| [1] |

BOBBILI R, RAMAKRISHNA B, MADHU V, et al. Prediction of flow stress of 7017 aluminium alloy under high strain rate compression at elevated temperatures [J]. Defence Technology, 2015, 11(1): 93–98. DOI: 10.1016/j.dt.2014.08.004.

|

| [2] |

PRAKASH G, SINGH N K, GUPTA N K. Deformation behaviours of Al2014-T6 at different strain rates and temperatures [J]. Structures, 2020, 26: 193–203. DOI: 10.1016/j.istruc.2020.03.068.

|

| [3] |

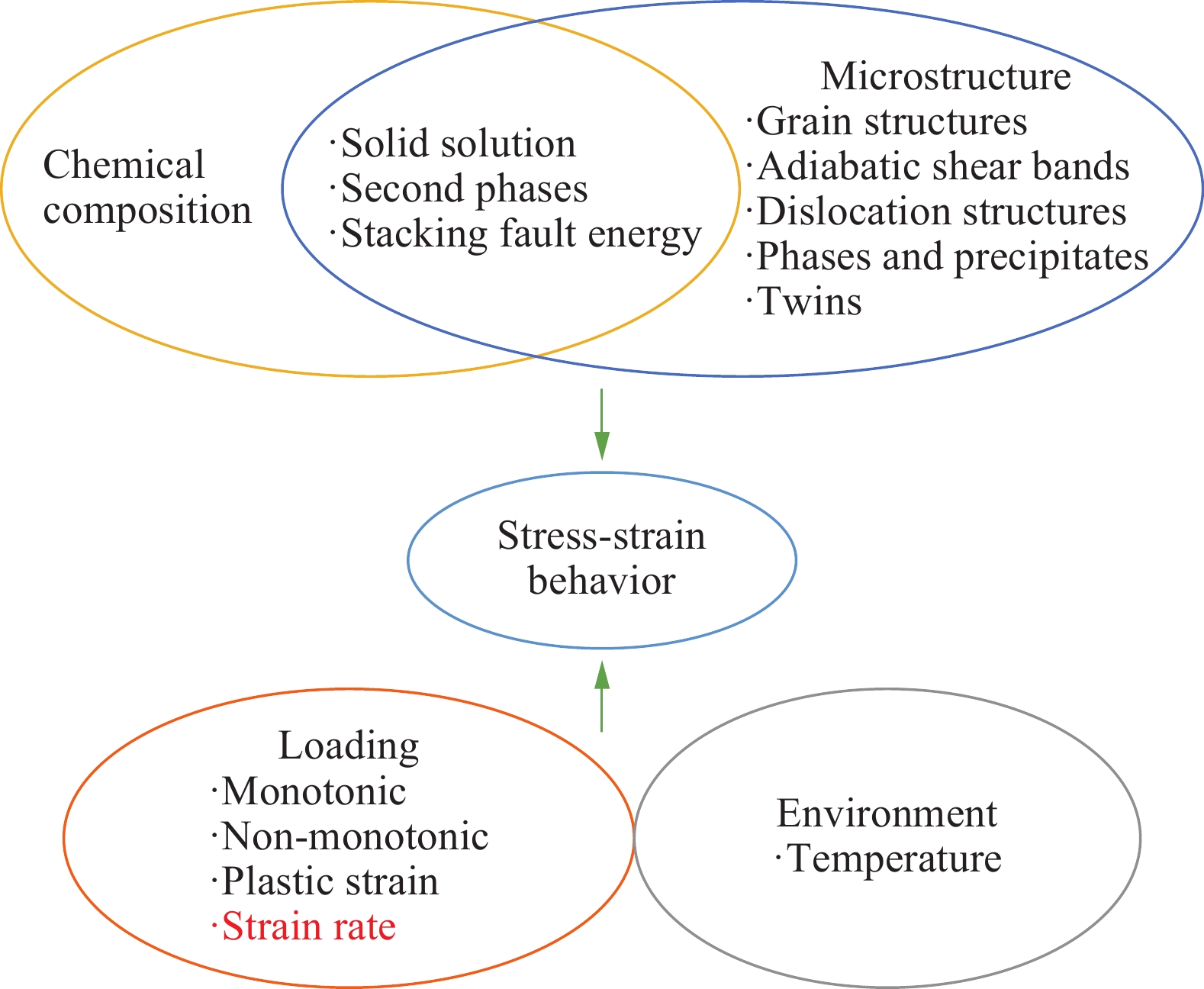

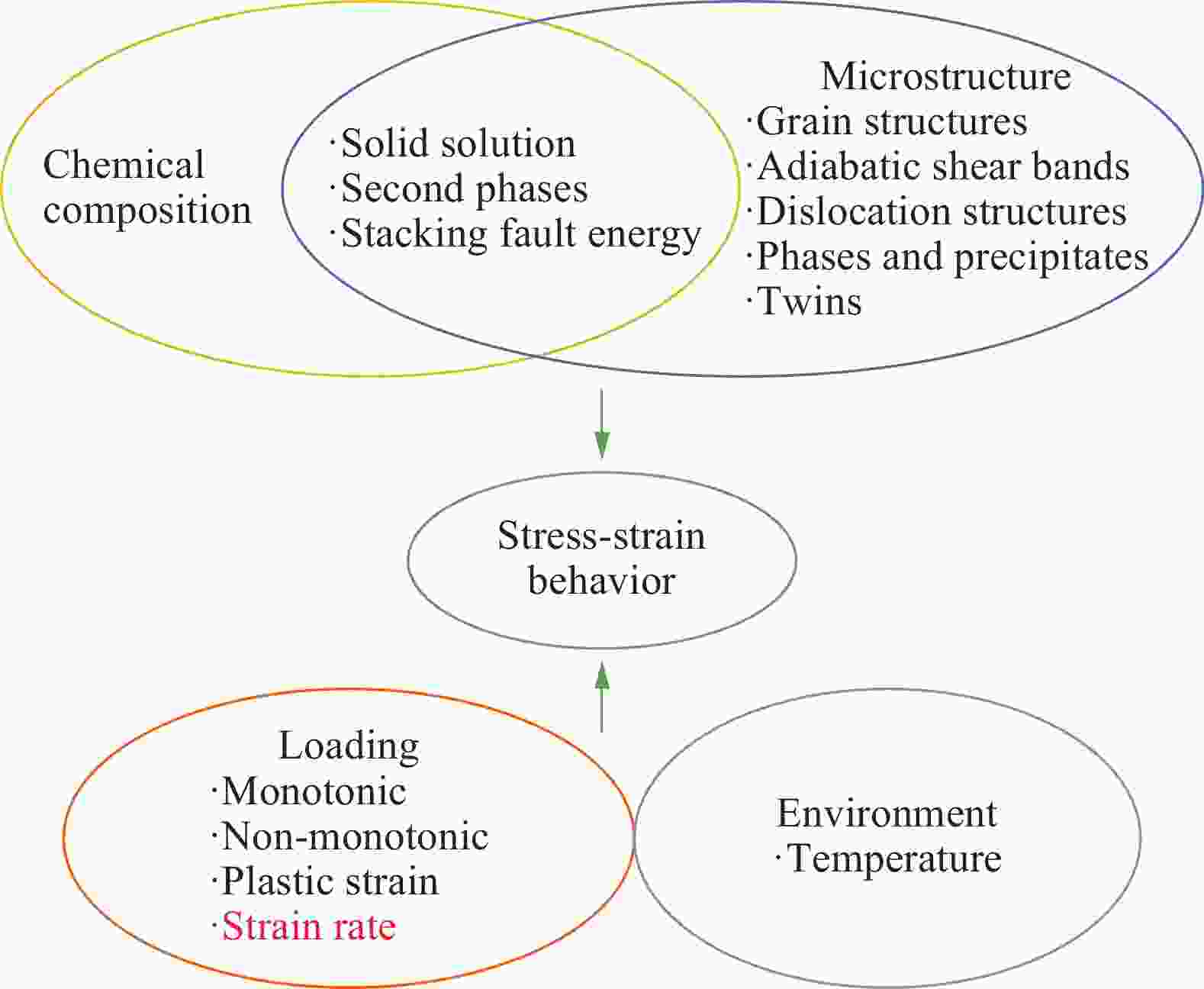

GRACIO J J, BARLAT F, RAUCH E, et al. A review of the relationship between microstructural features and the stress-strain behavior of metals [J]. Materialwissenschaft und Werkstofftechnik, 2005, 36(10): 572–577. DOI: 10.1002/mawe.200500916.

|

| [4] |

MIKHAYLOVSKAYA A, YAKOVTSEVA O, SITKINA M, et al. Grain-boundary and intragranular deformation in ultrafine-grained aluminum-based alloy at high strain rate [J]. Materials Letters, 2020, 276: 128242. DOI: 10.1016/j.matlet.2020.128242.

|

| [5] |

惠旭龙, 白春玉, 刘小川, 等. 宽应变率范围下2A16-T4铝合金动态力学性能 [J]. 爆炸与冲击, 2017, 37(5): 871–878. DOI: 10.11883/1001-1455(2017)05-0871-08.HUI X L, BAI C Y, LIU X C, et al. Dynamic mechanical properties of 2A16-T4 aluminum alloy at wide-ranging strain rates [J]. Explosion and Shock Waves, 2017, 37(5): 871–878. DOI: 10.11883/1001-1455(2017)05-0871-08.

|

| [6] |

惠旭龙, 白春玉, 葛宇静, 等. 2A16铝合金中应变率力学性能研究 [J]. 振动与冲击, 2017, 36(19): 66–70. DOI: 10.13465/j.cnki.jvs.2017.19.010.HUI X L, BAI C Y, GE Y J, et al. Dynamic properties of 2A16 aluminum alloy under intermediate strain rate [J]. Journal of Vibration and Shock, 2017, 36(19): 66–70. DOI: 10.13465/j.cnki.jvs.2017.19.010.

|

| [7] |

EL-ATY A A, XU Y, ZHANG S H, et al. Impact of high strain rate deformation on the mechanical behavior, fracture mechanisms and anisotropic response of 2060 Al-Cu-Li alloy [J]. Journal of Advanced Research, 2019, 18: 19–37. DOI: 10.1016/j.jare.2019.01.012.

|

| [8] |

ANDRADE U R, MEYERS M A, CHOKSHI A H. Constitutive description of work- and shock-hardened copper [J]. Scripta Metallurgica et Materialia, 1994, 30(7): 933–938. DOI: 10.1016/0956-716X(94)90418-9.

|

| [9] |

JOHNSON G R, HOLMQUIST T J. Evaluation of cylinder-impact test data for constitutive model constants [J]. Journal of Applied Physics, 1988, 64(8): 3901–3910. DOI: 10.1063/1.341344.

|

| [10] |

RULE W K, JONES S E. A revised form for the Johnson−Cook strength model [J]. International Journal of Impact Engineering, 1998, 21(8): 609–624. DOI: 10.1016/S0734-743X(97)00081-X.

|

| [11] |

高宁, 朱志武. 铝合金应变率效应综述及其机理研究 [J]. 应用数学和力学, 2014, 35(S1): 208–212.GAO N, ZHU Z W. Study on the strain rate effects and mechanisms for aluminum alloys [J]. Applied Mathematics and Mechanics, 2014, 35(S1): 208–212.

|

| [12] |

ZERILLI F J, ARMSTRONG R W. Dislocation-mechanics-based constitutive relations for material dynamics calculations [J]. Journal of Applied Physics, 1987, 61(5): 1816–1825. DOI: 10.1063/1.338024.

|

| [13] |

JIAO M Y, MA L F, JIA W T, et al. A new phenomenological model describing the compressive thermal deformation flow stress of cast-rolled AZ31B Mg alloy [J]. Materials Research Express, 2019, 6(9): 096597. DOI: 10.1088/2053-1591/ab30ae.

|

| [14] |

ZERILLI F J, ARMSTRONG R W. Description of tantalum deformation behavior by dislocation mechanics based constitutive relations [J]. Journal of Applied Physics, 1990, 68(4): 1580–1591. DOI: 10.1063/1.346636.

|

| [15] |

ZERILLI F J, ARMSTRONG R W. The effect of dislocation drag on the stress-strain behavior of FCC metals [J]. Acta Metallurgica et Materialia, 1992, 40(8): 1803–1808. DOI: 10.1016/0956-7151(92)90166-C.

|

| [16] |

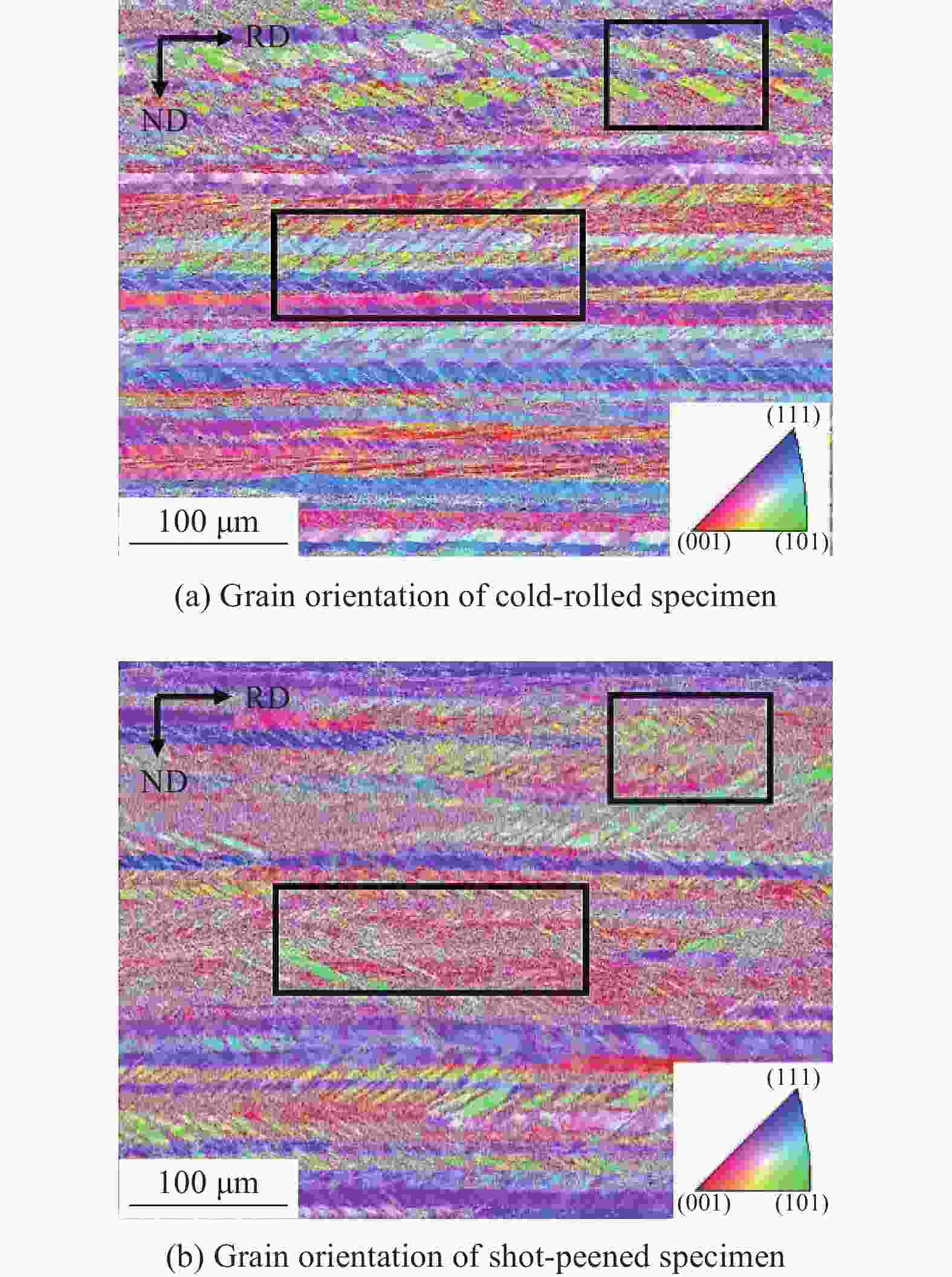

马鸣图, 李洁, 赵岩, 等. 汽车用金属材料在高应变速率下响应特性的研究进展 [J]. 机械工程材料, 2017, 41(9): 1–13, 24. DOI: 10.11973/jxgccl201709001.MA M T, LI J, ZHAO Y, et al. Research progress of response characteristics of metallic materials for automotive under high strain rates [J]. Materials for Mechanical Engineering, 2017, 41(9): 1–13, 24. DOI: 10.11973/jxgccl201709001.

|

| [17] |

朱建士, 胡晓棉, 王裴, 等. 爆炸与冲击动力学若干问题研究进展 [J]. 力学进展, 2010, 40(4): 400–423. DOI: 10.6052/1000-0992-2010-4-j2009-144.ZHU J S, HU X M, WANG P, et al. A review on research progress in explosion mechanics and impact dynamics [J]. Advances in Mechanics, 2010, 40(4): 400–423. DOI: 10.6052/1000-0992-2010-4-j2009-144.

|

| [18] |

卢泓昱, 刘志奇, 宋建丽, 等. 花键冷敲成形本构关系研究 [J]. 太原科技大学学报, 2015, 36(3): 184–189. DOI: 10.3969/j.issn.1673-2057.2015.03.005.LU H Y, LIU Z Q, SONG J L, et al. Study of constitutive relation in cold rolling spline [J]. Journal of Taiyuan University of Science and Technology, 2015, 36(3): 184–189. DOI: 10.3969/j.issn.1673-2057.2015.03.005.

|

| [19] |

KIM J B, SHIN H. Comparison of plasticity models for tantalum and a modification of the PTW model for wide ranges of strain, strain rate, and temperature [J]. International Journal of Impact Engineering, 2009, 36(5): 746–753. DOI: 10.1016/j.ijimpeng.2008.11.003.

|

| [20] |

刘旭红, 黄西成, 陈裕泽, 等. 强动载荷下金属材料塑性变形本构模型评述 [J]. 力学进展, 2007, 37(3): 361–374. DOI: 10.6052/1000-0992-2007-3-J2006-184.LIU X H, HUANG X C, CHEN Y Z, et al. A review on constitutive models for plastic deformation of metal materials under dynamic loading [J]. Advances in Mechanics, 2007, 37(3): 361–374. DOI: 10.6052/1000-0992-2007-3-J2006-184.

|

| [21] |

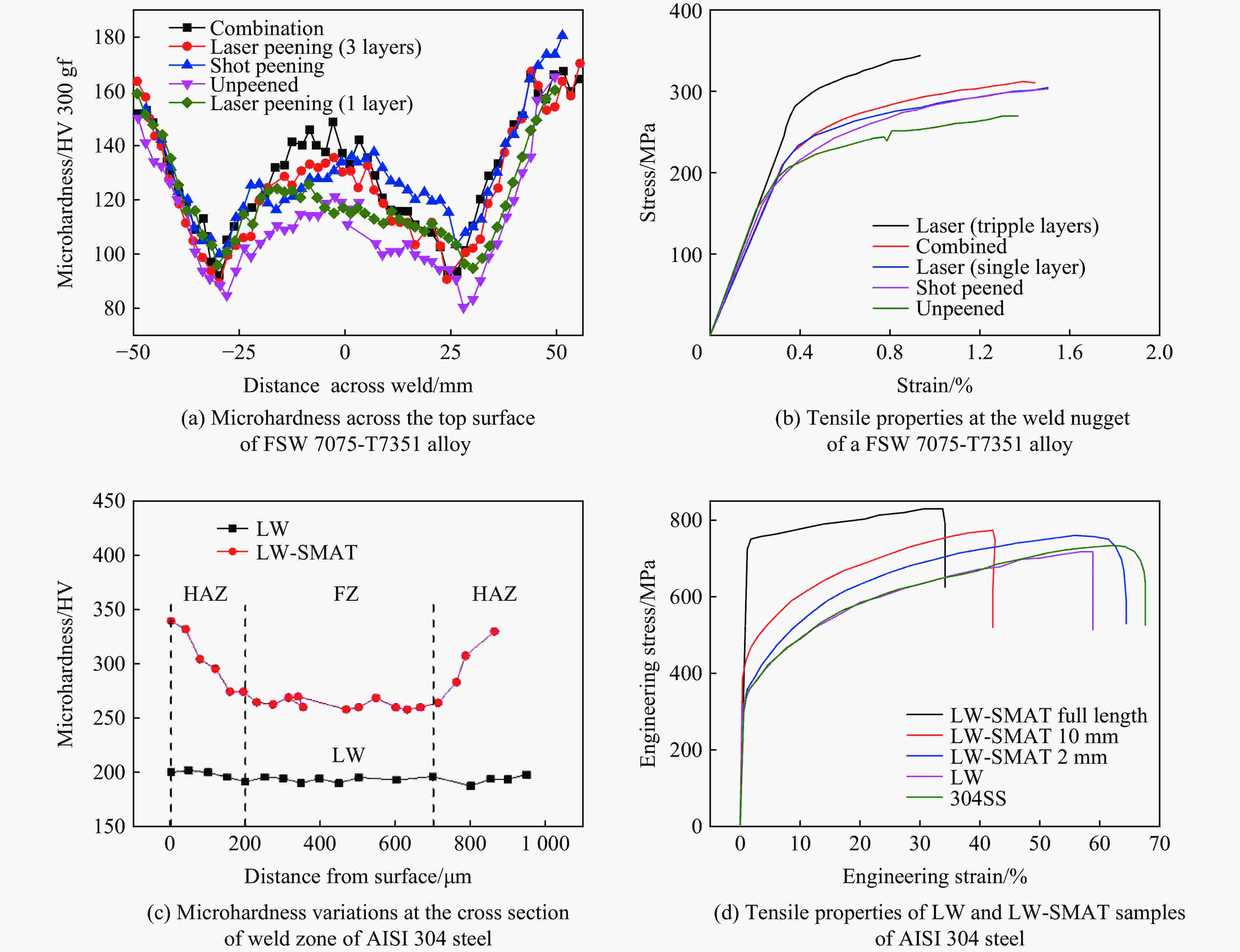

HATAMLEH O. The effects of laser peening and shot peening on mechanical properties in friction stir welded 7075-T7351 aluminum [J]. Journal of Materials Engineering and Performance, 2008, 17(5): 688–694. DOI: 10.1007/s11665-007-9163-7.

|

| [22] |

KHUN N W, TRUNG P Q, BUTLER D L. Mechanical and tribological properties of shot-peened SAE 1070 steel [J]. Tribology Transactions, 2016, 59(5): 932–943. DOI: 10.1080/10402004.2015.1121313.

|

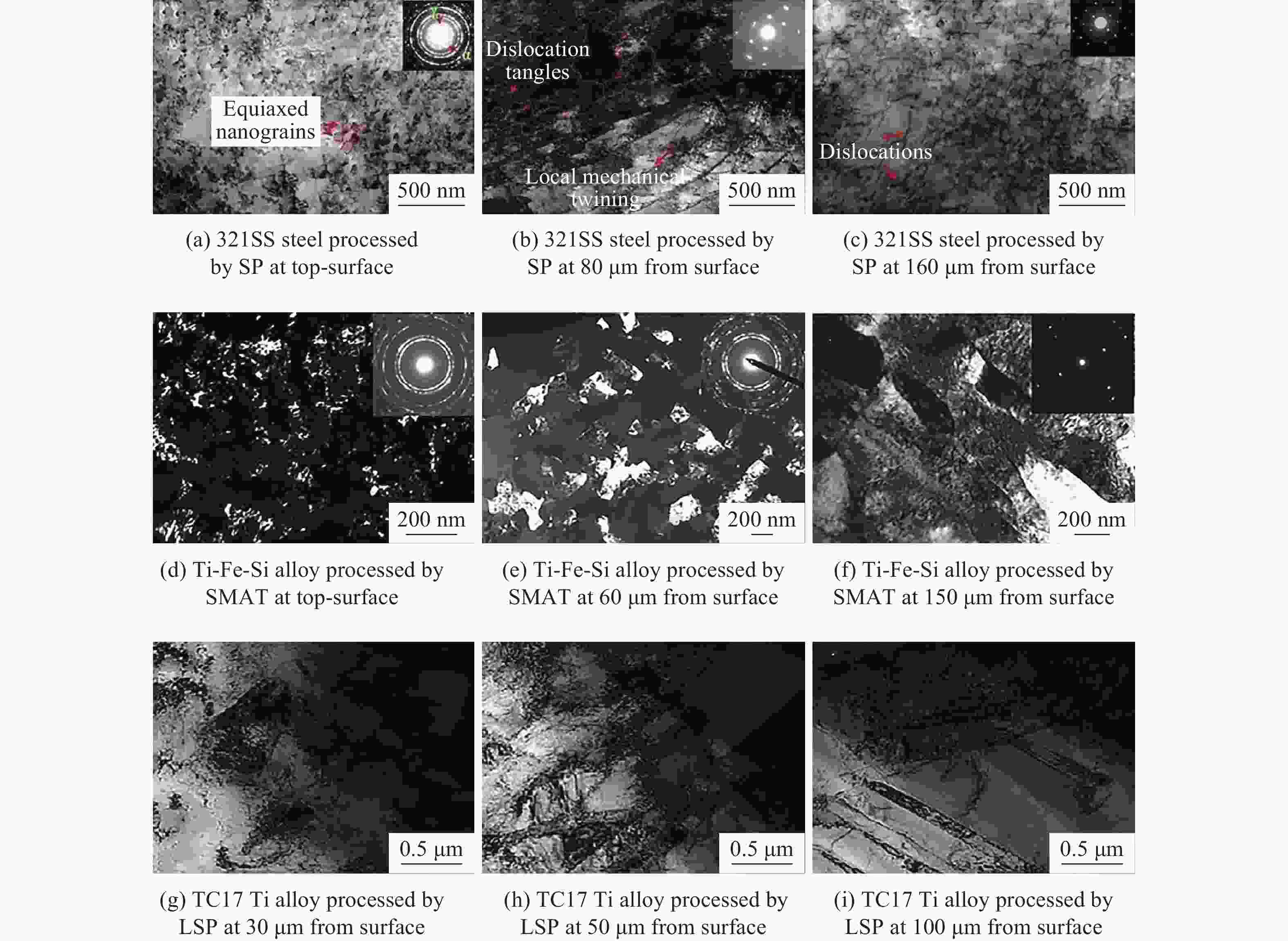

| [23] |

CHEN A Y, JIA Y Q, PAN D, et al. Reinforcement of laser-welded stainless steels by surface mechanical attrition treatment [J]. Materials Science and Engineering: A, 2013, 571: 161–166. DOI: 10.1016/j.msea.2013.02.018.

|

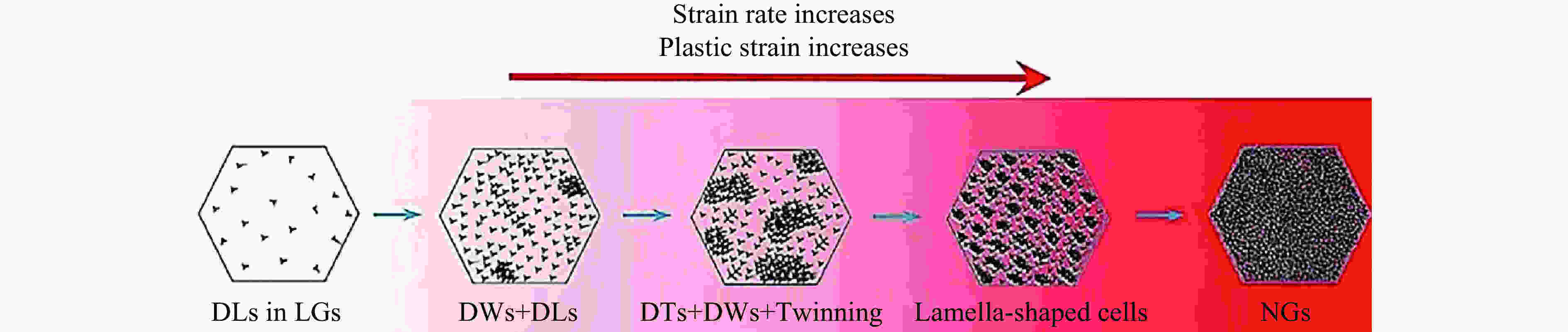

| [24] |

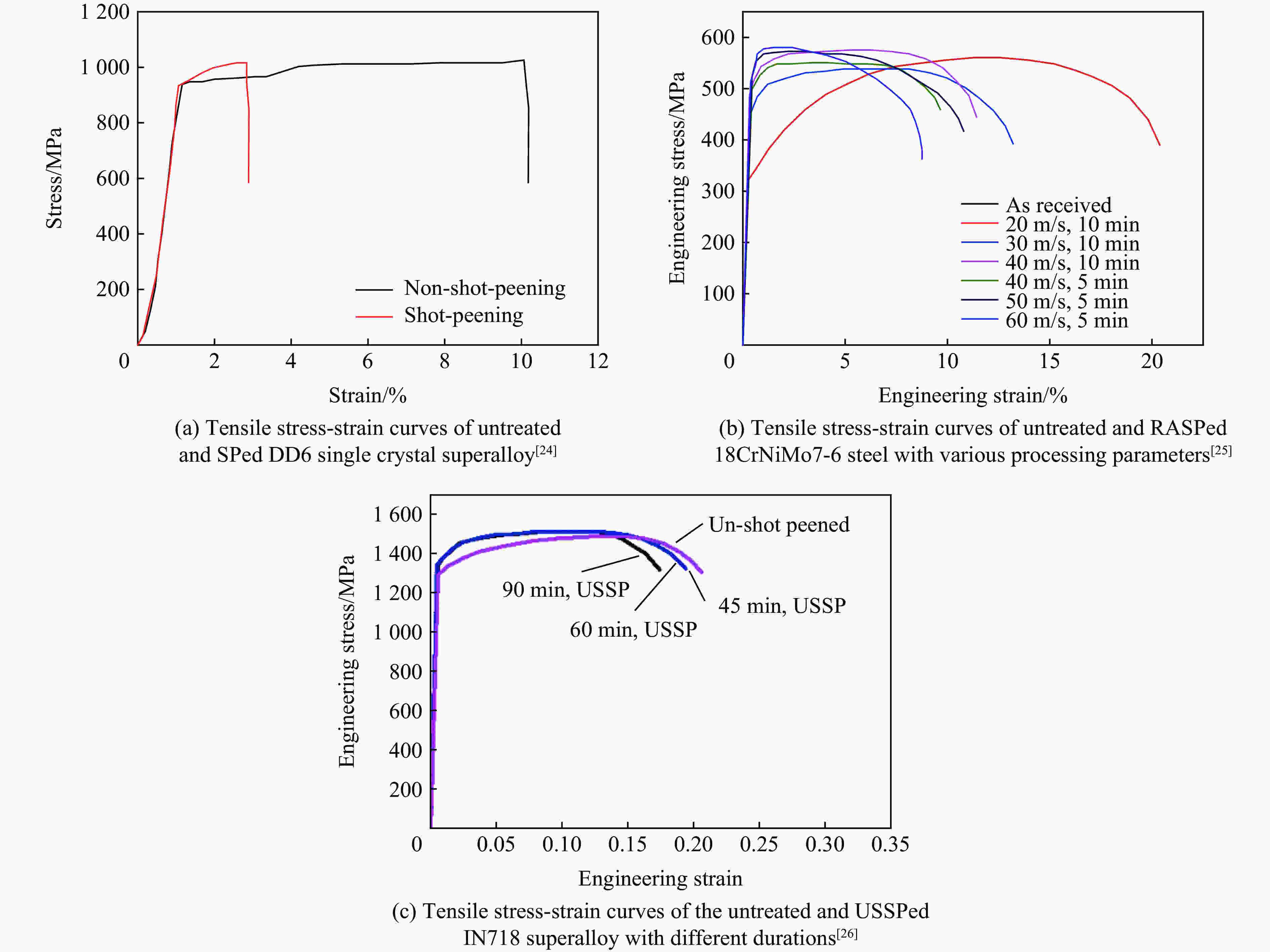

韩梅, 喻健, 李嘉荣, 等. 喷丸对DD6单晶高温合金拉伸性能的影响 [J]. 材料工程, 2019, 47(8): 169–175. DOI: 10.11868/j.issn.1001-4381.2019.000191.HAN M, YU J, LI J R, et al. Influence of shot peening on tensile properties of DD6 single crystal superalloy [J]. Journal of Materials Engineering, 2019, 47(8): 169–175. DOI: 10.11868/j.issn.1001-4381.2019.000191.

|

| [25] |

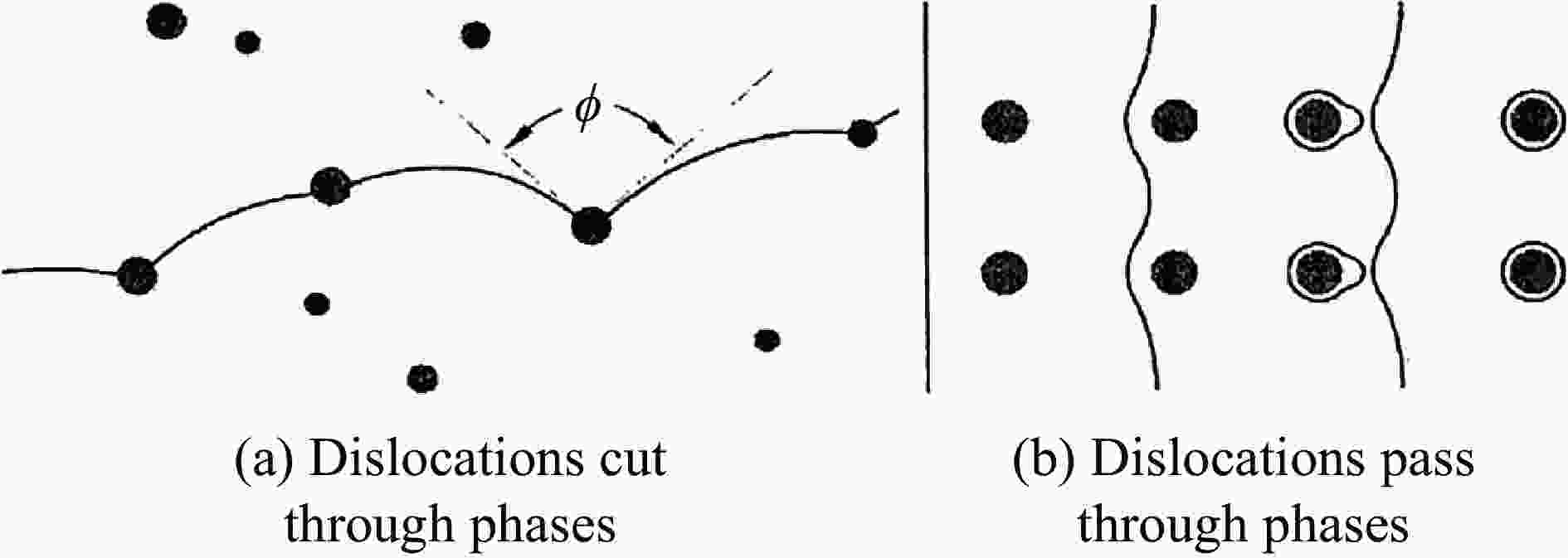

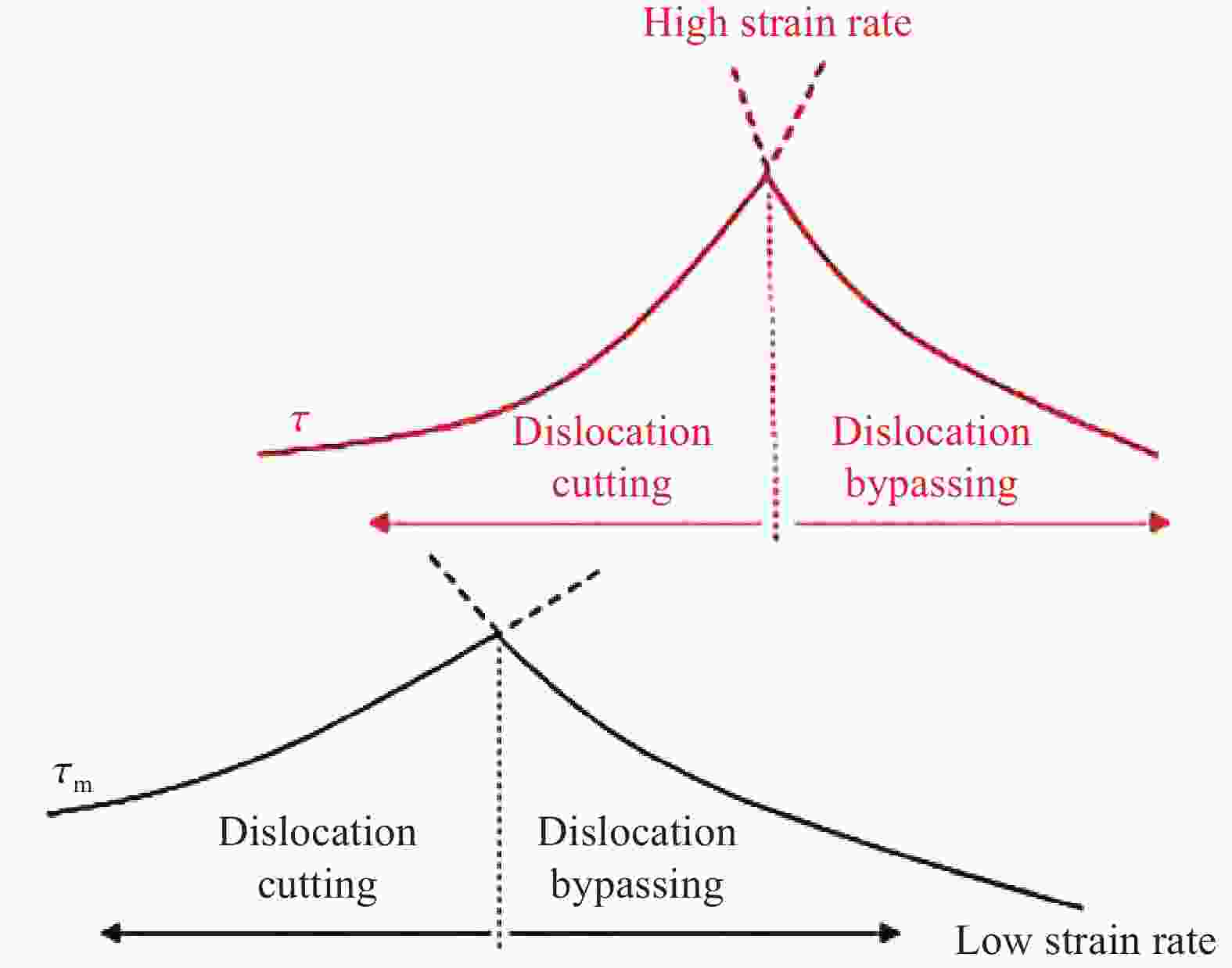

朱敏, 吴桂林, 李玉胜, 等. 旋转加速喷丸处理18CrNiMo7-6钢的微观结构与力学性能 [J]. 材料导报, 2018, 32(10): 1645–1649, 1662. DOI: 10.11896/j.issn.1005-023X.2018.10.014.ZHU M, WU G L, LI Y S, et al. Microstructure and mechanical properties of 18CrNiMo7-6 steel processed by rotationally accelerated shot peening [J]. Materials Reports, 2018, 32(10): 1645–1649, 1662. DOI: 10.11896/j.issn.1005-023X.2018.10.014.

|

| [26] |

KUMAR S, RAO G S, CHATTOPADHYAY K, et al. Effect of surface nanostructure on tensile behavior of superalloy IN718 [J]. Materials & Design, 2014, 62: 76–82. DOI: 10.1016/j.matdes.2014.04.084.

|

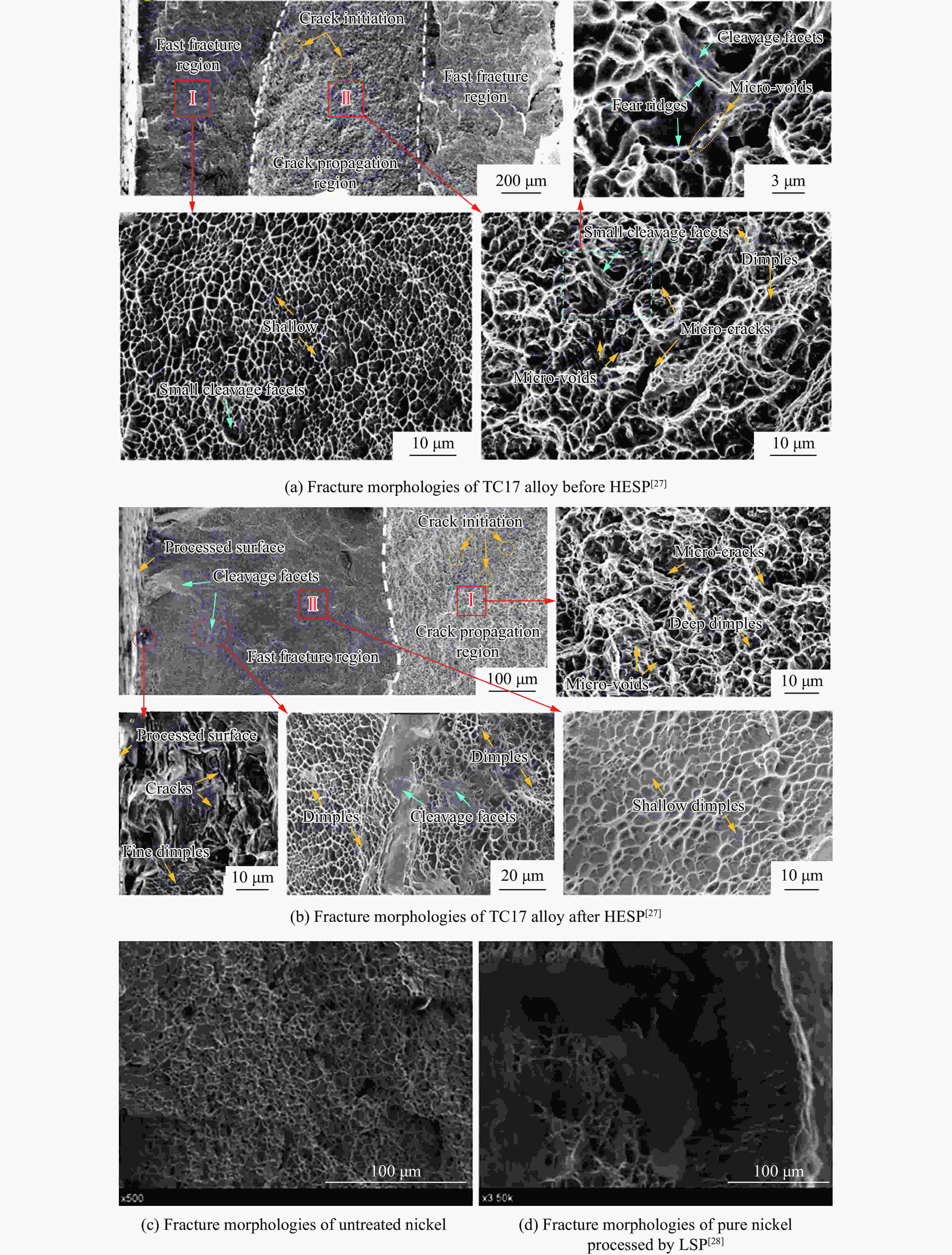

| [27] |

YANG C, LIU Y G, SHI Y H, et al. Microstructure characterization and tensile properties of processed TC17 via high energy shot peening [J]. Materials Science and Engineering: A, 2020, 784: 139298. DOI: 10.1016/j.msea.2020.139298.

|

| [28] |

ZHOU W F, REN X D, YANG Y, et al. Tensile behavior of nickel with gradient microstructure produced by laser shock peening [J]. Materials Science and Engineering: A, 2020, 771: 138603. DOI: 10.1016/j.msea.2019.138603.

|

| [29] |

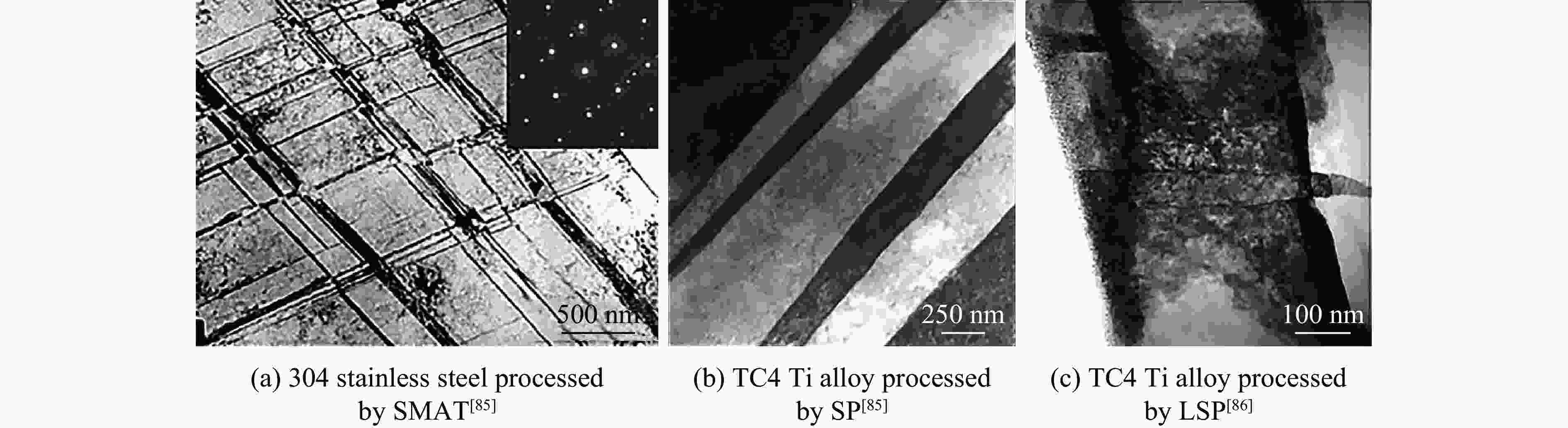

LU K. Making strong nanomaterials ductile with gradients [J]. Science, 2014, 345(6203): 1455–1456. DOI: 10.1126/science.1255940.

|

| [30] |

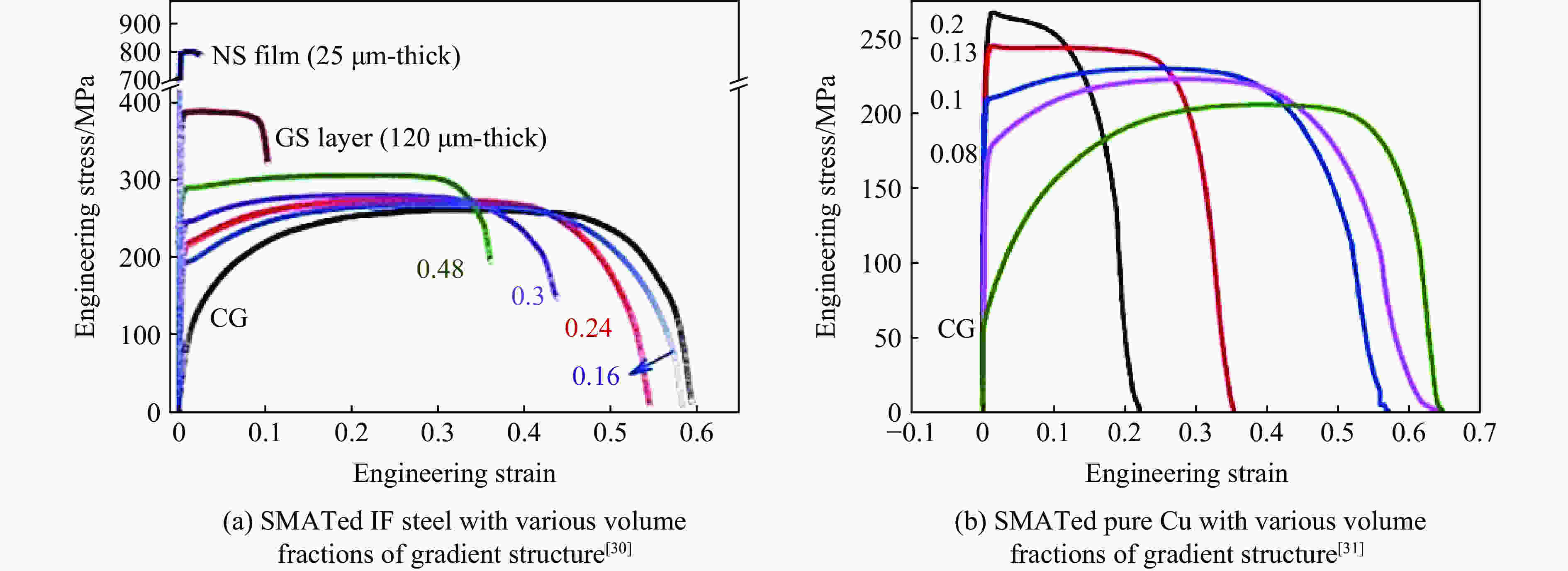

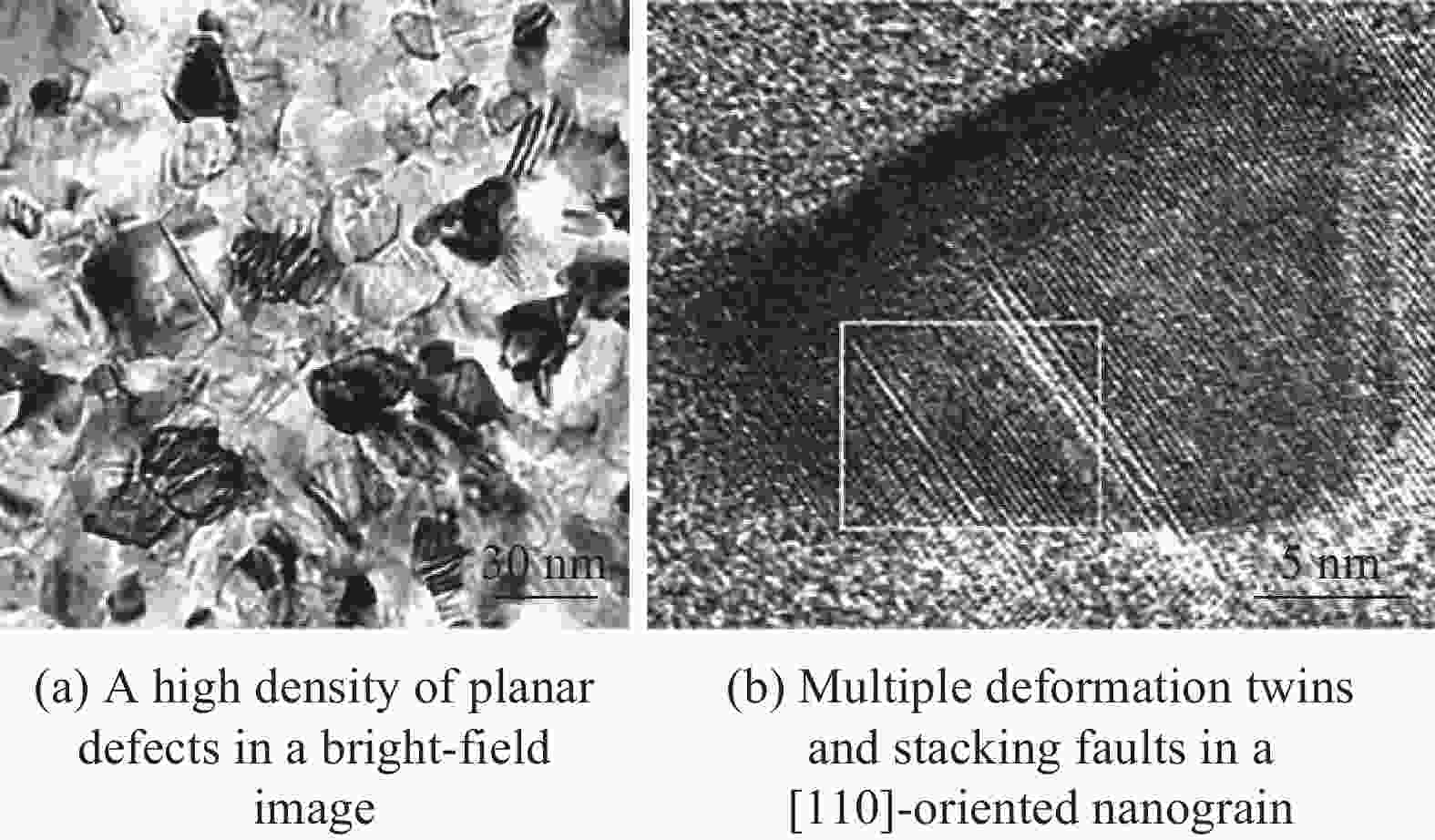

WU X L, JIANG P, CHEN L, et al. Synergetic strengthening by gradient structure [J]. Materials Research Letters, 2014, 2(4): 185–191. DOI: 10.1080/21663831.2014.935821.

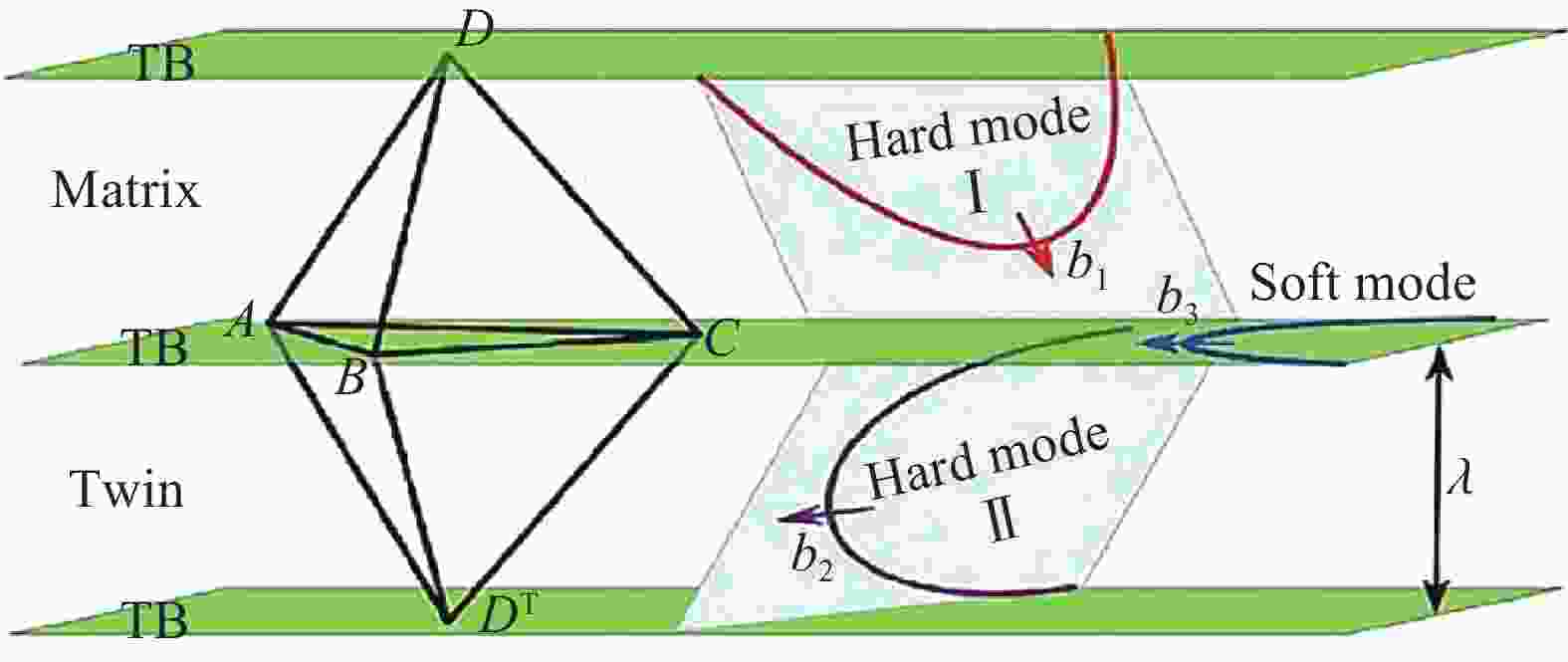

|

| [31] |

YANG X C, MA X L, MOERING J, et al. Influence of gradient structure volume fraction on the mechanical properties of pure copper [J]. Materials Science and Engineering: A, 2015, 645: 280–285. DOI: 10.1016/j.msea.2015.08.037.

|

| [32] |

高玉魁. 表面完整性理论与应用[M]. 北京: 化学工业出版社, 2014: 4−9.

|

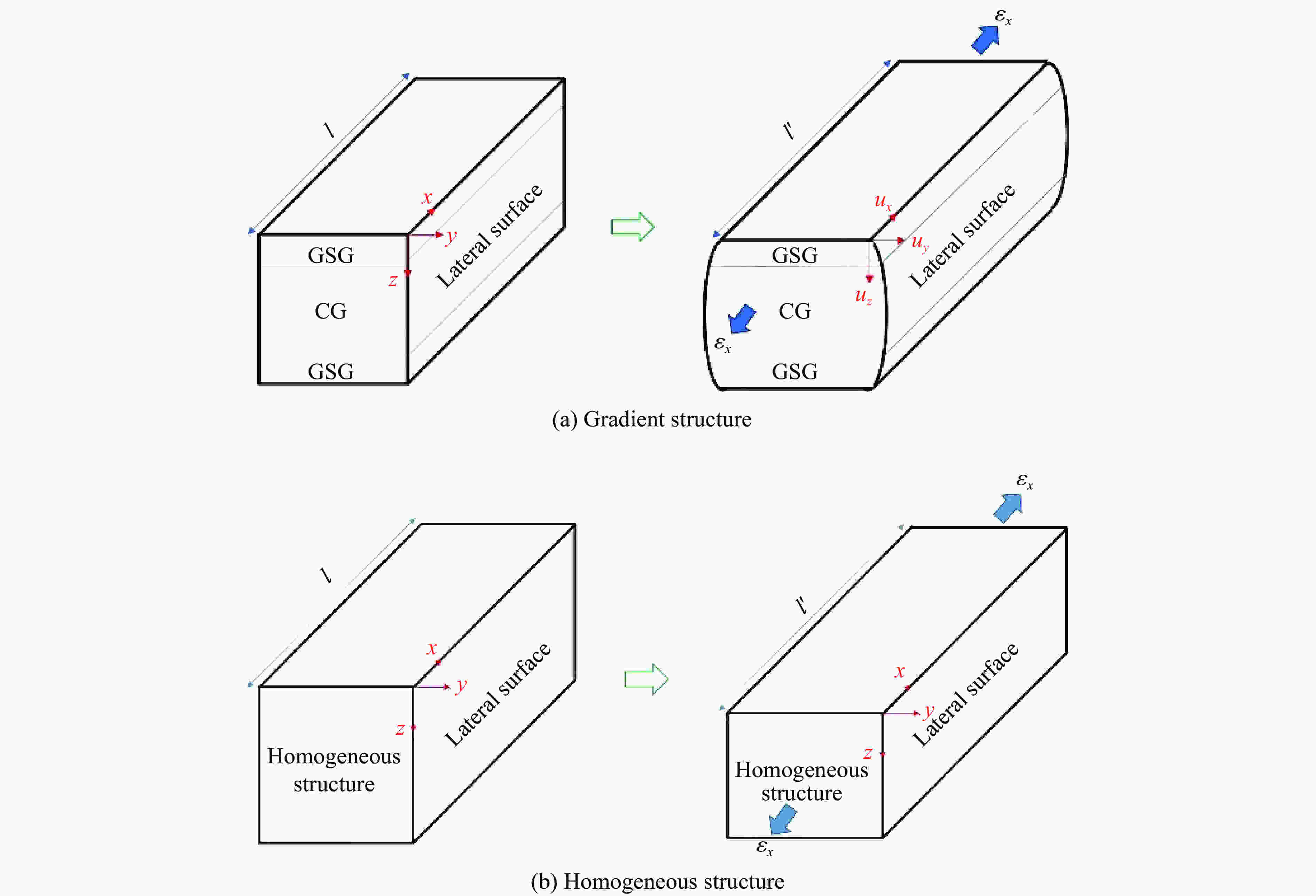

| [33] |

FENG X, SUN Y P, ZHOU S P, et al. Influence of strain rate on microstructures and mechanical properties of 2524Al alloy fabricated by a novel large strain rolling [J]. Materials Research Express, 2020, 7(2): 026519. DOI: 10.1088/2053-1591/ab70e0.

|

| [34] |

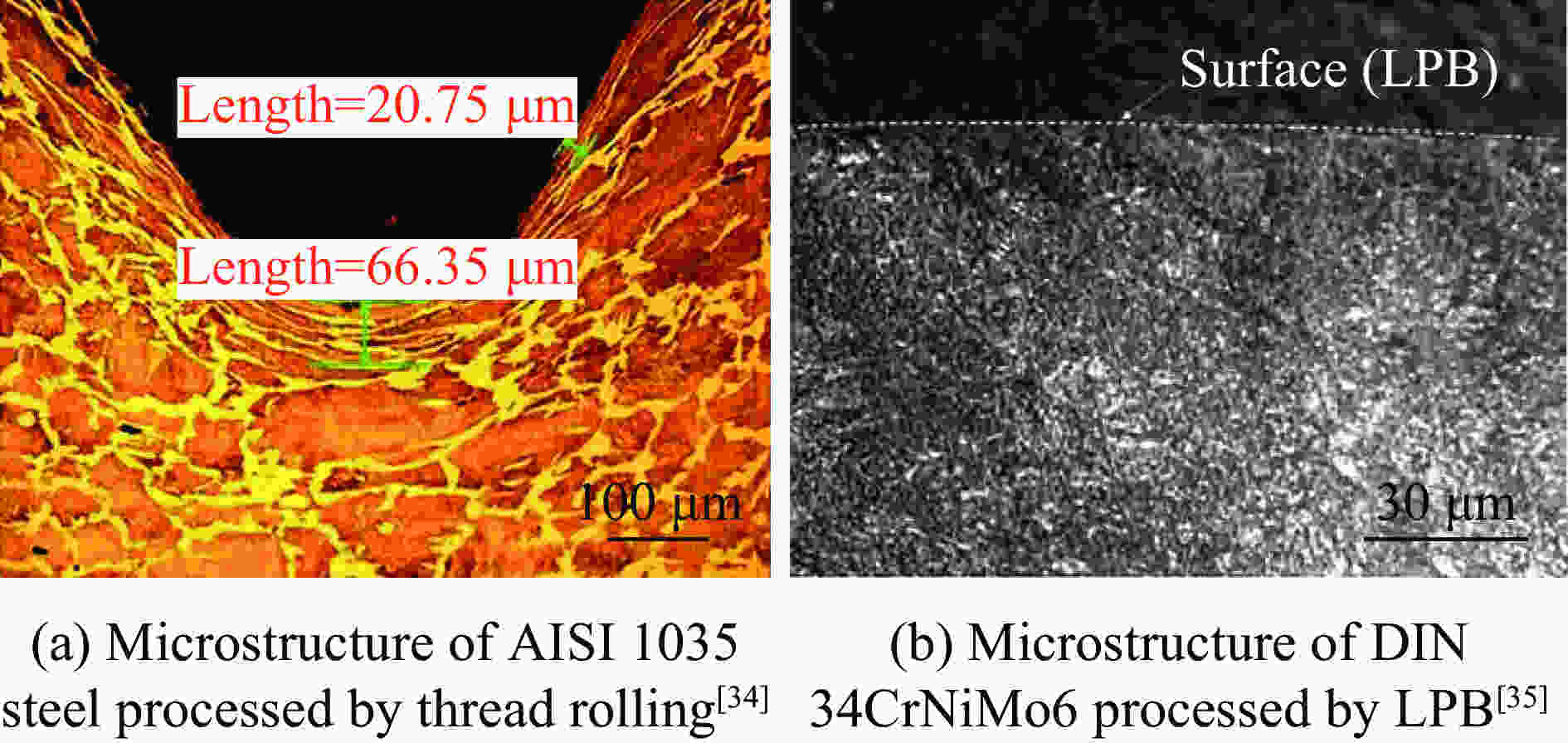

ZHANG S W, ZHANG D W, WANG Y F, et al. The planetary rolling process of forming the internal thread [J]. The International Journal of Advanced Manufacturing Technology, 2020, 107(7-8): 3543–3551. DOI: 10.1007/s00170-020-05289-8.

|

| [35] |

高玉魁, 柳鸿飞. 低塑性抛光技术对材料表面完整性影响的研究进展 [J]. 航空制造技术, 2019, 62(18): 14–22. DOI: 10.16080/j.issn1671-833x.2019.18.014.GAO Y K, LIU H F. Research progress of low plasticity burnishing on surface integrity of materials [J]. Aeronautical Manufacturing Technology, 2019, 62(18): 14–22. DOI: 10.16080/j.issn1671-833x.2019.18.014.

|

| [36] |

孟丽君. 应变速率对强塑性变形晶粒细化的影响[D]. 太原: 太原理工大学, 2006: 27−43.

|

| [37] |

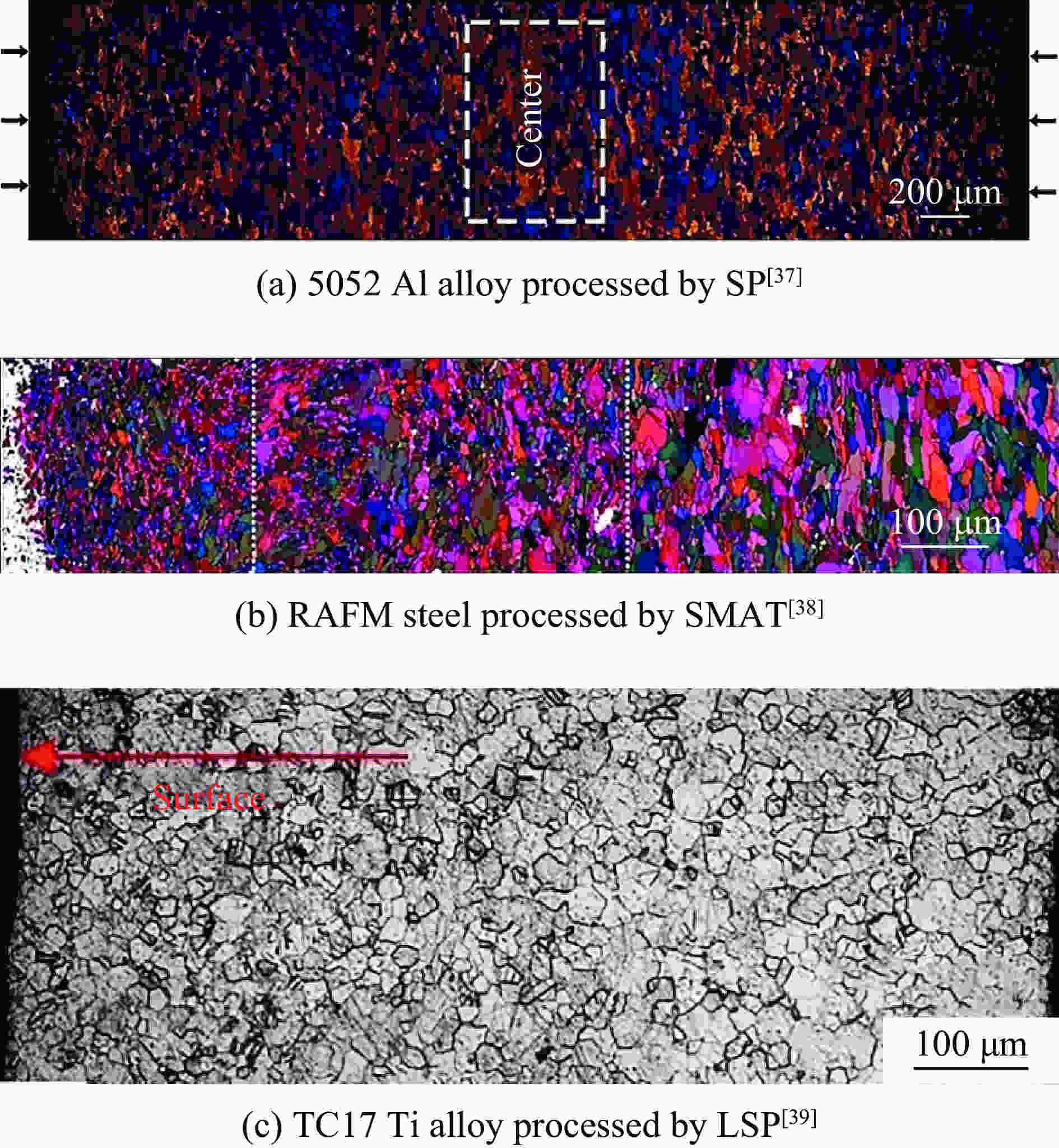

LI Y S, LI L Z, NIE J F, et al. Microstructural evolution and mechanical properties of a 5052 Al alloy with gradient structures [J]. Journal of Materials Research, 2017, 32(23): 4443–4451. DOI: 10.1557/jmr.2017.310.

|

| [38] |

LIU W B, JIN X, ZHANG B, et al. A coupled EBSD/TEM analysis of the microstructure evolution of a gradient nanostructured ferritic/martensitic steel subjected to surface mechanical attrition treatment [J]. Materials, 2019, 12(1): 140. DOI: 10.3390/ma12010140.

|

| [39] |

YANG Y, ZHANG H, QIAO H C. Microstructure characteristics and formation mechanism of TC17 titanium alloy induced by laser shock processing [J]. Journal of Alloys and Compounds, 2017, 722: 509–516. DOI: 10.1016/j.jallcom.2017.06.127.

|

| [40] |

ZHANG X D, HANSEN N, GAO Y K, et al. Hall-Petch and dislocation strengthening in graded nanostructured steel [J]. Acta Materialia, 2012, 60(16): 5933–5943. DOI: 10.1016/j.actamat.2012.07.037.

|

| [41] |

CHEN M W, MA E, HEMKER K J, et al. Deformation twinning in nanocrystalline aluminum [J]. Science, 2003, 300(5623): 1275–1277. DOI: 10.1126/science.1083727.

|

| [42] |

XIAO X D, SUN Y, YANG Z C, et al. Dynamic response of target with different peening media [J]. Surface Engineering, 2020, 36(4): 386–396. DOI: 10.1080/02670844.2019.1624302.

|

| [43] |

GURAO N P, KAPOOR R, SUWAS S. Texture evolution in high strain rate deformed Cu-10Zn alloy [J]. Materials Science and Engineering: A, 2012, 558: 761–765. DOI: 10.1016/j.msea.2012.07.112.

|

| [44] |

PANDEY A, KHAN A S, KIM E Y, et al. Experimental and numerical investigations of yield surface, texture, and deformation mechanisms in AA5754 over low to high temperatures and strain rates [J]. International Journal of Plasticity, 2013, 41: 165–188. DOI: 10.1016/j.ijplas.2012.09.006.

|

| [45] |

CANOVA G R, FRESSENGEAS C, MOLINARI A, et al. Effect of rate sensitivity on slip system activity and lattice rotation [J]. Acta Metallurgica, 1988, 36(8): 1961–1970. DOI: 10.1016/0001-6160(88)90298-2.

|

| [46] |

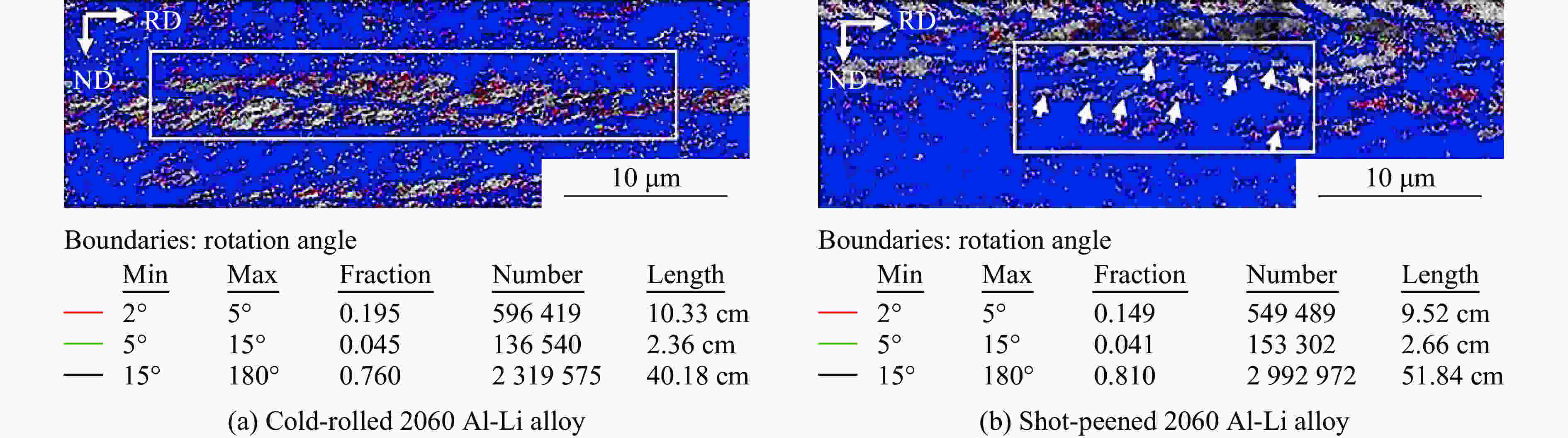

TAO X F, GAO Y K, KANG J M, et al. Softening effects induced by shot peening for an aluminum-lithium alloy [J]. Metallurgical and Materials Transactions A, 2020, 51(1): 410–418. DOI: 10.1007/s11661-019-05506-4.

|

| [47] |

邹途祥. 纯铝的晶粒细化机制及动态力学性能的研究[D]. 太原: 太原理工大学, 2008: 63.

|

| [48] |

HEMKER K J. Understanding how nanocrystalline metals deform [J]. Science, 2004, 304(5668): 221–223. DOI: 10.1126/science.1097058.

|

| [49] |

SCHIØTZ J, JACOBSEN K W. A maximum in the strength of nanocrystalline copper [J]. Science, 2003, 301(5638): 1357–1359. DOI: 10.1126/science.1086636.

|

| [50] |

YANG C F, PAN J H, LEE T H. Work-softening and anneal-hardening behaviors in fine-grained Zn-Al alloys [J]. Journal of Alloys and Compounds, 2009, 468(1–2): 230–236. DOI: 10.1016/j.jallcom.2008.01.067.

|

| [51] |

ZHANG W L, HE L J, LU Z G, et al. Microstructural characteristics and formation mechanism of adiabatic shear bands in Al-Zn-Mg-Cu alloy under dynamic shear loading [J]. Materials Science and Engineering: A, 2020, 791: 139430. DOI: 10.1016/j.msea.2020.139430.

|

| [52] |

KHAN M A, WANG Y W, YASIN G, et al. Adiabatic shear band localization in an Al-Zn-Mg-Cu alloy under high strain rate compression [J]. Journal of Materials Research and Technology, 2020, 9(3): 3977–3983. DOI: 10.1016/j.jmrt.2020.02.024.

|

| [53] |

NIE Y, CLAUS B, GAO J, et al. In situ observation of adiabatic shear band formation in aluminum alloys [J]. Experimental Mechanics, 2020, 60(2): 153–163. DOI: 10.1007/s11340-019-00544-w.

|

| [54] |

OWOLABI G M, ODESHI A G, SINGH M N K, et al. Dynamic shear band formation in aluminum 6061-T6 and aluminum 6061-T6/Al2O3 composites [J]. Materials Science and Engineering: A, 2007, 457(1-2): 114–119. DOI: 10.1016/j.msea.2006.12.034.

|

| [55] |

XIONG Y Y, LI N, JIANG H W, et al. Microstructural Evolutions of AA7055 aluminum alloy under dynamic and quasi-static compressions [J]. Acta Metallurgica Sinica (English Letters), 2014, 27(2): 272–278. DOI: 10.1007/s40195-014-0041-7.

|

| [56] |

王礼立. 冲击载荷下的材料动态失稳和动态屈服 [J]. 力学学报, 1989, 21(S1): 142–147. DOI: 10.6052/0459-1879-1989-s1-1989-249.WANG L L. The dynamic instability and dynamic yield of materials under impact loading [J]. Acta Mechanica Sinica, 1989, 21(S1): 142–147. DOI: 10.6052/0459-1879-1989-s1-1989-249.

|

| [57] |

高玉魁. 冲击强化对304奥氏体不锈钢拉伸性能的影响 [J]. 材料工程, 2014(8): 36–40. DOI: 10.11868/j.issn.1001-4381.2014.08.007.GAO Y K. Influence of impact enhancements on tensile property of 304 austenite steel [J]. Journal of Materials Engineering, 2014(8): 36–40. DOI: 10.11868/j.issn.1001-4381.2014.08.007.

|

| [58] |

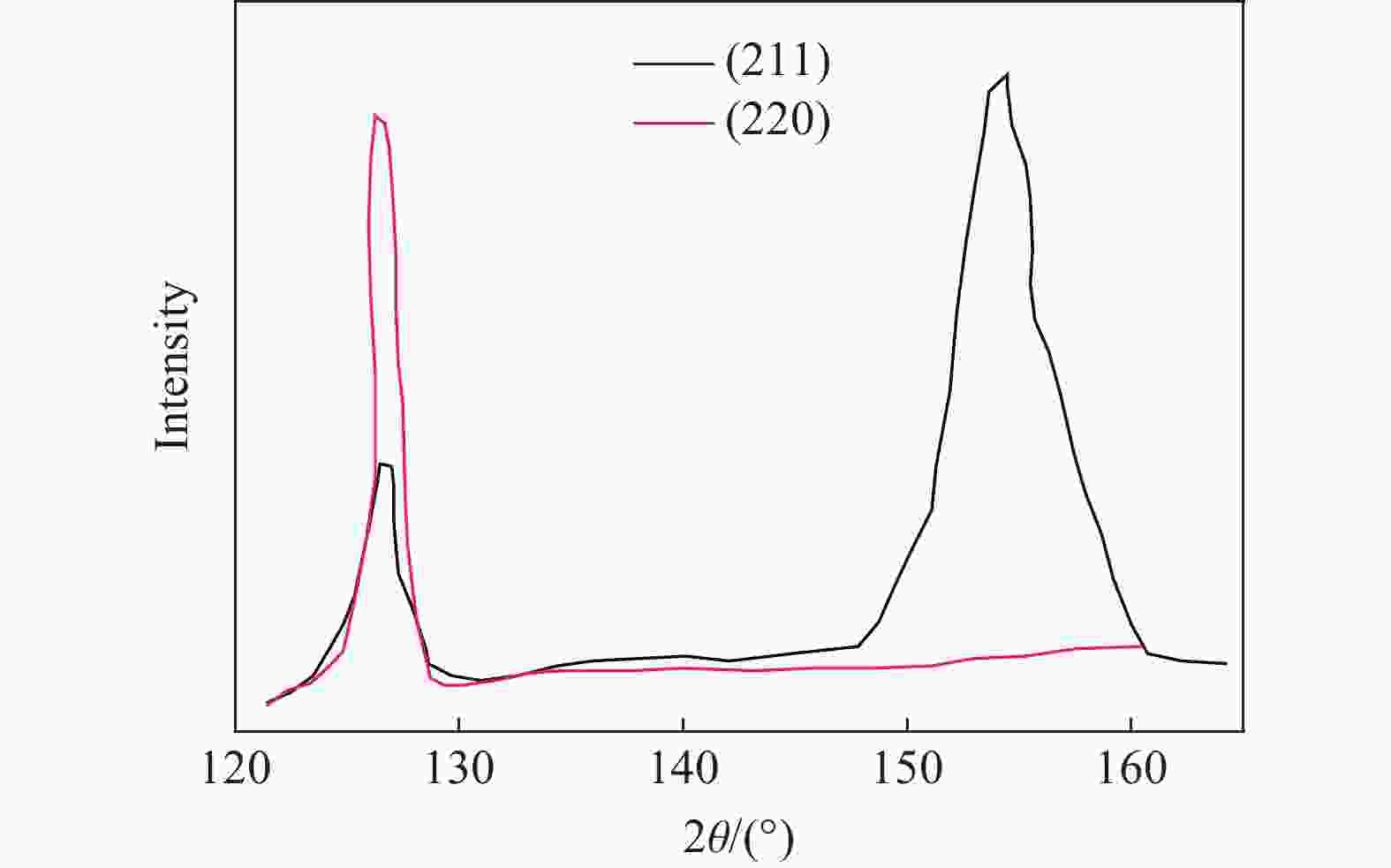

STARMAN B, HALLBERG H, WALLIN M, et al. Differences in phase transformation in laser peened and shot peened 304 austenitic steel [J]. International Journal of Mechanical Sciences, 2020, 176: 105535. DOI: 10.1016/j.ijmecsci.2020.105535.

|

| [59] |

LUO K Y, LU J Z, ZHANG Y K, et al. Effects of laser shock processing on mechanical properties and micro-structure of ANSI 304 austenitic stainless steel [J]. Materials Science and Engineering: A, 2011, 528(13–14): 4783–4788. DOI: 10.1016/j.msea.2011.03.041.

|

| [60] |

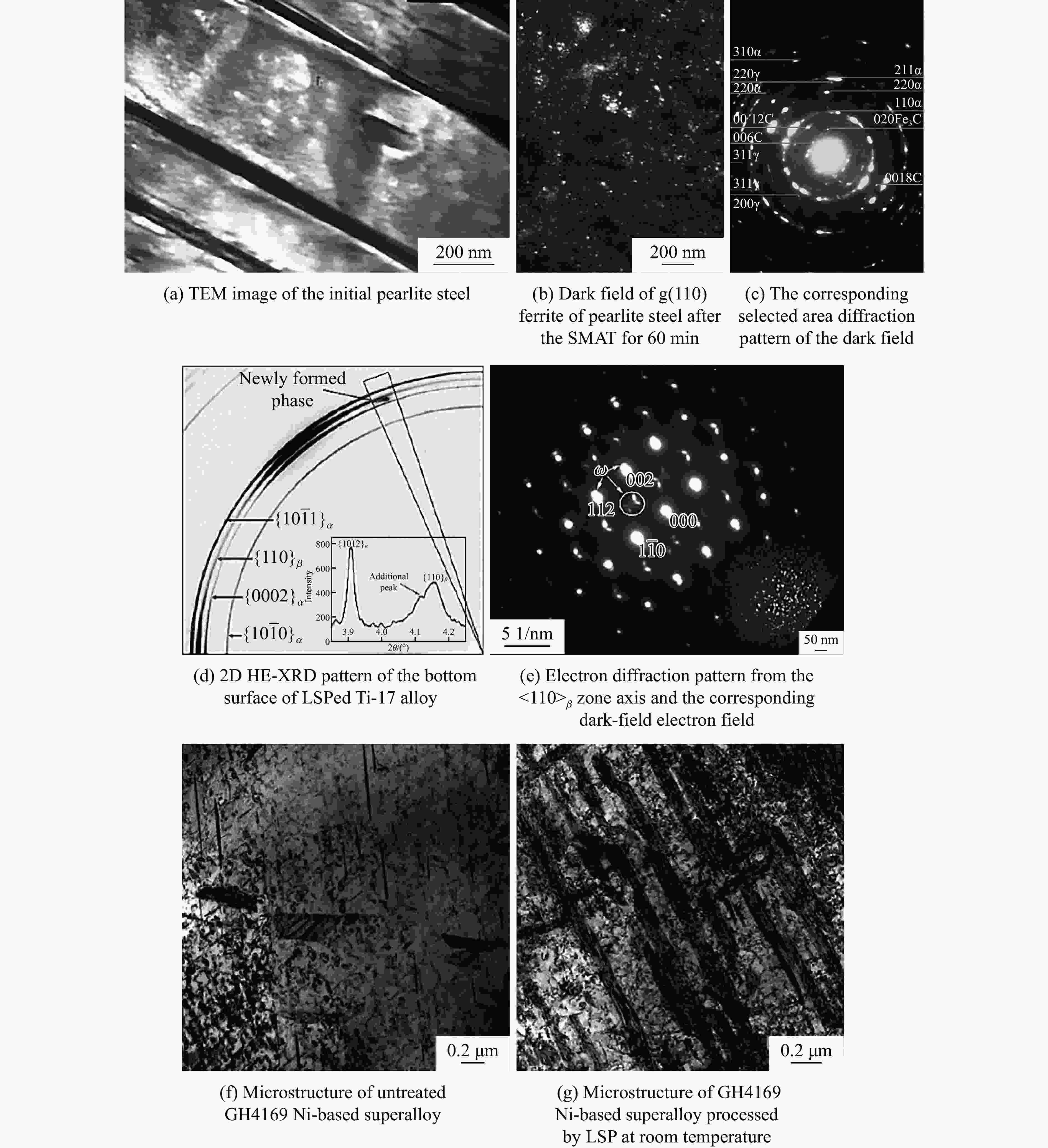

MIN N, LI W, JIN X J. α to γ transformation in the nanostructured surface layer of pearlitic steels near room temperature [J]. Scripta Materialia, 2008, 59(8): 806–809. DOI: 10.1016/j.scriptamat.2008.05.038.

|

| [61] |

CHEN S, MU J, WANG Y D, et al. Formation of omega phase induced by laser shock peening in Ti-17 alloy [J]. Materials Characterization, 2020, 159: 110017. DOI: 10.1016/j.matchar.2019.110017.

|

| [62] |

LU Y, ZHAO J B, QIAO H C, et al. A study on the surface morphology evolution of the GH4619 using warm laser shock peening [J]. AIP Advances, 2019, 9(8): 085030. DOI: 10.1063/1.5082755.

|

| [63] |

HSU H C, LIN Y C, WANG S H, et al. Corrigendum to “Inducement of bainite and carbide transformation from retained austenite based on a high strain rate” [Scr. Mater. 62 (2010) 372–375] [J]. Scripta Materialia, 2010, 62(9): 726. DOI: 10.1016/j.scriptamat.2010.01.029.

|

| [64] |

郎玉婧, 崔华, 蔡元华, 等. 应变诱导析出对7050合金连续热变形组织的影响 [J]. 中国有色金属学报, 2012, 22(10): 2726–2733. DOI: 10.19476/j.ysxb.1004.0609.2012.10.004.LANG Y J, CUI H, CAI Y H, et al. Effect of strain-induced precipitation on subsequent hot deformed microstructure of 7050 alloy [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2726–2733. DOI: 10.19476/j.ysxb.1004.0609.2012.10.004.

|

| [65] |

WANG Y, LIN D L, LAW C C. A correlation between tensile flow stress and Zener-Hollomon factor in TiAl alloys at high temperatures [J]. Journal of Materials Science Letters, 2000, 19(13): 1185–1188. DOI: 10.1023/A:1006723629430.

|

| [66] |

POUR-ALI S, KIANI-RASHID A R, BABAKHANI A, et al. Correlation between the surface coverage of severe shot peening and surface microstructural evolutions in AISI 321: a TEM, FE-SEM and GI-XRD study [J]. Surface and Coatings Technology, 2018, 334: 461–470. DOI: 10.1016/j.surfcoat.2017.11.062.

|

| [67] |

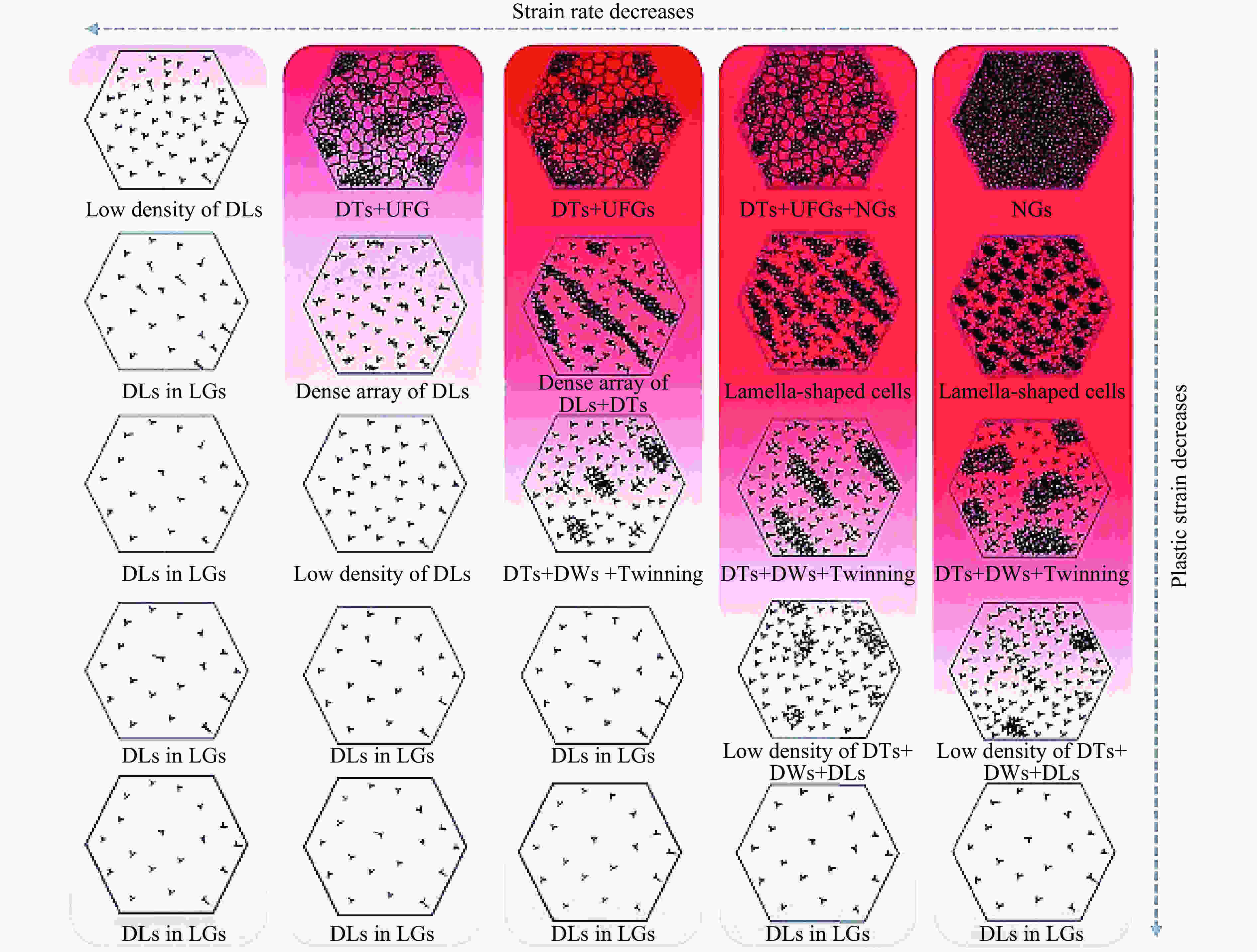

HUANG F, TAO N R. Effects of strain rate and deformation temperature on microstructures and hardness in plastically deformed pure aluminum [J]. Journal of Materials Science & Technology, 2011, 27(1): 1–7. DOI: 10.1016/S1005-0302(11)60017-0.

|

| [68] |

POUR-ALI S, KIANI-RASHID A R, BABAKHANI A. Surface nanocrystallization and gradient microstructural evolutions in the surface layers of 321 stainless steel alloy treated via severe shot peening [J]. Vacuum, 2017, 144: 152–159. DOI: 10.1016/j.vacuum.2017.07.016.

|

| [69] |

TAO N R, WANG Z B, TONG W P, et al. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment [J]. Acta Materialia, 2002, 50(18): 4603–4616. DOI: 10.1016/S1359-6454(02)00310-5.

|

| [70] |

YANG Y, ZHOU K, ZHANG H, et al. Thermal stability of microstructures induced by laser shock peening in TC17 titanium alloy [J]. Journal of Alloys and Compounds, 2018, 767: 253–258. DOI: 10.1016/j.jallcom.2018.06.030.

|

| [71] |

LEE W S, CHEN T H. Rate-dependent deformation and dislocation substructure of Al-Sc alloy [J]. Scripta Materialia, 2006, 54(8): 1463–1468. DOI: 10.1016/j.scriptamat.2005.12.054.

|

| [72] |

蔡大勇. GH169及GH696高温合金热加工工艺基础研究[D]. 秦皇岛: 燕山大学, 2003: 66−74.

|

| [73] |

YE C, SUSLOV S, KIM B J, et al. Fatigue performance improvement in AISI 4140 steel by dynamic strain aging and dynamic precipitation during warm laser shock peening [J]. Acta Materialia, 2011, 59(3): 1014–1025. DOI: 10.1016/j.actamat.2010.10.032.

|

| [74] |

LIAO Y L, YE C, GAO H, et al. Dislocation pinning effects induced by nano-precipitates during warm laser shock peening: dislocation dynamic simulation and experiments [J]. Journal of Applied Physics, 2011, 110(2): 023518. DOI: 10.1063/1.3609072.

|

| [75] |

BASAVAKUMAR K G, MUKUNDA P G, CHAKRABORTY M. Influence of grain refinement and modification on microstructure and mechanical properties of Al-7Si and Al-7Si-2.5Cu cast alloys [J]. Materials Characterization, 2008, 59(3): 283–289. DOI: 10.1016/j.matchar.2007.01.011.

|

| [76] |

MYHR O R, HOPPERSTAD O S, BØRVIK T. A combined precipitation, yield stress, and work hardening model for Al-Mg-Si alloys incorporating the effects of strain rate and temperature [J]. Metallurgical and Materials Transactions A, 2018, 49(8): 3592–3609. DOI: 10.1007/s11661-018-4675-3.

|

| [77] |

冯飞. 应变速率对GH4169合金拉伸变形行为的影响[D]. 沈阳: 东北大学, 2013: 55−57.

|

| [78] |

ZHANG P, WANG Y Q, XIE Y N, et al. A study on the dynamic shock performance of 7055-T6I4 aluminum alloy based on experimental and simulation [J]. Vacuum, 2018, 157: 306–311. DOI: 10.1016/j.vacuum.2018.08.042.

|

| [79] |

YANG Y, WANG H M, ZHOU K, et al. Effect of laser shock peening and annealing temperatures on stability of AA2195 alloy near-surface microstructure [J]. Optics & Laser Technology, 2019, 119: 105569. DOI: 10.1016/j.optlastec.2019.105569.

|

| [80] |

张孜昭, 许晓嫦, 刘志义, 等. 应变速率对强变形Al-Cu合金中析出相低温回溶速度的影响 [J]. 热处理, 2010, 25(2): 15–18. DOI: 10.3969/j.issn.1008-1690.2010.02.003.ZHANG Z Z, XU X C, LIU Z Y, et al. Effect of strain rate on redissolution rate of precipitated phase at low temperature in severely plastically deformed Al-Cu alloy [J]. Heat Treatment, 2010, 25(2): 15–18. DOI: 10.3969/j.issn.1008-1690.2010.02.003.

|

| [81] |

AN X H, WU S D, WANG Z G, et al. Significance of stacking fault energy in bulk nanostructured materials: insights from Cu and its binary alloys as model systems [J]. Progress in Materials Science, 2019, 101: 1–45. DOI: 10.1016/j.pmatsci.2018.11.001.

|

| [82] |

ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel [J]. Journal of Applied Physics, 1944, 15(1): 22–32. DOI: 10.1063/1.1707363.

|

| [83] |

LI Y S, ZHANG Y, TAO N R, et al. Effect of the Zener-Hollomon parameter on the microstructures and mechanical properties of Cu subjected to plastic deformation [J]. Acta Materialia, 2009, 57(3): 761–772. DOI: 10.1016/j.actamat.2008.10.021.

|

| [84] |

CHEN A Y, RUAN H H, WANG J, et al. The influence of strain rate on the microstructure transition of 304 stainless steel [J]. Acta Materialia, 2011, 59(9): 3697–3709. DOI: 10.1016/j.actamat.2011.03.005.

|

| [85] |

ZHANG H W, HEI Z K, LIU G, et al. Formation of nanostructured surface layer on AISI 304 stainless steel by means of surface mechanical attrition treatment [J]. Acta Materialia, 2003, 51(7): 1871–1881. DOI: 10.1016/S1359-6454(02)00594-3.

|

| [86] |

LAINÉ S J, KNOWLES K M, DOORBAR P J, et al. Microstructural characterisation of metallic shot peened and laser shock peened Ti-6Al-4V [J]. Acta Materialia, 2017, 123: 350–361. DOI: 10.1016/j.actamat.2016.10.044.

|

| [87] |

YMAKOV V, WOLF D, PHILLPOT S R, et al. Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation [J]. Nature Materials, 2002, 1(1): 45–49. DOI: 10.1038/nmat700.

|

| [88] |

LIAO X Z, ZHOU F, LAVERNIA E J, et al. Deformation twins in nanocrystalline Al [J]. Applied Physics Letters, 2003, 83(24): 5062–5064. DOI: 10.1063/1.1633975.

|

| [89] |

卢磊, 尤泽升. 纳米孪晶金属塑性变形机制 [J]. 金属学报, 2014, 50(2): 129–136. DOI: 10.3724/sp.j.1037.2013.00697.LU L, YOU Z S. Plastic deformation mechanisms in nanotwinned metals [J]. Acta Metallurgica Sinica, 2014, 50(2): 129–136. DOI: 10.3724/sp.j.1037.2013.00697.

|

| [90] |

LU K, LU L, SURESH S. Strengthening materials by engineering coherent internal boundaries at the nanoscale [J]. Science, 2009, 324(5925): 349–352. DOI: 10.1126/science.1159610.

|

| [91] |

马晓光. 层错能对面心立方金属冷拔微观组织及织构演化的影响[D]. 西安: 西北工业大学, 2018: 1−18.

|

| [92] |

LI X Y, WEI Y J, LU L, et al. Dislocation nucleation governed softening and maximum strength in nano-twinned metals [J]. Nature, 2010, 464(7290): 877–880. DOI: 10.1038/nature08929.

|

| [93] |

CHEN H, LI F G, LI J H, et al. Hardening and softening analysis of pure titanium based on the dislocation density during torsion deformation [J]. Materials Science and Engineering: A, 2016, 671: 17–31. DOI: 10.1016/j.msea.2016.06.046.

|

| [94] |

WANG X, LI Y S, ZHANG Q, et al. Gradient structured copper by rotationally accelerated shot peening [J]. Journal of Materials Science & Technology, 2017, 33(7): 758–761. DOI: 10.1016/j.jmst.2016.11.006.

|

| [95] |

HASSANI-GANGARAJ S M, CHO K S, VOIGT H J L, et al. Experimental assessment and simulation of surface nanocrystallization by severe shot peening [J]. Acta Materialia, 2015, 97: 105–115. DOI: 10.1016/j.actamat.2015.06.054.

|

| [96] |

FANG T H, LI W L, TAO N R, et al. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper [J]. Science, 2011, 331(6024): 1587–1590. DOI: 10.1126/science.1200177.

|

| [97] |

LIU X C, ZHANG H W, LU K. Strain-induced ultrahard and ultrastable nanolaminated structure in nickel [J]. Science, 2013, 342(6156): 337–340. DOI: 10.1126/science.1242578.

|

| [98] |

WANG C, WANG L, WANG C L, et al. Dislocation density-based study of grain refinement induced by laser shock peening [J]. Optics & Laser Technology, 2020, 121: 105827. DOI: 10.1016/j.optlastec.2019.105827.

|

| [99] |

ZHOU W F, REN X D, REN Y P, et al. Initial dislocation density effect on strain hardening in FCC aluminium alloy under laser shock peening [J]. Philosophical Magazine, 2017, 97(12): 917–929. DOI: 10.1080/14786435.2017.1285073.

|

| [100] |

WU X L, YANG M X, YUAN F P, et al. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility [J]. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(47): 14501–14505. DOI: 10.1073/pnas.1517193112.

|

下载:

下载: