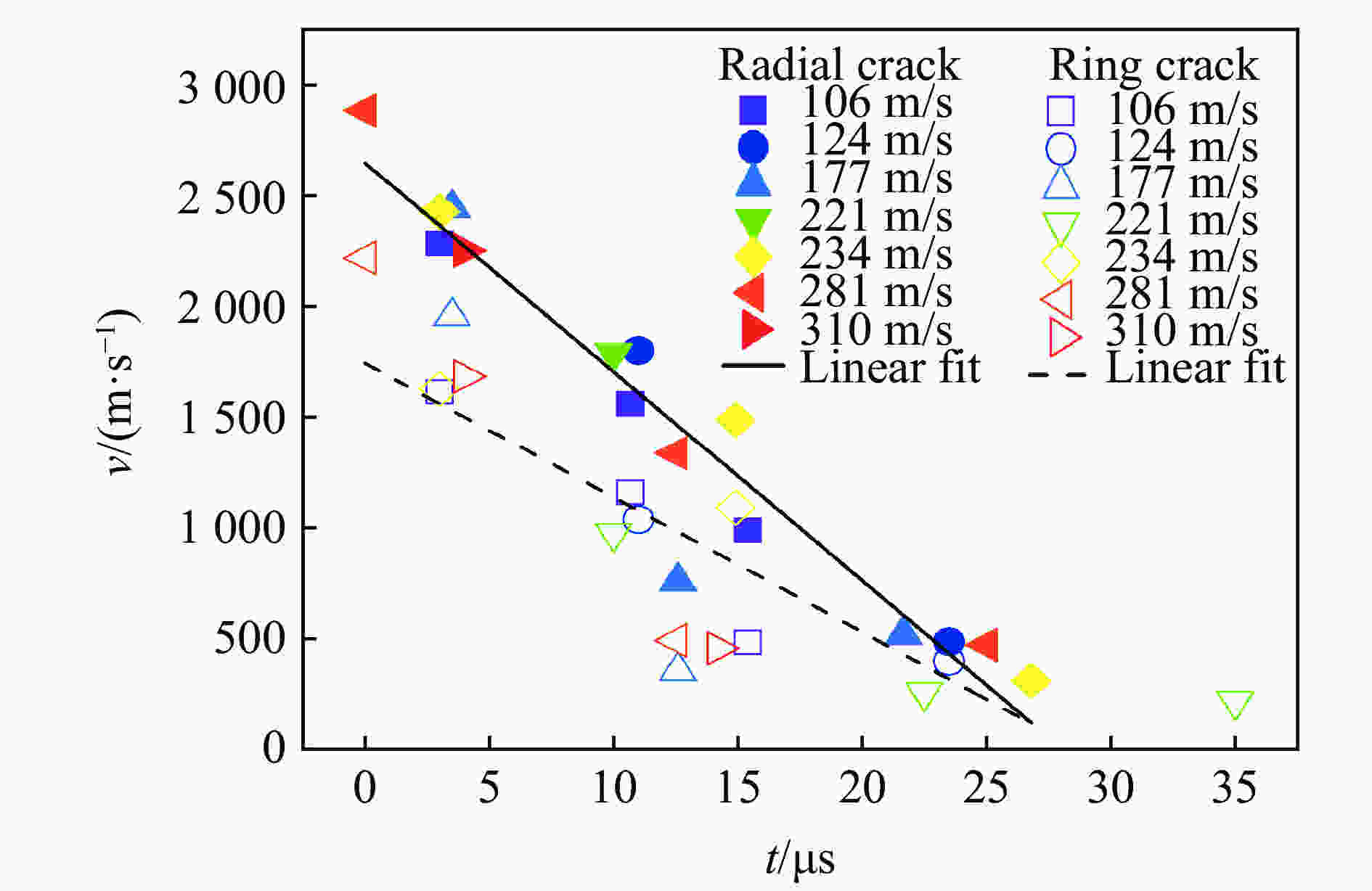

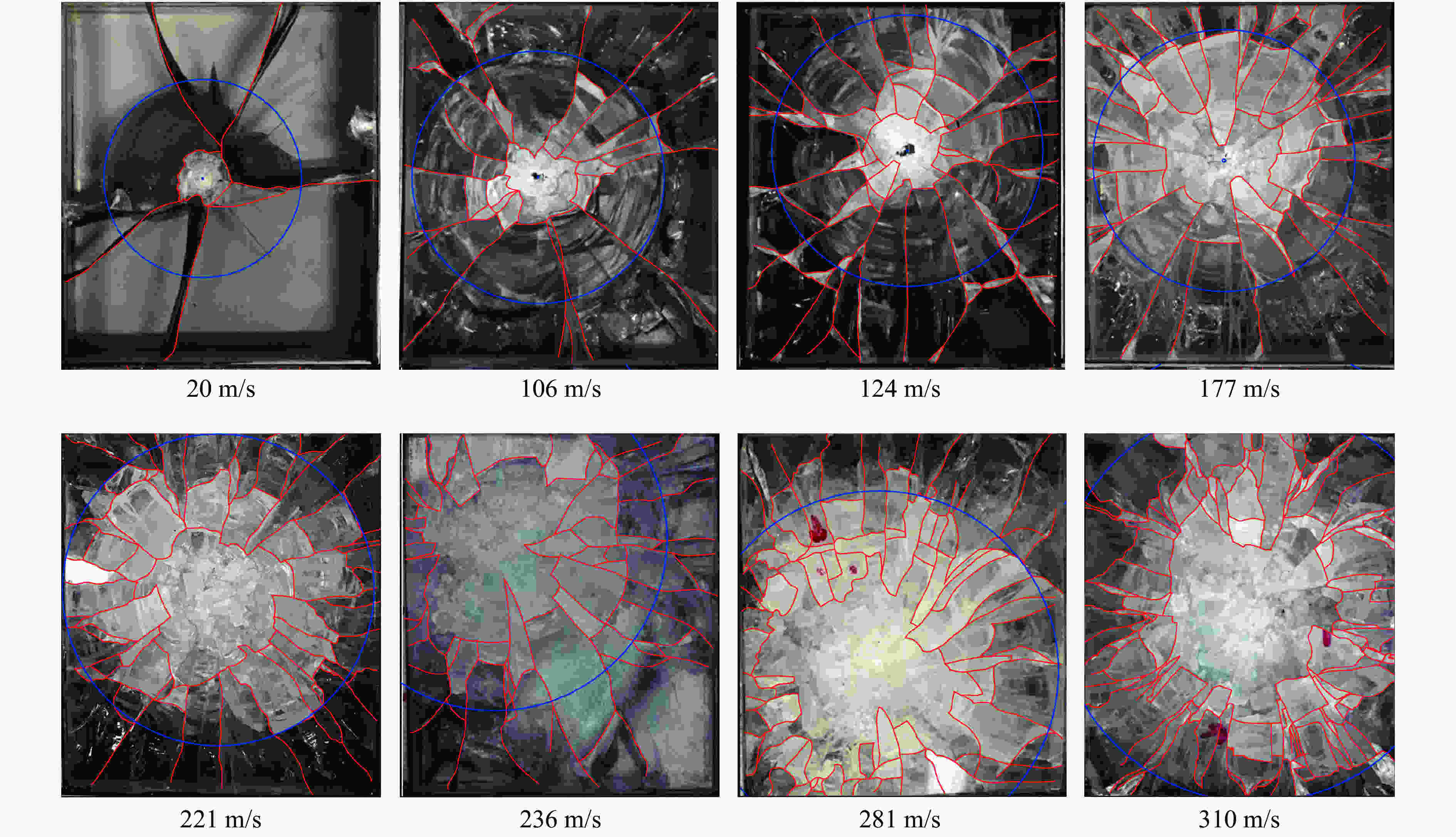

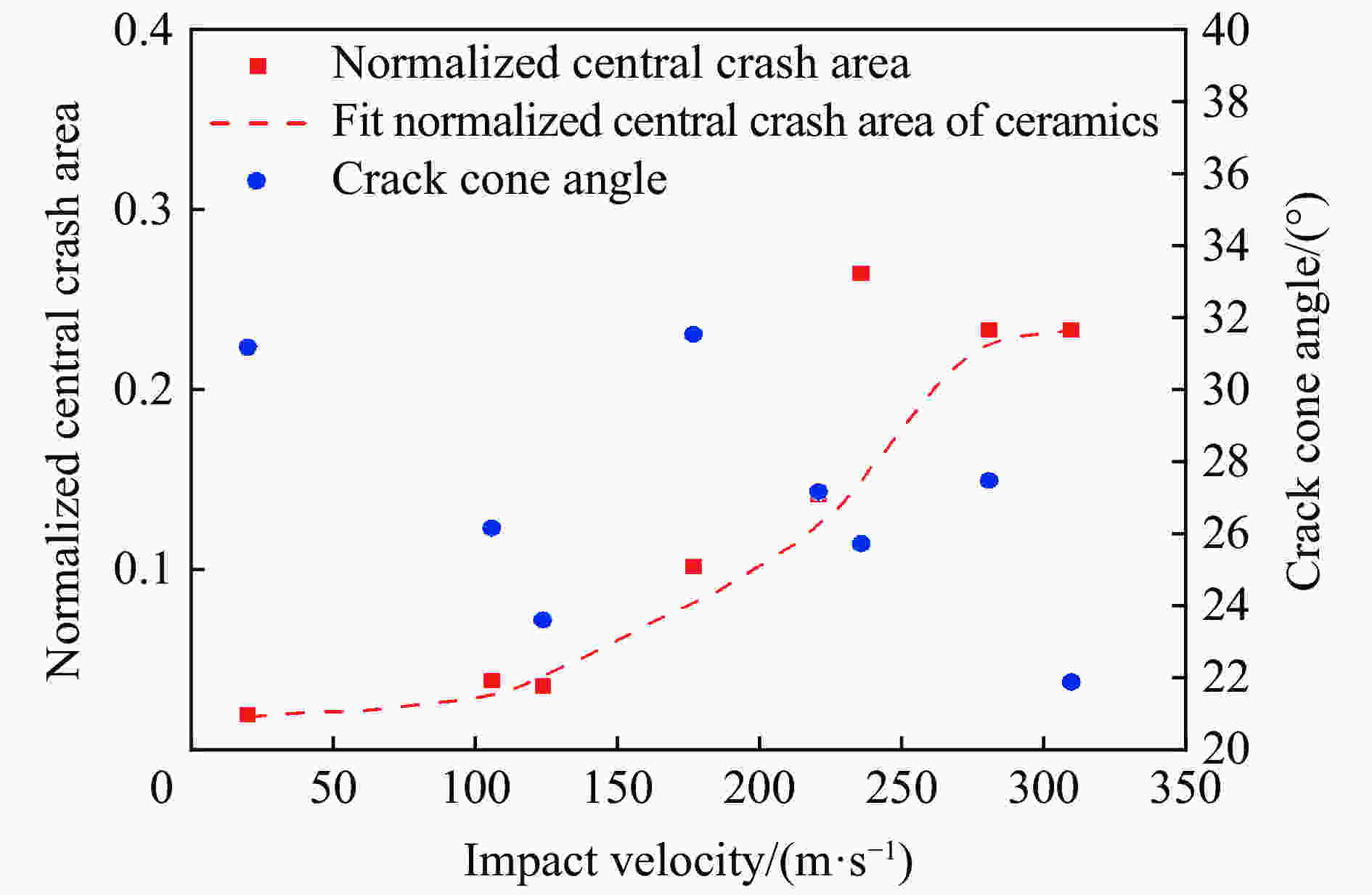

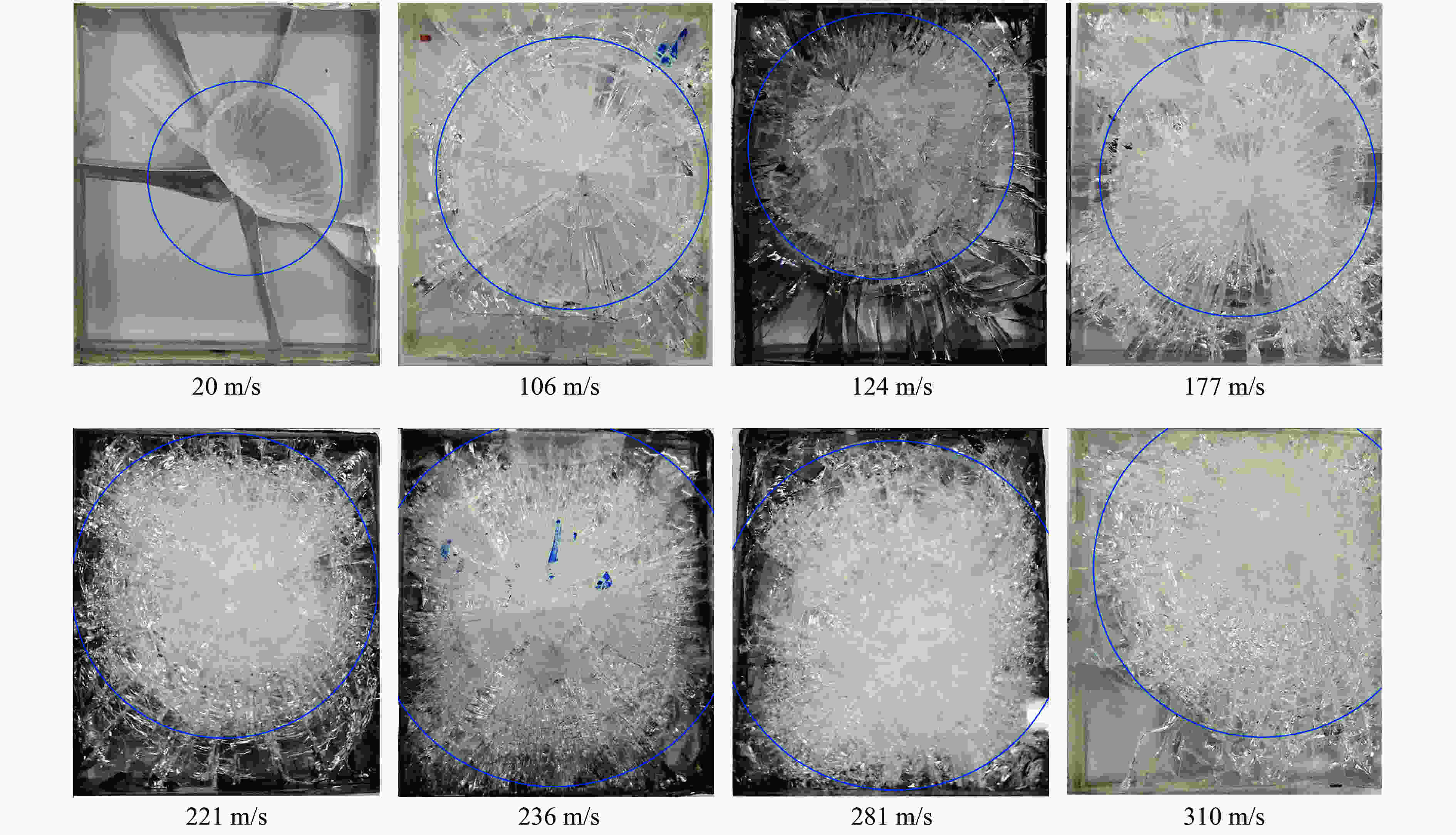

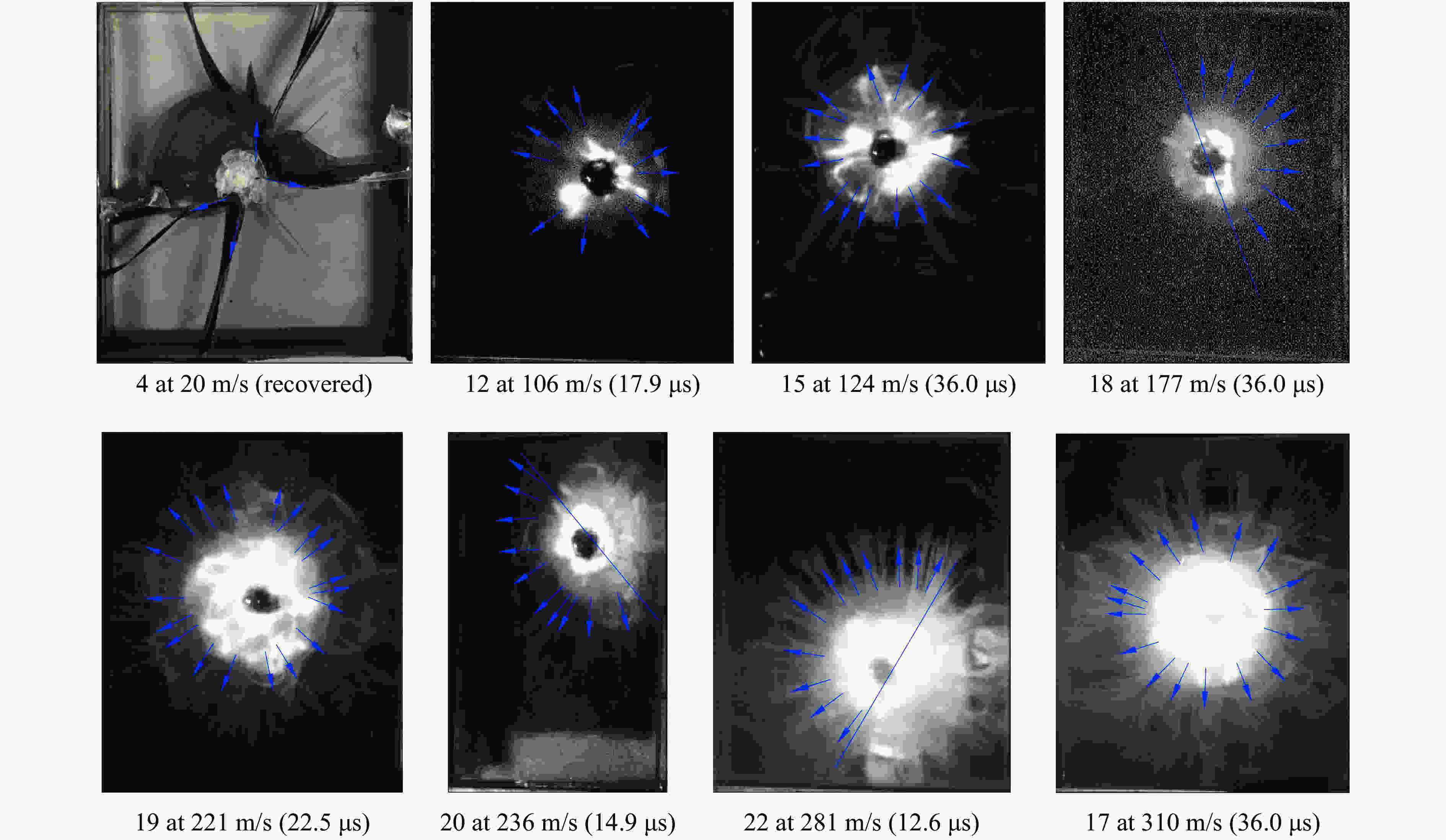

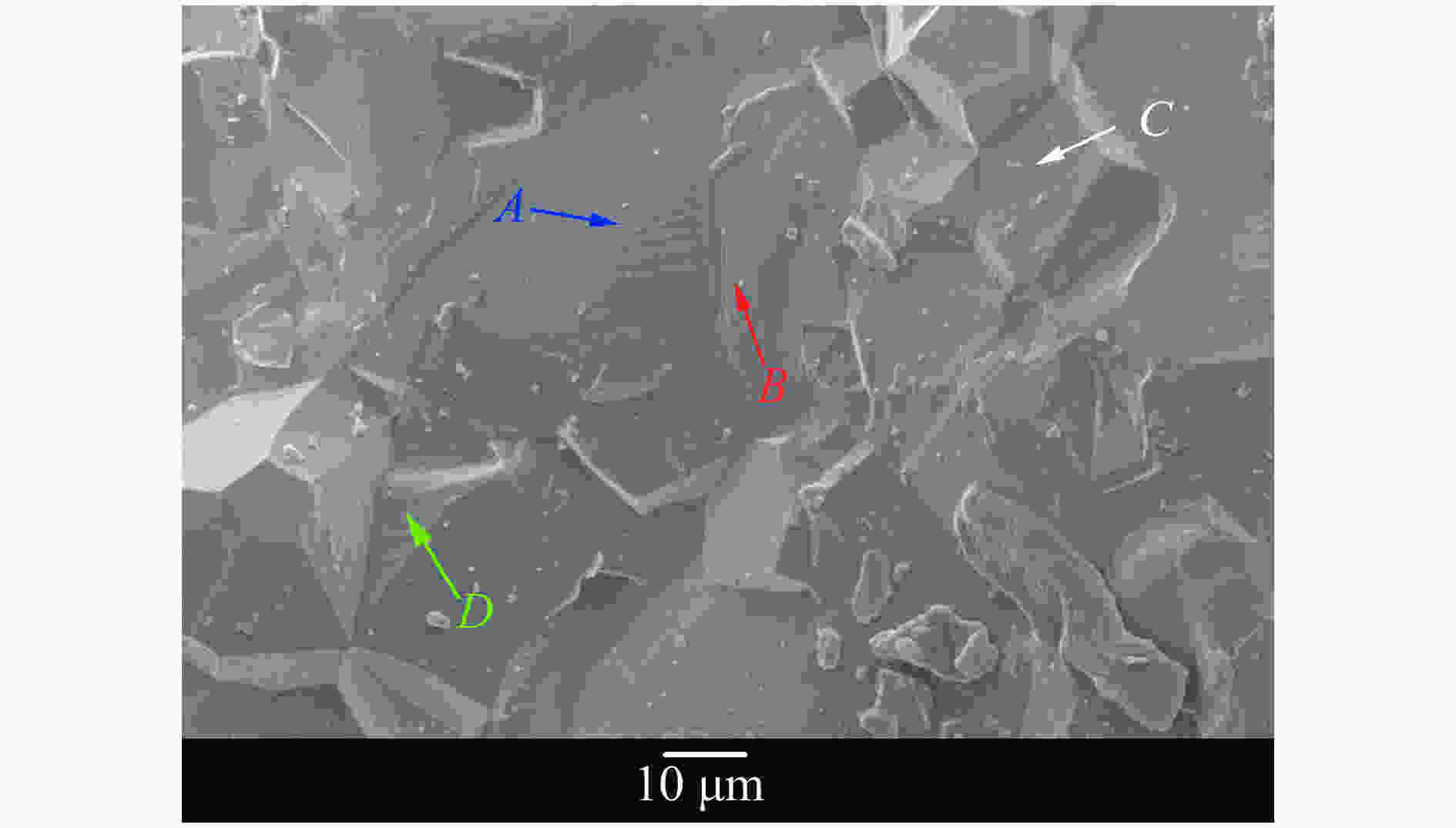

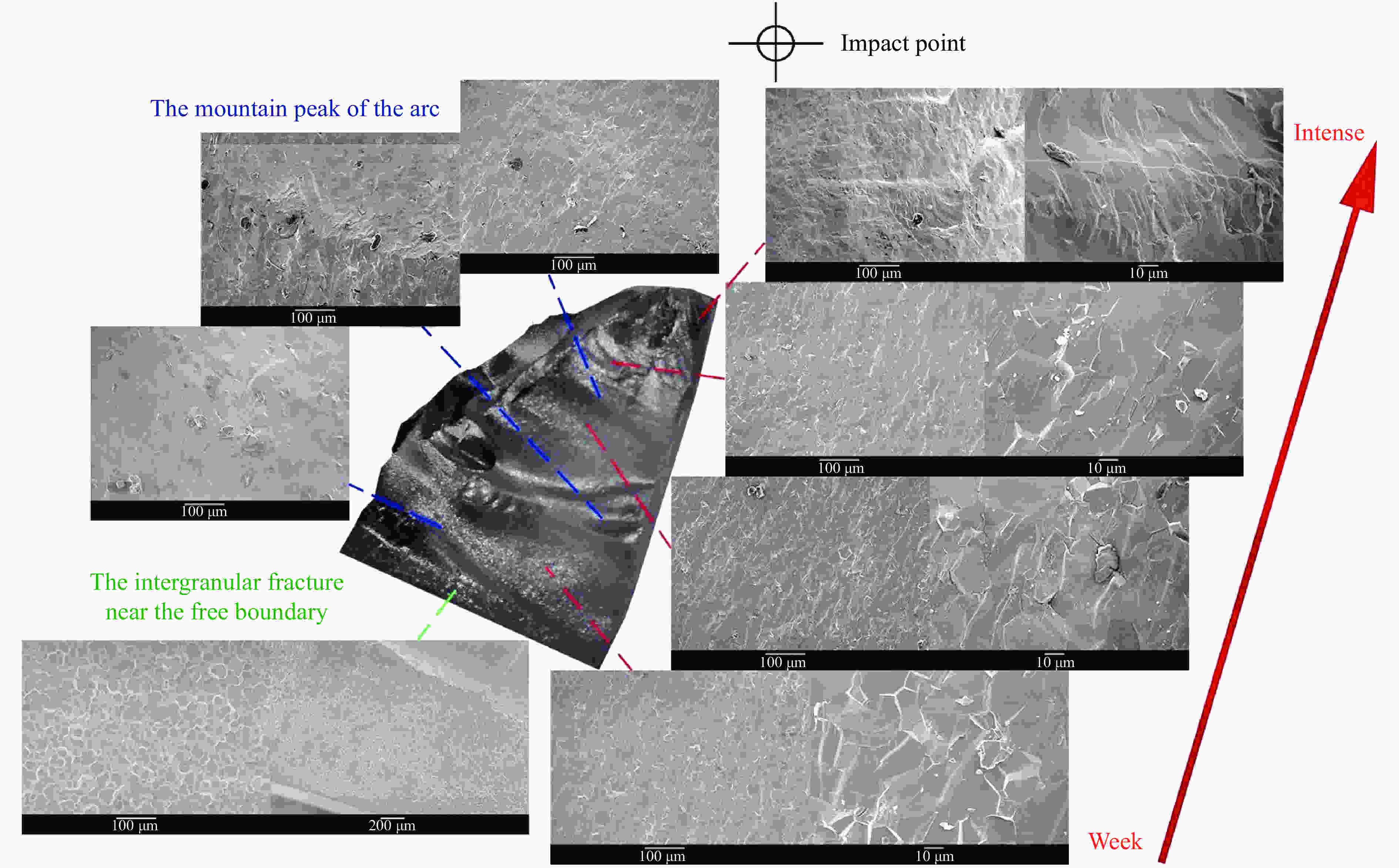

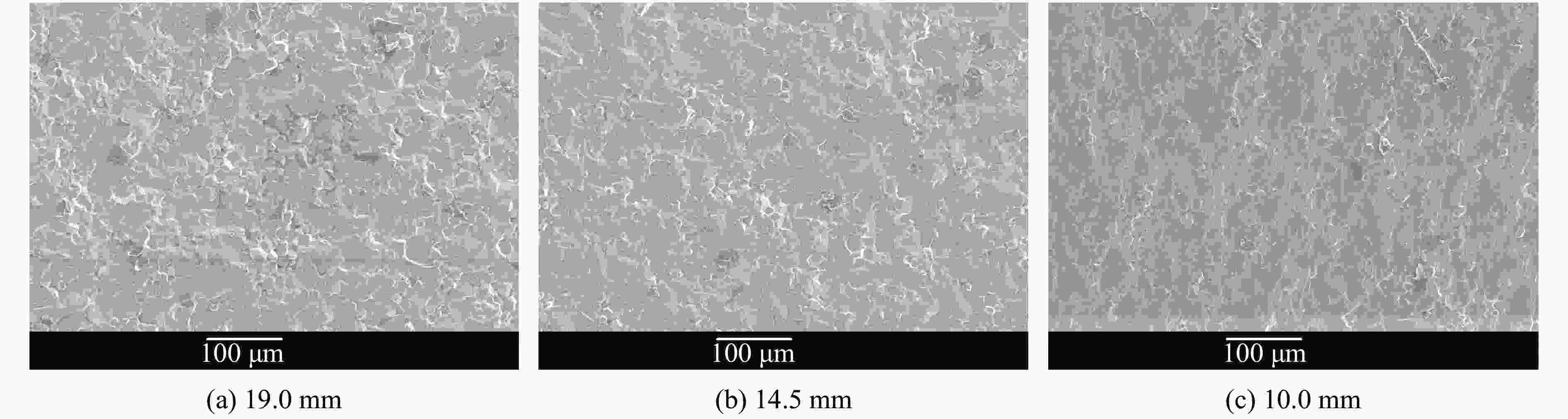

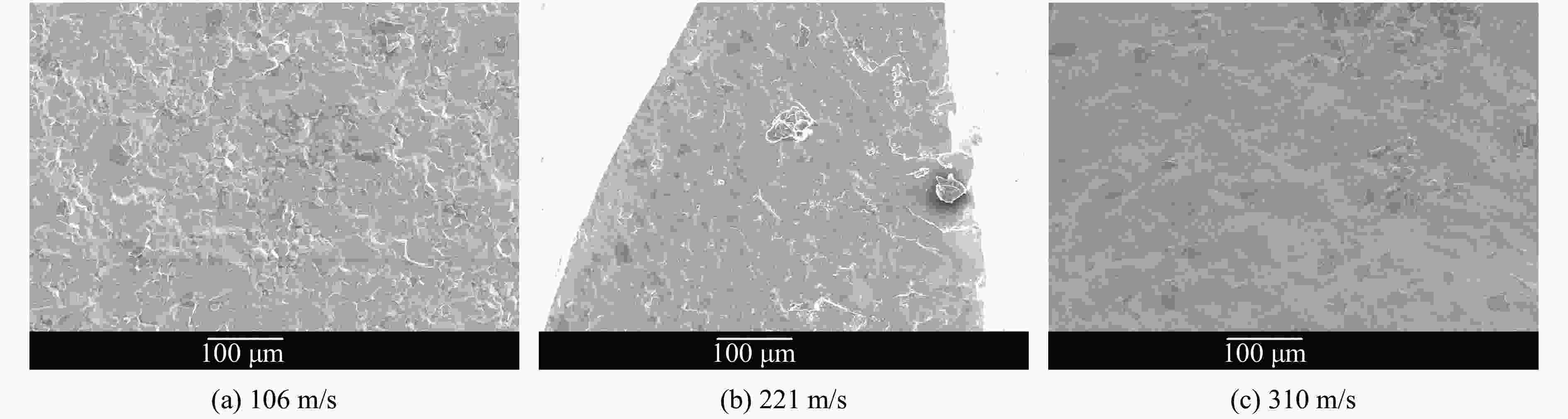

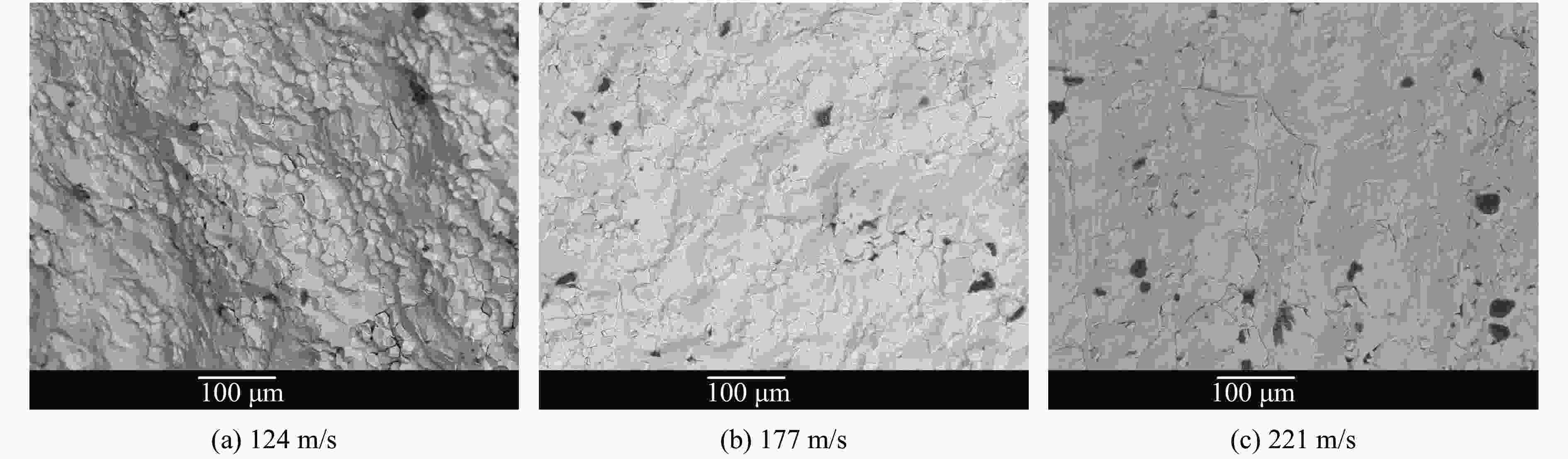

摘要: YAG透明陶瓷兼具有优秀的透光性能和抗冲击破坏性能,是武器装备透明部分的优秀防护材料,在军事装备、航天等国防领域具有良好的应用前景。冲击载荷下材料的加载响应特性对掌握材料破坏机制至关重要,能为透明复合靶设计提供依据。为获得YAG透明陶瓷多层复合靶的冲击破坏特性,利用内径9 mm的气体驱动发射平台进行了碳化钨球形破片在20~310 m/s速度下撞击YAG透明陶瓷复合靶的实验,通过高速摄影捕捉的陶瓷表面损伤演化过程,计算了典型径向、环向裂纹扩展速度。通过观测回收的靶体和YAG碎片的宏细观破坏特征,分析了撞击速度与靶体破坏特征之间的联系。结果表明,YAG陶瓷层径向裂纹和环向裂纹扩展速度均随着时间的延长线性降低,且裂纹扩展速度几乎不受撞击速度影响。陶瓷层中心粉碎区面积随撞击速度的提高而增大,且中间玻璃层破坏区域面积与陶瓷锥底面积相关联,陶瓷锥角与撞击速度关联性不强。同时,观察到陶瓷层在冲击破坏过程中出现了裂纹簇,获得了裂纹簇数量与破片撞击速度之间的关系,分析了裂纹簇的特征及其成因。裂纹变向、应力波作用会显著影响细观断面破坏特征。径向、环向和锥裂纹中沿晶断裂的比例均随着裂纹扩展距离的增大而增加,且穿晶比例随着撞击速度的提高而增加。

-

关键词:

- YAG透明陶瓷复合靶 /

- 破片冲击 /

- 裂纹扩展速度 /

- 沿晶断裂 /

- 穿晶断裂

Abstract: YAG (yttrium aluminum garnet) transparent ceramic, with excellent light transmittance and impact resistance, is an excellent protective material for transparent parts of weapons and equipments. It has a good application prospect in military equipment, aerospace and other national defense fields. The loading responses of material under impact loading are essential for understanding the fracture mechanism and can provide a basis for the composite target design. In order to obtain the fracture characteristics of YAG transparent ceramic composite targets under impact loading, a 9-mm-caliber gas-driven launch platform was used to carry out experiments on the impact of tungsten carbide spherical fragments into YAG transparent ceramic composite targets in the velocity range from 20 m/s to 310 m/s. The typical radial and ring crack propagation velocities were calculated by the surface damage evolution process captured by high-speed photography. The relationship between the impact velocity and the damage characteristics of the recovered targets was analyzed by observing the damage characteristics of the YAG fragments under a macroscope and a microscope. The results show that the propagation velocities of both the radial and ring cracks in the YAG ceramic layer decrease linearly with the increase of time and the crack propagation velocities are almost unaffected by the impact velocities. The central crushing area of the ceramic layer increases with the increase of the impact velocity, and the significant damage area of the intermediate glass layer is related to the area of the bottom ceramic cone. The correlation between ceramic cone angle and impact velocity is weak. Meanwhile, the crack crowns in the ceramic layer were found during the impact process. The relationship between the impact velocity of fragments and the number of crowns was obtained. The feature and the generating reason of the crack crowns were also analyzed. The fracture characteristics under a microscope were significantly affected by the crack orientation and stress wave action. The radial, ring and conical cracks produced more intergranular fracture with the increase of crack propagation distance, and more transgranular fracture with the increase of impact velocity. -

表 1 球形破片冲击实验配置

Table 1. Experimental conditions of spherical fragment impact experiments

序号 YAG陶瓷层尺寸 透过率/% 雾度/% 分辨率 撞击速度/(m·s−1) 回弹速度/(m·s−1) 1 82.6 mm×70.3 mm×9.6 mm 81.4 35.50 91.8 20 − 2 81.0 mm×70.1 mm×10.0 mm − − − 106 − 3 81.6 mm×70.7 mm×10.0 mm 74.0 22.70 96.6 124 4.13 4 81.2 mm×70.2 mm×10.0 mm − − − 177 − 5 80.7 mm×69.1 mm×9.9 mm 75.1 7.96 98.9 221 12.12 6 81.0 mm×70.0 mm×10.1 mm 74.8 13.70 97.6 236 16.50 7 80.8 mm×71.6 mm×10.0 mm 73.6 11.40 98.5 281 23.20 8 80.6 mm×71.6 mm×9.6 mm 82.0 32.50 91.9 310 22.45 注:表中“−”符号为未测量到数据。 -

[1] STRASSBURGER E, HUNZINGER M, PATEL P, et al. Analysis of the fragmentation of AlON and spinel under ballistic impact [J]. Journal of Applied Mechanics, 2013, 80(3): 031807. DOI: 10.1115/1.4023573. [2] STRASSBURGER E, BAUER S. Analysis of the interaction of projectiles with ceramic targets by means of flash X-ray cinematography and optical methods [C] // Proceedings of the 41st International Conference on Advanced Ceramics and Composites: Ceramic Engineering and Science Proceedings. The American Ceramic Society, 2018, 38(2): 205−219. DOI: 10.1002/9781119474678.ch20. [3] 焦文俊, 陈小伟. 长杆高速侵彻问题研究进展 [J]. 力学进展, 2019, 49(1): 201904. DOI: 10.6052/1000-0992-17-021.JIAO W J, CHEN X W. Review on long-rod penetration at hypervelocity [J]. Advances in Mechanics, 2019, 49(1): 201904. DOI: 10.6052/1000-0992-17-021. [4] 谈梦婷, 张先锋, 包阔, 等. 装甲陶瓷的界面击溃效应 [J]. 力学进展, 2019, 49(1): 201905. DOI: 10.6052/1000-0992-17-015.TAN M T, ZHANG X F, BAO K, et al. Interface defeat of ceramic armor [J]. Advances in Mechanics, 2019, 49(1): 201905. DOI: 10.6052/1000-0992-17-015. [5] LA SALVIA J C, LEAVY R B, HOUSKAMP J R, et al. Ballistic impact damage observations in a hot-pressed boron carbide [J]. Ceramic Engineering & Science Proceedings, 2010, 30(5): 45–55. DOI: 10.1002/9780470584330.ch5. [6] LA SALVIA J C, NORMANDIA M J, MILLER H T, et al. Sphere Impact Induced Damage in Ceramics: I. Armor-Grade SiC and TiB2 [M] // Advances in Ceramic Armor: A Collection of Papers Presented at the 29th International Conference on Advanced Ceramics and Composites, January 23−28, 2005. Cocoa Beach: John Wiley & Sons, Ltd, 2008. DOI: 10.1002/9780470291276.ch20. [7] MCCAULEY J W, STRASSBURGER E, PATEL P, et al. Experimental observations on dynamic response of selected transparent armor materials [J]. Experimental Mechanics, 2013, 53(1): 3–29. DOI: 10.1007/s11340-012-9658-5. [8] LA SALVIA J C, NORMANDIA M J, MILLER H T, et al. Sphere impact induced damage in ceramics: II. Armor-Grade B4C and WC [M] // Advances in Ceramic Armor: A Collection of Papers Presented at the 29th International Conference on Advanced Ceramics and Composites, January 23−28, 2005. Cocoa Beach, Florida: John Wiley & Sons Inc., 2008. DOI: 10.1002/9780470291276.ch21. [9] MURRAY N H, BOURNE N K, ROSENBERG Z, et al. The spall strength of alumina ceramics [J]. Journal of Applied Physics, 1998, 84(2): 734–738. DOI: 10.1063/1.368130. [10] CHEN M W, MCCAULEY J W, DANDEKAR D P, et al. Dynamic plasticity and failure of high-purity alumina under shock loading [J]. Nature Materials, 2006, 5(8): 614–618. DOI: 10.1038/nmat1689. [11] BOURNE N K, GREEN W H, DANDEKAR D P. On the one-dimensional recovery and microstructural evaluation of shocked alumina [J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2006, 462(2074): 3197–3212. DOI: 10.1098/rspa.2006.1713. [12] SUBHASH G, MAITI S, GEUBELLE, et al. Recent advances in dynamic indentation fracture, impact damage and fragmentation of ceramics [J]. Journal of the American Ceramic Society, 2008, 91(9): 2777–2791. DOI: 10.1111/j.1551-2916.2008.02624.x. [13] KWAN H Y, KOBAYASHI A S. Dynamic fracture responses of alumina and two ceramic composites [J]. Journal of the American Ceramic Society, 1990, 73(8): 2309–2315. DOI: 10.1111/j.1151-2916.1990.tb07593.x. [14] HANEY E J, SUBHASH G. Edge-on-impact response of a coarse-grained magnesium aluminate spinel rod [J]. International Journal of Impact Engineering, 2012, 40−41: 26–34. DOI: 10.1016/j.ijimpeng.2011.10.001. [15] JIANG W, CHENG X W, XIONG Z P, et al. Static and dynamic mechanical properties of Yttrium Aluminum Garnet (YAG) [J]. Ceramics International, 2019, 45(9): 12256–12263. DOI: 10.1016/j.ceramint.2019.03.136. [16] NEMAT-NASSER S, HORII H. Compression-induced nonplanar crack extension with application to splitting, exfoliation, and rockburst [J]. Journal of Geophysical Research: Solid Earth, 1982, 87(B8): 6805–6821. DOI: 10.1029/JB087iB08p06805. [17] HORII H, NEMAT-NASSER S. Compression-induced microcrack growth in brittle solids: Axial splitting and shear failure [J]. Journal of Geophysical Research: Solid Earth, 1985, 90(B4): 3105–3125. DOI: 10.1029/JB090iB04p03105. -

下载:

下载: