| [1] |

ZHANG Z B, HUANG F L, CAO Y, et al. A fragments mass distribution scaling relations for fragmenting shells with variable thickness subjected to internal explosive loading [J]. International Journal of Impact Engineering, 2018, 120: 79–94. DOI: 10.1016/j.ijimpeng.2018.05.013.

|

| [2] |

孙学清, 张国伟, 杨陕平. 定向战斗部破片飞散方向控制技术研究 [J]. 弹箭与制导学报, 2008, 28(1): 102–104. DOI: 10.3969/j.issn.1673-9728.2008.01.030.SUN X Q, ZHANG G W, YANG S P. Study on fragments dispersing direction control of directional warhead [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2008, 28(1): 102–104. DOI: 10.3969/j.issn.1673-9728.2008.01.030.

|

| [3] |

徐文灿, 张连玉. 导弹预制破片战斗部杀伤威力的工程计算 [J]. 兵工学报, 1992, 13(2): 24–30.XU W C, ZHANG L Y. Lethality calculation for preformed fragment warheads [J]. Acta Armamentarii, 1992, 13(2): 24–30.

|

| [4] |

GOTO D M, BECKER R, ORZECHOWSKI T J, et al. Investigation of the fracture and fragmentation of explosively driven rings and cylinders [J]. International Journal of Impact Engineering, 2008, 35(12): 1547–1556. DOI: 10.1016/j.ijimpeng.2008.07.081.

|

| [5] |

HOPSON M V, SCOTT C M. Applicability of statistical descriptions of AerMet100 steel subjected to different triaxial stress states for fracture calculations [J]. Procedia Engineering, 2013, 58: 684–691. DOI: 10.1016/j.proeng.2013.05.079.

|

| [6] |

HOPSON M V, SCOTT C M, LAMBERT D. Applicability of statistical flaw distributions of eglin steel for fracture calculations [J]. Procedia Engineering, 2015, 103: 213–220. DOI: 10.1016/j.proeng.2015.04.029.

|

| [7] |

GOLOVESHKIN V A, MYAGKOV N N. Fragmentation model for expanding cylinder [J]. International Journal of Fracture, 2014, 187(2): 239–243. DOI: 10.1007/s10704-014-9936-6.

|

| [8] |

BOLIS C, COUNILH D, LAGRANGE J M, et al. Fragmentation of a titanium alloy shell in expansion: from experiment to simulation [J]. Procedia Engineering, 2013, 58: 672–677. DOI: 10.1016/j.proeng.2013.05.077.

|

| [9] |

LIU M T, REN G W, FAN C, et al. Experimental and Numerical studies on the expanding fracture behavior of an explosively driven 1045 steel cylinder [J]. International Journal of Impact Engineering, 2017, 109: 240–252. DOI: 10.1016/j.ijimpeng.2017.07.008.

|

| [10] |

NING J G, DUAN Y, XU X Z, et al. Velocity characteristics of fragments from prismatic casing under internal explosive loading [J]. International Journal of Impact Engineering, 2017, 109: 29–38. DOI: 10.1016/j.ijimpeng.2017.05.018.

|

| [11] |

DONG X L, YU X L, PAN S J, et al. Analysis of fracture behaviour of exploded metal cylinders with varied charge [J]. EPJ Web of Conferences, 2018, 183: 01036. DOI: 10.1051/epjconf/201818301036.

|

| [12] |

刘龙飞, 周强. 表面粗糙度对6061铝合金薄壁管冲击膨胀断裂性能的影响 [J]. 爆炸与冲击, 2018, 38(4): 749–758. DOI: 10.11883/bzycj-2016-0389.LIU L F, ZHOU Q. Effect of surface roughness on impact expansion fracture of 6061 aluminum alloy thin-walled cylindrical tube [J]. Explosion and Shock Waves, 2018, 38(4): 749–758. DOI: 10.11883/bzycj-2016-0389.

|

| [13] |

GURNEY R W. The initial velocities of fragments from bombs, shell and grenades[R]. BRL Report No. 405, Aberdeen: Ballistic Research Laboratory, 1943.

|

| [14] |

MEYERS M A. Dynamic behavior of materials [M]. New York: John Wiley & Sons, Inc., 1994.

|

| [15] |

NEERAJ T, SAVAGE M F, TATALOVICH J, et al. Observation of tension-compression asymmetry in α and α/β titanium alloys [J]. Philosophical Magazine, 2005, 85(2/3): 279–295. DOI: 10.1080/14786430412331315707.

|

| [16] |

ZHOU P, BEEH E, FRIEDRICH H E. Influence of tension-compression asymmetry on the mechanical behavior of AZ31B magnesium alloy sheets in bending [J]. Journal of Materials Engineering and Performance, 2016, 25(3): 853–865. DOI: 10.1007/s11665-016-1961-3.

|

| [17] |

MAEDA T, NOMA N, KUWABARA T, et al. Experimental verification of the tension-compression asymmetry of the flow stresses of a high strength steel sheet [J]. Procedia Engineering, 2017, 207: 1976–1981. DOI: 10.1016/j.proeng.2017.10.1099.

|

| [18] |

HARDING J, WOOD E O, CAMPBELL J D. Tensile testing of materials at impact rates of strain [J]. Journal of Mechanical Engineering Science, 1960, 2(2): 88–96. DOI: 10.1243/JMES_JOUR_1960_002_016_02.

|

| [19] |

CHEN W W, SONG B. Split Hopkinson (Kolsky) bar-design, testing and applications [M]. New York: Springer, 2011. DOI: 10.1007/978-1-4419-7982-7.

|

| [20] |

JOHNSON P C, STEIN B A, DAVIS R S. Measurement of dynamic plastic flow properties under uniform stress [C] // Symposium on Dynamic Behavior of Materials. West Conshohocken: ASTM International, 1963: 195−197. DOI: 10.1520/STP42030S.

|

| [21] |

TANG T G, REN G W, GUO Z L, et al. An improved technique of expanding metal ring experiment under high explosive loading [J]. Review of Scientific Instruments, 2013, 84(4): 043908. DOI: 10.1063/1.4802255.

|

| [22] |

NIORDSON F I. A unit for testing materials at high strain rates [J]. Experimental Mechanics, 1965, 5(1): 29–32. DOI: 10.1007/BF02320901.

|

| [23] |

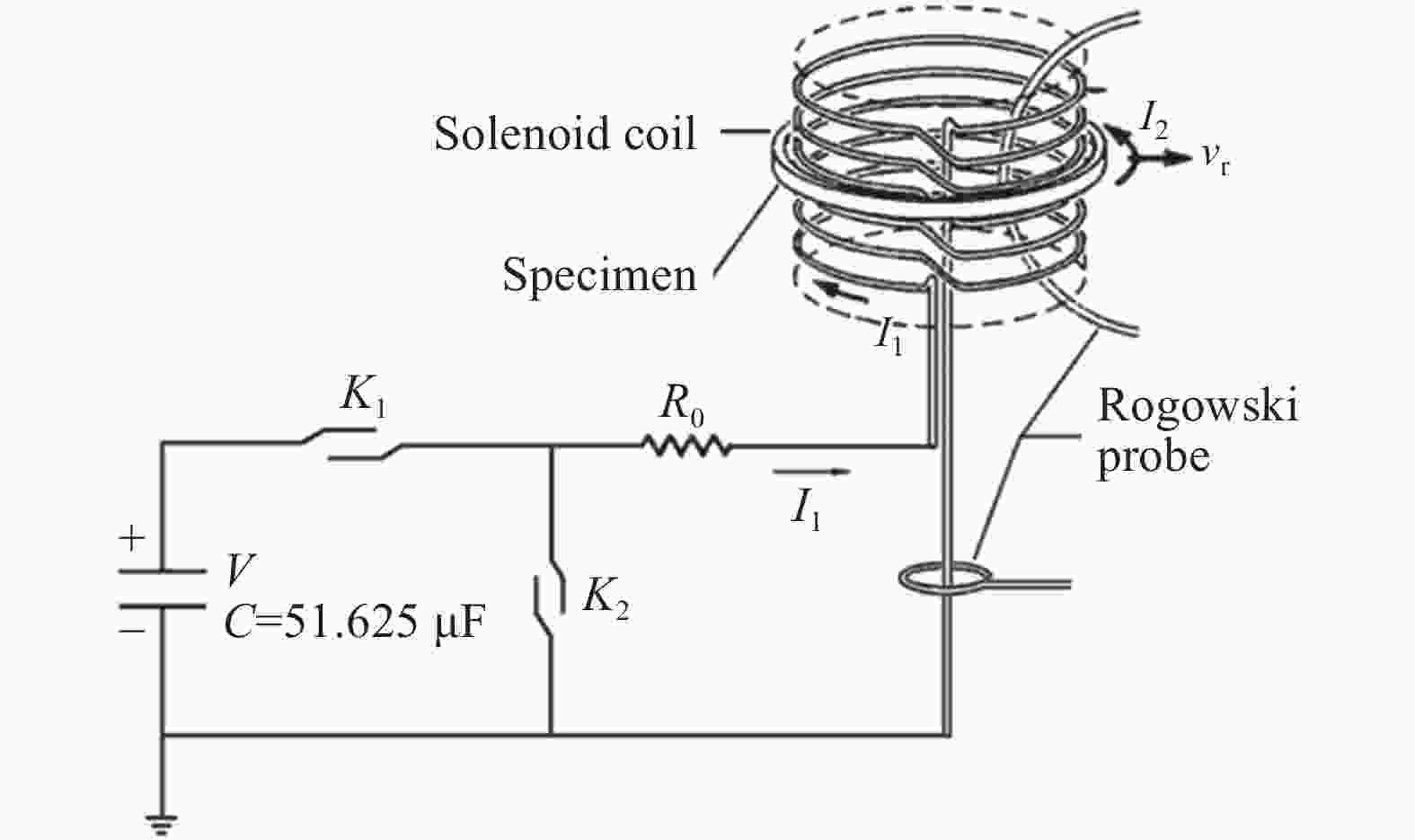

桂毓林, 孙承纬, 李强, 等. 实现金属环动态拉伸的电磁加载技术研究 [J]. 爆炸与冲击, 2006, 26(6): 481–485. DOI: 10.11883/1001-1455(2006)06-0481-05.GUI Y L, SUN C W, LI Q, et al. Experimental studies on dynamic tension of metal ring by electromagnetic loading [J]. Explosion and Shock Waves, 2006, 26(6): 481–485. DOI: 10.11883/1001-1455(2006)06-0481-05.

|

| [24] |

陈红. 电磁驱动金属膨胀环动态拉伸实验技术[D]. 宁波: 宁波大学, 2012.CHEN H. Dynamic tension experimental technique of electromagneticall driven expanding metal ring[D]. Ningbo: Ningbo University, 2012.

|

| [25] |

刘明涛, 汤铁钢, 郭昭亮, 等. 膨胀环实验平台及其在材料动力学行为研究中的应用 [J]. 实验力学, 2016, 31(1): 47–56. DOI: 10.7520/1001-4888-15-022.LIU M T, TANG T G, GUO Z L, et al. Expanding ring experimental platform and its application in material dynamic mechanical behavior investigation [J]. Journal of Experimental Mechanics, 2016, 31(1): 47–56. DOI: 10.7520/1001-4888-15-022.

|

| [26] |

LIANG M Z, LI X Y, QIN J G, et al. Improved expanding ring technique for determining dynamic material properties [J]. Review of Scientific Instruments, 2013, 84(6): 065114. DOI: 10.1063/1.4811658.

|

| [27] |

郑宇轩, 周风华, 胡时胜. 一种基于SHPB的冲击膨胀环实验技术 [J]. 爆炸与冲击, 2014, 34(4): 483–488. DOI: 10.11883/1001-1455(2014)04-0483-06.ZHENG Y X, ZHOU F H, HU S S. An SHPB-based experimental technique for dynamic fragmentations of expanding rings [J]. Explosion and Shock Waves, 2014, 34(4): 483–488. DOI: 10.11883/1001-1455(2014)04-0483-06.

|

| [28] |

AVRIEL E, LOVINGER Z, NEMIROVSKY R, et al. Investigating the strength of materials at very high strain rates using electro-magnetically driven expanding cylinders [J]. Mechanics of Materials, 2018, 117: 165–180. DOI: 10.1016/j.mechmat.2017.11.009.

|

| [29] |

TAYLOR G I. The fragmentation of tubular bombs [J]. Scientific Papers of GI Taylor, 1963, 3(44): 387–390.

|

| [30] |

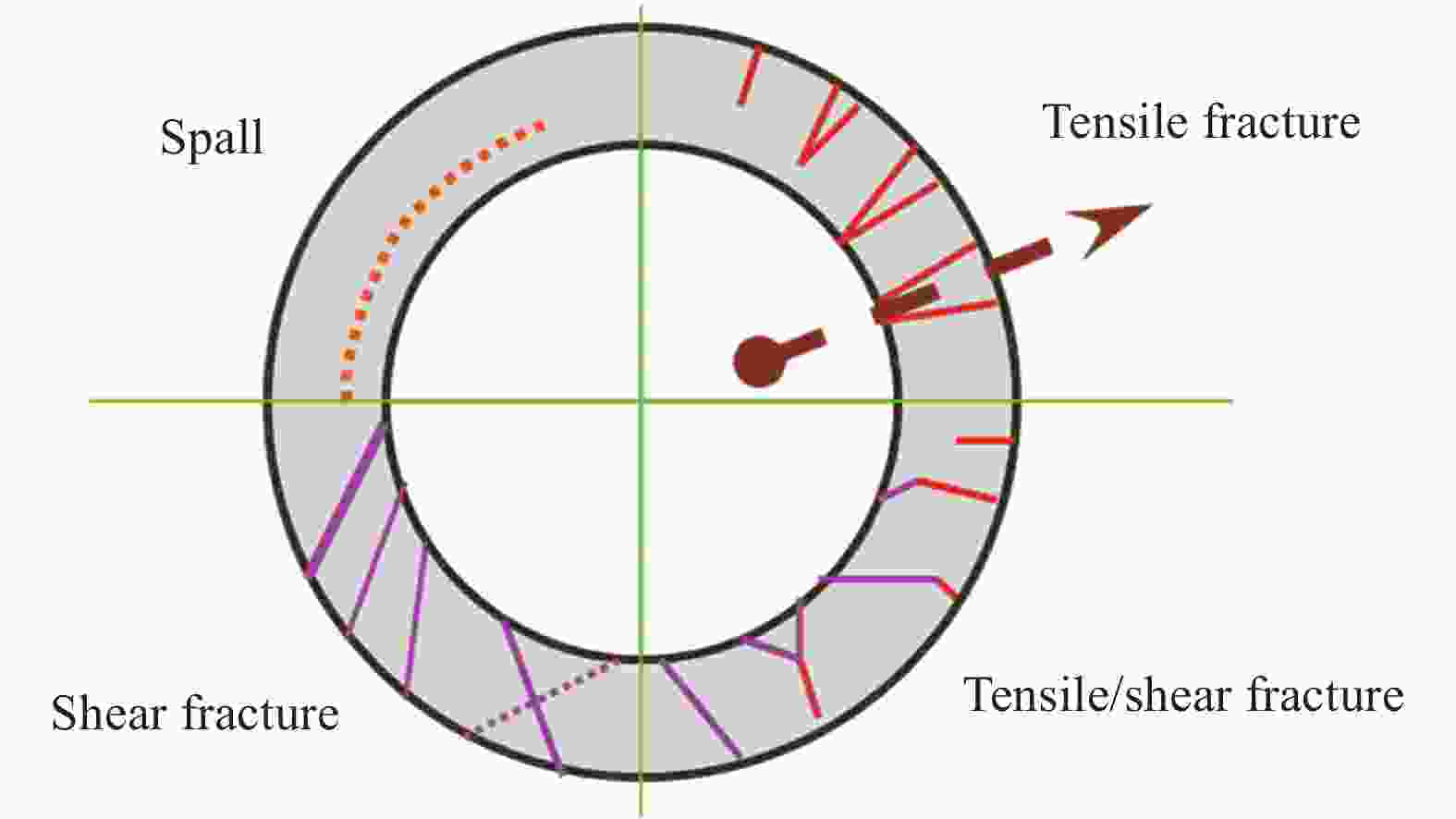

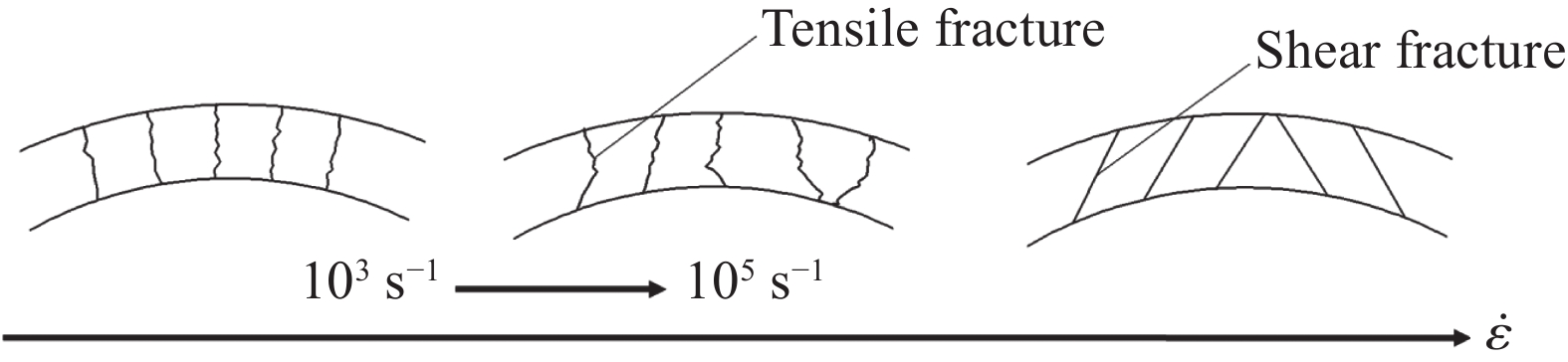

胡八一, 董庆东, 韩长生, 等. 爆炸金属管的绝热剪切断裂宏观研究 [J]. 爆炸与冲击, 1992, 12(4): 319–325.HU B Y, DONG Q D, HAN C S, et al. The macroscopic study of adiabatic shear fracture of metal tubes under explosive loading [J]. Explosion and Shock Waves, 1992, 12(4): 319–325.

|

| [31] |

胡八一, 董庆东, 韩长生, 等. 爆炸金属管绝热剪切断裂的细观研究 [J]. 爆炸与冲击, 1993, 13(4): 305–312.HU B Y, DONG Q D, HAN C S, et al. Mesoscopic study of adiabatic shear fracture of the metal tubes under internal explosive loading [J]. Explosion and Shock Waves, 1993, 13(4): 305–312.

|

| [32] |

胡八一, 董庆东, 韩长生, 等. 内部爆轰加载下的钢管膨胀断裂研究 [J]. 爆炸与冲击, 1993, 13(1): 49–54.HU B Y, DONG Q D, HAN C S, et al. Studies of expansion and fracture of explosive-filled steel cylinders [J]. Explosion and Shock Waves, 1993, 13(1): 49–54.

|

| [33] |

BEETLE J C, RINNOVATORE J V, CORRIE J D. Fracture morphology of explosively loaded steel cylinders [C] // Proceedings of the Scanning Electron Microscope Symposium. Chicago, 1971: 137−144.

|

| [34] |

MARTINEAU R L. A viscoplastic model of expanding cylindrical shells subjected to internal explosive detonations [R]. New Mexico: Los Alamos National Lab., 1998. DOI: 10.2172/663184.

|

| [35] |

MARTINEAU R L, PRIME M B, ANDERSON C A, et al. An explicit model of expanding cylindrical shells subjected to high explosive detonations[R]. New Mexico: Los Alamos National Lab., 1999. DOI: 10.2172/334315.

|

| [36] |

MARTINEAU R L, ANDERSON C A, SMITH F W. Expansion of cylindrical shells subjected to internal explosive detonations [J]. Experimental Mechanics, 2000, 40(2): 219–225. DOI: 10.1007/BF02325049.

|

| [37] |

李永池, 李大红, 魏志刚, 等. 内爆炸载荷下圆管变形、损伤和破坏规律的研究 [J]. 力学学报, 1999, 31(4): 442–449. DOI: 10.3321/j.issn:0459-1879.1999.04.008.LI Y C, LI D H, WEI Z G, et al. Research on the deformation, damage and fracture rules of circular tubes under inside-explosive loading [J]. Acta Mechanica Sinica, 1999, 31(4): 442–449. DOI: 10.3321/j.issn:0459-1879.1999.04.008.

|

| [38] |

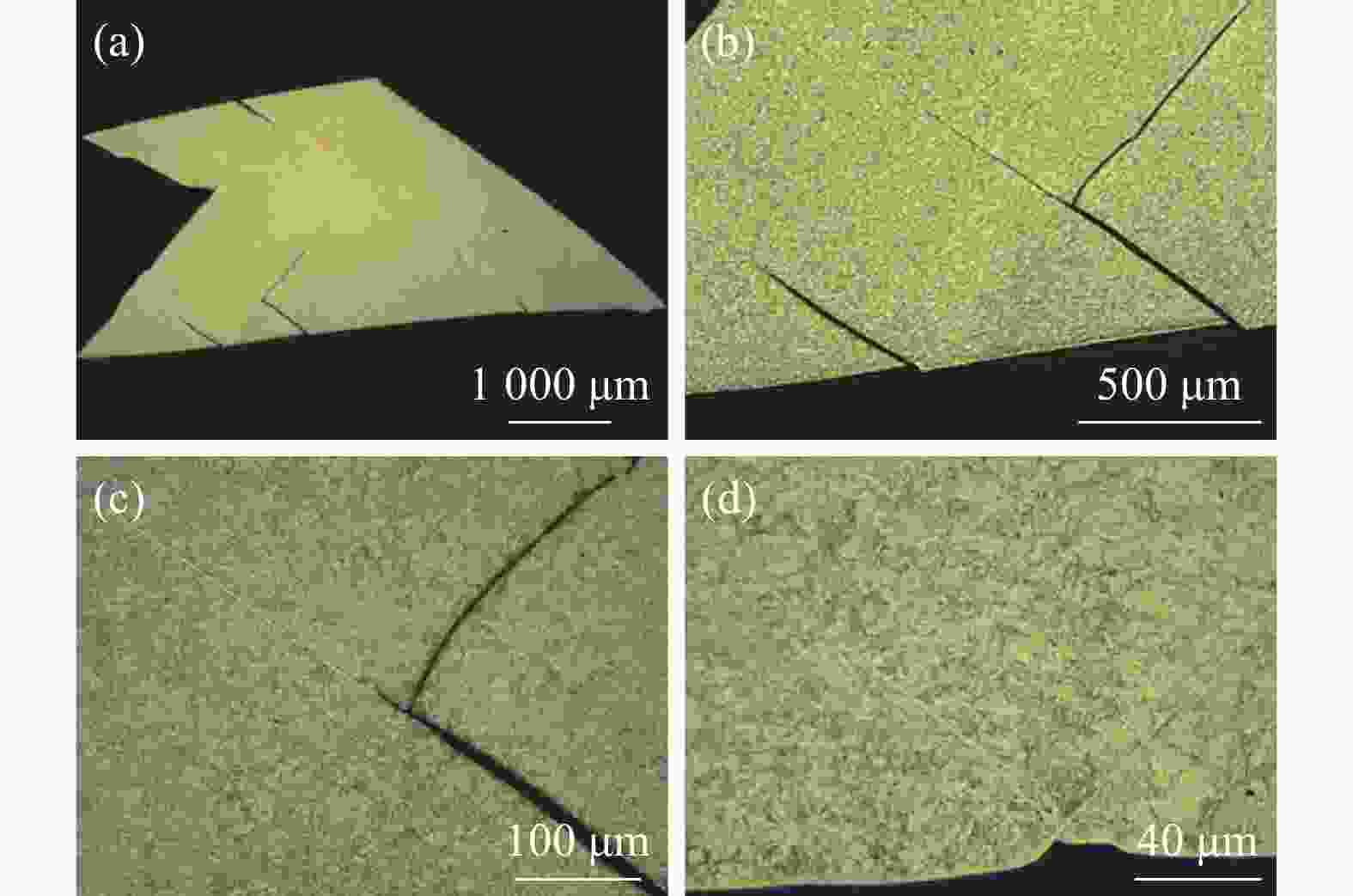

张世文, 刘仓理, 于锦泉. 微缺陷对圆管膨胀断裂的影响 [J]. 爆炸与冲击, 2008, 28(4): 316–323. DOI: 10.11883/1001-1455(2008)04-0316-08.ZHANG S W, LIU C L, YU J Q. Influences of microdefects on expanding fracture of a metal cylinder [J]. Explosion and Shock Waves, 2008, 28(4): 316–323. DOI: 10.11883/1001-1455(2008)04-0316-08.

|

| [39] |

HOGGATT C R, RECHT R F. Fracture behavior of tubular bombs [J]. Journal of Applied Physics, 1968, 39(3): 1856–1862. DOI: 10.1063/1.1656442.

|

| [40] |

IVANOV A G. Explosive deformation and destruction of tubes [J]. Strength of Materials, 1976, 8(11): 1303–1306. DOI: 10.1007/BF01528752.

|

| [41] |

OLIVE F, NICAUD A, MARILLEAU J, et al. Rupture behavior of metals in explosive expansion [J]. Institute of Physics Conference Series, 1979(17): 242–252.

|

| [42] |

陈大年, 王德生, 马松合, 等. 两类动态断裂 [J]. 爆炸与冲击, 1987, 7(1): 27–33.CHEN D N, WANG D S, MA S H, et al. Two kinds of dynamic fracture [J]. Explosion and Shock Waves, 1987, 7(1): 27–33.

|

| [43] |

陈大年, 尹志华. 对膨胀壳体材料失稳的一种简化处理 [J]. 爆炸与冲击, 1999, 19(3): 193–198.CHEN D N, YIN Z H. A simplified approach to material instability of expanding shells [J]. Explosion and Shock Waves, 1999, 19(3): 193–198.

|

| [44] |

FENG J P, JING F Q, ZHANG G R. Dynamic ductile fragmentation and the damage function model [J]. Journal of Applied Physics, 1997, 81(6): 2575–2578. DOI: 10.1063/1.363921.

|

| [45] |

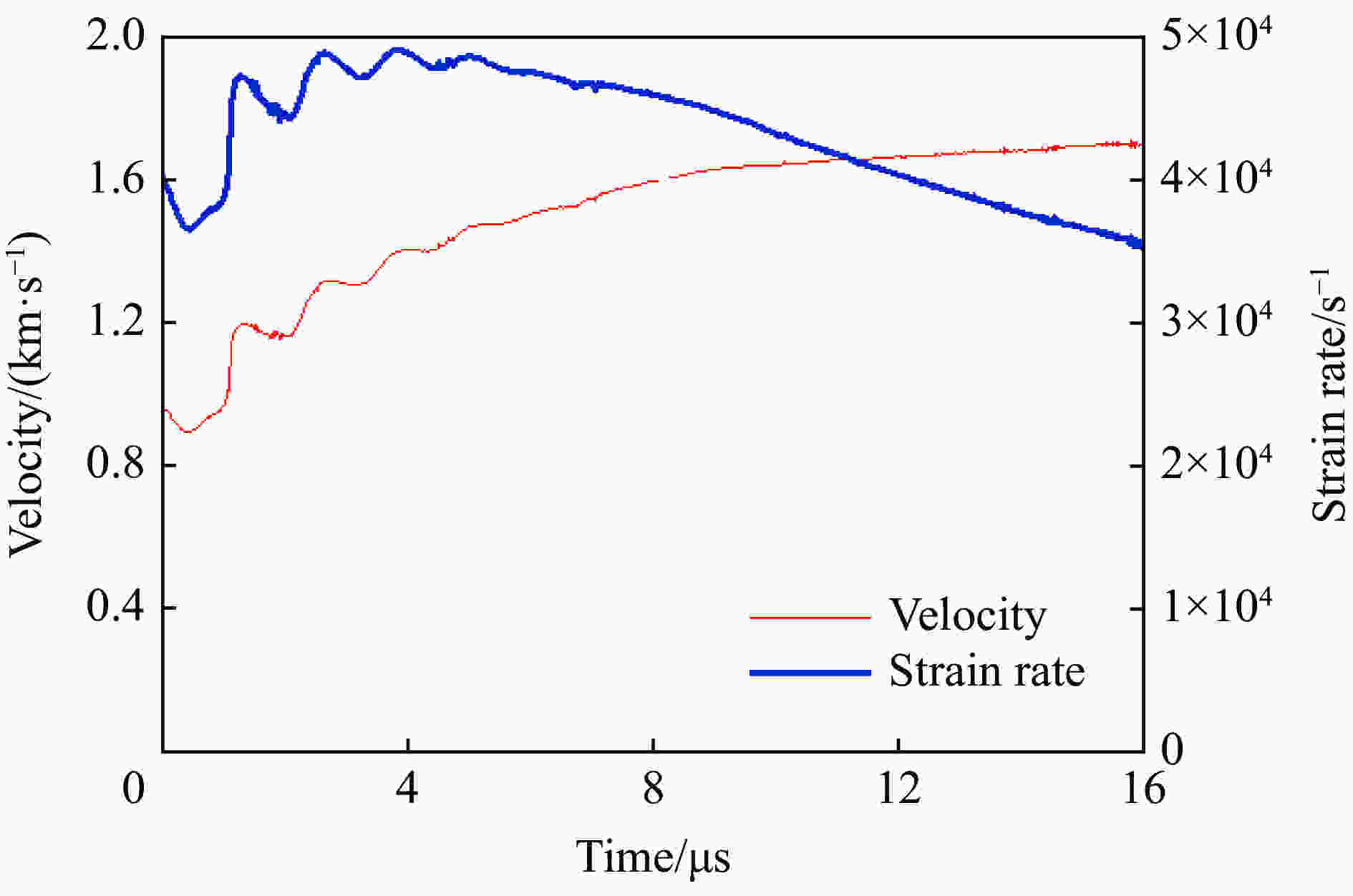

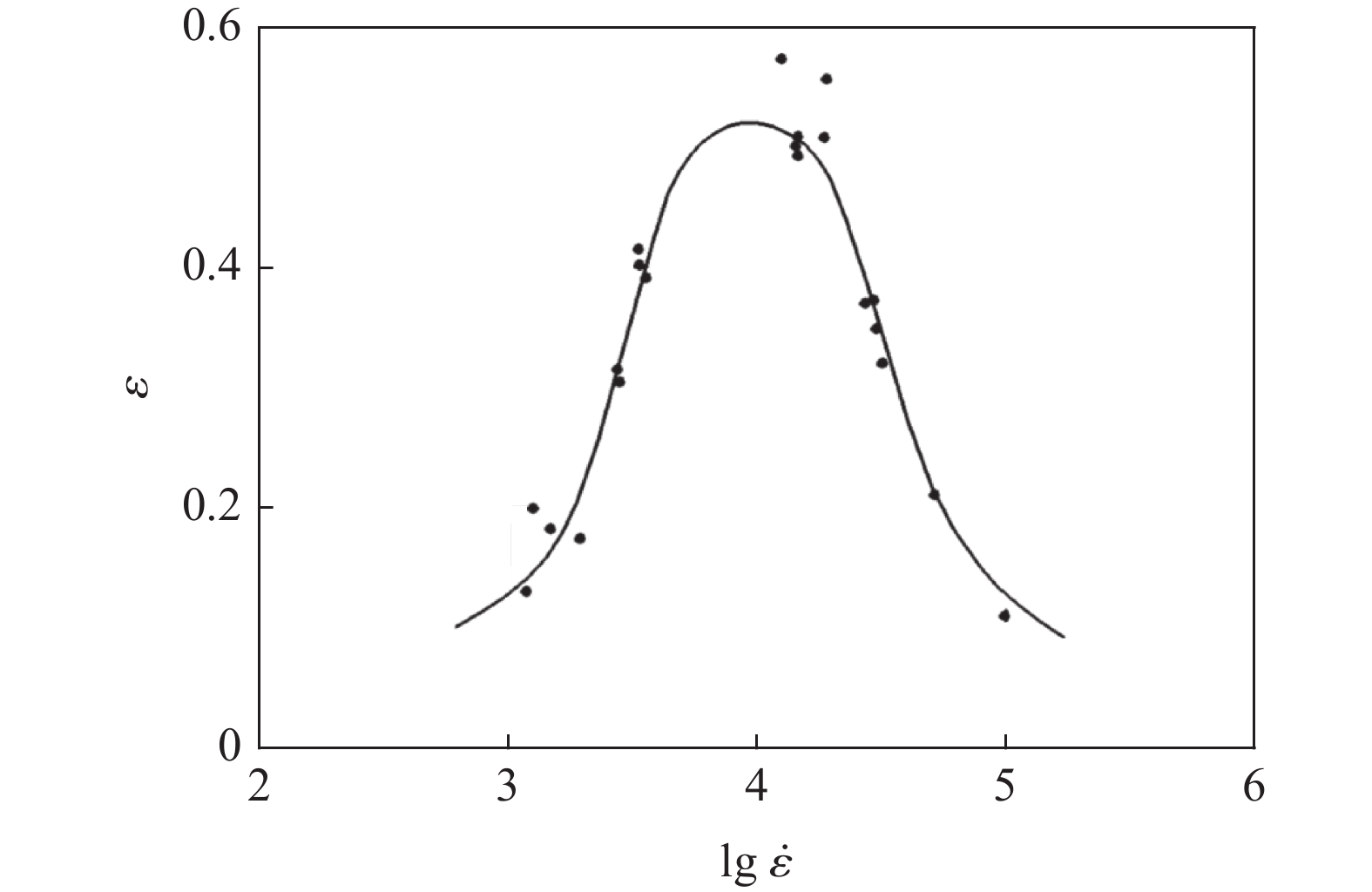

汤铁钢, 李庆忠, 孙学林, 等. 45钢柱壳膨胀断裂的应变率效应 [J]. 爆炸与冲击, 2006, 26(2): 129–133. DOI: 10.11883/1001-1455(2006)02-0129-05.TANG T G, LI Q Z, SUN X L, et al. Strain-rate effects of expanding fracture of 45 steel cylinder shells driven by detonation [J]. Explosion and Shock Waves, 2006, 26(2): 129–133. DOI: 10.11883/1001-1455(2006)02-0129-05.

|

| [46] |

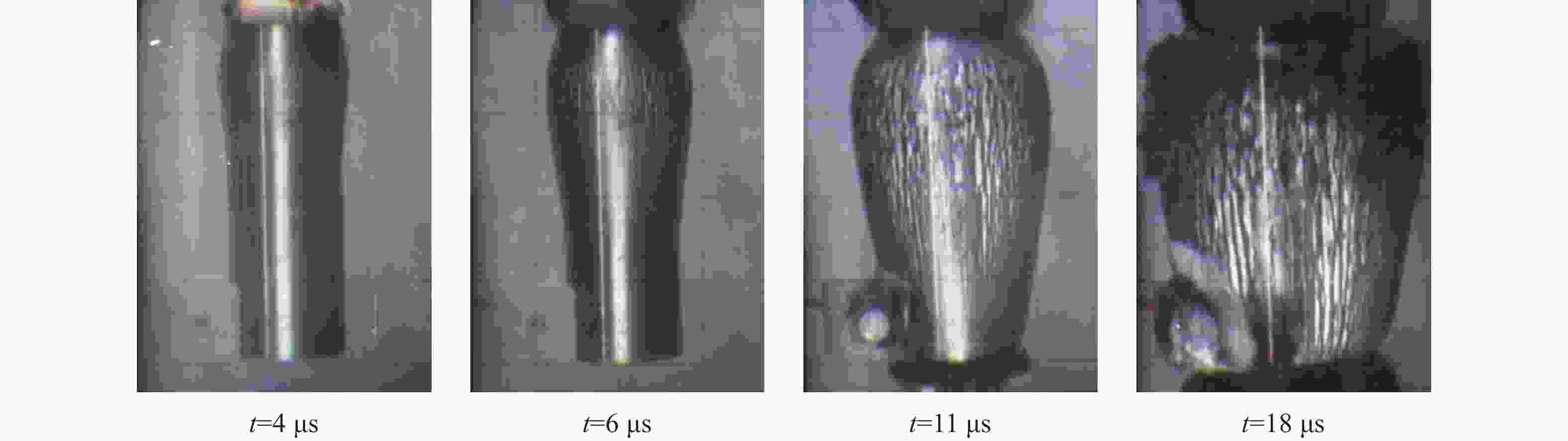

汤铁钢, 谷岩, 李庆忠, 等. 爆轰加载下金属柱壳膨胀破裂过程研究 [J]. 爆炸与冲击, 2003, 23(6): 529–533.TANG T G, GU Y, LI Q Z, et al. Expanding fracture of steel cylinder shell by detonation driving [J]. Explosion and Shock Waves, 2003, 23(6): 529–533.

|

| [47] |

金山, 汤铁钢, 孙学林, 等. 不同热处理条件下45钢柱壳的动态性能 [J]. 爆炸与冲击, 2006, 26(5): 423–428. DOI: 10.11883/1001-1455(2006)05-0423-06.JIN S, TANG T G, SUN X L, et al. Dynamic characteristics of 45 steel cylinder shell by different heat treatment conditions [J]. Explosion and Shock Waves, 2006, 26(5): 423–428. DOI: 10.11883/1001-1455(2006)05-0423-06.

|

| [48] |

金山, 汤铁钢, 李庆忠, 等. 铍青铜柱壳膨胀断裂研究 [J]. 高压物理学报, 2006, 20(4): 434–438. DOI: 10.11858/gywlxb.2006.04.016.JIN S, TANG T G, LI Q Z, et al. Expanding fracture of beryllium bronze cylinder shell [J]. Chinese Journal of High Pressure Physics, 2006, 20(4): 434–438. DOI: 10.11858/gywlxb.2006.04.016.

|

| [49] |

胡海波, 汤铁钢, 胡八一, 等. 金属柱壳在爆炸加载断裂中的单旋现象 [J]. 爆炸与冲击, 2004, 24(2): 97–107.HU H B, TANG T G, HU B Y, et al. An study of uniform shear bands orientation selection tendency on explosively loaded cylindrical shells [J]. Explosion and Shock Waves, 2004, 24(2): 97–107.

|

| [50] |

XUE Q, NESTERENKO V F, MEYERS M A. Evaluation of the collapsing thick-walled cylinder technique for shear-band spacing [J]. International Journal of Impact Engineering, 2003, 28(3): 257–280. DOI: 10.1016/S0734-743X(02)00103-3.

|

| [51] |

YANG Y, ZENG Y, GAO Z W. Numerical and experimental studies of self-organization of shear bands in 7075 aluminium alloy [J]. Materials Science and Engineering: A, 2008, 496(1/2): 291–302. DOI: 10.1016/j.msea.2008.07.043.

|

| [52] |

LOVINGER Z, RIKANATI A, ROSENBERG Z, et al. Electro-magnetic collapse of thick-walled cylinders to investigate spontaneous shear localization [J]. International Journal of Impact Engineering, 2011, 38(11): 918–929. DOI: 10.1016/j.ijimpeng.2011.06.006.

|

| [53] |

LOVINGER Z, RITTEL D, ROSENBERG Z. An experimental study on spontaneous adiabatic shear band formation in electro-magnetically collapsing cylinders [J]. Journal of the Mechanics and Physics of Solids, 2015, 79: 134–156. DOI: 10.1016/j.jmps.2015.04.007.

|

| [54] |

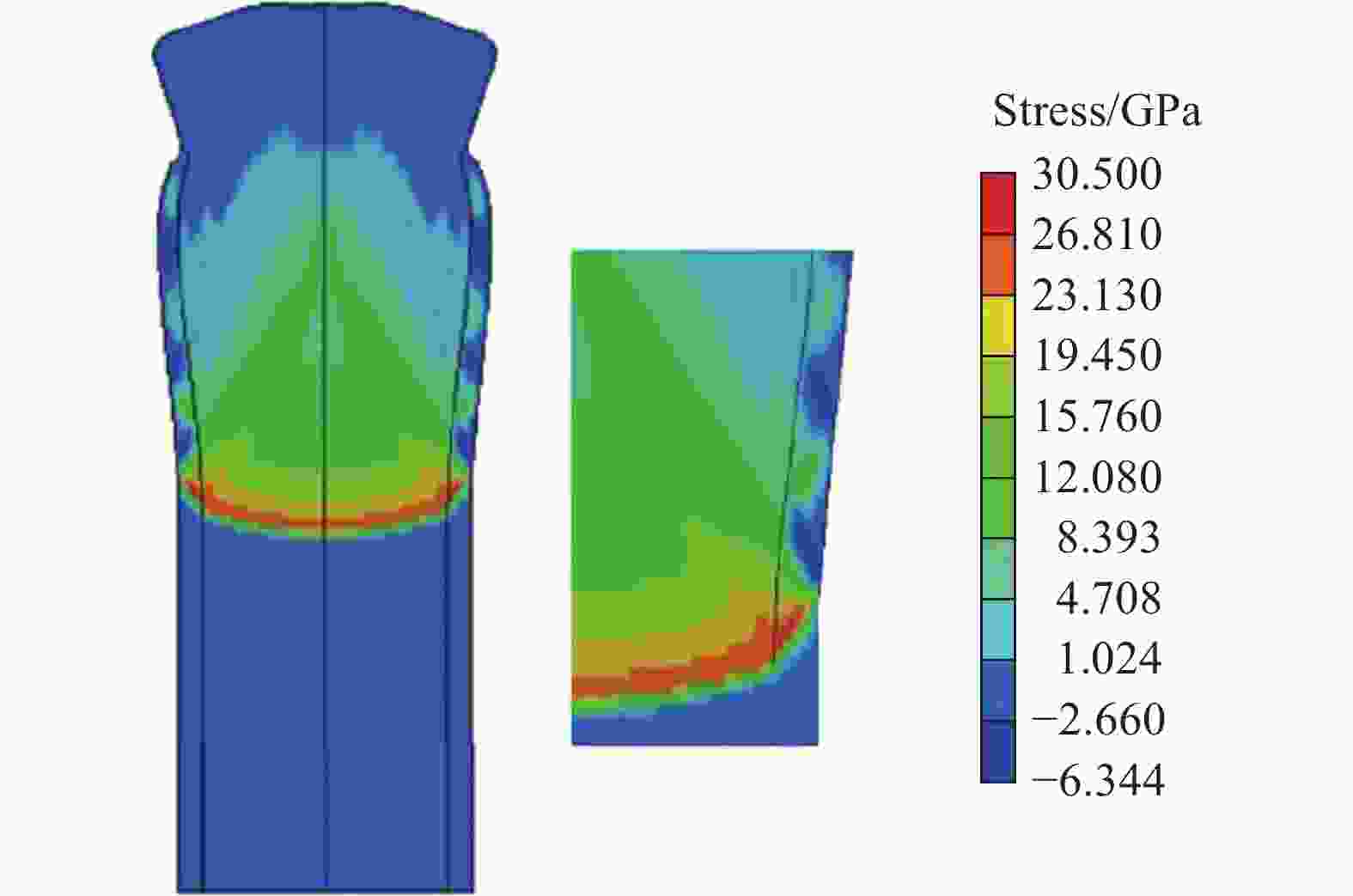

LIU M T, GUO Z L, FAN C, et al. Modeling spontaneous shear bands evolution in thick-walled cylinders subjected to external High-strain-rate loading [J]. International Journal of Solids and Structures, 2016, 97/98: 336–354. DOI: 10.1016/j.ijsolstr.2016.07.014.

|

| [55] |

REN G W, GUO Z L, FAN C, et al. Dynamic shear fracture of an explosively-driven metal cylindrical shell [J]. International Journal of Impact Engineering, 2016, 95: 35–39. DOI: 10.1016/j.ijimpeng.2016.04.012.

|

| [56] |

HIROE T, FUJIWARA K, HATA H, et al. Deformation and fragmentation behaviour of exploded metal cylinders and the effects of wall materials, configuration, explosive energy and initiated locations [J]. International Journal of Impact Engineering, 2008, 35(12): 1578–1586. DOI: 10.1016/j.ijimpeng.2008.07.002.

|

| [57] |

MOTT N F. Fragmentation of shell cases [J]. Proceedings of the Royal Society of London: Series A: Mathematical and Physical Sciences, 1947, 189(1018): 300–308. DOI: 10.1098/rspa.1947.0042.

|

| [58] |

GRADY D E, OLSEN M L. A statistics and energy based theory of dynamic fragmentation [J]. International Journal of Impact Engineering, 2003, 29(1/2/3/4/5/6/7/8/9/10): 293–306. DOI: 10.1016/j.ijimpeng.2003.09.026.

|

| [59] |

LAMBER D E, OSBORN J, HOPSON M V. Explosively driven fragmentation experiments for continuum damage modeling [J]. Journal of Pressure Vessel Technology, 2012, 134(3): 031209. DOI: 10.1115/1.4006119.

|

| [60] |

HOPSON M V, SCOTT C M, PATEL R. Computational comparisons of homogeneous and statistical descriptions of AerMet100 steel subjected to high strain rate loading [J]. International Journal of Impact Engineering, 2011, 38(6): 451–455. DOI: 10.1016/j.ijimpeng.2010.10.016.

|

| [61] |

HOPSON M V, LAMBERT D E, WEIDERHOLD J. Computational comparisons of homogeneous and statistical descriptions of steel subjected to explosive loading [C] // Proceedings of the ASME 2010 pressure Vessels and Piping Division/K-PVP Conference. Washington: ASME, 2010: 257−262. DOI: 10.1115/PVP2010-25330.

|

| [62] |

ZHOU F, MOLINARI J F, RAMESH K T. An elastic–visco-plastic analysis of ductile expanding ring [J]. International Journal of Impact Engineering, 2006, 33(1/2/3/4/5/6/7/8/9/10/11/12): 880–891. DOI: 10.1016/j.ijimpeng.2006.09.070.

|

| [63] |

陈磊, 周风华, 汤铁钢. 韧性金属圆环高速膨胀碎裂过程的有限元模拟 [J]. 力学学报, 2011, 43(5): 861–870. DOI: 10.6052/0459-1879-2011-5-lxxb2010-675.CHEN L, ZHOU F H, TANG T G. Finite element simulations of the high velocity expansion and fragmentation of ductile metallic rings [J]. Chinese Journal of Theoretical and Applied Mechanics, 2011, 43(5): 861–870. DOI: 10.6052/0459-1879-2011-5-lxxb2010-675.

|

| [64] |

郑宇轩, 陈磊, 胡时胜, 等. 韧性材料冲击拉伸碎裂中的碎片尺寸分布规律 [J]. 力学学报, 2013, 45(4): 580–587. DOI: 10.6052/0459-1879-12-338.ZHENG Y X, CHEN L, HU S S, et al. Characteristics of fragment size distribution of ductile materials fragmentized under high strainrate tension [J]. Chinese Journal of Theoretical and Applied Mechanics, 2013, 45(4): 580–587. DOI: 10.6052/0459-1879-12-338.

|

| [65] |

郑宇轩, 周风华, 胡时胜, 等. 固体的冲击拉伸碎裂 [J]. 力学进展, 2016, 46(1): 201612. DOI: 10.6052/1000-0992-16-004.ZHENG Y X, ZHOU F H, HU S S, et al. Fragmentations of solids under impact tension [J]. Advances in Mechanics, 2016, 46(1): 201612. DOI: 10.6052/1000-0992-16-004.

|

| [66] |

ZHANG H, RAVI-CHANDAR K. On the dynamics of necking and fragmentation–I. Real-time and post-mortem observations in Al 6061-O [J]. International Journal of Fracture, 2006, 142(3/4): 183–217. DOI: 10.1007/s10704-006-9024-7.

|

| [67] |

ZHANG H, RAVI-CHANDAR K. On the dynamics of necking and fragmentation-Ⅱ. Effect of material properties, geometrical constraints and absolute size [J]. International Journal of Fracture, 2008, 150: 3–36. DOI: 10.1007/s10704-008-9233-3.

|

| [68] |

ZHANG H, RAVI-CHANDAR K. On the dynamics of localization and fragmentation-Ⅳ. Expansion of Al 6061-O tubes [J]. International Journal of Fracture, 2010, 163(1): 41–65. DOI: 10.1007/s10704-009-9441-5.

|

下载:

下载: